Incorporating Environmental Perspective in Integrated Strategic-Tactical Economic Optimization Model of Biomass-to-Biofuel Supply Chain—A Real Case Study in Ethiopia

Abstract

:1. Introduction

2. State of the Art

- (a)

- An alternative semi-heuristic solution method that offers a feasible solution to the problem is provided as the attempt to solve the multi-objective optimization model with numerical solver ends without success. This is due to the abrupt rise in the size of the model because it is a real, national-level case study with many continuous decision variables and parameters as well as the availability of many binary variables due to strategic choices.

- (b)

- An integrated model is designed to make optimal or feasible strategic and tactical decisions simultaneously.

- (c)

- Contrary to many previous research endeavors that emphasize GHG emissions and global warming potential, this study attempts to formulate a comprehensive assessment of BBSC’s environmental impact by broadening the assessed mid-point impact categories. The assessed mid-point categories include global warming, photochemical oxidation, acidification, eutrophication, human toxicity, fine dust, freshwater aquatic ecotoxicity, land use, waste generation, fossil fuel depletion and metal and water scarcity potentials, despite most of them being insignificantly affected by the BBSC activities.

- (d)

- The environmental impacts are converted to monetary values using the ecocost approach to easily compare economic criteria. The ecocost is the marginal prevention cost required to halt the negative impact of toxic emissions. These emissions are associated with human health as well as ecosystems, emissions that cause global warming, and resource depletion (metals, rare earths, fossil fuels, water, and land use).

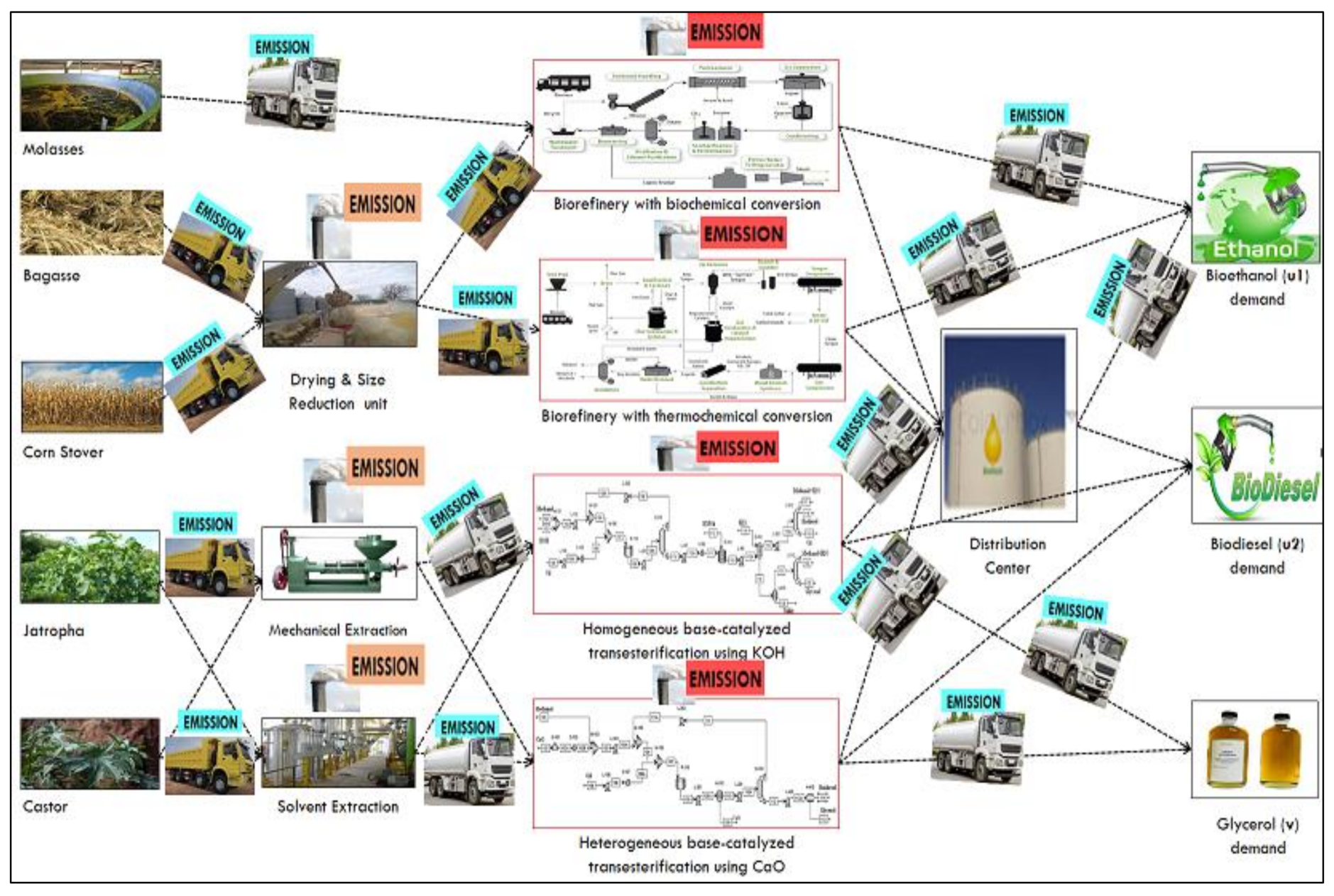

3. Materials and Methods

3.1. Model Formulation

3.1.1. Economic Objective Function

3.1.2. Environmental Objective Function

- i.

- Goal and scope definition

- ii.

- Inventory analysis

- Biomass preprocessing

- a.1.

- Drying and size reductionAt this prior stage of the life cycle, the corn stover and bagasse are subjected to solar drying to drop down their moisture content from 20% [26] and 50% (average moisture content of bagasse produced in Ethiopia sugar industries), respectively, to 10%. Thereafter, the sizes of the feedstocks are reduced using a hammer mill, operated at a speed of 2000 rpm for 2 mm mesh size screen with 90° hammers. The research by Bitra et al. [27] and Kakolaki et al. [28] was used to compute the energy requirement of the mill to process the corn stover and bagasse, respectively. Table 1 presents the mass flow of input and output components and energy requirements to process 1 ton of both lignocellulostic feedstocks through drying and a size reduction mechanism.

- a.2.

