Abstract

In the rural zones of Latin American and Caribbean developing countries, the poorest households rely on traditional fuels such as firewood to meet their daily cooking needs. Many of those countries are located near the equator, where they have a tropical climate and grass is one of the most common biomass crops. The aim of this study was to evaluate the effect of harvesting age (30, 44, and 57 days) in the performance of anaerobic digestion of King Grass (Pennisetum purpureum cv. King Grass) grown under tropical climate conditions. Three reduction methods of crop size were also compared. Results showed that 44-day harvesting age presented the greater specific methane yield (347.8 mLCH4 g−1VS) and area-specific methane yield (9773 m3CH4 ha−1 y−1). The machine chopped method (1–3 cm for stems and 1–10 cm for leaves) was the reduction method that maximized the methane production. From those results, the calculated area required for grass cultivation to provide the cooking energy to a typical family in the Colombian rural zones is 154 m2.

1. Introduction

About 3 billion people around the world use firewood or similar biomass to cook [1]. Firewood has a low calorific value and can cause toxicity evens if kitchens are not well ventilated and combustion is not complete. This causes around 4.3 million deaths every year [1]. Liquefied propane gas (LPG) is the main substitute of firewood in developing countries like Colombia, where is estimated that around 13 million people use it as cooking fuel and the annual consumption per housing unit is 132 kg, equivalent to approximately 6000 MJ [2]. However, its application is still limited due to its high costs and limited access of vehicle in certain areas. Biogas from anaerobic digestion (AD) of biomass in low-cost household digesters could substitute traditional biomass as firewood, which could reduce environmental impacts and improve safety and the standard of living of rural families [3].

Natural and cultivated pastures play an important role in global agriculture. They represent 67% of the world’s cultivated areas and is one of the lower-cost and common biomass in rural areas [4]. For instance, grasses in Colombia, which are mainly used to feed cattle, are productive throughout the year, and their growth rates mainly depend on water availability. The Pennisetum sp. grasses are the most common in the region and under non-irrigated conditions or low rainfall (between 600 and 1500 mm) green Elephant genotypes are recommended [5]. Moreover, Pennisetum grasses are one of the energy crops with the highest agronomic yield [6] and specific methane yield worldwide, above 300 mLCH4 g−1VS [7].

The harvesting age influence of Pennisetum grasses on biogas production has been studied. Specific methane yields range from 104 mLCH4 to 310 mLCH4 g−1VS for harvesting ages between 60 and 360 days, where young tissues produced more methane than the old tissues using the biochemical methane potential (BMP) test [8,9]. In lab continuous reactors, the literature reported yields range from 100 mLCH4 to 242 mLCH4 g−1VS (4803 m3CH4 to 7899 m3CH4 ha−1 y−1) for harvesting ages around 60 days [10,11,12]. In tropical countries, the common harvesting ages are between 30 and 60 days [13,14], which could enhance the methane yields [11].

Most of the studies of biogas potential of crops have been done with crops in temperate or boreal climates, where harvest ages are much higher and agronomic yields lower. Reliable information of biogas production in Latin America and the Caribbean (LAC) is still missing, as most of the information available on pastures refers to its use as feed for livestock.

This study evaluates the effect of harvesting age in King Grass (Pennisetum purpureum cv. King Grass)—on its specific methane yield and area-specific methane yield—evaluating three typical harvesting ages (30, 44, and 57 days) according to local practices in Colombia. Additionally, three reduction methods of particle size were compared in the same terms, with the previously selected best harvesting age. Finally, it was calculated the required area for crop cultivation to supply the cooking-energy of a rural household in LAC.

2. Materials and Methods

2.1. Crop Production and Characterization

The King Grass crop was grown at a farm located in Cali, Colombia (3°21′50.8′′ N; 76°33′45.8′′ W), with annual precipitation of 1173 mm and average temperature 23 °C (17 °C to 31 °C) [15]. The crop was fertilized following common local practices (N:P:K 325:22:42 kg ha−1 y−1).

There were nine plots, 25 m2 each, distributed randomly in three blocks. Grass crop was hand-harvested 5 cm above ground level [13] and refrigerated before characterization. Grass crop yield was calculated weighing 4–7 subsamples from each plot after chopped (sizes from 1–3 cm in stems and 1−10 cm in leaves).

