1. Introduction

Nowadays, energy in the form of electricity is considered to be an essential component of modern life across the globe. However, many countries of the world are facing severe electricity crises, including Pakistan. In Pakistan, the electricity outage ranges from 8–10 h in an urban area while up to 18 h in rural areas [

1]. The reason behind these outages is the gap between demand and supply. The demand for electricity in the country is increasing with the increasing population and urbanization; however, supply is 20%–25% short [

2]. The major reason behind a low energy supply is the great dependency on fossil fuels, which are limited and depleting. In Pakistan, 87.3% of the primary energy supply is based on fossil fuels; gas (37.9%) and oil (34.4%) have the highest share in the total primary energy supply by the end of 2016 [

3]. However, the energy produced by renewable energy sources (except large hydro) was less than 1% of the energy mix [

3]. Although Pakistan is blessed with renewable energy sources such as wind, biomass, and solar, share of renewable energy sources in energy production is almost negligible. Specifically, an abundant potential of solar energy is available in the country because of its location in the sunbelt. Solar energy can be utilized in two ways: solar photovoltaics (SPV) and concentrated solar power (CSP) [

4]. SPV systems are used to convert sunlight directly into electricity whereas CSP systems (also known as solar thermal systems) are used for concentrating and heating a heat transfer fluid (HTF) for a power cycle. In Pakistan, the installation and development of the SPV system is growing [

4]. Quaid-e-Azam solar park (QASP), which is the first ever power station in the country consisting of SPV with a capacity of 1000 MW, is under construction [

4]. Out of 1000 MW of QASP, 300 MW has been already added to the national grid. Also, several small to large scale projects consisting of solar photovoltaics are under operation and construction [

4]. However, CSP systems have not been utilized in Pakistan.

CSP is a promising technology for large scale power production. There are four families of CSP technology including (i) parabolic trough collectors (PTC), (ii) solar power tower (SPT), (iii) linear Fresnel reflects (LFR), and (iv) parabolic dish systems (PDs). There are numerous advantages of CSP, such as renewable, clean, low operating cost, etc. However, one of the issues with CSP is soiling of mirrors, where dirt is accumulated on the mirrors/reflectors. It causes a reduction in the electricity production. The soiling effect can be reduced by proper cleaning/washing of the mirrors [

5,

6,

7]. The commercialization of CSP is increasing. For instance, the CSP global capacity was 400 MW in 2006, which increased to 4800 MW in 2017 [

8]. The global leaders in CSP plants are Spain and the United States, having a power generation capacity of 2300 MW (48%) and 1738 MW (36%), respectively [

8]. However, the rest of the world contributes 762 MW (16%), as shown in

Figure 1 [

8]. The advent of the commercialization era has contributed significantly, increasing the research in CSP systems. Recent research on CSP systems is concerned with site selections, technological evaluations, performance analysis, economic investigations, and developments in the CSP process and materials.

Several studies have been conducted on the techno-economic evaluation of CSP plants for a different region of the world. Hinkley et al. [

9] presented a cost comparison analysis of 100 MWe PT and SPT plants in different areas of Australia using the System Advisor Model (SAM) software. Purohit et al. [

10] investigated CSP potential in Northwestern regions of India using SAM, and the evaluation was performed for four CSP technologies. SAM was also utilized by Guzamn et al. [

11] for the simulation study of a 50 MWe PT plant in Barranquilla, Colombia. Sundaray and Kandpal [

12] evaluated the techno-economic feasibility of a 100 MWe PT plant for different locations in India using SAM. Lemmer [

13] performed a techno-economic assessment of PT and PD plants in Morocco. The author presented a comparison of the two technologies in terms of economic feasibility, and SAM was used for the assessments. Wagner and Rubin [

14] presented the effects of thermal energy storage (TES) on the performance and economics of a 110 MWe PT plant operating with and without different backups. The investigation was performed by the authors using SAM. Kasesem et al. [

15] conducted a strengths, weaknesses, opportunities, and threats (SWOT) analysis for four CSP technologies in Saudi Arabia using SAM. SAM was also utilized by Praveen et al. [

16] for the performance assessment and optimization of a 100 MWe PT plant with TES in Abu Dhabi, United Arab Emirates. Belgasim et al. [

17] evaluated the potential of energy generation with a 50 MWe PT plant using SAM in Tajoura, Libya. All of the studies mentioned above have evaluated CSP potential for different countries worldwide using SAM. However, research on CSP potential and techno-economical investigations for Pakistan are rarely reported.

The current research is an attempt to investigate potential, performance, and economics of CSP generation in Pakistan. The investigations have been carried out for different locations in Pakistan, considering all CSP technologies. The performance and economic evaluations of CSP plants have been carried out utilizing SAM software. It is pertinent to mention that there are only a few other tools used for the analysis of CSP plants; however, as reported above, SAM is widely used for the analysis of CSP plants developed by national renewable energy laboratory (NREL) and that its licensing and support is quite reassuring. This paper is structured as follows.

Section 2 presents an overview of CSP technologies.

Section 3 provides an assessment of CSP sites in the country. Performance analysis is presented in

Section 4, while

Section 5 describes economic evaluation. Finally,

Section 6 concludes the paper.

