A Thermal Design of a 1 kW-Class Shell and Tube Methanol Steam Reforming System with Internal Evaporator

Abstract

:1. Introduction

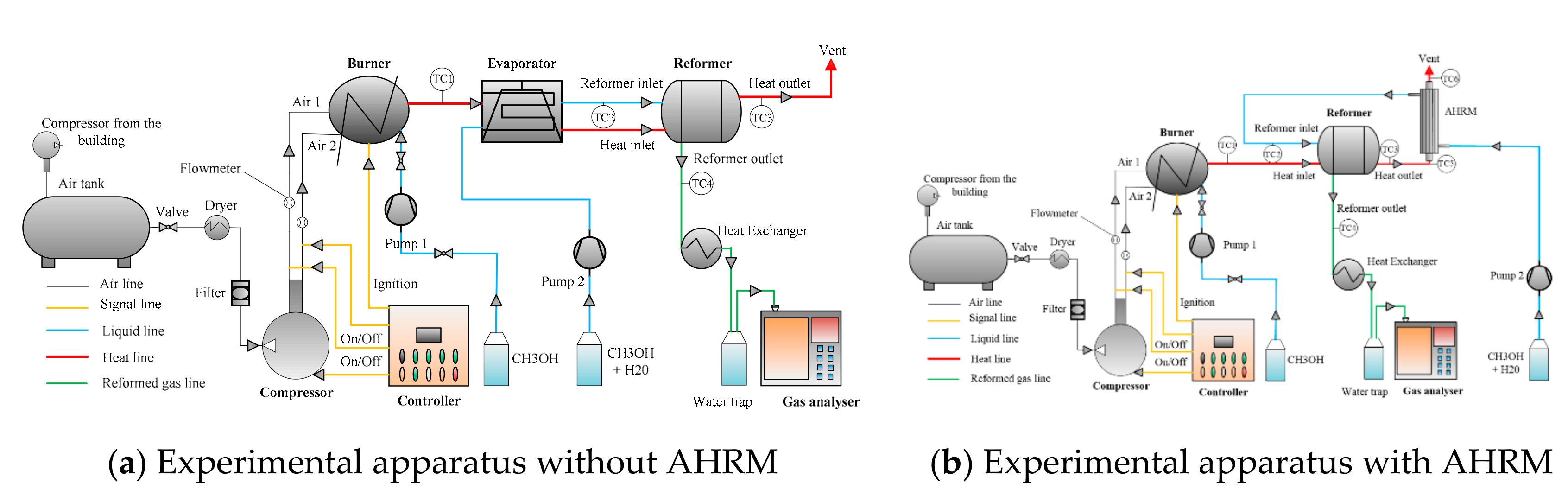

2. Design and Experiment of Methanol Steam Reformer

Design of 1 kW Class Methanol Steam Reformer

3. Results and Discussion

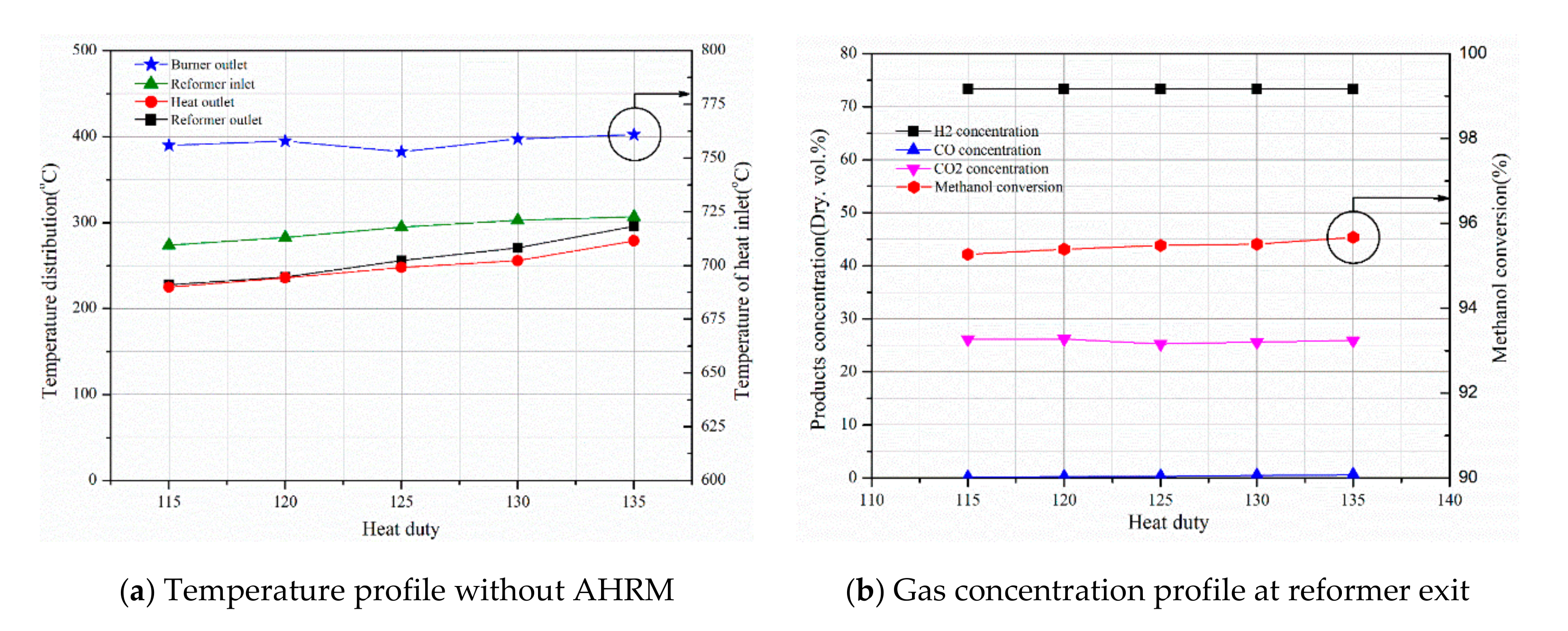

3.1. Performance of Methanol Steam Reforming System without AHRM

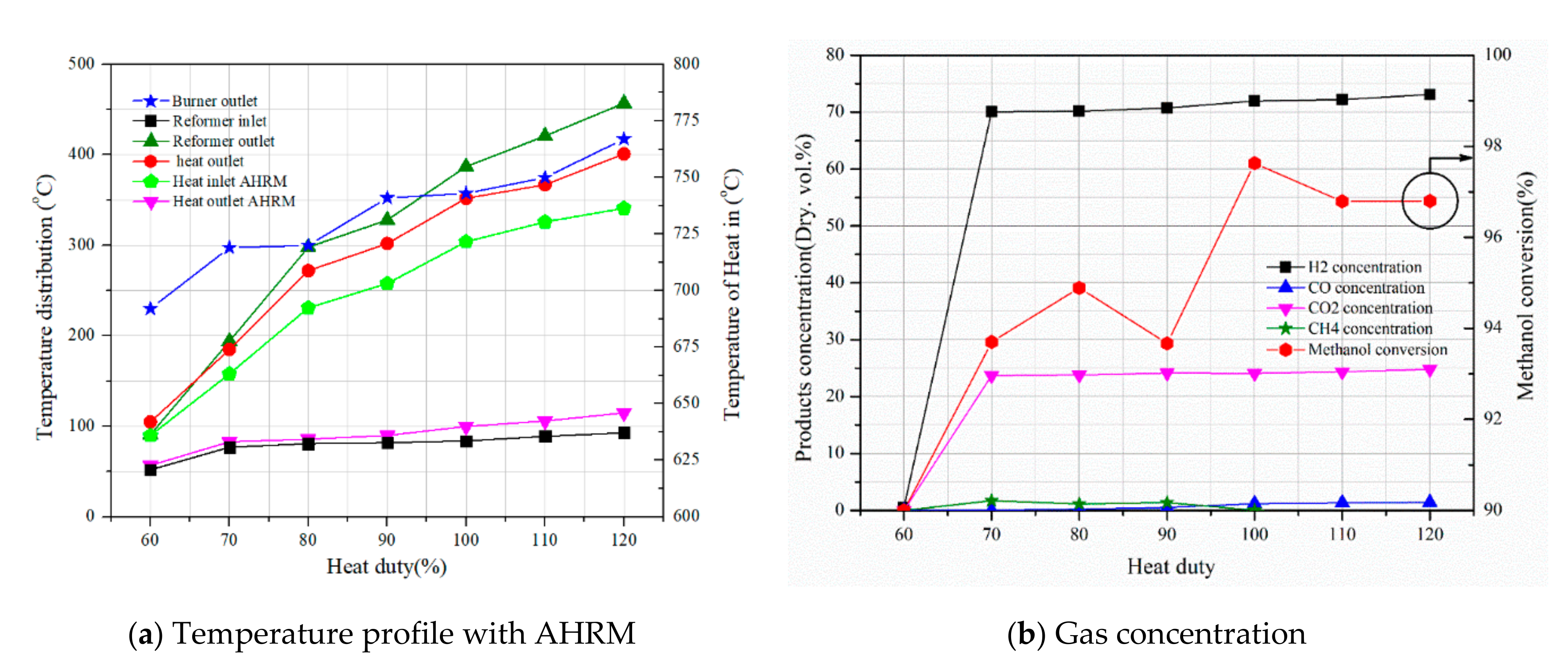

3.2. Performance of Methanol Steam Reforming System with AHRM

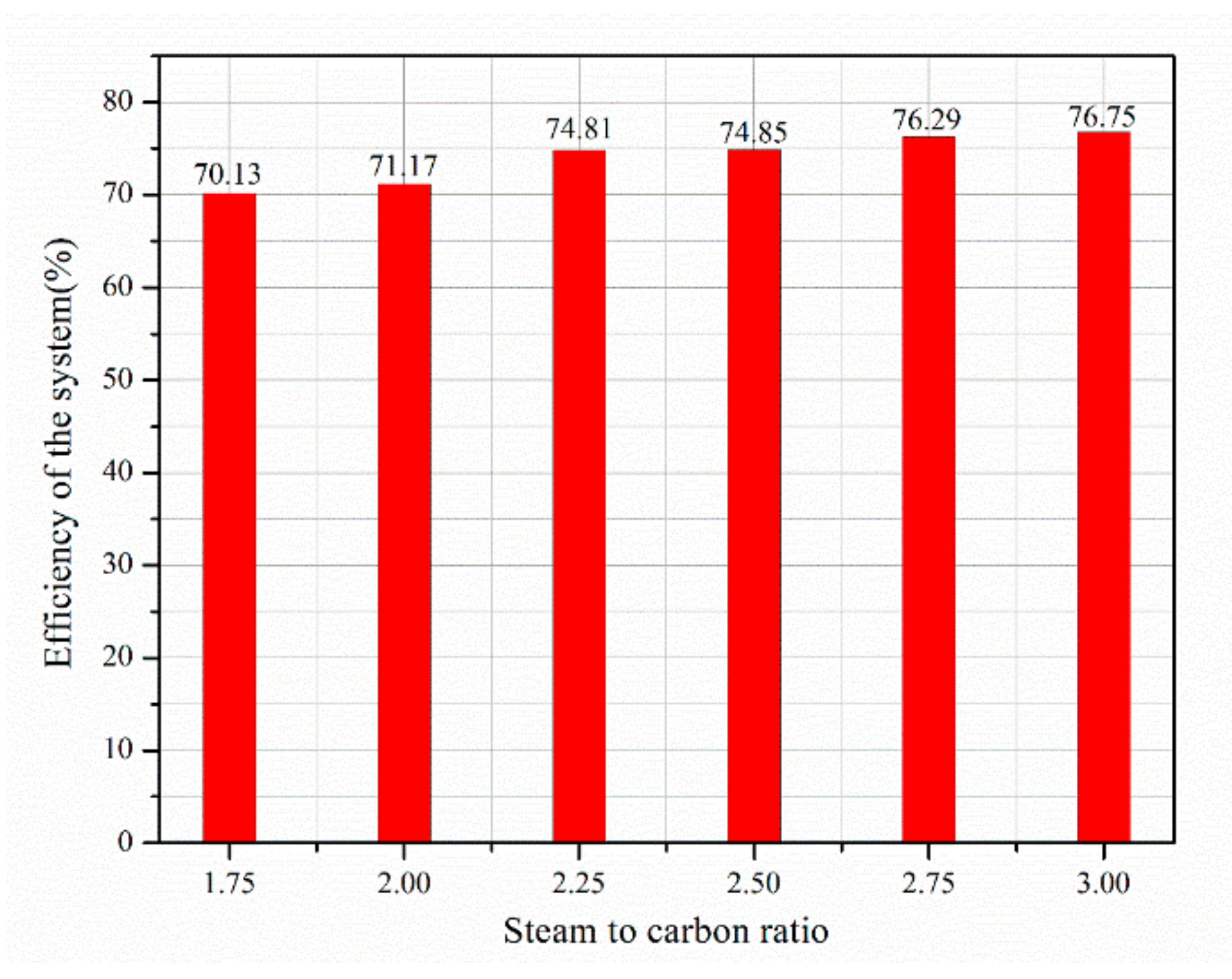

3.3. Effects of Steam to Carbon Ratio on the System Performance with Extra Heat Recovery Module

4. Conclusions

- The auxiliary heat recovery module is useful to extend the operability of the methanol/water mixture inside the shell and tube methanol steam reformer, such that the operating range of methanol steam reformer is extended to 70% heat duty.

