Use of Titanium Dioxide (TiO2) Nanoparticles as Reinforcement Agent of Polysaccharide-Based Materials

Abstract

1. Introduction

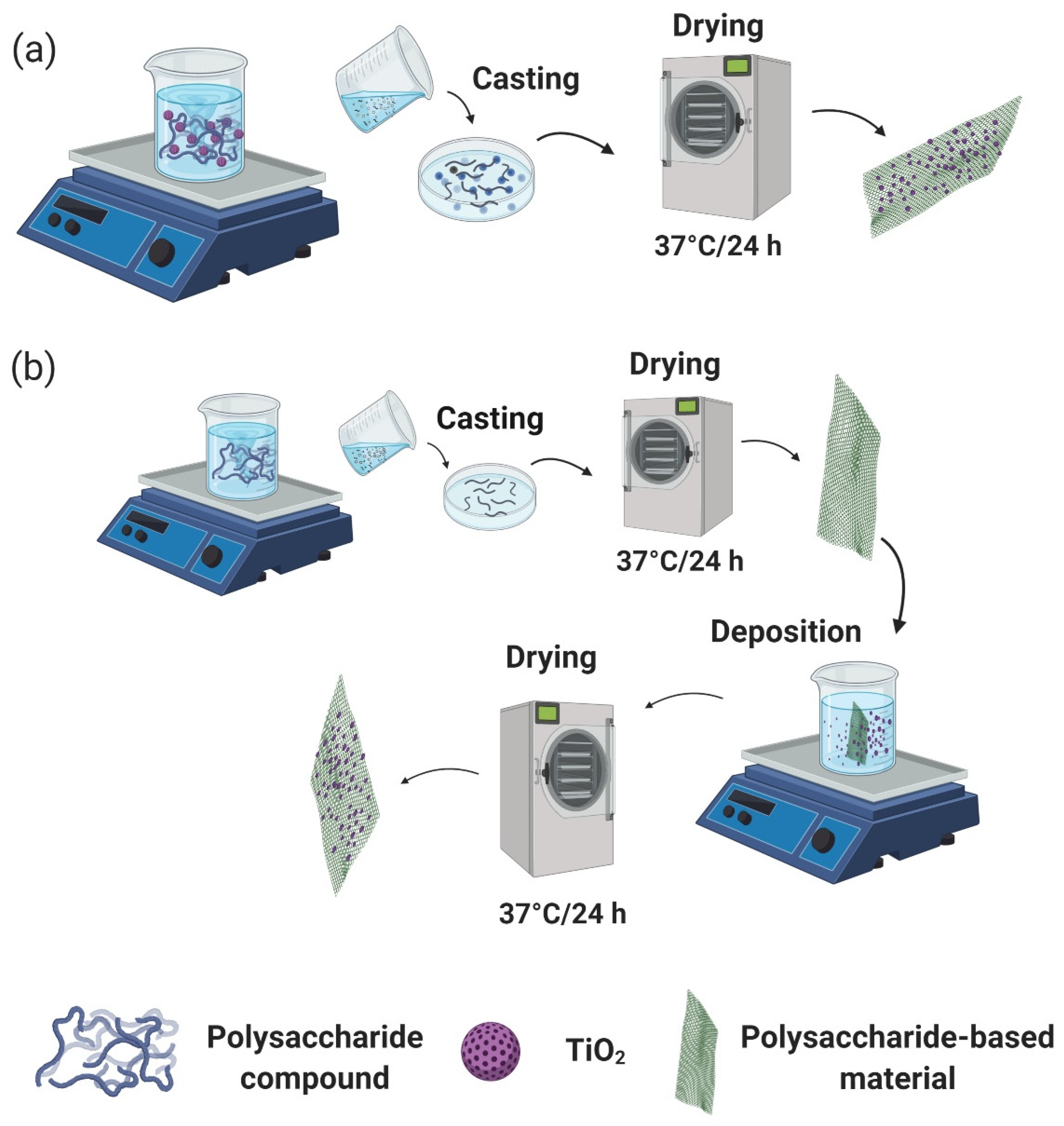

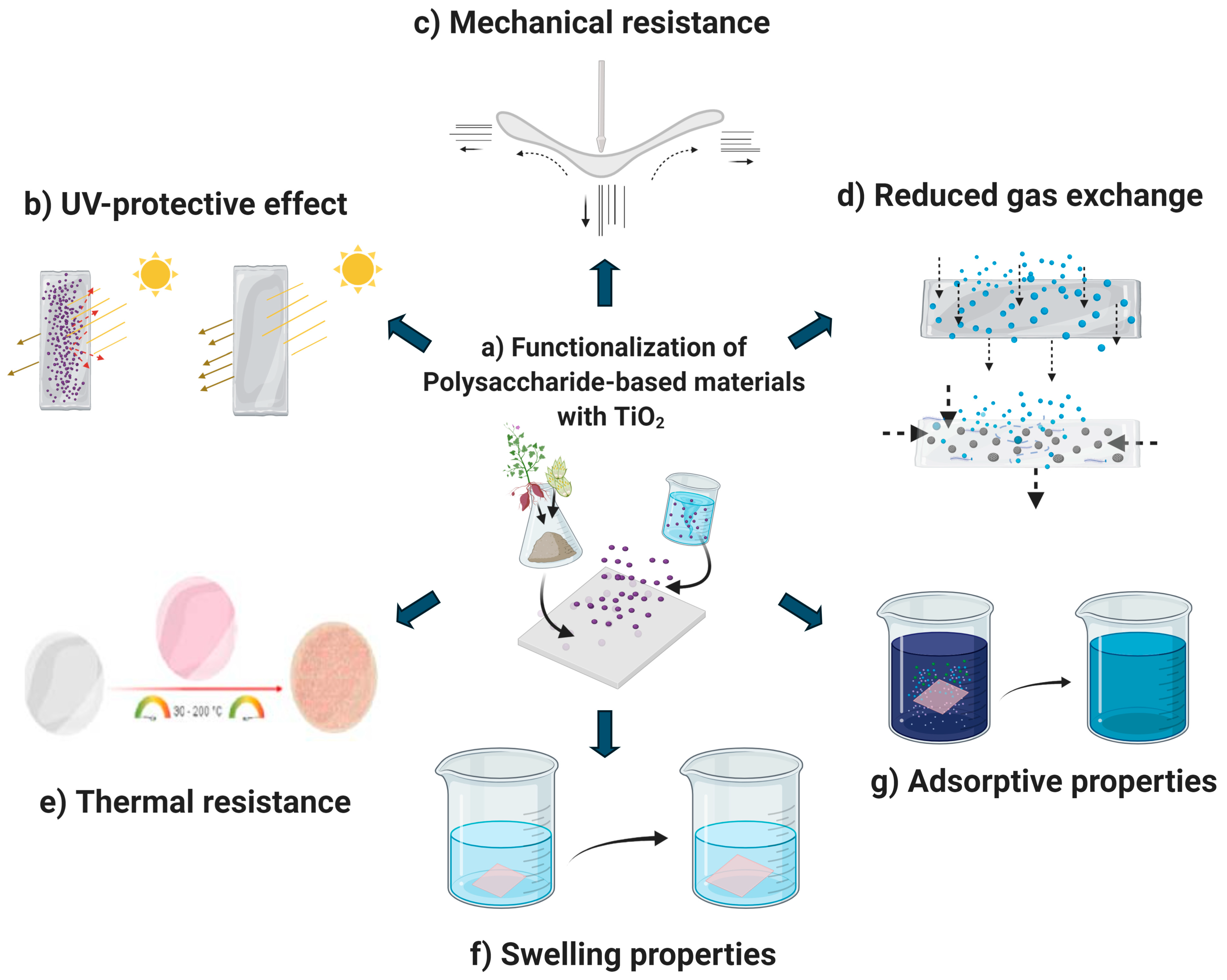

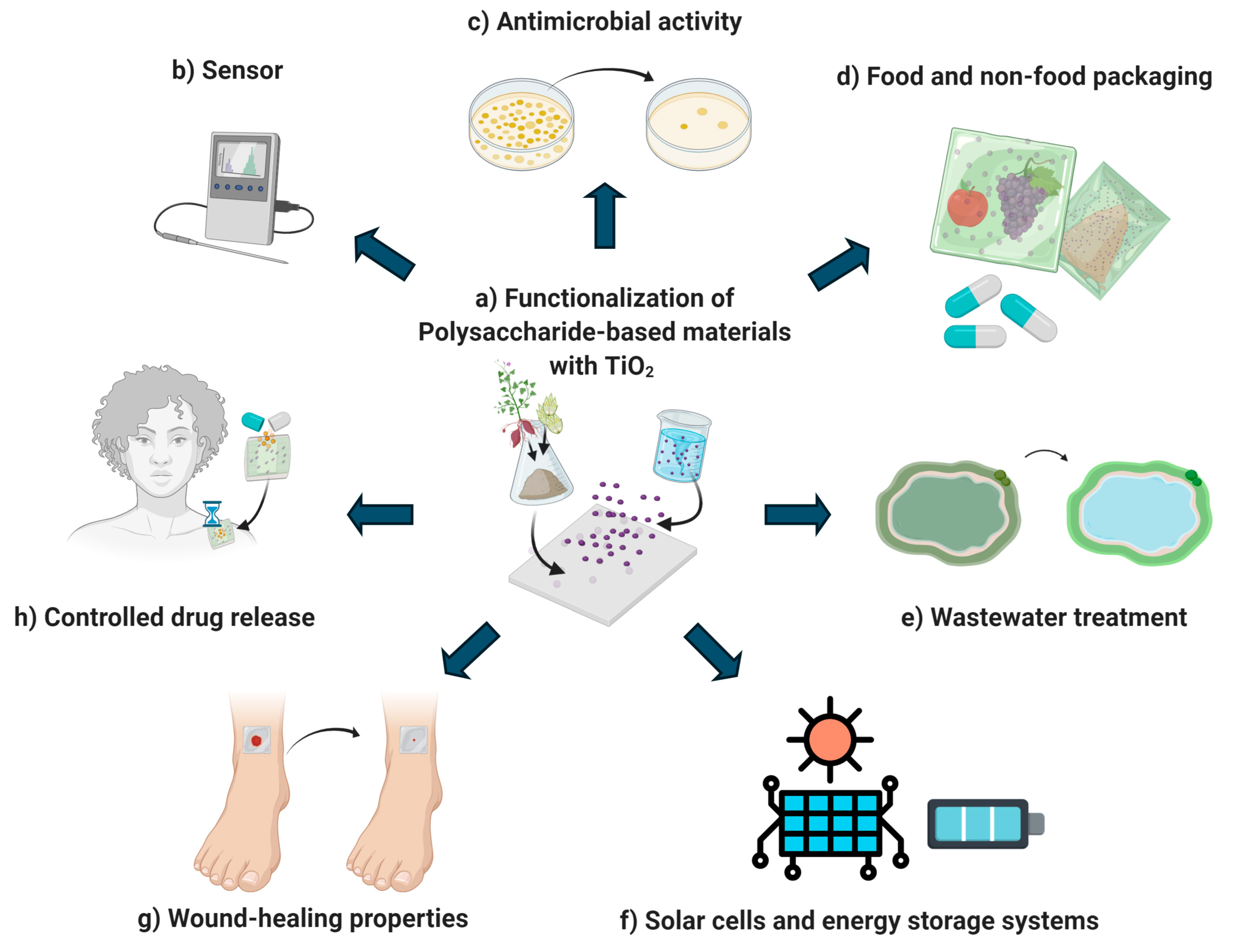

2. Hybrid Materials

3. Polysaccharide–TiO2 Hybrid Materials

3.1. Starch–TiO2 Hybrid Material

3.1.1. Food and Non-Food Packaging Applications of Starch–TiO2 Hybrid Material

3.1.2. Other Applications of Starch–TiO2 Hybrid Material

3.2. Sodium Alginate–TiO2 Hybrid Material

3.2.1. Environmental Applications of Sodium Alginate–TiO2 Hybrid Material

3.2.2. Biomedical Applications of Sodium Alginate–TiO2 Hybrid Material

3.2.3. Food and Non-Food Packaging Applications of Sodium Alginate–TiO2 Hybrid Material

3.2.4. Other Applications of Sodium Alginate–TiO2 Hybrid Material

3.3. Cellulose–TiO2 Hybrid Material

3.3.1. Food and Non-Food Applications of Cellulose–TiO2 Hybrid Material

3.3.2. Environment Applications of Cellulose–TiO2 Hybrid Material

3.3.3. Other Applications of Cellulose–TiO2 Hybrid Material

3.4. Chitosan–TiO2 Hybrid Material

3.4.1. Environmental Applications of Chitosan–TiO2 Hybrid Material

3.4.2. Food and Non-Food Applications of Chitosan–TiO2 Hybrid Material

3.4.3. Biomedical and Cosmetic Applications of Chitosan–TiO2 Hybrid Material

3.5. Other Polysaccharides Functionalized with TiO2

3.5.1. Food and Non-Food Applications of Nonconventional Polysaccharides Functionalized with TiO2

3.5.2. Biomedical Applications of Nonconventional Polysaccharides Functionalized with TiO2

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Anaya-Esparza, L.M.; Ruvalcaba-Gómez, J.M.; Maytorena-Verdugo, C.I.; González-Silva, N.; Romero-Toledo, R.; Aguilera-Aguirre, S.; Pérez-Larios, A.; Montalvo-González, E. Chitosan-TiO2: A versatile hybrid composite. Materials 2020, 13. [Google Scholar] [CrossRef] [PubMed]

- Zhu, P.; Wu, Y.; Reddy, M.V.; Sreekumaran Nair, A.; Chowdari, B.V.R.; Ramakrishna, S. Long term cycling studies of electrospun TiO2 nanostructures and their composites with MWCNTs for rechargeable Lithium-ion batteries. RSC Adv. 2012, 2, 531–537. [Google Scholar] [CrossRef]

- Vilela, C.; Pinto, R.; Pinto, S.; Marques, P.; Silvestre, A.; Freire, C. Polysaccharide Based Hybrid. Materials Metals and Metal. Oxides, Graphene and Carbon Nanotubes; Springer: Berlin, Germany, 2014; Volume 53, ISBN 9783030003463. [Google Scholar]

- Malathi, A.N.; Singh, A.K. Antimicrobial activity of rice starch based film reinforced with titanium dioxide (TiO2) nanoparticles. Agric. Res. J. 2019, 56, 111. [Google Scholar] [CrossRef]

- Urruela-Barrios, R.; Ramírez-Cedillo, E.; de León, A.D.; Alvarez, A.J.; Ortega-Lara, W. Alginate/gelatin hydrogels reinforced with TiO2 and β-TCP fabricated by microextrusion-based printing for tissue regeneration. Polymers 2019, 11. [Google Scholar] [CrossRef] [PubMed]