- Mechanical and solvent extractionAt this stage, the jatropha and castor seeds collected from the respective supply sources are converted to their respective oils either via mechanical extraction or solvent extraction technologies. The inventory data of the two extraction technologies are computed based on the previous research of Cheng et al. [29], Hou et al. [30] and Kebede [31]. Table 2 provides the mass flow of input and output components and energy requirement to process 1 ton of both non-edible feedstocks, i.e., jatropha and castor seeds, through mechanical and solvent extraction technologies. The required amount of raw materials to process 1 ton of jatropha and castor is assumed to be similar [30] despite the amount of products and byproducts being different depending on the conversion rate of the oil from the two feedstocks.

- Biofuel production

- b.1.

- Biochemical and thermochemical conversionThe bioethanol production from corn stover/sugarcane molasses/bagasse is conducted by using biochemical or thermochemical conversions. The inventory data for both technologies are estimated based on Aspen plus process models of Foust et al. [32] and Mu et al. [33], as well as a similar molasses-based bioethanol plant in Ethiopia. Table 3 presents the inventory data associated with input and output materials, energy used as well as waste generation to process 1 ton of molasses/corn stover/bagasse using both conversion technologies.

- b.2.

- Homogeneous and heterogeneous based catalyzed transesterificationAfter oil extraction, the transesterification step is carried out to yield biodiesel from the jatropha/castor oil. The two technologies considered at this stage are homogeneous and heterogeneous transesterification. The inventory data for both transesterification technologies are obtained from Aspen plus process models of Tasić et al. [34], Kaewcharoensombat et al. [35], and other referenced previous works [30,31,36]. Here, an assumption is taken that the input and output materials and energy for transesterification of jatropha and castor oil is similar since the conversion rate of both oils to biodiesel through both technologies is almost similar. Table 4 presents the inventory data associated with input and output materials, energy used as well as waste generation to process 1 ton of jatropha/castor oil using both homogeneous and heterogeneous transesterification processes.

- Biomass, preprocessed biomass and biofuel transportation

- iii.

- Impact analysis

| Drying and Size Reduction | ||

|---|---|---|

| Inventory | Corn Stover Based | Bagasse Based |

| Input | ||

| Biomass (tons) | 1.0 | 1.0 |

| Energy consumption (KWh) | 9.33 × 104 | 2.64 × 104 |

| Output | ||

| Biomass (tons) | 0.9 | 0.6 |

| Water (tons) | 0.1 | 0.4 |

| Mechanical Extraction | Solvent Extraction | ||||

|---|---|---|---|---|---|

| Inventory | Jatropha Based | Castor Based | Inventory | Jatropha Based | Castor Based |

| Input | Input | ||||

| Seed (tons) | 1.0 | 1.0 | Seed (tons) | 1.0 | 1.0 |

| Water (liter) | 70.00 | 70.00 | Hexane (tons) | 0.9 | 0.9 |

| H3PO4 (kg) | 0.33 | 0.33 | Water (liter) | 100.00 | 100.00 |

| Steam (ton) | 10.00 | 10.00 | H3PO4 (kg) | 0.72 | 0.72 |

| Electricity (kWh) | 6220.00 | 6220.00 | Steam (ton) | 1820.00 | 1820.00 |

| Electricity (kWh) | 1020.00 | 1020.00 | |||

| Output | Output | ||||

| Oil (tons) | 0.25 | 0.38 | Oil (tons) | 0.32 | 0.49 |

| Meal (tons) | 0.7 | 0.51 | Meal (tons) | 0.61 | 0.40 |

| Sludge (kg) | 17.00 | 25.84 | Sludge (kg) | 66.38 | 70.65 |

| Water (liter) | 92.37 | 140.40 | Water (liter) | 60.00 | 91.88 |

| H3PO4 (aq) (kg) | 7.96 | 12.10 | Hexane (tons) | 0.90 | 0.90 |

| Solid waste (kg) | 3.00 | 4.56 | H3PO4 (aq) (kg) | 7.74 | 11.85 |

| Solid waste (including hulls) (kg) | 36.00 | 37.59 | |||

| Biochemical Conversion | Thermochemical Conversion | |||||

|---|---|---|---|---|---|---|

| Inventory | Corn Stover Based | Molasses Based | Bagasse Based | Inventory | Corn Stover Based | Bagasse Based |

| Input | Input | |||||

| Biomass (ton) | 1.00 | 1.00 | 1.00 | Biomass (ton) | 1.00 | 1.00 |

| Water consumption (liter) | 1870.00 | 3580.00 | 760.00 | Water consumption (liter) | 540.00 | 320.00 |

| Enzyme (kg) | 9.08 | 4.12 | 3.65 | Air (m3) | 2953.78 | 1593.63 |

| Yeast (kg) | 2.26 | 3.41 | 2.26 | MgO (kg) | 0.18 | 0.02 |

| Lime (kg) | 22.48 | 12.97 | 14.37 | Bed materials (kg) | 2.30 | 1.35 |

| Sulfuric acid (kg) | 29.44 | 10.62 | 19.73 | Synthesis catalyst (kg) | 0.01 | 0.01 |

| Corn steep liquor (kg) | 11.19 | 7.73 | Tar reforming catalyst (kg) | 0.01 | 0.01 | |

| Diammonium phosphate (kg) | 1.18 | 0.28 | 0.91 | Oxidizer for S recovery (kg) | 1.35 | 0.71 |

| Sodium hydroxide (kg) | 10.01 | 7.32 | 10.01 | |||

| Urea (kg) | 1.77 | 1.02 | 1.77 | |||

| Output | Output | |||||

| Bioethanol (ton) | 0.23 | 0.26 | 0.27 | Bioethanol (ton) | 0.20 | 0.19 |

| Carbon dioxide (ton) | 0.87 | 0.24 | 0.67 | Carbon dioxide (ton) | 0.91 | 0.63 |

| Electricity output (KWh) | 701.03 | 307.21 | 701.03 | Mixed alcohol (kg) | 39.02 | 23.93 |

| Vinasse (kg) | 29.90 | 28.62 | 29.90 | Sulfur (solid) (kg) | 0.56 | 0.29 |

| Sand and ash (kg) | 73.88 | 7.69 | ||||

| Homogeneous Transesterification | Heterogeneous Transesterification | ||

|---|---|---|---|

| Inventory | Jatropha/Castor Oil Based | Inventory | Jatropha/Castor Oil Based |