Total solids (TS), volatile solids (VS), and pH were determined following APHA [16]; concentrations of C and N were measured according to ASTM [17] using elemental analyzer CHN 628 (LECO, St. Joseph—MI, USA); and crude protein (CP), ethereal extract (E.E.), cellulose, hemicellulose, and lignin were estimated after Van Soest [18].

A theoretical (stoichiometric) methane yield was calculated [19] to assess a possible correlation between methane yield and composition of the grass at different harvesting ages. To calculate the theoretical yield, empirical formulae for each organic component were estimated as protein (C5H7O2N), lipid (C57H104O6), lignin (C10H13O3), and carbohydrates (non-lignocellulosic carbohydrates, cellulose, and hemicellulose) (C6H10O5) [19]. The theoretical methane yield was estimated according to Equation (1):

where YCH4 is the theoretical methane yield of grass as mL CH4 g−1VS and 1.014 is the theoretical yield of lipid, 0.496 is the theoretical value for protein, 0.415 is the theoretical value for carbohydrate, and 0.727 is the theoretical value for lignin, all of them as g kg−1 VS.

2.2. Biochemical Methane Potential (BMP) Test

Methane quantification was performed in batch vials with the Oxitop® system (WTW—Xylem, Weilheim, Germany) incubated at 35.0 ± 0.5 °C in a thermostat cabinet TS 606-2 (WTW—Xylem, Weilheim, Germany). Reactors used have a working volume of 200 mL with a headspace of 50 mL. CO2 produced was trapped in NaOH before the Measuring head, this way the gas measured was methane [20]. The composition of gas was verified weekly via gas chromatography using a GC2014 chromatograph (Shimadzu, Kyoto, Japan).

The experiments were conducted at a substrate/inoculum ratio (S/I) of 1 gVSsubstrate.g−1VSinoculum, a solution of macro and micronutrients were used, and the pH was adjusted at 7.0 [21]. The inoculum used was from a batch dry grass anaerobic digester (pH: 8.31, TS: 11.0% and VS: 75.3% dry basis).

BMP tests were carried out per triplicate. When methane production increased less than 5% between measures, the assay was stopped (90 days). The net methane production under standard conditions was calculated by subtracting the methane production of the blanks (inoculum without substrate) from the methane production of the treatment vials. Finally, methane production was fitted to the Gompertz equation (Equation (2)) [22]:

where P is the accumulated methane production (mLCH4 g−1VS), Pm is the specific Methane yield (mLCH4 g−1VS), Rm is the maximum methane production rate (mLCH4 g−1VS day−1), and λ is the lag phase period of biogas production (day). The least-square sum of errors criterion was used in the fitting process and the Monte Carlo method to establish the 95% confidence interval of the estimated parameter values [23].

2.3. Experimental Design

Three harvesting ages (30, 44, and 57 days) were evaluated (n = 3), and the response variables were specific methane yield (mLCH4 g−1VS) and area-specific methane yield (m3CH4 ha−1 y−1). An ANOVA followed by a post hoc Fisher’s least significant difference test (LSD, p < 0.05) was applied to response variables using STATISTICA software, version 7.0 (StatSoft Inc., Tulsa—OK, USA).

For the harvesting age with the higher methane yield, three methods of particle reduction size were applied (n = 3). Minced (<1 cm for leaves and stems) obtained with a CB15 blender (Waring Commercial, Torrington, CT, USA) run at a speed of 15800 rpm for one minute (standard blender speed); machine chopped (1–3 cm stems and 1–10 cm leaves) obtained with a TRAPP® TR200 industrial (METALÚRGICA TRAPP LTDA, Jaraguá do Sul-SC, Brazil); and lastly, hand chopped (5–10 cm stems and 5–20 cm leaves) obtained by hand chopping using a bowie knife. The response variable was the specific methane yield (mLCH4 g−1VS) and also ANOVA followed by a post hoc Fisher’s was conducted.

