A Brief Introduction to the Polyurethanes According to the Principles of Green Chemistry

Abstract

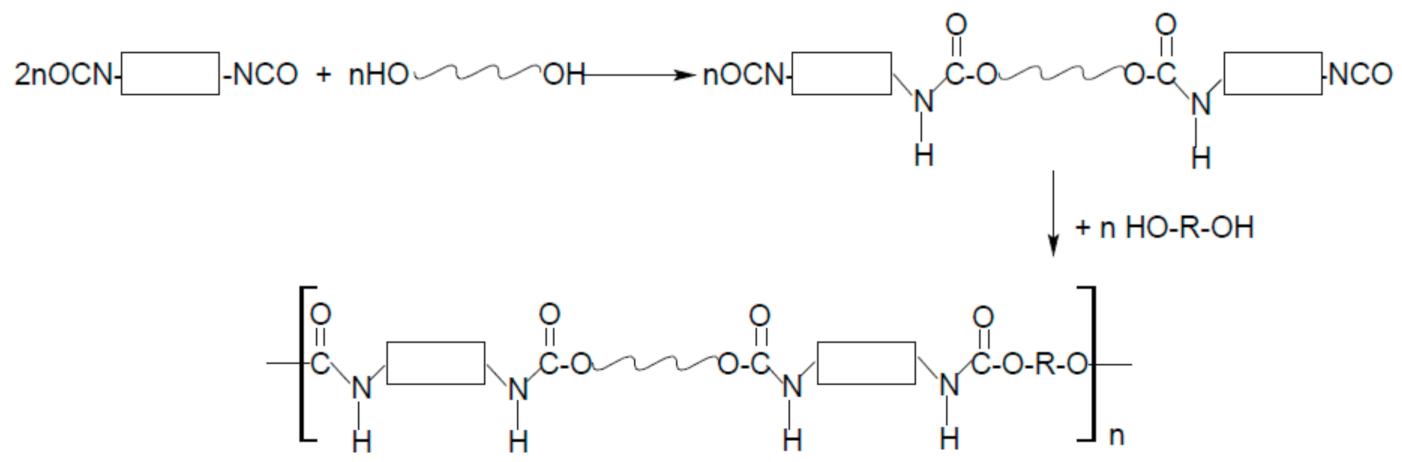

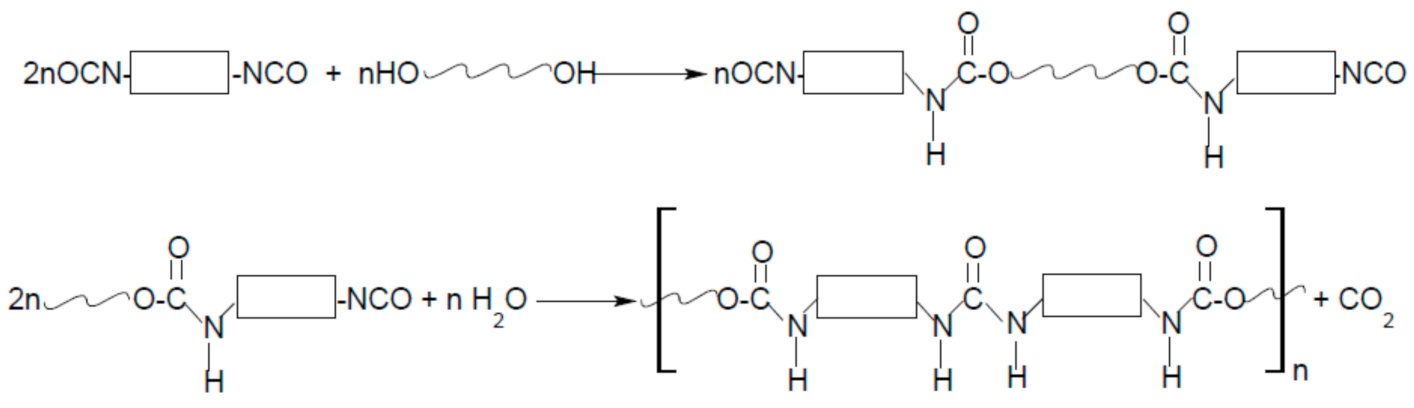

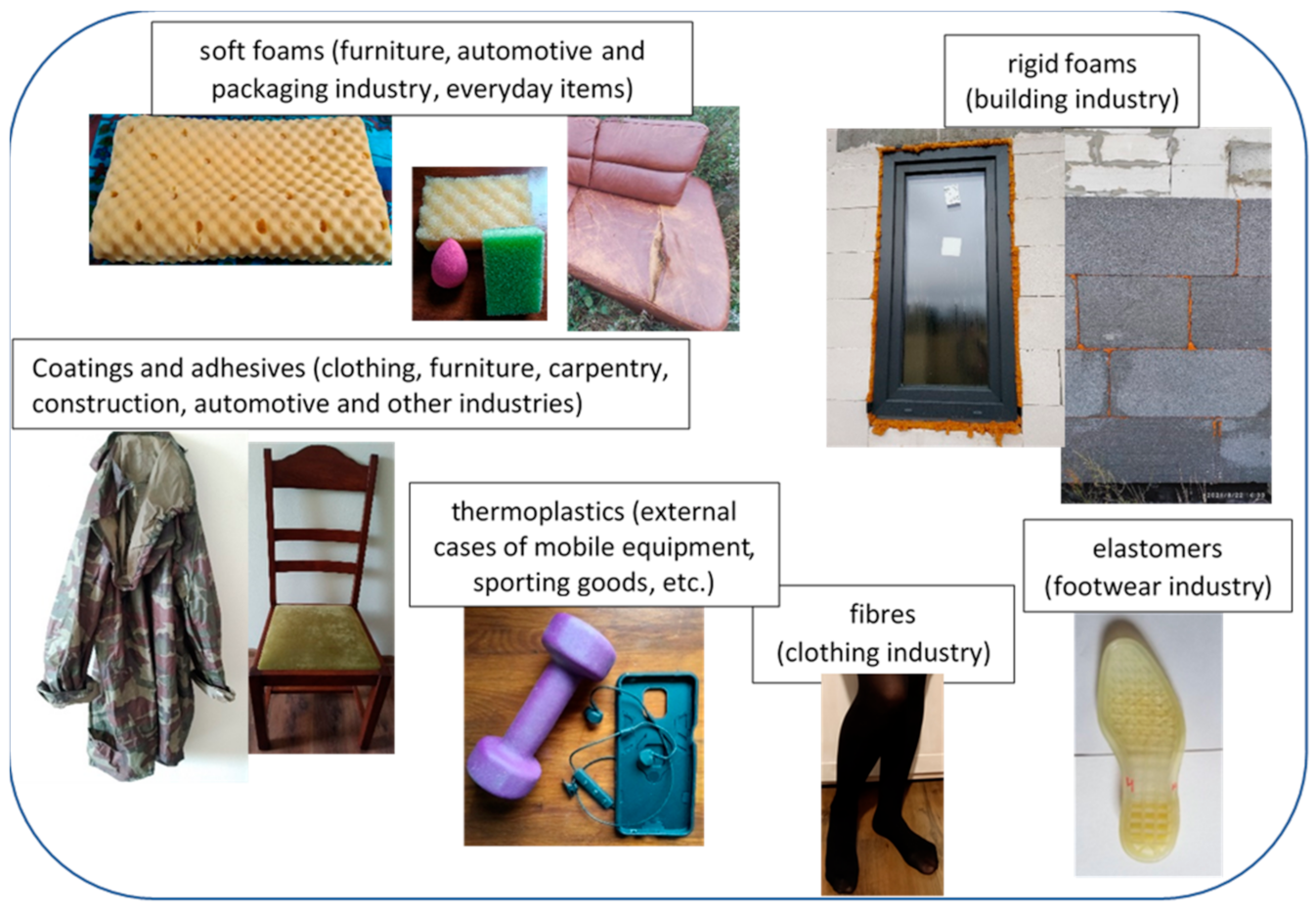

:1. Introduction

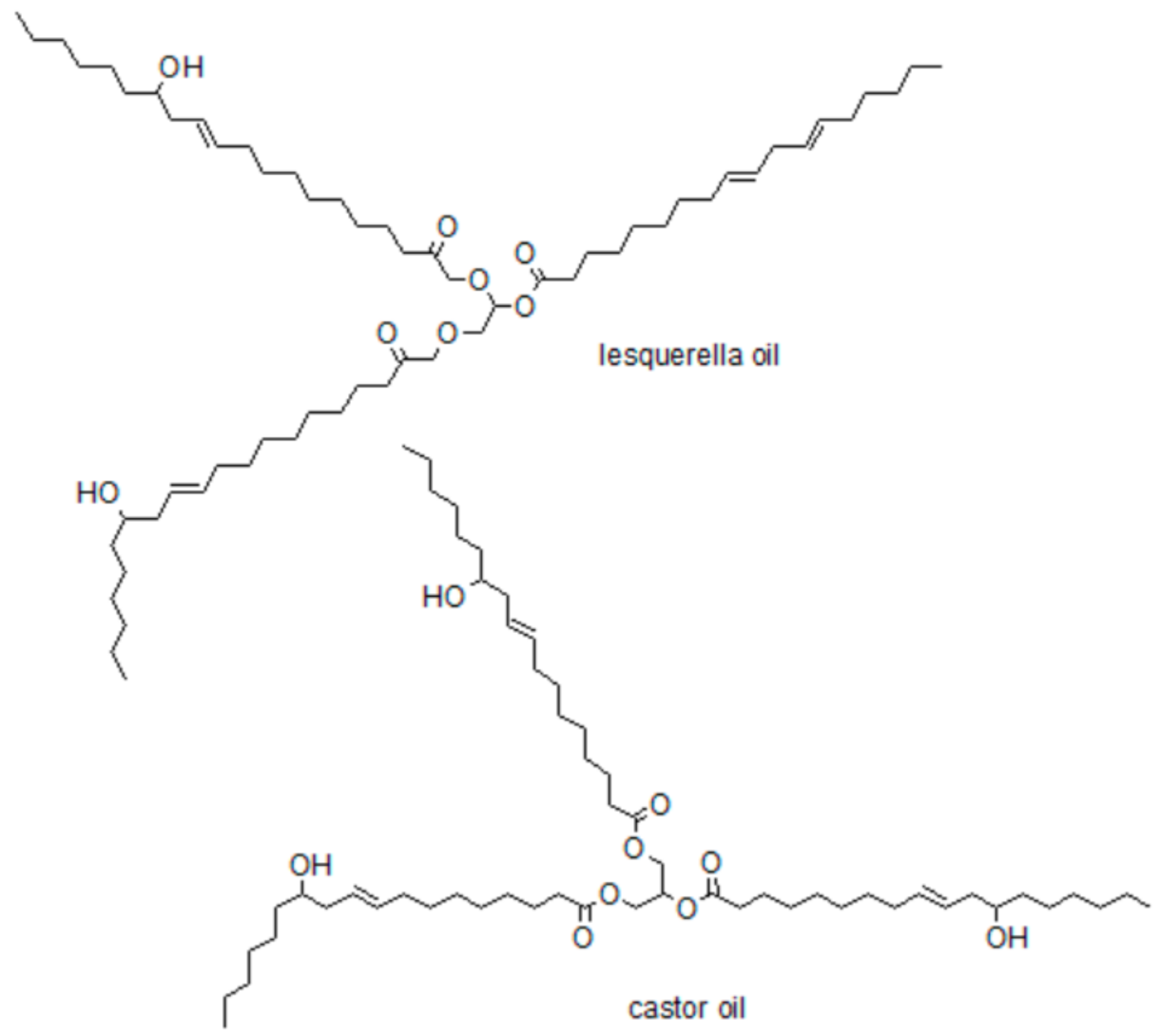

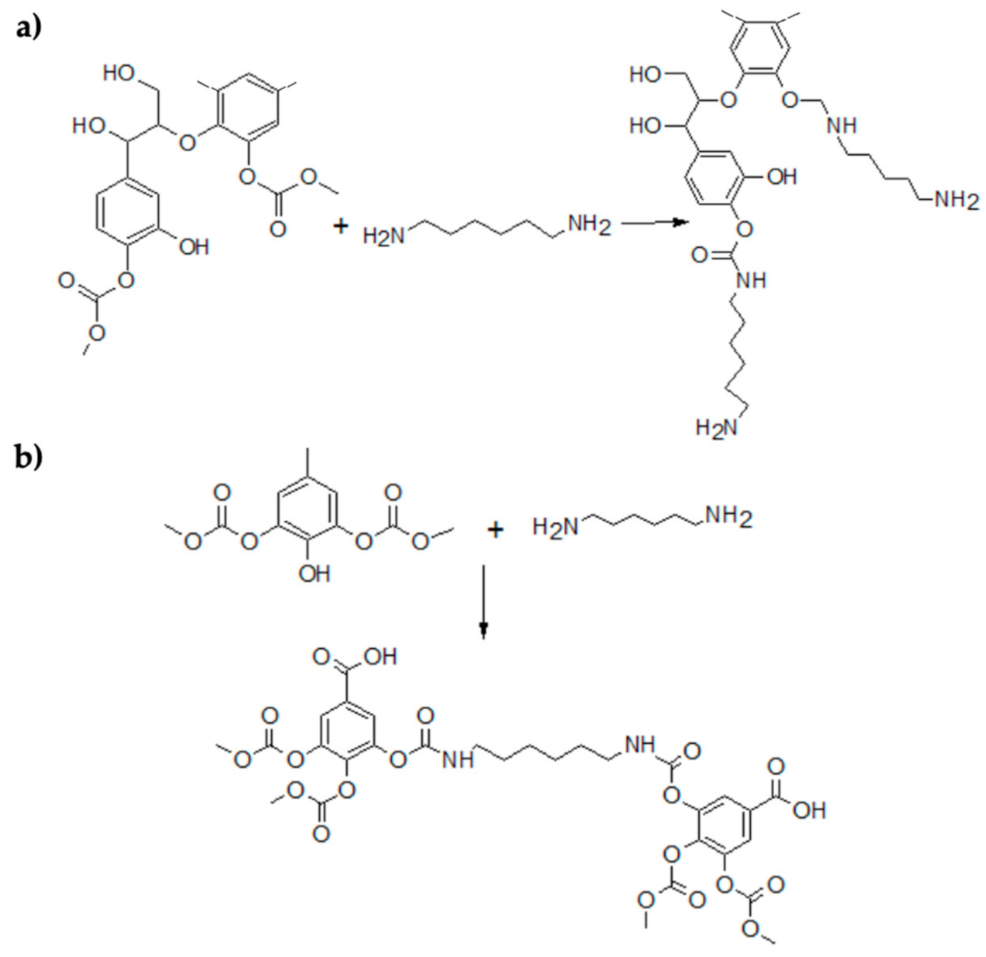

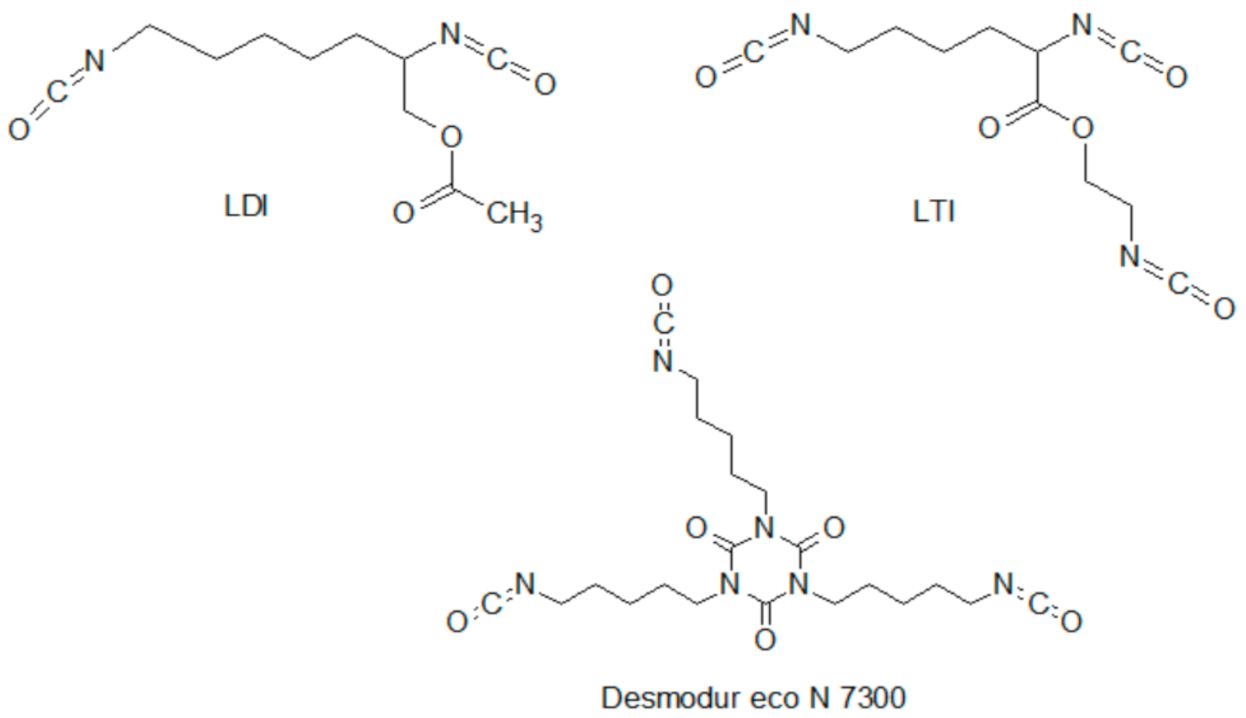

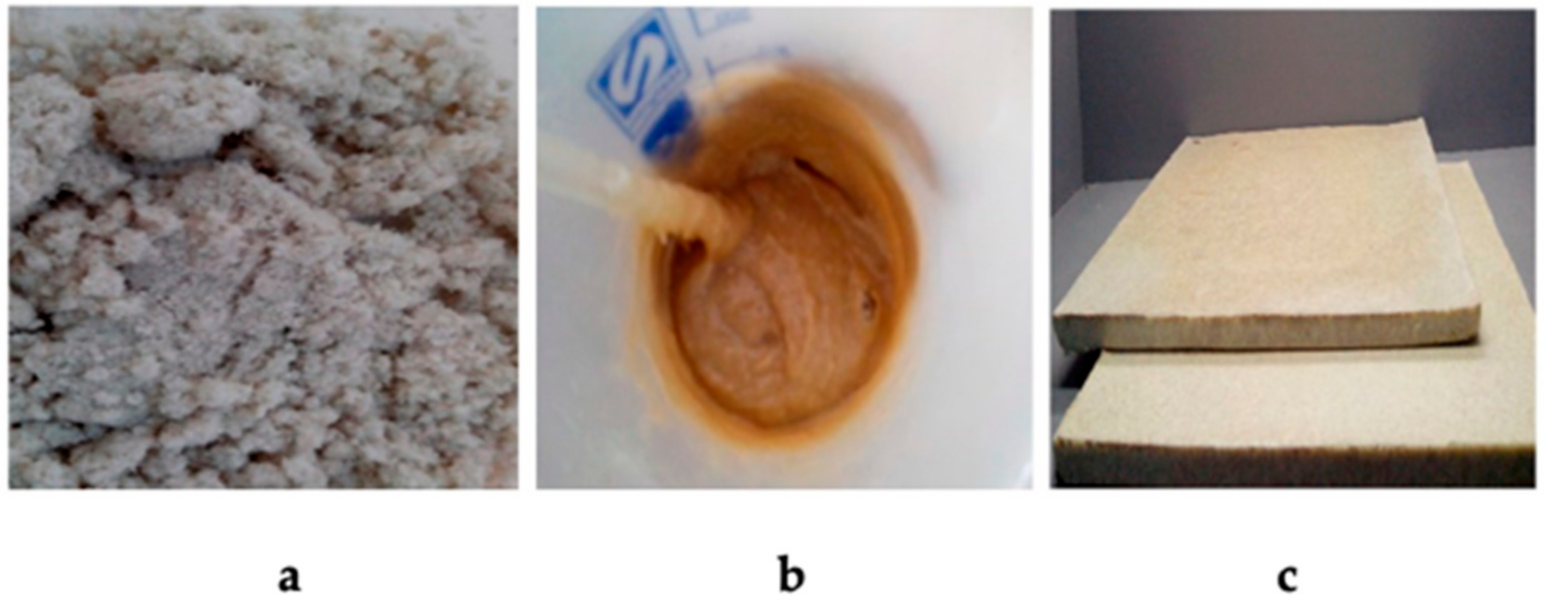

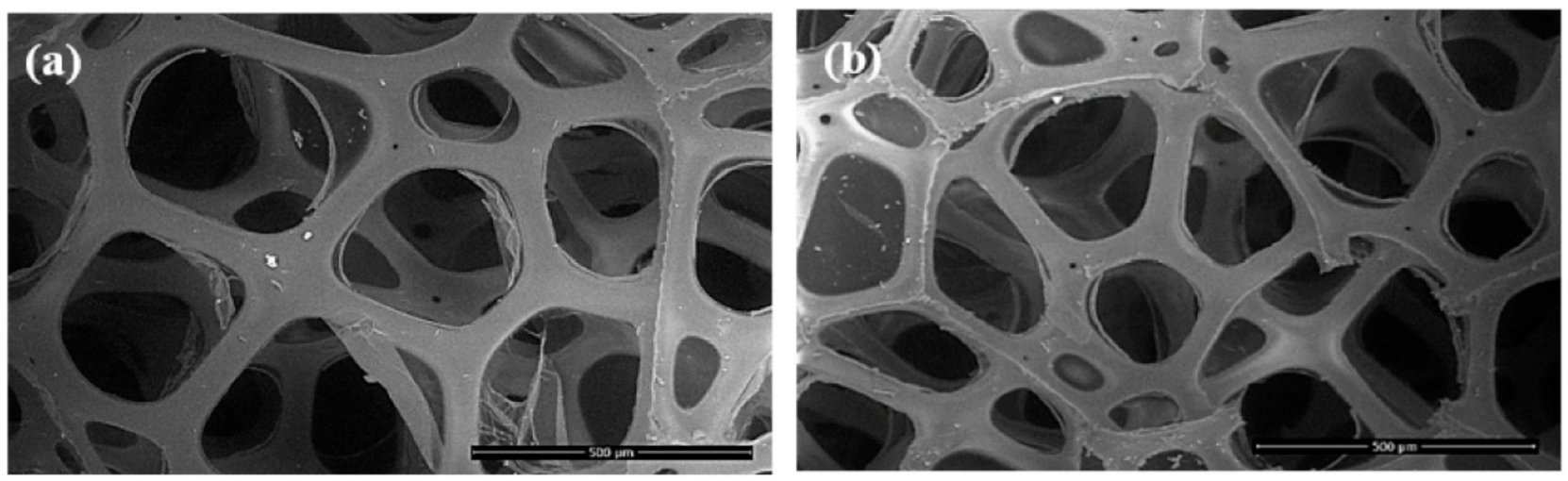

2. The Principles in the Green Chemistry of Polyurethanes

3. Future Perspectives and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- American Chemistry Council—Center for the Polyurethanes Industry (CPI). Available online: https://polyurethane.americanchemistry.com/History/ (accessed on 21 August 2021).

