The Biomass Potential and GHG (Greenhouse Gas) Emissions Mitigation of Straw-Based Biomass Power Plant: A Case Study in Anhui Province, China

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Biomass Production and Characterization

3.2. Assessment and Availability Analysis

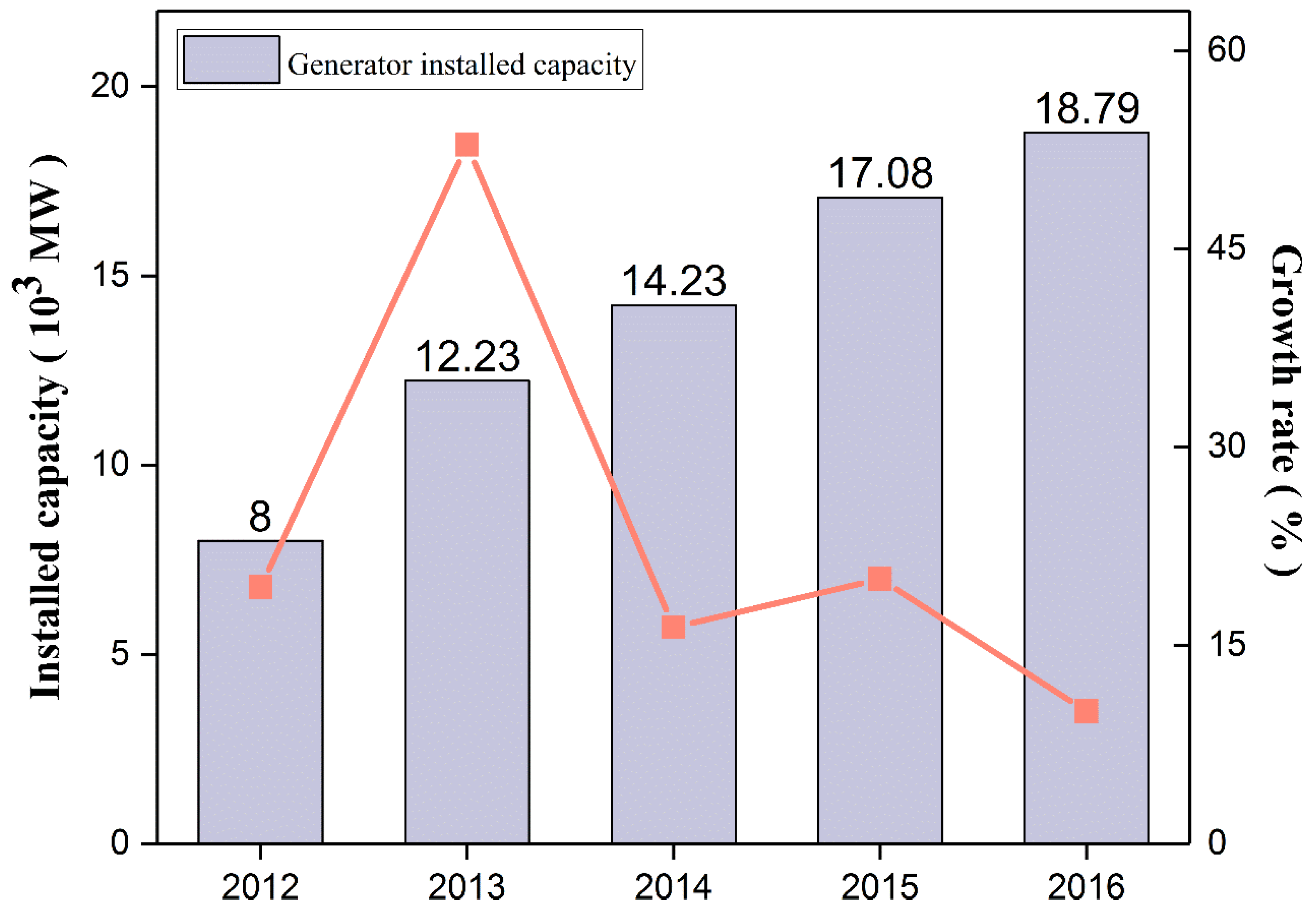

3.3. General Status of Biomass-Based Power Generation

3.4. GHG Emissions Mitigation Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

Appendix A.1. Statistical Methods for Biomass Resources

Appendix A.1.1. Crop Straw Resources

| Rice | Wheat | Maize | Beans | Potato | |

|---|---|---|---|---|---|

| Residue/grain ration | 1.28 | 1.38 | 2.05 | 1.68 | 1.16 |

| Collection Index | 0.64 | 0.73 | 0.92 | 0.83 | 0.86 |

Appendix A.1.2. Forestry Byproducts

- where F: Amount of agroforestry biomass resources (104 t)