| Input | Input | ||

| Oil (ton) | 1.00 | Oil (ton) | 1.00 |

| Methanol (kg) | 68.00 | Methanol (kg) | 58.09 |

| KOH (kg) | 10.00 | CaO (kg) | 50.48 |

| H3PO4 (kg) | 5.84 | Electricity (KWh) | 308.47 |

| Water (liter) | 138.53 | ||

| Electricity (KWh) | 779.79 | ||

| Output | Output | ||

| Biodiesel (ton) | 0.95 | Biodiesel (ton) | 0.96 |

| Glycerol (kg) | 89.00 | Glycerol (kg) | 98.00 |

| Unreacted oil (kg) | 33.05 | CaO (kg) | 50.48 |

| Water with waste methanol (liter) | 137.60 | ||

| Solid residues (K3PO4) (kg) | 12.72 | ||

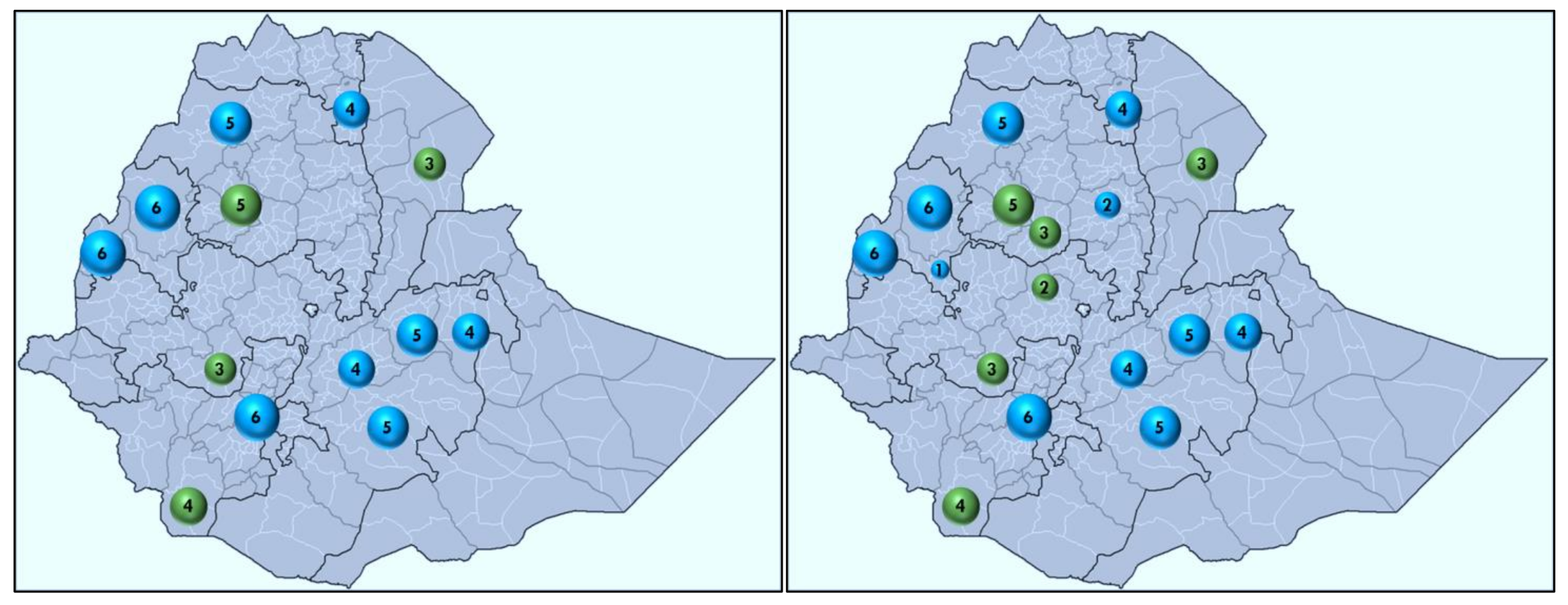

3.2. Case Study

- The annual production of molasses and bagasse is estimated based on the generation rate of the operational sugar factories in Ethiopia. Both the operational and under construction sugar factories, which are expected to start operation soon, are considered as potential suppliers of the two feedstocks. The amounts of molasses and bagasse were assumed to be zero in July and August as there was an experience of maintenance in the two months. The corn production data of each top corn producer zones in 2019/2020 [41] and corn stover-to-grain ratios [42] were used to estimate the stover generation amount. Since around 75% of the stover in Ethiopia is used as a cattle feed [43], the surplus 25% is considered. The land area (ha) dedicated to the cultivation of jatropha and castor in each zone [39,44,45] and their yield in terms of ton per ha (t.ha−1) acquired from the current study of MoMPNG (Ministry of Mines, Petroleum and Natural Gas) [46] and FAO data [47] were used to estimate the amount of jatropha and castor seed produced.

- The quantity of bagasse, molasses and stover generation was assumed to be the same in each annum of the planning years. Contrarily, based on the projection from Ministry of Agriculture experts, the jatropha and castor quantity was considered to be double after 10 years. A potential variation from this assumption was addressed by conducting a sensitivity analysis on the biomass availability.

- Considering the status-quo of biofuel development in Ethiopia, government plan and type of vehicles available in the country, a forecast is made on bioethanol and biodiesel demand in the transportation sector. Consequently, in the years 2020/2021–2024/2025, 2025/2026–2029/2030, 2030/2031–2034/2035, and 2035/2036–2039/2040, a bioethanol blend with gasoline at 10%, 15%, 20%, and 25% by volume, respectively, was considered, whereas between the years 2020/2021–2029/2030, and 2030/2031–2039/2040, a biodiesel blend with diesel at 5% and 10% by volume, respectively, is assumed. A potential variation from the forecasted biofuels demand is addressed by conducting a sensitivity analysis. The Ethiopian Customs and Revenues Authority import data were used to forecast glycerol demand.

- The current purchasing prices of the biomasses and selling prices of the biofuels were considered in this study. The effect of potential variation from these prices on the results is addressed by conducting a sensitivity analysis.

- Based on the recommendation from Ethiopian Ministry of Economic Development and Cooperation to evaluate projects, a 10% discount rate was used in this case study.

