RF-ICP Thermal Plasma for Thermoplastic Waste Pyrolysis Process with High Conversion Yield and Tar Elimination

Abstract

:1. Introduction

1.1. Thermochemical Processes Net Energy Production

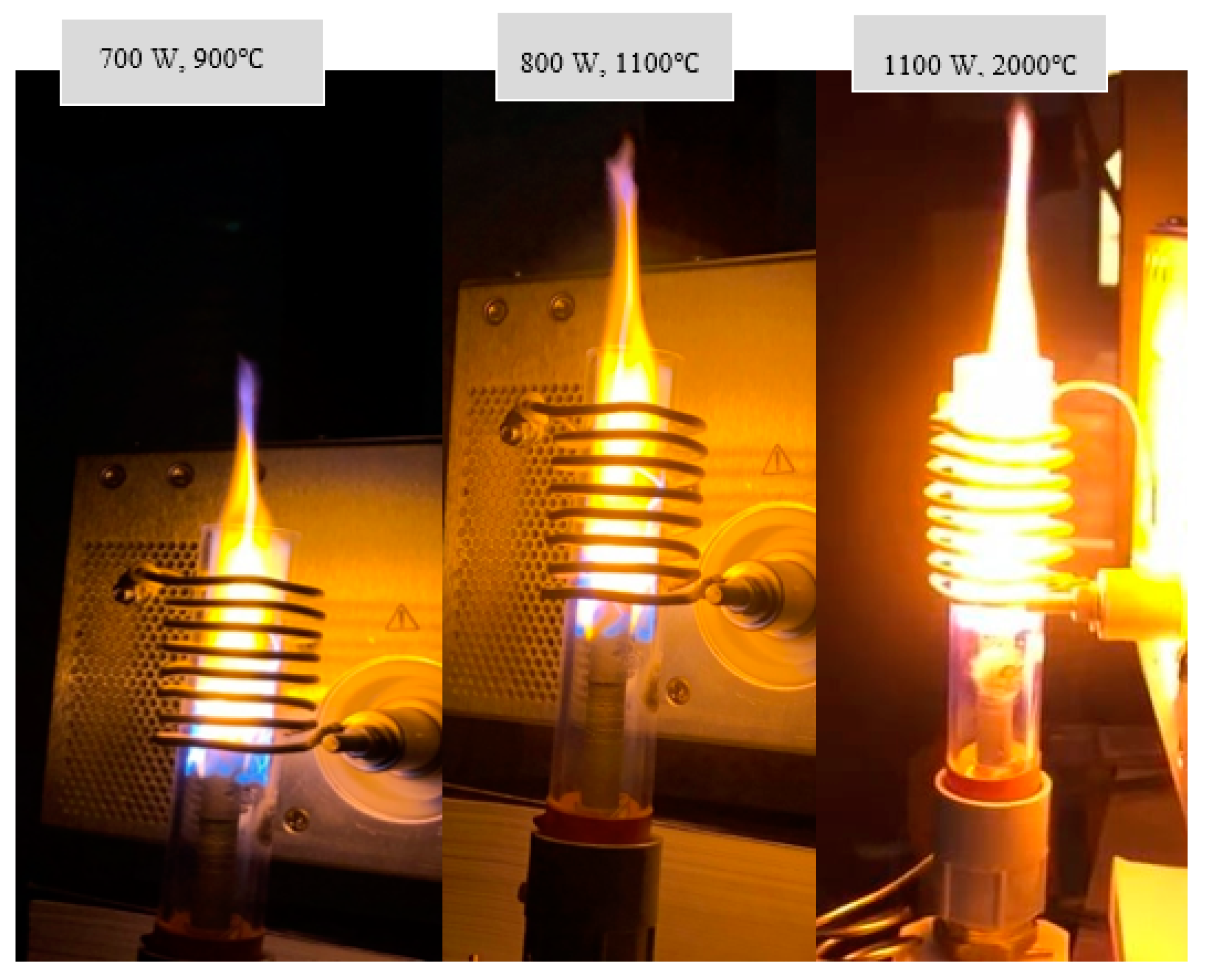

1.2. Characterization of Thermal Plasma Jets

- High energy density (105 W/cm2–107 W/cm2) and a high heat transfer surface area;

- A controllable reactive zone (flame) that achieves higher thermal control over reactivity;

- The presence of free ions and excited molecules that fastens reaction rates;

- Flexibility in carrier gases, either nitrogen, argon or oxygen, at low flow rates;

- High operating temperatures (1000 K to 10,000 K);

- High ionized particle concentration (1016–1017 particles/cm3).

