Abstract

The study aimed to enrich waffle products with grape seed flour, but without affecting their sensory properties. The grape seed flour was obtained from grape pomace, and as an ingredient rich in bioactive compounds such as fiber, polyphenols and minerals, it was used to fortify waffles in concentrations of 1, 3, 5 and 10%. The results for the total polyphenolic content, ferric ion reducing antioxidant power (FRAP) and 2,2-diphenyl-1-picryl-hydrazyl (DPPH) inhibition, showed the highest effect with 10% grape seed flour fortification, including 1.25 mg of gallic acid equivalent/g, 5.62 µmol Trolox/g and 26.65% DPPH inhibition, respectively. Texture analysis revealed an increase in hardness of the waffles along with the increase of grape seed flour percentage, while there was no evident change in moisture in any of the tested samples. Sensory evaluation showed no significant differences regarding overall impression or the estimated price value for all samples, even though evident changes were noted by the panelists in their color, consistency and sweetness. It may be concluded that fortification was successfully carried out, and that there is a great potential for utilizing grape seed flour as a by-product in the enrichment of products such as waffles.

1. Introduction

The food industry generates a large number of by-products rich in valuable substances which can be beneficial for further use, especially as ingredients in functional food. This is a popular trend nowadays, due to the positive impact on the environment, human health and economic viability of the production process. Consumers’ attitudes towards these foods are positive and thus the development of by-products enriched functional foods is constantly increasing [1].

Winemaking produces large amounts of grape pomace, a biological waste that consists of seeds, skins, stems and the remaining pulp [2]. It causes large environmental and economic issues if not properly utilized [3]. At present, attention is paid to waste-free technologies so that by-products can be used efficiently as ingredients for making functional foods [4,5]. There are several uses of grape pomace, among which we may find: livestock feed, composting or as a substrate in the production of seed oil and flour [6]. The last two are created after the separation of seeds from grape pomace, followed by cold pressing for obtaining the oil and milling the remaining residue to produce grape seed flour [7].

Grape seed flour exhibits a brown color and fruity smell. It contains a large amount of fiber, minerals and has high antioxidant capacity led by phenolic compounds such as phenolic acid, flavonoids, procyanidins and resveratrol [8].

Experiments conducted with the use of grape seed flour as the fortification ingredient have been the subject of many scientific studies. Successful applications include cookies [9,10], Turkish noodles [11], noodles, pancakes and cereal bars [12], butter biscuits [13], and bread [14]. The replacement of wheat flour by the grape flour, in those products, was conducted according to the product type. Bread was fortified up to 10% replacement, cookies up to 15%, butter biscuits up to 20% and Turkish noodles, noodles, pancakes and cereal bars up to 30% [9,10,11,12,13,14]. The most favorable concentration of grape flour was found to be 5% fortification, the study with butter biscuits fortification [13].

The aim of this work was the development of a novel functional food product: waffles enriched with various quantities of grape seed flour, a wine industry by-product, and to determine their impact on antioxidant activity, polyphenolic content, textural changes and sensory acceptability of the final product.

2. Materials and Methods

2.1. Preparation of Waffles

Grape seed flour, produced from ground grape seeds, has been obtained from the “Zdraví z přírody” company (Zlin, Czech Republic).

The waffles were prepared with different concentrations of grape flour. The control waffles were made from 300 g of wheat flour blend (semi-coarse wheat flour/plain wheat flour in the ratio 1:2), 350 mL of semi-skimmed milk, 75 g of powdered sugar, 100 g of plant-based butter for cooking (Hera; Upfield, Czech Republic), 1 egg yolk, 0.5 g of salt and 6 g of baking powder. The grape flour was added to the baking mixture in the amount of 1, 3, 5 and 10% based on wheat flour weight. Ingredients used for waffles preparation were mixed for 5 min by the food processor (Vorwerk Thermomix TM 31, Vorwerk & Co. Thermomix GmbH, Wuppertal, Germany) at increased speed level; subsequently, the dough was poured in the waffle maker (ETA SORENTO 3151/10, Hlinsko, Czech Republic) and cooked for about 15 min.

2.2. Measurement of Dry Matter

A homogenized sample was weighed and left to dry in the oven at 105 °C for 24 h, after which it was weighed again and calculated for dry matter in percentages.

2.3. Texture Assessment

Texture was assessed by measuring hardness and fracturability on the TA.XT.PLUS Texture Analyzer (Stable Micro Systems, Godalming, UK). The waffles were cut into quarters, and measurements carried out on several fragments of the sample. The samples were placed on the Circular Support Rig (A/CS) and a 5-mm puncture probe (SMS P/5) was used for penetration tests around the mid-region of the sample. The probe penetrated samples to the nearest 5 mm, pre-test and test speeds were adjusted at 1.5 mm/s while post-test speed was 10.0 mm/s.

2.4. Antioxidant Activity Assessment and Total Polyphenolic Content

Antioxidant activity was evaluated using the FRAP (Ferric reducing ability of plasma) and DPPH (2,2-diphenyl-1-picryl-hydrazyl) methods, and total polyphenolic content (TPC) was obtained using the Folin–Ciocalteu method for grape flour and waffle samples. The optical measurements in those methods were performed on a UV/VIS spectrophotometer CE7210 (Cecil Instruments, Cambridge, UK).