- As there is shortage of real biorefinery and preprocessing plants in Ethiopia, most of the techno-economic data were predicted using previous research. Aspen Plus process models of Foust et al. [32] were used to determine the production and investment costs of the bioethanol producing biorefineries. Similarly, the investment and production costs of the two base-catalyzed transesterification technologies were estimated based on Aspen plus process models of Tasić et al. [34]. The cost of a similar plant built in Ethiopia was used to estimate the production cost associated with bioethanol production from molasses. The Lang Factor method [48] and data from Cao and Rosentrater [49] were used to predict the investment and production costs of the drying and size reduction unit, respectively. A material and energy balance was performed to estimate the production and investment costs of mechanical extraction. Then, the production and investment costs of solvent extraction was predicted based on a correlation from Cheng et al. [50]. Chemical engineering cost index values were used to actualize all cost data before 2019, which was taken as a reference year for all costs in the study. The investment and production costs for preprocessing and biorefineries with the six capacity levels were obtained using Chilton’s law equation [38].

- To transport all materials within the BBSC, the only road transportation mode was assumed by considering the case study area’s features. The road transportation distance between each zone was obtained from a geographic information system.

- Based on the current practice in Ethiopia, heavy-duty Euro II and Euro III diesel-engine vehicles were considered in this case study for transporting the solid (raw and preprocessed biomasses) and liquid (biofuels, co-product and preprocessed oils) materials along the BBSC, respectively. The transportation costs are estimated based on Ministry of Transport data.

- The production yields of preprocessing units and biorefineries via the different technologies were obtained from previous scientific studies and laboratory works.

- To ensure an adequate biomass supply, the storage capacity of the biorefinery and preprocessing units were assumed to accommodate the preprocessed and raw biomasses utilized for a year, respectively. This assumption is taken because of seasonal variation of feedstock availability, unsustainable corn cultivation habits, low-quality road infrastructure in some zones and recurrent interruption of sugar production in Ethiopia.

- Either outside atmosphere storage, covered structure, or enclosed structure was considered for storing each type of materials in the BBSC based on the condition (raw, pretreated or processed), phase and size of the material. The storage cost and monthly deterioration in each storage system were obtained from a previous scientific study [51].