Finally, the biogas and area requirements to supply a cooking energy of 6000 MJ (150 m3CH4 equivalent), needed per housing unit per year in rural zones of Colombia, was estimated.

3. Results and Discussion

3.1. Substrate Production and Characterization

Results of the agronomic yields and substrate characterization are presented in Table 1.

Table 1.

Characterization and yields of King Grass according to harvesting age (n = 3 where standard deviation is presented) (numbers of a same parameter followed by the same letter are not significantly different (p = 0.05)).

Although a slight reduction in pH was observed with an increase in harvesting age, pH values for all the treatments were close to neutral. Regarding the variables related to organic matter, TS tends to increase with harvesting ages beyond 44 days, with a slight decrease in vs. (dry basis) observed. These values were similar to those obtained by Chanpla et al. [14] when growing Pennisetum purpureum with harvesting at ages of 35, 45, and 55 days, reporting a 18.4% and 19.2% and 20.2% of TS content respectively, with a vs. percentage between 87–89%.

The C/N ratios obtained were 15.7, 13.7, and 19.8 for harvesting ages of 30, 44, and 57 days, respectively. According to Dai et al. [24], who evaluated the co-digestion of activated sludge and ryegrass at pH 7.00, the highest specific CH4 yields were found with C/N ratios lower than 15, while the highest methane contents in the biogas were found with a C/N of 9.

Regarding fiber composition and structural components, there were not notable differences between harvesting ages except an increase of ethereal extract from 44 days and a decrease of crude protein observed at 57 days.

As expected, agronomic yields obtained were shown to be higher when increasing the harvesting age. The values obtained for cutting ages of 30 and 44 days (16.8 ± 2.0 and 28.1 ± 8.0 tDM ha−1 y−1) are similar to those reported for King Grass of similar ages: 22.86 and 28.95 tMS ha−1 y−1 for 30 and 45 days of age, respectively [13]. However, agronomic yield (38.6 ± 6.6 tDM ha−1 y−1) for a harvesting age of 57 days was higher than that obtained by Lounglawan et al. [13] of 28.93 tDM ha−1 y−1 for harvesting age of 60 days in Thailand.

However, from the grass composition at different harvesting ages, the theoretical estimated methane yield showed a higher value expected for the harvesting age of 44 days.

Results show that the harvesting age influences the substrate production and characterization of King Grass. According to those characteristics, it can be foreseen that, a 44-day harvesting age would be optimal for biogas production. A 44-day harvesting age shows a better C/N ratio and CP than a 57-day age, a better C/N, CP, EE and lignin concentrations than a 30-day age and the highest theoretical methane yield.

3.2. Influence of Harvesting Age on the Methane Yield

The ANOVA of methane yields at different harvesting ages presented significant differences (p = 0.000623); the post hoc Fisher’s showed that methane yield at 44-day age (347.8 ± 27.0 mLCH4 g−1VS) was significantly higher than the other two harvesting ages (Table 1) as expected from characterization results. Nevertheless, no significant differences were observed between 30 and 57 days. These results are similar to those reported by Chanpla et al. [14] for Pennisetum purpureum cv. Pakchong-1, who obtained the best specific methane yield in BMP tests for a 45-day harvesting age, followed by a 35-day and 55-day harvesting age.