The FRAP method was implemented by the ultrasonic extraction of 0.1 g of the homogenized sample in 20 mL of 75% methanol, after which the 180 µL filtered extract with the addition of 300 µL of distilled water was incubated with 3.6 mL of working solution (acetate buffer + TPTZ + FeCl3 × 6H2O in ratio 10:1:1) for 8 min in the dark and then measured for absorbance at 593 nm on a spectrophotometer (CE7210, UK). The obtained results are expressed in µmol Trolox/g since Trolox was used for making the calibration curve [15].

In the DPPH method, ultrasonic extraction of 0.1 g of the homogenized sample in 20 mL of ethanol was performed. Furthermore, 3 mL of ethanol as a blank and, in parallel, 3 mL of the filtered extract were incubated with 1 mL of 0.1 mM DPPH ethanolic solution in the dark for 30 min. After incubation, the absorbance of both solutions was measured on a spectrophotometer at 517 nm, and the results were expressed as the percentage of inhibition (degree of color loss) for free radical DPPH with a sample against the blank [16].

The total polyphenols were obtained after extraction of 1 g of the sample in water during 10 min of shaking. Then, 1 mL of the filtered extract was mixed with 5 mL of 1:10 Folin–Ciocalteu/water solution as well as 4 mL Na2CO3 (75 g/L), and incubated in a 25-mL volumetric flask in the dark for 30 min. After incubation, the flask was filled to the designated mark and the solution was measured at 765 nm on a spectrophotometer. The results are expressed as mg/g of gallic acid equivalent (GAE) for the reason that gallic acid was used for obtaining the calibration curve [17]. The equation for calibration curve was: y = 3.6574x + 0.0363; R2 = 0.9986.

2.5. Assessment of Sensory Properties

The assessment of sensory properties was done by 15 trained panelists. The panelists were persons (20 to 55 years old) chosen from the University, with the successfully passed sensory evaluation exams and workshops. The samples were coded with 3 numbers. The Sensory Laboratory was equipped according to the standard ISO 8589:2008. The evaluated parameters concerned color, consistency, smell, taste, sweetness, overall impression and price which the panelists would be willing to pay for the product. All evaluations were carried out on the questionnaire by marking the scale from 1 to 100 for each parameter, with higher values meaning higher intensity.

2.6. Statistics

Mean values ± standard deviation are recorded in the tables. All measurements were performed in triplicate. The results of the analyses were statistically evaluated using the IBM SPSS Statistics computer program. Statistical significance at the level of p < 0.05 was evaluated by one-way ANOVA, the Tukey post-hoc parametric test (when Levene’s test showed equal variance, p > 0.05) and the Games–Howell post hoc nonparametric test (when Levene’s test showed unequal variance, p < 0.05) to find differences within groups. Overall differences among samples were checked by principal component analysis (PCA).

3. Results

3.1. Dry Matter and Texture

The dry matter and textural properties hardness and fracturability in experimentally produced waffle products with and without the addition of grape flour are shown in Table 1.

Table 1.

Dry Matter, Hardness and Fracturability in Control Samples and in Samples with Added Grape Flour.

The addition of grape seed flour only minimally affects the dry matter of the products because there is no regularity between the values (Table 1). This was also concluded in the work by Samohvalova [13], in which there were no evident changes in physicochemical properties (including moisture content) of biscuits with 10%, 15% and 20% of grape seed flour, and the control.

For the tested parameter of hardness (Table 1), none of the tested waffle samples showed significant (p < 0.05) differences. This was confirmed in the study by Haye and Ross [14] in which there were no observed statistically significant differences for the sensory evaluation of bread hardness with incorporated grape seed flour in percentages up to 10%.

The fracturability results (Table 1) indicate that the incorporation of grape seed flour up to 1% does not have significant (p > 0.05) influence on this parameter in waffles, while more than 1% caused significant (p < 0.05) changes in the same parameter.

Both tested textural parameters are mainly evaluated in baked products since these parameters are, in most cases, connected with product freshness, and it is advantageous if those parameters have lower values in the sense of better quality [9].

3.2. Antioxidant Activity Assessment and Total Polyphenolic Content

The results obtained for antioxidant profile, including measurements of FRAP, DPPH and total polyphenol content (TPC), are shown in Table 2.

Table 2.

Results Obtained for Control and Waffle Samples with Added Grape Flour: TPC, FRAP and DPPH.

The resulting value of total polyphenols content for the tested grape flour (5.58 mg GAE/g) (Table 2) is in line with the previous study by Lutterodt [7] for flours made from cold-pressed seeds of Muscadine and Concord cultivars. For those, the obtained values were 5.93 and 6.66 mg GAE/g, respectively. In the same study, the results of TPC for Ruby red and Chardonnay were 67.9 and 89.6 mg GAE/g, which indicates that the TPC content is highly dependent on the cultivar. In the study of Ros [18], the FRAP value for grape seed flour obtained from Merlot cultivar was 373.4 μmol Trolox/g of dry weight. The evidently higher value could be due to the variety of antioxidant properties among the seed flours obtained from different grape cultivars. Scavenging activity of grape seed extract was assessed in the work by Babbar [19], for which the measured value was 77% of the DPPH radical inhibition.

