Effect of Thermally-Treated Chips on Density of AlMgSi Alloys Recycled Using Solid-State Technique

Abstract

:1. Introduction

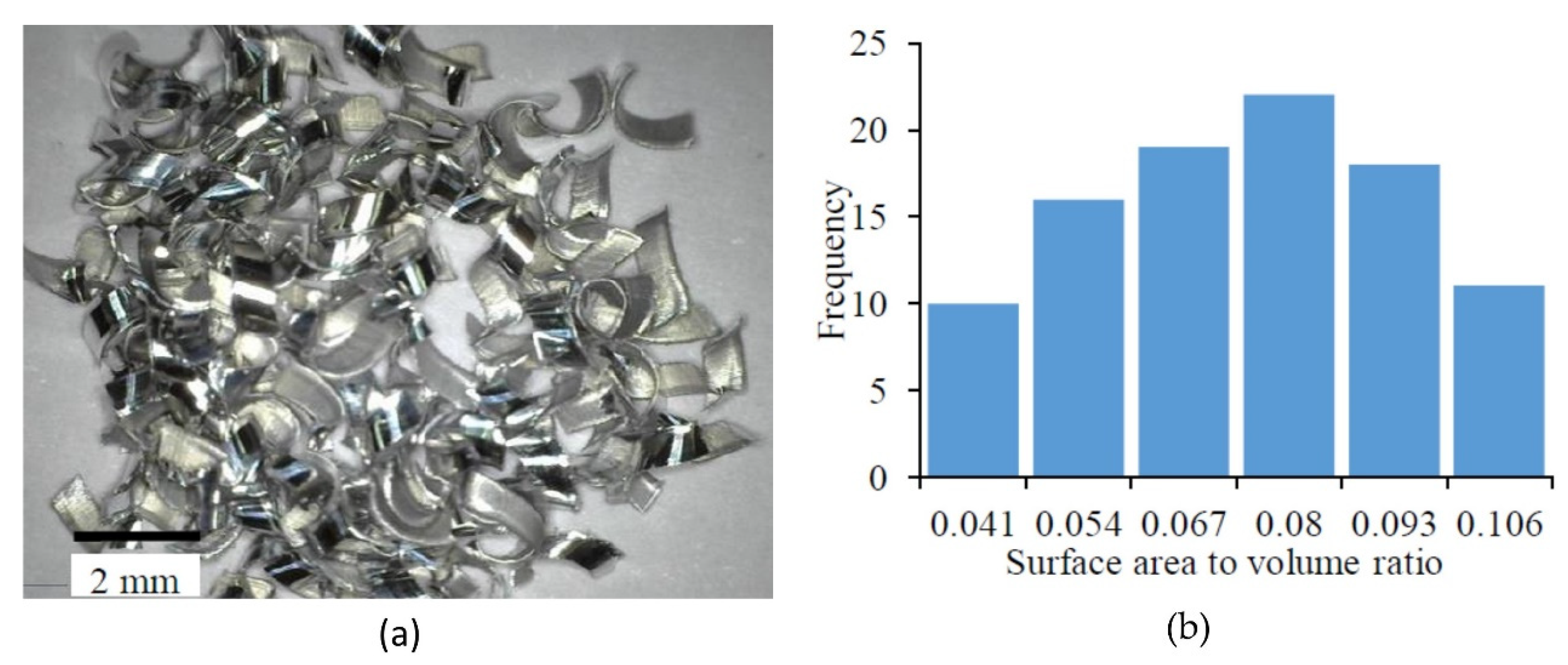

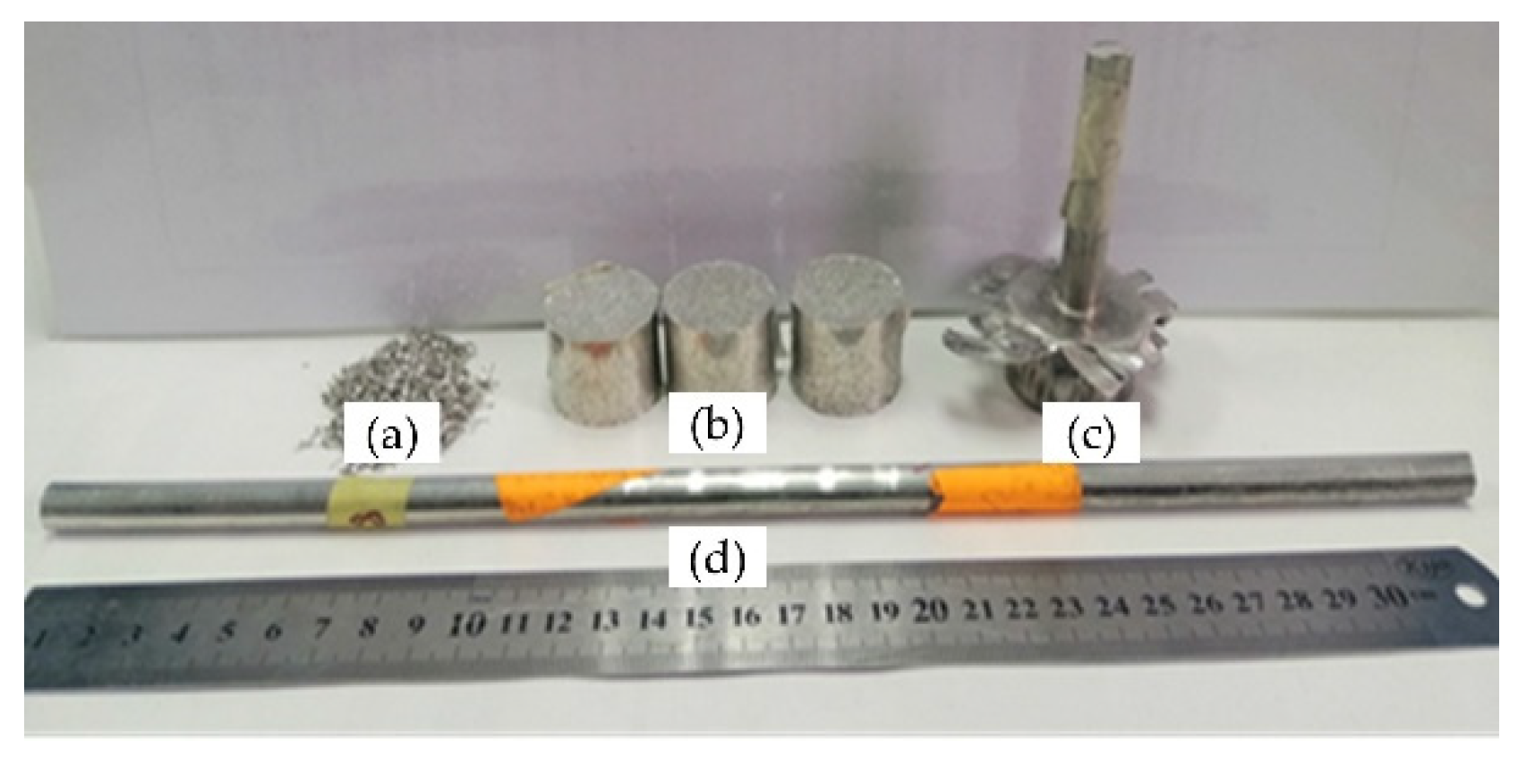

2. Materials and Methods

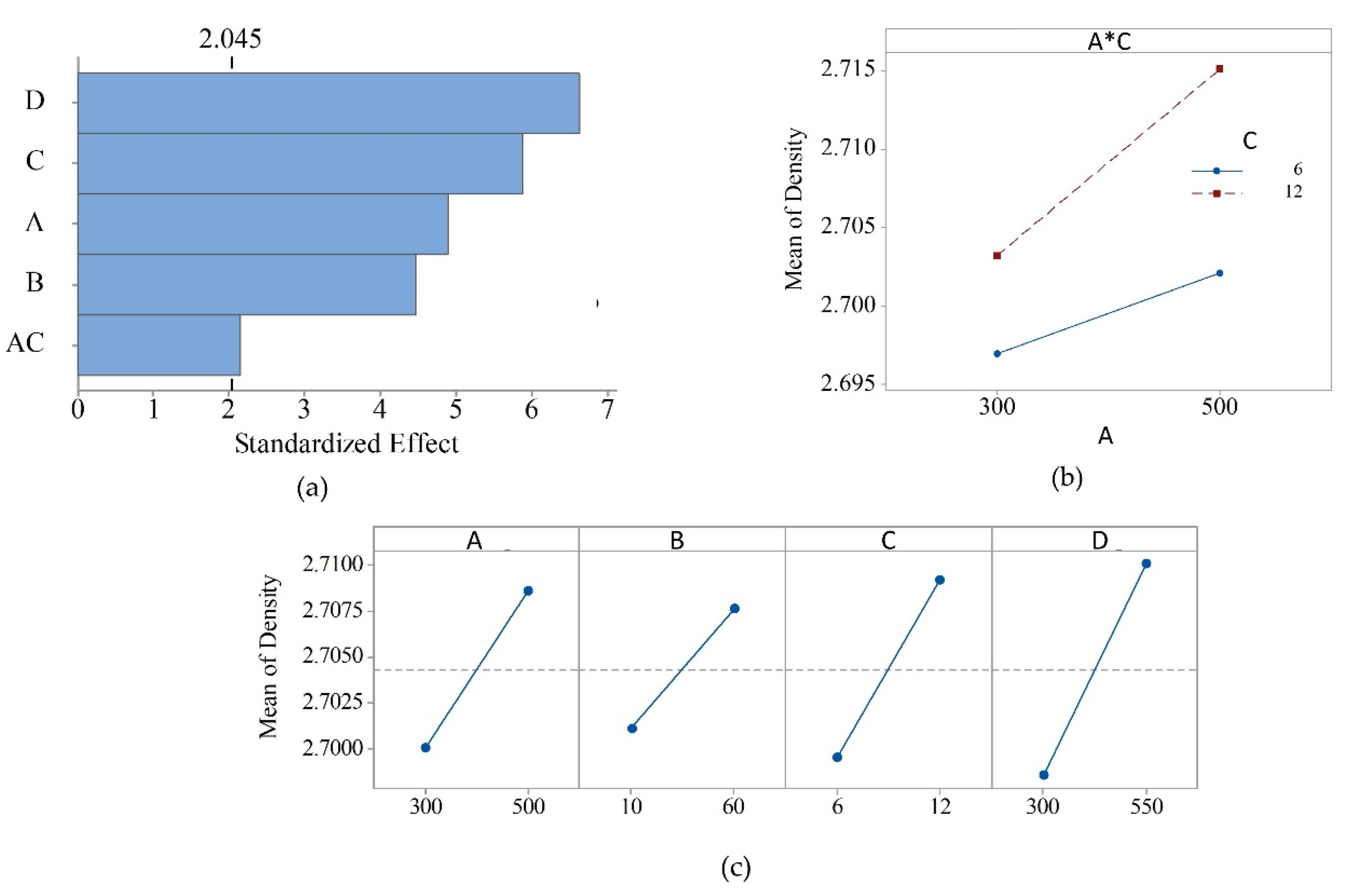

3. Results

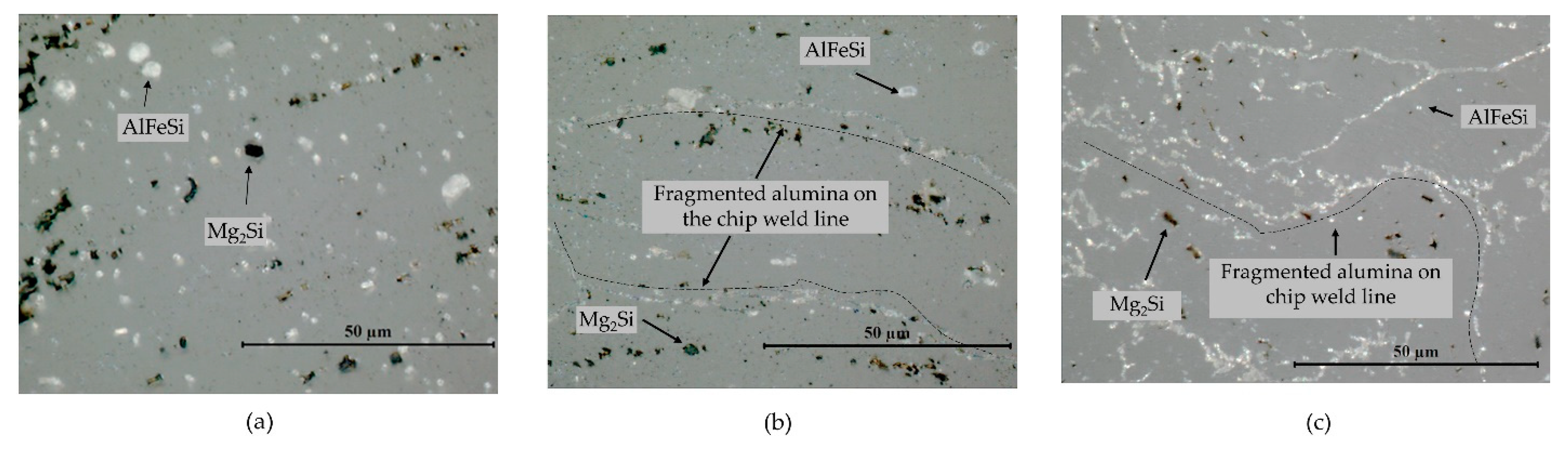

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Moldavska, A.; Welo, T. The concept of sustainable manufacturing and its definitions: A content-analysis based literature review. J. Clean. Prod. 2017, 166, 744–755. [Google Scholar] [CrossRef]

