Extraction Methods of Oils and Phytochemicals from Seeds and Their Environmental and Economic Impacts

Abstract

:1. Introduction

2. Mechanical Pressing

3. Solvent Extraction

4. Supercritical CO2 Extraction

5. Aqueous Extraction Processing

Enzyme-assisted Aqueous Extraction (EAEP)

6. Life Cycle and Environmental Impact Analyses

7. Techno-Economic Analysis (TEA)

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- United States 2030 Food Loss and Waste Reduction Goal. Available online: https://www.epa.gov/sustainable-management-food/united-states-2030-food-loss-and-waste-reduction-goal (accessed on 23 September 2021).

- Food Wastage: Key Facts and Figures. Available online: http://www.fao.org/news/story/en/item/196402/icode/ (accessed on 23 September 2021).

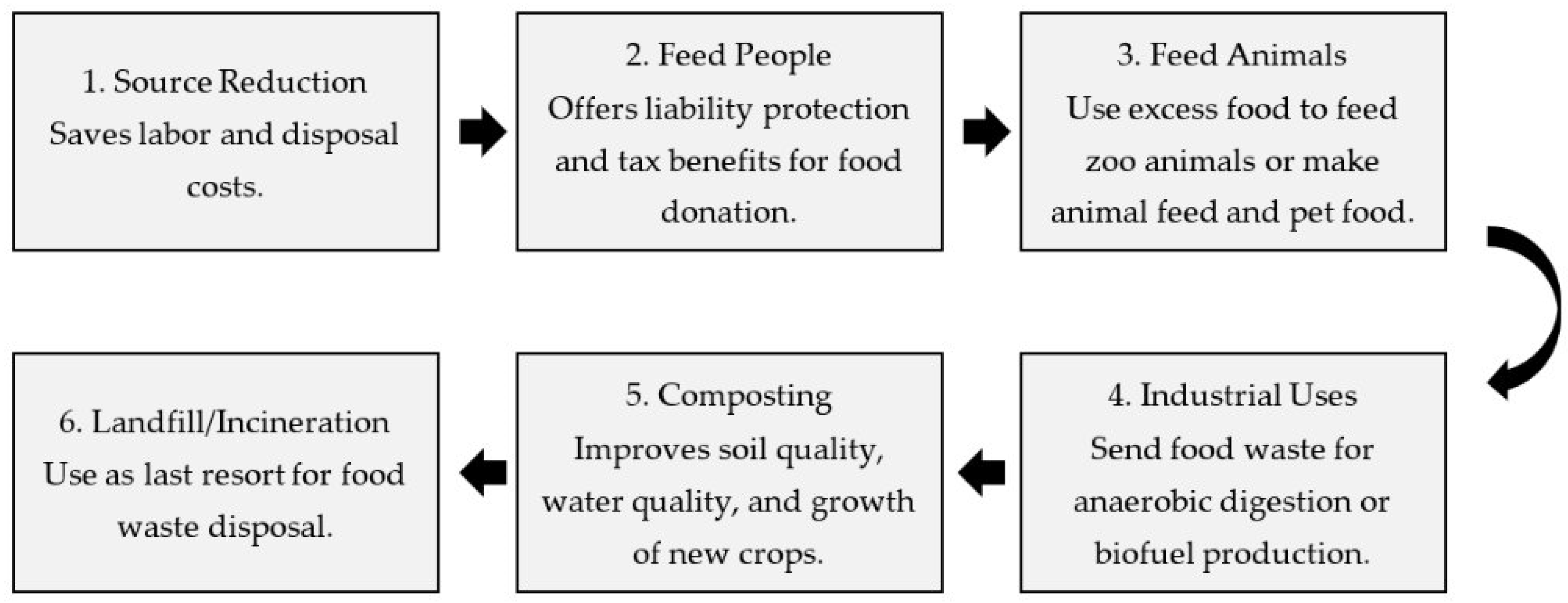

- Food Recovery Hierarchy. Available online: https://www.epa.gov/sustainable-management-food/food-recovery-hierarchy (accessed on 23 September 2021).

- Food Recovery Act. Available online: https://policyfinder.refed.org/federal-policy/food-recovery-act (accessed on 23 September 2021).

- Short-Lived Climate Pollutants (SLCP): Organic Waste Methane Emissions Reductions. Available online: https://www.calrecycle.ca.gov/climate/slcp (accessed on 15 June 2021).