- F11: Amount of residue from wood harvesting (104 t)

- F12: Amount of residue from wood production and processing (104 t)

- F13: Amount of residue from bamboo harvesting (104 t)

- F14: Amount of residue from bamboo production and processing

Amount of Residue from Wood Harvesting

Amount of Residue from Wood Production and Processing

Amount of Residue from Bamboo Harvesting

Amount of Residue from Bamboo Production and Processing

| Full Name | Unit | Value | Sources | |

| V | Wood yield | 104 m3 | 561 | Anhui Statistical Yearbook |

| b | Average air-dry density of the timber | t/m3 | 0.618 | Wang et al., 2017 |

| r1 | average wood outturn rate | % | 79.22 | Wang et al., 2017 |

| pr | Output ratio of production and processing residues | % | 20 | Zhang et al., 2015 |

| rr | Recoverable ratio of production and processing residues | % | 26.14 | Zhang et al., 2015 |

| A | Bamboo Yield | 104 | 16,031 | Anhui Statistical Yearbook |

| g | Unit Quantity Bamboo Weight | t | 150 | Wang et al., 2017 |

| r2 | The proportion of bamboo leaf weight equal to the bamboo weight | % | 38.07 | Wang et al., 2017 |

| r3 | The proportion of bamboo processing residue | % | 62 | Wang et al., 2017 |

Appendix A.2. The Calculation Method of GHG Emissions Reductions of Biomass Power Plants According to Clean Development Mechanism (CDM)

Appendix A.2.1. Baseline Emissions

Baseline Emissions from Electricity Generation

The Calculation of Uncontrolled Burning or Decay of Biomass Residues BEBR,y

Appendix A.2.2. Project Emission

Appendix A.2.3. Leakage Emissions

References

- IEA. Global Energy & CO2 Status Report 2017; IEA: Paris, France, 2018; p. 1. [Google Scholar]

- Tong, D.; Zhang, Q.; Davis, S.J.; Liu, F.; Zheng, B.; Geng, G.; Xue, T.; Li, M.; Hong, C.; Lu, Z.; et al. Targeted emission reductions from global super-polluting power plant units. Nat. Sustain. 2018, 1, 59–68. [Google Scholar] [CrossRef]

- Tao, S.; Ru, M.Y.; Du, W.; Zhu, X.; Zhong, Q.R.; Li, B.G.; Shen, G.F.; Pan, X.L.; Meng, W.J.; Chen, Y.L.; et al. Quantifying the rural residential energy transition in China from 1992 to 2012 through a representative national survey. Nat. Energy 2018, 3, 567–573. [Google Scholar] [CrossRef]

- Wang, L.; Dai, J. The perspectives on the long-term trend of China’s energy development. Int. Pet. Econ. 2017, 8, 58–61, (In Chinese with English abstract). [Google Scholar]

- Chu, S.; Cui, Y.; Liu, N. The path towards sustainable energy. Nat. Mater. 2017, 16, 16–22. [Google Scholar] [CrossRef] [PubMed]

- Chikkatur, A.P.; Chaudhary, A.; Sagar, A.D. Coal Power Impacts, Technology, and Policy: Connecting the Dots. Annu. Rev. Environ. Resour. 2011, 36, 101–138. [Google Scholar] [CrossRef]

- Li, H.; Liu, G.; Cao, Y. Levels and environmental impact of PAHs and trace element in fly ash from a miscellaneous solid waste by rotary kiln incinerator, China. Nat. Hazards 2015, 9, 811–822. [Google Scholar] [CrossRef]

- Li, H.; Liu, G.; Cao, Y. Content and Distribution of Trace Elements and Polycyclic Aromatic Hydrocarbons in Fly Ash from a Coal-Fired CHP Plant. Aerosol Air Qual. Res. 2014, 14, 1179–1188. [Google Scholar] [CrossRef]

- Li, H.; Chen, Y.; Cao, Y.; Liu, G.; Li, B. Comparative study on the characteristics of ball-milled coal fly ash. J. Therm. Anal. Calorim. 2016, 124, 839–846. [Google Scholar] [CrossRef]