- Gronostajski, J.Z.; Kaczmar, J.W.; Marciniak, H.; Matuszak, A. Direct recycling of aluminium chips into extruded products. J. Mater. Process. Technol. 1997, 64, 149–156. [Google Scholar] [CrossRef]

- Gronostajski, J.Z.; Kaczmar, J.W.; Marciniak, H.; Matuszak, A. Production of composites from Al and AlMg2 alloy chips. J. Mater. Process. Technol. 1998, 77, 37–41. [Google Scholar] [CrossRef]

- Khamis, S.S.; Lajis, M.A.; Albert, R.A.O. A sustainable direct recycling of aluminum chip (AA6061) in hot press forging employing Response surface methodology. Procedia CIRP 2015, 26, 477–481. [Google Scholar] [CrossRef] [Green Version]

- Chmura, W.; Gronostajski, Z. Bearing materials obtained by diffusion bonding of aluminium and aluminium bronze chips. Arch. Civ. Mech. Eng. 2007, 7, 53–66. [Google Scholar] [CrossRef]

- Lajis, M.A.; Ahmad, A.; Yusuf, N.K.; Azami, A.H.; Wagiman, A. Mechanical properties of recycled aluminium chip reinforced with alumina (Al2O3) particle. Mater. Sci. Eng. Technol. 2017, 48, 306–310. [Google Scholar] [CrossRef]

- Mustapa, M.S.; Mahdi, A.S.; Lajis, M.A.; Abd Rashid, M.W. Physical Properties of Recycling Milled Aluminium Chip (AA6061) for Various Sintering Temperature. Int. J. Mech. Ind. Technol. 2016, 3, 33–40. [Google Scholar]

- Yusuf, N.K.; Lajis, M.A.; Daud, M.I.; Noh, M.Z. Effect of Operating Temperature on Direct Recycling Aluminium Chips (AA6061) in Hot Press Forging Process. Appl. Mech. Mater. 2013, 315, 728–732. [Google Scholar] [CrossRef]

- Noga, P.; Wiewiora, J.; Wzorek, L. The influence of extrusion ratio on the strength of hot extruded aluminium alloy chips. In Proceedings of the Metal 2015, Brno, Czech Republic, 3 June 2015; pp. 3–8. [Google Scholar]

- Tokarski, T. Mechanical Properties of Solid-State Recycled 4xxx Aluminum Alloy Chips. J. Mater. Eng. Perform. 2016, 25, 3252–3259. [Google Scholar] [CrossRef]