2. Overview of CSP Technologies

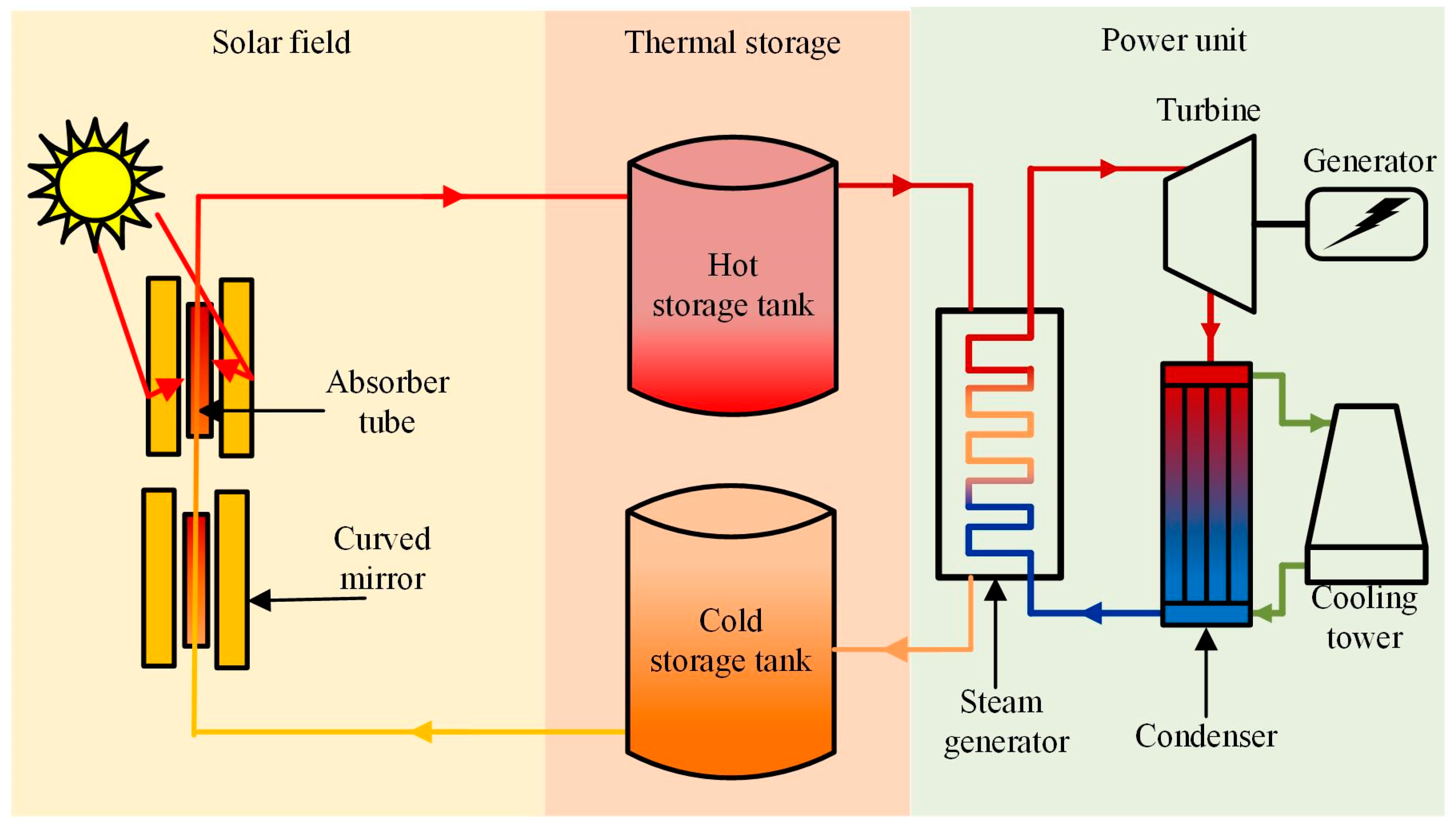

CSP is an extensive commercial method for electricity generation using solar energy. CSP is appropriate for the regions where the direct solar radiation and the number of sunshine hours are high. Generally, a CSP plant comprises of a solar field, TES system, and power block, as shown in

Figure 2. The solar field concentrates the solar radiation onto a specific point or line to heat an HTF. The heated HTFs can be used directly or indirectly [

17]. In the direct case, water is used as HTF for direct steam generations; whereas in the indirect case, different HTFs such as synthetic oil, molten salt, and Therminol VP-1 are used to heat water for a steam generation [

17]. Although direct HTF is cheaper, commercial storage for steam is lacking. On the other hand, indirect HTFs are expensive, but they can be stored. Thus, indirect HTFs are widely used in CSP plants worldwide [

15]. The heated HTF from the solar field flows into the TES system where additional energy is stored for continuous operation. Consequently, the HTF is used to produce steam in the steam generator, and the steam is used to drive the power unit to produce electricity. There are four main families of CSP technology which are classified by the approach how solar radiation is focused and received, as listed in

Table 1 [

18]. Fixed receivers remain, static independent of the focusing device, while mobile receivers move together with it. Besides, line focusing receivers concentrate the solar radiation onto a specific line while the solar radiation is focused onto a specific point in a point focusing receivers. Detailed overview of each CSP technology is presented in the following sections.

2.1. Parabolic Trough Systems

Parabolic trough (PT) systems are the most mature technologies used for CSP generation [

15,

17,

20,

21]. This is the reason that the PT plants are widely commercialized compared to other configurations of CSP [

15].