1.3. Tar Tolerance Levels in Pyrolysis Reactors

1.4. Proposed Solution Approach

2. DC and RF Thermal Plasma Generation Systems

2.1. DC Transferred and Non-Transferred Arcs

2.2. RF Inductively Coupled (ICP) and Capacively Coupled (CCP) Thermal Plasma

- -

- Independent control of ion flux and energy density;

- -

- Ability to operate in a wide range of frequencies and control temperature using current;

- -

- Ability to operate at a low power and low plasma density;

- -

- Ability to control the operating temperature using current, achieving a faster control response.

2.3. RF Thermal Plasma Conservation Equations and Process Control Algorithms

2.4. Process Control Modelling

End-Product Gas Yield Control Algorithms

3. RF Thermal Plasma Simulation

- Thermal plasma is under a local partial thermodynamic equilibrium (LTE);

- Plasma is considered a conductive fluid mixture and is modelled using magnetohydrodynamics (MHD) equations;

- The thermal plasma jet is axisymmetric, optically thin, and at a local thermodynamic equilibrium;

- The gaseous velocity is constant at laminar flow with no tangential components;

- The displacement current and electrostatic fields are neglected.

3.1. RF Torch Assumptions

- The RF thermal plasma torch model has an axisymmetric configuration;

- The torch consists of eight turns with a cross-sectional coil diameter of 3 mm;

- Flow is assumed to be steady state, laminar flow of pure argon flow at 7.5 L/min;

- The thermal plasma jet is thin and at local thermodynamic equilibrium (LTE) conditions;

- Viscous dissipation and change in pressure are neglected in energy conservation equations.

3.2. RF Thermal Plasma Comsol Simulation

4. Experimental Apparatus

4.1. Equipment Description and Experimental Procedures

4.2. Equipment Setup

- An RF thermal plasma cathode cooling water to prevent resistive heat;

- A constant argon gas supply at 7.5 L/min;

- Three gas analyzers: CO, CO2 and NOx;

- A startup graphite electrode (diameter: 10 mm);

- A 1000 W RF thermal plasma system;

- Diagnostic equipment including a gas chromatograph;

- A high-pressure steam boiler and steam turbine for energy generation.

Reaction Apparatus Legend

- (1).

- Comsol Simulation Software

- (2).

- Nitrogen and Argon Gas Cylinders

- (3).

- Pyrolysis Reactor

- (4).

- Gasification Reactor

- (5).

- Steam Boiler

- (6).

- Steam Turbine

- (7).

- DAQ (Data Acquisition System)

- (8).

- Gas Chromatography

- (9).