- Loreti, A.; Siri, G.; De Carli, M.; Fanelli, B.; Arelli, F.; Spallone, D.; Abate, O.; La Pinta, M.; Manna, E.; Meli, E.Z.; et al. Immediate Breast Reconstruction after mastectomy with polyurethane implants versus textured implants: A retrospective study with focus on capsular contracture. Breast 2020, 54, 127–132. [Google Scholar] [CrossRef] [PubMed]

- Naemonitou, F.; Mylvaganam, S.; Salem, F.; Vidya, R. Outcome of complete acellular dermal matrix wrap with polyurethane implant in immediate prepectoral breast reconstruction. Arch. Plast. Surg. 2020, 47, 567–573. [Google Scholar] [CrossRef]

- Cui, Z.X.; Shen, S.; Wu, J.H.; Si, J.H.; Wang, Q.T.; Turng, L.-S.; Chen, W.Z. Functionalization of 3-D porous thermoplastic polyurethane scaffolds by two-stage polydopamine/hydroxyapatite composite nanoparticles. Express Polym. Lett. 2020, 14, 794–807. [Google Scholar] [CrossRef]

- Yang, J.; Chen, H.; Yuan, Y.; Sarkar, D.; Zheng, J. Synthesis and characterization of biocompatible polyurethanes for controlled release of hydrophobic and hydrophilic drugs. Front. Chem. Sci. Eng. 2014, 8, 498–510. [Google Scholar] [CrossRef]

- González-Torres, M.; Serrano-Aguilar, I.H.; Cabrera-Wrooman, A.; Sánchez-Sánchez, R.; Pichardo-Bahena, R.; Melgarejo-Ramírez, Y.; Leyva-Gómez, G.; Cortés, H.; de los Angeles Moyaho-Bernal, M.; Lima, E.; et al. Gamma radiation-induced grafting of poly(2-aminoethyl methacrylate) onto chitosan: A comprehensive study of a polyurethane scaffold intended for skin tissue engineering. Carbohydr. Polym. 2021, 270, 117916. [Google Scholar] [CrossRef]

