Abstract

Lab-on-a-Disc (LoaD) biosensors are increasingly a promising solution for many biosensing applications. In the search for a perfect match between point-of-care (PoC) microfluidic devices and biosensors, the LoaD platform has the potential to be reliable, sensitive, low-cost, and easy-to-use. The present global pandemic draws attention to the importance of rapid sample-to-answer PoC devices for minimising manual intervention and sample manipulation, thus increasing the safety of the health professional while minimising the chances of sample contamination. A biosensor is defined by its ability to measure an analyte by converting a biological binding event to tangible analytical data. With evolving manufacturing processes for both LoaDs and biosensors, it is becoming more feasible to embed biosensors within the platform and/or to pair the microfluidic cartridges with low-cost detection systems. This review considers the basics of the centrifugal microfluidics and describes recent developments in common biosensing methods and novel technologies for fluidic control and automation. Finally, an overview of current devices on the market is provided. This review will guide scientists who want to initiate research in LoaD PoC devices as well as providing valuable reference material to researchers active in the field.

1. Introduction

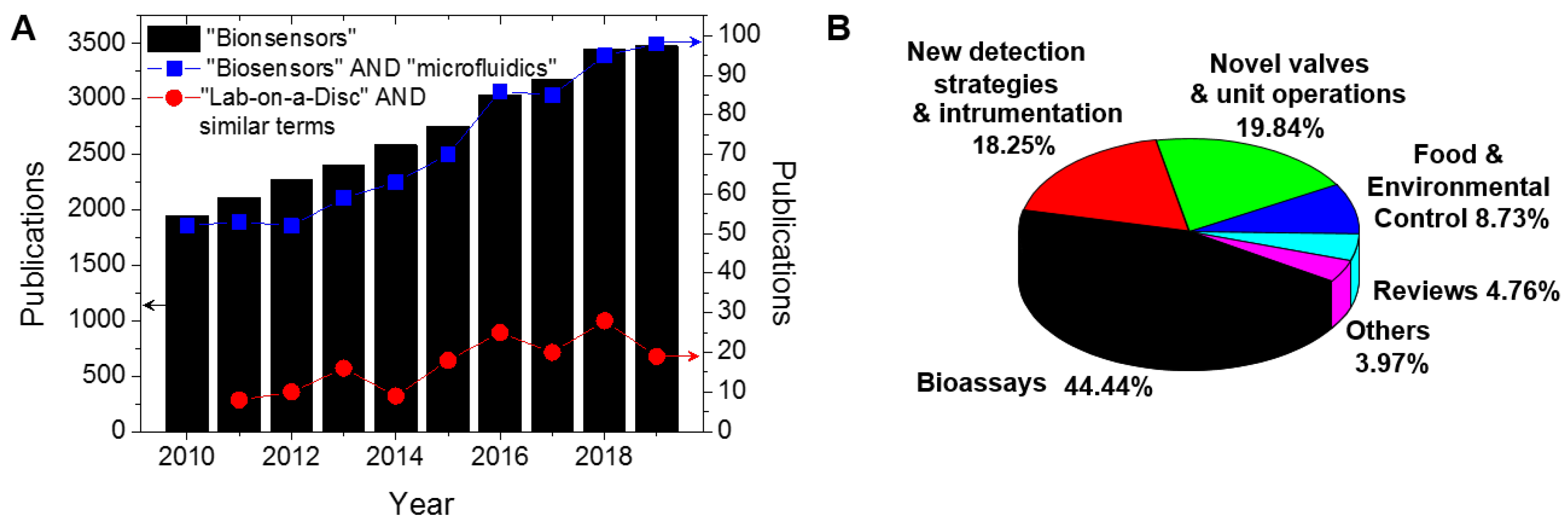

The development of microfluidic biosensors with rapid, sensitive, and selective response has been the focus of many research laboratories. Biosensors can be focused both on the clinical diagnosis of silent diseases, such as cancer, to guarantee that the patient is referred to as quickly as possible to the appropriate treatment, and in the routine control of chronic diseases such as diabetes, to give a rapid and easy indication of the medication dosage. Biosensors are defined by the International Union of Pure and Applied Chemistry (IUPAC) as “a device that uses specific biochemical reactions mediated by isolated enzymes, immunosystems, tissues, organelles or whole cells to detect chemical compounds usually by electrical, thermal or optical signals” [1]. The biomolecule responsible for the analyte recognition is denoted as the biorecognition element [2], and is the key for the specificity of the biosensor. Since 2010, about 28,000 articles have been published in accordance with ISI of knowledge (Web of Science) with the topic “biosensors” (black bars on Figure 1A). Biosensors exhibit advantages over the traditional analytical methods including low-cost of manufacture, fast response time, easy handling (does not demand trained operators), portability, better batch-to-batch reproducibility, and often have comparable sensitivity and selectivity. Despite this, few biosensors have been commercialised due to the challenges with translating laboratory-based platforms to devices and instruments suitable for widespread application in practical situations.

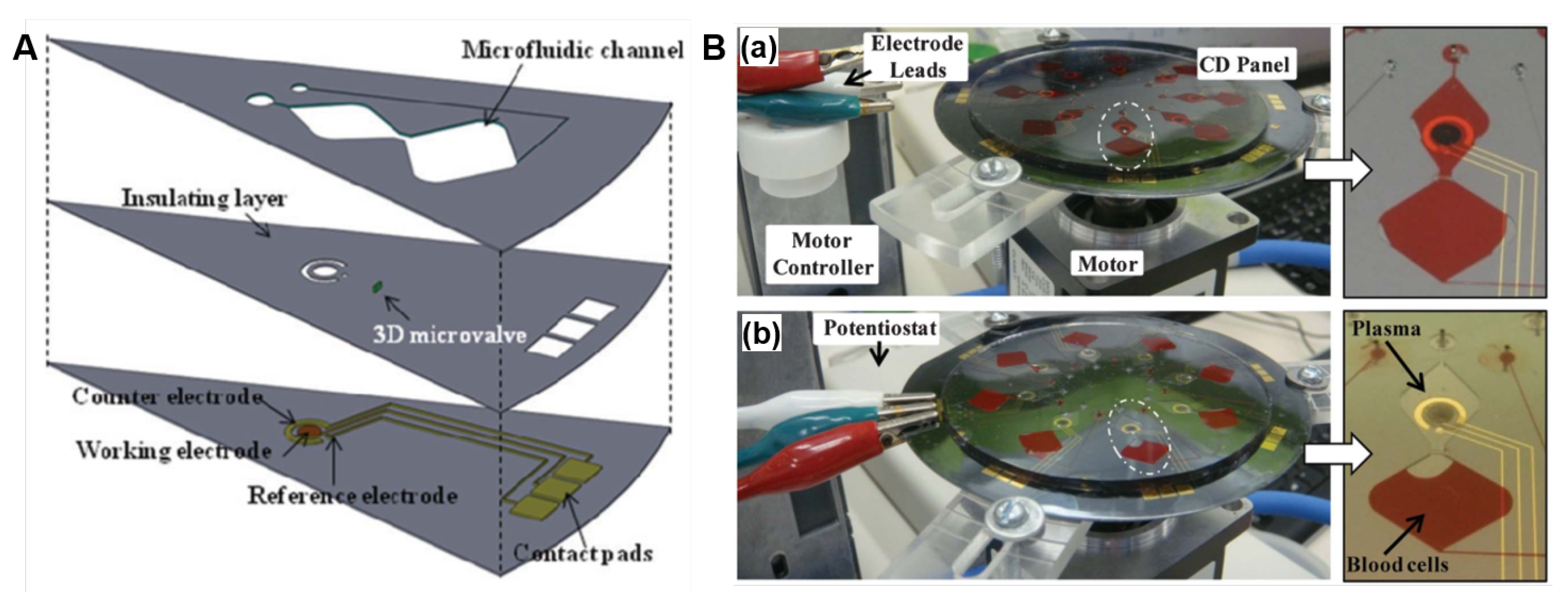

Figure 1.

Web of Science results analysis by publication year using the topic (A) “biosensors” (black bars), the combination of “biosensors” and “microfluidics” (connected blue squares), and the terms “lab-on-a-disc” or “lab-on-a-CD” or “bio-disk” or “lab-CD” or “lab-disc” (connected red circles). (B) “lab-on-a-disc” results distributed in applications focus. Data from Clarivate Analytics (ISI Web of Knowledge [6]) in 18 May 2020.

Sample preparation is a critical step in ensuring that a biosensor can meet the required sensitivity and specificity. Sample preparation is often an arduous and labour-intensive task involving a range of laboratory unit operations (LUOs) such as metering, mixing, separation, resuspension, and elution. The versatility and usefulness of a biosensor is greatly reduced if sample preparation must be performed manually. Therefore, much effort has been made to encapsulate biosensors within microfluidic devices, or Lab-on-a-Chip devices, which can fully automate the required LUOs and therefore offer sample-to-answer performance. Microfluidics is related to the science and technology of systems that process or manipulates small amounts of fluids [3,4]. Biosensors based on microfluidic technology can offer reduced reagent volumes, reduced sample volume, increased automation, and can function without requiring expensive and large instrumentation. These advantages, combined with the potential for mass manufacturing, can lead to low-cost tests and can prevent sample and operator contamination by minimising the user intervention [5]. The combination of “biosensors” and “microfluidics” has been a consistent focus of the research community as shown in Figure 1A (connected blue squares).

Flow control (via pumping and valving) is a critical technology for enabling microfluidic systems. Prior to undertaking the design and fabrication of LoaD technology, it is important to understand non-centrifugally induced fluid flow mechanisms. Many methods of fluid manipulation and delivery have been reported. Passively driven microfluidics is a popular method as it is operated without an external fluid delivery system or actuator. Techniques such as osmosis [7,8], capillary action [9], pressure [10], gravity-driven flow [11], surface tension [12], vacuum-driven pressure [13], and hydrostatic flow [14] techniques can all be applied to achieve adequate fluid flow within microchannels. Applying these methods to microfluidic devices creates a robust, self-sufficient platform which can be utilised in any POC setting. Applying external triggers can further the capabilities of the devices and incorporates a variety of active driven device techniques. Manipulating fluid using an external trigger can allow for more complicated assays to be carried out in situ. Active fluid flow methods include electroosmotic [15], acoustic [16], photo-actuated [17], and pumping [18]. Both passive and active pumping mechanisms are important in understanding the dynamics of microfluidic devices. These methods may also be applied to centrifugal devices and can be amalgamated to create highly comprehensive POC tools. Centrifugal platforms can incorporate both types of fluid flow techniques; however, centrifugal forces play the main role of fluid displacement within the platform architecture. The Lab-on-a-Disc (LoaD) platform uses a typically disc-shaped cartridge and the pumping is via the centrifugal force; the disc-shaped chip is rotated about its axis. The general advantages of polymer chip-based microfluidics are that (i) mass production is possible with non-expensive infrastructure and common polymers; (ii) low-cost acrylics or thermoplastics have replaced glass for chip production, and, therefore, the cost per unit is significantly reduced compared to other in vitro diagnostic (IVD) tests [19]; aside from those advantages, the LoaD systems present particular advantages, specifically that (i) the fluidic propulsion depends only on a low-cost and controllable spinning motor, without the need of pneumatic interfaces and pumps; (ii) liquid handling is widely independent of the sample properties, i.e., pH or ionic strength (pivotal for electrokinectic-based methods); (iii) possible full integration, automation, and miniaturisation are possible; and (iv) there is possible large-scale parallelisation and multiplexing of bioanalytical assays. Because of the optical transparency of polymer LoaDs and the no-contact nature of the detection set-up, the optical detection has been the most common approach in LoaD biosensors. Expertise developed in manufacture in disc-based storage media (Compact Disc TM and Digital Versatile Disc TM) provides a strong knowledge base to support process development for manufacture of LoaDs. Figure 1A (connected red circles) illustrates the number of publications concerning LoaD platforms. Because different terms have been used in the literature, the search was made using “Lab-on-a-disc” OR “lab-on-a-CD” OR “Bio-disk” OR “Lab-disc” OR “Lab-CD” as topic keywords. The number of publications are generally trending upwards demonstrating an increased interest in the LoaD platform while the variability in the trend likely reflects that LoaD remains a niche platform. The application focus distribution of LoaD publications is shown in Figure 1B.

Recent developments in microfluidic research has allowed for the integration of well-established detection methods, such as optical or electrochemical, to create robust platforms capable of a sample-to-answer within a significantly reduced time [20]. The use of centrifugal microfluidic platforms allows for complex and automated sample handling integrated within the microfluidic chip. Alongside the favourable features listed above, a key advantage of the LoaD platform is the capability to apply centrifugation to the preparation of the sample for the biosensor. This is particularly useful when processing complex sample matrices such as whole blood; here, for example, it can be separated into its constituent components (plasma, red blood cells, and white blood cells) in a single step [21]. Furthermore, the reduced costs of micro-processors has also resulted in the emerging area of electronic LoaDs (eLoaD) where the instrumentation required by the biosensor can be miniaturised into a support instrument and, in some cases, can co-rotate with the LoaD. This allows for detection and analysis of biomolecules with significantly reduced data acquisition times [22]. Contextualising, for the majority of electrochemical-LoaDs, the electrodes are integrated onto the platform to connect the biosensors to the instrumentation while the electrochemical readouts are often made from a stationary disc [23,24]. Recently, measurements during disc rotation were enabled by electrical slip-rings [25] or, where the high background electrical noise associated with some slip-rings may greatly interfere with the electrical readout signal, using integrated micro-controllers with wireless data transfer [26,27].

Lab-on-a-Chip platforms (which are often called micro total analysis systems (µTAS)) that are based on LoaD platform are particularly suitable for point-of-care (PoC) diagnostics in low-resource settings. Application of these platforms in poor and remote areas is termed extreme point-of-care [28]. Guidance from the World Health Organization (WHO) recommends that the development of diagnostic tests to resource-limited settings should follow the ASSURED (Affordable, Sensitive, Specific, User-friendly, Rapid/Robust, Equipment-free, Deliverable) criteria [29,30]. An updated acronym was proposed in 2019 as REASSURED, with the inclusions of R as Real-time connectivity and E as Ease of specimen collection and Environmental friendliness [31]. Researchers have made great efforts to meet all these criteria but challenges still remain [19,28,32]. Certainly, centrifugal microfluidics has features which position it as the ideal platform for PoC diagnostic testing and is, therefore, at the forefront of extreme PoC device development.