Figure 3 illustrates a schematic diagram of a PT system. The PT system consists of an array of parabolically curved mirrors/collectors and receivers. The collectors concentrate the solar radiation on the receivers which are filled with the HTF. The heated HTF is directed to the power unit for energy production via thermal storage. Generally, PT collectors consist of a single-axis tracking system to follow the solar radiation from east to west. The single tracking system leads to the reduction of material demand and land use factors. This is the reason that the initial cost of the PT plant is lower than dual tracking systems [

15]. Generally, the power block in a CSP plant uses a Rankine cycle consisting of a boiler/steam generator to produce electricity. Therefore, CSP plants have the flexibility to integrate with conventional power plants [

15]. Further characteristics of PT systems are summarized in

Table 2.

2.2. Solar Power Tower System

The solar power tower (SPT) system (also known as the central receiver system) is a type of point focusing system which consists of a number of circular two-axis tracking arrays. An array consists of numerous flat or slightly curved mirrors known as heliostats. The heliostats concentrate the solar radiation on a fixed point, which is a central receiver on top of a tower. The HTF is heated in the tower and then the HTF is directed to power block for energy production. A schematic diagram of the SPT system is presented in

Figure 4. The concentration ratio of SPT ranges from 300–1000, which leads to higher working temperatures [

17,

18,

22,

23]. This is the reason that the SPT plant has higher efficiency (20%–35%) compared to other CSP configurations [

17,

18,

22,

23]. However, due to dual tracking and relatively large land requirements, the initial/capital cost of the SPT plants is high. Nevertheless, numerous SPT plants are commercially demonstrated including the world’s largest CSP plant (Ivanpah) with a capacity of 392 MW in California, United States of America. It is important to mention that SPT systems continued to dominate the CSP market after PT systems [

8]. Further characteristics of SPT systems are presented in

Table 2.

2.3. Linear Fresnel Reflector System

A linear Fresnel reflector (LFR) system consists of an array of mirrors which concentrates the solar radiation on a fixed central receiver mounted on the top, as depicted in

Figure 5. Generally, LFR systems are considered a modified form of PT. The LFR systems are well known for their simplicity. LFR systems have almost flat or slightly concaved mirrors. In LFR systems, the receiver is separated from reflectors unlike in PT systems, thus reducing material demand and need of high pressure rotating components. In addition, the land use factor is also lowest for LFR systems. The simplicity of the mirrors, lowest material demand, and lowest land use factor leads to the reduction of the cost of the LFR system [

17]. However, the simplicity of the mirrors leads to low optical efficiency. This could be the reason that a few large scale LFR plants are installed worldwide. Further characteristics of LFR systems are summarized in

Table 2.