- Shaabani, A.; Sedghi, R. Synthesis of shape memory electroconductive polyurethane with self-healing capability as an intelligent biomedical scaffold for bone tissue engineering. Polymer 2021, 223, 123694. [Google Scholar] [CrossRef]

- Matsumura, S.; Soeda, Y.; Toshima, K. Perspectives for synthesis and production of polyurethanes and related polymers by enzymes directed toward green and sustainable chemistry. Appl. Microbiol. Biotechnol. 2006, 70, 12–20. [Google Scholar] [CrossRef]

- Sheldon, R. Metrics of Green Chemistry and Sustainability: Past, Present, and Future. ACS Sustain. Chem. Eng. 2017, 6, 32–48. [Google Scholar] [CrossRef] [Green Version]

- Bodner, G.M. The quadruple bottom line: The advantages of incorporating Green Chemistry into the undergraduate chemistry major. In Green Chemical Processes: Developments in Research and Education; Benvenuto, M.A., Ed.; Walter de Gruyter GmbH: Berlin, Germany; Boston, MA, USA, 2017. [Google Scholar]

- Etzkorn, F.A. Green Chemistry. Principles and Case Study; The Royal Society of Chemistry: London, UK, 2020; pp. XI–XIII. [Google Scholar]

- FACTS Hazardous Materials Accidents Knowledge Base. Available online: http://www.factsonline.nl/accidents/%205405/10158_POLYURETHANE%20FOAM/chemical-accidents-with-polyurethane-foam (accessed on 21 August 2021).

- Association for the Study of Failure—Self-Ignition of Soft Urethane Foam on Restarting Operation after Maintenance at a Depot. Available online: http://www.shippai.org/fkd/en/cfen/CC1000063.html (accessed on 20 August 2021).