- Lajis, M.A.; Yusuf, N.K.; Noh, M.Z. Mechanical Properties and Surface Integrity of Direct Recycling Aluminium Chips (AA6061) by Hot Press Forging Process. In Proceedings of the 11th Global Conference on Sustainable Manufacturing-Innovative Solutions, Berlin, Germany, 23–25 September 2013; pp. 375–380. [Google Scholar]

- Lajis, M.A.; Khamis, S.S.; Yusuf, N.K. Optimization of Hot Press Forging Parameters in Direct Recycling of Aluminium Chip (AA 6061). Key Eng. Mater. 2014, 622, 223–230. [Google Scholar] [CrossRef]

- Kadir, M.I.A.; Mustapa, M.S.; Mahdi, A.S.; Kuddus, S.; Samsi, M.A. Evaluation of hardness strength and microstructures of recycled Al chip and powder AA6061 fabricated by cold compaction method. IOP Conf. Ser. Mater. Sci. Eng. 2017, 166. [Google Scholar] [CrossRef] [Green Version]

- Chiba, R.; Nakamura, T.; Kuroda, M. Solid-state recycling of aluminium alloy swarf through cold profile extrusion and cold rolling. J. Mater. Process. Technol. 2011, 211, 1878–1887. [Google Scholar] [CrossRef]

- Suzuki, K.; Huang, X.S.; Watazu, A.; Shigematsu, I.; Saito, N. Recycling of 6061 Aluminum Alloy Cutting Chips Using Hot Extrusion and Hot Rolling. Mater. Sci. Forum 2007, 544–545, 443–446. [Google Scholar] [CrossRef]

- Allwood, J.M.; Huang, Y.; Barlow, C.Y. Recycling scrap aluminium by cold-bonding. In Proceedings of the 8th International Conference on Technology Plasticity, Verona, Italy, 9–13 October 2005; pp. 311–312. [Google Scholar]

- Kuddus, S.; Mustapa, M.S.; Ibrahim, M.R.; Shamsudin, S.; Lajis, M.A.; Wagiman, A. Physical Characteristics of Solid State Recycled Aluminum Chip AA6061 Reinforced with Silicon Carbide (SiC) by using Hot Extrusion Technique. J. Phys. Conf. Ser. 2019, 1150, 012004. [Google Scholar] [CrossRef]

- Rady, M.H.; Sukri Mustapa, M.; Shamsudin, S.; Lajis, M.A.; Wagiman, A. Microhardness and Microstructure of Hot Extrusion Parameters in Direct Recycling of Aluminium Chip (AA 6061) by ANOVA Method. J. Phys. Conf. Ser. 2019, 1150. [Google Scholar] [CrossRef]

- Shamsudin, S.; Lajis, M.A.; Zhong, Z.W.; Ahmad, A.; Wagiman, A. Weld strength in solid–state recycling of aluminum chips. Mater. Sci. Eng. Technol. 2017, 290–298. [Google Scholar] [CrossRef]

- Wagiman, A.; Sukri, M.; Asmawi, R.; Lajis, M.A. A review on direct hot extrusion technique in recycling of aluminium chips. Int. J. Adv. Manuf. Technol. 2020, 106, 641–653. [Google Scholar] [CrossRef]

- Fogagnolo, J.B.; Simón, M.A.; Martinez, M.A. Recycling of aluminium alloy and aluminium matrix composite chips by pressing and hot extrusion. J. Mater. Process. Technol. 2003, 144, 792–795. [Google Scholar] [CrossRef]

- Paraskevas, D.; Dadbakhsh, S.; Vleugels, J.; Vanmeensel, K.; Dewulf, W.; Duflou, J.R. Solid state recycling of pure Mg and AZ31 Mg machining chips via spark plasma sintering. Mater. Des. 2016, 109, 520–529. [Google Scholar] [CrossRef]

- Derakhshandeh, R.H.; Jahromi, A.J. An investigation on the capability of equal channel angular pressing for consolidation of aluminum and aluminum composite powder. Mater. Des. 2011, 32, 3377–3388. [Google Scholar] [CrossRef]