The existing academic literature contains a number of well-regarded review papers addressing both the general LoaD platform and specific aspects of this technology platform [5,28,33,34,35,36,37,38,39]. In this review, we discuss the recent advances in centrifugal microfluidics focusing on biosensing applications. We tried to concentrate our discussion (but do not limit) in the literature over the past 10 years. We divide this paper into sections concerning the main protocols in biosensors. We aim to provide an accessible guide for the ample audience of biosensor researchers with interest in leveraging LoaD technology to enhance their existing research while also providing a valuable resource for microfluidic specialists. Section 2 introduces the fluidic control in LoaD biosensors. Section 3 discusses the LoaD manufacture pointing both polymer microfabrication and biorecognition element immobilisation strategies. Section 4 describes the essential processing in LoaD biosensors while Section 5 discusses the existing and emerging LoaD PoC devices. We finalised with future perspectives and our final remarks in Section 6 and Section 7, respectively.

2. Fluidic Control in LoaD Biosensors

The main driven-force in LoaD biosensors is the centrifugal force which acts outwards from the centre of rotation. Other pseudo-forces which play a role are the Coriolis force (applied when a particle/fluid moves in a rotating reference frame) and Euler force (induced by accelerating or decelerating the disc rotation). A combination of channel design, capillary action, and the placement of valves control can control the movement and timing of fluid movement. When a disc spins, the centrifugal force induces fluid flow radially outwards from the centre to the edge of the disc. Considering a fluid of mass density on a planar disc rotating at a distance r from the central axis at an angular velocity , this liquid experiences a centrifugal force (Equation (1)) [34,35,40]

a Euler force given by Equation (2) [34,35]

with a rotational acceleration , and a Coriolis force (Equation (3)) [34,35,40]

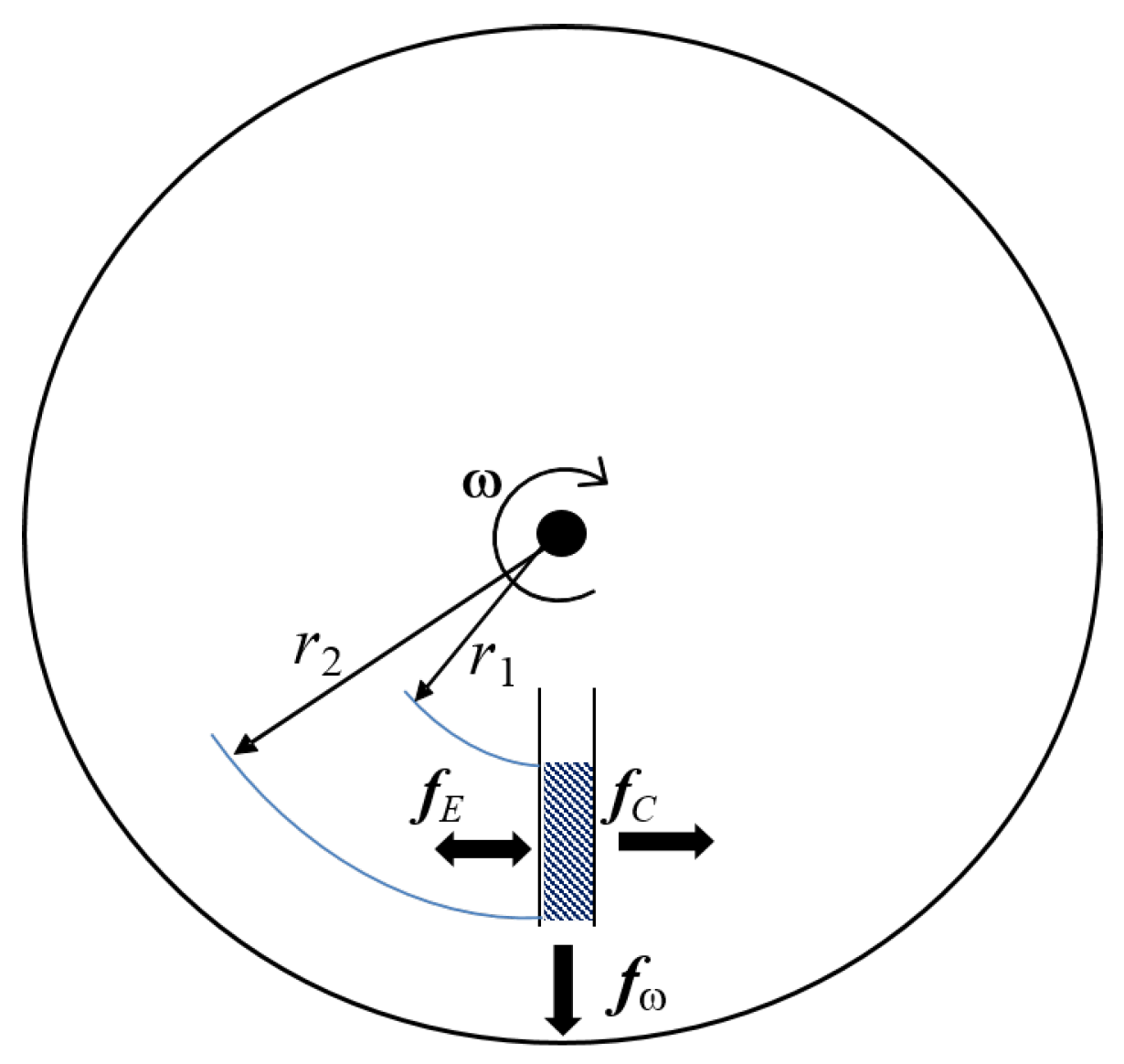

where is the fluid velocity in the plane. These three forces are represented in Figure 2, and can be controlled by the frequency of the rotation [35]. The centrifugal force induces the fluid to flow radially outward from the centre of the disc to the outer circumference [40]. The Coriolis force depends on the direction of rotation. If the direction changes, the direction of the Coriolis force changes [41]. It can be applied to mixing of samples, for flow switching, or directing of sample in specific channels [40]. In the “shake-mode” with continuous change in the spin speed, the angular momentum caused by the acceleration and deceleration induces Euler forces, resulting in a layer inversion of the fluid in the microfluidic chamber [34].

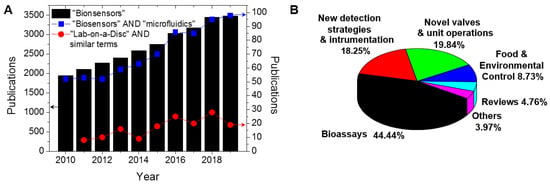

Figure 2.

Forces acting in centrifugal microfluidics. The centrifugal force acts radially outward, the Coriolis force acts perpendicular to and fluid speed, and the Euler force is proportional to the angular acceleration.

The centrifugal flow rate depends on the rotational speed, radial location of the fluid reservoirs, channel geometry, and fluid properties such as viscosity, density, etc. [36]. Physicochemical properties as pH and ionic strength have no significant influence on the centrifugal flow rate, making it possible to pump many different fluids and integrate various processes on the same disc.

In a non-rotating reference frame under gravity (i.e., on the surface of the earth), the hydrostatic pressure is defined by the simple equation where g is the acceleration due to gravity and h is the height of the fluid column. Analogously, the centrifugally induced hydrostatic pressure is dependent on the radially inward and radially outward locations of a liquid columm on the disc (defined by and respectively in Figure 2). The centrifugally induced pressure, is defined as

In literature, this equation is commonly represented in an alternative form

where is the radial height of the liquid column () and is the radial center of the liquid column () [5].

While rotating, the centrifugal force acts on all liquids present on the disc and, therefore, to automate common assays, valves are required. Valves act just like faucets that control if and when the channels will deliver the fluid. Different types of valves have been proposed in the past years ranging from simple designs to highly sophisticated implementations. On the LoaD valves are typically “normally closed” (NC) such that in their initial state, they are closed and will open with some stimulus. Valves can also be “normally open” (NO), but these are less common and useful on LoaD. Most valves are classified as “single use” (i.e., changing from closed state to open state), but others can be changed between open and closed states. Valves are also classified as rationally-actuated or instrument-actuated [42]. Rotationally-actuated valves (also called passive valves) are controlled by changes in the disc spin rate (centrifugal force) while instrument-actuated valves (also called active valves) use an external actuator or source of energy (e.g., a laser, a pneumatic pump, a robotic arm) to control on-disc valves. The different types of valves and flow control techniques have recently been thoroughly reviewed [34,43]. However, here, we will introduce some of the most common and relevant valves to demonstrate how they are key components in the integration and parallelisation of bio-analytical processes on LoaD platform.

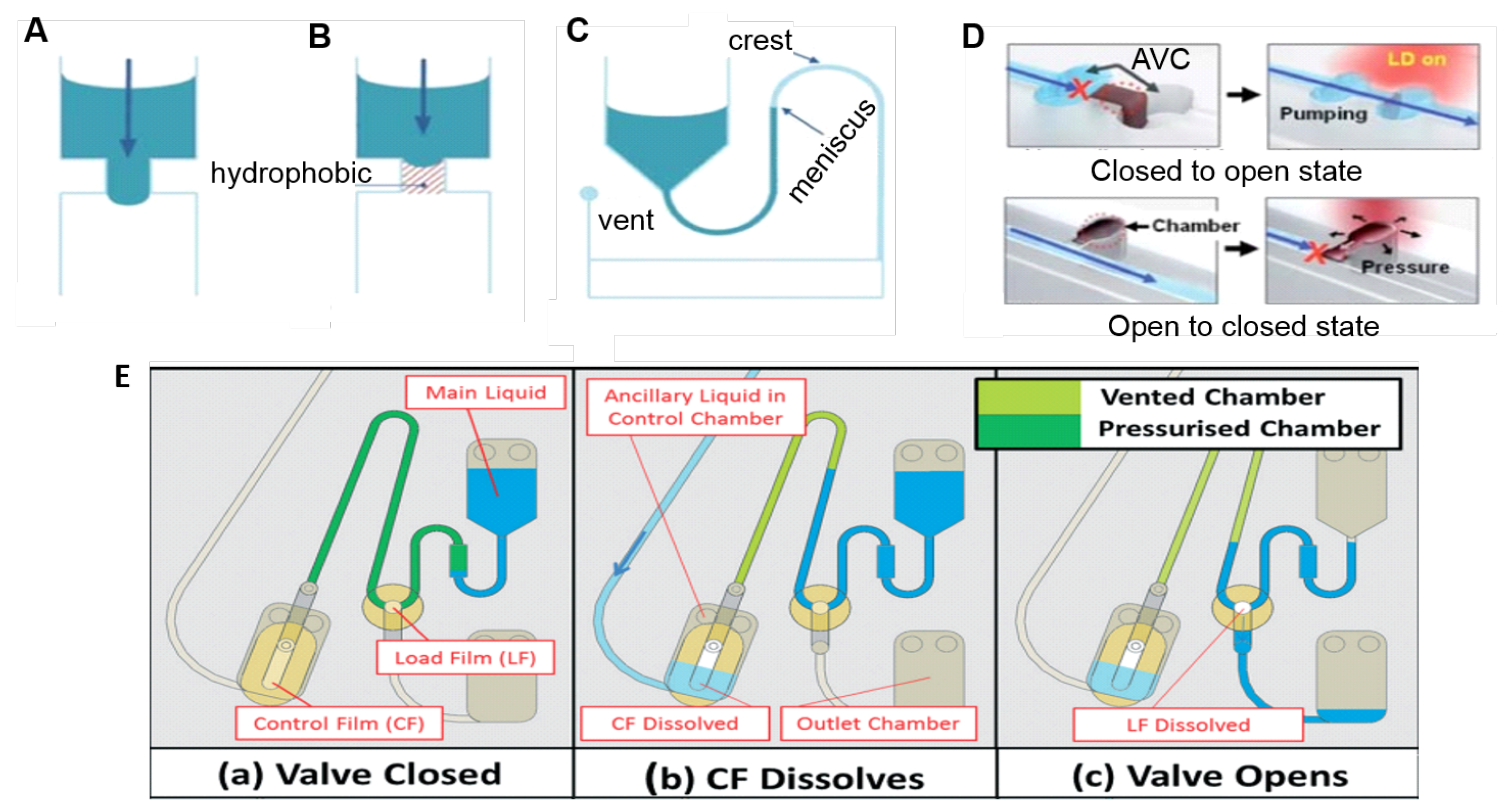

Capillary valves (see Figure 3A) are based on the balance between the capillary pressure and the centrifugally induced pressure [36]. In a common configuration, the capillary burst valve is connected to a reservoir through a straight channel, and when the disk is at rest or in low rotation speed, the liquid flows to fill the hydrophilic channel. However, it stops at the inlet of a suddenly expanded valve due to the capillary pressure [44], so the liquid will pass through a capillary valve only when the centrifugal force is high enough to break the capillary barrier pressure. In the hydrophobic valve (Figure 3B), hydrophobic regions in the microchannel prevent the fluidic movement. The valve opens when the centrifugal force overcomes a certain critical value [34,36]. In a siphon valve (Figure 3C), the disc is rotating in a high speed and the centrifugal force keeps prevents priming (via capillary pumping) of the siphon. With the decrease of the rotation speed, the siphon’s hydrophilic channel is primed by the capillary force (acting against the direction of the centrifugal force). The liquid in the siphon is pumped by the capillary force over the siphon crest and radially outwards until the liquid meniscus passes the radial inward location of the liquid column (i.e., location described in Figure 2). At this point, centrifugal pumping far exceeds capillary pumping and the siphon valve opens when emptying of the reservoir can be sped up by increasing the disc spin rate/centrifugal pumping force [36]. Variations of siphon valves including centrifugo-pneumatic siphon valves [45], sequential siphon valves [46,47], and interruptible siphon valves [48] can also be used for additional control.

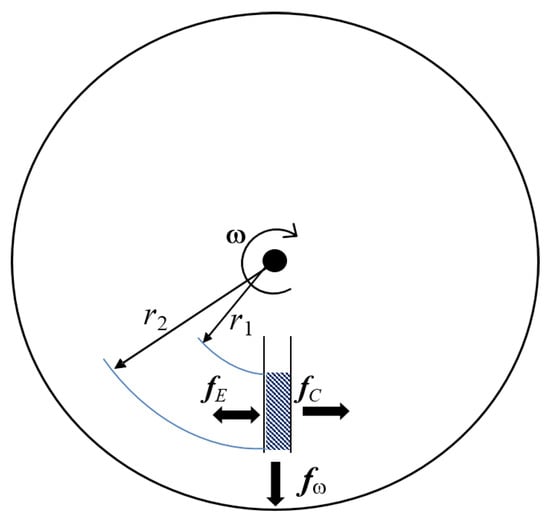

Figure 3.