The obtained results for TPC, FRAP and DPPH of the produced waffles indicate that there were significant (p < 0.05) differences for tested parameters between all samples (Table 2). The values for TPC and FRAP increase from the lowest values for the control sample towards the sample with the highest concentration of added grape seed flour. DPPH value decreased for the sample with a 1% addition of grape seed flour in comparison to the control. Values of DPPH in the remaining tested samples increased gradually with the increment of percentages regarding the incorporated grape seed flour. A similar study was carried out by Haye and Ross [14], in which the obtained results for TPC in bread with 10% of incorporated grape seed flour were at least 20 times higher than in the control. Another study in which 5% of grape seed flour was incorporated into the biscuits was conducted by Aksoylu [20]. The result for TPC was more than two times higher than in the control sample, while DPPH antioxidant activity was more than 30 times higher in comparison to the control with radical inhibition activity of 43.87%. The reason for such a high increase is possibly due to higher TPC of the flour itself. In our study, the TPC value of the applied grape seed flour was 5.58 mg GAE/g, thus the lower increase of phenolic values in the tested waffles was expected. An analogous conclusion could be deducted for the measured activity using the DPPH assay.

3.3. Assessment of Sensory Properties

The values in Table 3 show the results of sensory evaluation of waffle samples, with the higher number indicating higher intensity of the parameter.

Table 3.

Sensory Grades of Control Samples and of Samples with the Addition of Grape Flour.

The color value increases gradually with the higher percentage of incorporated grape seed flour. This is in line with the reddish to brown color of the flour itself, and was confirmed by several studies in which the reported darker and more red color of biscuits, cookies and bread were compared to the controls [10,20,21,22].

The statistically significant (p < 0.05) differences for consistency parameter were obtained only with regard to the sample containing the highest grape seed flour addition. This sample was graded as firmer than all of the other evaluated samples.

Concerning sweetness, a significant (p < 0.05) reduction was obtained only for WG10. The sweetest marked sample was the control with a decreasing trend for increasing the percentage of grape seed flour. This can be attributed to the presence of some phenolic compounds which evoke the bitter taste associated with grape seed flour. Since the bitterness and sweetness suppress each other in the mixtures, this may be the reason for the observed decrease in sweetness during sensory evaluation [8,23].

Smell, taste, overall impression and price, did not yield any statistically significant (p < 0.05) differences between the studied samples. Smell and taste of 10, 15 and 20% of grape seed flour fortified butter biscuits was also not affected in the study by Samohvalova et al. [13]. On the other research conducted by Pečivová [24], the bread formulations containing 8% and 10% of grape seed flour showed statistically different lower sensory grades for taste and overall acceptance in comparison to the control sample. Evaluation of the price factor implies that panelists did not mark differences in the value regarding any of the tested samples. This means that each formulation could have positive acceptance among consumers.

Considering the obtained results of this study, the added grape seed flour had a beneficial effect on antioxidant capacity of the fortified product. The change in color and consistency did not negatively affect the overall impression, similarly to purchase willingness (estimated as the price of the product). It is important to find balance when adding grape seed flour to obtain a fortified product which will not negatively affect acceptance among the consumers. The sample with the 5% addition of grape seed flour can be declared as the best choice because of increased antioxidant activity and not significantly decreased sweetness as an important acceptance parameter in those kinds of products.

