Effective Analysis of Different Gas Diffusers on Bubble Hydrodynamics in Bubble Column and Airlift Reactors towards Mass Transfer Enhancement

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Set-Up

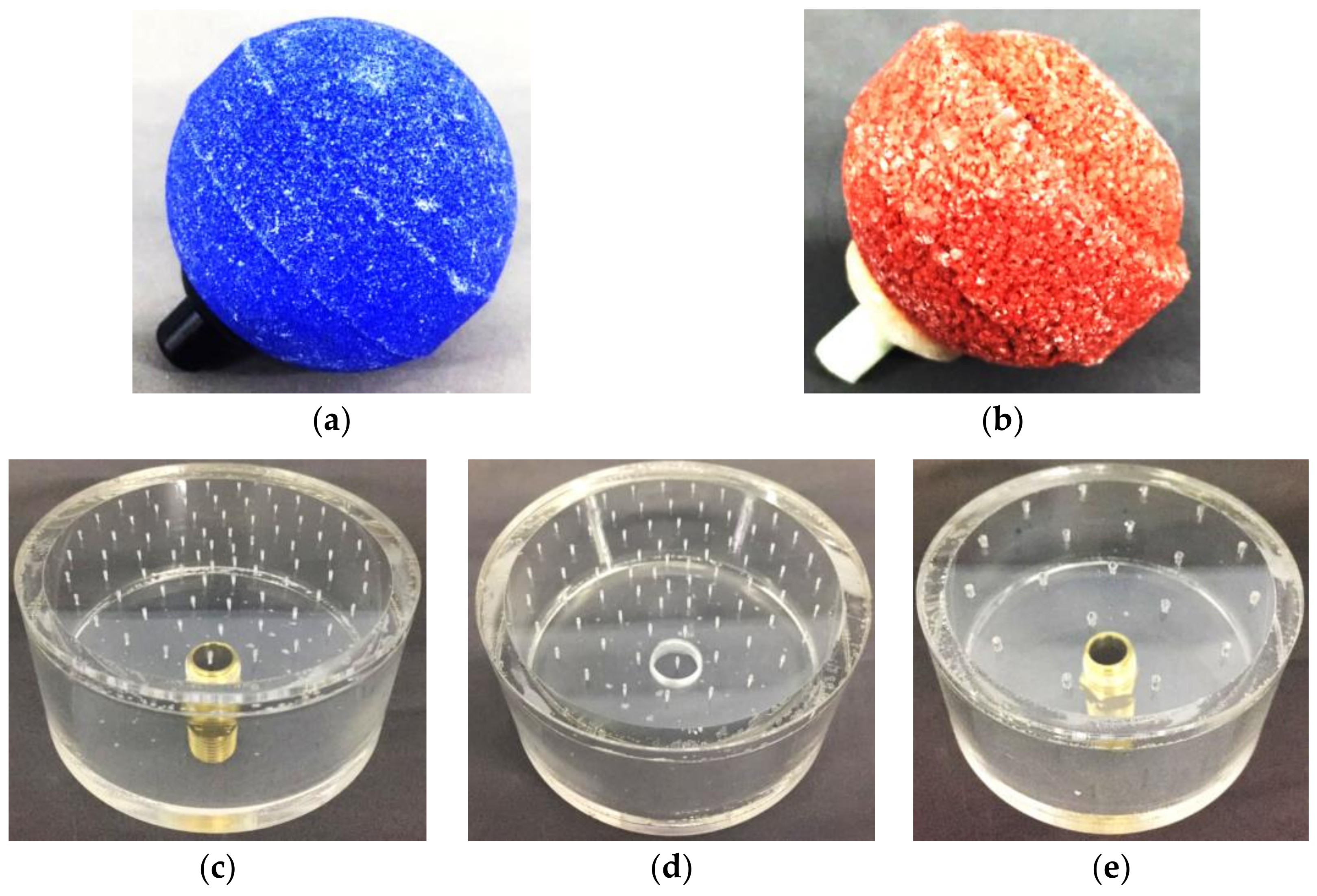

2.2. Gas Diffusers

2.3. Solid Media

2.4. Bubble Hydrodynamics Analysis

2.4.1. Bubble Size and Rising Velocity

2.4.2. Specific Interfacial Area (a) and Gas Hold-Up

2.5. Mass Transfer Coefficient (KLa) and Power Consumption Estimation

2.6. Residence Time Distribution (RTD) Technique

3. Results and Discussion

3.1. Bubble Diameter (D32) and Rising Velocity (UB)

3.2. Specific Interfacial Area (a) and Gas Hold-Up (εg)

3.3. Mass Transfer Coefficient (KLa)

3.4. Power Consumption

3.5. Effect of Plastic Media Addition Using Optimum Diffusers

3.5.1. Mass Transfer Coefficient

3.5.2. Gas Hold-Up

3.5.3. Liquid Flow Pattern

4. Conclusions

- Smaller bubbles were observed from the smaller orifice size diffusers, regardless of BCR or ALR. In both reactors, bubble size distributed between 3.14 and 11.28 mm of the Vg range studied. F-sand, the smallest orifice diffuser, illustrated the significantly smallest air bubble compared to other diffusers, followed by C-sand. Bubble sizes produced/maintained by F-sand in BCR and ALR were 3.14–4.90 mm and 3.27–4.55 mm, respectively. These bubble size results achieved are smaller than that of C-sand by about 22–28% on average. Moreover, ALR showed an ability to maintain smaller bubbles in the riser than BCR by about 3–8% at Vg ≥ 0.29 cm/s.

- In terms of bubble rising velocity, it ranges between 2.22 to 7.18 dm/s in both reactors, studied Vg range, and air diffusers. F-sand followed by the C-sand diffuser showed the slowest rising velocity due to a smaller bubble size and recirculated smaller bubbles between riser and downcomer compartments in ALR. F-sand and C-sand in ALR orderly provided the rising velocity 1.60–2.58 dm/s and 2.33–3.95 dm/s, which are slower than that in BCR by about 39–54% and 12–36%, respectively. Consequently, bubble interfacial area and gas hold-up were also analyzed and the results clearly showed that higher interfacial area and gas hold-up values were achieved from the use of F-sand diffusers, followed by C-sand type.