Centrifugal microfluidics valving methods: (A) capillary valve on a hydrophilic microchannel; (B) hydrophobic and (C) siphon valves. Adapted from [36] with permission from The Royal Society of Chemistry. (D) Laser irradiated ferrowax microvalves: at the top, from a closed to open state, the laser beam is focused at the ferrowax that melts and flows to an assistant valve chamber (AVC); at the bottom, to block an open channel, the laser is focused at the pre-loaded ferrowax located adjacent to the main channel. The molten ferrowax bursts into the main channel and solidifies, blocking it. Adapted from [49] with permission from The Royal Society of Chemistry; and (E) event-triggered valve based on dissolvable film (DF): (a) sample is loaded and the two DF tabs create a closed pneumatic chamber. The counteracting gas pressure keeps preventing the liquid to enter the pneumatic chamber; (b) the ancillary liquid enters and dissolves the control film (CF) and the pneumatic chamber is vented, allowing the main liquid to wet the load film (LF), and (c) sending liquid to the outlet chamber. Reproduced from [42] with permission from The Royal Society of Chemistry.

Sacrificial valves are another common valving technology. These valves involve the integration of some material which acts as a destructible barrier layer to allow liquid release. The release can be triggered externally, for example, by laser irradiation [49] (shown in Figure 3D). Laser irradiated ferrowax (iron oxide nanoparticles dispersed in paraffin) microvalves goes from a closed to open state by laser irradiating the ferrowax, which melts and flows to an assistant valve chamber (AVC). From open to closed state, the laser is focused at the pre-loaded ferrowax located adjacent to the main channel. The molten ferrowax bursts into the main channel and solidifies, blocking it [49]. Dissolvable films (DFs)-based valves [50,51,52] allow the passage of the fluid when its surface is wet, and can be used to implement an event-triggered system (Figure 3E) [42] which act analagous to a (single-use) electrical relay or transistor. DF valves are schematically positioned at specific sites on the disc, the arrival of liquid at this point triggers the release of liquid at another point [42]. In Figure 3E, the sample (main liquid) is loaded and the two DF tabs (named control film (CF) and load film (LF)) create a closed pneumatic chamber (dark green in (a)). The counteracting gas pressure keeps preventing the liquid to enter the pneumatic chamber, and thus wet the DF. At an appropriate timing, an ancillary liquid enters the control chamber and dissolves the CF, thus venting the pneumatic chamber (b), allowing the main liquid to wet the LF and finally, sending the liquid to the outlet chamber (c). This is particularly useful for sequential delivery steps when the arriving of a liquid in the waste chamber triggers the delivery of the next reagent/buffer. Many novel valving strategies have been described in the literature in the last years, always aiming to facilitate and automate disc protocols, as new passive [53,54,55] and active (magnetically induced [56], pinch-based valves [57], reversible [58,59,60,61], among others) valves. Some of them will be discussed in the next sections as they appear in the control of biosensors processes.

3. LoaD Fabrication

3.1. Polymer Microfabrication

At the end of the 1990s decade, polymers started to be used for microfabrication [62,63]. Opposite to silicon and glass, which are fragile and expensive, requiring time-consuming and complex processing, polymers are low-cost, of easy and scalable processing, and are available with a range of chemical and physical properties. LoaD fabrication techniques have followed the same strategies than conventional polymer-based chips. The choice of the material accounts on the cost, but especially on the desired properties, e.g., on-disc colorimetric measurement demands optically transparent polymers, some types of valves demands flexible structures, intricate design demands polymers which can be processed by high resolution techniques. As many specialised reviews have dedicated on microfabrication techniques [64,65,66], this review does not intend to go deep in such subject but displays the main LoaD fabrication approaches and offer the address to find out more about it.

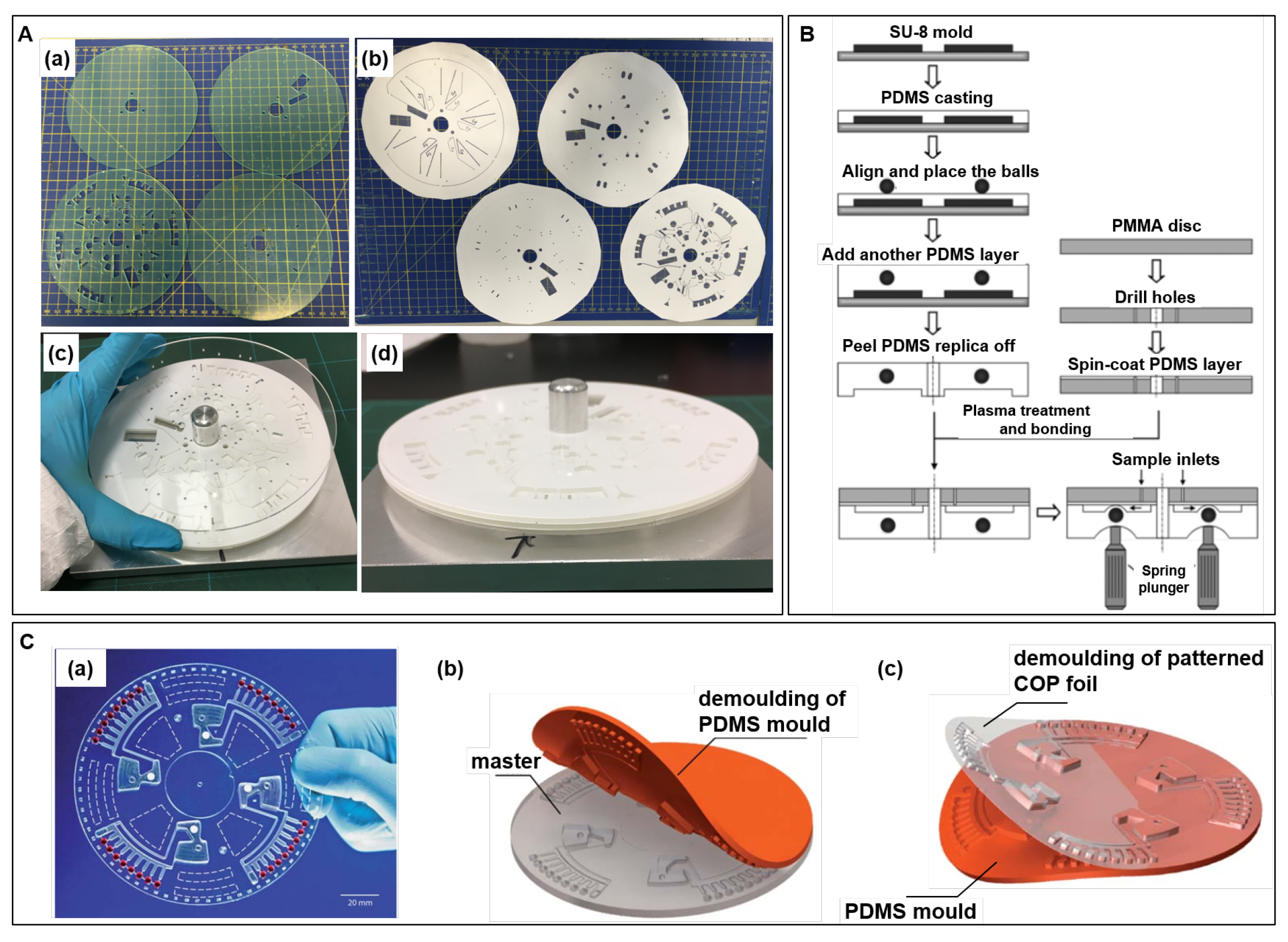

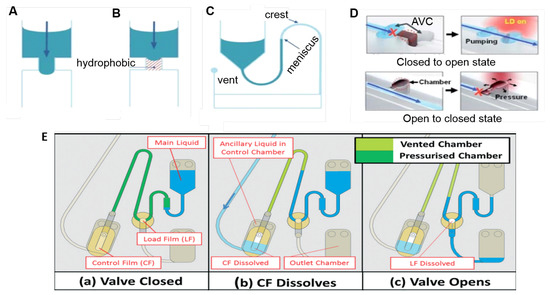

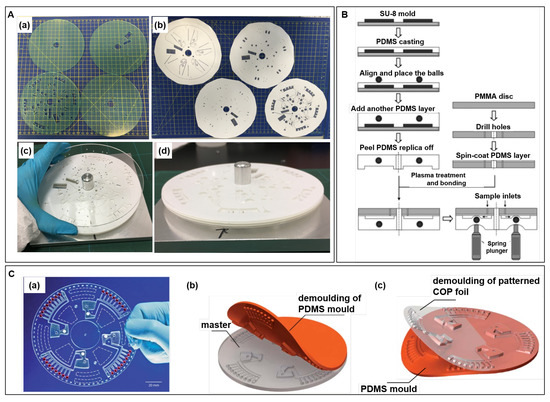

A LoaD biosensor shelters various LUOs and commonly a net of 3D channels and reservoirs are needed, which is obtained by stacking of independently processed layers bonded to each other. The LoaD architecture is created in a computer-aided design (CAD) software, and each layer is previously processed by techniques as replica moulding (soft-lithography), xurography, laser ablation, etc. Figure 4A illustrate (a) mm thick-poly(methyl methacrylate) (PMMA) plates machined using a CO laser ablation, and (b) 86 µm thick-pressure sensitive adhesive (PSA) processed by a knife-cutter. (c) After removing the protective covers, the LoaD is assembled by stacking the PMMA and PSA layers using an alignment jig and were rolled using a laminating machine. The side view is shown in (d). Although the cutting process is automated and scalable, the assembly stage is more difficult to be automated while the manual assembly of layers is time-consuming and laborious. Yet, researchers widely use this approach at the proof-of-concept stage because the prototyping is fast and without the need for mould fabrication.

Figure 4.

(A) Photographs of steps of layers assembly during the LoaD manufacture: (a) laser ablation cut PMMA discs, (b) knife-cut PSA layers, (c) stacking and alignment of layers, and (d) side view during the mounting of layers. (B) Schematics of PDMS moulding to fabricate the disc: Pinch valves-based disc fabricated by PDMS moulding. Reproduced from [57] with permission from Elsevier. (C) Hot embossing fabricated LoaD biosensor: (a) photograph of the LoaD, (b) fabrication of the PDMS mold using a milled PMMA master, and (c) demoulding of the hot embossed COP foil. Reproduced from [67] with permission from The Royal Society of Chemistry.

Polydimethylsiloxane (PDMS) is usually patterned by replica moulding (soft-lithography) in which the PDMS reagents (base + curing agent) is poured over the master mould and cured to solidify. Commonly, the master mould is fabricated using UV photolithography of SU-8 (negative photoresist) exposing the pattern through a mask. The unexposed parts are dissolved while the cured photoresist remains on the substrate defining the pattern. Figure 4B illustrates a schematics of fabrication of a microfluidic disc by PDMS casting over the SU-8 master mould. At the design suggested by the authors to create pinch-valves, metal balls were placed over the first cured PDMS layer, and covered with a new layer of PDMS. The PDMS replica containing the metal balls are peeled off and united to a PDMS-coated and plasma-treated PMMA disc [57]. The active valves are controlled by spring plungers which push the balls deforming the flexible PDMS to block the flow [57]. Alternative low-cost techniques for master fabrication, as micromilling, laser engraving, cutting plotters, are discussed in [66]. PDMS is optically transparent in the visible range, biocompatible, flexible, and can be easily sealed to glass or another PDMS part (no need of adhesive layers). Soft-lithography provides high-resolution replicas (nm-scale), but pattern deformations and defects in the moulded product can occur in the peeling process [64]. Other disadvantages concern the cost, relatively high when compared to common thermoplastics [65], and the difficult to implement mass production [66]. Details in PDMS micromolding can be found in [68,69].

Hot embossing and injection moulding of thermoplastic materials are remarkable concerning cost-efficient mass production [70,71,72]. At hot embossing processing, the temperature is elevated above the polymer glass transition temperature , and the mould is pressed against the polymer substrate transferring the pattern [73]. Nanometre range can be achieved by hot embossing [71]. As polymer pattern resolution depends on the mould resolution, delicate patterns usually demand lithography/etching processed silicon moulds [70,74] accompanied by time-consuming and expensive fabrication [64]. In addition, the masters have limited cycles of life due to cracking and warping from the stress and temperature conditions [75]. To overcome these drawbacks, µ-scale PDMS patterns were produced by photolithography to act as hot embossing mould [75,76]. PDMS moulds are relatively inexpensive, rapid to fabricate and reusable for many replications, and possess thermal stability that enables to stamp common thermoplastic polymers [75,76]. Figure 4C present (a) a photograph of a cyclic olefin polymer (COP) foil disk, fabricated by hot embossing and sealed with PSA, and representations of (b) demoulding of the PDMS mould from the milled PMMA master, and (c) demoulding of patterned COP foil after hot embossing, cooling, venting, and opening of the chamber [67].

3D printing is an emerging technology in microfluidics [77]. Yet, it has some limitations concerning resolution. Usually, supporting material is needed to fill the void spaces during the printing process. Later, its removal is manually made which is time-consuming and difficult to do in small channels. The solvent assisted removing is mostly hampered because the chemical composition of supporting and construction materials are often similar [78]. The produced rough surfaces may also cause dead volumes and irregular surface modifications [78]. Concerning LoaD applications, 3D printing has been used to fabricated specific parts, as valves [61] or valve actuating discs [57,59], or in the manufacture of peripheral structures [25].

3.2. Immobilisation of the Biorecognition Element

The immobilisation of the biorecognition element is always a concern in the construction of biosensors because the sensitivity depends on the total activity of proteins. LoaD platforms, like most microfluidic devices, are usually built in polymer materials, and the direct passive adsorption of proteins as antibodies and enzymes onto these surfaces is mainly driven by hydrophobic interactions. The adsorption-induced conformation changes can lead to protein denaturation and reduce protein activity by as much as 90% [79,80]. Since hydrophobic surfaces induces higher denaturation than hydrophilic ones [81], some surface modification strategies have been proposed to increase the hydrophilicity of conventional polymers for microfabrication. These strategies include plasma treatment [82], coverage with layers of hydrophilic polymers [83,84] and graphene oxide [85]. Poly(ethyleneimine) - PEI introduces hydrophilic amine groups and acts as a spacer (increases the space between the biomolecules and the hydrophobic surface) and has been applied in PMMA [80,84,85] and cycloolefin [83] surfaces. PEI coating [80], PEI coating following oxygen plasma treatment [84], and nanostructured layer-by-layer film of PEI and graphene oxide [85] have all demonstrated capacity to improve ELISA performance on PMMA surfaces. Functionalisation of metal surfaces is also crucial for electrochemical and reflectivity-based approaches. Conventional methods based on thiol functionalisation using cysteamine and alkanethiols followed by NHS-EDC chemistry have also been applied to the LoaD [86,87].