- Jeurgens, L.P.H.; Sloof, W.G.; Tichelaar, F.D.; Mittemeijer, E.J. Structure and morphology of aluminium-oxide films formed by thermal oxidation of aluminium. Thin Solid Films 2002, 418, 89–101. [Google Scholar] [CrossRef]

- Cui, J.; Kvithyld, A.; Roven, H.J. Degreasing aluminium turnings and implications for solid state recycling. In Proceedings of the Light Metals 2010, Seattle, WA, USA, 14–18 February 2010; pp. 675–678. [Google Scholar]

- Hu, M.; Ji, Z.; Chen, X.; Zhang, Z. Effect of chip size on mechanical property and microstructure of AZ91D magnesium alloy prepared by solid state recycling. Mater. Charact. 2008, 59, 385–389. [Google Scholar] [CrossRef]

- Vander Voort, G.; Suárez-Peña, B.; Asensio-Lozano, J. Microstructure investigations of streak formation in 6063 aluminum extrusions by optical metallographic techniques. Microsc. Microanal. 2013, 19, 276–284. [Google Scholar] [CrossRef]

- Xu, W.; Wu, X.; Honma, T.; Ringer, S.P.; Xia, K. Nanostructured Al-Al2O3 composite formed in situ during consolidation of ultrafine Al particles by back pressure equal channel angular pressing. Acta Mater. 2009, 57, 4321–4330. [Google Scholar] [CrossRef]

- Hunter, M.S.; Fowle, P. Natural and Thermally Formed Oxide Films on Aluminum. J. Electrochem. Soc. 1956, 103, 482–485. [Google Scholar] [CrossRef]

- Wagiman, A.; Mustapa, M.S.; Lajis, M.A.; Shamsudin, S.; Idrus, M.; Masirin, M.; Rady, M.H. Direct Recycling of Aluminium Chips into Composite Reinforced with In Situ Alumina Enrichment. Mater. Sci. Forum 2020, 975, 165–170. [Google Scholar] [CrossRef]

- Ahmad, A.; Lajis, M.A.; Yusuf, N.K.; Ab Rahim, S.N. Statistical optimization by the response surface methodology of direct recycled aluminum-alumina metal matrix composite (MMC-AlR) employing the metal forming process. Processes 2020, 8, 805. [Google Scholar] [CrossRef]