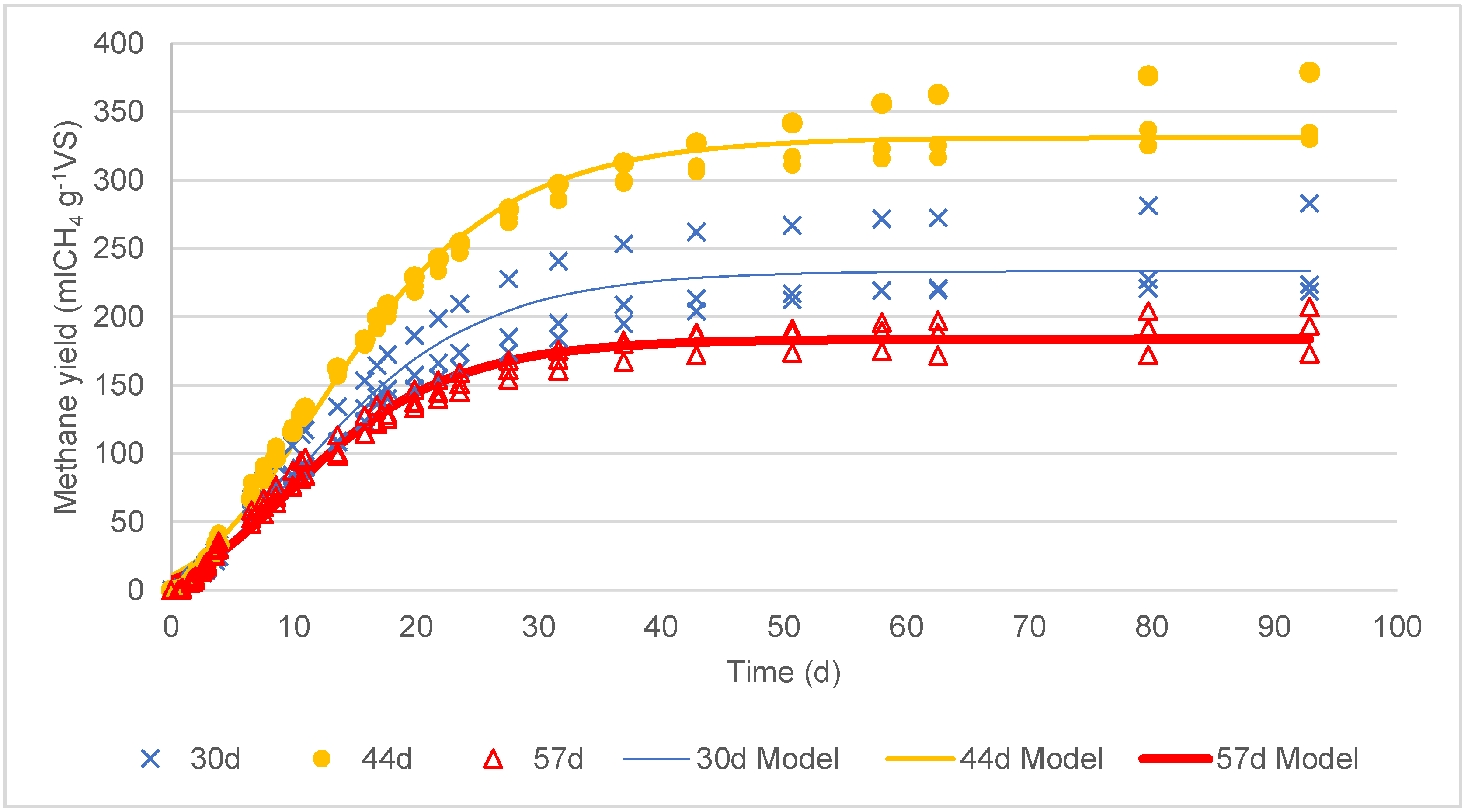

Figure 1 shows the timeline of biogas production and the Gompertz equation fits. Table 2 shows the parameters of the fitting. As can be seen the fitting displayed high determination coefficients (r2 > 0.96) and evidenced that the maximum methane production rate (Rm) of the 44-day harvesting age is the highest of the three evaluated ages. These results agreed with previous reports for fresh Pennisetum purpureum grasses between 10.64 mLCH4 and 13.97 mLCH4 g−1VS d−1 [25]. Regarding the λ parameter, very close values were observed between the treatments.

Figure 1.

Specific methane yield over time for harvesting ages (n = 3).

Table 2.

Parameters of the Gompertz equation adjustment on harvesting age biochemical methane potential (BMP) tests (Pm, Rm, and λ), confidence interval (CI with α = 0.05) and evaluation of the coefficient of determination (r2).

The statistical analysis of area-specific methane yields (Table 1) showed significant differences between all the treatments (p < 0.05). Results indicate the best yield was for 44-day harvesting age (9773 ± 759 m3CH4 ha−1 y−1). Although the specific methane yield obtained is within the ranges reported in the literature for digestion of non-silage grasses, the area-specific methane yields obtained for King Grass were much higher than those obtained for the same crop in subtropical climates. For instance, the study by Schank et al. [26] reported values between 5500–7500 m3CH4 ha−1 y−1.