The anchoring of bio-active beads within the LoaD to act for the biorecognition element anchoring is an alternative to direct immobilisation of biomarkers onto the flat polymer surface. Beads can be easily functionalised with the biorecognition element a priori off-chip and then be loaded to the microfluidic platform. This is particularly useful when the protein coating may cause difficulty sealing microfluidic chips when surfaces have been functionalised [88]. One of the most important advantages using beads is the higher surface to volume ratio (1 g of microbeads with a 0.1 µm-diameter has a surface area of 60 m) [89]. This can be achieved, for example, by a 3D column filled by the functionalised beads. Additionally, analytes and bioreagents can be easily transported in the fluidic system when attached to beads, by the centrifugal flow or by external forces as pressure-driven flow or especially, by the magnetic force [89,90]. Additionally, some protein-functionalised beads are commercially available or have well-established protein anchoring protocols. Immunoassays applications usually encompass the capture antibody anchoring via carbodiimide chemistry on carboxylated-beads [91,92], or by biotinylated antibodies on streptavidin-coated particles [93].

4. Essential processes in LoaD Biosensing

4.1. Reagents and Sample Storage and Supply

At the R & D stage, the input of reagents in a LoaD platform is usually by manual loading, via pipetting, of the reagents and samples. However, long-term storage strategies, which minimises operator handling, reduces cold-chain requirements, reduces the need for specialised user-training, and which avoids contamination of both user and sample, are of critical importance. A number of different technologies have been demonstrated including stick-packages [94,95], glass ampoules [96], and elastic-membrane micro-dispensers [97].

Pre-storage of reagents in glass ampoules placed on LoaD platforms for DNA extraction was demonstrated with no loss of ethanol and water for 300 days at room temperature. Frozen storage was also possible without ampoule rupture. The release of liquids (buffers and ethanol) is made by a mechanical force (fingertip pressure) through the elastic lid of the cartridge. While the liquid is centrifugally displaced, a filter prevents the glass shivers to go forward [96]. van Oordt et al. [94] have developed stick-packs of aluminium/polyethylene composite foil aiming at long-term storage of reagents. The transverse frangible seal was fabricated by ultrasonic welding and it is adjustable for a specific burst pressure. The hermetically sealed stick-packs can store both liquid or dry reagents, with the first frangible seal (that separates solid and liquid) bursting at lower rotation frequency. After mixing, the second frangible seal bursts to release the mixture [94]. These stick-packs were further applied in a LoaD for nucleic acid-based detection of respiratory pathogens [95].

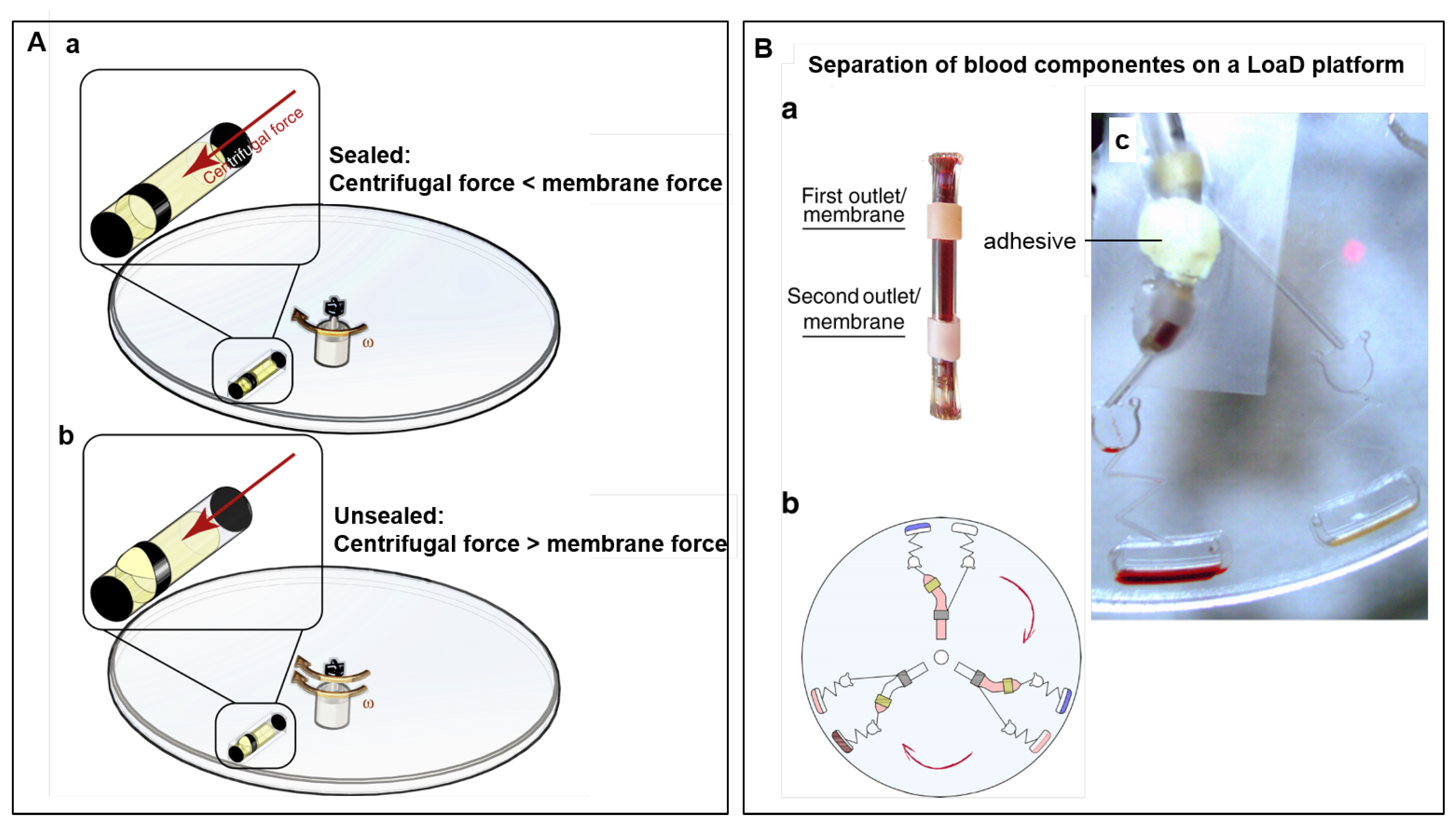

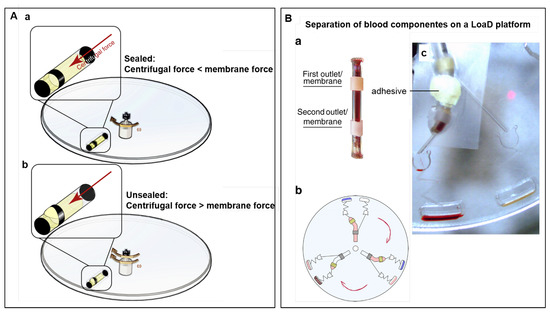

A long-term storage micro-dispenser was created by Kazemzadeh et al. [97] and tested in lab-on-a-chip and LoaD platforms. The micro-dispenser comprises a tube with a hole and an elastic membrane covering this hole. When the internal pressure is increased (by the centrifugal force) in enough amount to stretch the membrane, a path is provided for the liquid release. Figure 5A(a) illustrates the micro-dispenser placed on a disc. No liquid release happens while the centrifugal force does not exceed the membrane force. Increasing the internal pressure by the rotation speed, membrane stretches and releases the fluid (b). To implement this technology for blood separation, a micro-dispenser was created with a tube with two apertures, each one covered with different elastic materials (see Figure 5B(a)). The top and the bottom membranes are for plasma and blood cells delivery, respectively. The location of each aperture is well-planned, e.g., the first top aperture is located at a point above the level where the plasma is separated from blood cells. Figure 5B(b) illustrates three identical assays for blood separation on disc and (c) a single assay with a micro-dispenser placed on the disc with a piece of tape and a tacky adhesive. Because of the different elastic properties, each of the membranes releases the liquid at different rotation speeds. In this case, a higher centrifugal force is needed to release the blood cells (bottom membrane). The long-term stability of the micro-dispensers were demonstrated to be two and one year(s), for DI-water and ethanol 70%, respectively [97].

Figure 5.

(A) Micro-dispenser working principle in a LoaD platform. (a) When the centrifugal force is lower than the membrane resistance, no liquid is released. (b) Increasing the rotation speed, the centrifugal force overcomes the membrane force and the fluid is temporary released. (B) Separation of blood on a LoaD platform. (a) Micro-dispenser with two apertures covered with two different membranes, C-flex and latex, and (b) a schematic of the LoaD platform for 3 identical assays for blood separation. (c) Picture of the disc dispensing blood plasma and blood cells to two different chambers at different rotation frequencies due to the difference in the membranes properties. Reproduced from [97] under a Creative Commons Attribution 4.0 International License.

4.2. Samples and Reagents Processing

4.2.1. Blood Processing

Blood is the most utilised sample for diagnostics, and its separation is usually the first step of many biological assays. Cell isolation and pathogens detection demand an initial step of selective blood separation. Conventional benchtop processes typically use centrifugation. This is relatively simple but often requires large sample volumes and, in case of infectious disease, there are concerns about operator safety. Based on the different densities of blood components, it is quite easy to promote separations simply by the rotation of the disc. Common protocols for plasma extraction on disc use moderate (about 1200 RPM for 3–8 min [98,99]) to fast rotation (2000–5000 RPM for few seconds [100,101,102,103]). Due to the difference in density of the plasma and the red and white blood cells, blood cells are driven toward the bottom while the plasma forms the supernatant layer on the top [101]. One of the great advantages of LoaD platforms is that the plasma extraction step can be easily and conveniently integrated with the following metering, mixing, and detection steps. It has been reported for plasma extraction, metering and mixing with reagents for the prothrombin (PT) time tests [101,102,103], nitrate/nitrite assays [98], cancer cells detection [86,104], virus detection [90] and many other sensing platforms.

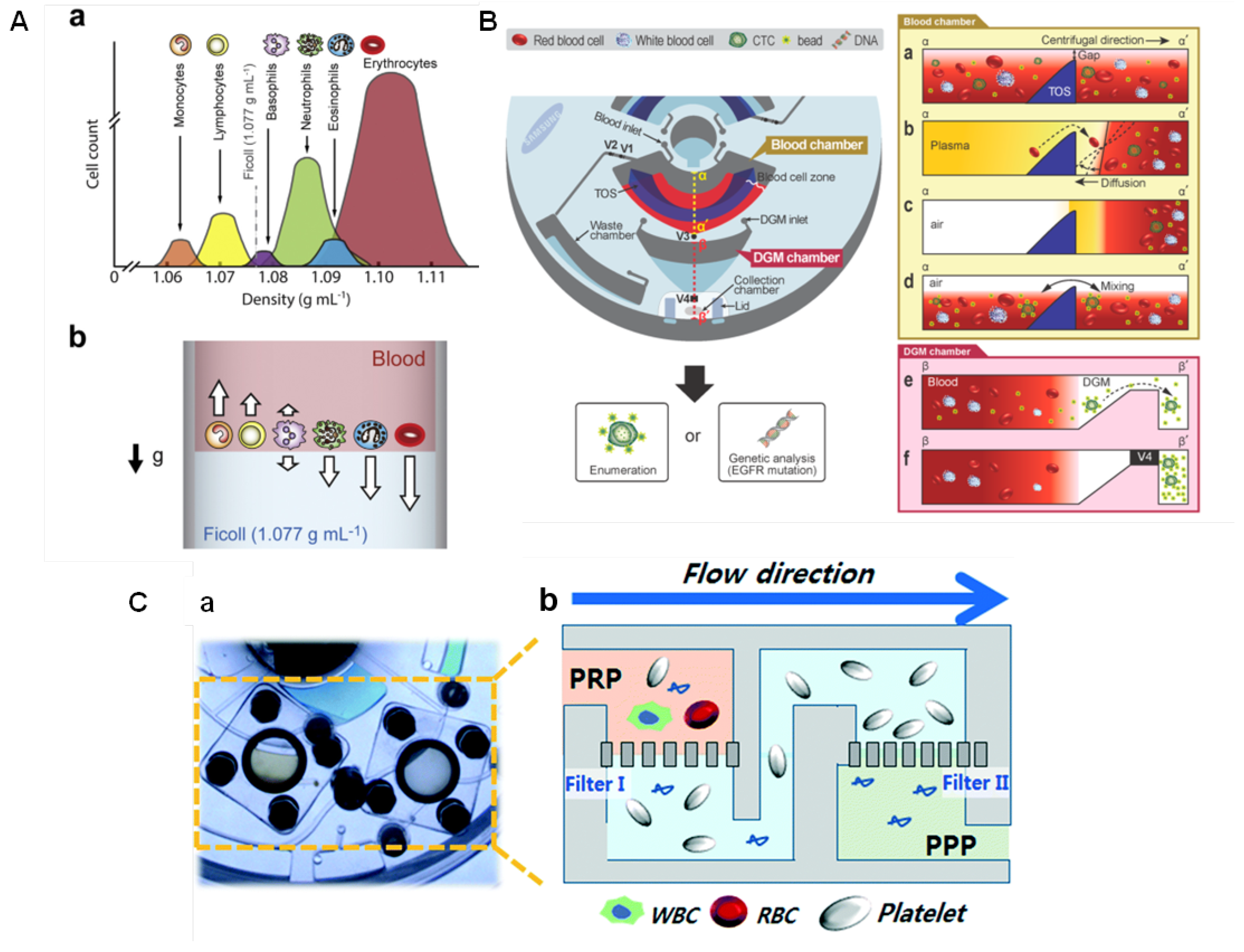

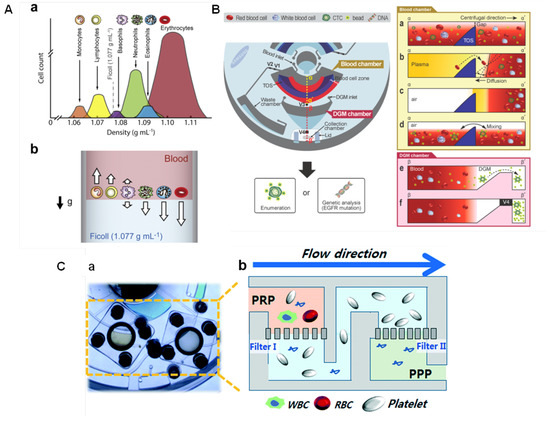

Some geometry parameters can be defined to increase the speed of blood separation. Kim et al. [105] found that higher tilt angles and narrower channels promote faster plasma separation. The enhanced sedimentation in inclined channels is known as Boycott effect [106], and it is associated with the increase in the surface area available for the particles settling [105]. The impact of the Coriolis force on blood sedimentation has also been investigated [107]. Spira mirabilis-like structures (equiangular spiral) demonstrated an enhanced speed of sedimentation due to the increased Boycott effect, herein applied with a density gradient medium (DGM) [108]. Sedimentation over DGM uses solutions with specific densities, such as Ficoll and Percoll, to separate and sort blood cells into layers according to their inherent density differences [109]. This can facilitate the collection of the separated components, and thus the analysis of multiple blood samples. Figure 6A(a) illustrates the density distribution of human blood cells and (b) a schematic of the separation using Ficoll (density = 1.077 g mL), with the dense cells moving to the bottom while the low density-cells remain on the top layer. Efforts have been done to develop DGM-based blood fractionation and separation of specific cells [21,86,104,110,111,112,113]. Morijiri et al. [113] proposed an elutriation-based separation in a centrifugal disc. Particles are introduced in the separation chamber with a low-density fluid under centrifugation. While particles experienced a centrifugal force in an outward direction, the fluid force acts in an inward direction. The retention position of each particle depends on the size and density, and are controlled by the balance of the centrifugal force and the fluid drag force. Small and low-density particles are not retained in the separation chamber and are the first to move towards the outlet. By introducing solutions with higher densities, the balance of forces is changed allowing a step-wise elution and recovery of particles [113].