- Teymourpour, S.; Abdorreza, M.N.; Nahidi, F. Functional, thermal, and antimicrobial properties of soluble soybean polysaccharide biocomposites reinforced by nano TiO2. Carbohydr. Polym. 2015, 134, 726–731. [Google Scholar] [CrossRef]

- Hejri, Z.; Seifkordi, A.A.; Ahmadpour, A.; Zebarjad, S.M.; Maskooki, A. Biodegradable starch/poly (vinyl alcohol) film reinforced with titanium dioxide nanoparticles. Int. J. Miner. Metall. Mater. 2013, 20, 1001–1011. [Google Scholar] [CrossRef]

- Suri, G.; Chhabra, P.; Gupta, R.; Saxena, S.; Tyagi, M.; Seshadri, G.; Verma, G.L.; Khandal, R.K. Challenges in preparation of metal-containing nanocomposites; Dispersion of titanium into plastics. E-Polymers 2010. [Google Scholar] [CrossRef][Green Version]

- Reddy, M.V.; Adams, S.; Liang, G.T.J.; Mingze, I.F.; Van Tu An, H.; Chowdari, B.V.R. Low temperature molten salt synthesis of anatase TiO2 and its electrochemical properties. Solid State Ionics 2014, 262, 120–123. [Google Scholar] [CrossRef]

- Zhou, J.J.; Wang, S.Y.; Gunasekaran, S. Preparation and characterization of whey protein film incorporated with TiO2 nanoparticles. J. Food Sci. 2009, 74. [Google Scholar] [CrossRef]

- Bardet, R.; Belgacem, M.N.; Bras, J. Different strategies for obtaining high opacity films of MFC with TiO2 pigments. Cellulose 2013, 20, 3025–3037. [Google Scholar] [CrossRef]

- Jesline, A.; John, N.P.; Narayanan, P.M.; Vani, C.; Murugan, S. Antimicrobial activity of zinc and titanium dioxide nanoparticles against biofilm-producing methicillin-resistant Staphylococcus aureus. Appl. Nanosci. 2015, 5, 157–162. [Google Scholar] [CrossRef]

- Popov, A.P.; Priezzhev, A.V.; Lademann, J.; Myllylä, R. TiO2 nanoparticles as an effective UV-B radiation skin-protective compound in sunscreens. J. Phys. D Appl. Phys. 2005, 38, 2564–2570. [Google Scholar] [CrossRef]

- Reddy, M.V.; José, R.; Teng, T.H.; Chowdari, B.V.R.; Ramakrishna, S. Preparation and electrochemical studies of electrospun TiO2 nanofibers and molten salt method nanoparticles. Electrochem. Acta 2010, 55, 3109–3117. [Google Scholar] [CrossRef]

- Reddy, M.V.; Valerie Teoh, X.W.; Nguyen, T.B.; Michelle Lim, Y.Y.; Chowdari, B.V.R. Effect of 0.5 M NaNO3: 0.5 M KNO3 and 0.88 M LiNO3: 0.12 M LiCl molten salts, and heat treatment on electrochemical properties of TiO2. J. Electrochem. Soc. 2012, 159, A762–A769. [Google Scholar] [CrossRef]

- Peining, Z.; Yongzhi, W.; Reddy, M.V.; Sreekumaran Nair, A.; Shengjie, P.; Sharma, N.; Peterson, V.K.; Chowdari, B.V.R.; Ramakrishna, S. TiO2 nanoparticles synthesized by the molten salt method as a dual functional material for dye-sensitized solar cells. RSC Adv. 2012, 2, 5123–5126. [Google Scholar] [CrossRef]

