Carbon Sequestration in Support of the “4 per 1000” Initiative Using Compost and Stable Biochar from Hazelnut Shells and Sunflower Husks

Abstract

1. Introduction

2. Materials and Methods

2.1. Feedstock

2.2. Experimental Set-Up

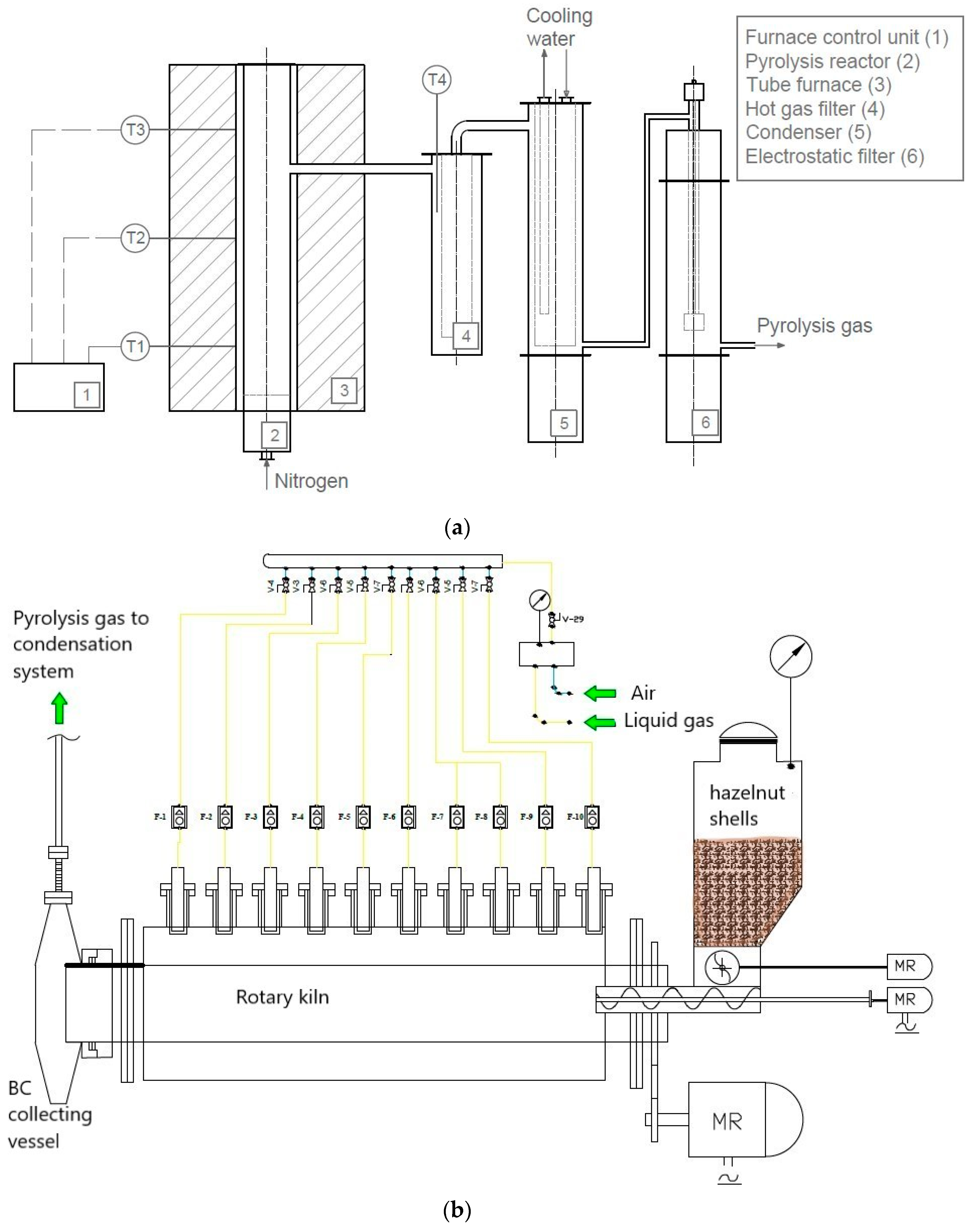

2.2.1. Fixed Bed Reactor

2.2.2. Rotary Kiln

2.2.3. Screw Reactor

2.2.4. Elemental Analysis of the Biochars

2.2.5. SOC as Carbon Sink in Austrian Soils

2.2.6. Data Analysis

3. Results

3.1. Process Comparisons in Different Reactors

3.2. Ultimate and Proximate Analyses of Biochars

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Smith, P. Soil carbon sequestration and biochar as negative emission technologies. Glob. Chang. Biol. 2016, 22, 1315–1324. [Google Scholar] [CrossRef] [PubMed]