Figure 6.

(A) Sorting of blood cells based on the DGM centrifugation. (a) The density distribution of human blood cells and (b) the movement of blood cells upon centrifugation with blood layer placed on the top of the Ficoll solution. The arrows indicate the movement direction of cells. Reproduced from [109] with permission from Elsevier. (B) Disc design for sorting CTCs from whole blood. TOS: triangle obstacle structure; V1, V2, V3, and V4 are on/off operation valves (wax that changes from liquid to solid state) controlled by laser irradiation. (a) Cross-sectional view of the blood chamber after injection of blood and microbeads; (b) after plasma separation; (c) after removal of the plasma with opening V1; (d) during incubation to bind CTCs to the antibody-functionalised beads; (e) the cross-sectional view of the DGM chamber showing that only CTC-microbead complexes (with higher density than DGM) are moved to the collection chamber; (f) V4 is closed to prevent sample contamination during collection. Reprinted with permission from [104]. Copyright 2014 American Chemical Society. (C) Filtration-based platelet isolation disc: (a) photograph and (b) schematics. Filter-I to eliminate both white blood cells and red blood cells from a platelet-rich-plasma (PRP). PRP runs through Filter-II which captures platelets while washing platelet-poor plasma (PPP) out to the waste chamber. Reproduced from [117] with permission from The Royal Society of Chemistry.

Leukocytes extraction can be particularly important. Abnormal leukocytes counts can be related to anemia, infection, inflammatory conditions, and certain cancers [114]. Furthermore, they can interfere with the detection of circulating tumor cells (CTCs) [104]. CTCs have large size variation and their size can overlap with leukocytes causing unreliable size-based separations. Because CTCs are disseminated from primary tumors or metastatic sites to the bloodstream, LoaD platforms to separate them from whole blood have been developed [115,116]. Park et al. [104] developed a centrifugal platform with the selectivity based on the anti-EpCAM covered microbeads, which specifically bind to the CTCs, and thus make them heavier than other blood cells. This leads to sedimentation through a DGM and thus being isolated. Figure 6B shows the disc designed for sorting CTCs (left). The blood sample and microbeads conjugated with anti-EpCAM were injected via the blood chamber inlet while the DGM (Percoll) was pipetted through the DGM chamber inlet. Blood and microbeads are shown in the blood chamber (a), and after plasma separation, the triangle obstacle structure (TOS) played a role to retard the convection of the separated blood cells in the blood cell zone while the disc is stopped to open valve 1 - V1 (to remove plasma to the waste chamber) (b). After the complete removal of plasma (c), V2 is closed to initiate the bead-binding (incubation) process by mixing (d). V3 is opened and the sample was transferred to the DGM chamber, where under centrifugation the microbeads-CTCs complexes were moved to the collection chamber, passing through the DGM layer due to their higher density, while the other cells remain on the top (e). After the complete separation, V4 is closed before the collection to avoid contamination (f) [104]. Here, the valving was based on the laser irradiation ferrowax [49], discussed previously.

Filtration-based strategies have also been successfully applied for blood separation. Sequential and tangential flow filtration using two track-etched polycarbonate membranes were integrated in the chambers by Kim et al. [117]. The pore size of the filters was carefully selected considering the size of platelets and blood cells. Figure 6C(a) depicts a photograph of the platelet isolation disc highlighting the filters. Schematics in Figure 6C(b) shows Filter-I (3 µm) to eliminate both white blood cells (8–15 µm) and red blood cells (6–8 µm). The plasma runs through Filter-II (600 nm) which captures platelets while washing residual plasma contents out to the waste chamber, as extracellular vesicles, proteins, lipids, and cell-free DNA [117]. Platelet analysis revealed high purity (>99%), free of white blood cells contamination, and the yield of the platelets recovery was significantly superior (>fourfold) than that conventional benchtop centrifugation [117]. Refer to the source for more details [117]. Table 1 summarises the blood separation and analysis integrated into LoaD platforms.

Table 1.

Summary of the blood separation strategies performed in LoaD platforms. WB: whole blood, DGM: density gradient medium, PT: prothrombin time, HBV: hepatitis B virus, PBMC: peripheral blood mononuclear cell, CTC: circulating tumour cells, CRP: C-reactive protein, IL-6: interleukin-6.

4.2.2. Volume Metering and Aliquoting

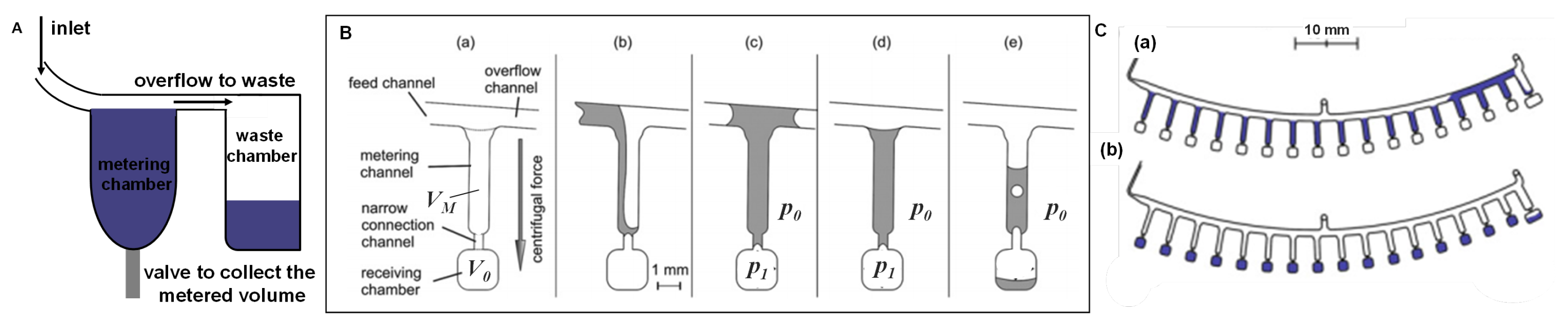

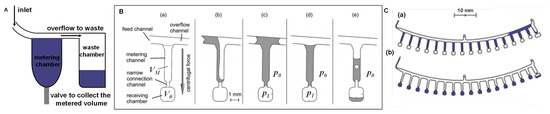

Accurate metering of reagents and samples is an essential step in sample preparation to guarantee a reproducible and quantitatively reliable response from the biosensor. Although different architectures are found in the literature, the volume metering in LoaD is based on the chamber volume (controlled by its geometric parameters). Typically, an overflow channel is connected to this metering chamber to guarantee that any excess of liquid is sent to a waste/overflow chamber, as illustrated in Figure 7A. The same overflow principle can be applied to implement aliquoting and serial dilutions on disc, which are usually time-consuming and susceptible to errors (specially when working in µL-scale) when performed manually. As depicted in Figure 7B, Mark et al. [119] developed a metering structure whereby a dead-end pneumatic chamber enhanced system performance. In this structure, a single metering chamber is connected upstream and downstream by a feeding/overflow channel. The volume metering is based on centrifugo-pneumatic valve structure in which the metering chamber is connected by a narrow channel to an unvented receiving chamber (a). The volume metering chamber is filled but the receiving chamber, which may, for example, contain lyophilised reagents, remains dry (b). When liquid reaches the narrow connection at the bottom, a meniscus is formed which prevents the air from escaping the unvented receiving chamber (creates a pressurised chamber with pressure ) (c). Aliquoting is performed by continuing the liquid feed. After complete the first (d), the overflow channel deliveries the liquid for the next metering channel and so on, as illustrated in Figure 7C(a). After all the metering channels are completed, an increase in the centrifugal frequency reaches a point (burst frequency) in which the centrifugal force overcomes , releasing the liquid to the receiving chambers, as shown in Figure 7B(e),C(b).

Figure 7.

(A) Simple metering design based on overflow. (B) Metering structure based on the centrifugo-pneumatic valve: (a) design of a single metering structure with the volume defined by the metering channel . (b) At a first centrifugal frequency, liquid fills the metering channel while air is displaced. (c) The pressure prevents the liquid to enter the receiving chamber . (d) After metering, (e) an increase in the centrifugal frequency above the burst frequency (to an amount that overcomes ) releases the liquid. Adapted from [120] with permission from The Royal Society of Chemistry. (C) Layout of an aliquoting structure: (a) multiple chambers been fed by liquid, and (b) aliquots distributed to the receiving chambers. Adapted by permission from Springer Nature [119], Copyright 2011.

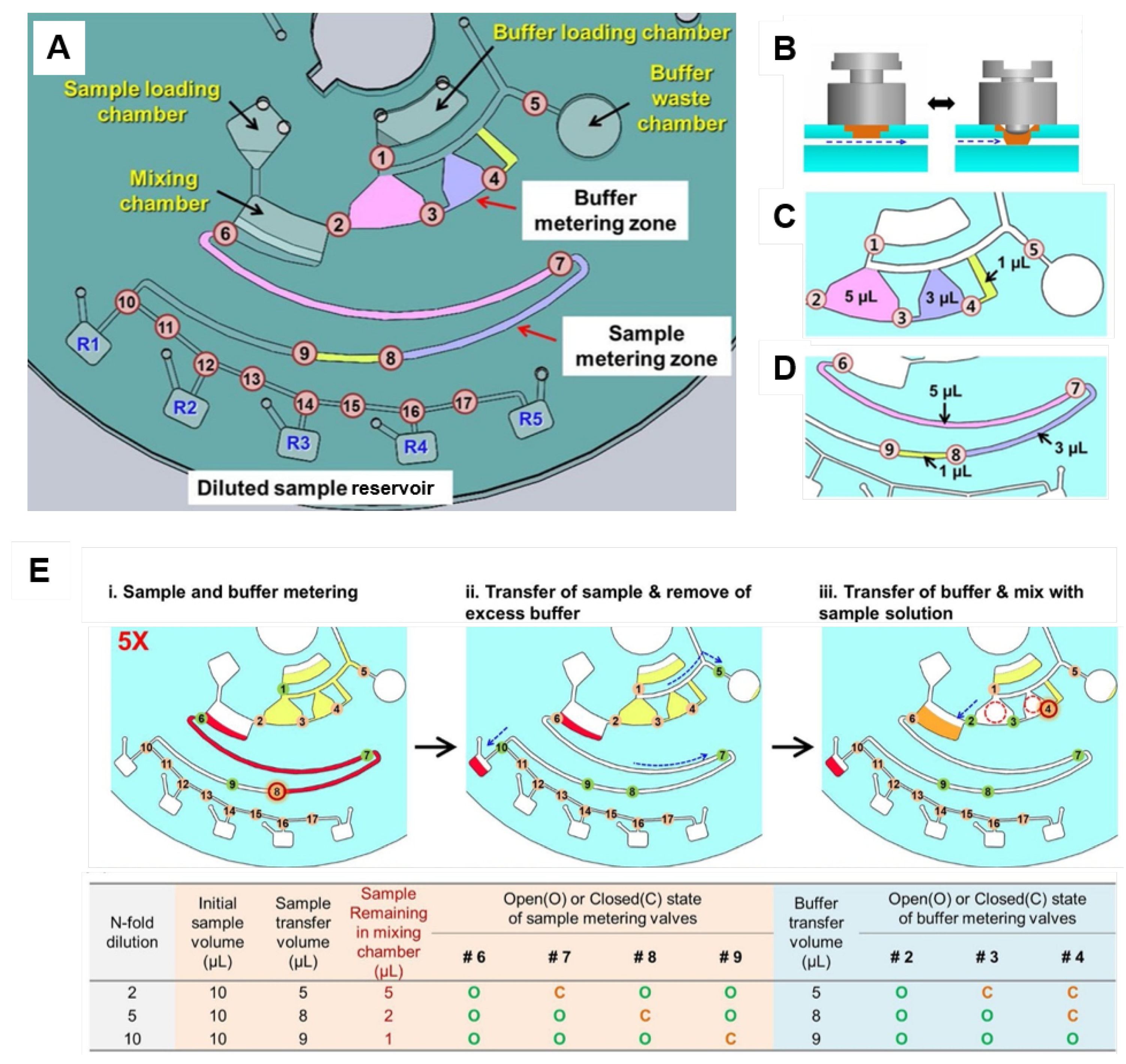

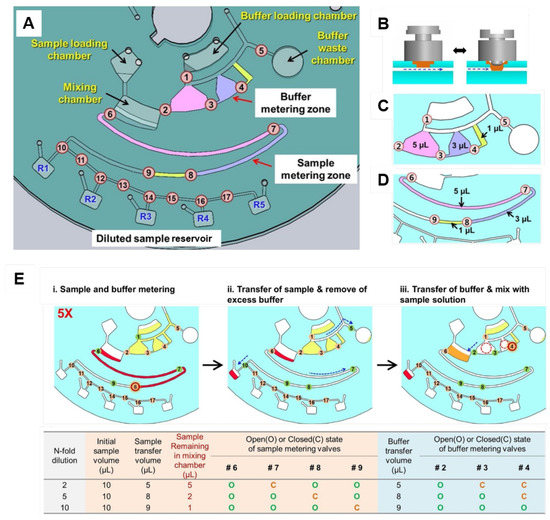

Active valving based on individually addressable diaphragm (ID) valves [61] was used for on-disc serial dilutions by Kim et al. [121] (Figure 8A). These valves are assembled from an elastic epoxy diaphragm and a 3D printed actuator (Figure 8B). A simple push-and-twist action is required for closing and opening the channel. This open/close functionality allows the volume of sample and buffer to be metered in the two different zones; thus dictating the degree of dilution. These two zones are detailed in Figure 8C,D. An example of fivefold dilution is presented in Figure 8E (opened and closed valves represented by green and red colours, respectively): (i) at buffer metering zone, valve 1 (V1) is opened while V2, V3, V4, and V5 are closed for metering of total 9 µL-buffer. Simultaneously, at the sample metering zone, V6 and V7 are opened while V8 is closed, totaling 8 µL sample metered; (ii) at the sample metering zone, V6 is closed and the 8 µL-metered sample is sent to R1 (with valves 7, 8, 9, and 10 opened while V11 is closed). From the initial 10 µL sample, 2 µL remains in the mixing chamber. At the buffer metering zone, only the V5 is kept open, sending the buffer excess to the waste chamber; (iii) the 2 µL sample in the mixing chamber is diluted by the delivery of 8 µL buffer (only V2 and V3 are opened while V4 is kept closed keeping 1 µL buffer retained). Finally, the 5-fold diluted solution is metered (5 µL, by keeping V6 opened while V7 is closed) and sent to R2. The next dilution can be performed to the remained solution in the mixing chamber based on the similar steps (protocols for 2-,5-, and 10-fold dilutions are summarised in the table of Figure 8E). Buffer can be re-loaded by opening V1 [121]. Although the system at first appears complex and unwieldy, the recent miniaturisation and cost-reduction in micro-controllers means this approach can be easily automated and can flexibly address a wide array of biosensor applications.