| Factors | Factors Symbol | Levels | ||

|---|---|---|---|---|

| Low | Centre | High | ||

| Chip treatment temperature (°C) | A | 300 | 400 | 500 |

| Chip treatment time (minute) | B | 10 | 35 | 60 |

| Extrusion ratio | C | 6 | 9 | 12 |

| Preheating temperature (°C) | D | 300 | 425 | 550 |

| Sample | Run Order | A (°C) | B (min) | C | D (°C) | Density (kg/m3) |

|---|---|---|---|---|---|---|

| 1 | 9 | 300 | 10 | 6 | 300 | 2.683 |

| 2 | 20 | 500 | 10 | 6 | 300 | 2.688 |

| 3 | 32 | 300 | 60 | 6 | 300 | 2.689 |

| 4 | 34 | 500 | 60 | 6 | 300 | 2.699 |

| 5 | 27 | 300 | 10 | 12 | 300 | 2.694 |

| 6 | 35 | 500 | 10 | 12 | 300 | 2.707 |

| 7 | 28 | 300 | 60 | 12 | 300 | 2.701 |

| 8 | 4 | 500 | 60 | 12 | 300 | 2.711 |

| 9 | 16 | 300 | 10 | 6 | 550 | 2.703 |

| 10 | 7 | 500 | 10 | 6 | 550 | 2.702 |

| 11 | 6 | 300 | 60 | 6 | 550 | 2.706 |

| 12 | 24 | 500 | 60 | 6 | 550 | 2.710 |

| 13 | 1 | 300 | 10 | 12 | 550 | 2.705 |

| 14 | 11 | 500 | 10 | 12 | 550 | 2.721 |

| 15 | 30 | 300 | 60 | 12 | 550 | 2.719 |

| 16 | 10 | 500 | 60 | 12 | 550 | 2.724 |

| 17 | 2 | 300 | 10 | 6 | 300 | 2.687 |

| 18 | 5 | 500 | 10 | 6 | 300 | 2.698 |

| 19 | 22 | 300 | 60 | 6 | 300 | 2.698 |

| 20 | 31 | 500 | 60 | 6 | 300 | 2.707 |

| 21 | 12 | 300 | 10 | 12 | 300 | 2.687 |

| 22 | 33 | 500 | 10 | 12 | 300 | 2.707 |

| 23 | 26 | 300 | 60 | 12 | 300 | 2.705 |

| 24 | 15 | 500 | 60 | 12 | 300 | 2.713 |

| 25 | 8 | 300 | 10 | 6 | 550 | 2.702 |

| 26 | 3 | 500 | 10 | 6 | 550 | 2.708 |

| 27 | 13 | 300 | 60 | 6 | 550 | 2.706 |

| 28 | 17 | 500 | 60 | 6 | 550 | 2.703 |

| 29 | 21 | 300 | 10 | 12 | 550 | 2.705 |

| 30 | 29 | 500 | 10 | 12 | 550 | 2.717 |

| 31 | 25 | 300 | 60 | 12 | 550 | 2.708 |

| 32 | 23 | 500 | 60 | 12 | 550 | 2.719 |

| 33 | 18 | 400 | 35 | 9 | 425 | 2.705 |

| 34 | 14 | 400 | 35 | 9 | 425 | 2.708 |

| 35 | 19 | 400 | 35 | 9 | 425 | 2.707 |

| Source | Degree of Freedom | Adj. Sum of Square | Adj. Mean of Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 5 | 0.002314 | 0.000463 | 25.40 | 0.000 |

| Linear | 4 | 0.002230 | 0.000557 | 30.59 | 0.000 |

| A | 1 | 0.000435 | 0.000435 | 23.88 | 0.000 |

| B | 1 | 0.000364 | 0.000364 | 20.00 | 0.000 |

| C | 1 | 0.000630 | 0.000630 | 34.58 | 0.000 |

| D | 1 | 0.000800 | 0.000800 | 43.90 | 0.000 |

| AC | 1 | 0.000084 | 0.000084 | 4.64 | 0.040 |

| Curvature | 1 | 0.000049 | 0.000049 | 2.83 | 0.103 |

| Lack-of-fit | 10 | 0.000089 | 0.000009 | 0.41 | 0.923 |

| Pure error | 18 | 0.000391 | 0.000022 | ||

| Total | 34 | 0.002843 |

| Test | Factor Condition | Predicted Density (kg/m3) | Measured Density (kg/m3) | Error (%) | |||

|---|---|---|---|---|---|---|---|

| A (°C) | B (Min) | C | D (°C) | ||||

| 1 | 300 | 35 | 6 | 300 | 2.692 | 2.678 | −0.5% |

| 2 | 500 | 60 | 12 | 425 | 2.715 | 2.725 | 0.4% |

| 3 | 400 | 35 | 9 | 425 | 2.703 | 2.703 | −0.4% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wagiman, A.; Mustapa, M.S.; Shamsudin, S.; Lajis, M.A.; Asmawi, R.; Rady, M.H.; Yahya, M.S. Effect of Thermally-Treated Chips on Density of AlMgSi Alloys Recycled Using Solid-State Technique. Processes 2020, 8, 1406. https://doi.org/10.3390/pr8111406

Wagiman A, Mustapa MS, Shamsudin S, Lajis MA, Asmawi R, Rady MH, Yahya MS. Effect of Thermally-Treated Chips on Density of AlMgSi Alloys Recycled Using Solid-State Technique. Processes. 2020; 8(11):1406. https://doi.org/10.3390/pr8111406

Chicago/Turabian StyleWagiman, Abdullah, Mohammad Sukri Mustapa, Shazarel Shamsudin, Mohd Amri Lajis, Rosli Asmawi, Mohammed H Rady, and Mohd Shahir Yahya. 2020. "Effect of Thermally-Treated Chips on Density of AlMgSi Alloys Recycled Using Solid-State Technique" Processes 8, no. 11: 1406. https://doi.org/10.3390/pr8111406