- Balasubramanian, R.; Kim, S.S.; Lee, J.; Lee, J. Effect of TiO2 on highly elastic, stretchable UV protective nanocomposite films formed by using a combination of k-Carrageenan, xanthan gum and gellan gum. Int. J. Biol. Macromol. 2019, 123, 1020–1027. [Google Scholar] [CrossRef]

- Afzal, S.; Samsudin, E.M.; Mun, L.K.; Julkapli, N.M.; Hamid, S.B.A. Room temperature synthesis of TiO2 supported chitosan photocatalyst: Study on physicochemical and adsorption photo-decolorization properties. Mater. Res. Bull. 2017, 86, 24–29. [Google Scholar] [CrossRef]

- Xiong, J.; Sheng, C.; Wang, Q.; Guo, W. Toughened and water-resistant starch/TiO2 bio-nanocomposites as an environment-friendly food packaging material. Mater. Res. Express 2019, 6. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Y.; Han, K.; Cai, Y.; Ma, M.; Tong, Q.; Sheng, L. Effect of nano-TiO2 on the physical, mechanical and optical properties of pullulan film. Carbohydr. Polym. 2019, 218, 95–102. [Google Scholar] [CrossRef]

- Ahmadi, R.; Tanomand, A.; Kazeminava, F.; Kamounah, F.S.; Ayaseh, A.; Ganbarov, K.; Yousefi, M.; Katourani, A.; Yousefi, B.; Kafil, H.S. Fabrication and characterization of a titanium dioxide (TiO2) nanoparticles reinforced bio-nanocomposite containing miswak (Salvadora persica L.) extract—The antimicrobial, thermo-physical and barrier properties. Int. J. Nanomed. 2019, 14, 3439–3454. [Google Scholar] [CrossRef]

- Tunma, S. Starch based nanocomposites in active packaging for extended shelf life of fresh fruits. Walailak J. Sci. Technol. 2018, 15, 273–281. [Google Scholar] [CrossRef]

- Khodadadi, B.; Sabeti, M.; Moradi, S.; Aberomand Azar, P.; Raeis Farshid, S. Synthesis of Cu-TiO2 nanocomposite and investigation of the effectiveness of PEG, Pectin, and CMCas Additives. Q. J. Appl. Chem. Res. 2012, 6, 33–41. [Google Scholar]

- Khanmirzaei, M.H.; Ramesh, S. Nanocomposite polymer electrolyte based on rice starch/ionic liquid/TiO2 nanoparticles for solar cell application. Meas. J. Int. Meas. Confed. 2014, 58, 68–72. [Google Scholar] [CrossRef]

- Kuz, P.; Ateş, M. Starch-based bioplastic materials for packaging industry. J. Sustain. Constr. Mater. Technol. 2020, 5, 399–406. [Google Scholar] [CrossRef]

- Amin, M.R.; Chowdhury, M.A.; Kowser, M.A. Characterization and performance analysis of composite bioplastics synthesized using titanium dioxide nanoparticles with corn starch. Heliyon 2019, 5. [Google Scholar] [CrossRef] [PubMed]

- Yousefi, A.R.; Savadkoohi, B.; Zahedi, Y.; Hatami, M.; Ako, K. Fabrication and characterization of hybrid sodium montmorillonite/TiO2 reinforced cross-linked wheat starch-based nanocomposites. Int. J. Biol. Macromol. 2019, 131, 253–263. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Xiong, Z.; Xiong, H.; Wang, Z.; Din, Z.U.; Nawaz, A.; Wang, P.; Hu, C. Effects of nano-TiO2 on bonding performance, structure stability and film-forming properties of starch-g-VAc based wood adhesive. Carbohydr. Polym. 2018, 200, 477–486. [Google Scholar] [CrossRef]

- Miyazaki, T.; Ishikawa, K.; Shirosaki, Y.; Ohtsuki, C. Organic–inorganic composites designed for biomedical applications. Biol. Pharm. Bull. 2013, 36, 1670–1675. [Google Scholar] [CrossRef]

- Premakshi, H.G.; Kariduraganavar, M.Y.; Mitchell, G.R. Crosslinked nanocomposite sodium alginate-based membranes with titanium dioxide for the dehydration of isopropanol by pervaporation. Molecules 2020, 25. [Google Scholar] [CrossRef]

- Tang, S.; Wang, Z.; Li, P.; Li, W.; Li, C.; Wang, Y.; Chu, P.K. Degradable and photocatalytic antibacterial Au-TiO2/sodium alginate nanocomposite films for active food packaging. Nanomaterials 2018, 8. [Google Scholar] [CrossRef]

- Fei, P.; Shi, Y.; Zhou, M.; Cai, J.; Tang, S.; Xiong, H. Effects of nano-TiO2 on the properties and structures of starch/poly(ε-caprolactone) composites. J. Appl. Polym. Sci. 2013, 130, 4129–4136. [Google Scholar] [CrossRef]

- Razali, M.H.; Ismail, N.A.; Amin, K.A.M. Fabrication and characterization of antibacterial titanium dioxide nanorods incorporating gellan gum films. J. Pure Appl. Microbiol. 2019, 13, 1909–1916. [Google Scholar] [CrossRef]

- Hou, X.; Xue, Z.; Liu, J.; Yan, M.; Xia, Y.; Ma, Z. Characterization and property investigation of novel eco-friendly agar/carrageenan/TiO2 nanocomposite films. J. Appl. Polym. Sci. 2019, 136, 1–12. [Google Scholar] [CrossRef]

- Goudarzi, V.; Shahabi-Ghahfarrokhi, I. Development of photo-modified starch/kefiran/TiO2 bio-nanocomposite as an environmentally-friendly food packaging material. Int. J. Biol. Macromol. 2018, 116, 1082–1088. [Google Scholar] [CrossRef]

- De Moura, M.R.; Zucolotto, V.; Aouada, F.A.; Mattoso, L.H.C. Efficiency improvement of cellulose derivative nanocomposite using titanium dioxide nanoparticles. J. Nanosci. Nanotechnol. 2017, 17, 2206–2211. [Google Scholar] [CrossRef]

- Dai, J.; Tian, Q.; Sun, Q.; Wei, W.; Zhuang, J.; Liu, M.; Cao, Z.; Xie, W.; Fan, M. TiO2-alginate composite aerogels as novel oil/water separation and wastewater remediation filters. Compos. Part. B Eng. 2019, 160, 480–487. [Google Scholar] [CrossRef]

- Ismail, N.A.; Amin, K.A.M.; Majid, F.A.A.; Razali, M.H. Gellan gum incorporating titanium dioxide nanoparticles biofilm as wound dressing: Physicochemical, mechanical, antibacterial properties and wound healing studies. Mater. Sci. Eng. C 2019, 103, 109770. [Google Scholar] [CrossRef]

- AL-Mokaram, A.M.A.A.A.; Yahya, R.; Abdi, M.M.; Mahmud, H.N.M.E. The development of non-enzymatic glucose biosensors based on electrochemically prepared polypyrrole-chitosan-titanium dioxide nanocomposite films. Nanomaterials 2017, 7. [Google Scholar] [CrossRef]

- Ciesielski, W.; Krystyjan, M. Starch-metal complexes and their rheology. E-Polymers 2009, 1–13. [Google Scholar] [CrossRef][Green Version]

- Wang, C.R.; Yan, X.Z.; Yu, L.L.; Fang, R. Preparation and properties of glycerol plasticized-corn starch/titanium dioxide-Starch bionanocomposites. Adv. Mater. Res. 2014, 997, 480–483. [Google Scholar] [CrossRef]

- Kochkina, N.E.; Butikova, O.A. Effect of fibrous TiO2 filler on the structural, mechanical, barrier and optical characteristics of biodegradable maize starch/PVA composite films. Int. J. Biol. Macromol. 2019, 139, 431–439. [Google Scholar] [CrossRef] [PubMed]

- Sreekumar, P.A.; Al-Harthi, M.A.; De, S.K. Reinforcement of starch/polyvinyl alcohol blend using nano¢ titanium dioxide. J. Compos. Mater. 2012, 46, 3181–3187. [Google Scholar] [CrossRef]

- Liu, C.; Xiong, H.; Chen, X.; Lin, S.; Tu, Y. Effects of nano-TiO2 on the performance of high-amylose starch based antibacterial films. J. Appl. Polym. Sci. 2015, 132, 2–8. [Google Scholar] [CrossRef]

- Ostafińska, A.; Mikešová, J.; Krejčíková, S.; Nevoralová, M.; Šturcová, A.; Zhigunov, A.; Michálková, D.; Šlouf, M. Thermoplastic starch composites with TiO2 particles: Preparation, morphology, rheology and mechanical properties. Int. J. Biol. Macromol. 2017, 101, 273–282. [Google Scholar] [CrossRef]

- Goudarzi, V.; Shahabi-Ghahfarrokhi, I.; Babaei-Ghazvini, A. Preparation of ecofriendly UV-protective food packaging material by starch/TiO2 bio-nanocomposite: Characterization. Int. J. Biol. Macromol. 2017, 95, 306–313. [Google Scholar] [CrossRef]