- Agegnehu, G.; Srivastava, A.K.; Bird, M.I. The role of biochar and biochar-compost in improving soil quality and crop performance: A review. Appl. Soil Ecol. 2017, 119, 156–170. [Google Scholar] [CrossRef]

- Minasny, B.; Malone, B.P.; McBratney, A.B.; Angers, D.A.; Arrouays, D.; Chambers, A.; Chaplot, V.; Chen, Z.S.; Cheng, K.; Das, B.S.; et al. Soil carbon 4 per mille. Geoderma 2017, 292, 59–86. [Google Scholar] [CrossRef]

- Schwarzer, S. Putting Carbon Back Where it Belongs–The Potential of Carbon Sequestration in the Soil. Available online: https://wedocs.unep.org/bitstream/handle/20.500.11822/28453/Foresight013.pdf?sequence=1&isAllowed=y (accessed on 30 May 2020).

- Spanischberger, A.; Mitterböck, N. Boden und Klima: Einflussfaktoren, Daten, Maßnahmen und Anpassungsmöglichkeiten; Bundesministerium für Land- und Forstwirtschaft, Umwelt und Wasserwirtschaft: Vienna, Austria, 2015; Available online: http://docplayer.org/30997831-Boden-und-klima-einflussfaktoren-daten-massnahmen-und-anpassungs-moeglichkeiten.html (accessed on 30 May 2020).

- Müller, H.; Spatny, N.; Feichtinger, F.; Tulnik, R.; Strebl, H.; Humer, J.; Swoboda, M. Richtlinie für die Anwendung von Kompost aus Biogenen Abfällen in der Landwirtschaft; Fachbeirat für Bodenfruchtbarkeit und Bodenschutz beim Bundesministerium für Land- und Forstwirtschaft: Vienna, Austria, 2010; Available online: https://www.ages.at/download/0/0/6ed0e2214265d1f2986c4339e77d1ee14d3bf647/fileadmin/AGES2015/Service/Landwirtschaft/Boden_Datein/Broschueren/Kompost_2010.pdf (accessed on 30 May 2020).

- Wang, J.; Xiong, Z.; Kuzyakov, Y. Biochar stability in soil: Meta-analysis of decomposition and priming effects. GCB Bioenergy 2016, 8, 512–523. [Google Scholar] [CrossRef]

- Singh, B.P.; Cowie, A.L. Long-term influence of biochar on native organic carbon mineralisation in a low-carbon clayey soil. Sci. Rep. 2014, 4, 3687. [Google Scholar] [CrossRef] [PubMed]

- Ding, F.; Van Zwieten, L.; Zhang, W.; Weng, Z.; Shi, S.; Wang, J.; Meng, J. A meta-analysis and critical evaluation of influencing factors on soil carbon priming following biochar amendment. J. Soils Sediments 2018, 18, 1507–1517. [Google Scholar] [CrossRef]

- Foereid, B.; Lehmann, J.; Major, J. Modeling black carbon degradation and movement in soil. Plant Soil 2011, 345, 223–236. [Google Scholar] [CrossRef]

- Simmons, C.W.; Guo, H.Y.; Claypool, J.T.; Marshall, M.N.; Perano, K.M.; Stapleton, J.J.; VanderGheynst, J.S. Managing compost stability and amendment to soil to enhance soil heating during soil solarization. Waste Manag. 2013, 33, 1090–1096. [Google Scholar] [CrossRef][Green Version]

- Lim, S.S.; Lee, K.S.; Lee, S.I.; Lee, D.S.; Kwak, J.H.; Hao, X.; Ro, H.M.; Choi, W.J. Carbon mineralization and retention of livestock manure composts with different substrate qualities in three soils. J. Soils Sediments 2012, 12, 312–322. [Google Scholar] [CrossRef]

- Eghball, B. Soil Properties as Influenced by Phosphorus- and Nitrogen-Based Manure and Compost Applications. Agron. J. 2002, 94, 128–135. [Google Scholar] [CrossRef]

- Spokas, K. Review of the stability of biochar in soils: Predictability of O:C molar rations. Carbon Manag. 2010, 1, 289–303. [Google Scholar] [CrossRef]

- Seiler, G.J.; Gulya, T.J. The world of food grains—Sunflower hulls. In Encyclopedia of Food Grains, 2nd ed.; Academic Press: Waltham, MA, USA, 2016; pp. 247–253. [Google Scholar] [CrossRef]

- Milosevic, T.; Milosevic, N. Determination of size and shape features of hazelnuts using multivariate analysis. Acta Sci. Pol. Hortorum Cultus 2017, 16, 49–61. [Google Scholar] [CrossRef]