- Food Loss and Food Waste. Available online: http://www.fao.org/3/i4807e/i4807e.pdf (accessed on 28 April 2020).

- Gustavsson, J.; Cederberg, C.; Sonesson, U.; Emanuelsson, A. The Methodology of the FAO Study: “Global Food Losses and Food Waste-Extent, Causes and Prevention”; FAO: Sweden, 2013; Available online: http://www.diva-portal.org/smash/get/diva2:944159/FULLTEXT01.pdf (accessed on 18 July 2021).

- Oilseeds: World Market and Trade. Available online: https://downloads.usda.library.cornell.edu/usda-esmis/files/tx31qh68h/8g84nh663/3r075q71r/oilseeds.pdf (accessed on 25 September 2021).

- Edible Oil & Fats Market Worth $162.51 Billion by 2025 | CAGR 7.6%. Available online: https://www.grandviewresearch.com/press-release/global-edible-oil-fats-market (accessed on 15 June 2021).

- Turrini, F.; Zunin, P.; Boggia, R. Potentialities of rapid analytical strategies for the identification of the botanical species of several specialty or gourmet oils. Foods 2021, 10, 183. [Google Scholar] [CrossRef]

- Gulcin, İ. Antioxidants and antioxidant methods: An updated overview. Arch. Toxicol. 2020, 94, 651–715. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Global Vegetable Oil Consumption, 2019/20. Available online: https://www.statista.com/statistics/263937/vegetable-oils-global-consumption/ (accessed on 16 June 2021).

- Gourmet and Specialty Oils. Available online: https://extension.okstate.edu/fact-sheets/gourmet-and-specialty-oils.html (accessed on 16 June 2021).

- Cheng, M.H.; Dien, B.S.; Singh, V. Economics of plant oil recovery: A review. Biocatal. Agric. Biotechnol. 2019, 18, 101056. [Google Scholar] [CrossRef]

- De Oliveira, R.C.; Davantel De Barros, S.T.; Gimenes, M.L. The extraction of passion fruit oil with green solvents. J. Food Eng. 2013, 117, 458–463. [Google Scholar] [CrossRef]

- Kasote, D.M.; Badhe, Y.S.; Hegde, M.V. Effect of mechanical press oil extraction processing on quality of linseed oil. Ind. Crops Prod. 2013, 42, 10–13. [Google Scholar] [CrossRef]

- Savoire, R.; Lanoisellé, J.L.; Vorobiev, E. Mechanical continuous oil expression from oilseeds: A review. Food Bioprocess Technol. 2013, 6, 1–16. [Google Scholar] [CrossRef]

- Oilseed Fact Sheet: Oilseed Presses. Available online: https://www.uvm.edu/sites/default/files/media/Oilseed_Presses.pdf (accessed on 23 September 2021).

- Expanding and Expelling. Available online: https://lipidlibrary.aocs.org/edible-oil-processing/expanding-and-expelling (accessed on 21 August 2021).

- Bogaert, L.; Mathieu, H.; Mhemdi, H.; Vorobiev, E. Characterization of oilseeds mechanical expression in an instrumented pilot screw press. Ind. Crops Prod. 2018, 121, 106–113. [Google Scholar] [CrossRef]

- Romuli, S.; Karaj, S.; Latif, S.; Müller, J. Performance of mechanical co-extraction of Jatropha curcas L. kernels with rapeseed, maize or soybean with regard to oil recovery, press capacity and product quality. Ind. Crops Prod. 2017, 104, 81–90. [Google Scholar] [CrossRef]

- Uitterhaegen, E.; Evon, P. Twin-screw extrusion technology for vegetable oil extraction: A review. J. Food Eng. 2017, 212, 190–200. [Google Scholar] [CrossRef] [Green Version]

- Vandenbossche, V.; Candy, L.; Evon, P.; Rouilly, A.; Pontalier, P.Y. Extrusion. In Green Food Processing Techniques: Preservation, Transformation, and Extraction; Elsevier: Amsterdam, The Netherlands, 2019; pp. 289–314. [Google Scholar]

- Cheng, M.H.; Rosentrater, K.A. Techno-economic analysis of extruding-expelling of soybeans to produce oil and meal. Agriculture 2019, 9, 87. [Google Scholar] [CrossRef] [Green Version]

