Abstract

A novel method based on the combination of simultaneous cold plasma treatment with Mg nanoparticles deposition, applied to Mung bean seeds by improving their quality, is presented. The SRIM simulation reveals that only the very top layer of the seeds surface can be altered by the plasma. The experimental analysis indicates surface composition changes with a polar groups formation. These groups initiate the shift of surface characteristics from hydrophobic to hydrophilic. The chemical bond analysis shows the formation of MgO and Mg(OH)2 compounds, which acts as a positive factor for seeds germination and growth. The germination experiments showed a 70% outcome with an average of 73.9 mm sprouts length after 30 min of plasma treatment compared to the initial seeds (40% outcome and 71.3 mm sprouts length).

1. Introduction

Mung beans are an important crop widely cultivated across Asia and some parts of America [1]. According to the IMARC group (market forecasters), the global market of Mung beans reached an amount of 3.4 million tons in 2019 where India is a leader with 60% of the total production. The Mung beans have gained their popularity as edible sprouts due to the numerous health benefits and their high nutritional value, which include proteins, fibers, vitamins, minerals, antioxidants, and phytoestrogens [2,3]. Since the demand of sprouts is still increasing, the crop yield and rate of seeds germination should increase, respectively.

However, some factors and an insufficient germination of seeds could lead to a reduction in the production yield of Mung bean sprouts. The main causes of the low germination of plant seeds are usually connected to genetic factors, the quality of the seeds surface and soil contamination with microorganisms, as well as the lack of moisture or macronutrients [4,5]. Moreover, adverse environmental conditions can negatively affect the germination.

The conventional methods used to enhance the germination rate are fertilization and increased irrigation but it still faces economic and environmental issues [4,6]. The agrochemicals used for yield improvement might be hazardous for the human health [7]. Moreover, current consumers are interested in less chemically treated food products. Alternatively, genetic engineering, seeds sterilization with sodium chlorite, treatment with acids, antibiotics, hot water, or additional macro elements can be employed for better germination [1,8,9]. However, these processes are considered complex, expensive, not always efficient, and sometimes even harmful. Therefore, eco-friendly and non-hazardous alternative methods are desired.

It is noted that seed germination begins with a water uptake, which induces biochemical processes [5,10]. The absorption of the water rate is influenced by environmental and plant seed surface properties (morphological and chemical state). Although increased surface wettability and water uptake are necessary, they are not sufficient conditions for better germination.

Recently, the treatment of plant seeds surface using non-thermal plasma is one of the emerging technologies in the agriculture, which can breakdown seed dormancy, control water absorption, kill bacteria, or positively stimulate germination and growth [11]. Consequently, it gets more and more attention in China, which uses plasma treating seed technologies commercialized by Russia [12]. However, the existing devices still need many improvements.

The non-thermal plasma consisting of ions, electrons, excited atoms, radicals, molecules, and UV radiation can modify the surface from several up to tenths of nanometers [13]. During the non-thermal plasma treatment, plant seeds undergo only a very low stress via plasma activation and are kept intact. Due to such characteristics, the plasma can induce a mild surface etching (via ions bombardment) or even enrich the seeds surface with oxygen containing functional groups [5]. These groups can significantly increase the surface wettability, which has a very positive effect on seeds metabolism and germination, as well as surface permeability for nutrients [3,7]. Another positive effect of plasma modification is the sterilization of the seeds surface and elimination of unwanted microbes [1,14,15]. Moreover, the non-thermal plasma is suitable for heat sensitive surfaces, as well as being a fast and environmental-friendly (without any hazardous chemicals) method, which provides a uniform and non-destructive surface treatment of plant seeds [7,16]. It is demonstrated that various treatment parameters can accelerate germination, increase sprout growth, plant height, weight or root growth, decontaminate the seed surface, or improve the survivability [17]. However, the process mechanism can still be investigated in more detail.

Among different common gases (such as Ar, He, N, O2), very promising results are shown after the exposure of seeds to the atmospheric air plasma where enhanced germination and seedling vigor were observed [17,18,19,20]. In the air plasma, reactive nitrogen and oxygen species are generated (RONS and ROS, respectively). Furthermore, the air plasma consists of predominant excited oxygen (O2*) and nitrogen (N2*) molecules, atomic nitrogen (N) and oxygen (O), superoxide anions (O2−), and some radicals such as, H2O+, OH−, and OH* [21,22]. The reactive oxygen and nitrogen species have a huge impact on seeds activation in the plasma [8,23].

Nevertheless, the impact of micro nutrients on seeds germination should not be forgotten. Magnesium plays an important role in plants as a regulator of biochemical functions and can have a positive impact on seeds germination, as well as plant growth [24]. It activates enzymes and is an essential element in the photosynthesis process. Moreover, it is a very important nutrient for human health [24,25]. S. Shinde et al. synthesized magnesium hydroxide (Mg(OH)2) nanoparticles and investigated their influence on the germination of Zea mays [26]. The authors found a significant increase in seeds germination and growth (i.e., enhanced shoot height and root length). Another research group demonstrated that magnesium oxide nanoparticles also improved the green gram (V. radiata) seeds germination performance [27]. Generally, the plasma treatment of plants and seeds as well as the usage of additional nutrients are separate approaches and studies for an increment of germination efficiency. Magnesium is one of the most important elements for the healthy growth of plants and one of the most limiting macronutrients in agriculture [26,28].

This study focused on the theoretical and experimental analysis of Mung bean seeds surface modifications, by an implanted gaseous species from the plasma and nanoparticles, which arrive from magnesium cathodes used during the cold plasma treatment. The oxygen and nitrogen implantation could promote beans germination and initial growth. Moreover, magnesium nano clusters could act as nano fertilizers, which improve the plant nutrition level during growth. Basically, magnesium salts are used as fertilizers in order to increase their concentration in soil. Here, we show an original approach attaching magnesium nanoparticles directly to the seeds. Specifically, we investigate the influence of the treatment on the chemical state characteristics of the seeds surface, the change in the elemental composition, as well as germination by applying various surface analysis techniques. In this study, we demonstrate that a combination of simultaneous non-thermal plasma treatment with Mg nanoparticles deposition on the surface have a significant potential for improving the outcome of seeds germination.