- Palumbo, F.S.; Federico, S.; Pitarresi, G.; Fiorica, C.; Giammona, G. Synthesis and characterization of redox-sensitive polyurethanes based on L-glutathione oxidized and poly(ether ester) triblock copolymers. React. Funct. Polym. 2021, 166, 104986. [Google Scholar] [CrossRef]

- Błażek, K.; Kasprzyk, P.; Datta, J. Diamine derivatives of dimerized fatty acids and bio-based polyether polyol as sustainable platforms for the synthesis of non-isocyanate polyurethanes. Polymer 2020, 205, 112768. [Google Scholar] [CrossRef]

- Chan, J.P.; Battiston, K.G.; Santerre, J.P. Synthesis and characterization of electrospun nanofibrous tissue engineering scaffolds generated from in situ polymerization of ionomeric polyurethane composites. Acta Biomater. 2019, 96, 161–174. [Google Scholar] [CrossRef]

- Munn, A. Hazards of isocyanates. Ann. Occup. Hyg. 1965, 8, 163–169. [Google Scholar]

- Tanser, A.R.; Bourke, M.P.; Blandford, A.G. Isocyanate asthma: Respiratory symptoms caused by diphenyl-methane di-isocyanate. Thorax 1973, 28, 596–600. [Google Scholar] [CrossRef] [Green Version]

- Bello, D.; Herrick, C.A.; Smith, T.J.; Woskie, S.R.; Streicher, R.P.; Cullen, M.R.; Liu, Y.; Redlich, C.A. Skin Exposure to Isocyanates: Reasons for Concern. Environ. Health Perspect. 2007, 115, 328–335. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mukai, M.; Woods, L.W.; Stump, S.; Ebel, J.G., Jr.; Levitt, A.S.; Frey, M.W.; Smith, J.; Uzal, F.A.; Poppenga, R.H.; Puschner, B. Detection of diisocyanates in nesting material associated with mortality in pigeon chicks. J. Vet. Diagn. Investig. 2014, 26, 327–333. [Google Scholar] [CrossRef] [PubMed]

- Xiang, F.; Yin, J.; Asri, L.; Loontjens, T. Functional polyurethanes based on blocked isocyanates. In Polyurethanes; Hope, F.L., Ed.; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2016; pp. 1–16. [Google Scholar]

- Waghmare, B.; Mahanwar, P. Review on synthesis of isocyanate free polyurethane using sustainable routes and its applications. Paintindia 2019, 83–98. Available online: https://colourpublications.in/product/paintindia/ (accessed on 21 August 2021).

- Lambeth, R.H. Progress in Hybrid Non-Isocyanate Polyurethanes. Polym. Int. 2021, 70, 696–700. [Google Scholar] [CrossRef]

- Gomez-Lopez, A.; Grignard, B.; Calvo, I.; Detrembleur, C.; Sardon, H. Synergetic Effect of Dopamine and Alkoxysilanes in Sustainable Non-Isocyanate Polyurethane Adhesives. Macromol. Rapid Commun. 2020, 42, 2000538. [Google Scholar] [CrossRef]

- Filippi, L.; Meier, M.A.R. Fully renewable non-isocyanate polyurethanes via the lossen rearrangement. Macromol. Rapid Commun. 2021, 42, 2000440. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Jin, B.; Wang, H.; Wu, W.; Cao, Z.; Wu, J.; Huang, G. A Degradable and Self-Healable Vitrimer Based on Non-isocyanate Polyurethane. Front. Chem. 2020, 8, 585569. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Chen, S.; Zhao, J.; Zhang, Z. Synthesis and characterization of self-healing cross-linked non-isocyanate polyurethanes based on Diels-Alder reaction with unsaturated polyester. Mater. Today Commun. 2020, 23, 101138. [Google Scholar] [CrossRef]

- Wolfgang, J.D.; White, B.T.; Long, T.E. Non-isocyanate Polyurethanes from 1,1′-Carbonyldiimidazole: A Polycondensation Approach. Macromol. Rapid Commun. 2021, 42, 2100163. [Google Scholar] [CrossRef]

- Boisaubert, P.; Kébir, N.; Schuller, A.-S.; Burel, F. Photo-crosslinked coatings from an acrylate terminated non-isocyanate polyurethane (NIPU) and reactive diluent. Eur. Polym. J. 2020, 138, 109961. [Google Scholar] [CrossRef]

- Wu, Z.; Tang, L.; Dai, J.; Jinqing, Q.J. Synthesis and properties of fluorinated non-isocyanate polyurethanes coatings with good hydrophobic and oleophobic properties. J. Coat. Technol. Res. 2019, 16, 1233–1241. [Google Scholar] [CrossRef]

- Zareanshahraki, F.; Asemani, H.R.; Skuza, J.; Mannari, V. Synthesis of non-isocyanate polyurethanes and their application in radiation-curable aerospace coatings. Progr. Org. Coat. 2020, 138, 105394. [Google Scholar] [CrossRef]

- Kanchana, R. Review of Eco friendly green polyurethanes with non-isocyanates: Current and future trends in green coatings. Paintindia 2017, 55–79. Available online: https://colourpublications.in/product/paintindia/ (accessed on 21 August 2021).