Figure 8.

(A) Disc design for serial dilution consisting of sample and buffer loading chambers, mixing chamber and buffer waste chamber, two metering zones (for sample and buffer), five collecting reservoirs (R1–R5) for the diluted samples and seventeen ID valves (numbered circles). (B) A reversible ID valve composed of a diaphragm (orange) embedded on a top layer and 3D printed valve actuator (gray). Simple push and twist actions open and close the channel. Detailed buffer (C) and sample (D) metering zones. (E) 5-fold dilution steps: (i) in the buffer metering zone, a total of 9 µL is metered keeping V1 opened while V2, V3, V4, and V5 are closed. At the sample metering zone, V6 and V7 are opened while V8 is closed, totaling 8 µL metered; (ii) at the sample metering zone, V6 is closed and the metered liquid within the channel is sent to R1 (V7, V8, V9, and V10 are open while V11 is closed). At the buffer metering zone, V1, V2, V3, and V4 are closed and V5 is opened to send the excess to the waste chamber; (iii) 8 µL buffer is delivered (just V2 and V3 are open while V4 is kept closed keeping 1 µL of buffer retained) into the mixing chamber, where remains 2 µL sample. Thus, a dilution of 2 µL sample to a final 10 µL volume solution was achieved. The table presents the summary of the metered volume of sample and buffer, and the state of the valves to achieve 2-, 5-, and 10-fold dilutions. Reproduced from [121] with permission from Elsevier.

4.3. Mixing and Washing

Mixing protocols should provide an effective and fast homogenisation of the fluids. However, adaptation of simple bench-top protocols as agitation, vortexing and stirring onto the LoaD can cause unwanted opening of rotationally actuated valves; and the subsequent uncontrolled pumping of liquid. Therefore, systems which require rigorous mixing must be carefully designed. Several studies have been focused on developing disc protocols to allow an integrated and adequate mixing. On-disc mixing can be passive, just based on the rotation control, based on intrinsic forces as Euler or Coriolis [122,123,124] or by means of control of geometry [125,126]; or can be active based on external perturbations, e.g., compression by external actuators [127] or use of magnetic-beads inside the disc in combination with permanent magnets [128,129]. Several micromixing technologies are discussed in [130].

One of the most utilised mixing protocol is the “shake-mode” mixing [124] comprising periodic changes in the sense of rotation and rapid changes of the spinning frequency. The difference in the angular momentum leads to the appearance of a shear force that drives an advective current within the liquid [124]. The mixing time was down to 3.0 s for 25 µL-volume while a mere diffusion-based mixing took about 7 min. Combining the “shake-mode” mixing with magnetic beads (pre-filled in the mixing chamber) periodically deflected by a set of permanent magnets resting in the lab-frame, an effective homogenisation was attained in only 0.5 s [124].

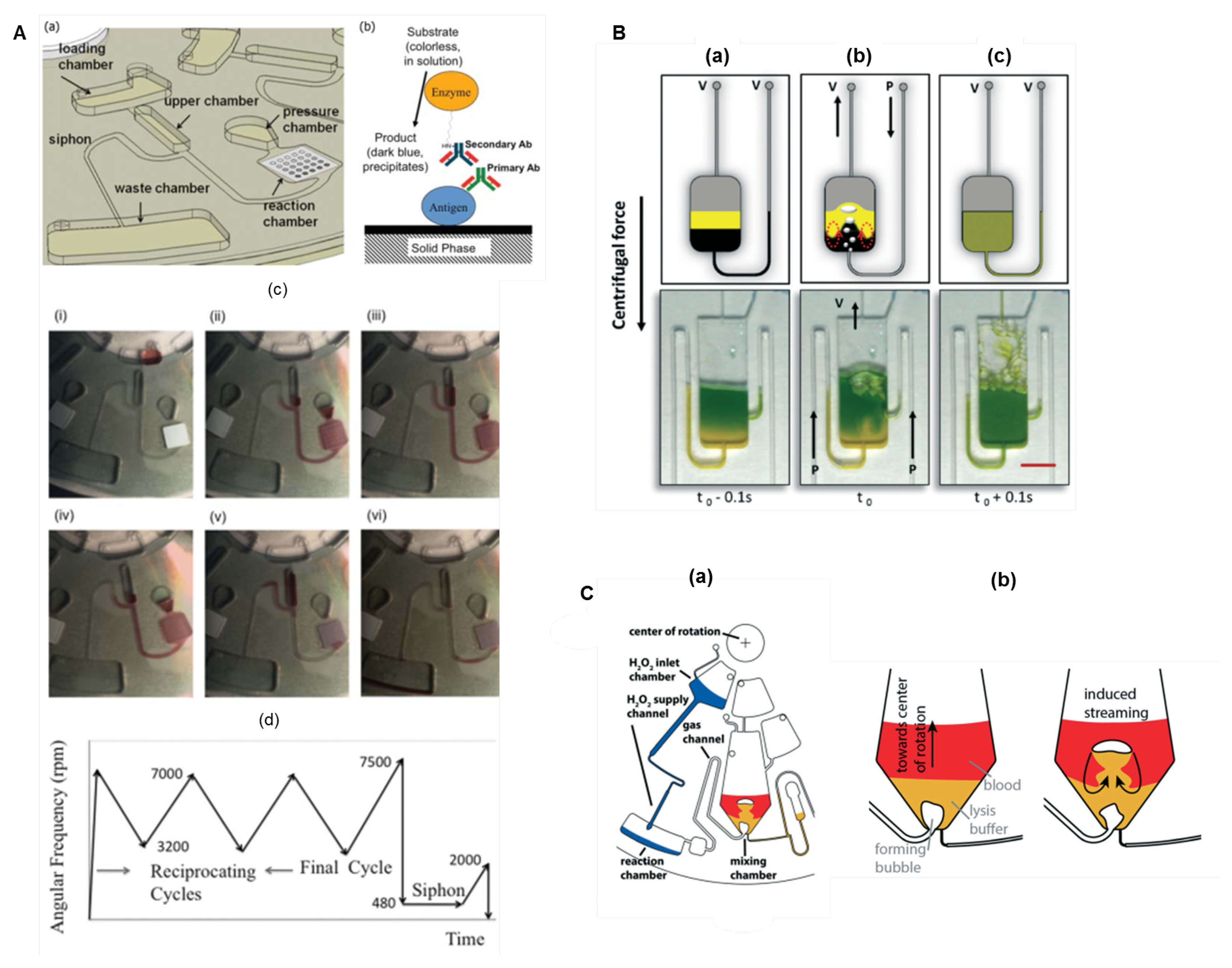

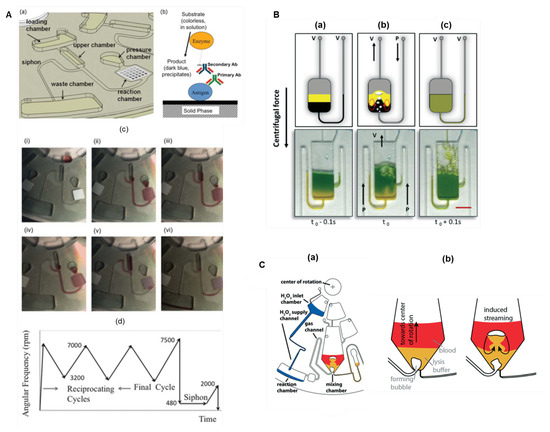

The use of pneumatic pressure to promote reciprocating flow-based mixing [131] was introduced later, and has been successfully applied in LoaD biosensors [87,132]. This scheme utilises an auxiliary pneumatic chamber, and the sequential decrease and increase in the centrifugal force causes the compression and decompression of air pushing the liquid through different chambers and thus allowing an accelerate mixing [131]. Figure 9A(a) depicts an immunoassay disc. The biorecognition element (antigen) is immobilised on the reaction chamber to specifically capture the primary antibody (sample) while the secondary antibody is to allow the colorimetric detection. The schematics is illustrated in Figure 9B(b). The sequence of images in (c) describes: (i) the sample stored in the loading chamber; (ii) acceleration causing air compression in the pressure chamber; (iii) by deceleration, the air expansion in the pressurised chamber pushes the liquid back to the upper chamber; (ii and iii) the increase and decrease in rotation speed (3200–7000 RPM) are reciprocated to effective and rapid mixing; (iv) the rotation frequency is increased to the maximum (7500 RPM); followed by (v) a rapid decrease to very low value (480 RPM). This increases the liquid level above the crest point, primes the siphon valve and sends liquid to the waste chamber, (vi) leaving an empty reaction chamber [132]. Pneumatic valving and mixing are reviewed in [133]. Another reciprocating mixing technology demands lower rotation frequency (0–1500 RPM) and encompass the micro-balloon pumping [134]. With higher centrifugal force, the liquid is pushed into an air chamber inflating a latex micro-balloon. A reciprocating mixing can be performed increasing (inflating the micro-balloon) and decreasing (flattening the micro-balloon) the rotation frequency [134].

Figure 9.

(A) Pneumatic pressure flow-based reciprocating mixing. Schematics of (a) the fluidic system and (b) the antibody capture assay to take place in the reaction chamber; (c) images of the system in operation: (i) sample is loaded; (ii) the increase in the rotation frequency promotes the air compression in the pressure chamber; (iii) the decrease in the rotation speed promotes the air expansion that pumps the liquid towards the center; (ii) and (iii) can be repeated in a reciprocated manner. (iv) The increase of rotation to the highest speed (7500 RPM) followed by (v) a decrease to the lowest rotation frequency (480 RPM, see protocol in (d)) allow the liquid to prime the siphon valve and (vi) send the liquid to the waste chamber. Reprinted from [132], with permission of AIP Publishing. (B) Bubble-based mixing schematics with an external pump: (a) from an unmixed state of two dyes, (b) under bubbling mixing, to (c) a homogeneous solution. Reproduced from [135] with permission from The Royal Society of Chemistry. (C) Buoyancy driven bubble mixer set-up. (a) Hydrogen peroxide flows into the reaction chamber and the decomposition reaction produces oxygen which is directed through the gas channel to the mixing chamber. (b) The mixing chamber with blood and lysis buffer in separated layers (left) and a bubble detaching and ascending through the liquid (right). Reproduced from [136] with permission from The Royal Society of Chemistry.

Additionally, mixing can be done with gas bubbles integrating external pumps [135] or with gas generation by internal reactions [136]. Figure 9B illustrates the schematics and images from two separated layers of solutions contained in a vented reservoir (top channel) (a), air pushing through the lower channel creates bubbles that promote the mixing (b), thus creating a homogeneous solution in about 100 ms (c) [135]. To avoid the need of external apparatus, Burger et al. [136] implemented a bubble-based mixing by gas produced through a chemical reaction (Figure 9C(a)). The oxygen bubbles are generated in the reaction chamber by the hydrogen peroxide decomposition, which provokes a drag flow through the liquid. A strong buoyancy causes deformation and rupture of these bubbles inducing mixing flows, as represented in (b). In a DNA extraction experiment, this approach allowed a similar performance compared to the “shake-mode” mixing and can be an alternative approach when mixing has to be performed at a fixed rotational frequency.

Mixing and washing steps are crucial for biosensors concerning especially the incubation of the sample with the biorecognition element, which is fundamental for biochemical reactions to occur. Incubation can be performed at a constant low rotation for some assays (400–600 RPM for few minutes [98,137]), while longer periods are necessary for some complex assays such as nucleic acid amplification, e.g., LAMP assays (about 60 min at low or paused rotation [138,139,140,141]), NASBA (about 70 min [142]), and RPA (about 15–30 min [143,144]). In ELISA the incubation protocols have been performed even in constant spinning (at 20 Hz for 15 min [85]) or in mixing modes (“shake-mode” mixing from 15 to 30 Hz for 10 min [99] or by magneto-balloon assisted mixing at 900 RPM for 30 min [60]). Incubation protocols should be developed and optimised individually for an assay. In biosensors based on the formation of a complex of magnetic nanoclusters with antibody- [145] or aptamer- [146], the presence of the target triggers the magnetic particles agglutination, which is quantified with an optomagnetic readout. A two-step protocol promoted reliable results with reduced incubation time: the first 1 s incubation step occurs in a strong magnetic field to facilitate clusters formation, followed by the second step of 2 s mixing by shaking to break unspecific bindings and to facilitate the reorientation of the beads for the readout [145,146]. A protocol with 180 cycles of incubation and mixing was established to detect the NS1 Dengue biomarker in serum [145].

After any incubation, the washing step has to guarantee that any impurities, as well as unspecific binders are removed. Washing is usually performed in “shake-mode” mixing with proper buffer solutions, and can be performed more than once if necessary. For each LoaD platform, it is important to select the most suitable approach. “Shake-mode” mixing is the simplest way to achieve good mixing in a passive set-up (no need of external devices), but demands to vary the speed rotation for relatively high frequencies. If this is not possible, external forces (e.g., magnetic or pressure) can be introduced, or bubbles can be generated internally, however, this demands a precious disc area (additional storage reservoirs) and disc area can be quite limited since many lab protocols has to be included in a LoaD biosensor.