2. Experimental Details

2.1. Plasma Treatment

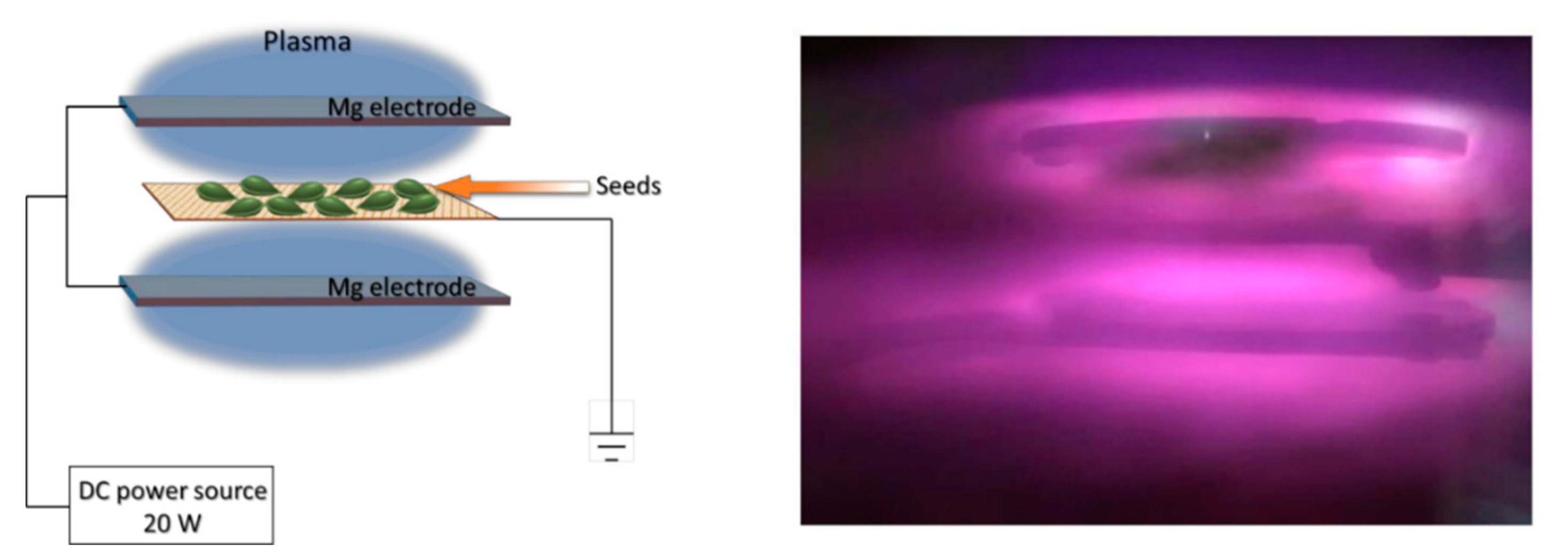

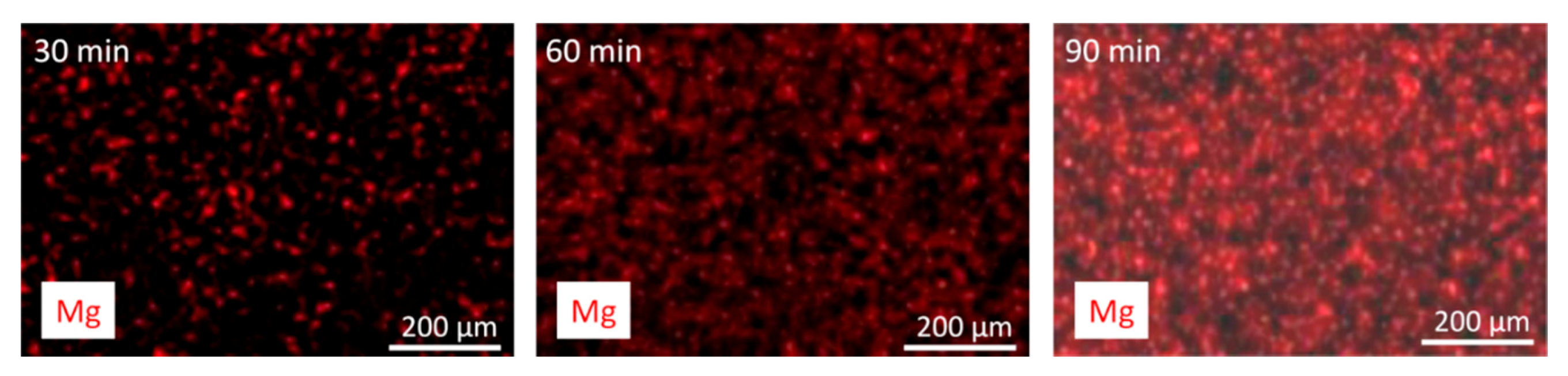

During the plasma treatment, the Mung bean seeds were placed in a vacuum chamber on metal mesh between two Mg electrodes (produced by KJLC, Clairton, PA, USA 99.9% purity). The principle scheme of the plasma treatment as well as the image of the real plasma treatment process is shown in Figure 1. The two electrodes and metal mesh between them was used in order to ensure a homogeneous treatment process for all the seeds surface. The direct current power source (20 W) was used for plasma generation, while air was used as a working gas. The pressure of 10 Pa was kept constant during the plasma treatment process (gas flow was maintained around 30 mL/min). The distance between each Mg electrode and metal mesh was 4 cm. Mung bean seeds were treated in plasma for 10, 30, 60, and 90 min.

Figure 1.

Experimental setup of seeds plasma treatment.

2.2. Plasma Treatment Process Simulations

The air-plasma ion penetration into the Mung bean seeds was evaluated by using SRIM—a free available Monte Carlo simulation code with a full name: Stopping and Range of Ions in Materials. SRIM is the most widespread simulation code mainly used for calculations of sputtering and its application areas. The SRIM software is based on the TRIM code (TRansport of Ions in Matter), which uses Biersack’s magic formula and the ZBL (Ziegler-Biersack-Littmark) universal interaction potential for its calculations [29,30].

2.3. Characterization

The surface wettability was evaluated by water contact angle (WCA) measurements, which were performed immediately (in less than 5 min) after the plasma treatment process. The laboratory made equipment with a camera and PC computer was used for high resolution pictures of the water drop on the seeds surface. Deionized water was syringed on the surface of the seeds and the pictures were taken during the next 3 s. Three seeds were used for each measurement and averaged values were calculated. The surface elemental composition and chemical bond analysis of the plasma treated Mung bean seeds were analyzed by an X-ray photoelectron spectroscope (XPS, PHI 5000 Versaprobe, Chanhassen, MN, USA). During the XPS analysis, the monochromated 1486.6 eV Al radiation, 25 W beam power, 100 μm beam size, and 45° were used. The Multipak software and NIST Standard Reference Database were used for the XPS spectra processing and analysis. The elemental mapping of Mung bean seeds was done using a scanning electron microscope (Hitachi S-3400N, Tokyo, Japan) equipped with energy dispersive X-ray spectroscopy (EDS, Bruker Quad 5040, Berlin, Germany).

2.4. Germination

The germination rate is presented as a percentage by indicating the proportion of germinated and total number of Mung bean seeds, which were seeding for 7 days at room temperature (the temperature was kept between 21–23 °C during the whole germination process) with 12 h light and 12 h dark. Twenty Mung bean seeds of each group (initial, 10, 30, 60, and 90 min of the plasma treatment) were used for the germination experiments. The humidity was set between 60–70%. The calculation of the germination rate is presented by the following equation:

3. Results and Discussion

3.1. Simulation Results

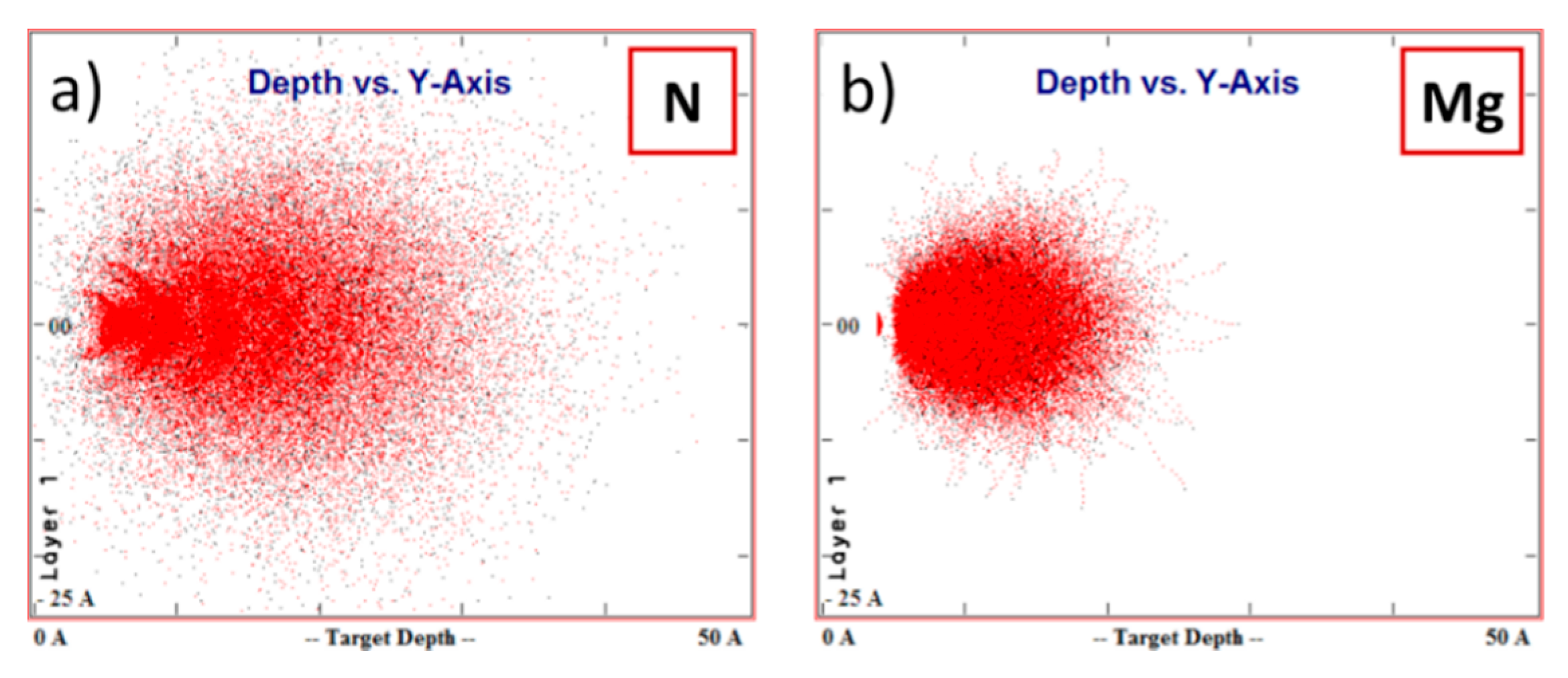

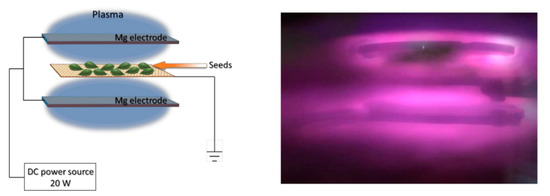

During the SRIM simulation, some assumptions were taken into account, therefore, the real penetration depth might vary by several nanometers. First, it was assumed that the surface of the Mung bean seeds consists of carbon only. The elemental analysis experiments, which are presented below, revealed that the surface of the Mung bean seeds consist of carbon (more than 80%) and some other elements: O, Si, and Ca. This result was observed by analyzing a very thin surface layer, which was up to 10 nm. Moreover, it is known that the carbon concentration could even increase to a very top layer due to the adventitious carbon [31]. Therefore, the simulation was performed by approaching the plasma ions that penetrate through the carbon layer of the analyzed seeds and using the density of carbon during the simulation. Second, nitrogen is a main component of air, which was used for the plasma treatment. Therefore, the simulation was simplified by taking into account nitrogen as an ion source. Finally, the calculated air plasma as well as the Mg ion energy, which are required for the simulation, were about 0.1–0.2 keV.