2.4. Parabolic Dish System

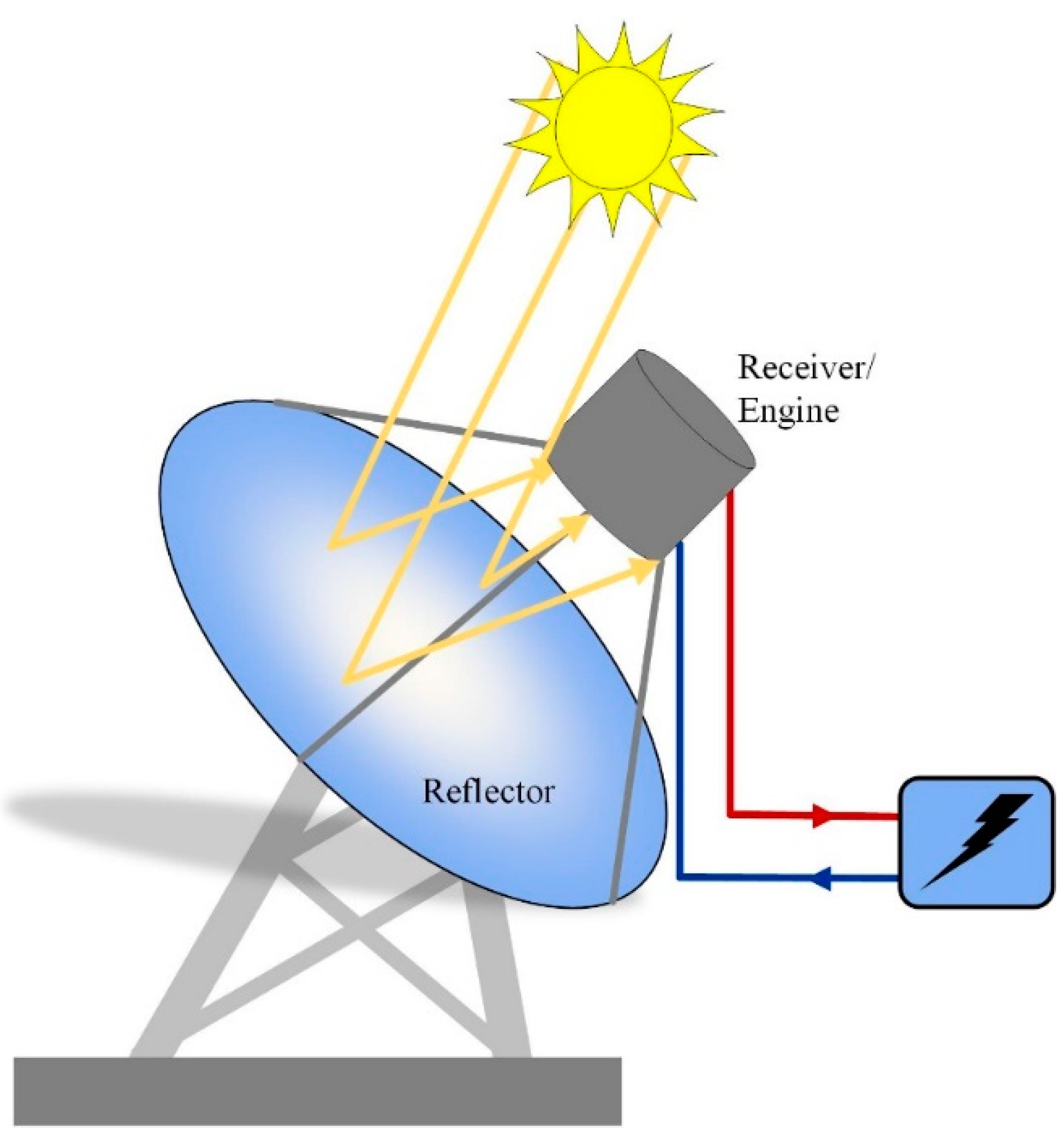

The parabolic dish (PD) system is a two-axis point focused system which concentrates the solar radiation on a focal point of the dish, as shown in

Figure 6. The focal point/receiver is filled with HTF. Generally, fluid or gas is used as HTF in parabolic dish systems. HTF systems are generally heated up to 1000 °C due to highest concertation ratio of the PD systems. Then, the HTF is directed to either the Stirling engine or gas turbine which convert the thermal energy of the fluid to electrical energy. Highest concentration ratio and optical efficiency result in higher energy production and low cost. However, the limited size of the PD systems limits the installation of large plants. Moreover, most of the existing PD plants are off-grid, and their capital cost is high [

15,

17]. This is the reason that PD systems are rarely commercialized. A summary of the characteristics of PD systems is presented in

Table 2.

3. Assessment of CSP Sites in Pakistan

There are several technical parameters which should be considered for the site selection of a CSP plant. Specifically, solar energy potential, land, and water availability should be cautiously considered while designing a CSP plant. Therefore, this section presents an overview of solar resources, land, and water availability in Pakistan.

3.1. Solar Resource Availability

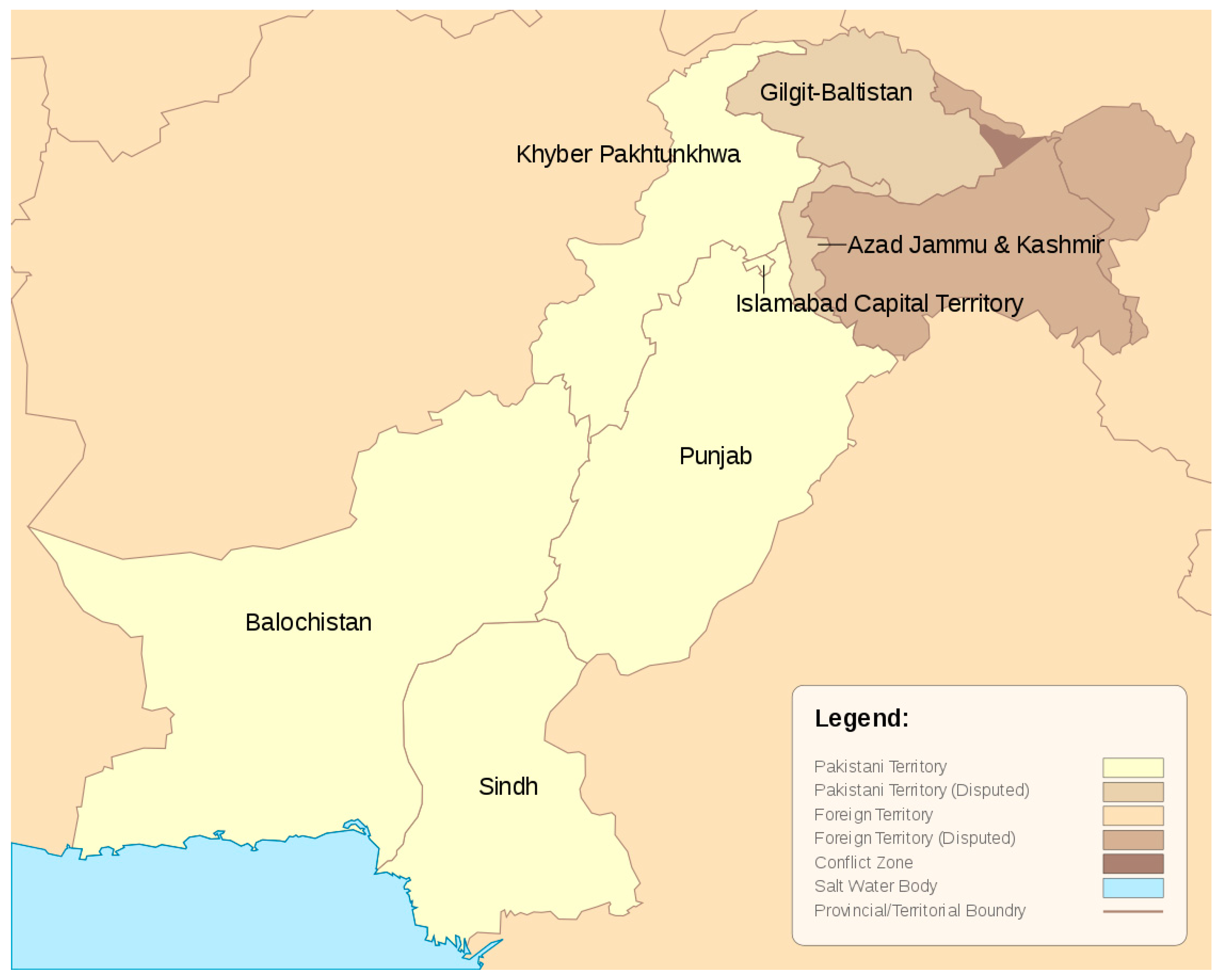

Pakistan is situated between latitude 30.3753° N and longitude 69.3451° E. Pakistan is divided into four provinces and four federal administered territories, as shown in