The high agronomic yield of King Grass resulted also in a high area-specific CH4 yield. The area-specific methane yields obtained here are higher to those reported for other climate conditions with different types of grass feedstock: 702 m3CH4 ha−1 y−1 in Denmark [27], 3500 m3CH4 ha−1 y−1 in Finland [28], and 4689 m3CH4 ha−1 y−1 in Ireland [29].

3.3. Influence of the Size Reduction Method on Specific Methane Yields

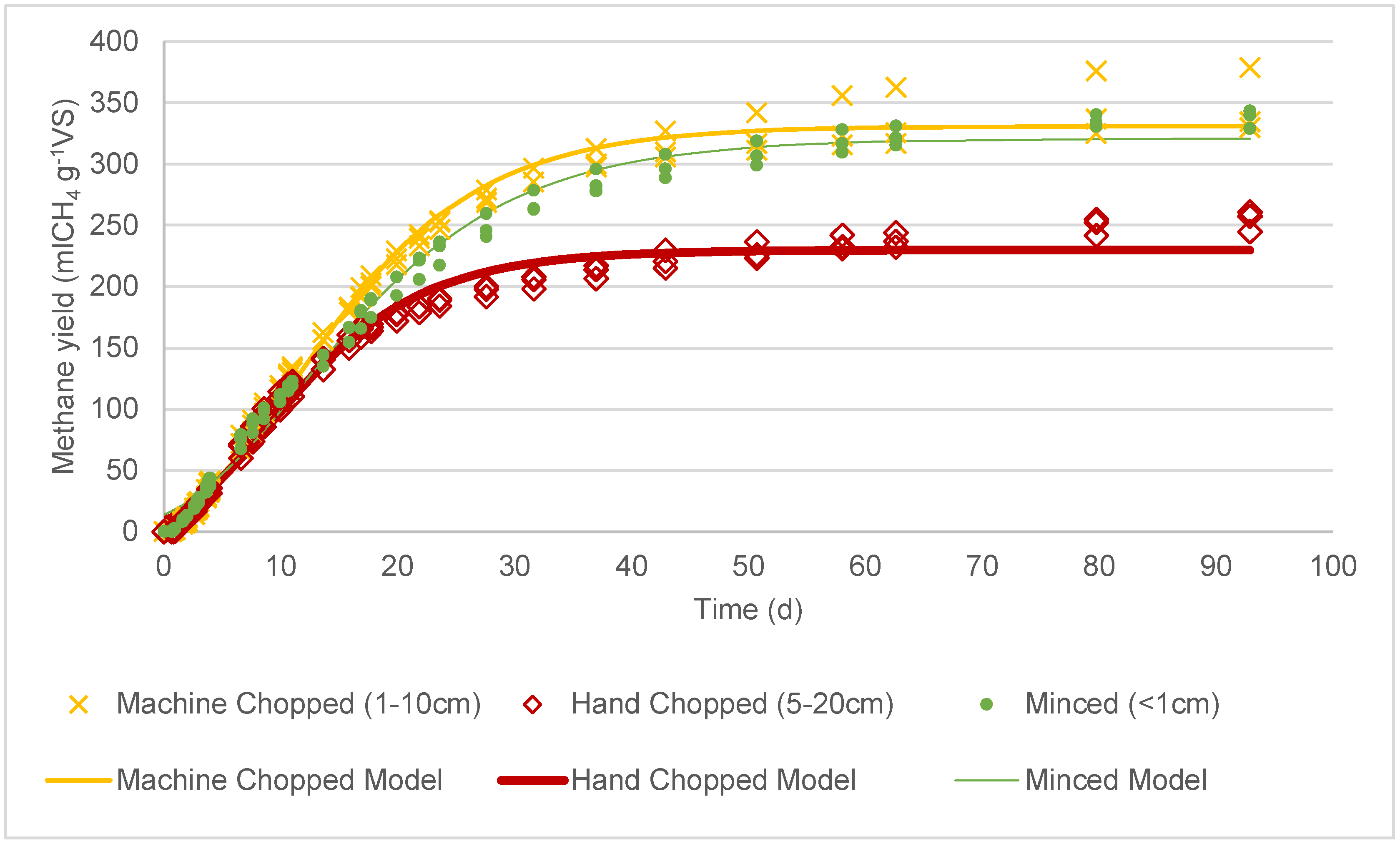

Figure 2 presents the specific methane yield over time for the three used methods of size reduction with a 44-day harvesting age. The statistical analysis evidenced significant differences with p = 0.000130 applying the ANOVA. The post hoc Fisher’s showed that the methane yields of the hand-chopped sized method was significantly lower than those obtained with machine chopped and minced methods (Table 3). Nevertheless, there were no significant differences between machine chopped and minced.

Figure 2.

Specific methane yield over time for the three size reduction methods (n = 3).

Table 3.

Yields of King Grass of 44-day age according to the size reduction method (n = 3 where standard deviation is presented) (numbers of a same parameter followed by the same letter are not significantly different (p = 0.05)).

Additionally, the kinetic behavior (Table 4) analyzed through the Gompertz equation (r2 = 0.99) showed that the machine chopped method presented the highest Rm. Differences in Rm applying different methods of size reduction have been reported by Tsapekos et al. [30]. These results suggest that a further reduction size of grass with a typical industrial mincer for organic wastes does not improve the kinetics of biogas production. This is in accordance with the study of Narinthorna et al. [31], who found no significant differences in methane yields of Pennisetum between sizes of 2−3 cm and <0.6 mm.

Table 4.

Parameters of the Gompertz equation fits on the BMP tests data according the size reduction method (Pm, Rm and λ), confidence interval (CI with α = 0,05) and evaluation of the coefficient of determination (r2).