- Oleyaei, S.A.; Zahedi, Y.; Ghanbarzadeh, B.; Moayedi, A.A. Modification of physicochemical and thermal properties of starch films by incorporation of TiO2 nanoparticles. Int. J. Biol. Macromol. 2016, 89, 256–264. [Google Scholar] [CrossRef]

- Dash, K.K.; Ali, N.A.; Das, D.; Mohanta, D. Thorough evaluation of sweet potato starch and lemon-waste pectin based-edible films with nano-titania inclusions for food packaging applications. Int. J. Biol. Macromol. 2019, 139, 449–458. [Google Scholar] [CrossRef]

- Goudarzi, V.; Shahabi-Ghahfarrokhi, I. Photo-producible and photo-degradable starch/TiO2 bionanocomposite as a food packaging material: Development and characterization. Int. J. Biol. Macromol. 2018, 106, 661–669. [Google Scholar] [CrossRef]

- Arezoo, E.; Mohammadreza, E.; Maryam, M.; Abdorreza, M.N. The synergistic effects of cinnamon essential oil and nano TiO2 on antimicrobial and functional properties of sago starch films. Int. J. Biol. Macromol. 2020, 157, 743–751. [Google Scholar] [CrossRef]

- Chueangchayaphan, N.; Ting, K.A.; Yusoff, M.; Chueangchayaphan, W. Influence of Al2O3 particle size on properties of thermoplastic starch–TiO2–Al2O3 composites. Polym. Bull. 2019, 76, 5889–5902. [Google Scholar] [CrossRef]

- Hajizadeh, H.; Peighambardoust, S.J.; Peighambardoust, S.H.; Peressini, D. Physical, mechanical, and antibacterial characteristics of bio-nanocomposite films loaded with Ag-modified SiO2 and TiO2 nanoparticles. J. Food Sci. 2020, 85, 1193–1202. [Google Scholar] [CrossRef] [PubMed]

- Yun, Y.H.; Youn, Y.N.; Yoon, S.D.; Lee, J.U. Preparation and physical properties of starch-based nanocomposite films with the addition of titanium oxide nanoparticles. J. Ceram. Process. Res. 2012, 13, 59–64. [Google Scholar]

- Ghozali, M.; Restu, W.K.; Triwulandari, E.; Anwar, M. Effect of metal oxide as antibacterial agent on thermoplastic starch/metal oxide biocomposites properties. Polym. Technol. Mater. 2020, 59, 1317–1325. [Google Scholar] [CrossRef]

- Yun, Y.-H.; Hwang, K.-J.; Wee, Y.-J.; Yoon, S.-D. Synthesis, physical properties, and characterization of starch-based blend films by adding nano-sized TiO2/poly(methyl methacrylate-co-acrylamide). J. Appl. Polym. Sci. 2010, 116, 2658–2667. [Google Scholar] [CrossRef]

- Ahmed, A.; Niazi, M.B.K.; Jahan, Z.; Ahmad, T.; Hussain, A.; Pervaiz, E.; Janjua, H.A.; Hussain, Z. In-vitro and in-vivo study of superabsorbent PVA/Starch/g-C3N4/Ag@TiO2 NPs hydrogel membranes for wound dressing. Eur. Polym. J. 2020, 130, 109650. [Google Scholar] [CrossRef]

- Ujcic, A.; Krejcikova, S.; Nevoralova, M.; Zhigunov, A.; Dybal, J.; Krulis, Z.; Fulin, P.; Nyc, O.; Slouf, M. Thermoplastic starch composites with titanium dioxide and vancomycin antibiotic: Preparation, morphology, thermomechanical properties, and antimicrobial susceptibility testing. Front. Mater. 2020, 7, 1–13. [Google Scholar] [CrossRef]

- Lin, D.; Huang, Y.; Liu, Y.; Luo, T.; Xing, B.; Yang, Y.; Yang, Z.; Wu, Z.; Chen, H.; Zhang, Q.; et al. Physico-mechanical and structural characteristics of starch/polyvinyl alcohol/nano-titania photocatalytic antimicrobial composite films. Lwt 2018, 96, 704–712. [Google Scholar] [CrossRef]

- Mousazadeh, S.; Shakouri, A.; Hojjat, M.; Etemad, S.G.; Heris, S.Z. Rheological behavior of starch–poly(vinyl alcohol)–TiO2 nanofluids and their main and interactive effects. J. Appl. Polym. Sci. 2016, 133, 1–9. [Google Scholar] [CrossRef]

- Ujcic, A.; Nevoralova, M.; Dybal, J.; Zhigunov, A.; Kredatusova, J.; Krejcikova, S.; Fortelny, I.; Slouf, M. Thermoplastic starch composites filled with isometric and elongated TiO2-based nanoparticles. Front. Mater. 2019, 6, 1–13. [Google Scholar] [CrossRef]

- Longo, V.M.; Picon, F.C.; Zamperini, C.; Albuquerque, A.R.; Sambrano, J.R.; Vergani, C.E.; Machado, A.L.; Andrés, J.; Hernandes, A.C.; Varela, J.A.; et al. Experimental and theoretical approach of nanocrystalline TiO2 with antifungal activity. Chem. Phys. Lett. 2013, 577, 114–120. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, K.; Ma, S.; Liu, T.; Yao, M.; Li, J.; Wang, X.; Guan, F. Preparing an injectable hydrogel with sodium alginate and Type I collagen to create better MSCs growth microenvironment. E-Polymers 2019, 19, 87–91. [Google Scholar] [CrossRef]

- Thakur, S.; Arotiba, O. Synthesis, characterization and adsorption studies of an acrylic acid-grafted sodium alginate-based TiO2 hydrogel nanocomposite. Adsorpt. Sci. Technol. 2018, 36, 458–477. [Google Scholar] [CrossRef]

- Reveendran, G.; Ong, S.T. Application of experimental design for dyes removal in aqueous environment by using sodium alginate-TiO2 thin film. Chem. Data Collect. 2018, 15–16, 32–40. [Google Scholar] [CrossRef]

- Thomas, M.; Natarajan, T.S.; Sheikh, M.U.D.; Bano, M.; Khan, F. Self-organized graphene oxide and TiO2 nanoparticles incorporated alginate/carboxymethyl cellulose nanocomposites with efficient photocatalytic activity under direct sunlight. J. Photochem. Photobiol. A Chem. 2017, 346, 113–125. [Google Scholar] [CrossRef]

- Naik, K.; Chandran, V.G.; Rajashekaran, R.; Waigaonkar, S.; Kowshik, M. Mechanical properties, biological behaviour and drug release capability of nano TiO2-HAp-Alginate composite scaffolds for potential application as bone implant material. J. Biomater. Appl. 2016, 31, 387–399. [Google Scholar] [CrossRef]

- Selvi, R.T.; Prasanna, A.P.S.; Niranjan, R.; Kaushik, M.; Devasena, T.; Kumar, J.; Chelliah, R.; Oh, D.H.; Swaminathan, S.; Venkatasubbu, G.D. Metal oxide curcumin incorporated polymer patches for wound healing. Appl. Surf. Sci. 2018, 449, 603–609. [Google Scholar] [CrossRef]

- Amjadi, S.; Almasi, H.; Ghorbani, M.; Ramazani, S. Preparation and characterization of TiO2NPs and betanin loaded zein/sodium alginate nanofibers. Food Packag. Shelf Life 2020, 24, 100504. [Google Scholar] [CrossRef]

- Uddin, M.J.; Islam, J.M.M.; Rahman, M.A.; Khan, M.A. Development of photoactive titanium dioxide doped sodium alginate film for dye sensitized solar cell Application. Int. J. Thin Film. Sci. Technol. 2017, 6, 135–138. [Google Scholar] [CrossRef]

- Padma, G.T.; Rao, T.S.; Naidu, K.C.B. Preparation, characterization and dielectric properties of sodium alginate/titanium dioxide composite membranes. SN Appl. Sci. 2019, 1, 1–8. [Google Scholar] [CrossRef]

- Mohamed, M.A.; Salleh, W.N.W.; Jaafar, J.; Ismail, A.F.; Abd Mutalib, M.; Jamil, S.M. Incorporation of N-doped TiO2 nanorods in regenerated cellulose thin films fabricated from recycled newspaper as a green portable photocatalyst. Carbohydr. Polym. 2015, 133, 429–437. [Google Scholar] [CrossRef]

- Alavi, M. Modifications of microcrystalline cellulose (MCC), nanofibrillated cellulose (NFC), and nanocrystalline cellulose (NCC) for antimicrobial and wound healing applications. E-Polymers 2019, 19, 103–119. [Google Scholar] [CrossRef]

- El-Wakil, N.A.; Hassan, E.A.; Abou-Zeid, R.E.; Dufresne, A. Development of wheat gluten/nanocellulose/titanium dioxide nanocomposites for active food packaging. Carbohydr. Polym. 2015, 124, 337–346. [Google Scholar] [CrossRef] [PubMed]

- Fathi-Achachlouei, B.; Zahedi, Y. Fabrication and characterization of CMC-based nanocomposites reinforced with sodium montmorillonite and TiO2 nanomaterials. Carbohydr. Polym. 2018, 199, 415–425. [Google Scholar] [CrossRef] [PubMed]