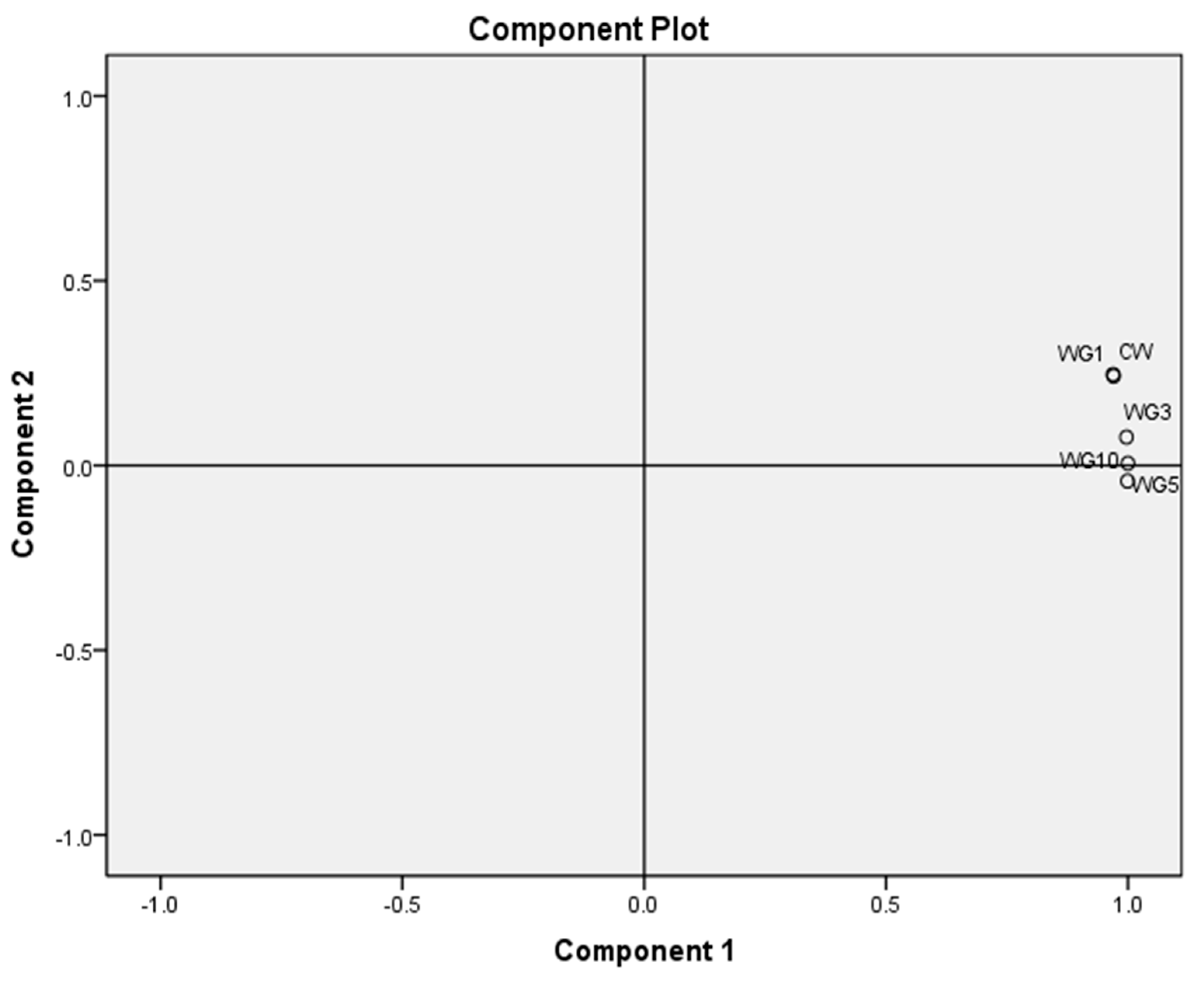

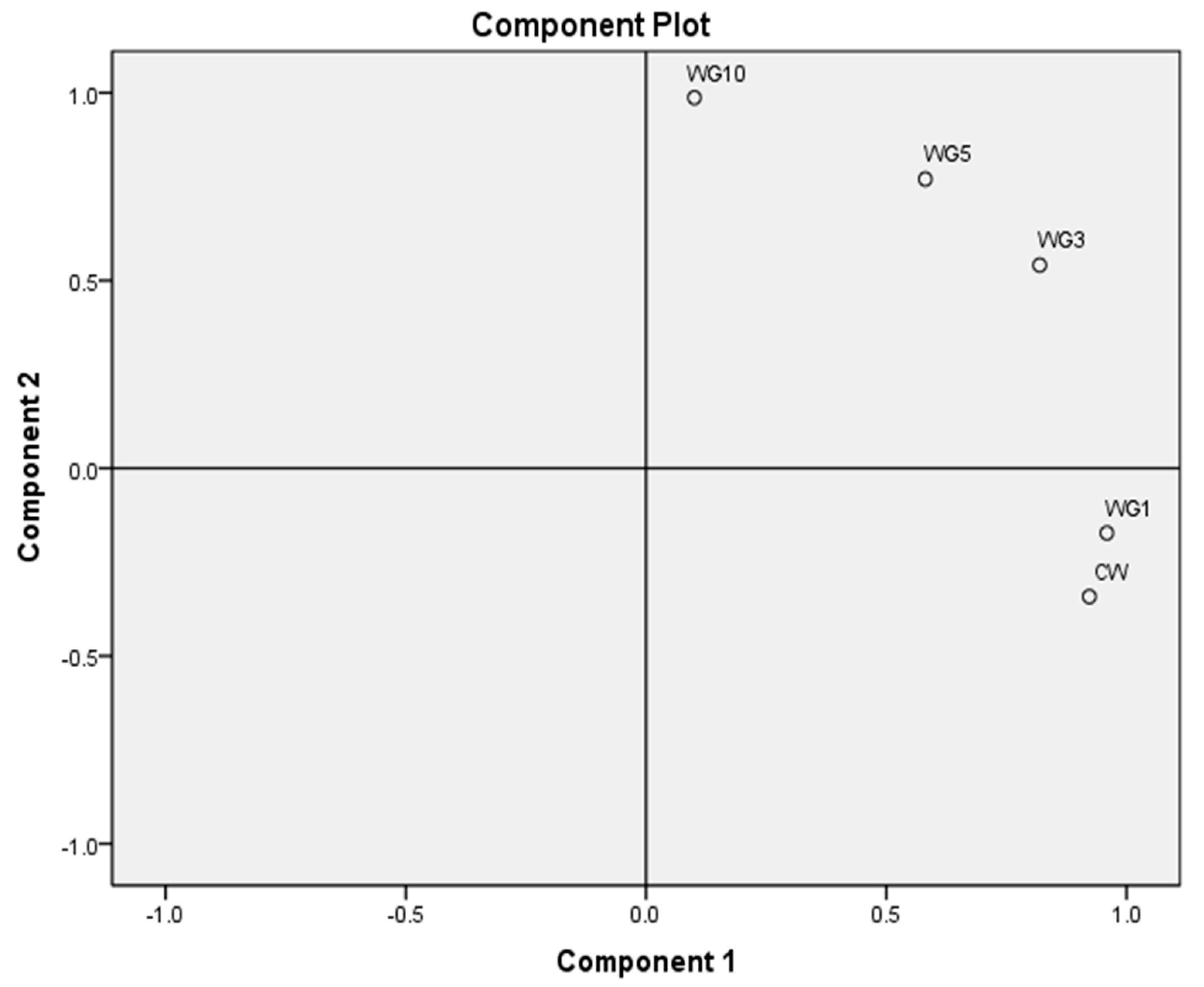

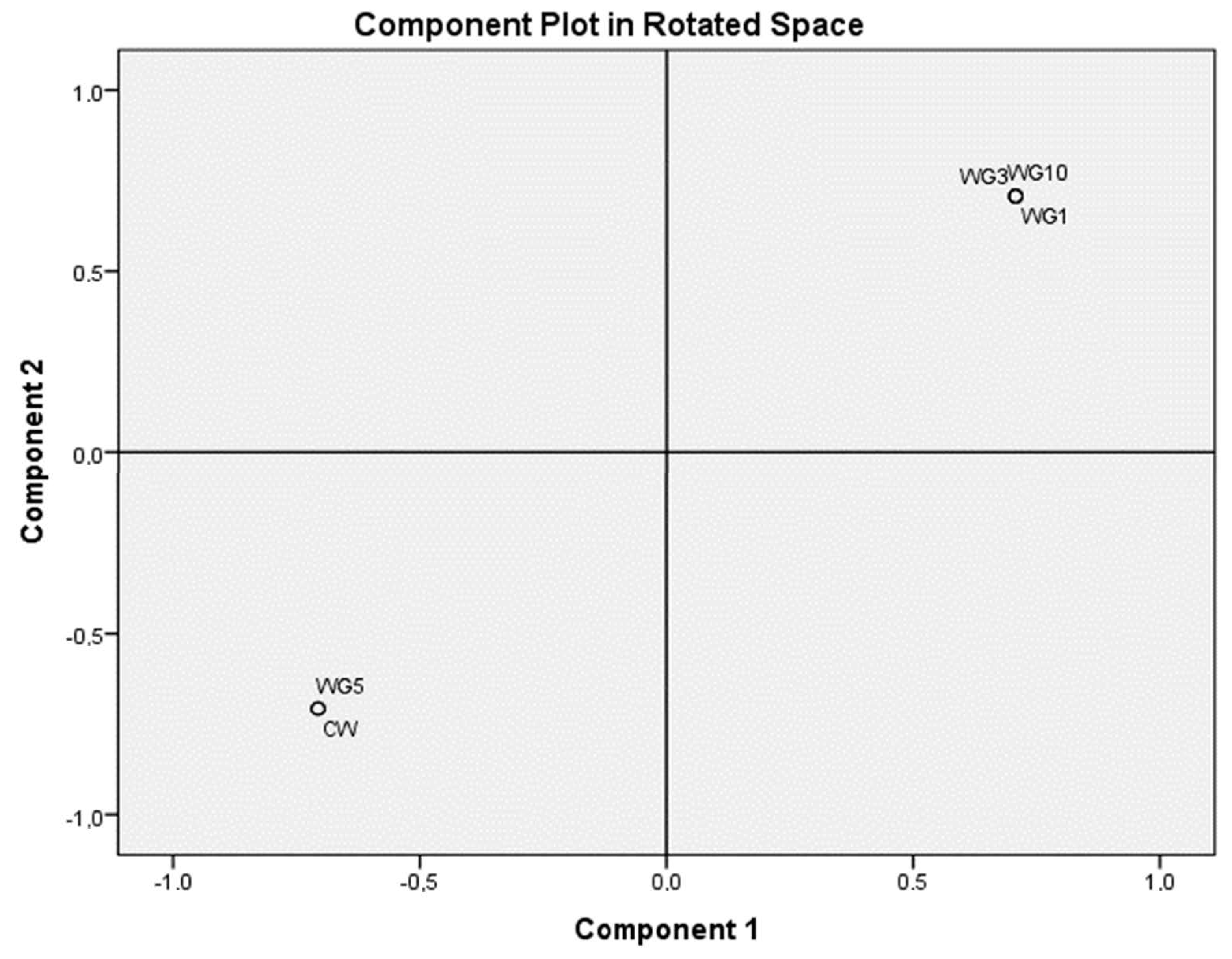

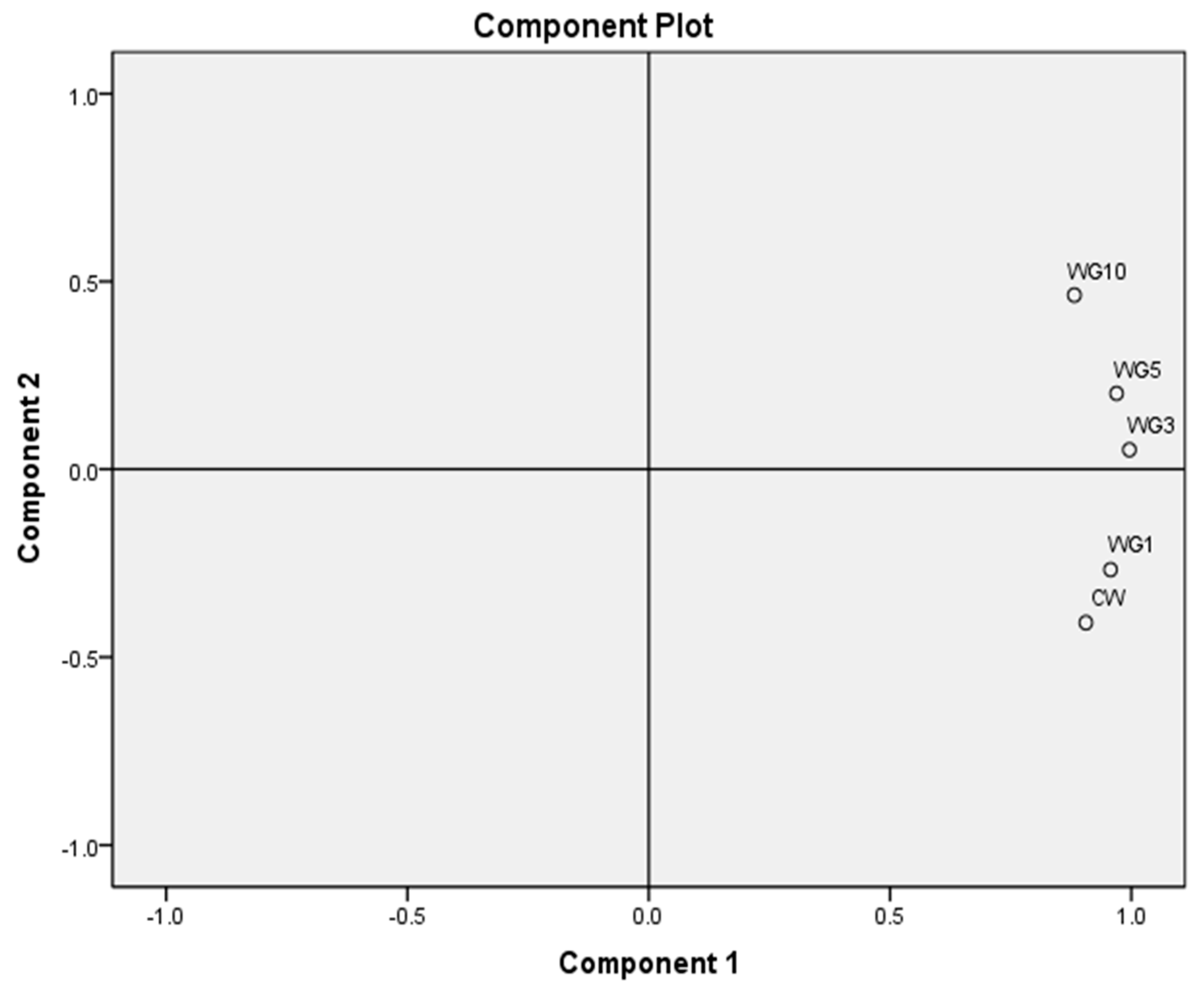

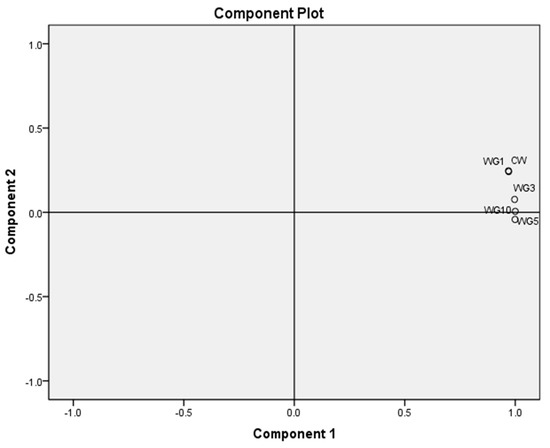

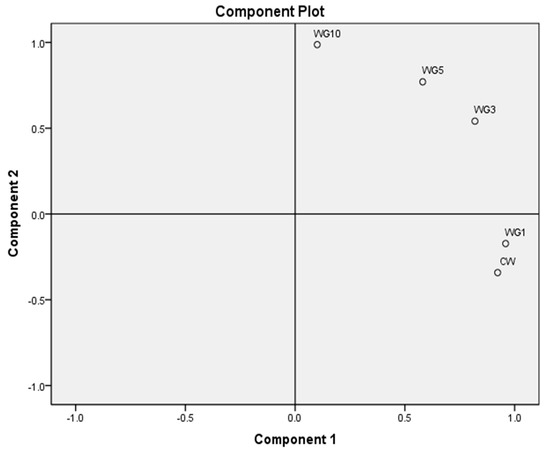

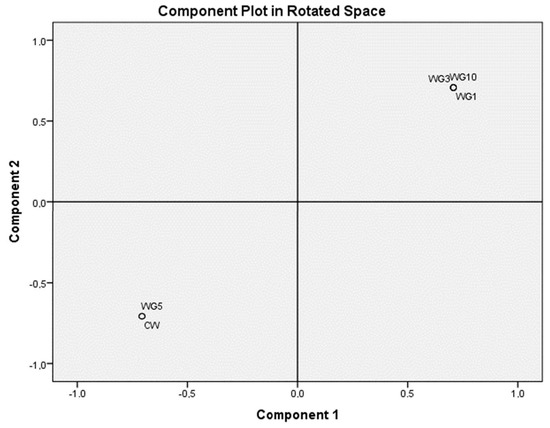

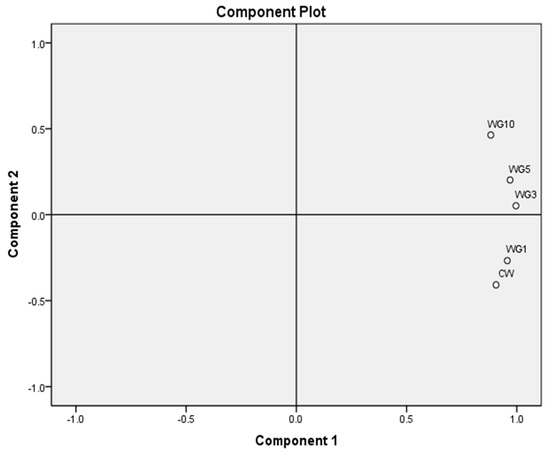

The results obtained for the experimentally produced waffles with different grape seed flour concentrations were compared with principal component analysis (PCA) (Figure 1, Figure 2, Figure 3 and Figure 4). PCA shows highly significant (p < 0.05) differences in sensory properties of the waffle samples. The closest sensory properties to the control sample (CW: without grape seed flour addition) were found in the sample with a 1% addition of grape seed flour (WG1), and the waffle sample with 10% of grape seed flour (WG10) had the most significantly (p < 0.05) different sensory properties in comparison to CW. The same findings were observed in PCA carried out for all measured parameters (chemical analysis, textural and sensory properties) of the waffle (Figure 4). Differences between waffle samples according to their textural parameters are presented in Figure 3. The gained results emphasized the greatest similarity between CW (control sample) and WG5 sample.