Methane yields of 337.6 ± 7.5 and 347.8 ± 27.0 mLCH4 g−1VS, obtained with the minced and machine chopped method, respectively are close to values of 330 mLCH4 g−1VS for particle sizes of 0–1 cm of public space pastures in Japan [32] and values of 373 to 438 mLCH4.g−1VS obtained from Festulolium grasses with particle sizes of 1–1.5 cm.

4. Conclusions

Under tropical climate conditions, a significant increase in the performance of the anaerobic digestion of King Grass was detected with harvesting ages bellow 60 days, that is the lowest age usually evaluated and reported by literature. An optimal harvesting age of 44 days, with a highest methane yield of 347.8 mLCH4 g−1VS and 9773 m3CH4 ha−1 y−1 was found, even when the agronomic yield increase with the harvesting age. The machine-chopped method of size reduction (1−10 cm) was the most efficient pre-treatment, although, it did not have a significant difference to the smallest size tested (<1 cm). Cooking supply energy for a typical family in rural zones of Colombia would require 154 m2 of King Grass crop, an area that can be easily assumed by this type of housing.

Author Contributions

Conceptualization, C.A.P.-L. and A.B.; Methodology, C.A.P.-L., A.B., J.P., J.I., and P.T.-L.; Software, J.P. and J.I.; Writing—original draft preparation, C.A.P.-L.; Writing—review and editing, C.A.P.-L., A.B., and P.T.-L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The authors would like to thank Colciencias for the Ph.D. Scholarship provided to C.A. Pizarro-Loaiza; the La Carmela plantation in La Buitrera, Cali, for facilitating the access to grass cultivation data and sample collection; and the GIRO Joint Research Unit IRTA-UPC, the Universitat de Lleida, and the Universidad del Valle for providing access to office and laboratory facilities and field-work equipment.

Conflicts of Interest

The authors declare no conflict of interest.

References

- World Bank. Energy Overview. 2018. Available online: http://www.worldbank.org/en/topic/energy/overview (accessed on 8 February 2018).

- GASNOVA (2019) Informe del Sector del GLP 2019. Available online: http://www.gasnova.co/wp-content/uploads/2019/08/INFORME-DEL-SECTOR-DEL-GLP-2019.pdf (accessed on 8 February 2020).