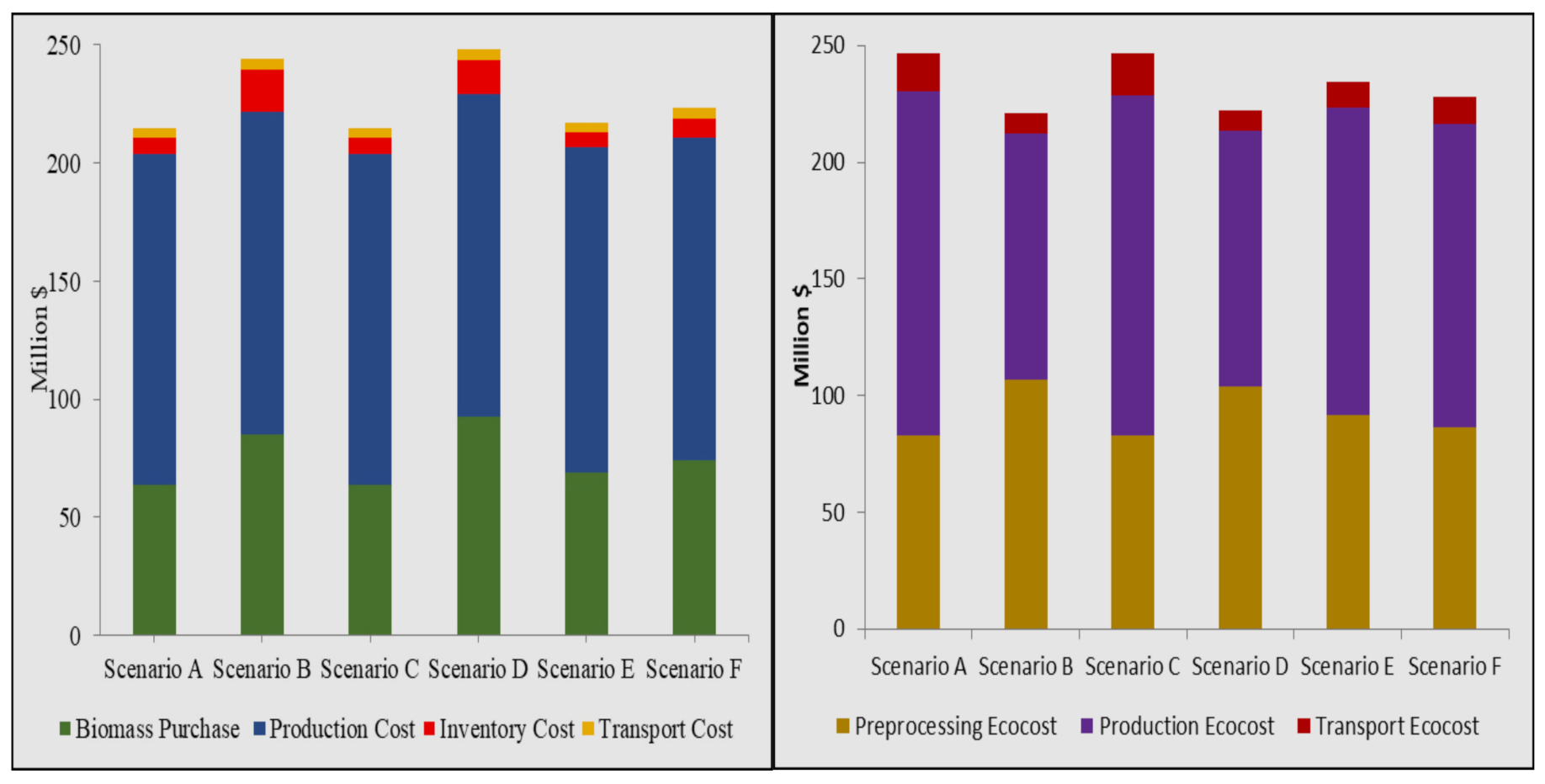

4. Results and Discussion

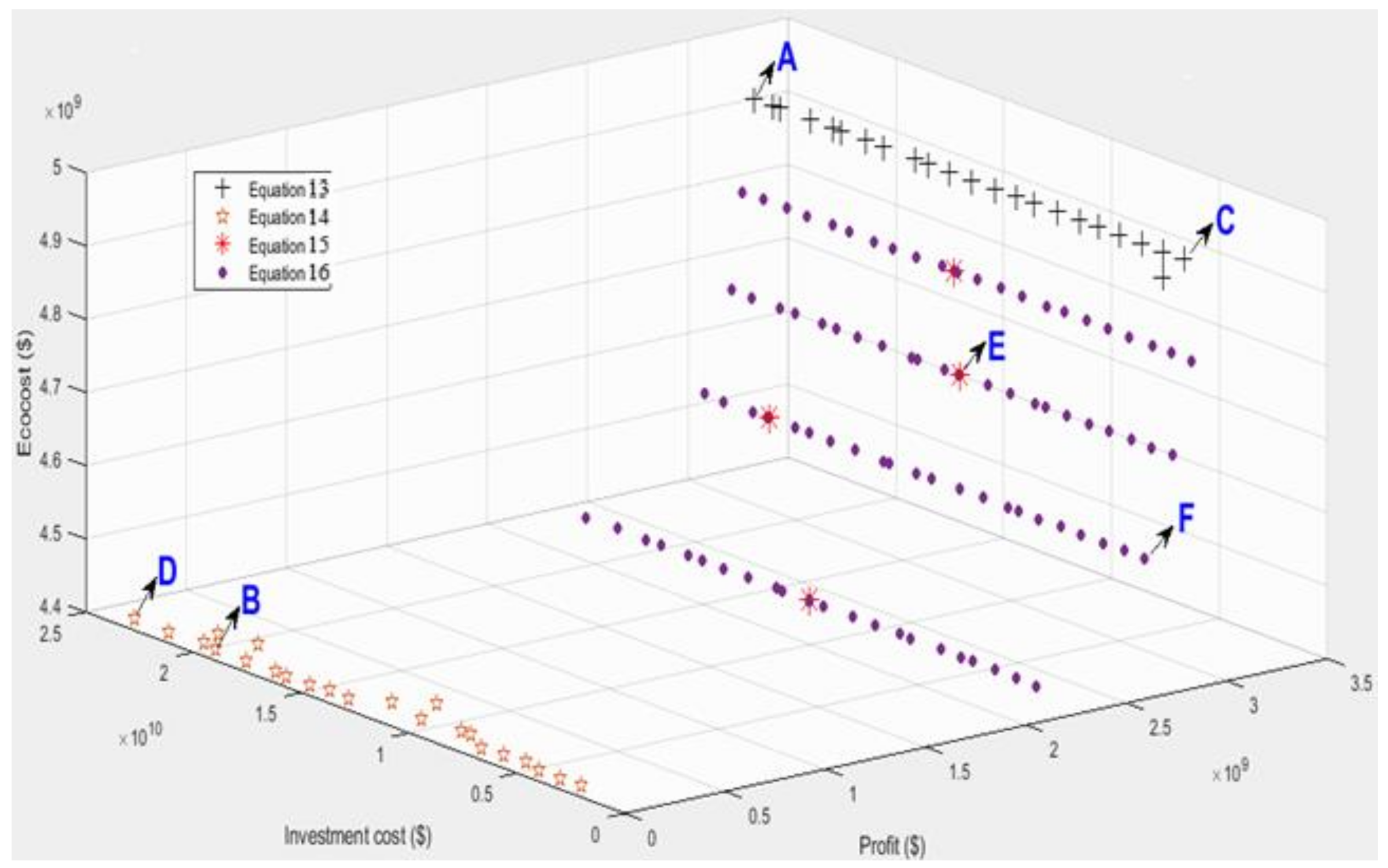

4.1. Multiobjective Optimization Strategy

4.2. Optimum Solutions for Mono-Objectives

4.3. Feasible Solutions for Bi-Objectives

4.4. Feasible Solutions for Multi-Objectives

5. Conclusions and Perspectives

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

- (a)

- Supply and Demand satisfaction

- (b)

- Inventory balance

- (c)

- Production amount

- (d)

- Binary and non-negativity decision variables

- (e)

- Continuous process equations

- (f)

- Inventory and weight capacity constraints

- (g)

- Initial year inventory and facility installation constraints

Appendix B

| Process | Eco-Costs of GWP | Eco-Costs of Acidification | Eco-Costs of Eutrophication | Eco-Costs of Ecotoxicity (Freshwater) | Eco-Costs of Photochemical Oxidants | Eco-Costs of Fine Dust | Eco-Costs of Human Tocicity | Eco-Costs of Energy Carriers | Eco-Costs of Baseline Water Stress | Eco-Costs of Land-Use | Eco-Costs of Waste | Eco-Costs of Metals Scarcity | Eco-Costs of Carbon Footprint | Eco-Costs of Ecosystem | Eco-Costs of Human Health | Eco-Costs of ReSource Scarcity | Total Eco-Costs |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Corn Stover Drying and Size Reduction | 0.14 | 0.00 | 0.00 | 0.00 | 0.00 | 5.07 | 0.00 | 11.20 | 0.02 | 0.00 | 0.00 | 0.00 | 0.14 | 0.00 | 5.07 | 11.18 | 16.39 |

| Corn Stover Biochemical Conversion | 299.75 | 32.14 | 0.00 | 0.00 | 43.54 | 6.60 | 0.00 | 4.17 | 0.23 | 0.00 | 0.00 | 0.00 | 299.75 | 32.14 | 50.15 | 4.40 | 386.43 |

| Corn Stover Thermochemical Conversion | 408.49 | 12.11 | 0.00 | 0.00 | 17.18 | 2.13 | 0.00 | 10.20 | 0.29 | 0.00 | 0.00 | 0.00 | 408.49 | 12.11 | 19.31 | 10.49 | 450.41 |

| Molasses Biochemical Conversion | 271.48 | 3.72 | 3.20 | 0.00 | 6.88 | 0.89 | 0.00 | 3.34 | 0.20 | 0.00 | 0.00 | 0.00 | 271.48 | 6.92 | 7.77 | 3.54 | 289.72 |

| Bagasse Drying and Size Reduction | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 | 3.05 | 0.00 | 8.06 | 0.02 | 0.00 | 0.00 | 0.00 | 0.01 | 0.00 | 3.05 | 8.05 | 11.11 |