Figure 1.

Principal component analysis (PCA) of chemical parameters (TPC, FRAP and DPPH) in the waffle samples.

Figure 2.

Principal component analysis (PCA) of sensory properties in the waffle samples.

Figure 3.

Principal component analysis (PCA) of textural properties in the waffle samples.

Figure 4.

Principal component analysis (PCA) of all measured parameters (chemical, textural and sensory properties) in the waffle samples.

4. Conclusions

Based on the experiments conducted with grape seed flour and its incorporation in waffles, it may be concluded that its total phenolic content and antioxidant activity was successfully transferred to the final product. This is in line with other similar studies in which fortification of different products types was undertaken. The measured texture revealed some deviation in the sense of harder consistency of fortified products in comparison to the control, while the results for the dry matter showed no significant changes. The sensory evaluation emphasized differences between the samples in color, consistency and sweetness. However, these differences did not have an impact on the overall impression or price that the panelist would pay for evaluated samples. The incorporation of grape seed flour even at the concentration of 10% showed that the most notable changes in the physical properties of the final product could be acceptable for consumers. This indicates the great potential of grape seed flour utilization as a by-product in wine production and enriching waffles as a functional food.

Author Contributions

Conceptualization, B.A. and D.D.; methodology, D.H.; software, S.J.; validation, B.T., B.A., and D.D.; formal analysis, S.J.; investigation, B.A.; resources, B.T.; data curation, S.J.; writing—original draft preparation, B.A.; writing—review and editing, D.D. and P.K.; visualization, B.A.; supervision, B.T.; project administration, B.T.; funding acquisition, B.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by grant number FVHE/Tremlová/ITA2020.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Helkar, P.B.; Sahoo, A.K.; Patil, N.J. Review: Food industry by-products used as a functional food ingredients. Int. J. Waste Resour. 2016, 6, 1–6. [Google Scholar]