- Garfí, M.; Castro, L.; Montero, N.; Escalante, H.; Ferrer, I. Evaluating environmental benefits of low-cost biogas digesters in small-scale farms in Colombia: A life cycle assessment. Bioresour. Technol. 2019, 274, 541–548. [Google Scholar] [CrossRef] [PubMed]

- Food and Agriculture Organization of United Nations FAO. Food and Agriculture Data. In FAOSTAT. 2014. Available online: http://www.fao.org/faostat/en/#data/GG (accessed on 1 November 2017).

- Murillo-Solano, J.; Barros-Henríquez, J.A.; Roncallo-Fandiño, B.; Arrieta-Pico, G. Water requirement of four cutting grasses water efficiency in the Colombian dry Caribbean region. Corpoica. Cienc. Tecnol. Agropecu. 2014, 15, 83–99. [Google Scholar]

- Mitchell, R.B.; Schmer, M.R.; Anderson, W.F.; Jin, V.; Balkcom, K.S.; Kiniry, J.; Coffin, A.; White, P. Dedicated Energy Crops and Crop Residues for Bioenergy Feedstocks in the Central and Eastern USA. Bioenergy Res. 2016, 9, 384–398. [Google Scholar] [CrossRef]

- Gunaseelan, V.N. Anaerobic digestion of biomass for methane production: A review. Biomass Bioenergy 1997, 13, 83–114. [Google Scholar] [CrossRef]

- Chynoweth, D.P.; Turick, C.E.; Owens, J.M.; Jerger, D.E.; Peck, M.W. Biochemical methane potential of biomass and waste feedstocks. Biomass Bioenergy 1993, 5, 95–111. [Google Scholar] [CrossRef]

- Surendra, K.C.; Khanal, S.K. Effects of crop maturity and size reduction on digestibility and methane yield of dedicated energy crop. Bioresour. Technol. 2015, 178, 187–193. [Google Scholar] [CrossRef]

- Thaemngoen, A.; Saritpongteeraka, K.; Leu, S.Y.; Phuttaro, C.; Sawatdeenarunat, C.; Chaiprapat, S. Anaerobic Digestion of Napier Grass (Pennisetum purpureum) in Two-Phase Dry Digestion System Versus Wet Digestion System. Bioenergy Res. 2020, 1–13. [Google Scholar] [CrossRef]

- Pizarro-Loaiza, C.A.; Torres-Lozada, P.; Palatsi, J.; Bonmati, A. Cooking gas from anaerobic digestion of tropical grasses harvested in Valle del Cauca—Colombia. In Proceedings of the XIII Latin American Workshop and Symposium on Anaerobic Digestion, Medellín, Colombia, 21–24 October 2018; IWA: London, UK, 2018. [Google Scholar]

- Janejadkarn, A.; Chavalparit, O. Biogas Production from Napier Grass (Pak Chong 1) (Pennisetum purpureum × Pennisetum americanum). Adv. Mater. Res. 2014, 856, 327–332. [Google Scholar]

- Lounglawan, P.; Lounglawan, W.; Suksombat, W. Effect of Cutting Interval and Cutting Height on Yield and Chemical Composition of King Napier Grass (Pennisetum Purpureum × Pennisetum Americanum). APCBEE Procedia 2014, 8, 27–31. [Google Scholar] [CrossRef]

- Chanpla, M.; Kullavanijaya, P.; Janejadkarn, A.; Chavalparit, O. Effect of harvesting age and performance evaluation on biogasification from Napier grass in separated stages process. KSCE J. Civ. Eng. 2017, 1–6. [Google Scholar] [CrossRef]

- Climate-Data (2017). In Clima Cali. Available online: https://es.climate-data.org/location/3426/ (accessed on 8 February 2018).