- Steam Turbine

4.3. RF Thermal Plasma Torch Dimensions and Temperature Profile

4.4. Experimental Analysis and Results

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations & Nomenclature

| Abbreviations | |

| CCP | Capacitively Coupled Plasma |

| DC | Direct Current |

| FID | Flame Ionization Detector Gas Chromatograph |

| F-T | Fischer-Tropsch process |

| G | Gasification |

| GC-FID | Gas Chromatograph-Flame Ionization Detector method |

| GHG | Greenhouse Gas Emissions |

| I | Incineration |

| ICP | Inductively Coupled Plasma |

| LDPE | Low Density Polyethylene |

| MSW | Municipal Solid Waste |

| OECD | Organization for Economic Co-operation and Development |

| P | Pyrolysis |

| P-G | Combined Pyrolysis and Gasification Process |

| RF | Radio Frequency |

| Nomenclature | |

| Fr | Force in the radial direction |

| Fz | Force in the axial direction |

| Number of particles per m3 | |

| Jr | Plasma flux density in radial direction, (kg/m3) |

| K | Kelvin |

| KWh | kilowatt-hour |

| Density (kg/m3) | |

| Electron temperature, K | |

| Ti | Initial operating temperature, K |

| Atmospheric temperature, K | |

| Change in time, seconds | |

| Reaction residence time (minutes) | |

| Velocity, (m/s) | |

| vr | Velocity in the radial direction, (m/s) |

| vz | Velocity in the axial direction, (m/s) |

| wt.% | Weight percentage |

| Angular velocity, (m/s) | |

| Change in axial direction, m |

References

- Kawai, K.; Tasaki, T. Revisiting estimates of municipal solid waste generation per capita and their reliability. J. Mater. Cycles Waste Manag. 2016, 18, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Karak, T.; Bhagat, R.M.; Bhattacharyya, P. Municipal solid waste generation, composition, and management: The world scenario. Crit. Rev. Env. Sci. Technol. 2012, 42, 1509–1630. [Google Scholar] [CrossRef]

- Alhumid, H.A.; Haider, H.; Alsaleem, S.S.; Alinizzi, M.; Shafiquzaman, M.; Sadiq, R. Performance assessment model for municipal solid waste management systems: Development and implementation. Environments 2019, 6, 19. [Google Scholar] [CrossRef] [Green Version]

- David, A. Technical Document on Municipal Solid Waste Organics Processing. Available online: https://www.ec.gc.ca/gdd-mw/3E8CF6C7-F214-4BA2-A1A3-163978EE9D6E/13-047-ID-458-PDF_accessible_ANG_R2-reduced%20size.pdf (accessed on 30 January 2020).

- Niessen, W.R. Combustion and Incineration Processes. J. Chem. Inf. Model. 2010, 52, 11. [Google Scholar]

- Mohareb, A.K.; Warith, M.A.; Diaz, R. Modelling greenhouse gas emissions for municipal solid waste management strategies in Ottawa, Ontario, Canada. Resour. Conserv. Recycl. 2008, 52, 1241–1251. [Google Scholar] [CrossRef]

- Global Waste Management Outlook. 2016. Available online: https://www.unenvironment.org/resources/report/global-waste-management-outlook (accessed on 30 January 2020).

- Fabry, F.; Rehmet, C.; Rohani, V.; Fulcheri, L. Waste gasification by thermal plasma: A review. Waste Biomass Valorization 2013, 4, 421–439. [Google Scholar] [CrossRef] [Green Version]

- Arena, U.; Nelles, M.; Werther, J. Advanced aspects of thermal treatment of solid wastes: From a flue gas to a fuel gas technology? Waste Manag. 2012, 32, 623–624. [Google Scholar] [CrossRef] [PubMed]

- Albores, P.; Petridis, K.; Dey, P.K. Analysing Efficiency of Waste to Energy Systems: Using Data Envelopment Analysis in Municipal Solid Waste Management. Procedia Environ. Sci. 2016, 35, 265–278. [Google Scholar] [CrossRef]

- Rajasekhar, M.; Rao, N.V.; Rao, G.C.; Priyadarshini, G.; Kumar, N.J. Energy Generation from Municipal Solid Waste by Innovative Technologies – Plasma Gasification. Procedia Mater. Sci. 2015, 10, 513–518. [Google Scholar] [CrossRef] [Green Version]

- Ruj, B.; Ghosh, S. Technological aspects for thermal plasma treatment of municipal solid waste-A review. Fuel Process. Technol. 2014, 126, 298–308. [Google Scholar] [CrossRef]

- Gomez, E.; Rani, D.A.; Cheeseman, C.R.; Deegan, D.; Wise, M.; Boccaccini, A.R. Thermal plasma technology for the treatment of wastes: A critical review. J. Hazard. Mater. 2009, 161, 614–626. [Google Scholar] [CrossRef]

- Samal, S. Thermal plasma technology: The prospective future in material processing. J. Cleaner Prod. 2017, 142, 3131–3150. [Google Scholar] [CrossRef]

- Trelles, J.P.; Chazelas, C.; Vardelle, A.; Heberlein, J.V.R. Arc Plasma Torch Modeling. J. Therm. Spray Technol. 2009, 18, 728. [Google Scholar] [CrossRef] [Green Version]