- Bender, A.B.B.; Speroni, C.S.; Moro, K.I.B.; Morisso, F.D.P.; dos Santos, D.R.; da Silva, L.P.; Penna, N.G. Effects of micronization on dietary fiber composition, physicochemical properties, phenolic compounds, and antioxidant capacity of grape pomace and its dietary fiber concentrate. LWT-Food Sci. Technol. 2020, 117, 108652. [Google Scholar] [CrossRef]

- Balbinoti, T.C.V.; Stafussa, A.P.; Haminiuk, C.W.I.; Maciel, G.M.; Sassaki, G.L.; de Matos Jorge, L.M.; Jorge, R.M.M. Addition of grape pomace in the hydration step of parboiling increases the antioxidant properties of rice. Inter. J. Food Sci. Technol. 2019, 55, 2370–2380. [Google Scholar] [CrossRef]

- Shi, J.; Nawaz, H.; Pohorly, J.; Mittal, G.; Kakuda, Y.; Jiang, Y. Extraction of polyphenolics from plant material for functional foods—Engineering and technology. Food Rev. Inter. 2005, 21, 139–166. [Google Scholar] [CrossRef]

- Gorodyska, O.; Grevtseva, N.; Samokhvalova, O.; Gubsky, S.; Gavrish, T.; Denisenko, S.; Grigorenko, A. Influence of grape seeds powder on preservation of fats in confectionary glaze. East.-Eur. J. Enterpr. Technol. 2018, 6, 36–43. [Google Scholar] [CrossRef][Green Version]