- The thermal efficiency of the steam reformer with external evaporator ranges from 59.5% to 65.24%. Since the lower limit of heat duty is extended for the methanol reformer with internal evaporate, the thermal efficiency is improved to be 77.75% at 70% heat duty.

- As the S/C ratio is increased from 1.75 to 3.0, the wasted energy of the methanol reformer with an internal evaporator is reduced. The thermal efficiency is then increased from 70.13% to 76.65% at 80% heat duty.

Author Contributions

Funding

Conflicts of Interest

References

- Liang, M.; Luo, B.; Zhi, L. Application of graphene and graphene-based materials in clean energy-related devices. Int. J. Energy Res. 2009, 33, 1161–1170. [Google Scholar] [CrossRef]

- Molino, A.; LaRocca, V.; Chianese, S.; Musmarra, D. Biofuels Production by Biomass Gasification: A Review. Energies 2018, 11, 811. [Google Scholar] [CrossRef] [Green Version]

- Sikarwar, V.S.; Zhao, M.; Fennell, P.S.; Shah, N.; Donat, F. Progress in biofuel production from gasification. Prog. Energy Combust. Sci. 2017, 61, 189–248. [Google Scholar] [CrossRef]

- Rathour, R.K.; Ahuja, V.; Bhatia, R.K.; Bhatt, A.K. Biobutanol: New era of biofuels. Int. J. Energy Res. 2018, 42, 4532–4545. [Google Scholar] [CrossRef]

- Faungnawakij, K.; Kikuchi, R.; Eguchi, K. Thermodynamic evaluation of methanol steam reforming for hydrogen production. J. Power Sources 2006, 161, 87–94. [Google Scholar] [CrossRef]

- Agrell, J.; Birgersson, H.; Boutonnet, M. Steam reforming of methanol over a Cu/ZnO/Al2O3 catalyst: A kinetic analysis and strategies for suppression of CO formation. J. Power Sources 2002, 106, 249–257. [Google Scholar] [CrossRef]

- Amphlett, J.C.; Evans, M.J.; Jones, R.A.; Mann, R.F.; Weir, R.D. Hydrogen production by the catalytic steam reforming of methanol part 1: The thermodynamics. Can. J. Chem. Eng. 1981, 59, 720–727. [Google Scholar] [CrossRef]

- Breen, J.P.; Ross, J.R. Methanol reforming for fuel-cell applications: Development of zirconia-containing Cu–Zn–Al catalysts. Catal. Today 1999, 51, 521–533. [Google Scholar] [CrossRef]

- Purnama, H.; Ressler, T.; Jentoft, R.; Soerijanto, H.; Schlögl, R.; Schomäcker, R. CO formation/selectivity for steam reforming of methanol with a commercial CuO/ZnO/Al2O3 catalyst. Appl. Catal. A Gen. 2004, 259, 83–94. [Google Scholar] [CrossRef] [Green Version]

- Agrell, J.; Boutonnet, M.; Fierro, J.L. Production of hydrogen from methanol over binary Cu/ZnO catalysts: Part II Catalytic activity and reaction pathways. Appl. Catal. A Gen. 2003, 253, 213–223. [Google Scholar] [CrossRef]

- Günter, M.M.; Ressler, T.; Jentoft, R.E.; Bems, B. Redox Behavior of Copper Oxide/Zinc Oxide Catalysts in the Steam Reforming of Methanol Studied by in Situ X-Ray Diffraction and Absorption Spectroscopy. J. Catal. 2001, 203, 133–149. [Google Scholar] [CrossRef] [Green Version]