- Amalia Kartika, I.; Pontalier, P.Y.; Rigal, L. Twin-screw extruder for oil processing of sunflower seeds: Thermo-mechanical pressing and solvent extraction in a single step. Ind. Crops Prod. 2010, 32, 297–304. [Google Scholar] [CrossRef]

- Sriti, J.; Msaada, K.; Talou, T.; Faye, M.; Kartika, I.A.; Marzouk, B. Extraction of coriander oil by twin-screw extruder: Screw configuration and operating conditions effect. Ind. Crops Prod. 2012, 40, 355–360. [Google Scholar] [CrossRef]

- Kartika, I.A.; Pontalier, P.Y.; Rigal, L. Oil extraction of oleic sunflower seeds by twin screw extruder: Influence of screw configuration and operating conditions. Ind. Crops Prod. 2005, 22, 207–222. [Google Scholar] [CrossRef]

- Kumar, S.P.J.; Prasad, S.R.; Banerjee, R.; Agarwal, D.K.; Kulkarni, K.S.; Ramesh, K.V. Green solvents and technologies for oil extraction from oilseeds. Chem. Cent. J. 2017, 11, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Fine, F.; Fabiano-Tixier, A.S.; Abert-Vian, M.; Carre, P.; Pages, X.; Chemat, F. Evaluation of alternative solvents for improvement of oil extraction from rapeseeds. Comptes Rendus Chim. 2014, 17, 242–251. [Google Scholar] [CrossRef]

- Soystats. Available online: https://soygrowers.com/wp-content/uploads/2019/10/Soy-Stats-2019_FNL-Web.pdf (accessed on 22 September 2021).

- Hexane. Available online: https://www.epa.gov/sites/production/files/2016-09/documents/hexane.pdf (accessed on 21 June 2021).

- Toxic Chemicals: Banned in Organics But Common in “Natural” Food Production. Available online: https://www.cornucopia.org/hexane-guides/nvo_hexane_report.pdf (accessed on 23 September 2021).

- Yousefi, M.; Yousefi, M.; Hosseini, H. Evaluation of hexane content in edible vegetable oils consumed in Iran. J. Exp. Clin. Toxicol. 2017, 1, 27–30. [Google Scholar] [CrossRef]

- Directive 2009/32/EC of the European Parliament and of the Council of 23 April 2009 on the Approximation of the Laws of the Member States on Extraction Solvents Used in the Production of Foodstuffs and Food Ingredients. Available online: https://webarchive.nationalarchives.gov.uk/eu-exit/https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:02009L0032-20161109 (accessed on 23 September 2021).

- Dagostin, J.L.A.; Carpiné, D.; Corazza, M.L. Extraction of soybean oil using ethanol and mixtures with alkyl esters (biodiesel) as co-solvent: Kinetics and thermodynamics. Ind. Crops Prod. 2015, 74, 69–75. [Google Scholar] [CrossRef]

- Jin, C.; Zhang, X.; Geng, Z.; Pang, X.; Wang, X.; Ji, J.; Wang, G.; Liu, H. Effects of various co-solvents on the solubility between blends of soybean oil with either methanol or ethanol. Fuel 2019, 244, 461–471. [Google Scholar] [CrossRef]

- Carré, P.; Citeau, M.; Dauguet, S. Hot ethanol extraction: Economic feasibility of a new and green process. OCL 2018, 25, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Baümler, E.R.; Carrín, M.E.; Carelli, A.A. Extraction of sunflower oil using ethanol as solvent. J. Food Eng. 2016, 178, 190–197. [Google Scholar] [CrossRef]

- Sbihi, H.M.; Nehdi, I.A.; Mokbli, S.; Romdhani-Younes, M.; Al-Resayes, S.I. Hexane and ethanol extracted seed oils and leaf essential compositions from two castor plant (Ricinus communis L.) varieties. Ind. Crops Prod. 2018, 122, 174–181. [Google Scholar] [CrossRef]

- Santos, K.A.; da Silva, E.A.; da Silva, C. Ultrasound-assisted extraction of favela (Cnidoscolus quercifolius) seed oil using ethanol as a solvent. J. Food Process. Preserv. 2021, 46, e15497. [Google Scholar]

- Lohani, U.C.; Fallahi, P.; Muthukumarappan, K. Comparison of ethyl acetate with hexane for oil extraction from various oilseeds. J. Am. Oil Chem. Soc. 2015, 92, 743–754. [Google Scholar] [CrossRef]