- Dwyer, K.; Hosseinian, F.; Rod, M.R. The market potential of grape waste alternatives. J. Food Res. 2014, 3, 91. [Google Scholar] [CrossRef]

- Lutterodt, H.; Slavin, M.; Whent, M.; Turner, E.; Yu, L.L. Fatty acid composition, oxidative stability, antioxidant and antiproliferative properties of selected cold-pressed grape seed oils and flours. Food Chem. 2011, 128, 391–399. [Google Scholar] [CrossRef]

- Yu, J.; Ahmedna, M. Functional components of grape pomace: Their composition, biological properties and potential applications. Inter. J. Food Sci. Technol. 2013, 48, 221–237. [Google Scholar] [CrossRef]

- Kuchtová, V.; Kohajdová, Z.; Karovičová, J.; Lauková, M. Physical, textural and sensory properties of cookies incorporated with grape skin and seed preparations. Pol. J. Food Nutr. Sci. 2018, 68, 309–317. [Google Scholar]

- Acun, S.; Gül, H. Effects of grape pomace and grape seed flours on cookie quality. Qual. Assur. Saf. Crops Foods 2014, 6, 81–88. [Google Scholar] [CrossRef]

- Koca, I.; Tekguler, B.; Yilmaz, V.A.; Hasbay, I.; Koca, A.F. The use of grape, pomegranate and rosehip seed flours in Turkish noodle (erişte) production. J. Food Process. Pres. 2018, 42, e13343. [Google Scholar] [CrossRef]

- Rosales Soto, M.U.; Brown, K.; Ross, C.F. Antioxidant activity and consumer acceptance of grape seed flour-containing food products. Inter. J. Food Sci. Technol. 2012, 47, 592–602. [Google Scholar] [CrossRef]

- Samohvalova, O.; Grevtseva, N.; Brykova, T.; Grigorenko, A. The effect of grape seed powder on the quality of butter biscuits. East.-Eur. J. Enterpr. Technol. 2016, 3, 61–66. [Google Scholar] [CrossRef][Green Version]

- Hoye, C., Jr.; Ross, C.F. Total phenolic content, consumer acceptance, and instrumental analysis of bread made with grape seed flour. J. Food Sci. 2011, 76, 428–436. [Google Scholar] [CrossRef] [PubMed]

- Behbahani, B.A.; Shahidi, F.; Yazdi, F.T.; Mortazavi, S.A.; Mohebbi, M. Use of Plantago major seed mucilage as a novel edible coating incorporated with Anethum graveolens essential oil on shelf life extension of beef in refrigerated storage. Int. J. Biol. Macromol. 2017, 94, 515–526. [Google Scholar] [CrossRef]

- Sivarooban, T.; Hettiarachchy, N.S.; Johnson, M.G. Physical and antimicrobial properties of grape seed extract, nisin, and EDTA incorporated soy protein edible films. Food Res. Int. 2008, 41, 781–785. [Google Scholar] [CrossRef]

- Tomadoni, B.; Cassani, L.; Ponce, A.; Moreira, M.D.R.; Agüero, M.V. Optimization of ultrasound, vanillin and pomegranate extract treatment for shelf-stable unpasteurized strawberry juice. LWT-Food Sci. Technol. 2016, 72, 475–484. [Google Scholar] [CrossRef]

- Ross, C.F.; Hoye, C., Jr.; Fernandez-Plotka, V.C. Influence of heating on the polyphenolic content and antioxidant activity of grape seed flour. J. Food Sci. 2011, 76, 884–890. [Google Scholar] [CrossRef]

- Babbar, N.; Oberoi, H.S.; Uppal, D.S.; Patil, R.T. Total phenolic content and antioxidant capacity of extracts obtained from six important fruit residues. Food Res. Int. 2011, 44, 391–396. [Google Scholar] [CrossRef]

- Aksoylu, Z.; Çağindi, Ö.; Köse, E. Effects of blueberry, grape seed powder and poppy seed incorporation on physicochemical and sensory properties of biscuit. J. Food Qual. 2015, 38, 164–174. [Google Scholar] [CrossRef]

- Davidov-Pardo, G.; Moreno, M.; Arozarena, I.; Marín-Arroyo, M.R.; Bleibaum, R.N.; Bruhn, C.M. Sensory and consumer perception of the addition of grape seed extracts in cookies. J. Food Sci. 2012, 77, 430–438. [Google Scholar] [CrossRef] [PubMed]

- Meral, R.; Doğan, İ.S. Grape seed as a functional food ingredient in bread-making. Int. J. Food Sci. Nutr. 2013, 64, 372–379. [Google Scholar] [CrossRef] [PubMed]

- Lesschaeve, I.; Noble, A.C. Polyphenols: Factors influencing their sensory properties and their effects on food and beverage preferences. Am. J. Clin. Nutr. 2005, 81, 330S–335S. [Google Scholar] [CrossRef] [PubMed]

- Pečivová, P.B.; Kráčmar, S.; Kubáň, V.; Mlček, J.; Jurikova, T.; Sochor, J. Effect of addition of grape seed flour on chemical, textural and sensory properties of bread. Mitteilungen Kloster. 2014, 64, 114–119. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).