Figure 2 shows the simulation results of the air-plasma and Mg ions penetration in to the Mung bean seeds. The results show that the air-plasma ions penetrated into approximately 3 nm depth of the Mung bean seeds, while the highest concentration of plasma ions penetration was fixed at a 2 nm depth. This means that only a very top layer of the seeds surface is altered during the plasma treatment and such a method does not make any changes on the seeds bulk. However, a majority of the researchers claimed that the plasma ion penetration depth into the various seeds is up to 10 nm [10,32,33]. This disparity between the calculated results and the ion penetration depth provided by other authors could be related to several approaches. First, a majority of the other authors used the term “up to 10 nm” without any ion penetration depth calculations, while it is widely known that the plasma can influence only the “very top layer” of the treated material. Up to our knowledge, there are no articles that indicate a particular penetration depth of cold plasma ions into the seed. Moreover, the existing ion penetration depth models into other materials used different plasma parameters including ion flux, temperature, plasma composition, etc. Therefore, it is hard to evaluate the real difference between our suggested model and the penetration depth results presented by the other authors.

Figure 2.

Simulation results of (a) air-plasma and (b) Mg ions penetration in to the Mung bean seeds: Visualization of ions distribution.

Moreover, our suggested model revealed that the deposited Mg nanoparticles could penetrate into 1–2 nm of the Mung bean surface (Figure 2b). The result that air-plasma ions can penetrate deeper than Mg is reasonable, while both air-plasma and Mg ions have a similar energy during the plasma treatment and air-plasma ions have a lower diameter, determining an easier penetration process.

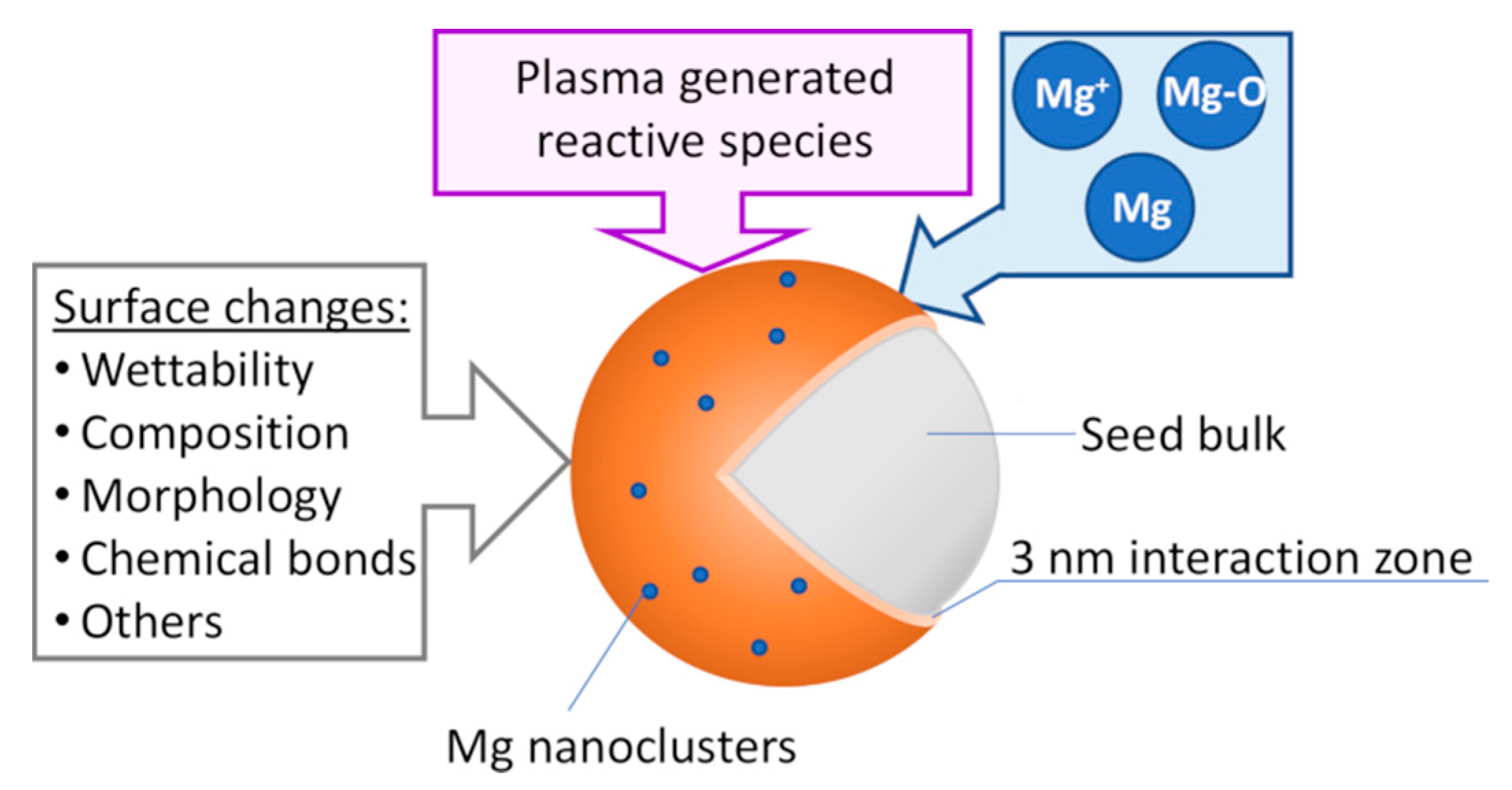

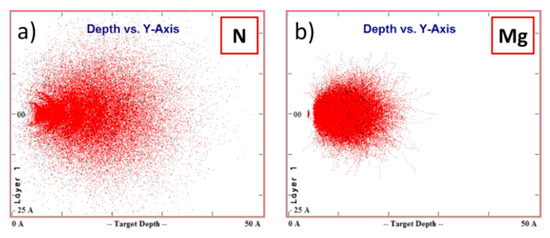

The air plasma consists of a variety of different particles and radicals (electrons, neutral, particles, excited atoms, molecules), as well as UV irradiation. Therefore, it is well known that the gas plasma can result in various effects upon the treated surface including cleaning or alteration of the surface. Many processes can occur during the interaction of air plasma with the seeds surface: The removal of surface contamination, the formation of an altered layer by the implantation of magnesium ions and active ions from air plasma near the surface, the adsorption of magnesium atoms on the surface, the formation of polar molecule groups on the surface which promote surface wettability, the changes in the surface topography on the nanoscale, etc. [8,34]. Under certain conditions, magnesium particles from the used electrodes are sputtered by ions existing in the air plasma. The sputtered magnesium with enough energy is deposited on the seeds surface and oxidized by an active oxygen species in the air plasma (Figure 3).

Figure 3.

The scheme of the plasma treatment process with Mg nanoclusters deposition on the seed surface.