- KLa coefficient ranged from 4.68 to 63.00 hr−1 of BCR and 3.89 to 69.12 hr−1 of ALR was obtained in this study condition. F-sand and C-sand exhibited a higher KLa value over other diffuser types. Up to 270% higher KLa coefficient in both reactors can be obtained from F-sand and C-sand compared to others. These significant outcomes can be explained through their better bubble hydrodynamics. Plus 10% higher KLa value in ALR using F-sand over C-sand can be demosntrated. Additionally, the power consumption from the use of F-sand is also higher than C-sand at low Vg (≤0.59 cm/s). It means that if the same power per unit volume is provided to F-sand and C-sand, a comparable value of the KLa coefficient will be acquired. However, a better KLa coefficient will be achieved from F-sand over C-sand even the same power consumption is supplied under the higher Vg (>0.59 cm/s).

- F-sand and C-sand were considered as the optimum diffusers for enhancing oxygen transfer, their performance with additional plastic media were evaluated. The result showed that 10% solid loading, whichever was found as the optimum one in our previous work [5], was also found as the optimum condition for F-sand and C-sand in both reactors. A remarkable KLa value improvement from 8% to 39% was come by adding plastic media. Their gas hold-up and liquid pattern behaviors without and with solid media addition were also analyzed.

- Lastly, the flow pattern inside the column had a significant effect on the mass transfer in the column. With the increase in mixed flow inside the column, the KLa was enhanced. The geometry of ALR had a better performance in promoting the mixed flow regime than the BCR due to the separation between riser and downcomer zone. The addition of solid also promoted the mixed flow regime due to the movement of the solid inside the column.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| a | Specific interfacial area | [m−1] |

| C | Concentration | [g m−1] |

| DB | Bubble diameter | [m] |

| D32 | Sauter mean bubble diameter | [m] |

| H | Height | [m] |

| KLa | Volumetric oxygen mass transfer coefficient | [s−1] |

| KL | Liquid side mass transfer coefficient | [m s−1] |

| NTank | Number of tanks | [#] |

| P | Power | [W] |

| Q | Flow rate | [m3 s−1] |

| Qw | Liquid or water flow rate | [m3 s−1] |

| t | Time | [s] |

| tm | Mean residence time | [s] |

| ttheo | Theoretical residence time | [s] |

| UB | Terminal rising velocity | [m s−1] |

| V | Volume | [m3] |

| Vg | Superficial gas velocity | [m s−1] |

| ε | Gas hold-up | [-] |

| σ2 | Variance | [s2] |

| ΔPTotal | Total pressure drop | [Pa] |

| B | Air bubble |

| g | Gas phase |

| w | Water or liquid phase |

| S | Solid phase |

| * | Equilibrium state |

References

- Jakobsen, H.A.; Lindborg, H.; Dorao, C.A. Modeling of Bubble Column Reactors: Progress and Limitations. Ind. Eng. Chem. Res. 2005, 44, 5107–5151. [Google Scholar] [CrossRef]