- Del Valle, J.M. Extraction of natural compounds using supercritical CO2: Going from the laboratory to the industrial application. J. Supercrit. Fluids 2015, 96, 180–199. [Google Scholar] [CrossRef]

- Ye, X.; Xue, S.J.; Shi, J. Green separation technology in food processing: Supercritical-CO2 fluid extraction. In Advances in Food Processing Technology; Jia, J., Liu, D., Ma, H., Eds.; Springer: Singapore, 2019; pp. 73–99. [Google Scholar]

- Sánchez-Vicente, Y.; Cabañas, A.; Renuncio, J.A.R.; Pando, C. Supercritical fluid extraction of peach (Prunus persica) seed oil using carbon dioxide and ethanol. J. Supercrit. Fluids 2009, 49, 167–173. [Google Scholar] [CrossRef]

- Smigic, N.; Djekic, I.; Tomic, N.; Udovicki, B.; Rajkovic, A. The potential of foods treated with supercritical carbon dioxide (SCO2) as novel foods. Br. Food J. 2019, 121, 815–834. [Google Scholar] [CrossRef]

- Mushtaq, M.; Sultana, B.; Anwar, F.; Adnan, A.; Rizvi, S.S.H. Enzyme-assisted supercritical fluid extraction of phenolic antioxidants from pomegranate peel. J. Supercrit. Fluids 2015, 104, 122–131. [Google Scholar] [CrossRef]

- Todd, R.; Baroutian, S. A techno-economic comparison of subcritical water, supercritical CO2 and organic solvent extraction of bioactives from grape marc. J. Clean. Prod. 2017, 158, 349–358. [Google Scholar] [CrossRef]

- Carvalho, P.I.N.; Osorio-Tobón, J.F.; Rostagno, M.A.; Petenate, A.J.; Meireles, M.A.A. Techno-economic evaluation of the extraction of turmeric (Curcuma longa L.) oil and ar-turmerone using supercritical carbon dioxide. J. Supercrit. Fluids 2015, 105, 44–54. [Google Scholar] [CrossRef]

- İncedayi, B.; Suna, S.; Çopur, Ö.U. Use of supercritical CO2 in food industry. Bulg. Chem. Commun. 2014, 46, 126–130. [Google Scholar]

- Aladić, K.; Jarni, K.; Barbir, T.; Vidović, S.; Vladić, J.; Bilić, M.; Jokić, S. Supercritical CO2 extraction of hemp (Cannabis sativa L.) seed oil. Ind. Crops Prod. 2015, 76, 472–478. [Google Scholar] [CrossRef]

- Ekinci, M.S.; Gürü, M. Extraction of oil and β-sitosterol from peach (Prunus persica) seeds using supercritical carbon dioxide. J. Supercrit. Fluids 2014, 92, 319–323. [Google Scholar] [CrossRef]

- Wu, H.; Shi, J.; Xue, S.; Kakuda, Y.; Wang, D.; Jiang, Y.; Ye, X.; Li, Y.; Subramanian, J. Essential oil extracted from peach (Prunus persica) kernel and its physicochemical and antioxidant properties. LWT-Food Sci. Technol. 2011, 44, 2032–2039. [Google Scholar] [CrossRef]

- Mu, J.; Wu, G.; Chen, Z.; Brennan, C.S.; Tran, K.; Dilrukshi, H.N.N.; Shi, C.; Zhen, H.; Hui, X. Identification of the fatty acids profiles in supercritical CO2 fluid and soxhlet extraction of samara oil from different cultivars of Elaeagnus mollis Diels seeds. J. Food Compos. Anal. 2021, 101, 1–9. [Google Scholar] [CrossRef]

- Ruttarattanamongkol, K.; Siebenhandl-Ehn, S.; Schreiner, M.; Petrasch, A.M. Pilot-scale supercritical carbon dioxide extraction, physico-chemical properties and profile characterization of Moringa oleifera seed oil in comparison with conventional extraction methods. Ind. Crops Prod. 2014, 58, 68–77. [Google Scholar] [CrossRef]

- Caseiro, M.; Ascenso, A.; Costa, A.; Creagh-Flynn, J.; Johnson, M.; Simões, S. Lycopene in human health. LWT 2020, 127, 109323. [Google Scholar] [CrossRef]