3.2. Experimental Results

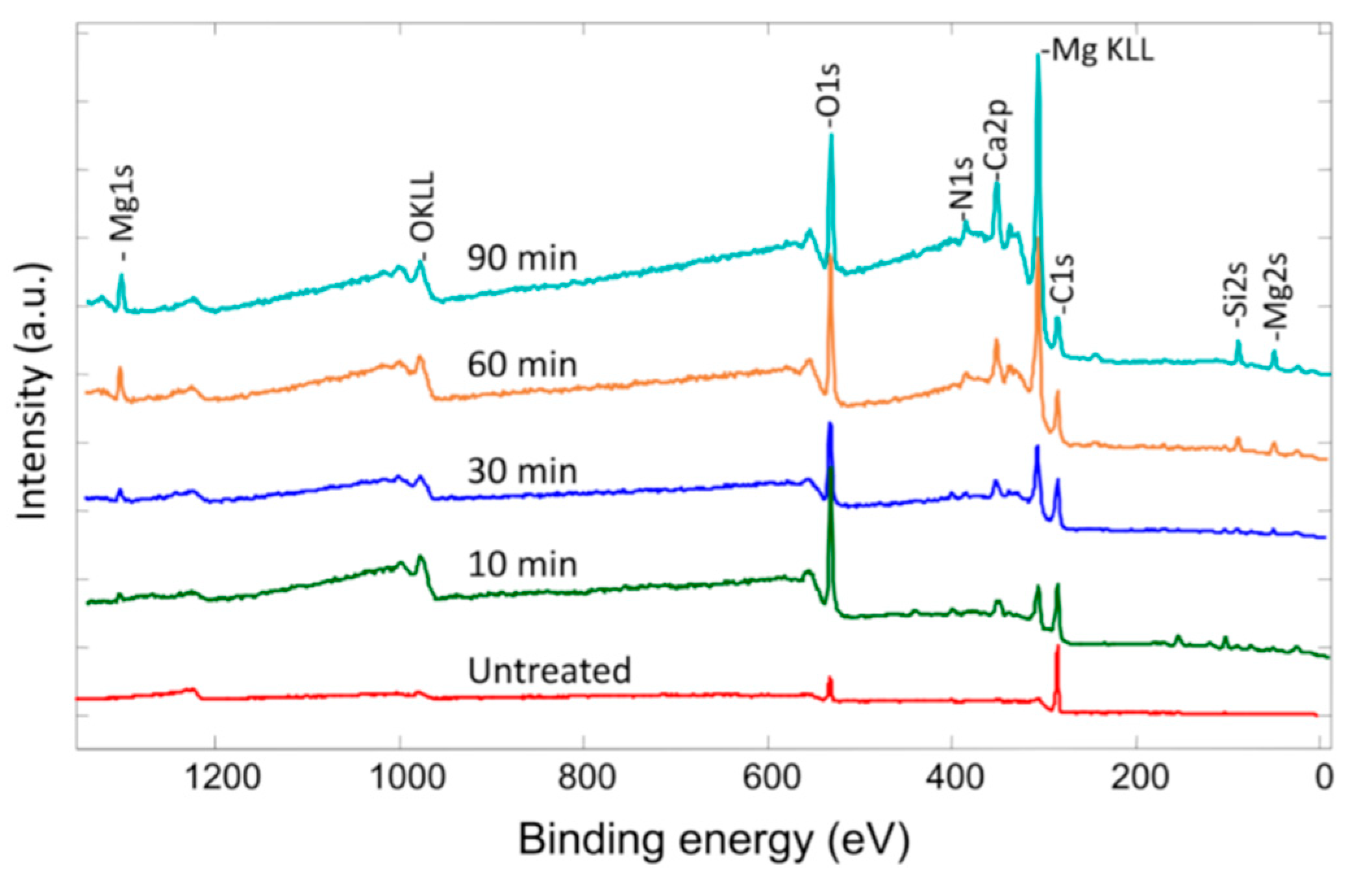

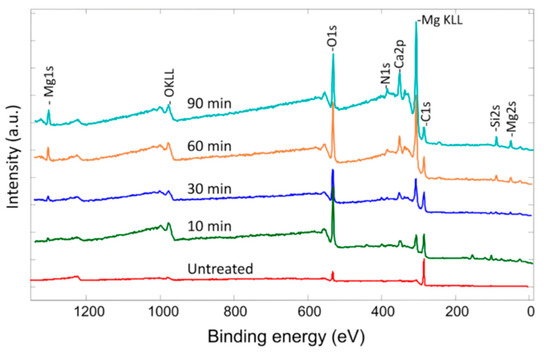

An elemental analysis of the very top layer of initial and plasma-treated Mung bean seeds was performed by XPS measurement (Figure 4). The surface of the initial seeds consists of carbon (80.5 at%), oxygen (15.3 at%), nitrogen (2.0 at%) and a small amount of trace elements (2.2 at%). The clear changes of the Mung bean seeds surface elemental composition were observed after the plasma treatment. The amount of carbon decreased approximately two times even after 10 min of the plasma treatment (43.7 at%). A longer treatment time invoked the reduction of carbon which varied from 24 to 34.7 at%. On the contrary, the increment of oxygen was observed after the first 10 min of the plasma treatment up to 42.3 at%. Such an amount of oxygen remained relatively stable despite a longer treatment time. Similar tendencies were observed by estimating the amount of nitrogen, in which the concentration slightly increased after the plasma treatment and varied in a narrow range (from 2.4 to 3.6 at%).

Figure 4.

XPS survey spectra of initial- and plasma-treated Mung bean seeds.

These results are determined by the native characteristics of the plasma, while two main processes (known as plasma cleaning and free radical sites formation) complement each other during the plasma treatment. The plasma cleaning initiates the removal of organic contaminants, as well as an adventitious carbon from the surface of the sample. Such a process can be related to the carbon amount reduction, as well as the oxygen promotion during the plasma treatment. Meanwhile, the formation of free radical sites usually improves the free surface energy and induces a re-orientation with new chemical bonds formation (see Figure 5) [35,36,37,38].

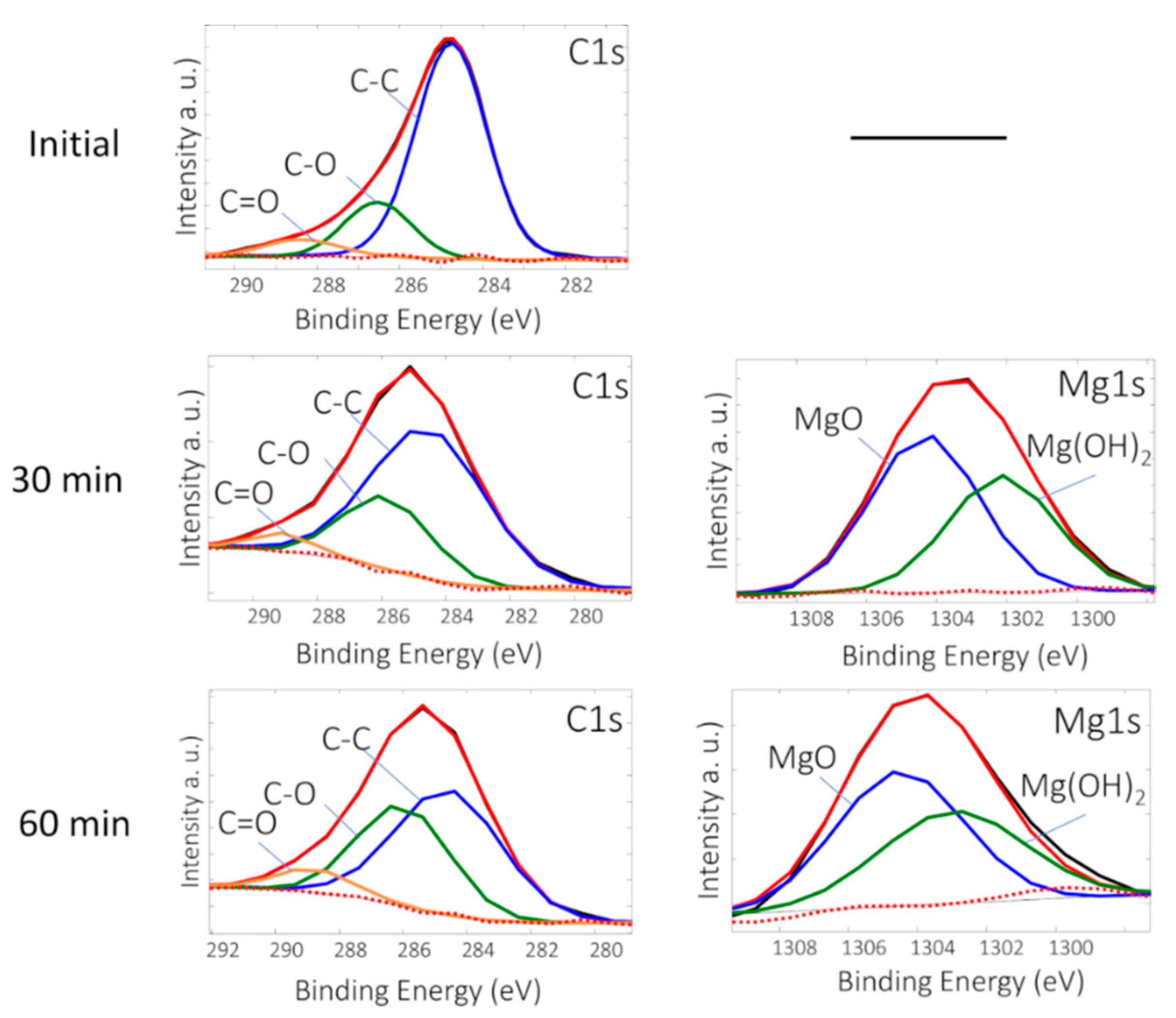

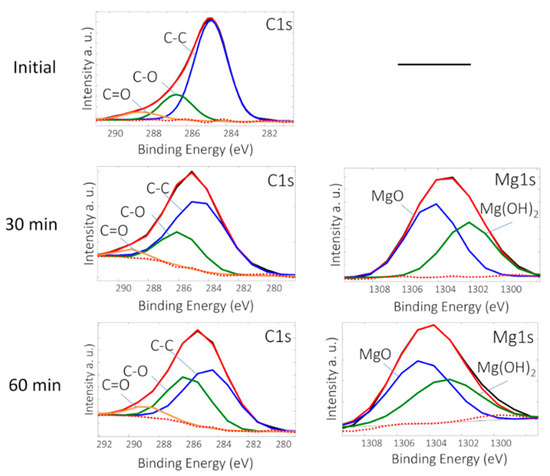

Figure 5.

XPS fitting results of C1s and Mg1s peaks.