- Greenblatt, J.B.; Brown, N.R.; Slaybaugh, R.; Wilks, T.; Stewart, E.; McCoy, S.T. The Future of Low-Carbon Electricity. Annu. Rev. Environ. Resour. 2017, 42, 289–316. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, F.; Hu, H.; Yang, L.; Guo, P.; Xiao, B. Assessment of sustainable biomass resource for energy use in China. Biomass Bioenergy 2011, 35, 1–11. [Google Scholar] [CrossRef]

- Bentsen, N.S.; Felby, C. Biomass for energy in the European Union—A review of bioenergy resource assessments. Biotechnol. Biofuels 2012, 5, 25. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Spaargaren, G.; Heerink, N.; Mol, A.P.J.; Wang, C. Energy consumption practices of rural households in north China: Basic characteristics and potential for low carbon development. Energy Policy 2013, 55, 128–138. [Google Scholar] [CrossRef]

- Panwar, N.L.; Kaushik, S.C.; Kothari, S. Role of renewable energy sources in environmental protection: A review. Renew. Sustain. Energy Rev. 2011, 15, 1513–1524. [Google Scholar] [CrossRef]

- Robertson, G.P.; Hamilton, S.K.; Barham, B.L.; Dale, B.E.; Izaurralde, R.C.; Jackson, R.D.; Landis, D.A.; Swinton, S.M.; Thelen, K.D.; Tiedje, J.M. Cellulosic biofuel contributions to a sustainable energy future: Choices and outcomes. Science 2017, 356, eaal2324. [Google Scholar] [CrossRef] [PubMed]

- Zhao, G. Assessment of potential biomass energy production in China towards 2030 and 2050. Int. J. Sustain. Energy 2018, 37, 47–66. [Google Scholar] [CrossRef]

- McKendry, P. Energy production from biomass (part 2): Conversion technologies. Bioresour. Technol. 2002, 83, 47–54. [Google Scholar] [CrossRef]

- Wu, C.; Yin, X.; Yuan, Z.; Zhou, Z.; Zhuang, X. The development of bioenergy technology in China. Energy 2010, 35, 4445–4450. [Google Scholar] [CrossRef]

- Wang, H.W.; Shi, Y.J.; Hong-Li, L.I.; Zhao, B.G.; Zhu, C. Analysis on Energy-Saving Emissions Effect of Biomass Power Generation. Power Syst. Technol. 2007, 31, 344–346. [Google Scholar]

- Sanchez, D.L.; Nelson, J.H.; Johnston, J.; Mileva, A.; Kammen, D.M. Biomass enables the transition to a carbon-negative power system across western North America. Nat. Clim. Chang. 2015, 5, 230–235. [Google Scholar] [CrossRef]

- Rosillo-Calle, F.; Woods, J. The Biomass Assessment Handbook: Energy for a Sustainable Environment; Routledge: New York, NY, USA, 2015; p. 7. [Google Scholar]

- Zheng, H.; Xing, X.; Hu, T.; Zhang, Y.; Zhang, J.; Zhu, G.; Li, Y.; Qi, S. Biomass burning contributed most to the human cancer risk exposed to the soil-bound PAHs from Chengdu Economic Region, western China. Ecotoxicol. Environ. Saf. 2018, 159, 63–70. [Google Scholar] [CrossRef]

- Liu, J.; Wang, S.; Wei, Q.; Yan, S. Present situation, problems and solutions of China׳s biomass power generation industry. Energy Policy 2014, 70, 144–151. [Google Scholar] [CrossRef]

- Fournel, S.; Palacios, J.H.; Morissette, R.; Villeneuve, J.; Godbout, S.; Heitz, M.; Savoie, P. Influence of biomass properties on technical and environmental performance of a multi-fuel boiler during on-farm combustion of energy crops. Appl. Energy 2015, 141, 247–259. [Google Scholar] [CrossRef]

- Hao, L.; Hao, D.; Zhou, D.Q.; Peng, Z. A site selection model for a straw-based power generation plant with CO2 emissions. Sustainability 2014, 6, 7466–7481. [Google Scholar]

- Jumpponen, M.; Rönkkömäki, H.; Pasanen, P.; Laitinen, J. Occupational exposure to solid chemical agents in biomass-fired power plants and associated health effects. Chemosphere 2014, 104, 25–31. [Google Scholar] [CrossRef] [PubMed]