- Amphlett, J.C.; Mann, R.F.; Weir, R.D. Hydrogen production by the catalytic steam reforming of methanol: Part 3: Kinetics of methanol decomposition using C18HC catalyst. Can. J. Chem. Eng. 1988, 66, 950–956. [Google Scholar] [CrossRef]

- Wieland, I.; Melin, I.; Lamm, I. Membrane reactors for hydrogen production. Chem. Eng. Sci. 2002, 57, 1571–1576. [Google Scholar] [CrossRef]

- Iulianelli, A.; Ribeirinha, P.; Mendes, A.; Basile, A. Methanol steam reforming for hydrogen generation via conventional and membrane reactors: A review. Renew. Sustain. Energy Rev. 2014, 29, 355–368. [Google Scholar] [CrossRef] [Green Version]

- Basile, A.; Iulianelli, A.; Longo, T.; Liguori, S.; De Falco, M. Pd-based Selective Membrane State-of-the-Art. In Membrane Reactors for Hydrogen Production Processes; Springer: Berlin/Heidelberg, Germany, 2011; Volume 2, pp. 21–55. [Google Scholar]

- Cho, K.; Yun, J.; Yu, S. Experimental Study on Catalytic Characteristics of 1-kW Methanol Reformer. Trans. Korean Soc. Mech. Eng.B 2019, 43, 817–823. [Google Scholar] [CrossRef]

- Lotrič, A.; Sekavčnik, M.; Hočevar, S. Methanol Steam Reformer–High Temperature PEM Fuel Cell System Analysis. In Proceedings of the Military Green 2012 Conference-Exhibition-Demonstration Call for Exhibits and Demonstrations, Brussels, Belgium, 19–20 June 2012; p. 1000. [Google Scholar]

| Parameter | Value | Unit |

|---|---|---|

| Flow rate of methanol at reformer inlet | 5.77 | g/min |

| Flow rate of water at reformer inlet | 8.11 | g/min |

| Total flow rate of the system | 924.77 | L/h |

| Shell diameter | 72 | mm |

| Tube diameter | 6.35 | mm |

| Number of tubes | 38 | ea |

| Reaction zone length | 135 | mm |

| Reactor volume | 0.5470 | L |

| Tube volume | 0.1617 | L |

| Shell volume | 0.3853 | L |

| Gas hourly space velocity | 2400 | 1/h |

| Parameter | Value | Unit |

|---|---|---|

| Reference state | ||

| Temperature of reactants for reforming | 25 | |

| Flow rate of methanol for reforming | 0.003 | mol/s |

| Flow rate of methanol for burner | 0.0015 | mol/s |

| Steam to carbon ratio | 2.5 | - |

| Gas hourly space velocity | 2400 | 1/h |

| Experimental variables | ||

| S/C ratio (SCR) | 1.75, 2, 2.25, 2.5, 2.75, 3 | - |

| Flow rate of methanol for burner | 60, 70, 80, 90, 100, 110, 120 | % |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, D.; Trinh Van, N.; Yun, J.; Yu, S. A Thermal Design of a 1 kW-Class Shell and Tube Methanol Steam Reforming System with Internal Evaporator. Processes 2020, 8, 1509. https://doi.org/10.3390/pr8111509

Yu D, Trinh Van N, Yun J, Yu S. A Thermal Design of a 1 kW-Class Shell and Tube Methanol Steam Reforming System with Internal Evaporator. Processes. 2020; 8(11):1509. https://doi.org/10.3390/pr8111509

Chicago/Turabian StyleYu, Dongjin, Ngoc Trinh Van, Jinwon Yun, and Sangseok Yu. 2020. "A Thermal Design of a 1 kW-Class Shell and Tube Methanol Steam Reforming System with Internal Evaporator" Processes 8, no. 11: 1509. https://doi.org/10.3390/pr8111509

APA StyleYu, D., Trinh Van, N., Yun, J., & Yu, S. (2020). A Thermal Design of a 1 kW-Class Shell and Tube Methanol Steam Reforming System with Internal Evaporator. Processes, 8(11), 1509. https://doi.org/10.3390/pr8111509