One of the main aims of this work was to form Mg nanoclusters on the surface of Mung bean seeds during the plasma treatment. The analysis showed that 2.9 at% of Mg was observed even after 10 min of the plasma treatment. Moreover, the concentration of Mg increased with a longer plasma treatment time and reached 19.0 at% after 90 min of the plasma treatment. This result confirms that Mg nanoparticles were deposited on the surface of Mung bean seeds during the plasma treatment. The small amount of trace elements (Si, Ca), which is a component of the seed sheath, was observed by analyzing all types of seeds. The small increase of Si and Ca elements after the plasma treatment compared to the initial seeds concentration might be related to the plasma cleaning process, where organic contaminants are removed and a more certain elemental composition of seed sheath could be observed. The detailed results of the Mung bean surface elemental composition before and after the plasma treatment are presented in Table 1.

Table 1.

Concentrations of elemental composition (up to 10 nm) before and after the plasma treatment.

The chemical bond analysis of Mung bean surface chemical elements was performed by XPS measurement. Figure 5 shows the C1s and Mg1s peaks fitting results of the initial and plasma-treated (30 and 60 min) Mung bean seeds. The analysis of the Mg1s peak showed two types of chemical bonds, MgO and Mg(OH)2, with binding energies at 1304.5 and 1302.3 eV, respectively, which match well with the theoretical values [39]. The ratio between MgO and Mg(OH)2 remains relatively stable (roughly 1:1) and Mg does not form any other bond despite a longer treatment time.

It should be mentioned that the analysis of the O1s peak confirmed the MgO and Mg(OH)2 chemical bond formation with a similar area ratio as in the Mg1s spectra. Moreover, two additional chemical bonds were found (C-O and C=O). These chemical bonds were identified in detail by analyzing the C1s spectra. Nevertheless, any relevant information was found by analyzing the O1s spectra. Therefore, the fitting results of the O1s peak are not presented as a figure.

The results of carbon peak (C1s) deconvolution revealed that it consists of three components: C-C, C-O, and C=O at binding energies of 284.8, 286.1, and 288.3 eV, respectively. It is important to mention that the chemical bond C-C covers the majority of the C1s peak area by analyzing the initial seeds (76.0% of the area). However, this value decreased until 51.5% of the area after 90 min of the plasma treatment, while the total amount of C-O and C=O chemical bonds increased with each longer treatment time. It is known that carbon chains (C-C bond) are recognized as non-polar groups, which are responsible for surface hydrophobicity. Meanwhile, the higher amount of polar groups (C-O and C=O) increase the surface tension and induce its hydrophilicity [40]. These results revealed that the plasma treatment invoked a reduction of non-polar groups on the seeds surface and increased its energy. Hence, the surface energy increment determined the formation of strongly polar functional groups on the seeds surface [41,42]. The polar/non-polar groups ratio and chemical bonds concentrations of the C1s peak are presented in Table 2.

Table 2.

Concentrations of polar/non-polar groups.

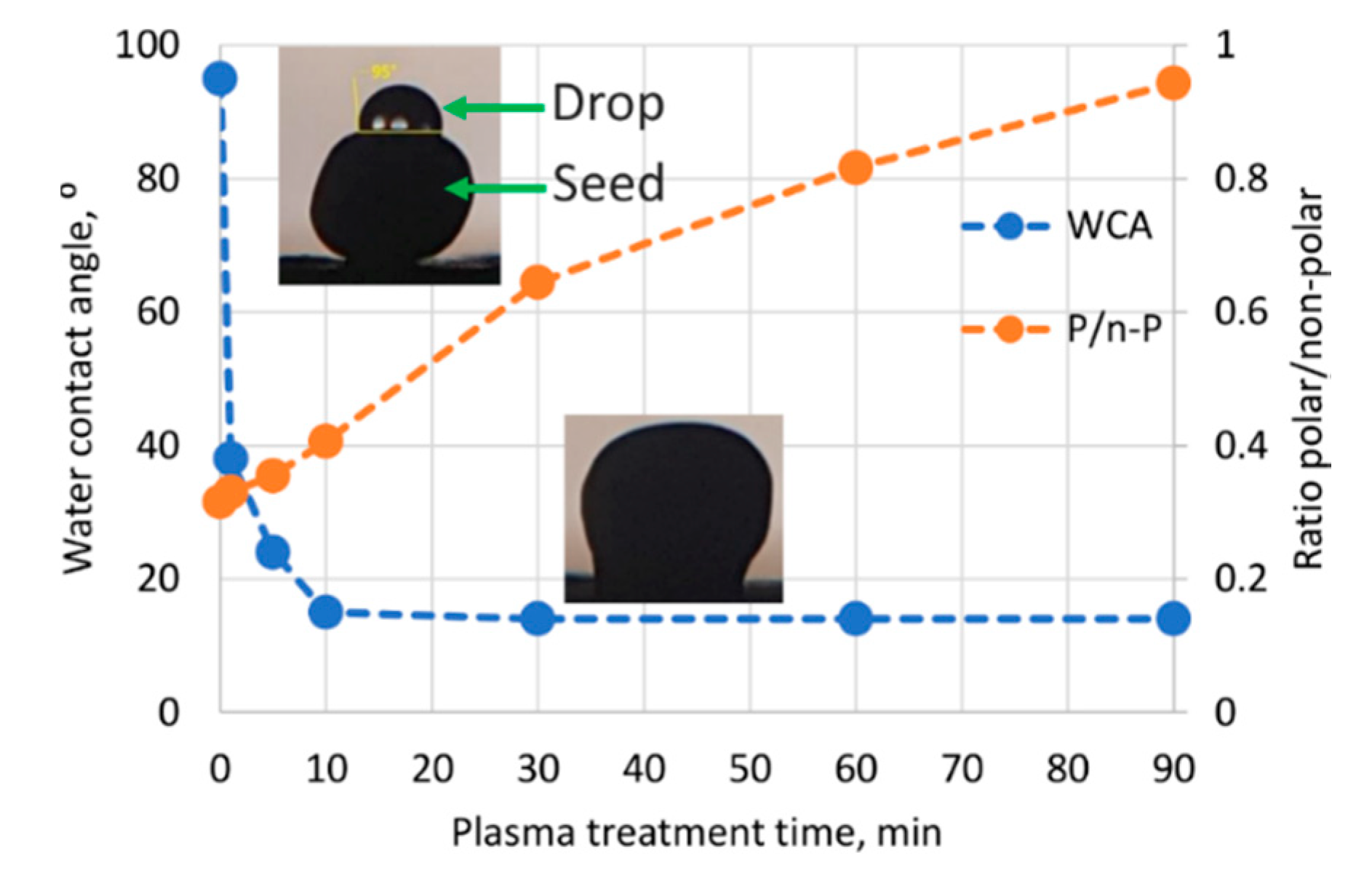

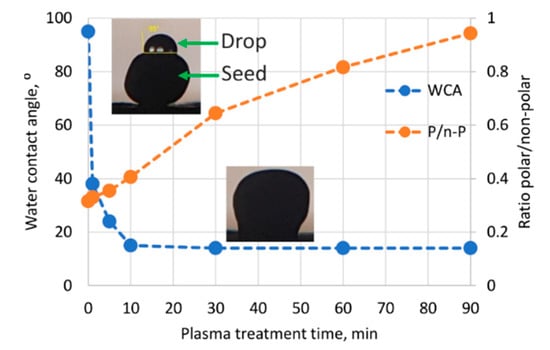

The water contact angle measurement is a simple technique which is used for a qualitative evaluation of surface wettability. The WCA measurement was performed after each plasma treatment time, as well as for the initial Mung bean seeds. The significant reduction of WCA was observed by comparing initial and any other plasma-treated seeds. The WCA value for the initial seed was about 96°. This value decreased until approximately 38° after 1 min and 24° after 5 min. A further analysis revealed that the value of WCA remained relatively stable (about 15°) after 10 min of plasma treatment, while the ratio of polar/non-polar groups increased with a longer treatment time (Figure 6). Such an obvious reduction of WCA determined clear changes of the seeds surface. The surface conversion from hydrophobic to hydrophilic indicated the increment of free surface energy [40]. This, in turn, determined a better water absorption into the seed. G. de Groot et al. used the cold plasma treatment for cotton seed germination improvement [8]. They showed that the cold plasma treatment invoked the seeds surface hydrophilicity and improved water absorption. Moreover, they showed that the enlarged water absorption, compared to the initial seed, was directly related to a better seed germination. The similar germination tendencies were observed by other authors as well, when the plasma treatment encouraged the seeds surface hydrophilicity, which is directly related to a better germination process [10,43,44].

Figure 6.

Water contact angle (WCA) and polar/non-polar groups ratio (P/n-P) dependence on the plasma treatment time.