- Freiberg, A.; Scharfe, J.; Murta, V.C.; Seidler, A. The Use of Biomass for Electricity Generation: A Scoping Review of Health Effects on Humans in Residential and Occupational Settings. Int. J. Environ. Res. Public Health 2018, 15, 354. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.G.; Li, A. A multi-objective sustainable location model for biomass power plants: Case of China. Energy 2016, 112, 1184–1193. [Google Scholar] [CrossRef]

- Juntarawijit, C.; Juntarawijit, Y.; Boonying, V. Health impact assessment of a biomass power plant using local perceptions: Cases studies from Thailand. Impact Assess. Proj. Apprais. 2014, 32, 170–174. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhou, D.; Zhou, P.; Ding, H. Cost Analysis of straw-based power generation in Jiangsu Province, China. Appl. Energy 2013, 102, 785–793. [Google Scholar] [CrossRef]

- Nguyen, T.L.T.; Hermansen, J.E.; Mogensen, L. Environmental performance of crop residues as an energy source for electricity production: The case of wheat straw in Denmark. Appl. Energy 2013, 104, 633–641. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhou, D.; Fang, X. Analysis on the policies of biomass power generation in China. Renew. Sustain. Energy Rev. 2014, 32, 926–935. [Google Scholar] [CrossRef]

- Xingang, Z.; Zhongfu, T.; Pingkuo, L. Development goal of 30GW for China’s biomass power generation: Will it be achieved? Renew. Sustain. Energy Rev. 2013, 25, 310–317. [Google Scholar] [CrossRef]

- Yang, Q.; Fei, H.; Chen, Y.Q.; Yang, H.P.; Chen, H.P. Greenhouse gas emissions of a biomass-based pyrolysis plant in China. Renew. Sustain. Energy Rev. 2016, 53, 1580–1590. [Google Scholar] [CrossRef]

- Wu, H.; Yuan, Z.; Zhang, Y.; Gao, L.; Liu, S. Life-cycle phosphorus use efficiency of the farming system in Anhui Province, Central China. Resour. Conserv. Recycl. 2014, 83, 1–14. [Google Scholar] [CrossRef]

- Li, H.; Cao, Y.; Wang, X.; Ge, X.; Li, B.; Jin, C. Evaluation on the Production of Food Crop Straw in China from 2006 to 2014. BioEnergy Res. 2017, 10, 949–957. [Google Scholar] [CrossRef]

- Krukanont, P.; Prasertsan, S. Geographical distribution of biomass and potential sites of rubber wood fired power plants in Southern Thailand. Biomass Bioenergy 2004, 26, 47–59. [Google Scholar] [CrossRef]

- Wang, X.W.; Cai, Y.P.; Chao, D. Evaluating China’s biomass power production investment based on a policy benefit real options model. Energy 2014, 73, 751–761. [Google Scholar] [CrossRef]

- Ding, C. Industrial Boiler Equipment; China Machine Press: Beijing, China, 2005. [Google Scholar]

- Rodríguez-Monroy, C.; Mármol-Acitores, G.; Nilsson-Cifuentes, G. Electricity generation in Chile using non-conventional renewable energy sources—A focus on biomass. Renew. Sustain. Energy Rev. 2018, 81, 937–945. [Google Scholar] [CrossRef]

- Suramaythangkoor, T.; Gheewala, S.H. Potential of practical implementation of rice straw-based power generation in Thailand. Energy Policy 2008, 36, 3193–3197. [Google Scholar] [CrossRef]

- Sun, Y.; Cai, W.; Chen, B.; Guo, X.; Hu, J.; Jiao, Y. Economic analysis of fuel collection, storage, and transportation in straw power generation in China. Energy 2017, 132, 194–203. [Google Scholar] [CrossRef]

- Lin, B.; He, J. Is biomass power a good choice for governments in China? Renew. Sustain. Energy Rev. 2017, 73, 1218–1230. [Google Scholar] [CrossRef]

- Wang, T.; Huang, H.; Yu, C.; Fang, K.; Zheng, M.; Luo, Z. Understanding cost reduction of China’s biomass direct combustion power generation—A study based on learning curve model. J. Clean. Prod. 2018, 188, 546–555. [Google Scholar] [CrossRef]

- Opinions on the Implementation of Financial Awards for Crop Residue Electricity Generation. Available online: http://ah.anhuinews.com/system/2014/07/17/006489341.shtml (accessed on 7 September 2019).