- Alizadeh Sani, M.; Ehsani, A.; Hashemi, M. Whey protein isolate/cellulose nanofibre/TiO2 nanoparticle/rosemary essential oil nanocomposite film: Its effect on microbial and sensory quality of lamb meat and growth of common foodborne pathogenic bacteria during refrigeration. Int. J. Food Microbiol. 2017, 251, 8–14. [Google Scholar] [CrossRef]

- Alizadeh-Sani, M.; Mohammadian, E.; McClements, D.J. Eco-friendly active packaging consisting of nanostructured biopolymer matrix reinforced with TiO2 and essential oil: Application for preservation of refrigerated meat. Food Chem. 2020, 322, 126782. [Google Scholar] [CrossRef]

- Alizadeh-Sani, M.; Khezerlou, A.; Ehsani, A. Fabrication and characterization of the bionanocomposite film based on whey protein biopolymer loaded with TiO2 nanoparticles, cellulose nanofibers and rosemary essential oil. Ind. Crops Prod. 2018, 124, 300–315. [Google Scholar] [CrossRef]

- Yu, Z.; Wang, W.; Sun, L.; Kong, F.; Lin, M.; Mustapha, A. Preparation of cellulose nanofibril/titanium dioxide nanoparticle nanocomposites as fillers for PVA-based packaging and investigation into their intestinal toxicity. Int. J. Biol. Macromol. 2020, 156, 1174–1182. [Google Scholar] [CrossRef]

- de Matos Fonseca, J.; Valencia, G.A.; Soares, L.S.; Dotto, M.E.R.; Campos, C.E.M.; Moreira, R.F.P.M.; Fritz, A.R.M. Hydroxypropyl methylcellulose-TiO2 and gelatin-TiO2 nanocomposite films: Physicochemical and structural properties. Int. J. Biol. Macromol. 2020, 151, 944–956. [Google Scholar] [CrossRef]

- Miao, S.; Miao, Z.; Liu, Z.; Han, B.; Zhang, H.; Zhang, J. Synthesis of mesoporous TiO2 films in ionic liquid dissolving cellulose. Microporous Mesoporous Mater. 2006, 95, 26–30. [Google Scholar] [CrossRef]

- Uddin, M.J.; Cesano, F.; Bonino, F.; Bordiga, S.; Spoto, G.; Scarano, D.; Zecchina, A. Photoactive TiO2 films on cellulose fibres: Synthesis and characterization. J. Photochem. Photobiol. A Chem. 2007, 189, 286–294. [Google Scholar] [CrossRef]

- Zeng, J.; Liu, S.; Cai, J.; Zhang, L. TiO2 immobilized in cellulose matrix for photocatalytic degradation of phenol under weak UV light irradiation. J. Phys. Chem. C 2010, 114, 7806–7811. [Google Scholar] [CrossRef]

- Ortelli, S.; Blosi, M.; Albonetti, S.; Vaccari, A.; Dondi, M.; Costa, A.L. TiO2 based nano-photocatalysis immobilized on cellulose substrates. J. Photochem. Photobiol. A Chem. 2014, 276, 58–64. [Google Scholar] [CrossRef]

- Jo, S.; Oh, Y.; Park, S.; Kan, E.; Lee, S.H. Cellulose/carrageenan/TiO2 nanocomposite for adsorption and photodegradation of cationic dye. Biotechnol. Bioprocess. Eng. 2017, 22, 734–738. [Google Scholar] [CrossRef]

- Wang, J.; Liu, W.; Li, H.; Wang, H.; Wang, Z.; Zhou, W.; Liu, H. Preparation of cellulose fiber–TiO2 nanobelt–silver nanoparticle hierarchically structured hybrid paper and its photocatalytic and antibacterial properties. Chem. Eng. J. 2013, 228, 271–280. [Google Scholar] [CrossRef]

- Nelson, K.; Deng, Y. Enhanced light scattering from hollow polycrystalline TiO2 particles in a cellulose matrix. Langmuir 2008, 24, 975–982. [Google Scholar] [CrossRef]

- Kale, B.M.; Wiener, J.; Militky, J.; Rwawiire, S.; Mishra, R.; Jacob, K.I.; Wang, Y. Coating of cellulose-TiO2 nanoparticles on cotton fabric for durable photocatalytic self-cleaning and stiffness. Carbohydr. Polym. 2016, 150, 107–113. [Google Scholar] [CrossRef] [PubMed]

- Veronovski, N.; Sfiligoj-Smole, M.; Viota, J.L. Characterization of TiO2/TiO2-SiO2 coated cellulose textiles. Text. Res. J. 2010, 80, 55–62. [Google Scholar] [CrossRef]

- Pang, Z.; Yang, Z.; Chen, Y.; Zhang, J.; Wang, Q.; Huang, F.; Wei, Q. A room temperature ammonia gas sensor based on cellulose/TiO2/PANI composite nanofibers. Coll. Surf. A Physicochem. Eng. Asp. 2016, 494, 248–255. [Google Scholar] [CrossRef]

- Behnezhad, M.; Goodarzi, M.; Baniasadi, H. Fabrication and characterization of polyvinyl alcohol/carboxymethyl cellulose/titanium dioxide degradable composite films: An RSM study. Mater. Res. Express 2019, 6. [Google Scholar] [CrossRef]

- Tripathi, S.; Mehrotra, G.K.; Dutta, P.K. Chitosan based antimicrobial films for food packaging applications. E-Polymers 2008, 1–7. [Google Scholar] [CrossRef]

- Mahmoud, G.A.; Sayed, A.; Thabit, M.; Safwat, G. Chitosan biopolymer based nanocomposite hydrogels for removal of methylene blue dye. SN Appl. Sci. 2020, 2. [Google Scholar] [CrossRef]

- El-Ella, A.A.; Youssef, A.M.; Ghannam, H.E.; Zedan, A.F.; Aboulthana, W.M.; Al-Sherbini, A.S.A. Synthesis of high efficient CS/PVDC/TiO2-Au nanocomposites for photocatalytic degradation of carcinogenic ethidium bromide in sunlight. Egypt. J. Chem. 2020, 63, 1619–1638. [Google Scholar] [CrossRef]

- Ikhlef-Taguelmimt, T.; Hamiche, A.; Yahiaoui, I.; Bendellali, T.; Lebik-Elhadi, H.; Ait-Amar, H.; Aissani-Benissad, F. Tetracycline hydrochloride degradation by heterogeneous photocatalysis using TiO2(P25) immobilized in biopolymer (Chitosan) under UV irradiation. Water Sci. Technol. 2020, 2, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Huang, G.; An, C.; Huang, J.; Chen, X.; Xin, X.; Song, P.; Feng, R.; Li, Y. Low-cost microbiological purification using a new ceramic disk filter functionalized by chitosan/TiO2 nanocomposites. Sep. Purif. Technol. 2020, 248, 116984. [Google Scholar] [CrossRef]

- Marey, A. Synthesis composite of TiO2/chitosan and TiO2/bentonite for removing turbidity from Ismailia canal as water treatment plant. Afr. J. Chem. Educ. 2020, 10, 124–133. [Google Scholar]

- Hussein, L.I.; Abdaleem, A.H.; Darwish, M.S.A.; Mostafa, M.H.; Elsawy, M.A. Chitosan/TiO2 nanocomposites: Effect of microwave heating and solution mixing techniques on physical properties. Egyp. J. Chem. 2020, 63, 449–460. [Google Scholar] [CrossRef]

- Nugraheni, A.D.; Purnawati, D.; Rohmatillah, A.; Mahardika, D.N.; Kusumaatmaja, A. Swelling of PVA/chitosan/TiO2 nanofibers membrane in different pH. Mater. Sci. Forum 2020, 990 MSF, 220–224. [Google Scholar] [CrossRef]

- Taspika, M.; Desiati, R.D.; Mahardika, M. Influence of TiO2/Ag particles on the properties of chitosan film. Adv. Nat. Sci. Nanosci. Nanotechnol. 2020, 11, 015017. [Google Scholar] [CrossRef]

- Hosseinzadeh, S.; Partovi, R.; Talebi, F.; Babaei, A. Chitosan/TiO2 nanoparticle/Cymbopogon citratus essential oil film as food packaging material: Physico-mechanical properties and its effects on microbial, chemical, and organoleptic quality of minced meat during refrigeration. J. Food Process. Preserv. 2020, 44, 1–12. [Google Scholar] [CrossRef]

- Hanafy, M.S.; Desoky, W.M.; Hussein, E.M.; El-Shaer, N.H.; Gomaa, M.; Gamal, A.A.; Esawy, M.A.; Guirguis, O.W. Biological applications study of bio-nanocomposites based on chitosan/TiO2 nanoparticles polymeric films modified by oleic acid. J. Biomed. Mater. Res. Part. A 2020. [Google Scholar] [CrossRef]

- Cheng, C.W.; Yang, C.I.; Ou, S.L.; Chi, H.W.; Lui, P.W.; Chen, W.Y.; Ao, W.; Lai, F.M. Bending mattress and antibacterial effect of TiO2/nAg/chitosan-nanoparticle-applied intelligent patient bed. Sensors Mater. 2020, 32, 1757–1766. [Google Scholar] [CrossRef]