- Cachaza, E.M.; Díaz, M.E.; Montes, F.J.; Galán, M.A. Simultaneous Computational Fluid Dynamics (CFD) Simulation of the Hydrodynamics and Mass Transfer in a Partially Aerated Bubble Column. Ind. Eng. Chem. Res. 2009, 48, 8685–8696. [Google Scholar] [CrossRef]

- Chisti, M.; Moo-Young, M. Airlift reactors: Characteristics, applications and design considerations. Chem. Eng. Commun. 1987, 60, 195–242. [Google Scholar] [CrossRef]

- Wongwailikhit, K.; Warunyuwong, P.; Chawaloesphonsiya, N.; Dietrich, N.; Hébrard, G.; Painmanakul, P. Gas Sparger Orifice Sizes and Solid Particle Characteristics in a Bubble Column—Relative Effect on Hydrodynamics and Mass Transfer. Chem. Eng. Technol. 2017, 41, 461–468. [Google Scholar] [CrossRef]

- Bun, S.; Chawaloesphonsiya, N.; Ham, P.; Wongwailikhit, K.; Chaiwiwatworakul, P.; Painmanakul, P. Experimental and empirical investigation of mass transfer enhancement in multi-scale modified airlift reactors. Multiscale Multidiscip. Model. Exp. Des. 2019, 3, 89–101. [Google Scholar] [CrossRef]

- Bun, S.; Chawaloesphonsiya, N.; Nakajima, F.; Tobino, T.; Painmanakul, P. Comparative study of local gas-liquid hydrody-namics and mass transfer between conventional and modified airlift reactors. J. Environ. Chem. Eng. 2019, 7, 103206. [Google Scholar] [CrossRef]

- Nikakhtari, H.; Hill, G.A. Enhanced oxygen mass transfer in an external loop airlift bioreactor using a packed bed. Ind. Eng. Chem. Res. 2005, 44, 1067–1072. [Google Scholar] [CrossRef]

- Chisti, Y.; Jauregui-Haza, U.J. Oxygen transfer and mixing in mechanically agitated airlift bioreactors. Biochem. Eng. J. 2002, 10, 143–153. [Google Scholar] [CrossRef] [Green Version]

- Zheng, Z.; Chen, Y.; Zhan, X.; Gao, M.; Wang, Z. Mass transfer intensification in a novel airlift reactor assembly with helical sieve plates. Chem. Eng. J. 2018, 342, 61–70. [Google Scholar] [CrossRef]

- Sastaravet, P.; Bun, S.; Wongwailikhit, K.; Chawaloesphonsiya, N.; Fujii, M.; Painmanakul, P. Relative Effect of Additional Solid Media on Bubble Hydrodynamics in Bubble Column and Airlift Reactors towards Mass Transfer Enhancement. Processes 2020, 8, 713. [Google Scholar] [CrossRef]

- Kulkarni, A.V.; Joshi, J.B. Design and selection of sparger for bubble column reactor. Part I: Performance of different spargers. Chem. Eng. Res. Des. 2011, 89, 1972–1985. [Google Scholar] [CrossRef]

- Gouveia, E.; Hokka, C.; Badino-Jr, A. The effects of geometry and operational conditions on gas holdup, liquid circulation and mass transfer in an airlift reactor. Braz. J. Chem. Eng. 2003, 20, 363–374. [Google Scholar] [CrossRef]

- Sastaravet, P.; Chuenchaem, C.; Thaphet, N.; Chawaloesphonsiya, N.; Painmanakul, P. Comparative Study of Mass Transfer and Bubble Hydrodynamic Parameters in Bubble Column Reactor: Physical Configurations and Operating Conditions. Environ. Eng. Res. 2014, 19, 345–354. [Google Scholar] [CrossRef]

- Kanaris, A.G.; Pavlidis, T.I.; Chatzidafni, A.P.; Mouza, A.A. The Effects of the Properties of Gases on the Design of Bubble Columns Equipped with a Fine Pore Sparger. ChemEngineering 2018, 2, 11. [Google Scholar] [CrossRef]

- Zhang, X.; Guo, K.; Qi, W.; Zhang, T.; Liu, C. Gas holdup, bubble behaviour, and mass transfer characteristics in a two-stage internal loop airlift reactor with different screens. Can. J. Chem. Eng. 2017, 95, 1202–1212. [Google Scholar] [CrossRef]