- Bai, L.; He, J.; Ouyang, Y.; Liu, W.; Liu, H.; Yao, H.; Li, Z.; Song, J.; Wang, Y.; Yuan, F. Modeling and selection of RF thermal plasma hot-wall torch for large-scale production of nanopowders. Materials 2019, 12, 2141. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rao, L.; Rivard, F.; Carabin, P. Thermal plasma torches for metallurgical applications. In Proceedings of the 4th International Symposium on High-Temperature Metallurgical Processing, San Antonio, TX, USA, 3–7 March 2013. [Google Scholar]

- Ochoa Brezmes, A.; Breitkopf, C. Simulation of inductively coupled plasma with applied bias voltage using COMSOL. Vacuum 2014, 109, 52–60. [Google Scholar] [CrossRef]

- Kim, T.H.; Kim, K.N.; Mishra, A.K.; Seo, J.S.; Jeong, H.B.; Bae, J.O.; Yeom, G.Y. Plasma characteristics of inductively coupled plasma using dual-frequency antennas. Jpn. J. Appl. Phys. 2013, 52, 5S2. [Google Scholar] [CrossRef]

- Bernardi, D.; Colombo, V.; Coppa, G.G.M.; D’Angola, A. Simulation of the ignition transient in RF inductively-coupled plasma torches. Eur. Phys. J. D. 2001, 14, 337–348. [Google Scholar] [CrossRef]

- Taghavipour, A.; Vajedi, M.; Azad, N.L. Nonlinear Model Predictive Control. In Intelligent Control of Connected Plug-in Hybrid Electric Vehicles; Advances in Industrial Control; Springer: Cham, Switzerland, 2019; pp. 45–47. [Google Scholar]

- Wickramasinghe, D.G.C.; Narayana, M.; Witharana, S. Optimization of Process Parameters for Organic Municipal Solid Waste Torrefaction. In Proceedings of the 2019 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, UAE, 26 March–10 April 2019. [Google Scholar]

| Process Variable | Non-Thermal Plasma | Low Temperature Thermal Plasma | High Temperature Thermal Plasma |

|---|---|---|---|

| Operating Temperature | Ti Te < 300 K | Ti Te < 103 K | Ti Te > 106 K |

| Applications | Thermal arc emissions, low pressure glow discharges | Waste-to-energy, metallurgical applications | Fusion experimental work |

| Reactor Configuration | Tar Rates (g/Nm3) Process Units | Tar Rates (g/Nm3) Internal Combustion Engines and Turbines | ||||

|---|---|---|---|---|---|---|

| Min | Max | Average | Min | Max | Average | |

| Updraft | 1 | 150 | 20–100 | 0.1 | 3 | 0.1–1 |

| Downdraft | 0.05 | 6 | 0.1–1.5 | 0.01 | 10 | 0.1–0.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aboughaly, M.; Gabbar, H.A.; Damideh, V.; Hassen, I. RF-ICP Thermal Plasma for Thermoplastic Waste Pyrolysis Process with High Conversion Yield and Tar Elimination. Processes 2020, 8, 281. https://doi.org/10.3390/pr8030281

Aboughaly M, Gabbar HA, Damideh V, Hassen I. RF-ICP Thermal Plasma for Thermoplastic Waste Pyrolysis Process with High Conversion Yield and Tar Elimination. Processes. 2020; 8(3):281. https://doi.org/10.3390/pr8030281

Chicago/Turabian StyleAboughaly, Mohamed, Hossam A. Gabbar, Vahid Damideh, and Isaac Hassen. 2020. "RF-ICP Thermal Plasma for Thermoplastic Waste Pyrolysis Process with High Conversion Yield and Tar Elimination" Processes 8, no. 3: 281. https://doi.org/10.3390/pr8030281

APA StyleAboughaly, M., Gabbar, H. A., Damideh, V., & Hassen, I. (2020). RF-ICP Thermal Plasma for Thermoplastic Waste Pyrolysis Process with High Conversion Yield and Tar Elimination. Processes, 8(3), 281. https://doi.org/10.3390/pr8030281