- Petrick, J.; Ibadurrohman, M. Slamet Synthesis of chitosan/TiO2 nanocomposite for antibacterial sunscreen application. Int. Conf. Trends Mater. Sci. Inven. Mater. Ictmim 2020, 2259, 060020. [Google Scholar] [CrossRef]

- Kolsuz Ozcetin, H.; Surmelioglu, D. Effects of bleaching gel containing TiO2 and chitosan on tooth surface roughness, microhardness and colour. Aust. Dent. J. 2020. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Geng, C.; Xue, Z.; Xia, Y. Preparation and properties investigation of agar/TiO2 fibers. J. Appl. Sci. Eng. Inno. 2018, 5, 109–112. [Google Scholar]

- Vejdan, A.; Ojagh, S.M.; Adeli, A.; Abdollahi, M. Effect of TiO2 nanoparticles on the physico-mechanical and ultraviolet light barrier properties of fish gelatin/agar bilayer film. LWT Food Sci. Technol. 2016, 71, 88–95. [Google Scholar] [CrossRef]

- Vejdan, A.; Ojagh, S.M.; Abdollahi, M. Effect of gelatin/agar bilayer film incorporated with TiO2 nanoparticles as a UV absorbent on fish oil photooxidation. Int. J. Food Sci. Technol. 2017, 52, 1862–1868. [Google Scholar] [CrossRef]

- Abdel-Baky, E.; El-Duma Abdullah, Z.; El Din Aboul-Anean, H. Application of nano edible films to improve some sates in Saudi Arabia. Int. J. Pharm. Res. Allied Sci. 2020, 9, 69–84. [Google Scholar]

- Nasiri, M.; Sani, A.M.; Hakimzadeh, V.; Shahidi, M. Antimicrobial effects of edible nano-composite based on bean pod shell gum, nano-TiO2, and Mentha pulegium essential oil. J. Appl. Biol. Biotechnol. 2019, 7, 75–78. [Google Scholar] [CrossRef]

- Jin, B.; Li, X.; Zhou, X.; Xu, X.; Jian, H.; Li, M.; Guo, K.; Guan, J.; Yan, S. Fabrication and characterization of nanocomposite film made from a jackfruit filum polysaccharide incorporating TiO2 nanoparticles by photocatalysis. RSC Adv. 2017, 7, 16931–16937. [Google Scholar] [CrossRef]

- Salarbashi, D.; Tafaghodi, M.; Bazzaz, B.S.F.; Jafari, B. Characterization of soluble soybean (SSPS) polysaccharide and development of eco-friendly SSPS/TiO2 nanoparticle bionanocomposites. Int. J. Biol. Macromol. 2018, 112, 852–861. [Google Scholar] [CrossRef]

- Razali, M.H.; Ismail, N.A.; Mat Amin, K.A. Titanium dioxide nanotubes incorporated gellan gum bio-nanocomposite film for wound healing: Effect of TiO2 nanotubes concentration. Int. J. Biol. Macromol. 2020, 153, 1117–1135. [Google Scholar] [CrossRef] [PubMed]

| Application | Method/Presentation | * Composition | Relevant Results | Ref. |

|---|---|---|---|---|

| Food and non-food packaging | Evaporative casting/Film | Rice starch (3 g 100 mL−1), TiO2 (1% of total solid content), glycerol (1.5 g) | TiO2 enhanced antimicrobial activity and physicochemical properties of rice starch-film. | [4] |

| Food and non-food packaging | Evaporative casting/Film | Corn starch (40% w/v), PVA (60% w/v), glycerol (30% w/v), TiO2 (5% w/v) | The thermal resistance of corn starch/PVA composite was improved by adding TiO2. | [7] |

| Food and non-food packaging | Evaporative casting/Film | Potato starch (60%), glycerol (40%), TiO2 (2.5% of total mixture) | TiO2 increased the hydrophobicity of the starch-film and improved their mechanical and thermal properties. | [19] |

| Food and non-food packaging | Evaporative casting/Film | Cassava starch (NI), TiO2 (0.01% w/w), glycerol (NI) | The fruits treated with the hybrid film exhibited longer shelf life than that treated with petroleum-based films. | [22] |

| Food and non-food packaging | Condensation polymerization/Film | Corn starch (10 g 100 mL−1), TiO2 (3% of total solid content), glycerol (8 mL), HCl 0.1M (12 mL) | The hybrid material showed high-pressure resistance. | [25] |

| Food and non-food packaging | Evaporative casting/Film | Corn starch (16 g 100 mL−1), TiO2 (10%), glycerol (8 g) | The thermal resistance of starch-based film increased by adding TiO2. | [26] |

| Food and non-food packaging | Evaporative casting/Film | Wheat starch (2 g 50 mL−1), TiO2 (4% of total solid content), glycerol (50% w/w of starch) | TiO2 improved the thermal, mechanical, water-related, and UV-barrier properties of starch-based films. | [27] |

| Food and non-food packaging | Evaporative casting/Film | Starch (6 g), poly(ε-caprolactone) (100 g), TiO2 (6 g), glycerin (18 g), ethyl alcohol (600 mL) | The starch–PCL–TiO2 composite showed improved physicochemical properties compared to the starch–PCL film. | [32] |

| Food and non-food packaging | Evaporative casting/Film | Corn starch (5 g 100 mL−1), TiO2 (3%), glycerol (0.5 g) | The composite reinforced with TiO2 showed improved mechanical properties. | [41] |

| Food and non-food packaging | Evaporative casting/Film | Starch (2.5 g 100 mL−1), PVA (2.5 g 100 mL−1), TiO2 (0.03 g), glycerol (0.5 g) | The hybrid film showed bacteriostatic activity against E. coli and L. monocytogenes and favorable photocatalytic properties on methylene blue dye. | [32] |

| Food and non-food packaging | NI/Nanofluids | Corn starch (NI), PVA (NI), TiO2 (NI) | The rheological behavior of the starch–PVA film-forming solution is influenced by TiO2 concentration. | [33] |

| Food and non-food packaging | Evaporative casting/Film | Maize starch (2 g 37 mL−1), PVA (2 g 38 mL−1), TiO2 (0.05% of total solid content), glycerol (1.2 g) | Starch–PVA–TiO2 exhibited improved thermal, mechanical, and optical properties. | [42] |

| Food and non-food packaging | Evaporative casting/Film | Corn starch (10 g 100 mL−1), PVA (10 g), TiO2 (1% w/w) glycerol (3.5 g) | The mechanical properties of corn starch–PVA film were improved by adding TiO2. | [43] |

| Food and non-food packaging | Evaporative casting/Membrane | High amylose starch (10 g 100 mL−1), PVA (6 g 150 mL−1), TiO2 (1% w/w), glycerol (3 g 100 mL−1) | TiO2 enhanced the antimicrobial activity and mechanical properties of the starch–PVA membrane. | [44] |

| Food and non-food packaging | Evaporative casting/Film | Wheat starch (5 g 100 mL−1), TiO2 (3% w/w), glycerol (40% w/w) | The functional properties of the starch/TiO2 composite could be positively modified by a low UVA exposure time. | [35] |

| Food and non-food packaging | Evaporative casting/Film | Tapioca (65.8%) or wheat (65.8%) starch, TiO2 (6%), glycerol (28.2%) | The effect of TiO2 as a reinforcement agent depends on the type of starch. | [45] |

| Food and non-food packaging | Evaporative casting/Film | Wheat starch (1 g 100 mL−1), TiO2 (5% w/w), glycerol (40% w/w) | TiO2 incorporation increases the hydrophobicity and UV-blocking ability of starch film. | [39] |

| Food and non-food packaging | Evaporative casting/Film | Wheat starch (68.1%), TiO2 (3%), glycerol (28.9%) | The preparation method influences the functional properties of starch-based hybrid materials. | [46] |

| Food and non-food packaging | Evaporative casting/Film | Potato starch (1 g 100 mL−1), TiO2 (1% w/w), glycerol (40% w/w) | TiO2 improved the thermal, water-related, and UV-barrier properties of starch-based films. | [47] |

| Food and non-food packaging | Evaporative casting/Film | potato starch (NI), TiO2 (1% w/w) | The hybrid film showed enhanced UV-blocking properties. | [48] |

| Food and non-food packaging | Evaporative casting/Film | Wheat starch (5 g 100 mL−1), kefiran (2 g 100 mL−1), TiO2 (3% w/w), glycerol (40% w/w) | The functional properties of the starch/kefiran/TiO2 composite could be positively modified by a low UVA exposure time. | [49] |

| Food and non-food packaging | Evaporative casting/Film | Sago starch (4 g 100 mL−1), CEO (2%), TiO2 (5% w/w), glycerol (40% w/w) | The hybrid film had antimicrobial activity against E. coli, S. Typhimurium, and S. aureus and improved UV-barrier properties. | [50] |

| Food and non-food packaging | Evaporative casting/Film | Cassava starch (70 g 100 mL−1), TiO2–Al2O3 (2:1), glycerol (30% w/w) | Starch–TiO2:Al2O3 showed enhanced physicochemical properties compared with the starch–TiO2 hybrid film. | [51] |