- APHA. Standard Methods for the Examination of Water and Wastewater, 21st ed.; American Public Health Association; American Water Works Association; Water Environment Federation: Washington, DC, USA, 2005. [Google Scholar]

- ASTM. ASTM D5373 Standard Test Methods for Determination of Carbon, Hydrogen and Nitrogen in Analysis Samples of Coal and Carbon in Analysis Samples of Coal and Coke; ASTM: West Conshohocken, PA, USA, 2007. [Google Scholar]

- Van Soest, P.J. Use of detergents in the analysis of fibrous feeds. II. A rapid method for the determination of fiber and lignin. J. Ass. Off. Agr. Chem. 1963, 46, 829–835. [Google Scholar]

- Triolo, J.M.; Sommer, S.G.; Møller, H.B.; Weisbjerg, M.R.; Jiang, X.Y. A new algorithm to characterize biodegradability of biomass during anaerobic digestion: Influence of lignin concentration on methane production potential. Bioresour. Technol. 2011, 102, 9395–9402. [Google Scholar] [CrossRef]

- Pabón Pereira, C.P.; Castañares, G.; Van Lier, J.B. An OxiTop® protocol for screening plant material for its biochemical methane potential (BMP). Water Sci. Technol. 2012, 66, 1416–1423. [Google Scholar] [CrossRef]

- Parra-Orobio, B.A.; Donoso-Bravo, A.; Ruiz-Sánchez, J.C.; Valencia-Molina, K.J.; Torres-Lozada, P. Effect of inoculum on the anaerobic digestion of food waste accounting for the concentration of trace elements. Waste Manag. 2017, 71, 342–349. [Google Scholar] [CrossRef]

- Gadhamshetty, V.; Arudchelvam, Y.; Nirmalakhandan, N.; Johnson, D.C. Modeling dark fermentation for biohydrogen production: ADM1-based model vs. Gompertz model. Int. J. Hydrog. Energy 2010, 35, 479–490. [Google Scholar] [CrossRef]

- Hauser, J.R. Numerical Methods for Nonlinear Engineering Models, 1st ed.; Springer: Dordrecht, The Netherlands, 2009. [Google Scholar]

- Dai, X.; Li, X.; Chen, Y.; Dai, L. Simultaneous enhancement of methane production and methane content in biogas from waste activated sludge and perennial ryegrass anaerobic co-digestion: The effects of pH and C/N ratio. Bioresour. Technol. 2016, 216, 323–330. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Yuan, Z.; Sun, Y.; Kong, X.; Dong, P.; Zhang, J. A reused method for molasses-processed wastewater: Effect on silage quality and anaerobic digestion performance of Pennisetum purpereum. Bioresour. Technol. 2017, 241, 1003–1011. [Google Scholar] [CrossRef]

- Schank, S.C.; Chynoweth, D.P.; Turick, C.E.; Mendoza, P.E. Napiergrass genotypes and plant parts for biomass energy. Biomass Bioenergy 1993, 4, 1–7. [Google Scholar] [CrossRef]

- Molinuevo-Salces, B.; Larsen, S.U.; Ahring, B.K.; Uellendahl, H. Biogas production from catch crops: Increased yield by combined harvest of catch crops and straw and preservation by ensiling. Biomass Bioenergy 2015, 79, 3–11. [Google Scholar] [CrossRef]

- Seppälä, M.; Paavola, T.; Lehtomäki, A.; Rintala, J. Biogas production from boreal herbaceous grasses—Specific methane yield and methane yield per hectare. Bioresour. Technol. 2009, 100, 2952–2958. [Google Scholar] [CrossRef] [PubMed]

- Meehan, P.; Burke, B.; Doyle, D.; Barth, S.; Finnan, J. Exploring the potential of grass feedstock from marginal land in Ireland: Does marginal mean lower yield? Biomass Bioenergy 2017, 107, 361–369. [Google Scholar] [CrossRef]

- Tsapekos, P.; Kougias, P.G.; Egelund, H.; Larsen, U.; Pedersen, J.; Trénel, P.; Angelidaki, I. Mechanical pretreatment at harvesting increases the bioenergy output from marginal land grasses. Renew. Energy 2017, 111, 914–921. [Google Scholar] [CrossRef]

- Narinthorna, R.; Chooritab, W.; Chistic, Y. Alkaline and fungal pretreatments for improving methane potential of Napier grass. Biomass Bioenergy 2019, 127, 105262. [Google Scholar] [CrossRef]

- Hidaka, T.; Arai, S.; Okamoto, S.; Uchida, T. Anaerobic co-digestion of sewage sludge with shredded grass from public green spaces. Bioresour. Technol. 2013, 130, 667–672. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).