- Matos, J.; Nahas, C.; Rojas, L.; Rosales, M. Synthesis and characterization of activated carbon from sawdust of Algarroba wood. 1. Physical activation and pyrolysis. J. Hazard. Mater. 2011, 196, 360–369. [Google Scholar] [CrossRef]

- Leng, L.; Huang, H.; Li, H.; Li, J.; Zhou, W. Biochar stability assessment methods: A review. Sci. Total Environ. 2019, 647, 210–222. [Google Scholar] [CrossRef]

- EBC. Guidelines for a Sustainable Production of Biochar; European Biochar Foundation: Arbaz, Switzerland, 2012; pp. 1–36. Available online: http://www.european-biochar.org/biochar/media/doc/ebc-guidelines.pdf (accessed on 30 May 2020).

- Haslmayr, H.; Baumgarten, A.; Schwarz, M.; Huber, S.; Weiss, P.; Aust, G.; Englisch, M.; Horvath, D.; Jandl, R.; Leitgeb, E.; et al. ASOC—Österreichische Karte des Organischen Bodenkohlenstoffs; Bundesministerium für Nachhaltigkeit und Tourismus: Vienna, Austria, 2018; Available online: https://www.dafne.at/prod/dafne_plus_common/attachment_download/f9047e2694415b850dbe6eafc9b20109/ASOC_Endbericht.pdf (accessed on 30 May 2020).

- Weber, K.; Quicker, P. Properties of biochar. Fuel 2018, 217, 240–261. [Google Scholar] [CrossRef]

- Wei, S.; Zhu, M.; Fan, X.; Song, J.; Peng, P.; Li, K.; Jia, W.; Song, H. Influence of pyrolysis temperature and feedstock on carbon fractions of biochar produced from pyrolysis of rice straw, pine wood, pig manure and sewage sludge. Chemosphere 2019, 218, 624–631. [Google Scholar] [CrossRef]

- Liu, Z.X.; Niu, W.J.; Chu, H.Y.; Zhou, T.; Niu, Z.Y. Effect of the Carbonization Temperature on the Properties of Biochar Produced from the Pyrolysis of Crop Residues. BioResources 2018, 13, 3429–3446. [Google Scholar] [CrossRef]

- Wijitkosum, S.; Jiwnok, P. Elemental Composition of Biochar Obtained from Agricultural Waste for Soil Amendment and Carbon Sequestration. Appl. Sci. 2019, 9, 3980. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, S.; Ju, M.; Liu, L. Preparation and modification of biochar materials and their application in soil remediation. Appl. Sci. 2019, 9, 1365. [Google Scholar] [CrossRef]

- Dötzl, M.; Peyr, S. Agrarstrukturerhebung; Statistisches Bundesamt: Vienna, Austria, 2016; Available online: http://www.statistik.at/web_de/statistiken/wirtschaft/land_und_forstwirtschaft/agrarstruktur_flaechen_ertraege/betriebsstruktur/113147.html (accessed on 30 May 2020).

- BMLFUW. Agrarumweltprogramm ÖPUL 2015—Landwirtschaft und Natur; Bundesministerium für Landwirtschaft, Regionen und Tourismus: Vienna, Austria, 2016; Available online: https://www.bmnt.gv.at/service/publikationen/land/agrarumweltprogramm-oepul-2015.html (accessed on 30 May 2020).

- Sonnenerde. 2019. Available online: https://www.sonnenerde.at/de/produkt/bio-pflanzenkohle/ (accessed on 30 May 2020).

- Khater, E.S.G. Some Physical and Chemical Properties of Compost. Int. J. Waste Resour. 2015, 5, 1–5. [Google Scholar] [CrossRef]

- Shaaban, M.; Van Zwieten, L.; Bashir, S.; Younas, A.; Núñez-Delgado, A.; Chhajro, M.A.; Kubar, K.A.; Ali, U.; Rana, M.S.; Mehmood, M.A.; et al. A concise review of biochar application to agricultural soils to improve soil conditions and fight pollution. J. Environ. Manag. 2018, 228, 429–440. [Google Scholar] [CrossRef] [PubMed]

- Giagnoni, L.; Maienza, A.; Baronti, S.; Vaccari, F.P.; Genesio, L.; Taiti, C.; Martellini, T.; Scodellini, R.; Cincinelli, A.; Costa, C.; et al. Long-term soil biological fertility, volatile organic compounds and chemical properties in a vineyard soil after biochar amendment. Geoderma 2019, 344, 127–136. [Google Scholar] [CrossRef]