- Mohamed, H.B.; Duba, K.S.; Fiori, L.; Abdelgawed, H.; Tlili, I.; Tounekti, T.; Zrig, A. Bioactive compounds and antioxidant activities of different grape (Vitis vinifera L.) seed oils extracted by supercritical CO2 and organic solvent. LWT 2016, 74, 557–562. [Google Scholar] [CrossRef]

- Güçlü-Üstündaǧ, Ö.; Temelli, F. Solubility behavior of ternary systems of lipids, cosolvents and supercritical carbon dioxide and processing aspects. J. Supercrit. Fluids 2005, 36, 1–15. [Google Scholar] [CrossRef]

- Asep, E.K.; Jinap, S.; Jahurul, M.H.A.; Zaidul, I.S.M.; Singh, H. Effects of polar cosolvents on cocoa butter extraction using supercritical carbon dioxide. Innov. Food Sci. Emerg. Technol. 2013, 20, 152–160. [Google Scholar] [CrossRef]

- Belayneh, H.D.; Wehling, R.L.; Reddy, A.K.; Cahoon, E.B.; Ciftci, O.N. Ethanol-modified supercritical carbon dioxide extraction of the bioactive lipid components of Camelina sativa seed. J. Am. Oil Chem. Soc. 2017, 94, 855–865. [Google Scholar] [CrossRef]

- Da Porto, C.; Natolino, A. Supercritical fluid extraction of polyphenols from grape seed (Vitis vinifera): Study on process variables and kinetics. J. Supercrit. Fluids 2017, 130, 239–245. [Google Scholar] [CrossRef]

- Moghadas, H.C.; Rezaei, K. Laboratory-scale optimization of roasting conditions followed by aqueous extraction of oil from wild almond. J. Am. Oil Chem. Soc. 2017, 94, 867–876. [Google Scholar] [CrossRef]

- Fu, S.; Wu, W. Optimization of conditions for producing high-quality oil and de-oiled meal from almond seeds by water. J. Food Process. Preserv. 2019, 43, e14050. [Google Scholar] [CrossRef]

- Akinoso, R.; Raji, A.O. Optimization of oil extraction from locust bean using response surface methodology. Eur. J. Lipid Sci. Technol. 2011, 113, 245–252. [Google Scholar] [CrossRef]

- Jung, S.; Mahfuz, A.A. Low temperature dry extrusion and high-pressure processing prior to enzyme-assisted aqueous extraction of full fat soybean flakes. Food Chem. 2009, 114, 947–954. [Google Scholar] [CrossRef]

- Zhang, W.; Peng, H.; Sun, H.; Hua, X.; Zhao, W.; Yang, R. Effect of acidic moisture-conditioning as pretreatment for aqueous extraction of flaxseed oil with lower water consumption. Food Bioprod. Process. 2020, 121, 20–28. [Google Scholar] [CrossRef]

- Evon, P.; Vandenbossche, V.; Pontalier, P.Y.; Rigal, L. Direct extraction of oil from sunflower seeds by twin-screw extruder according to an aqueous extraction process: Feasibility study and influence of operating conditions. Ind. Crops Prod. 2007, 26, 351–359. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.J.; Gasmalla, M.A.A.; Li, P.; Yang, R. Enzyme-assisted extraction processing from oilseeds: Principle, processing and application. Innov. Food Sci. Emerg. Technol. 2016, 35, 184–193. [Google Scholar] [CrossRef]

- Valladares-Diestra, K.; de Souza Vandenberghe, L.P.; Soccol, C.R. Oilseed enzymatic pretreatment for efficient oil recovery in biodiesel production industry: A review. Bioenergy Res. 2020, 13, 1016–1030. [Google Scholar] [CrossRef]

- Jegannathan, K.R.; Nielsen, P.H. Environmental assessment of enzyme use in industrial production—A literature review. J. Clean. Prod. 2013, 42, 228–240. [Google Scholar] [CrossRef] [Green Version]

- Cheng, M.H.; Rosentrater, K.A.; Sekhon, J.; Wang, T.; Jung, S.; Johnson, L.A. Economic feasibility of soybean oil production by enzyme-assisted aqueous extraction processing. Food Bioprocess Technol. 2019, 12, 539–550. [Google Scholar] [CrossRef]

- Yusoff, M.; Gordon, M.H.; Niranjan, K. Aqueous enzyme assisted oil extraction from oilseeds and emulsion de-emulsifying methods: A review. Trends Food Sci. Technol. 2015, 41, 60–82. [Google Scholar] [CrossRef]