Figure 7 [

22]. The provinces are named Khyber–Pakhtunkhwa (KPK), Punjab, Sindh, and Baluchistan. Providentially, Pakistan is located in the sunbelt, which means that the potential of solar energy in the country is high with long sun shining hours. The distribution map of average annual global horizontal irradiation (GHI) and direct normal irradiation (DNI) across Pakistan is presented in

Figure 8 and

Figure 9, respectively [

25]. In

Figure 8, it can be seen that the average GHI is 1800 kWh/m

2 in northern regions (KPK and northern parts of Punjab province), and 2100 kWh/m

2 in southern regions (Sindh province). However, the highest average GHI is over 2200 kWh/m

2 in the western region, i.e., Baluchistan province. On the other hand, the average DNI is 1300 kWh/m

2 in the northern region, and it is 1700 kWh/m

2 in southern regions. However, the highest average DNI is over 2100 kWh/m

2 in the western region. Generally, CSP plants are considered economically feasible for the locations with DNI above 1800 kWh/m

2/year [

17]. Based on this fact, the western region (Baluchistan province) and most of the parts in the southern region (Sindh and few parts of Punjab province) of Pakistan are very promising for electricity production using CSP plants. Specifically, Quetta region and Kharan Desert in Baluchistan province, Hyderabad region and the Thar Desert in Sindh province, and Bahawalpur region and the Cholistan Desert in Punjab province are favorable places for CSP plants. However, soiling of mirrors could be a major issue in desert and arid regions.

3.2. Land Availability

In addition to the potential of solar energy, site selection based on land availability is an important activity related to planning and designing a CSP plant. Land occupancy of CSP technologies varies from 16,000 to 83,600 m

2/MW depending on configurations [

10]. For instance, the land occupancy of a PT plant is 40,000 m

2/MW [

10]. Therefore, a large area is required for a CSP plant. It is important to note that high agricultural and residential areas should be avoided for the installation of a CSP plant [

17]. Thus, remote and deserted areas represent the most suitable sites for CSP development [

17]. However, essential infrastructure, such as accessibility and connectivity, should also be considered.

Geographically, Pakistan is divided into three areas: the Northern Highlands (KPK and northern parts of Punjab province); Baluchistan plateau (Baluchistan province in the west region); and Indus River plain (consists of Sindh province and major subdivisions of Punjab province) [

26]. A topographical map of Pakistan is shown in

Figure 10 [

25]. As shown, northern highlands consist of mountains hence large flat land in that region is rear. However, the Indus River plain consists of mostly flat land. Major areas in the Indus River plain include Karachi, Hyderabad, Thar Desert, Sukkur, Bahawalpur, Cholistan Desert, and Multan. Thus, most of the Indus River plain is suitable for CSP development.

On the other hand, the Baluchistan plateau consists of upper highlands, lower highlands, plains, and deserts. The upper and lower highlands comprise of higher and lower mountains, which may not be suitable for CSP plants. However, plains and deserts such as the Kharan desert have flat areas which could be suitable for CSP development. It can be concluded that most of the areas with higher potential of solar energy such as the Indus River plain and Baluchistan plateau have flat land availability. Thus, it would not be a significant restriction for the establishment of CSP plants in Pakistan.

3.3. Water Availability

Water availability is an essential parameter for the operation of either a conventional or CSP plant. Generally, water is required to fulfill three purposes in a CSP power plant: (i) steam generation for power block cycle, (ii) cooling the power cycle, and (iii) mirror washing to reduce soiling effect. Water requirements of CSP plants ranged from 3.0–3.5 m

3/MWh [

17]. However, almost 95% of water is used for cooling whereas the remaining is used for mirrors washing and as working fluid [

17]. Water cooling (also known as wet or evaporative cooling) is an efficient cooling technology. Water cooling technology is usually employed at the region which has abundant water sources. On the other hand, dry cooling (also known as air cooling) can be employed in arid region or regions where water availability is not adequate. Although dry cooling increases the capital cost, it reduces the efficiency of the plant, and increases the levelized cost of energy (LCOE) [

15,

17]. Nevertheless, it can be employed to run the plants in an arid region and produce energy.

Rivers are the major source of water in Pakistan. A map of rivers and lakes in Pakistan is presented in

Figure 11 [

27]. It is important to mention here that most of the existing conventional power plants in Pakistan are located near rivers, specifically the Indus River. It can be seen in

Figure 11 that Pakistan has uneven water distribution. The Indus River plain (Sindh and Punjab province) have a wide network of rivers which makes this region most suitable for power plants with wet cooling. On the other hand, the Baluchistan plateau does not have many networks of rivers except for a few areas. Thus, the CSP plant with dry cooling could be a better option.