- Jia, X.; Hu, W.; Yuan, X.; Yu, K. Effect of surfactant type on interfacial area and liquid mass transfer for CO2 absorption in a bubble column. Chin. J. Chem. Eng. 2015, 23, 476–481. [Google Scholar] [CrossRef]

- Kracht, W.; Gomez, C.; Finch, J. Controlling bubble size using a frit and sleeve sparger. Miner. Eng. 2008, 21, 660–663. [Google Scholar] [CrossRef]

- Painmanakul, P.; Loubiere, K.; Hébrard, G.; Mietton-Peuchot, M.; Roustan, M. Effect of surfactants on liquid-side mass transfer coefficients. Chem. Eng. Sci. 2005, 60, 6480–6491. [Google Scholar] [CrossRef] [Green Version]

- Painmanakul, P.; Hébrard, G. Effect of different contaminants on the α-factor: Local experimental method and modeling. Chem. Eng. Res. Des. 2008, 86, 1207–1215. [Google Scholar] [CrossRef]

- Painmanakul, P.; Loubiere, K.; Hebrard, G.; Buffiere, P. Study of different membrane spargers used in waste water treatment: Characterisation and performance. Chem. Eng. Process. Process. Intensif. 2004, 43, 1347–1359. [Google Scholar] [CrossRef] [Green Version]

- Hebrard, G.; Zeng, J.; Loubiere, K. Effect of surfactants on liquid side mass transfer coefficients: A new insight. Chem. Eng. J. 2009, 148, 132–138. [Google Scholar] [CrossRef] [Green Version]

- Christi, M.Y. Airlift Bioreactors: Experimental Techniques of Investigation Into Bioreactors; Elsevier Applied Science: London, UK, 1989. [Google Scholar]

- He, Z.; Petiraksakul, A.; Meesapya, W. Oxygen-Transfer measurement in clean water. J. KMITNB 2003, 13, 14–19. [Google Scholar]

- Bouaifi, M.; Hebrard, G.; Bastoul, D.; Roustan, M. A comparative study of gas hold-up, bubble size, interfacial area and mass transfer coefficients in stirred gas–liquid reactors and bubble columns. Chem. Eng. Process. Process. Intensif. 2001, 40, 97–111. [Google Scholar] [CrossRef]

- Fogler, H.S. Elements of Chemical Reaction Engineering, 4th ed.; Pearson Education: London, UK, 2006. [Google Scholar]

- Levenspiel, O. Chemical Reaction Engineering; John Wiley & Sons: Hoboken, NJ, USA, 1998. [Google Scholar]

- Li, X.; Li, G.; Segovia-Hernandez, J.G. Modeling and Simulation of Hydrodynamic Bubble-Liquid Turbulent Flows in Bubble-Column Reactors. Chem. Eng. Technol. 2016, 39, 2380–2388. [Google Scholar] [CrossRef]

- Kalaga, D.V.; Pant, H.J.; Dalvi, S.V.; Joshi, J.B.; Roy, S. Investigation of hydrodynamics in bubble column with internals using radioactive particle tracking (RPT). AIChE J. 2017, 63, 4881–4894. [Google Scholar] [CrossRef]

- Al Ba’Ba’A, H.B.; Amano, R.S. A study of optimum aeration efficiency of a lab-scale air-diffused system. Water Environ. J. 2017, 31, 432–439. [Google Scholar] [CrossRef]

- Albdiri, A.D.Z.; Ojha, A.; Al-Dahhan, M.; Zmat, A.D. Study of Local Gas Holdup and Specific Interfacial Area in a Split-Column Airlift Bioreactor Using Sphosticated 4-Point Optical Probe for Culturing Microlgae/Cyanobacteria. Chem. Eng. Commun. 2014, 202, 892–898. [Google Scholar] [CrossRef]

- Yang, T.; Geng, S.; Yang, C.; Huang, Q. Hydrodynamics and mass transfer in an internal airlift slurry reactor for process intensification. Chem. Eng. Sci. 2018, 184, 126–133. [Google Scholar] [CrossRef]

- Bun, S.; Wongwailikhit, K.; Chawaloesphonsiya, N.; Lohwacharin, J.; Ham, P.; Painmanakul, P. Development of modified airlift reactor (MALR) for improving oxygen transfer: Optimize design and operation condition using ‘design of experiment’ methodology. Environ. Technol. 2019, 41, 2670–2682. [Google Scholar] [CrossRef]