- Yao, H. Potential to Decrease GHG Emissions from Biomass Resources in China. Master’s Thesis, Lappeenranta University of Technology, Lappeenranta, Finland, 2016. [Google Scholar]

- Wang, X.; Sun, C.; Long, Z.; Peng, L.; Zeng, M. Research on the Emission Reduction Problem of Biomass Power Generation. In Proceedings of the International Conference on Computer Engineering, Information Science & Application Technology, Guilin, China, 24–25 September 2016. [Google Scholar]

- Muench, S. Greenhouse gas mitigation potential of electricity from biomass. J. Clean. Prod. 2015, 103, 483–490. [Google Scholar] [CrossRef]

- Sebastián, F.; Royo, J.; Gómez, M.; Duic’, N.; Guzovic, Z. Cofiring versus biomass-fired power plants: GHG (Greenhouse Gases) emissions savings comparison by means of LCA (Life Cycle Assessment) methodology. Energy 2011, 36, 2029–2037. [Google Scholar] [CrossRef]

| Biomass Power Plant | Installed Capacity (MW) | Annual Power Supply (MWh) | Emission Reductions (t CO2-Eq) | Reduction Per Unit of Production (t/MWh) |

|---|---|---|---|---|

| Anqin Datang | 30 | 184,200 | 149,540 | 0.81 |

| Fuyang Guozhen | 24 | 176,060 | 232,115 | 1.32 |

| Bengbu Kaidi | 24 | 153,160 | 125,216 | 0.82 |

| Tongcheng Kaidi | 24 | 112,550 | 91,914 | 0.82 |

| Wangjiang Kaidi | 24 | 158,140 | 126,343 | 0.80 |

| Suzhou Huadian | 25 | 183,010 | 117,354 | 0.64 |

| Guzhen National Energy | 30 | 220,910 | 141,973 | 0.64 |

| Dangshan Guangda | 30 | 244,450 | 141,078 | 0.58 |

| Nanling Kaidi | 30 | 203,980 | 137,606 | 0.67 |

| Huoqiu Kaidi | 30 | 202,810 | 133,082 | 0.66 |

| Huainan Kaidi | 30 | 131,050 | 88,324 | 0.67 |

| Shouxian Guoneng | 30 | 230,970 | 147,971 | 0.64 |

| Lujiang Kaidi | 30 | 187,910 | 125,121 | 0.67 |

| Jinzhai Kaidi | 30 | 209,220 | 137,281 | 0.66 |

| Huoshan Kaidi | 30 | 190,020 | 125,006 | 0.66 |

| Hanshan Guangda | 30 | 237,290 | 311,148 | 1.31 |

| Chizhou 325 | 25 | 160,540 | 98,131 | 0.61 |

| Linquan National Energy | 30 | 243,210 | 154,907 | 0.64 |

| Shucheng Zhongjieneng | 30 | 98,270 | 69,359 | 0.71 |

| Mengcheng National Energy | 30 | 242,960 | 152,971 | 0.63 |

| Langxi Li’ang | 30 | 148,360 | 146,837 | 0.99 |

| Huaiyuan Guangda | 30 | 58,300 | 41,217 | 0.71 |

| Dingyuan Guangda | 30 | 59,320 | 41,995 | 0.71 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Min, X.; Dai, M.; Dong, X. The Biomass Potential and GHG (Greenhouse Gas) Emissions Mitigation of Straw-Based Biomass Power Plant: A Case Study in Anhui Province, China. Processes 2019, 7, 608. https://doi.org/10.3390/pr7090608

Li H, Min X, Dai M, Dong X. The Biomass Potential and GHG (Greenhouse Gas) Emissions Mitigation of Straw-Based Biomass Power Plant: A Case Study in Anhui Province, China. Processes. 2019; 7(9):608. https://doi.org/10.3390/pr7090608

Chicago/Turabian StyleLi, Hui, Xue Min, Mingwei Dai, and Xinju Dong. 2019. "The Biomass Potential and GHG (Greenhouse Gas) Emissions Mitigation of Straw-Based Biomass Power Plant: A Case Study in Anhui Province, China" Processes 7, no. 9: 608. https://doi.org/10.3390/pr7090608

APA StyleLi, H., Min, X., Dai, M., & Dong, X. (2019). The Biomass Potential and GHG (Greenhouse Gas) Emissions Mitigation of Straw-Based Biomass Power Plant: A Case Study in Anhui Province, China. Processes, 7(9), 608. https://doi.org/10.3390/pr7090608