4. Simulations of CSP Plants in Pakistan

The performance analysis of CSP plants at typical climate conditions in Pakistan have been presented in this study. Based on the potential of solar energy, land, and water availability, four locations from four provinces of Pakistan were selected for the proposed study. The sites selected for the proposed work are as follows:

(i) Quetta (Province: Baluchistan; Region: Baluchistan Plateau)

This region has the abundant potential of solar energy, and flat land availability is not a concern specifically in plains and deserts. However, water availability is a major issue in the region.

(ii) Hyderabad (Province: Sindh; Region: Indus River plain)

The region has a good potential of solar energy, and availability of flat land and water is not an issue in the region since it is a part of Indus River plain.

(iii) Multan (Province: Punjab; Region: Indus River plain)

The region has a fair potential of solar energy, and availability of flat land and water is not an issue in the region.

(iv) Peshawar (Province: Khyber Pakhtunkhwa; Region: Northland highland)

Solar energy availability is not high and flat land is rare in the region. However, water scarcity is not an issue in the region. Therefore, the purpose of selecting Peshawar is to evaluate the CSP generation potential in KPK province and northland highlands region.

The performance of a CSP plant is highly affected by meteorological conditions such as solar radiation, ambient temperature, wind speed, relative humidity, soiling, sunshape, and atmospheric extinction. The average meteorological conditions of the proposed locations are listed in

Table 3 [

28].

Specifically, DNI is the most important parameters affecting the performance of a CSP plant. The meteorological data of the proposed location in a typical meteorological year (.TMY) format was obtained from the national renewable energy laboratory (NREL) database [

29]. The DNI of the proposed locations is presented in

Figure 12 [

29].

4.1. Simulation Results of the Proposed 50 MWe PT Plant

In this section, the system description and performance evaluation of the 50 MWe PT plant for four locations in Pakistan, which include Quetta, Hyderabad, Multan, and Peshawar are presented. The reason for considering the 50 MWe PT plant is that most of the commercial PT plants are operating under the same capacity [

17]. The performance simulations of all CSP plants have been carried out using SAM software. SAM software is developed and provided by the NREL, which is operated by the Alliance for Sustainable Energy, for the United States (U.S.) Department of Energy (DOE) and may be used for any purpose whatsoever [

28]. SAM can be used to simulate the techno-economic evaluations of different renewable energy sources, including CSP technologies [

28]. Numerous studies have been conducted on CSP technologies using SAM [

14,

15,

17,

30,

31]. The technical assumptions considered for the simulations of the 50 MWe PT plant are presented in

Table 4.

Firstly, simulations were carried for the proposed PT plant with evaporative cooling. Simulation results for monthly electric power produced by the 50 MWe PT plant for all locations is depicted in

Figure 13. It can be observed that maximum electricity production is obtained in summers whereas minimum in winters for all cases. It is attributed to higher solar radiation in summers, which leads to increased thermal energy and consequently increased electricity production, and vice versa for winters. Although hourly highest solar radiation is obseverd in winter for all cases, monthly highest DNI is not obtained in winters. The reason is inconsistency of solar radiation which is due to sunshape, atmospheric extinction, and soiling. On the other hand, the consistency of solar radiation can be seen for summer which leads to the highest monthly DNI. The higher monthly DNI leads to higher electricy production.

Specifically, it can be observed that monthly electricity production in Quetta is highest compared to other cities, followed by Hyderabad, Peshawar, and Multan. This is because of the potential of solar radiation in the region which highly affects electricity production. In addition, other annual performance parameters of the simulation are presented in

Table 5. It was found that maximum annual energy production, gross-to-net-conversion, and capacity factor contributed to Quetta and Hyderabad. Therefore, the performance of the PT plant is promising in Pakistan, specifically Quetta and Hyderabad. In addition, cooling water requirements increased with increased energy production, as listed in

Table 5. For instance, the highest energy production in Quetta leads to highest cooling water demand. Since the supply of cooling water could be an issue in regions such as Quetta, the simulations have been carried out with a dry/air-cooling system to investigate the effect on system performance.

The simulation results for monthly electricity production with air cooling for all regions are presented in

Figure 14. Comparing

Figure 13 and

Figure 14, it was found that electricity production reduced considerably. For instance, maximum electricity production was 17.848 GWh in September with evaporative cooling, which reduced to 15.75 GWh with air cooling in Quetta. Other performance parameters of the simulations with the air cooling system are presented in

Table 6. Comparing

Table 5 and

Table 6, it can be seen that annual energy production, gross-to-net-conversion, and capacity factor also reduced. For example, annual energy production, gross-to-net-conversion, and capacity factor were 148.59 GWh, 94.4%, 37.7%, respectively, with evaporative cooling in Quetta which reduced to 133.253 GWh, 90.2%, 33.8%, respectively, with air cooling. Nevertheless, electricity production through the PT plant with air cooling is still promising, especially in Quetta and Hyderabad.