- Yunos, M.A.S.M.; Halim, N.K.A.; Hussain, S.A. Investigations of bubble size, gas hold-up, and bubble rise velocity in quad-rilateral bubble column using high-speed camera. Am. J. Eng. Technol. Soc. 2017, 4, 1–18. [Google Scholar]

| Parameter | F-Sand | C-Sand | H-0.3 | H-0.6 | H-1.2 |

|---|---|---|---|---|---|

| Number of orifices (#) | - | - | 75 | 75 | 19 |

| Orifice diameter (mm) | 0.08–0.15 | 0.20–0.25 | 0.3 | 0.6 | 1.2 |

| Active surface area (cm2) | 39 | 39 | 39 | 39 | 39 |

| Pitch area (mm2) | - | - | 5.3 | 21.2 | 21.5 |

| Reactor | Media [v/v, %] | Vg [cm/s] | Mean Time, tm [min] * | Compartment Model ** | Tank-in-Series NTank [-] | ||

|---|---|---|---|---|---|---|---|

| Mixed Flow [%] | Plug Flow [%] | Dead Volume [%] | |||||

| BCR | 0 | 0.0 | 6.10 | 78.88 | 4.33 | 16.79 | 1.77 |

| 0.3 | 6.33 | 82.69 | 3.67 | 13.63 | 1.80 | ||

| 0.6 | 6.46 | 84.96 | 3.17 | 11.87 | 1.77 | ||

| 1.2 | 6.63 | 87.64 | 2.71 | 9.64 | 1.71 | ||

| ALR | 0 | 0.0 | 6.22 | 78.85 | 6.03 | 15.12 | 1.59 |

| 0.3 | 6.96 | 89.65 | 5.22 | 5.12 | 1.69 | ||

| 0.6 | 7.00 | 90.96 | 4.54 | 4.49 | 1.67 | ||

| 1.2 | 7.18 | 95.53 | 2.40 | 2.07 | 1.53 | ||

| BCR | 10 | 0.0 | 6.92 | 90.38 | 3.96 | 5.65 | 1.56 |

| 0.3 | 7.06 | 92.75 | 3.51 | 3.73 | 1.60 | ||

| 0.6 | 7.11 | 93.69 | 3.30 | 3.00 | 1.49 | ||

| 1.2 | 7.22 | 95.43 | 3.01 | 1.55 | 1.52 | ||

| ALR | 10 | 0.0 | 6.83 | 84.95 | 8.20 | 6.84 | 1.45 |

| 0.3 | 7.10 | 92.47 | 4.36 | 3.16 | 1.63 | ||

| 0.6 | 7.19 | 94.16 | 3.92 | 1.91 | 1.59 | ||

| 1.2 | 7.31 | 96.13 | 3.49 | 0.38 | 1.50 | ||

| BCR | 5 | 0.6 | 7.00 | 91.12 | 4.39 | 4.48 | 1.70 |

| 15 | 0.6 | 7.11 | 93.69 | 3.30 | 3.00 | 1.49 | |

| 25 | 0.6 | 7.02 | 92.47 | 3.21 | 4.32 | 1.62 | |

| ALR | 5 | 0.6 | 7.15 | 93.58 | 3.85 | 2.56 | 1.54 |

| 15 | 0.6 | 7.19 | 94.16 | 3.92 | 1.91 | 1.59 | |

| 25 | 0.6 | 7.04 | 92.02 | 3.93 | 4.04 | 1.57 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ham, P.; Bun, S.; Painmanakul, P.; Wongwailikhit, K. Effective Analysis of Different Gas Diffusers on Bubble Hydrodynamics in Bubble Column and Airlift Reactors towards Mass Transfer Enhancement. Processes 2021, 9, 1765. https://doi.org/10.3390/pr9101765

Ham P, Bun S, Painmanakul P, Wongwailikhit K. Effective Analysis of Different Gas Diffusers on Bubble Hydrodynamics in Bubble Column and Airlift Reactors towards Mass Transfer Enhancement. Processes. 2021; 9(10):1765. https://doi.org/10.3390/pr9101765

Chicago/Turabian StyleHam, Phaly, Saret Bun, Pisut Painmanakul, and Kritchart Wongwailikhit. 2021. "Effective Analysis of Different Gas Diffusers on Bubble Hydrodynamics in Bubble Column and Airlift Reactors towards Mass Transfer Enhancement" Processes 9, no. 10: 1765. https://doi.org/10.3390/pr9101765

APA StyleHam, P., Bun, S., Painmanakul, P., & Wongwailikhit, K. (2021). Effective Analysis of Different Gas Diffusers on Bubble Hydrodynamics in Bubble Column and Airlift Reactors towards Mass Transfer Enhancement. Processes, 9(10), 1765. https://doi.org/10.3390/pr9101765