| Bagasse Biochemical Conversion | 286.17 | 32.14 | 0.00 | 0.00 | 43.54 | 6.60 | 0.00 | 3.71 | 0.23 | 0.00 | 0.00 | 0.00 | 286.17 | 32.14 | 50.15 | 3.94 | 372.40 |

| Bagasse Thermochemical Conversion | 394.92 | 12.11 | 0.00 | 0.00 | 17.18 | 2.13 | 0.00 | 9.08 | 0.29 | 0.00 | 0.00 | 0.00 | 394.92 | 12.11 | 19.31 | 9.38 | 435.73 |

| Jatropha Mechanical Extraction | 53.46 | 1.48 | 0.00 | 0.00 | 1.88 | 1.17 | 0.00 | 195.01 | 0.00 | 0.00 | 0.00 | 0.00 | 53.46 | 1.48 | 3.05 | 195.01 | 253.01 |

| Jatropha Solvent Extraction | 7.80 | 0.22 | 0.00 | 0.00 | 0.27 | 0.17 | 0.00 | 26.65 | 0.00 | 0.00 | 0.00 | 0.00 | 7.80 | 0.22 | 0.45 | 26.65 | 35.12 |

| Jatropha Homogeneous Transesterification | 105.99 | 1.02 | 0.00 | 0.00 | 1.28 | 0.65 | 0.00 | 84.15 | 0.01 | 0.00 | 0.00 | 0.00 | 105.99 | 1.02 | 1.93 | 84.15 | 193.08 |

| Jatropha Heterogeneous Transesterification | 52.98 | 0.39 | 0.00 | 0.00 | 0.49 | 0.25 | 0.00 | 32.33 | 0.00 | 0.00 | 0.00 | 0.00 | 52.98 | 0.39 | 0.74 | 32.33 | 86.44 |

| Castor Mechanical Extraction | 53.46 | 1.48 | 0.00 | 0.00 | 1.88 | 1.17 | 0.00 | 195.01 | 0.00 | 0.00 | 0.00 | 0.00 | 53.46 | 1.48 | 3.05 | 195.01 | 253.01 |

| Castor Solvent Extraction | 7.80 | 0.22 | 0.00 | 0.00 | 0.27 | 0.17 | 0.00 | 26.65 | 0.00 | 0.00 | 0.00 | 0.00 | 7.80 | 0.22 | 0.45 | 26.65 | 35.12 |

| Castor Homogeneous Transesterification | 17.27 | 16.69 | 0.00 | 0.00 | 20.61 | 4.40 | 0.00 | 84.15 | 0.01 | 0.00 | 0.00 | 0.00 | 17.27 | 16.69 | 25.01 | 84.15 | 143.12 |

| Castor Heterogeneous Transesterification | 17.27 | 16.69 | 0.00 | 0.00 | 20.61 | 4.40 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 17.27 | 16.69 | 25.01 | 0.00 | 58.97 |

| Vehicle Type | Eco-Cost |

|---|---|

| Euro II diesel engine (for solid materials transportation) | 0.03636 |

| Euro III diesel engine (for liquid materials transportation) | 0.02997 |

References

- FDRE. Ethiopia’s Climate-Resilient Green Economy (CRGE) Strategy. 2011. Available online: https://www.undp.org/content/dam/ethiopia/docs/Ethiopia%20CRGE.pdf (accessed on 29 May 2020).

- Negash, M.; Riera, O. Biodiesel value chain and access to energy in Ethiopia: Policies and business prospects. Renew. Sustain. Energy Rev. 2014, 39, 975–985. [Google Scholar] [CrossRef]

- Tesfamichael, B.; Montastruc, L.; Negny, S.; Yimam, A. Designing and planning of Ethiopia’s biomass-to-biofuel supply chain through integrated strategic-tactical optimization model considering economic dimension. Comput. Chem. Eng. 2021, 153, 107425. [Google Scholar] [CrossRef]

- Pérez, A.T.E.; Camargo, M.; Rincon, P.C.N.; Marchant, M.A. Key challenges and requirements for sustainable and industrialized biorefinery supply chain design and management: A bibliographic analysis. Renew. Sustain. Energy Rev. 2017, 69, 350–359. [Google Scholar] [CrossRef]

- Li, Q.; Hu, G. Supply chain design under uncertainty for advanced biofuel production based on bio-oil gasification. Energy 2014, 74, 576–584. [Google Scholar] [CrossRef] [Green Version]

- You, F.; Tao, L.; Graziano, D.J.; Snyder, S.W. Optimal design of sustainable cellulosic biofuel supply chains: Multiobjective optimization coupled with life cycle assessment and input-output analysis. AIChE J. 2012, 58, 1157–1180. [Google Scholar] [CrossRef] [Green Version]

- Cambero, C.; Sowlati, T.; Pavel, M. Economic and life cycle environmental optimization of forest-based biorefinery supply chains for bioenergy and biofuel production. Chem. Eng. Res. Des. 2016, 107, 218–235. [Google Scholar] [CrossRef]

- Murillo-Alvarado, P.E.; Guillén-Gosálbez, G.; Ponce-Ortega, J.M.; Castro-Montoya, A.J.; Serna-González, M.; Jiménez, L. Multi-objective optimization of the supply chain of biofuels from residues of the tequila industry in Mexico. J. Clean. Prod. 2015, 108, 422–441. [Google Scholar] [CrossRef]

- Santibañez-Aguilar, J.E.; González-Campos, B.; Ponce-Ortega, J.M.; Serna-González, M.; El-Halwagi, M. Optimal planning and site selection for distributed multiproduct biorefineries involving economic, environmental and social objectives. J. Clean. Prod. 2014, 65, 270–294. [Google Scholar] [CrossRef]

- Babazadeh, R.; Razmi, J.; Pishvaee, M.S.; Rabbani, M. A sustainable second-generation biodiesel supply chain network design problem under risk. Omega 2017, 66, 258–277. [Google Scholar] [CrossRef] [Green Version]

- Zore, Ž.; Čuček, L.; Kravanja, Z. Synthesis of sustainable production systems using an upgraded concept of sustainability profit and circularity. J. Clean. Prod. 2018, 201, 1138–1154. [Google Scholar] [CrossRef]

- Barbosa-Póvoa, A.P.; da Silva, C.; Carvalho, A. Opportunities and challenges in sustainable supply chain: An operations research perspective. Eur. J. Oper. Res. 2018, 268, 399–431. [Google Scholar] [CrossRef]