4.2. Simulation Results of the Proposed 50 MWe SPT Plant

This section presents the system description and performance evaluation of the 50 MWe SPT plant in Pakistan. The technical assumptions of the 50 MWe SPT plant for simulations are summarized in

Table 7, and 50 MWe SPT plant’s heliostat field is presented in

Figure 15. For the SPT plant, the simulations were carried for both the evaporative cooling and air cooling. Firstly, the simulation results of the 50 MWe SPT plant with evaporative cooling for four locations in Pakistan are shown in

Figure 16. A similar trend can be observed for maximum electricity production in summers, whereas minimum in winters, as discussed in

Section 4.1. Also, the highest monthly electricity production was achieved in Quetta. Also,

Table 8 presents the annual performance parameters of the 50 MWe SPT plant with evaporative cooling. It was found that the maximum annual energy production, gross-to-net- conversion, and capacity factor contributed to Quetta followed by Hyderabad, Peshawar, and Multan. Moreover, 50 MWe SPT simulations have been carried out with air cooling, and the monthly electricity production is illustrated in

Figure 17. With air cooling, highest electricity production was also obtained in Quetta followed by Hyderabad, Peshawar, and Multan. However, comparing the simulation results of the 50 MWe SPT plant with evaporative and air cooling, the electricity generation dropped significantly for all locations. The annual performance of the 50 MWe SPT plant with air cooling is reported in

Table 9. Comparing

Table 8 and

Table 9, it can be noticed that the annual energy production, gross-to-net-conversion, and capacity factor also reduced. For example, annual energy production, gross-to-net-conversion, and capacity factor with evaporative cooling in Quetta were 233.23 GWh, 95.8%, 57.6%, respectively, which reduced to 209.80 GWh, 89.98%, 53.2%, respectively, with air cooling. Nonetheless, comparing the simulation results of the PT and SPT plant, the SPT plant shows better performance in terms of monthly electricity production and annual performance parameters. The reason behind this is the higher concentration ratio and higher efficiency. Furthermore, it is important to note that cooling water requirements of the SPT plant are lower than the PT plant for all locations.

4.3. Simulation Results of the Proposed 50 MWe LFR Plant

The technical assumptions for simulations of a 50 MWe LFR plant are listed in

Table 10, and monthly electricity production from the plant with evaporative cooling is illustrated in

Figure 18. It can be observed that the highest monthly energy production corresponds to summers and lowest to winters. This observation is similar to the PT plant and SPT plant. Also, to the maximum energy production to Quetta. In addition, annual performance parameters of the proposed 50 MWe LFR plant with evaporative cooling are presented in

Table 11. Similar to the PT plant and SPT plant, maximum annual energy production, gross-to-net-conversion, and capacity factor contributed to Quetta followed by Hyderabad, Peshawar, and Multan.

Figure 19 illustrated the monthly electricity production of the proposed 50 MWe LFR plant with air cooling. A reduction in monthly electricity production for all cities can be observed for the plant with air cooling. Similarly, a reduction in annual performance parameters for the LFR plant with air cooling can be observed in

Table 12. Furthermore, comparing the simulation results of the LFR with PT and SPT plant, it can be observed that the monthly energy production and annual performance parameters of the LFR plant showed lower performance in terms of monthly electricity production and annual performance parameters. The reason behind this is its simple design, low concentration ratio, and lower efficiency. However, the cooling water requirements of the LFR plant are lowest among all CSP technologies.

4.4. Simulation Results of the Proposed 5 MWe PD System

The performance of the 5 MWe parabolic dish system for different locations in Pakistan is presented in this section. Since large-scale parabolic dish systems are rarely commercialized, investigations have been carried out with a capacity of 5 MWe. The technical assumptions of the proposed parabolic dish system are listed in

Table 13, and monthly electricity production is presented in

Figure 20. As seen, the highest monthly electricity production corresponds to Quetta while lowest to Multan. Annual performance parameters (

Table 14) indicated that the higher annual energy production, gross-to-net conversion, and capacity factor correspond to Quetta. Specifically, comparing the annual results of the 5 MW PD system with the other 50 MWe CSP plant, it was found that the results of the PD system are very promising. This is attributed to the higher concertation ratio and high operating temperature. However, the capital and operation and maintenance (O & M) cost of the PD systems are highest [

15]. In addition, the technology is at the demonstration stage, and most of the existing PD systems are not connected to the grids [

15]. Thus, for Pakistan, which already lacks in the large scale CSP plant, it would be a tough decision to invest in PD systems at present. However, PD systems are attractive for small scale projects at remote areas.

5. Economic Analyses

The purpose of economic analysis is to evaluate the profitability/feasibility of CSP plants. Generally, the economic feasibility of power plants is evaluated in terms of LCOE. The LCOE evaluates the electricity costs produced throughout the lifetime of the CSP plant. Specifically, real LCOE and nominal LCOE were evaluated for the CSP plants. The nominal LCOE uses the current value of the dollar, and it is used for short term analysis. Whereas real LCOE uses constant and inflation adjusted value of the dollar, and it is used for long term analysis [

28,

32]. Determination of nominal LCOE takes into account different factors including

Electricity generation;

Direct capital cost: Equipment and installation cost;

Indirect capital cost: Approvals, engineering, and land cost;

Operation and maintenance (O&M) cost: Equipment operation, labor cost, and maintenance cost, etc.

The economic analyses of the proposed CSP plants at different locations of Pakistan were carried out using SAM. The economic assumptions considered for the simulations of CSP plants are listed in

Table 15. The LCOE of the CSP plants with evaporative cooling and air cooling are summarized in

Table 16. It is important to mention here that the water costs are not considered in the evaluation of LCOE.