- Mwaurah, P.W.; Kumar, S.; Kumar, N.; Kumar, A.; Panghal, A.A.; Kumar, V.; Mukesh, S.; Garg, K. Novel oil extraction technologies: Process conditions, quality parameters, and optimization. Compr. Rev. Food Sci. Food Saf. 2019, 19, 3–20. [Google Scholar] [CrossRef] [Green Version]

- Tabtabaei, S.; Diosady, L.L. Aqueous and enzymatic extraction processes for the production of food-grade proteins and industrial oil from dehulled yellow mustard flour. Food Res. Int. 2013, 52, 547–556. [Google Scholar] [CrossRef]

- Zúñiga, M.E.; Soto, C.; Mora, A.; Chamy, R.; Lema, J.M. Enzymic pre-treatment of Guevina avellana mol oil extraction by pressing. Process Biochem. 2003, 39, 51–57. [Google Scholar] [CrossRef]

- Rui, H.; Zhang, L.; Li, Z.; Pan, Y. Extraction and characteristics of seed kernel oil from white pitaya. J. Food Eng. 2009, 93, 482–486. [Google Scholar] [CrossRef]

- Latif, S.; Anwar, F.; Hussain, A.I.; Shahid, M. Aqueous enzymatic process for oil and protein extraction from Moringa oleifera seed. Eur. J. Lipid Sci. Technol. 2011, 113, 1012–1018. [Google Scholar] [CrossRef]

- Souza, T.S.P.; Dias, F.F.G.; Koblitz, M.G.B.; Juliana, J.M.L.N. Aqueous and enzymatic extraction of oil and protein from almond cake: A comparative study. Processes 2019, 7, 472. [Google Scholar] [CrossRef] [Green Version]

- De Almeida, N.M.; Dias, F.F.G.; Rodrigues, M.I.; de Moura Bell, J.M.L.N. Effects of processing conditions on the simultaneous extraction and distribution of oil and protein from almond flour. Processes. 2019, 7, 844. [Google Scholar] [CrossRef] [Green Version]

- de Souza, T.S.P.; Dias, F.F.G.; Koblitz, M.G.B.; de Moura Bell, J.M.L.N. Effects of enzymatic extraction of oil and protein from almond cake on the physicochemical and functional properties of protein extracts. Food Bioprod. Process. 2020, 122, 280–290. [Google Scholar] [CrossRef]

- Gai, Q.Y.; Jiao, J.; Wei, F.Y.; Luo, M.; Wang, W.; Zu, Y.G.; Fu, Y.J. Enzyme-assisted aqueous extraction of oil from Forsythia suspense seed and its physicochemical property and antioxidant activity. Ind. Crops Prod. 2013, 51, 274–278. [Google Scholar] [CrossRef]

- Yao, L.; Jung, S. 31P NMR Phospholipid profiling of soybean emulsion recovered from aqueous extraction. J. Agric. Food Chem. 2010, 58, 4866–4872. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.B.; Liu, X.J.; Lu, Q.Y.; Wang, Z.W.; Zhao, X. Enzymatic demulsification of the oil-rich emulsion obtained by aqueous extraction of peanut seeds. J. Am. Oil Chem. Soc. 2013, 90, 1261–1270. [Google Scholar] [CrossRef]

- Vidergar, P.; Perc, M.; Lukman, R.K. A survey of the life cycle assessment of food supply chains. J. Clean. Prod. 2021, 286, 125506. [Google Scholar] [CrossRef]

- Muralikrishna, I.V.; Manickam, V. Life cycle assessment. Environ. Manage 2017, 57–75. [Google Scholar]

- Jeswani, H.K.; Azapagic, A.; Schepelmann, P.; Ritthoff, M. Options for broadening and deepening the LCA approaches. J. Clean. Prod. 2010, 18, 120–127. [Google Scholar] [CrossRef]

- Morero, B.; Rodriguez, M.B.; Campanella, E.A. Environmental impact assessment as a complement of life cycle assessment. Case study: Upgrading of biogas. Bioresour. Technol. 2015, 190, 402–407. [Google Scholar] [CrossRef]

- Khatri, P.; Jain, S. Environmental life cycle assessment of edible oils: A review of current knowledge and future research challenges. J. Clean. Prod. 2017, 152, 63–76. [Google Scholar] [CrossRef]