- Lam, H.L.; Varbanov, P.; Klemeš, J.J. Optimisation of regional energy supply chains utilising renewables: P-graph approach. Comput. Chem. Eng. 2010, 34, 782–792. [Google Scholar] [CrossRef]

- Čuček, L.; Martin, M.; Grossmann, I.E.; Kravanja, Z. Multi-period synthesis of optimally integrated biomass and bioenergy supply network. Comput. Chem. Eng. 2014, 66, 57–70. [Google Scholar] [CrossRef]

- Akhtari, S.; Sowlati, T.; Griess, V.C. Integrated strategic and tactical optimization of forest-based biomass supply chains to consider medium-term supply and demand variations. Appl. Energy 2018, 213, 626–638. [Google Scholar] [CrossRef]

- Vogel, T.; Almada-Lobo, B.; Almeder, C. Integrated versus hierarchical approach to aggregate production planning and master production scheduling. OR Spectr. 2017, 39, 193–229. [Google Scholar] [CrossRef]

- Paradis, G.; Lebel, L.; D’Amours, S.; Bouchard, M. On the risk of systematic drift under incoherent hierarchical forest management planning. Can. J. For. Res. 2013, 43, 480–492. [Google Scholar] [CrossRef]

- Lin, T.; Rodríguez, L.F.; Shastri, Y.N.; Hansen, A.C.; Ting, K. Integrated strategic and tactical biomass–biofuel supply chain optimization. Bioresour. Technol. 2014, 156, 256–266. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Osmani, A.; Awudu, I.; Gonela, V. An integrated optimization model for switchgrass-based bioethanol supply chain. Appl. Energy 2013, 102, 1205–1217. [Google Scholar] [CrossRef]

- Ekşioğlu, S.D.; Acharya, A.; Leightley, L.E.; Arora, S. Analyzing the design and management of biomass-to-biorefinery supply chain. Comput. Ind. Eng. 2009, 57, 1342–1352. [Google Scholar] [CrossRef]

- Russo, D.; Spreafico, C. TRIZ-Based Guidelines for Eco-Improvement. Sustainability 2020, 12, 3412. [Google Scholar] [CrossRef] [Green Version]

- International Organization for Standardization. ISO 14040, Environmental Management-Life Cycle Assessment-Principles and Framework (ISO 14040:2006); International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Federal Transport Authority. Global Fuel Economy Initative, Final Draft Report on Pilot Global Fuel Economy Initiative Study in Ethiopia, Addis Ababa, 2012; Federal Transport Authority: Abu Dhabi, United Arab Emirates, 2012.

- Khoshnevisan, B.; Rafiee, S.; Tabatabaei, M.; Ghanavati, H.; Mohtasebi, S.S.; Rahimi, V.; Shafiei, M.; Angelidaki, I.; Karimi, K. Life cycle assessment of castor-based biorefinery: A well to wheel LCA. Int. J. Life Cycle Assess. 2018, 23, 1788–1805. [Google Scholar] [CrossRef]

- Soam, S.; Kumar, R.; Gupta, R.P.; Sharma, P.K.; Tuli, D.K.; Das, B. Life cycle assessment of fuel ethanol from sugarcane molasses in northern and western India and its impact on Indian biofuel programme. Energy 2015, 83, 307–315. [Google Scholar] [CrossRef]

- Tesfamichael, B.; Gessese, N. Effect of Biochar Application Rate, Production (Pyrolysis) Temperature and Feedstock Type (Rice Husk/Maize Straw) on Amendment of Clay-Acidic Soil. In Lecture Notes of the Institute for Computer Sciences, Social Informatics and Telecommunications Engineering; Springer: Berlin/Heidelberg, Germany, 2019; pp. 135–144. [Google Scholar]

- Bitra, V.S.; Womac, A.; Chevanan, N.; Miu, P.I.; Igathinathane, C.; Sokhansanj, S.; Smith, D.R. Direct mechanical energy measures of hammer mill comminution of switchgrass, wheat straw, and corn stover and analysis of their particle size distributions. Powder Technol. 2009, 193, 32–45. [Google Scholar] [CrossRef]

- Kinamehr, M.H.; Abooali, B. Influence of feed moisture and hammer mill operating factors on bagasse particle size distributions. Agric. Eng. Int. CIGR J. 2020, 22, 180–188. [Google Scholar]

- Cheng, M.-H.; Sekhon, J.J.; Rosentrater, K.A.; Wang, T.; Jung, S.; Johnson, L.A. Environmental impact assessment of soybean oil production: Extruding-expelling process, hexane extraction and aqueous extraction. Food Bioprod. Process. 2018, 108, 58–68. [Google Scholar] [CrossRef]

- Hou, J.; Zhang, P.; Yuan, X.; Zheng, Y. Life cycle assessment of biodiesel from soybean, jatropha and microalgae in China conditions. Renew. Sustain. Energy Rev. 2011, 15, 5081–5091. [Google Scholar] [CrossRef]

- Abebe, D.K. A Life Cycle Assessment on Liquid Biofuel Use in the Transport Sector of Ethiopia. Ph.D. Thesis, University of South Africa, Pretoria, South Africa, 2013. [Google Scholar]

- Foust, T.; Aden, A.; Dutta, A.; Phillips, S. An economic and environmental comparison of a biochemical and a thermochemical lignocellulosic ethanol conversion processes. Cellulose 2009, 16, 547–565. [Google Scholar] [CrossRef]

- Mu, D.; Seager, T.; Rao, P.S.; Zhao, F. Comparative Life Cycle Assessment of Lignocellulosic Ethanol Production: Biochemical Versus Thermochemical Conversion. Environ. Manag. 2010, 46, 565–578. [Google Scholar] [CrossRef]

- Tasić, M.B.; Stamenković, O.S.; Veljković, V.B. Cost analysis of simulated base-catalyzed biodiesel production processes. Energy Convers. Manag. 2014, 84, 405–413. [Google Scholar] [CrossRef]

- Kaewcharoensombat, U.; Prommetta, K.; Srinophakun, T. Life cycle assessment of biodiesel production from jatropha. J. Taiwan Inst. Chem. Eng. 2011, 42, 454–462. [Google Scholar] [CrossRef]