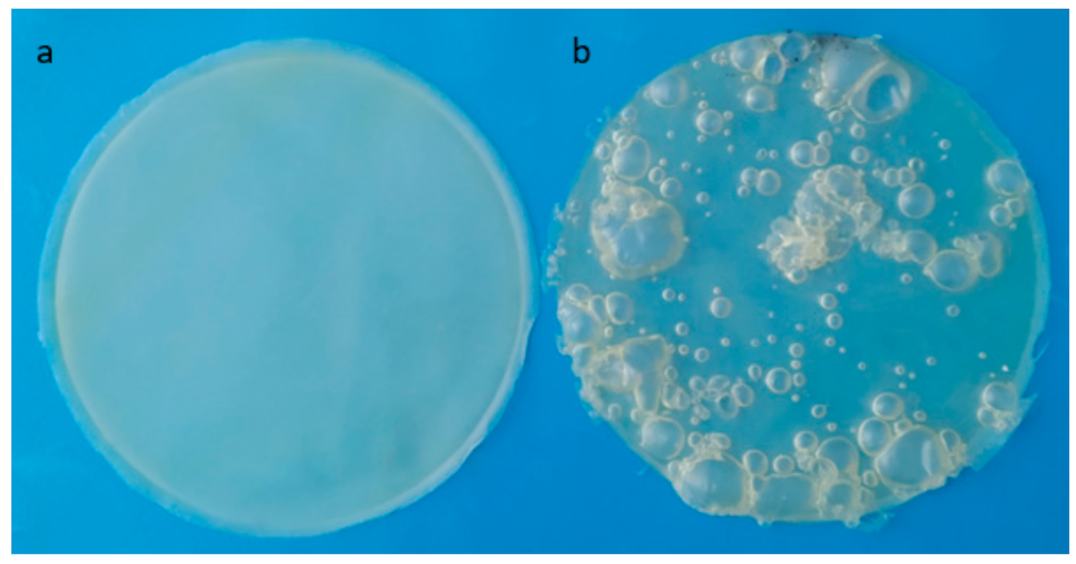

- Monie, F.; Grignard, B.; Thomassin, J.-M.; Mereau, R.; Thierry Tassaing, T.; Jerome, C.; Detrembleur, C. Chemo- and regio-selective additions of nucleophiles to cyclic carbonates for the preparation of self-blowing non-isocyanate polyurethane foams. Angew. Chem. Int. Ed. 2020, 132, 17181–17189. [Google Scholar] [CrossRef]

- Gholami, H.; Yeganeh, H. Soybean oil-derived non-isocyanate polyurethanes containing azetidinium groups as antibacterial wound dressing membranes. Eur. Polym. J. 2021, 142, 110142. [Google Scholar] [CrossRef]

- Stachak, P.; Łukaszewska, I.; Hebda, E.; Pielichowski, K. Recent Advances in Fabrication of Non-Isocyanate Polyurethane-Based Composite Materials. Materials 2021, 14, 3497. [Google Scholar] [CrossRef]

- Wołosz, D.; Parzuchowski, P.G.; Świderska, A. Synthesis and characterization of the non-isocyanate poly(carbonate-urethane)s obtained via polycondensation route. Eur. Polym. J. 2021, 155, 110574. [Google Scholar] [CrossRef]

- Kohale, D.G. Recent developments in water base paint for automotive paints. Paintindia 2018, 62–68. Available online: https://colourpublications.in/product/paintindia/ (accessed on 21 August 2021).

- Agnol, L.D.; Dias, F.T.G.D.; Ornaghi, H.L., Jr.; Sangermano, M.; Bianchi, O. UV-curable waterborne polyurethane coatings: A state-of-the-art and recent advances review. Prog. Org. Coat. 2021, 154, 106156. [Google Scholar] [CrossRef]

- Gong, R.; Cao, H.; Zhang, H.; Qiao, L.; Wang, X. UV-curable cationic waterborne polyurethane from CO2-polyol with excellent water resistance. Polymer 2021, 218, 123536. [Google Scholar] [CrossRef]

- Wei, Z.; Liu, Z.; Fu, X.; Wang, Y.; Yuan, A.; Lei, J. Effect of crystalline structure on water resistance of waterborne polyurethane. Eur. Polym. J. 2021, 157, 110647. [Google Scholar] [CrossRef]

- Zhang, Z.; Peng, P.; Wu, Q.; Zhang, J.; Wu, M.; Liu, J.; Yang, J. Preparation and antibacterial properties of poly(hexamethylene guanidine hydrochloride) modified ionic waterborne polyurethane. Prog. Org. Coat. 2021, 156, 106246. [Google Scholar] [CrossRef]

- Peng, X.; Liu, Y.; Xin, B.; Guo, H.; Yu, Y. Preparation and characterization of waterborne polyurethane nail enamel modified by silane coupling agent. J. Coat. Technol. Res. 2020, 17, 1377–1387. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, H.; Hu, G.; Wang, J.; Xin, Y.; Xiang, C.; Zhou, Y. Excellent water resistance and mechanically robust waterborne polyurethane-acrylate based on dithiol post-chain extension. J. Coat. Technol. Res. 2020, 17, 1065–1074. [Google Scholar] [CrossRef]

- Xu, W.; Wang, W.; Hao, L.; Liu, H.; Hai, F.; Wang, X. Synthesis and properties of novel triazine-based fluorinated chain extender modified waterborne polyurethane hydrophobic films. Prog. Org. Coat. 2021, 157, 106282. [Google Scholar] [CrossRef]

- Stefanović, I.S.; Džunuzović, J.V.; Džunuzović, E.S.; Brzić, S.J.; Jasiukaitytė-Grojzdek, E.; Basagni, A.; Marega, C. Tailoring the properties of waterborne polyurethanes by incorporating different content of poly(dimethylsiloxane). Prog. Org. Coat. 2021, 161, 106474. [Google Scholar] [CrossRef]

- Wu, J.; Wang, C.; Lin, W.; Ngai, T. A facile and effective approach for the synthesis of fluorinated waterborne polyurethanes with good hydrophobicity and antifouling properties. Prog. Org. Coat. 2021, 159, 106405. [Google Scholar] [CrossRef]

- Longfang, R.; Congcong, L.; Pingchuan, L. Preparation and properties of catechol-based waterborne polyurethane based on thiol-ene click chemistry reaction. Prog. Org. Coat. 2021, 157, 106303. [Google Scholar]

- Wang, X.; Cui, Y.; Wang, Y.; Ban, T.; Zhang, Y.; Zhang, J.; Zhu, X. Preparation and characteristics of crosslinked fluorinated acrylate modified waterborne polyurethane for metal protection coating. Prog. Org. Coat. 2021, 158, 106371. [Google Scholar] [CrossRef]