Firstly, comparing evaporative cooling and air cooling, it was found that LCOE of CSP plants with evaporative cooling was lower for all cases compared to air cooling. For instance, real LCOE was 3.69 ¢/kWh with evaporative cooling for the PT plant in Quetta, and it increased to 4.12 ¢/kWh with air cooling. It is due to the fact that air cooling reduces the plant’s efficiency, which reduces energy production and increases the LCOE. Then, it was found that the LCOE is lowest for the PD system. It is attributed to its high concentration ratio, high temperature operation, and higher efficiency, which led to high power production and consequently reduced the energy cost. However, the PD system are not commercialized yet, as discussed in

Section 4.4. Subsequently, the LCOE for the PT plant is second lowest. Even though the capital cost of the PT plant is high, but an adequate amount of energy production led to reduce the LCOE. The LCOE for LFR plant is high compared to the PD system and PT plant. In the LFR plant, the capital cost is lowest, but lower energy production due to lower efficiency led to increase the LCOE. The highest LCOE was observed for the SPT plant. Although energy production of the SPT plant was highest, the high capital cost increased the LCOE.

Nevertheless, the energy cost is competitive with the energy cost of existing conventional power plants in Pakistan [

32]. Specifically, the LCOE of the PT Plant is much lower. Also, the LCOE of CSP plants for different locations in Pakistan is in good agreement with the LCOE of CSP plants available in the most recent literature [

15,

21,

33,

34,

35]. Thus, it can be concluded that the CSP plants in Pakistan are economically feasible/viable.

Additionally, it has been observed that solar field cost contributes the biggest in the net capital cost of the CSP plant. The simulations revealed that the contribution of solar field cost in net capital cost of CSP plants was as follows: PT plant (32.4%), SPT (35.6%), LFR plant (28.6%), and PD system (47.9%). In Pakistan, the land cost in the Baluchistan plateau and Indus plain is low, which could reduce the net capital cost of CSP plants. On the other hand, since most of the CSP equipment are imported, which increases the overall cost, the net capital can be reduced by localization. Localization will enhance the local industry and create more jobs in the country. Consequently, the socio-economic condition of the country will improve. Also, the LCOE of the CSP plants can be further reduced by carbon trading under the clean development mechanism (CDM) of the Kyoto Protocol (KP).

In summary, the results of the CSP plants simulations are promising for different regions of Pakistan. Specifically, Quetta and Hyderabad regions are very attractive for CSP development, and PT and SPT could be suitable CSP technologies in the region. Specifically, SPT plants with air cooling could be a promising option for energy production in Quetta. Moreover, low LCOE revealed that CSP plants are economically viable too. Therefore, the utilization of solar energy for CSP generation could provide opportunities for clean energy production and eradicate environmental pollution in the country.

6. Conclusions

This paper has investigated the potential of CSP, performance, and economic analyses of four CSP technologies for different locations in Pakistan. Following a brief introduction of the CSP technologies, assessment of CSP sites, including solar resource, land, and water availability in Pakistan, was investigated. It was found that CSP potential is promising in Baluchistan, Sindh, and the lower (southern) parts of Punjab province. Particularly, Quetta (Baluchistan province) has the highest CSP potential in the country with DNI 2100 kWh/m2. Also, the availability of flat land is abundant in the Indus River plain (Sindh and Punjab province). On the other hand, the plains and deserts (especially Kharan Desert) in the Baluchistan plateau are suitable for CSP plants whereas vast flatlands are rear in northern highlands which make these areas less suitable for the CSP installation.

Furthermore, water availability is uneven in Pakistan. Sindh and Punjab provinces have a wide network of rivers which makes these regions most suitable for power plants with wet cooling. On the other hand, Baluchistan plateau does not have many networks of rivers except for a few areas. Thus, the CSP plant with dry cooling could be a better option.

Based on site selection, performance simulations of four CSP technologies for four cities of Pakistan, including Quetta, Hyderabad, Multan, and Peshawar were investigated with SAM software. Design gross output for the PT, SPT, and LFR plant was considered to be 50 MWe, whereas 5 MWe for the PD system. The simulations revealed that the highest energy production was obtained in summers, whereas the lowest in winters. For all CSP technologies, maximum energy production was obtained for Quetta followed by Hyderabad, Multan, and Peshawar. For 50 MWe plants, the performance and power production capacity was higher for the SPT plant followed by the PT plant and LFR plant. The performance of CSP plants with evaporative cooling was higher compared to air cooling.

Nevertheless, the performance of all 50 MWe plants with air cooling was found quite satisfactory, especially the SPT plant in Quetta. The performance of the 5 MWe PD system was highest among all CSP plants, but it cannot be commercialized on a large scale because the technology is still at the demonstration stage. However, PD systems could be promising for small scale projects in remote areas. Generally, Quetta, Hyderabad, Sukkur, and Multan regions are very attractive for CSP development, and PT and SPT could be suitable CSP technologies in the region. Specifically, the SPT plant with air cooling could be a promising option for energy production in Quetta.

Economic analyses of the CSP plants for different locations were undertaken using SAM software. The assessment revealed that the net capital cost was highest for the PD system, followed by the SPT plant, PT plant, and LFR plant, respectively. The solar field cost contributed major share in the net capital cost of all CSP plants. Furthermore, energy cost evaluation showed that the LCOE was lowest for PD systems followed by the PT plant and LFR plant. The highest LCOE was observed for the SPT plant. Although energy production of the SPT plant was higher, high capital cost increased the LCOE. The calculated LCOE is in good agreement with the LCOE of CSP plants available in the literature, and competitive with an energy cost of existing conventional power plants in Pakistan. Thus, it can be concluded that the CSP plants in Pakistan are economically feasibility. Therefore, the utilization of solar energy for CSP generation could provide opportunities for clean energy production and eradicate environmental pollution in the country.