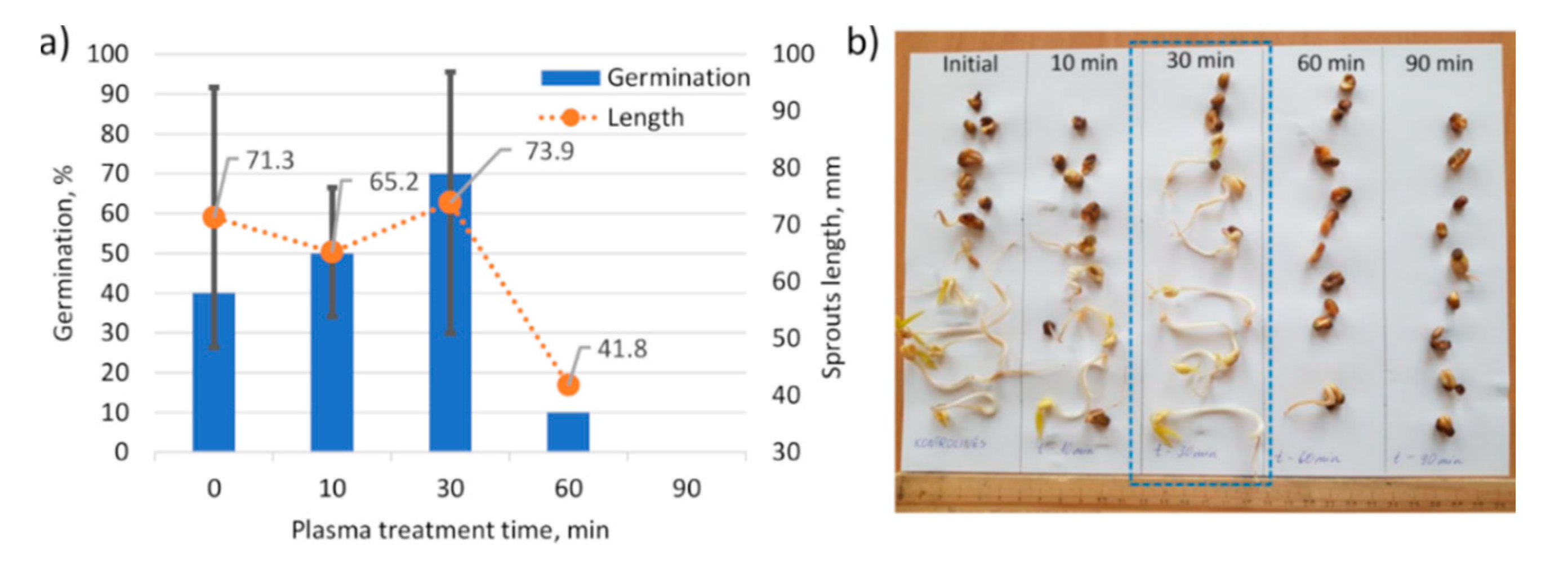

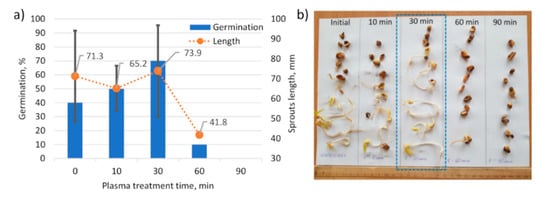

The Mung bean germination experiments were performed with the seeds before and after the plasma treatment process. First, the initial seeds showed approximately 40% germination (Figure 7a). The increment of the germination process was observed after 10 and 30 min of the plasma treatment (50% and 70% germination, respectively). However, a longer treatment time determined a total reduction of the germination process (10% and 0% after 60 and 90 min of the plasma treatment, respectively). The results of the sprouts length average values with the standard deviation (SD) are shown in Figure 7a. The measurements revealed that the longest sprouts were observed after 30 min of the plasma treatment with the average values of 73.9 mm (SD—23.0). Meanwhile, the length of the initial and 10-min plasma-treated Mung bean sprouts were fixed at 71.3 mm (SD—22.8) and 65.2 mm (SD 11.3), respectively.

Figure 7.

Mung bean germination: (a) Germination percentage with sprouts length averages and (b) real sprouts images of initial and plasma-treated seeds. Black vertical lines in (a)—errors presented as standard deviation.

We speculate that 30 min of the plasma treatment leads to formation of the most suitable number of polar groups and, in turn, an enhanced water absorption, which is directly related to the seeds germination process. On the other hand, a longer treatment time (60 and 90 min) inhibits the germination process by initiating a too intensive polar groups formation (more than 0.6 of polar/non-polar groups ratio) and invokes an even higher water absorption through the surface sheath, as well as induces harmful stress in the seeds surface.

Magnesium plays an important role as a cationic macronutrient, which is a component of the chlorophyll molecule and participates in the activation of photosynthetic enzymes [24]. The deficiency of magnesium limits the photosynthesis process and leads to deprivation of carbohydrates in roots, seeds, and tubers [24,45].

Furthermore, the plasma treatment also helps improve the activity of numerous plant enzymes including seedling germination enzymes, which impact the overall metabolism of the plant and increase its growth [46]. On the other hand, the plasma treatment has a positive influence on the regulation of water uptake balance and physiological metabolic processes by modulating the activity of antioxidant enzymes [47,48].

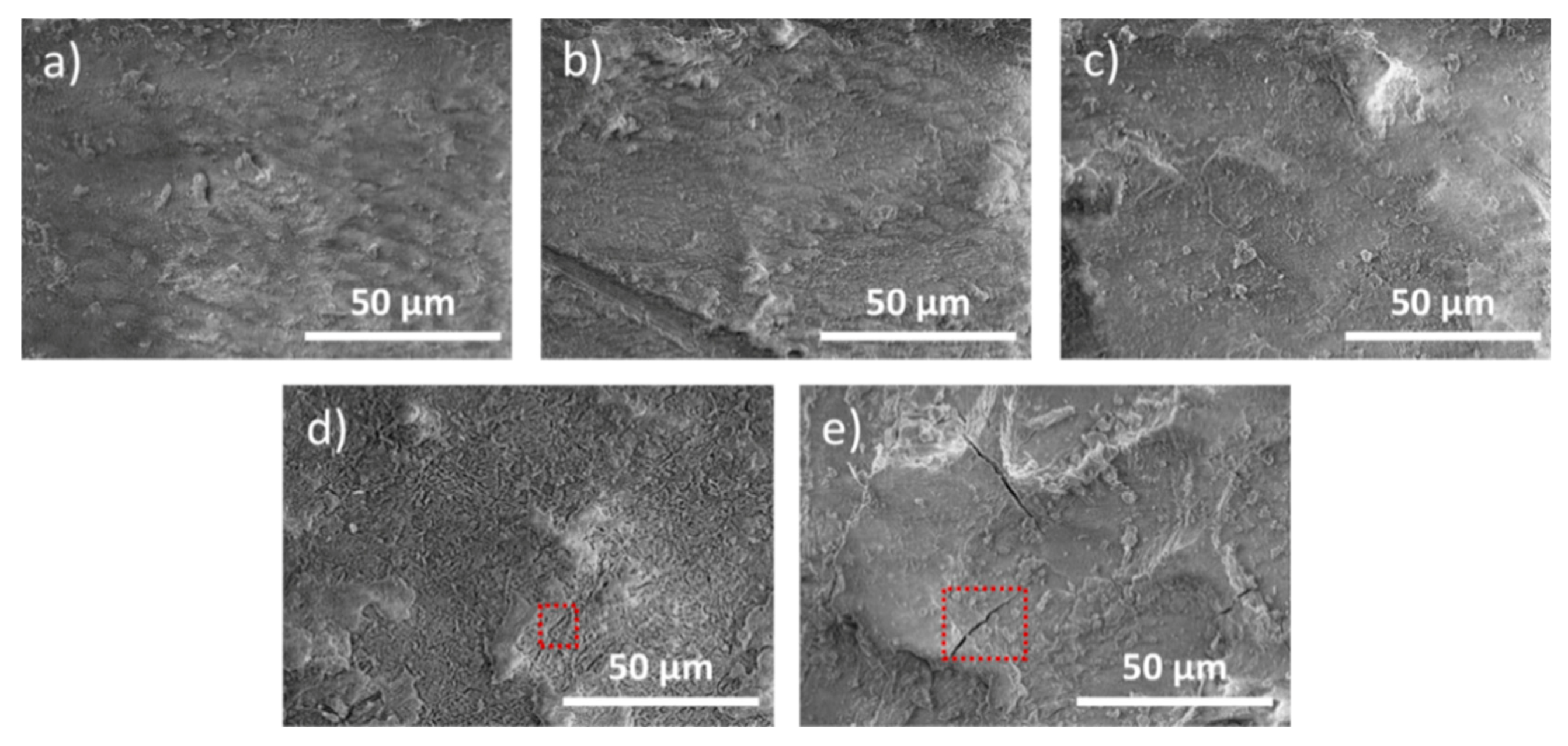

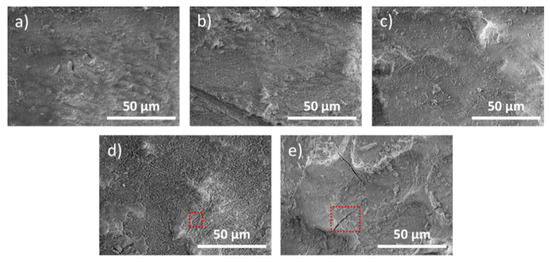

The surface morphology views of Mung beans before and after the plasma treatment are shown in Figure 8. By comparing the initial and plasma-treated Mung beans surface, the results revealed that its structure remained relatively stable and does not form any obvious changes after 10 and 30 min of the plasma treatment (Figure 8b,c). Nevertheless, a clear evidence of surface morphology changes was observed after 60 and 90 min of the plasma treatment, which contains small and significant cracks (see the red dots in Figure 8d,e). It was assumed that the extensive plasma treatment could influence the appearance of cracks by composing surface stress. These cracks might act as a water uptake center itself and inhibit the seeds germination at higher treatment times, as seen in Figure 7.