4.4. Detection Methodologies

A broad variety of analytical approaches have been used in LoaD biosensors. There is no rule to follow concerning which method should be or should not be used in LoaD platforms, but all of them exhibit advantages and limitations that should be considered. A complete review of detection methods for centrifugal microfluidic platforms is found in [39]. If the analyte is detectable with enough sensitivity and selectivity, the optical colorimetric strategy is the most cost-effective and easy integrated readout method. With technological advances and miniaturisation of detection systems, other approaches raise attention to PoC devices. Special attention to the label-free methods as electrochemical impedance spectroscopy (EIS) and SPR (surface plasmon resonance), which can greatly simplify immunoassays by reducing fabrication-cost and fluid handling. Table 2 lists some detection techniques used in LoaD biosensors comparing the advantages, limitations and solutions, some of them especially thought to adapt the analytical detection set-up to the LoaD platform. Following, this section discusses recent and relevant developments concerning optical and electrochemical detection.

Table 2.

Detection strategies in LoaD biosensors, advantages, limitations and solutions.

4.4.1. Optical Detection

Optical strategies require three basic components: a light source, a photodetector, and a reaction chemistry, which is analyte concentration-dependent. Particularly to the absorption and fluorescence techniques, considering that the discs can be fabricated in transparent polymers, easy integration of the detection module is possible with the optical transducer placed as a peripheral optical device without the need of electric contacts and wires. Optical strategies for centrifugal microfluidic devices are reviewed previously in [38,39]. Especially for biosensors, optical approaches are widely used because many biological analytes absorb light in a specific wavelength or can be easily marked to do so. In addition, many commercial kits were available for quantitative determination by colorimetric and fluorimetric approaches, which greatly simplifies the R & D stages of LoaD optical biosensors.

The Beer–Lambert Law shows the dependence of the light absorption with the absorbing species concentration, which allows a simple approach of sample quantification. A simple set of light emitting diode (LED) with the adequate wavelength emission and a proper photodetector perpendicularly aligned to the disc plane can be used to create a compact and low-cost detection module [154]. The Lambert-Beer Law also states that the absorbance depends on the optical length. Because of that, achieving a reasonable limit of detection in thin discs can be difficult. This can be overcome with thick discs, or by increasing the light path length with an optical beam-guidance set-up based on the total internal reflection (TIR) [147,148].

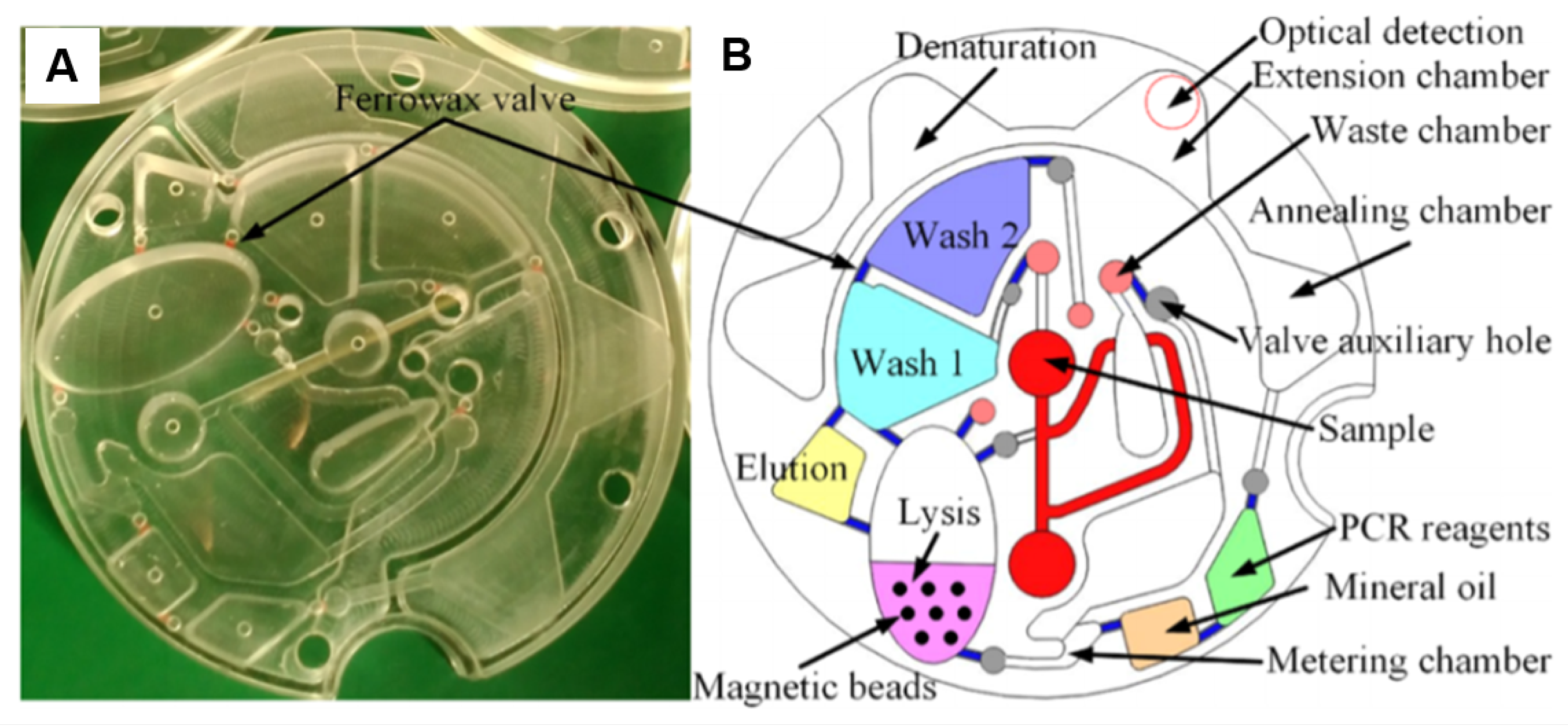

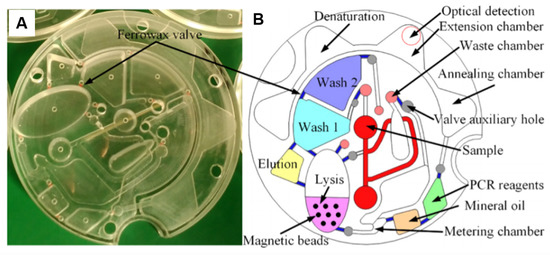

Various well-established colorimetric lab protocols were successfully implemented in LoaD platforms as loop mediated isothermal amplification (LAMP) and polymerase chain reaction (PCR) as well as the immunoreactions-based fluorescence-linked immuno-sorbent assay (FLISA) and enzyme-linked immuno-sorbent assay (ELISA). LAMP-based LoaD platforms for bacteria [138,139,141] and virus [155,156,157] detection, as well as PCR for virus [90,95,158] and bacteria [137,159] detection have been published. DNA amplification is a reliable detection method and has existed for decades. The implementation of this technique on a LoaD however is a more difficult task. The LoaD proposed by Li et al. [90] is illustrated in Figure 10, a PoC apparatus for Hepatitis B Virus (HBV) detection which boasts the same diagnostic capabilities as that of a centralised laboratory test. On-board valving allows for serum separation and reagent storage which allow for a fully automated test. A laser diode activates the valves allow for the release of reagents. Centrifugal forces generated by the double rotation axis of the microfluidic platform, which rotate to allow the stationary magnets to displace the internal capture magnetic beads for nucleic extraction. The complex system includes three resistors and thermistors which control the specific temperatures required for the PCR process. Finally, a 470 nm-blue LED served as an excitation source. The fluorescent signal was then detected using two optic fibers when the turntable containing the LoaD was position to the fixed detection region. The only user interaction required is the insertion of 500 µL of whole blood where the systems boasts an LOD of 10 copies/mL in just 48 min [90].

Figure 10.

(A) The optically transparent disc and (B) the schematic of the LoaD architecture for HBV DNA detection in whole blood. Sample is inserted into the centre reservoir of device where pre-stored DNA extraction reagents in wash 1, 2, elution ad lysis buffers and magnetic beads. Ferrowax valves control the release and flow of each reagent to initiate the DNA extraction which then mixes with pre-stored primer and PCR reagents for amplification purposes. Reprinted with permission from [90]. Copyright 2019 American Chemical Society.

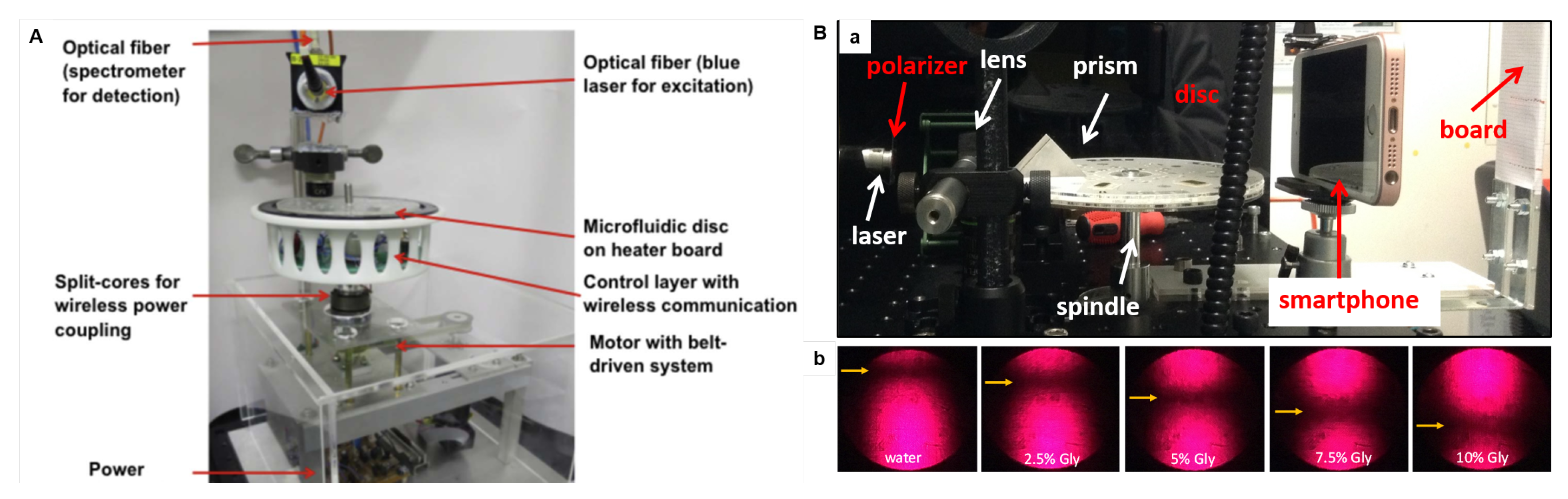

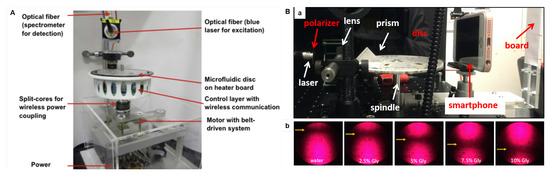

As exemplified before, nucleic acid amplification strategies, as LAMP and PCR assays, demand controlled temperature raising. Temperature sensors and heating system can be also integrated into the LoaD platform. Technologies using hot air gun [160] and heater boards [139,155] have been proposed to control temperature profiles. Figure 11A depicts a set-up for a LAMP-based bacterial infection sensing. The heater board with embedded resistive heating elements and thermistors was connected to a printed circuit board (PCB) which allows temperature control and wireless communication with a remote computer [139].

Figure 11.

(A) LoaD set-up for LAMP assay-based bacterial infection sensor. A belt-driven motor to provide the centrifugal force; power coupling device; wireless data communication module for temperature control and signal detection; light source (blue laser at 488 nm) for the fluorescence excitation; and spectrometer linked to a data acquisition computer. The disc is on an electronic circuit board (PCB) accommodating the heating elements for microfluidic disc to the temperature control. Reproduced from [139] with permission from Elsevier. (B) SPR immunosensor set-up: photographs of (a) SPR optics integrated to a spin stand, and (b) the reflected laser spots from aqueous glycerol pattern solutions (with different refractive indexes) showing the position of the dark lines (caused by the plasmon absorption). Adapted from [87] with permission from Elsevier.

Immunoassays in format of ELISA [99,161] and FLISA [98,162] have also been implemented on LoaD platforms. Conventionally, the detection is made by the absorption (or emission) measurement using a monochromatic light source and an optical sensor, as demonstrated by Thiha and Ibrahim [161] with a PoC sandwich-type ELISA platform for Dengue detection. Oh et al. [163] have applied a similar colorimetric measurement, combined with LAMP, for detection of food-borne pathogens.

Immunoturbidimetry method was used to measure hemoglobin A1c (HbA1c), a glycated hemoglobin recommended by the American Diabetes Association for diabetes diagnosis [164]. The process automated on disc includes the rupture of erythrocytes by a hemolysis reagent, the attaching of the hemoglobin on latex particles, and the specific agglutination of HbA1c, which causes the solution turbidity. The specificity is given by the HbA1c monoclonal antibody added to induce the particles agglutination. A calibration curve reading the absorbance in 660 nm against Hb1Ac concentration was plotted for further quantification of hemoglobin in unknown samples. Fourteen blood samples were tested giving a rapid response (8 min), a good correlation with laboratory results (ion-exchange chromatography), and a standard deviation of ± 0.36% HbA1c (of order with standard laboratory equipment) [164].

Despite ELISA presenting the advantage of the easy colorimetric detection, it requires labeled proteins. Label-free methods as those based on surface plasmon resonance (SPR) simplify the disc design (less reagents and washings) and reduce the production cost (labeled proteins are expensive). SPR biosensing is based on changes in the refractive index very close to the sensor surface (usually gold or silver) caused when the analyte (in solution) binds to the biorecognition element immobilised on the sensor surface [165]. Grating-based [166] and prism-based [87] SPR approaches have been proposed. We have demonstrated an SPR-LoaD platform to simple multi-analyte immunoassay adaptable to detect specific diseases just by changing the capture antibody loaded onto the gold sensor [87]. The gold sensor was attached to the top of the disc immediately before the assay running exempting the need for special storage and transport cares and generalizing the device manufacture. The SPR optics (Kretschmann configuration) were integrated to a spin stand (Figure 11B(a)), and were tested in glycerol solutions to check on the dependence of the SPR angle position with the refractive index of solution. Pictures of the reflected light spot were recorded with a smartphone camera in a dark room (shown in b), and further image analysis provided a plot of reflected light intensity versus incident angle, with the minimum reflectivity (SPR angle) caused by the plasmon absorption. Shifts in the SPR angle were proportional to the antigen concentration when the biorecognition element (specific antibody) was immobilised on the gold sensor. Details can be found in the source [87]. Although the SPR optics can appear to be complex when integrated into LoaD, automated approaches turn SPR a very sensitive optical detection technology for LoaD biosensors. The company Biosurfit (Lisbon, Portugal) already commercialises SPR-based platforms [167].