| Food and non-food packaging | Evaporative casting/Film | Yellow dent corn starch (5 g 100 mL−1), TiO2:Ag (4% w/w), glycerol (1.9% w/w) | Starch–TiO2:Ag exhibited antimicrobial activity against E. coli and S. aureus; it was enhanced in 70 and 40%, respectively, compared with the starch–TiO2 hybrid film. | [52] |

| Photocatalysis | Evaporative casting/Film | Starch (5 g 100 mL−1), PVA (5 g 100 mL−1), TiO2 (8%), glycerol (40%) | The hybrid film showed photocatalytic degradation of bisphenol A and 2,4-D. | [53] |

| Photocatalysis | Evaporative casting/Film | Starch (4 g 100 mL−1), TiO2 (0.08 g 100 mL−1) | The hybrid film showed a low-moderate antibacterial effect against S. aureus. | [54] |

| Photocatalysis | Evaporative casting/Film | Corn starch (1 g 100 mL−1), PVA (1 g 100 mL−1), PMMA-co-AM (0.6 g 100 mL−1), TiO2 (0.2 g), glycerol (0.8 g) | The hybrid film exhibited photocatalytic properties against methylene blue and acetaldehyde. | [55] |

| Biomedical | Evaporative casting/Hydrogel membrane | PVA (5 g), starch (3.5 g), g–C3–N4 (0.1 g), Ag–TiO2 (0.7 g), water (80 mL) | In an animal model, the hybrid membrane had better wound-healing properties than a conventional cotton gauze wound dressing. | [56] |

| Biomedical | Evaporative casting/Composite | Wheat starch (56.2%), TiO2 (10%), vancomycin (10%), glycerin (23.8%) | The composite exhibited antimicrobial activity and controlled drug release. | [57] |

| Solar cell | Evaporative casting/Nanocomposite | Rice starch–lithium iodide (65:35%), TiO2 (2 wt.% of total solid content) | TiO2 enhanced the conductivity of the starch/ionic liquid composite. | [24] |

| Application | Method/Presentation | * Composition | Relevant Results | Ref. |

|---|---|---|---|---|

| Photocatalyst | Evaporative casting/Hydrogel | SA (0.5 g 50 mL−1), TiO2 (150 mg) | The hydrogel showed good adsorption and removal efficiency of methyl violet dye. | [63] |

| Photocatalyst | Evaporative casting/Film | SA (2 g 17 mL−1), TiO2 (0.15 g) | The hybrid film showed good photocatalytic properties against Congo red dye. | [64] |

| Photocatalyst | Evaporative casting/Film | SA (1 g 100 mL−1), TiO2 (10% w/w) | The hybrid film exhibited excellent oil/water separation efficiency and methyl orange degradation. | [37] |

| Photocatalyst | Freeze-drying/Composite | SA (2% w/w), CMC (3% w/w), TiO2 (20% w/w), GO (0.05 g) | The SA–CMC–TiO2:GO composite showed good photocatalytic degradation (98%) against Congo red dye. | [65] |

| Biomedical | Freeze-drying/Hydrogel | SA (2% w/v), gelatin (0.5% w/v), TiO2 (0.1% w/v), β-tP (1% w/v) | The hybrid hydrogel had adequate porosity and mechanical resistance for biomedical applications. | [5] |

| Biomedical | Freeze-drying/Scaffolds | SA (2 g 100 mL−1), TiO2:HAp (1% w/v), | Hybrid scaffolds are biocompatible with the human MG-63 cell line and showed controlled drug release. | [66] |

| Biomedical | Evaporative casting/Patches | SA (2 g 100 mL−1), PVA (16 g 100 mL−1), TiO2 (0.1 g), curcumin (0.5 g) | Hybrid biocomposite showed antimicrobial activity against B. subtilis and K. pneumoniae. | [67] |

| Food and non-food packaging | Evaporative casting/Film | SA (10% w/v), TiO2:Au (2.5% w/w), glycerol (10% w/w) | SA–TiO2:Au showed higher antimicrobial activity against S. aureus and E. coli than SA–TiO2 films. | [31] |

| Food and non-food packaging | Evaporative casting/ Film | Zein:SA (90:10), TiO2 (0.5%), betanin (1%) | The hybrid film showed antimicrobial activity against E. coli and S. aureus. | [68] |

| Dye-sensitized solar cell | Evaporative casting/Film | SA (2.5 g 100 mL−1), TiO2 (8% w/w) | Ionic conductivity of the SA-based film was enhanced by adding TiO2 in a temperature-dependent response. | [69] |

| Molecular electronics | Evaporative casting/Membrane | Sodium alginate (4 g/90 mL), TiO2 (5% in total solid content) | TiO2 improved dielectric and ac-electrical conductivity properties of an SA solution. | [70] |

| Separation processes | Evaporative casting/Membrane | SA (4 g 100 mL−1), TiO2 (40% w/w), poly(styrene sulfonic acid-co-maleic acid) (0.5% w/w) | The hybrid membrane showed good separation of isopropanol in an alcohol–water mixture solution. | [30] |

| Application | Method/Presentation | * Composition | Relevant Results | Ref. |

|---|---|---|---|---|

| Food and non-food packaging | Sol-gel/Coating | MFC–TiO2 (0.74:1) | The sol-gel method is a viable strategy for cellulose–TiO2 hybrid materials development. | [11] |

| Food and non-food packaging | Evaporative casting/ Film | CMC (2g 50 mL−1), TiO2 (2% w/w), glycerol (50% w/v) | TiO2 improved the mechanical, thermal, and antimicrobial properties of CMC-based film. | [21] |

| Food and non-food packaging | Evaporative casting/ Film | HMC (NI), TiO2 (0.001 g 100 mL−1) | The hybrid film exhibited significant antimicrobial activity against S. aureus and E. coli. | [36] |

| Food and non-food packaging | Evaporative casting/ Film | Wheat gluten (9 g 100 mL−1), cellulose (7.5% in gluten content), TiO2 (0.6% in gluten content), glycerol (2% w/v) | The hybrid film showed improved antimicrobial activity against S. cerevisiae, E. coli, and S. aureus. | [73] |

| Food and non-food packaging | Evaporative casting/ Film | CMC (1.5 g 100 mL−1), Na-MMT (5%), TiO2 (1%) | The hybrid film exhibited remarkable UV-light blocking properties. | [74] |

| Food and non-food packaging | Casting/Film | WPI (10% w/v), cellulose (1% w/v), glycerol (6% w/v), TiO2 (1% w/v), REO (2% w/v) | Coated meat treated showed acceptable microbial quality without changes in sensory attributes for 6 days at 4 °C. | [75] |

| Food and non-food packaging | Casting/Film | WPI (10% w/v), cellulose (1% w/v), glycerol (6% w/v), TiO2 (1% w/v), REO (2% w/v) | Meat treated with the hybrid film showed reduced lipid peroxidation during cold storage. | [76] |

| Food and non-food packaging | Evaporative casting/Film | WPI (10% w/v), cellulose (1% w/v), glycerol (6% w/v), TiO2 (1% w/v), REO (2% w/v) | The hybrid film exhibited antimicrobial and antioxidant activities. | [77] |

| Food and non-food packaging | Mixing/Film | Cellulose (0.3% w/v), TiO2 (0.15% w/v), PVA (3% w/v), glycerol (1% w/v) | Hybrid composite did not show toxicity in normal cells and did not affect the typical intestinal bacteria profile. | [78] |

| Photocatalyst | Phase inversion technique/Film | Cellulose:TiO2:water (81:12:7) | The hybrid film showed high methylene blue degradation under UVA and visible light. | [71] |

| Photocatalyst | Casting/Film | Hydroxypropyl methylcellulose (4 g 100 mL−1), TiO2 (1 wt%), glycerol 25 (wt%) | The hybrid composite showed barrier, thermal, mechanical, physicochemical, and structural properties appropriate to degrade ethylene or other substrates | [79] |

| Photocatalyst | Sol-gel/Composite | The TiO2–cellulose mass ration of 0.5 | The TiO2–cellulose composite showed a photocatalytic reduction of Ag(I) to Ag and Au(III) to Au. | [80] |

| Photocatalyst | Sol-gel/Fibers | Cellulose fiber (NI), TiO2 (0.02 mol 50 mL−1 of isopropanol) | The hybrid film showed high adsorptive and photocatalytic properties against methylene blue dye under simulated sunlight. | [81] |

| Photocatalyst | Sol-gel/Coating | Cellulose (NI), TiO2 (NI) | TiO2 coated in cellulose showed photocatalytic degradation against phenol dye. | [82] |

| Photocatalyst | Dip coating/Film | Cellulose (NI), TiO2 (NI) | The hybrid composite showed Rhodamine B degradation. | [83] |

| Photocatalyst | Evaporative casting/Hydrogel | Cellulose (7% w/w), TiO2 (0.7% w/w), carrageenan (5.6% w/w) | Ternary hydrogel exhibited enhanced adsorptive and photocatalytic properties against methylene blue dye. | [84] |

| Photocatalyst | Casting/Film | Paper stock (0.1 g) TiO2: Ag (40% w/w) | The hybrid composite showed stable degradation rates of methyl orange dye up to six catalytic cycles. | [85] |

| Textile | Sol-gel/Coating | Cotton pulp (NI), TiO2 (NI) | The hybrid coating exhibited UV-barrier properties. | [86] |