- Liang, S.; Xu, M.; Zhang, T. Life cycle assessment of biodiesel production in China. Bioresour. Technol. 2013, 129, 72–77. [Google Scholar] [CrossRef]

- Vogtlander, J.G.; Bijma, A. The ‘Virtual Pollution Prevention Costs ‘99’. Int. J. Life Cycle Assess. 2000, 5, 113–120. [Google Scholar] [CrossRef]

- Miret, C.; Chazara, P.; Montastruc, L.; Negny, S.; Domenech, S. Design of bioethanol green supply chain: Comparison between first and second generation biomass concerning economic, environmental and social criteria. Comput. Chem. Eng. 2016, 85, 16–35. [Google Scholar] [CrossRef] [Green Version]

- Berhanu, M.; Jabasingh, S.A.; Kifile, Z. Expanding sustenance in Ethiopia based on renewable energy resources – A comprehensive review. Renew. Sustain. Energy Rev. 2017, 75, 1035–1045. [Google Scholar] [CrossRef]

- Marinković, D.; Stanković, M.V.; Veličković, A.V.; Avramović, J.M.; Miladinović, M.R.; Stamenković, O.; Veljković, V.B.; Jovanović, D.M. Calcium oxide as a promising heterogeneous catalyst for biodiesel production: Current state and perspectives. Renew. Sustain. Energy Rev. 2016, 56, 1387–1408. [Google Scholar] [CrossRef]

- CSA. Agricultural Sample Survey 2019/20: Report on Area and Production Of Major Crops, I. 2020. Available online: https://www.statsethiopia.gov.et/ (accessed on 29 May 2020).

- Marvin, W.A.; Schmidt, L.D.; Benjaafar, S.; Tiffany, D.G.; Daoutidis, P. Economic Optimization of a Lignocellulosic Biomass-to-Ethanol Supply Chain. Chem. Eng. Sci. 2012, 67, 68–79. [Google Scholar] [CrossRef]

- FAO. Ethiopia: Report on Feed Inventory and Feed Balance; FAO: Rome, Italy, 2018. [Google Scholar]

- Lakew, H.; Shiferaw, Y. Rapid Assessment of Biofuels Development Status in Ethiopia and Proceedings of the National Workshop on Environmental Impact Assessment and Biofuels; MELCA Mahiber: Addis Ababa, Ethiopia, 2008. [Google Scholar]

- Salehu, F.; Abebe, S.; Walle, T. Implementing Biofuels Programme for Household and Transport Energy Use; Case Study On Regulatory Reforms for Adoption of Biofuels Programme in Ethiopia; MELCA Mahiber: Addis Ababa, Ethiopia, 2015. [Google Scholar]

- MoMPNG. Baseline, Suitability Map, and Value Chain Study on Biofuel Development of Ethiopia; MELCA Mahiber: Addis Ababa, Ethiopia, 2018. [Google Scholar]

- FAO. FAOSTAT. 2019. Available online: http://www.fao.org/faostat/en/#home (accessed on 26 December 2019).

- Peters, M.S.; Timmerhaus, K.D.; West, R.E. Plant Design and Economics for Chemical Engineers; McGraw-Hill: New York, NY, USA, 2003. [Google Scholar]

- Cao, X.; Rosentrater, K.A. LCA and TEA of Corn Stover Size Reduction. In Proceedings of the 2016 ASABE International Meeting, Orlando, FL, USA, 17–20 July 2016. [Google Scholar] [CrossRef] [Green Version]

- Cheng, M.-H.; Dien, B.S.; Singh, V. Economics of plant oil recovery: A review. Biocatal. Agric. Biotechnol. 2019, 18, 101056. [Google Scholar] [CrossRef]

- Yue, D.; Slivinsky, M.; Sumpter, J.; You, F. Sustainable Design and Operation of Cellulosic Bioelectricity Supply Chain Networks with Life Cycle Economic, Environmental, and Social Optimization. Ind. Eng. Chem. Res. 2014, 53, 4008–4029. [Google Scholar] [CrossRef]

| Mono-Objective Optimization Case | Profit Value (M USD) | Investment Cost Value (M USD) | Ecocost Value (M USD) |

|---|---|---|---|

| Max profit Equation (10) | 3110 | 22,081 | 4936 |

| Min investment cost Equation (11) | - | - | - |

| Min ecocost Equation (12) | 0.00 | 18,985 | 4416 |

| Equation (13) | Equation (14) | Equation (15) | Equation (16) | ||

|---|---|---|---|---|---|

| Number of constraints | 1,348,768 | 1,348,768 | 1,348,768 | 1,348,772 | |

| Number of binary variables | 174 | 174 | 174 | 174 | |

| Number of continuous variables | 2,404,430 | 2,404,430 | 2,404,430 | 2,404,430 | |

| CPU time using an Intel 2.60-GHz processor (minutes) | Min | 32.49 | 29.05 | 58.42 | 157.21 |

| Max | 176.01 | 169.45 | 102.42 | 668.58 | |

| Iterations | Min | 3,079,950 | 2,989,417 | 3,258,726 | 4,484,996 |

| Max | 6,332,344 | 6,051,353 | 5,187,132 | 25,247,564 | |

| Relative optimality gap (%) | 0.01 | ||||

| Absolute optimality gap (%) | 0.0001 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tesfamichael, B.; Montastruc, L.; Negny, S.; Yimam, A. Incorporating Environmental Perspective in Integrated Strategic-Tactical Economic Optimization Model of Biomass-to-Biofuel Supply Chain—A Real Case Study in Ethiopia. Processes 2021, 9, 1879. https://doi.org/10.3390/pr9111879

Tesfamichael B, Montastruc L, Negny S, Yimam A. Incorporating Environmental Perspective in Integrated Strategic-Tactical Economic Optimization Model of Biomass-to-Biofuel Supply Chain—A Real Case Study in Ethiopia. Processes. 2021; 9(11):1879. https://doi.org/10.3390/pr9111879

Chicago/Turabian StyleTesfamichael, Brook, Ludovic Montastruc, Stéphane Negny, and Abubeker Yimam. 2021. "Incorporating Environmental Perspective in Integrated Strategic-Tactical Economic Optimization Model of Biomass-to-Biofuel Supply Chain—A Real Case Study in Ethiopia" Processes 9, no. 11: 1879. https://doi.org/10.3390/pr9111879