Raman [168] and surface enhanced Raman scattering (SERS) [169,170] based discs for the detection of organic compounds have been recently published bringing good perspectives for future LoaD biosensors. Because of the expensive and complex detection set-up, these methods are not appropriate to PoC devices at this point. However, certain exigent applications can be worth due to the single-molecule sensitivity [171]. Optical methodologies are far the most explored approach for LoaD platforms due to the cost-effectiveness, the possibility of miniaturisation and personalising of PoC devices, being the closest to fully satisfy the (RE)ASSURED criteria. There are a huge number of publications on optical detection-based LoaD sensors, some of them are summarised in Table 3 to exemplify the variety of detection approaches, analytes, assay types and processes integrated on LoaD biosensors.

Table 3.

Summary of some optical detection-based LoaD biosensors. DR: detection range, LOD: limit of detection, WB: whole blood.

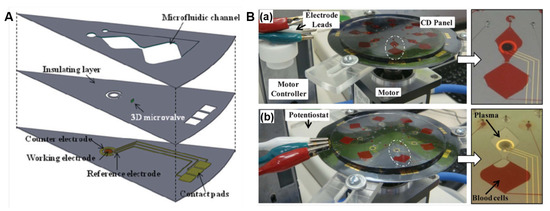

4.4.2. Electrochemical Detection

Electrochemical methods are widely used in conventional off-chip sensors because of the fast response, high sensitivity, and relatively low-cost, however, they have been under explored in LoaD devices. This is related to the complexity in integrating the electrochemical signal transducer to the LoaD platform, which demands electrodes included in the disc, and a potentiostat in direct contact with these electrodes. In other words, this usually implicates that the rotation should be stopped to connect the electric contacts to the disc electrodes to perform the measurement. Nwankire et al. [86] implemented gold electrodes functionalised with capture biomolecules where label-free electrochemical detection methods were deployed for measurement. Whole blood was centrifuged on-board, where the cancer cell rich plasma is extracted via a siphon microchannel. Centrifuge-pneumatic DF valves control the realise of reagent for the assay to be carried out. Five identical testing sites exist on the electrochemical-LoaD, allowing for multiple assays being carried out in parallel. The disc was stopped to Electrochemical Impedance Spectroscopy (EIS) measurement for each compartment invidually. The device boasts an 87% capture efficiency over a dynamic range of three orders of magnitude with a lower LOD of 214 cells/mm. The lower LOD equates to just 2% of the total working electrode surface [86]. The detection method of label-free EIS allowed for rapid cancer cell detection. The change in the electrical interfacial properties of the surface due to biological binding events is detected. For label-free detection, the changes in the dielectric constant, resistance and capacitance on the surface due to the capture of the target molecule is measured. The change in the impedance would be an indication of whether an analyte has been captured or not, and depending on the change, whether it is a high or low concentration of the target analyte.

Electrochemical biosensors of this nature have attracted major interest for label-free analysis as they don’t require as many assay steps as their labelled counterpart for signal acquisition. This form of biosensing attains sensitivity and simplicity which makes them a reliable, quantifiable diagnostic tool for whole cell capture and detection [176]. Opting for whole cell detection rather than DNA detection also reduces the cost and time of detection, as no cell lysis or additional reagents are necessary. The use of sputter-coated electrodes allows for the platform to be disposed of after a single-use and more cost effective, making this type of PoC device economical. These results give a true insight into the huge potential that exists for electrochemical-LoaDs as they are an efficient prognostic devices where minimal sample preparation is required and can be further developed for clinical applications [86]. The relative changes in impedance (difference between values of the anti-EpCAM coated gold electrodes before and after interaction with different concentrations of SKOV3 cells) varies linearly with the captured cell number [86].

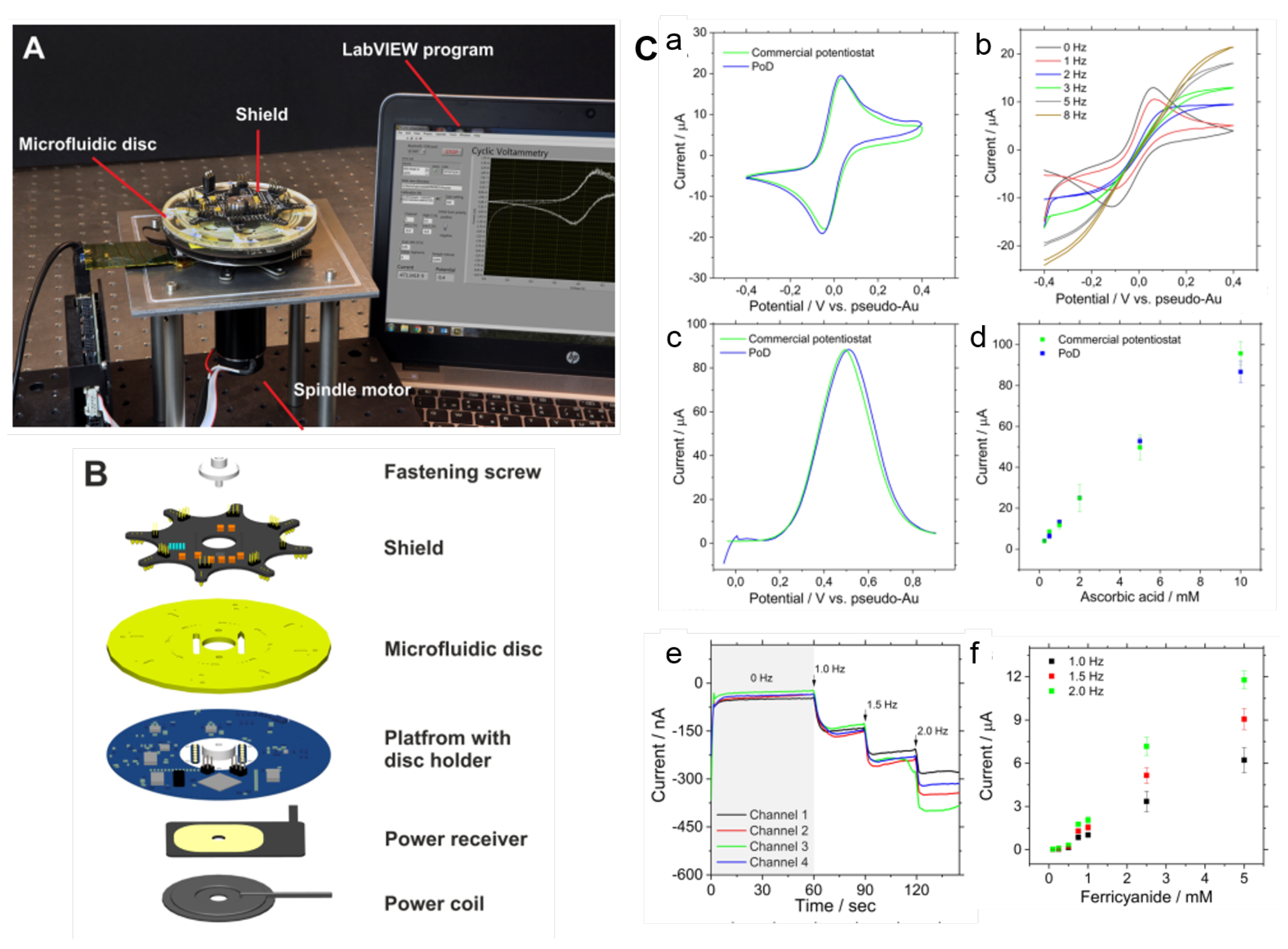

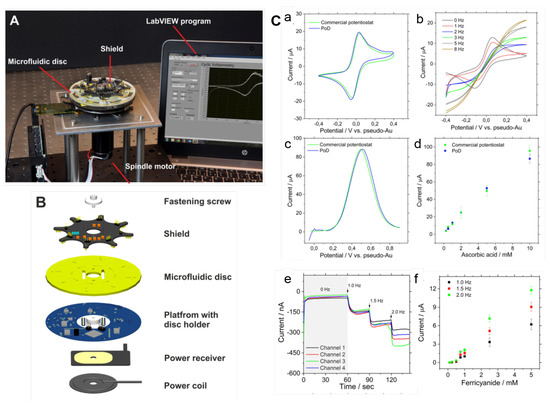

To overcome the drawback concerning the integration of the detection system, recent works have focused on the electrochemical modules to allow measurements during the disc rotation [25,153]. This opening up opportunities of real-time monitoring of bioreactions on disc [25,153]. Andreasen et al. [25] developed a low-noise component (electrical slip-ring) to on-disc electrochemical measurements. Cyclic voltammetry tests performed from 0–600 RPM indicated only a small perturbation of the peak currents with the spin rate. Recently, Rajendran et al. [153] demonstrated a modular lightweight (127 g) and wireless potentiostat-on-a-disc (PoD) able to perform square-wave voltammetry (SWV) and amperometry, controlled by a custom-made software. The current resolution of 200 pA was in agreement with commercial potentiostats. During the experiment, data was transmitted via Bluetooth to a Windows PC, plotted live and displayed in a custom-developed LabVIEW program (Figure 12A). The PoD detection unit was composed by a Qi-based wireless power supply, a core circuit platform and a module (shield) (an exploded view in Figure 12B). Figure 12C(a) presents the cyclic voltammograms (CV) of 1 mM potassium ferricyanide (FiC) collected in stationary-mode using the PoD and a commercial potentiostat and (b) CVs collected in different spinning rates by the PoD. At 0 and 1 Hz, the reaction was diffusion-limited while reaction-limited (due to the mass transfer) at 2 Hz and above [153]. The comparison between PoD and the commercial equipment was extended to SWV: (c) voltammograms of 10 mM ascorbic acid and (d) the respective calibration curve. Both cyclic voltammetry and SWV measurements obtained by the PoD were comparable to the commercial system. The dependence of the amperometric response with the spin rate was tested in a multichannel shield, shown in (e), with the current response for 500 µM FiC increasing with the rotation frequency, as observed in current versus FiC concentration plot, shown in (f). Refer to the source for details [153].

Figure 12.

(A) Photograph of the experimental set-up with the spindle motor, LoaD platform, PoD and computer to control the software interface. (B) Exploded view of the PoD and LoaD device. (C) PoD results: (a) CVs of 1 mM FiC (Au working electrode with area of 50 mm, scan rate of 50 mV/s comparing PoD and commercial potentiostat results, and (b) CVs collected in various rotation speeds at scan-rate of 100 mV/s; (c) SWVs of 10 mM ascorbic acid (carbon working electrode with 50 mm, potential step 0.004 V, frequency of 10 Hz and amplitude of 0.025 V), and (d) calibration curve for ascorbic acid concentrations. (e) Amperometric response for 500 µM FiC (pH 7.4 PBS as supporting electrolyte, applied potential of −0.4 V vs pseudo-Au reference electrode; working electrode area: 0.69 mm; Au counter-electrode) in different rotation speeds, and (f) the normalised current changes recorded for different FiC concentrations during rotation at 1.0, 1.5, and 2.0 Hz (n = 3). Adapted with permission from [153]. Copyright 2019 American Chemical Society.

Sanger et al. [177] report a centrifugal platform capable of capturing and sensing pathogens. The robust LoaD contains an integrated sample pre-treatment system where SWV are used for cell free detection of a secondary metabolite, p-Coumaric acid (pCHA), a biomolecule produced by genetically modified strains of E-Coli bacteria. A common attribute of LoaD platforms is their ability to contain multiple, identical testing sites. A total of eight regions are available for individual biosensing, where a 0.2 µm filter membrane system exists in each section for sample filtration. This filtration and separation occur under centrifugal conditions for 5 min at approximately 12 Hz. The supernatant is metered and then displaced into the detection chamber. Unlike other electrochemical-LoaDs, the sensors are patterned onto an acrylic base of the platform using e-bean evaporation. Contact points connecting both potentiostat and sensor exist through the depth of the LoaD to establish a connection through a slip-ring. Measurements are obtained under static conditions and showed very promising results for the detection and quantification of the two E. coli pCHA metabolites compared to results obtained from other detection methods such as HPLC [152].

This group also reported a novel, on-board pre-treatment based on supported liquid membrane (SLM) technology. This extraction method is used to purify and enrich analytes directly from complex matrices such urine and saliva [23,49]. Using the SLM to facilitate on-disc separation, the main hindering compound, Tyrosine, is subsequently removed and the pCHA is enriched. The platform enables multiple measuremtns to be obtained at certain stages of the production process when the target analyte is quite low (typically 100 µM). The main biosensing technique deployed were CV and SWV measurements. As the device is deemed as low-cost it was aimed to be a single use device, however it has been shown that the device can be re-used using typical electrode cycling to clean the surfaces. This work poses a significant insight into the exciting advantages and potential of on-disc sample pre-treatment and electrical detection for analytes in a compact, portable testing [152].

Amperometry is another electrochemical technique where the current response due to a redox on the surface of the biosensor is measured over a period of time at a constant potential [178,179]. It is often used as a detection technique when coupled with electrochemical-LoaD platforms. The potential is maintained at the working electrode via the reference electrode where the current is recorded due to oxidation or reduction of electroactive species. In cases where the analyte is not electrochemically active, the target cannot be measured directly but indirect approaches can be used. Screen-printed carbon electrodes (SPCE) which were modified using graphene-polyaniline nanocomposites were incorporated onto a LoaD to enhance electrochemical detection of glucose. The enzyme and glucose solutions, loaded into separate chambers, mix in a serpentine channel under centrifugal conditions creating the hydrogen peroxide through the enzymatic reaction in under 8 min. The electrochemically active hydrogen peroxide was quantified to deduce the amount of glucose present in the sample, with a reported LOD of 0.29 mM [152]. Common interfering compounds ascorbic and uric acid were tested where the sensor remained specific towards glucose. This is a critical attribute of a biosensor, as it is important to determine to working capability of the sensor for real applications.