| Textile | Sol gel/Coating | Cellulose (10% w/v), TiO2 (5% w/v) | Hybrid material showed self-cleaning properties without affecting the comfort properties of cotton fabrics. | [87] |

| Textile | Sol-gel/Coating | Cellulose (5 g L−1), TiO2:SiO2 (NI) | The hybrid coating showed stain degradation under sunlight conditions. | [88] |

| Ammonia gas sensor | Electrospinning and immersion/Nanofibers | Cellulose nanofibers (NI), TiO2 (NI), polyaniline (NI) | Cellulose/TiO2–polyaniline showed higher gas–ammonia sensitivity performance than cellulose–polyaniline. | [89] |

| Application | Method/ Presentation | * Composition | Relevant Results | Ref. |

|---|---|---|---|---|

| Photocatalysts | γ-radiation-induced copolymerization/Hydrogel | CS (NI), AA (NI), TiO2 (1 wt.%) | CS–AA–TiO2 hydrogels showed a major removal percentage of MB compared to CS-AA hydrogel. | [92] |

| Photocatalysts | Evaporative casting/Film | CS (0.64% w/v), PVDC (20 mL), TiO2:Au (20 mg) | The hybrid film showed 70 to 90% of EtBr dye removal with 60% of it photodegraded in the first 60 min under sunlight. | [93] |

| Photocatalyst | Evaporative casting/Film | CS (NI), TiO2 (NI) | Tetracycline degradation using the chitosan–TiO2 hybrid composite is multifactorial-dependent. | [94] |

| Photocatalyst | NI/Disks | CDF (0.04g), CS (0.2 g), TiO2 (0.05g) | CDF–CS–TiO2 showed enhanced antibacterial activity against E. coli (99%) compared with CDF (93%). | [95] |

| Photocatalyst | Evaporative casting/Film | CS (1 g 100 mL−1), TiO2 (2 g 100 mL−1) | The hybrid composite showed good removal of turbidity efficiency from wastewater. | [96] |

| Food and non-food packaging | Microwave-assisted/Film | CS (0.5 g 50 mL−1), TiO2 (0.5 g) | Chemical synthesis of CS–TiO2 films enhanced thermal stability compared to physical synthesis. | [97] |

| Food and non-food packaging | Evaporative casting/Film | PVA–CS (80:20), TiO2 (NI) | The swelling properties of PVA–CS–TiO2 were pH-dependent. | [98] |

| Food and non-food packaging | Evaporative casting/Film | CS (0.5 g 50 mL−1), TiO2:Ag (10% w/v) | The elasticity of CS-based films could be affected by high amounts of TiO2:Ag nanoparticles. | [99] |

| Food and non-food packaging | Evaporative casting/Film | CS (2 g 100 mL−1), TiO2 (1% w/v), CCEO (1.5%), glycerol (0.75 mL g−1 chitosan) | Hybrid film is effective in extending the shelf life of minced meat in 10 days at cold storage. | [100] |

| Biomedical | Evaporative casting/Film | CS (0.5 g 100 mL−1), TiO2 (10% w/v) | The hybrid film showed better wound-healing properties than chitosan-based film. | [101] |

| Biomedical | Coating/Foam | NI | Mattress coated with CS–TiO2 showed antimicrobial activity against S. aureus. | [102] |

| Cosmetic | Wet impregnation/Hydrogel | CS (NI), TiO2 (10%), CMC (NI) | The CS–CMC–TiO2 hydrogel showed a low–moderate solar protection factor with an antibacterial effect against E. coli. | [103] |

| Cosmetic | NI/Hydrogel | CS (0.2 g 100 mL−1), TiO2 (0.05g), H2O2 (6%) | Hydrogel showed good bleaching effects on the tooth surface | [104] |

| Application | Method/Presentation | * Composition | Relevant Results | Ref. |

|---|---|---|---|---|

| Food and non-food packaging | Evaporative casting/Film | k-Carrageenan (0.6 g), xanthan gum (0.1 g), gellan gum (0.2 g), TiO2 (5% w/w), glycerol (2 g) | TiO2 enhanced the physicochemical properties of the biopolymer mixture film. | [17] |

| Food and non-food packaging | Evaporative casting/Film | Pullulan (4 g 100 mL−1), TiO2 (0.04 g 100 mL−1), glycerol (0.6 g 100 mL−1) | TiO2 improved the mechanical and water-barrier properties of pullulan in a dose-dependent response. | [20] |

| Food and non-food packaging | Evaporative casting/Film | Gellan gum (1 g 100 mL-1), TiO2 (0.01 g 100 mL−1) | The hybrid film showed antimicrobial activity against S. aureus, Streptococcus sp., E. coli, and P. aeruginosa without changes in the film transparency. | [33] |

| Food and non-food packaging | Wet spinning process/Fiber | Agar (13.6 g 100 mL−1), TiO2 (0.3 g 100 mL−1) | Hybrid fibers showed improved mechanical, water- and UV-barrier properties. | [105] |

| Food and non-food packaging | Evaporative casting/Film | Agar (1 g 100 mL−1), carrageenan (1 g 100 mL−1), TiO2 (1% w/w), glycerol (30% w/w) | TiO2 enhanced the mechanical, UV-barrier, and water-related properties of the agar–carrageenan film. | [34] |

| Food and non-food packaging | Evaporative casting/Film | Agar (1.5 g 100 mL−1), gelatin (4 g 100 mL−1), TiO2 (0.5 g), glycerol (35% w/v) | The hybrid film showed marked UV-light scattering ability and improved water resistance. | [106] |

| Food and non-food packaging | Evaporative casting/Film | Agar (1.5 g 100 mL−1), gelatin (4 g 100 mL−1), TiO2 (0.5 g), glycerol (35% w/v) | The hybrid film could retard fish oil oxidation. | [107] |

| Food and non-food packaging | Evaporative casting/Film | Guar gum (NI), TiO2 (NI), glycerol (NI) | The coated fruits maintained quality parameters and increased the shelf life up to 8 weeks at 0 °C. | [108] |

| Food and non-food packaging | Evaporative casting/Film | BPSG (4% w/w), MPEO (4% w/v), TiO2 (2% w/w), glycerol (2% w/w), PEG (4% w/w) | The hybrid film showed higher antimicrobial activity against gram-positive bacteria than gram-negative bacteria. | [109] |

| Food and non-food packaging | Solvent casting/Film | JFPS (10 g 100 mL−1), TiO2 (3% w/w), glycerol (3 g g−1 of JFP) | The hybrid film showed antimicrobial activity against E. coli and S. aureus. | [110] |

| Food and non-food packaging | Evaporative casting/Film | SSPS (2.4 g 40 mL−1), TiO2 (5% w/w) | The physicochemical properties of SSPS-based films were improved by adding TiO2. | [111] |

| Biomedical | Evaporative casting/Biofilm | Gellan gum (1 g 100 mL−1), TiO2 (1% w/w) | Hybrid biofilm promoted cell proliferation and cell migration to accelerate the open-excision wound-healing process in an animal model. | [38] |

| Biomedical | Evaporative casting/Biofilm | Gellan gum (1 g 100 mL−1), TiO2 (1% w/w) | Hybrid biofilm is compatible with 3T3 mouse fibroblast cells and showed accelerated re-epithelialization without an inflammatory phenomenon in an animal model. | [112] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anaya-Esparza, L.M.; Villagrán-de la Mora, Z.; Ruvalcaba-Gómez, J.M.; Romero-Toledo, R.; Sandoval-Contreras, T.; Aguilera-Aguirre, S.; Montalvo-González, E.; Pérez-Larios, A. Use of Titanium Dioxide (TiO2) Nanoparticles as Reinforcement Agent of Polysaccharide-Based Materials. Processes 2020, 8, 1395. https://doi.org/10.3390/pr8111395

Anaya-Esparza LM, Villagrán-de la Mora Z, Ruvalcaba-Gómez JM, Romero-Toledo R, Sandoval-Contreras T, Aguilera-Aguirre S, Montalvo-González E, Pérez-Larios A. Use of Titanium Dioxide (TiO2) Nanoparticles as Reinforcement Agent of Polysaccharide-Based Materials. Processes. 2020; 8(11):1395. https://doi.org/10.3390/pr8111395

Chicago/Turabian StyleAnaya-Esparza, Luis Miguel, Zuamí Villagrán-de la Mora, José Martín Ruvalcaba-Gómez, Rafael Romero-Toledo, Teresa Sandoval-Contreras, Selene Aguilera-Aguirre, Efigenia Montalvo-González, and Alejandro Pérez-Larios. 2020. "Use of Titanium Dioxide (TiO2) Nanoparticles as Reinforcement Agent of Polysaccharide-Based Materials" Processes 8, no. 11: 1395. https://doi.org/10.3390/pr8111395

APA StyleAnaya-Esparza, L. M., Villagrán-de la Mora, Z., Ruvalcaba-Gómez, J. M., Romero-Toledo, R., Sandoval-Contreras, T., Aguilera-Aguirre, S., Montalvo-González, E., & Pérez-Larios, A. (2020). Use of Titanium Dioxide (TiO2) Nanoparticles as Reinforcement Agent of Polysaccharide-Based Materials. Processes, 8(11), 1395. https://doi.org/10.3390/pr8111395