- Pandit, N.R.; Mulder, J.; Hale, S.E.; Zimmerman, A.R.; Pandit, B.H.; Cornelissen, G. Multi-year double cropping biochar field trials in Nepal: Finding the optimal biochar dose through agronomic trials and cost-benefit analysis. Sci. Total Environ. 2018, 637–638, 1333–1341. [Google Scholar] [CrossRef] [PubMed]

- Roobroeck, D.; Hood-Nowotny, R.; Nakubulwa, D.; Tumuhairwe, J.; Mwanjalolo, M.J.G.; Ndawula, I.; Vanlauwe, B. Biophysical potential of crop residues for biochar carbon sequestration, and co-benefits, in Uganda. Ecol. Appl. 2019, 29, e01984. [Google Scholar] [CrossRef]

| Input-Material | T in °C | C | H | N | S | O | Ash |

|---|---|---|---|---|---|---|---|

| HNS | 350 | 69.0 ± 0.2 | 4.88 ± 0.03 | 0.52 ± 0.03 | <1 | 23.4 ± 0.2 | 1.2 ± 0.1 |

| HNS | 400 | 76.6 ± 0.3 | 4.03 ± 0.02 | 0.43 ± 0.02 | <1 | 16.6 ± 0.2 | 1.3 ± 0.1 |

| HNS | 500 | 80.2 ± 3.0 | 3.55 ± 0.23 | 0.53 ± 0.02 | <1 | 13.2 ± 3.4 | 1.6 ± 0.6 |

| HNS | 600 | 81.5 ± 0.1 | 3.32 ± 0.03 | 0.52 ± 0.01 | <1 | 12.1 ± 0.1 | 1.6 ± 0.1 |

| SFH | 450 | 68.6 ± 0.6 | 2.6 ± 0.4 | 3.4 ± 0.4 | n.d. | 7.9 ± 5.9 | 17.4 ± 6.4 |

| SFH | 600 | 71.1 ± 0.6 | 2.3 ± 0.4 | 3.4 ± 0.1 | n.d. | 12.0 ± 0.1 | 11.1 ± 0.1 |

| T in °C | Fixed C | Volatiles |

|---|---|---|

| 350 | 45.4 ± 1.3 | 53.4 ± 1.3 |

| 400 | 63.4 ± 0.1 | 35.4 ± 0.1 |

| 500 | 70.3 ± 3.9 | 28.1 ± 4.5 |

| 600 | 73.5 ± 0.2 | 24.9 ± 0.3 |

| Land Use Form | Area in Mha | SOC Stock in t/ha (30 cm) | SOC Stock in Mt (30 cm) | ||

|---|---|---|---|---|---|

| agricultural area | 2.66 | 75.0 | 199.8 | ||

| permanent grassland | 1.26 | 72.6 | 91.4 | ||

| crops, vineyards and orchards | 1.40 | 69.1 | 97.1 | ||

| crops | 1.34 | 69.7 | 93.7 | ||

| vineyards and orchards | 0.06 | 56.7 | 3.5 | ||

| forestry area | 3.41 | 106.0 | 361.2 | ||

| unproductive area of holding | 1.18 | 50 *** | 59.1 | ||

| other (urban and sealed area, surface waters, Alpine regions, etc) | 1.13 * | 10 ** | 11.3 | ||

| Country area TOTAL | 8.38 | 75.3 | 631.4 | ||

| Required annual increase (for 4‰) | 2.53 | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mikula, K.; Soja, G.; Segura, C.; Berg, A.; Pfeifer, C. Carbon Sequestration in Support of the “4 per 1000” Initiative Using Compost and Stable Biochar from Hazelnut Shells and Sunflower Husks. Processes 2020, 8, 764. https://doi.org/10.3390/pr8070764

Mikula K, Soja G, Segura C, Berg A, Pfeifer C. Carbon Sequestration in Support of the “4 per 1000” Initiative Using Compost and Stable Biochar from Hazelnut Shells and Sunflower Husks. Processes. 2020; 8(7):764. https://doi.org/10.3390/pr8070764

Chicago/Turabian StyleMikula, Klaus, Gerhard Soja, Cristina Segura, Alex Berg, and Christoph Pfeifer. 2020. "Carbon Sequestration in Support of the “4 per 1000” Initiative Using Compost and Stable Biochar from Hazelnut Shells and Sunflower Husks" Processes 8, no. 7: 764. https://doi.org/10.3390/pr8070764

APA StyleMikula, K., Soja, G., Segura, C., Berg, A., & Pfeifer, C. (2020). Carbon Sequestration in Support of the “4 per 1000” Initiative Using Compost and Stable Biochar from Hazelnut Shells and Sunflower Husks. Processes, 8(7), 764. https://doi.org/10.3390/pr8070764