Figure 8.

Morphology views of Mung beans: (a) Initial, (b) 10 min, (c) 30 min, (d) 60 min, (e) 90 min of the plasma treatment. Red dots—appeared cracks.

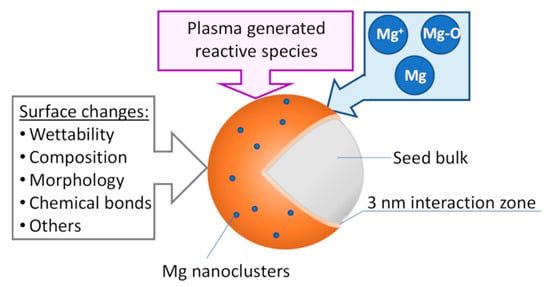

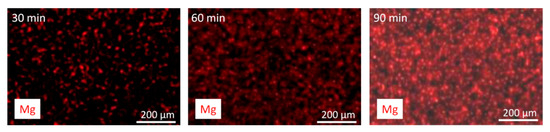

Moreover, as observed from the XPS elemental composition results, the amount of Mg increased with the longer treatment time (5.6 at% after 30 min and 19.0 at% after 90 min of the plasma treatment). The results of Mg elemental mapping after 30, 60, and 90 min of the plasma treatment are shown in Figure 9. The elemental mapping results showed that the Mg nanoparticles (red dots) distributed randomly on the seeds surface after 30 min of the plasma treatment and the highest part of the seeds surface remained uncovered by the Mg nanoparticles. The different results were observed after 60 and 90 min of the plasma treatment. The significant higher surface area was covered by Mg nanoparticles with a clear evidence of Mg clusters formation after 90 min of the plasma treatment. Presumably, the formation of enlarged Mg clusters might have a negative influence on the Mung bean seeds germination process, which act as a physical barrier. Nevertheless, further investigations of Mg, as well as the influence of other minerals on seeds germination and growth, are required.

Figure 9.

Elemental mapping results of Mg nanoparticles distribution on Mung bean seeds surface after 30, 60 and 90 min of the plasma treatment.

4. Conclusions

In this study, a new technique based on the combination of simultaneous non-thermal air plasma treatment with Mg nanoparticles deposition processes were applied to Mung bean seeds by enhancing their quality. This method revealed an original approach in order to increase the macronutrients level on the seeds, which could be controlled during the plasma treatment process. The simulation of the plasma treatment process showed that ions can penetrate into approximately 3 nm depth of Mung bean seeds, while Mg ions can penetrate into a 3 nm depth. The two processes known as plasma cleaning and free radical sites formation invoked composition changes on the seeds surface during the plasma treatment with the reduction of carbon and increment of oxygen components, as well as Mg nanoparticles deposition. This stimulates new chemical bonds formation on the seeds surface. The formation of polar chemical bonds (C-O and C=O) lead to the shift of surface characteristics from hydrophobic to hydrophilic and, in turn, improve water uptake. Meanwhile, the deposited Mg nanoparticles formed MgO and Mg(OH)2 compounds, which can help in plant growth promotion. Finally, the experiments showed that almost a two times better germination (70% outcome with a 73.9 mm average sprouts length) was observed after 30 min of the plasma treatment compared to the initial Mung bean seeds (40% outcome with a 71.3 mm average sprouts length).

Author Contributions

Writing—original draft preparation, writing—review and editing, S.V. (Sarunas Varnagiris) and M.U.; investigation, formal analysis, and methodology, S.V. (Simona Vilimaite), I.M. and S.T.; conceptualization and supervision, D.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhou, R.; Li, J.; Zhou, R.; Zhang, X.; Yang, S. Atmospheric-pressure plasma treated water for seed germination and seedling growth of mung bean and its sterilization effect on mung bean sprouts. Innov. Food Sci. Emerg. Technol. 2019, 53, 36–44. [Google Scholar] [CrossRef]

- Xiang, Q.; Liu, X.; Liu, S.; Ma, Y.; Xu, C.; Bai, Y. Effect of plasma-activated water on microbial quality and physicochemical characteristics of mung bean sprouts. Innov. Food Sci. Emerg. Technol. 2019, 52, 49–56. [Google Scholar] [CrossRef]

- Šerá, B.; Šerý, M. Non-thermal plasma treatment as a new biotechnology in relation to seeds, dry fruits, and grains. Plasma Sci. Technol. 2018, 20, 044012. [Google Scholar] [CrossRef]

- Sivachandiran, L.; Khacef, A. Enhanced seed germination and plant growth by atmospheric pressure cold air plasma: Combined effect of seed and water treatment. RSC Adv. 2017, 7, 1822–1832. [Google Scholar] [CrossRef]

- Bibwe, B.; Kannaujia, P.K.; Mahawar, M.K.; Aradwad, P. Cold plasma - Improving seed germination and seedling vigour. Agric. Food 2019, 1, 1–4. [Google Scholar]

- Morison, J.I.L.; Baker, N.R.; Mullineaux, P.M.; Davies, W.J.; Morison, J.I.L.; Baker, N.R.; Mullineaux, P.M.; Davies, W.J. Improving water use in crop production. Philos. Trans. R. Soc. B Biol. Sci. 2008, 363, 639–658. [Google Scholar] [CrossRef]

- Pérez-Pizá, M.C.; Prevosto, L.; Grijalba, P.E.; Zilli, C.G.; Cejas, E.; Mancinelli, B.; Balestrasse, K.B. Improvement of growth and yield of soybean plants through the application of non-thermal plasmas to seeds with different health status. Heliyon 2019, 5, e01495. [Google Scholar] [CrossRef]

- de Groot, G.J.J.B.; Hundt, A.; Murphy, A.B.; Bange, M.P.; Mai-Prochnow, A. Cold plasma treatment for cotton seed germination improvement. Sci. Rep. 2018, 8, 1–10. [Google Scholar] [CrossRef]

- Huang, W.Z.; Hsiao, A.I. Factors affecting seed dormancy and germination of Paspalum distichum. Weed Res. 1987, 27, 405–415. [Google Scholar] [CrossRef]

- Molina, R.; López-Santos, C.; Gómez-Ramírez, A.; Vílchez, A.; Espinós, J.P.; González-Elipe, A.R. Influence of irrigation conditions in the germination of plasma treated Nasturtium seeds. Sci. Rep. 2018, 8, 1–11. [Google Scholar] [CrossRef]

- Lotfy, K.; Al-Harbi, N.A.; Abd El-Raheem, H. Cold Atmospheric Pressure Nitrogen Plasma Jet for Enhancement Germination of Wheat Seeds. Plasma Chem. Plasma Process. 2019, 39, 897–912. [Google Scholar] [CrossRef]

- Zhang, B.; Li, R.; Yan, J. Study on activation and improvement of crop seeds by the application of plasma treating seeds equipment. Arch. Biochem. Biophys. 2018, 655, 37–42. [Google Scholar] [CrossRef] [PubMed]

- Adamovich, I.; Baalrud, S.D.; Bogaerts, A.; Bruggeman, P.J.; Cappelli, M.; Colombo, V.; Czarnetzki, U.; Ebert, U.; Eden, J.G.; Favia, P.; et al. The 2017 Plasma Roadmap: Low temperature plasma science and technology. J. Phys. D Appl. Phys. 2017, 50, 323001. [Google Scholar] [CrossRef]

- Khamsen, N.; Onwimol, D.; Teerakawanich, N.; Dechanupaprittha, S.; Kanokbannakorn, W.; Hongesombut, K.; Srisonphan, S. Rice (Oryza sativa L.) Seed Sterilization and Germination Enhancement via Atmospheric Hybrid Nonthermal Discharge Plasma. ACS Appl. Mater. Interfaces 2016, 8, 19268–19275. [Google Scholar] [CrossRef]

- Los, A.; Ziuzina, D.; Boehm, D.; Cullen, P.J.; Bourke, P. Investigation of mechanisms involved in germination enhancement of wheat (Triticum aestivum) by cold plasma: Effects on seed surface chemistry and characteristics. Plasma Process. Polym. 2019, 16, 1–12. [Google Scholar] [CrossRef]

- Dobrin, D.; Magureanu, M.; Mandache, N.B.; Ionita, M.D. The effect of non-thermal plasma treatment on wheat germination and early growth. Innov. Food Sci. Emerg. Technol. 2015, 29, 255–260. [Google Scholar] [CrossRef]