- Khatri, P.; Jain, S.; Pandey, S. A cradle-to-gate assessment of environmental impacts for production of mustard oil using life cycle assessment approach. J. Clean. Prod. 2017, 166, 988–997. [Google Scholar] [CrossRef]

- Potrich, E.; Miyoshi, S.C.; Machado, P.F.S.; Furlan, F.F.; Ribeiro, M.P.A.; Tardioli, P.W.; Giordano, R.L.C.; Cruz, A.J.G.; Giordano, R.C. Replacing hexane by ethanol for soybean oil extraction: Modeling, simulation, and techno-economic-environmental analysis. J. Clean. Prod. 2020, 244, 118660. [Google Scholar] [CrossRef]

- Cheng, M.H.; Sekhon, J.J.K.; Rosentrater, K.A.; Wang, T.; Jung, S.; Johnson, L.A. Environmental impact assessment of soybean oil production: Extruding-expelling process, hexane extraction and aqueous extraction. Food Bioprod. Process. 2018, 108, 58–68. [Google Scholar] [CrossRef]

- Cheng, M.H.; Zhang, W.; Rosentrater, K.; Sekhon, J.; Wang, T.; Jung, S.; Johnson, L. Environmental impact analysis of soybean oil production from expelling, hexane extraction and enzyme assisted aqueous extraction. In Proceedings of the 2016 ASABE Annual International Meeting, Orlando, FL, USA, 17–20 July 2016; p. 484. [Google Scholar]

- Cheng, M.H.; Rosentrater, K.A. Economic feasibility analysis of soybean oil production by hexane extraction. Ind. Crops Prod. 2017, 108, 775–785. [Google Scholar] [CrossRef]

- Cheng, M.H.; Rosentrater, K.A. Profitability analysis of soybean oil processes. Bioengineering 2017, 4, 83. [Google Scholar] [CrossRef] [Green Version]

- Fiori, L. Supercritical extraction of grape seed oil at industrial-scale: Plant and process design, modeling, economic feasibility. Chem. Eng. Process. Process Intensif. 2010, 49, 866–872. [Google Scholar] [CrossRef]

| Oilseed | Other Seed Type |

|---|---|

| Canola/Rapeseed | Almond |

| Linseed (also known as flaxseed) | Coriander |

| Jatropha curcas | Hemp |

| Soybean | Favela |

| Sunflower | Passionfruit |

| Camelina | Peach |

| Castor | Elaeagnus mollis |

| Mustard | Moringa |

| Peanut | Grape |

| Forsythia suspense |

| Extraction Method | Oil Yields | Profitable Capacity of Annual Oil Production | Revenue Sources | Environmental Impact Analysis |

|---|---|---|---|---|

| EAEP 1 | Over 80% | >17 million kg | 24% from oil >70% from insoluble fibers | Similar environmental impacts to expelling Lower greenhouse gas and criteria pollutants emissions |

| Extruder-expelling | 72% | 13 million kg | 23% from oil 77% from meal | Lowest environmental impacts Highest greenhouse gas and criteria pollutants emissions |

| Hexane | Over 99% | 87 million kg | 39% from oil >60% from meal and hulls | Highest environmental impact Most energy efficient Lowest greenhouse gas and criteria pollutants emissions |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lavenburg, V.M.; Rosentrater, K.A.; Jung, S. Extraction Methods of Oils and Phytochemicals from Seeds and Their Environmental and Economic Impacts. Processes 2021, 9, 1839. https://doi.org/10.3390/pr9101839

Lavenburg VM, Rosentrater KA, Jung S. Extraction Methods of Oils and Phytochemicals from Seeds and Their Environmental and Economic Impacts. Processes. 2021; 9(10):1839. https://doi.org/10.3390/pr9101839

Chicago/Turabian StyleLavenburg, Valerie M., Kurt A. Rosentrater, and Stephanie Jung. 2021. "Extraction Methods of Oils and Phytochemicals from Seeds and Their Environmental and Economic Impacts" Processes 9, no. 10: 1839. https://doi.org/10.3390/pr9101839

APA StyleLavenburg, V. M., Rosentrater, K. A., & Jung, S. (2021). Extraction Methods of Oils and Phytochemicals from Seeds and Their Environmental and Economic Impacts. Processes, 9(10), 1839. https://doi.org/10.3390/pr9101839