- Nalwa, C.; Thakur, A.K. Seed quality enhancement through plasma treatment: A review. Indian J. Ecol. 2018, 45, 814–821. [Google Scholar]

- Ito, M.; Hori, M. Current status and future prospects of agricultural applications using atmospheric-pressure plasma technologies. Plasma Process. Polym. 2017, 15, 1700073. [Google Scholar] [CrossRef]

- Măgureanu, M.; Daniela, R.S.; Mihai, D. Stimulation of the Germination and Early Growth of Tomato Seeds by Non-thermal Plasma. Plasma Chem. Plasma Process. 2018, 38, 989–1001. [Google Scholar] [CrossRef]

- Ahn, C.; Gill, J.; Ruzic, D.N. Growth of Plasma-Treated Corn Seeds under Realistic Conditions. Sci. Rep. 2019, 9, 1–7. [Google Scholar] [CrossRef]

- Scholtz, V.; Šerá, B.; Khun, J.; Šerý, M.; Julák, J. Effects of Nonthermal Plasma on Wheat Grains and Products. J. Food Qual. 2019, 2019, 7917825. [Google Scholar] [CrossRef]

- Sadhu, S.; Thirumdas, R.; Deshmukh, R.R.; Annapure, U.S. Influence of cold plasma on the enzymatic activity in germinating mung beans (Vigna radiate). LWT Food Sci. Technol. 2017, 78, 97–104. [Google Scholar] [CrossRef]

- Bogdanov, T.; Tsonev, I.; Marinova, P.; Benova, E.; Rusanov, K.; Rusanova, M.; Atanassov, I.; Kozáková, Z.; Krčma, F. Microwave plasma torch generated in argon for small berries surface treatment. Appl. Sci. 2018, 8, 1870. [Google Scholar] [CrossRef]

- Ceylan, Y.; Kutman, U.B.; Mengutay, M.; Cakmak, I. Magnesium applications to growth medium and foliage affect the starch distribution, increase the grain size and improve the seed germination in wheat. Plant. Soil 2016, 406, 145–156. [Google Scholar] [CrossRef]

- Cai, L.; Liu, M.; Liu, Z.; Yang, H.; Sun, X.; Chen, J.; Xiang, S.; Ding, W. MgoNPs can boost plant growth: Evidence from increased seedling growth, morpho-physiological activities, and Mg uptake in Tobacco (Nicotiana tabacum L.). Molecules 2018, 23, 3375. [Google Scholar] [CrossRef]

- Shinde, S.; Paralikar, P.; Ingle, A.P.; Rai, M. Promotion of seed germination and seedling growth of Zea mays by magnesium hydroxide nanoparticles synthesized by the filtrate from Aspergillus niger. Arab. J. Chem. 2020, 13, 3172–3182. [Google Scholar] [CrossRef]

- Vijai Anand, K.; Anugraga, A.R.; Kannan, M.; Singaravelu, G.; Govindaraju, K. Bio-engineered magnesium oxide nanoparticles as nano-priming agent for enhancing seed germination and seedling vigour of green gram (Vigna radiata L.). Mater. Lett. 2020, 271, 127792. [Google Scholar] [CrossRef]

- Zhang, B.; Cakmak, I.; Feng, J.; Yu, C.; Chen, X.; Xie, D.; Wu, L.; Song, Z.; Cao, J.; He, Y. Magnesium Deficiency Reduced the Yield and Seed Germination in Wax Gourd by Affecting the Carbohydrate Translocation. Front. Plant. Sci. 2020, 11, 1–10. [Google Scholar] [CrossRef]

- Yuan, M.; Zhang, X.; Saeedi, A.M.A.; Cheng, W.; Guo, C.; Liao, B.; Zhang, X.; Ying, M.; Gehring, G.A. Study of the radiation damage caused by ion implantation in ZnO and its relation to magnetism. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2019, 455, 7–12. [Google Scholar] [CrossRef]

- Medvids, A.; Varnagiris, S.; Letko, E.; Milcius, D.; Grase, L.; Gaidukovs, S.; Mychko, A.; Pludons, A.; Onufrijevs, P.; Mimura, H. Phase transformation from rutile to anatase with oxygen ion dose in the TiO2 layer formed on a Ti substrate. Mater. Sci. Semicond. Process. 2020, 106, 104776. [Google Scholar] [CrossRef]

- Greczynski, G.; Hultman, L. Reliable determination of chemical state in x-ray photoelectron spectroscopy based on sample-work-function referencing to adventitious carbon: Resolving the myth of apparent constant binding energy of the C 1s peak. Appl. Surf. Sci. 2018, 451, 99–103. [Google Scholar] [CrossRef]

- Hertwig, C.; Meneses, N.; Mathys, A. Cold atmospheric pressure plasma and low energy electron beam as alternative nonthermal decontamination technologies for dry food surfaces: A review. Trends Food Sci. Technol. 2018, 77, 131–142. [Google Scholar] [CrossRef]

- Dubinov, A.E.; Lazarenko, E.M.; Selemir, V.D. Effect of Glow Discherge Air Plasma on Grain Corps Seef. IEEE Trans. Plasma Sci. 2000, 28, 180–183. [Google Scholar] [CrossRef]

- Conrad, J.R. Handbook of Plasma Immersion Ion. Implantation and Deposition; Anders, A., Ed.; John Wiley & Sons: New York, NY, USA, 2000. [Google Scholar]

- Rifna, E.J.; Ramanan, K.R.; Mahendran, R. Emerging technology applications for improving seed germination. Trends Food Sci. Technol. 2019, 86, 95–108. [Google Scholar] [CrossRef]

- Bourke, P.; Ziuzina, D.; Boehm, D.; Cullen, P.J.; Keener, K. The Potential of Cold Plasma for Safe and Sustainable Food Production. Trends Biotechnol. 2018, 36, 615–626. [Google Scholar] [CrossRef] [PubMed]

- Butscher, D.; Waskow, A.; von Rohr, P.R. Chapter 6—Disinfection of granular food products using cold plasma. In Advances in Cold Plasma Applications for Food Safety and Preservation; Bermudez-Aguirre, D., Ed.; Academic Press: Cambridge, MA, USA, 2020; pp. 185–228. ISBN 978-0-12-814921-8. [Google Scholar]

- Dhayal, M.; Alexander, M.R.; Bradley, J.W. The surface chemistry resulting from low-pressure plasma treatment of polystyrene: The effect of residual vessel bound oxygen. Appl. Surf. Sci. 2006, 252, 7957–7963. [Google Scholar] [CrossRef]

- NIST. NIST X-ray photoelectron spectroscopy database. In NIST Standard Reference Database 20; Version 4.1. Available online: https://srdata.nist.gov/xps/ (accessed on 29 November 2020).

- Long, J.; Zhong, M.; Zhang, H.; Fan, P. Superhydrophilicity to superhydrophobicity transition of picosecond laser microstructured aluminum in ambient air. J. Colloid Interface Sci. 2015, 441, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Urbonavicius, M.; Varnagiris, S.; Milcius, D. Generation of hydrogen through the reaction between plasma-modified aluminum and water. Energy Technol. 2017, 5, 2300–2308. [Google Scholar] [CrossRef]

- Azimi, G.; Dhiman, R.; Kwon, H.; Paxson, A.T.; Varanasi, K.K. Hydrophobicity of rare-earth oxide ceramics. Nat. Mater. 2013, 12, 315–320. [Google Scholar] [CrossRef]

- Nantapan, J.; Sarapirom, S.; Janpong, K. The effects of atmospheric plasma jet treatment to the germination and enhancement growth of sunflower seeds. J. Phys. Conf. Ser. 2019, 1380, 012131. [Google Scholar] [CrossRef]

- Bormashenko, E.; Grynyov, R.; Bormashenko, Y.; Drori, E. Cold radiofrequency plasma treatment modifies wettability and germination speed of plant seeds. Sci. Rep. 2012, 2, 3–10. [Google Scholar] [CrossRef] [PubMed]

- Naseeruddin, R.; Sumathi, V.; Prasad, T.N.V.K.V.; Sudhakar, P.; Chandrika, V.; Reddy, B.R. Unprecedented Synergistic Effects of Nanoscale Nutrients on Growth, Productivity of Sweet Sorghum [Sorghum bicolor (L.) Moench], and Nutrient Biofortification. J. Agric. Food Chem. 2018, 66, 1075–1084. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Jiang, J.; Li, J.; Shen, M.; He, X.; Shao, H.; Dong, Y. Effects of cold plasma treatment on seed germination and seedling growth of soybean. Sci. Rep. 2014, 4, 5859. [Google Scholar]

- Ling, L.; Jiangang, L.; Minchong, S.; Chunlei, Z.; Yuanhua, D. Cold plasma treatment enhances oilseed rape seed germination under drought stress. Sci. Rep. 2015, 5, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Henselová, M.; Slováková, Ľ.; Martinka, M.; Zahoranová, A. Growth, anatomy and enzyme activity changes in maize roots induced by treatment of seeds with low-temperature plasma. Biologia 2012, 67, 490–497. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).