- Shan, J.; Jiang, L.; Wang, L.; Zhao, H.; Ding, X.; Zhou, C. Improvement of low-temperature damping performance by the control of three-dimensional network structure formed by renewable oil in modified waterborne polyurethane. Results Mater. 2021, 10, 100171. [Google Scholar] [CrossRef]

- Qian, Y.; Dong, F.; Guo, L.; Xu, X.; Liu, H. Terpene derivative-containing silicone two-component waterborne polyurethane for coatings. Prog. Org. Coat. 2021, 153, 106137. [Google Scholar] [CrossRef]

- Chen, Y.; Yu, Z.; Oguzlu, H.; Jiang, J.; Cho, M.; Karaaslan, M.; Renneckar, S.; Jiang, F. Superelastic and flexible 3D printed waterborne polyurethane/cellulose nanofibrils structures. Addit. Manuf. 2021, 46, 102107. [Google Scholar]

- Fan, W.; Wang, J.; Li, Z. Antiglare waterborne polyurethane/modified silica nanocomposite with balanced comprehensive properties. Polym. Test. 2021, 99, 107072. [Google Scholar] [CrossRef]

- Bramhecha, I.; Sheikh, J. Antibacterial and waterproof breathable waterborne polyurethane functionalised by graphene to develop UV and NIR-protective cotton fabric. Carbon Trends 2021, 4, 100067. [Google Scholar] [CrossRef]

- Smith, C.A.; Cramail, H.; Tassaing, T. Insights into the Organocatalyzed Synthesis of Urethanes in Supercritical Carbon Dioxide: An In Situ FTIR Spectroscopic Kinetic Study. Chem. Cat. Chem. 2014, 6, 1380–1391. [Google Scholar] [CrossRef]

- Ihata, O.; Kayaki, Y.; Ikariya, T. Synthesis of Thermoresponsive Polyurethane from 2-Methylaziridine and Supercritical Carbon Dioxide. Angew. Chem. Int. Ed. 2004, 43, 717–719. [Google Scholar] [CrossRef]

- Wang, J.; Li, J.; Li, H.; Zhou, H. Thermoplastic polyurethane (TPU) modifier to develop bimodal cell structure in polypropylene/TPU microcellular foam in presence of supercritical CO2. J. Vinyl. Addit. Technol. 2021, 27, 127–136. [Google Scholar] [CrossRef]

- Huang, A.; Wang, H.; Ellingham, T.; Peng, X.; Turng, L.-S. An improved technique for dispersion of natural graphite particles in thermoplastic polyurethane by sub-critical gas-assisted processing. Comp. Sci. Tech. 2019, 182, 107783. [Google Scholar] [CrossRef]

- Primel, A.; Férec, J.; Ausias, G.; Tirel, Y.; Veillé, J.-M.; Grohens, Y. Solubility and interfacial tension of thermoplastic polyurethane meltin supercritical carbon dioxide and nitrogen. J. Supercrit. Fluids 2017, 122, 52–57. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, T.; Hu, D.; Xu, Z.; Zhao, L. Foaming window for preparation of microcellular rigid polyurethanes using supercritical carbon dioxide as blowing agent. J. Supercrit. Fluids 2019, 147, 254–262. [Google Scholar] [CrossRef]

- Wang, W.; Liao, X.; Yusong, H.; Li, J.; Jiang, Q.; Li, G. Thermoplastic polyurethane/polytetrafluoroethylene composite foams with enhanced mechanical properties and anti-shrinkage capability fabricated with supercritical carbon dioxide. J. Supercrit. Fluids 2020, 163, 104861. [Google Scholar] [CrossRef]

- Savaris, M.; Garcia, C.S.C.; Roesch-Ely, M.; Henriques, J.A.P.; dos Santos, V.; Brandalise, R.N. Polyurethane/poly(D,L-lactic acid) scaffolds based on supercritical fluid technology for biomedical applications: Studies with L929 cells. Mat. Sci. Eng. C 2019, 96, 539–551. [Google Scholar] [CrossRef] [PubMed]

- Qu, Z.; Yin, D.; Zhou, H.; Wang, X.; Zhao, S. Cellular morphology evolution in nanocellular poly (lactic acid)/thermoplastic polyurethane blending foams in the presence of supercritical N2. Europ. Polym. J. 2019, 116, 291–301. [Google Scholar] [CrossRef]

- Filardo, G.; Galia, A.; Gambino, S.; Silvestri, G. Supercritical-Fluid Extraction of Chlorofluoroalkanes from Rigid Polyurethane Foams. J. Supercrit. Fluids 1996, 9, 234–237. [Google Scholar] [CrossRef]

- Chen, S.-C.; Chang, C.-W.; Tseng, C.Y.; Shen, E.-N.; Feng, C.-T. Using P(Pressure)-T(Temperature) Path to Control the Foaming Cell Sizes in Microcellular Injection Molding Process. Polymers 2021, 13, 1843. [Google Scholar] [CrossRef]

- Sirrine, J.M.; Ashraf-Khorassani, M.; Moon, N.G.; Mondschein, R.J.; Long, T.E. Supercritical Fluid Chromatography with Evaporative Light Scattering Detection (SFC-ELSD) for Determination of Oligomer Molecular Weight Distributions. Chromatographia 2016, 79, 977–984. [Google Scholar] [CrossRef]

- Biswas, A.; Appell, M.; Liu, Z.; Cheng, H.N. Microwave-assisted synthesis of cyclodextrin polyurethanes. Carbohydr. Polym. 2015, 133, 74–79. [Google Scholar] [CrossRef]

- Lubczak, R. New Method of Synthesis of Oligoetherols with Carbazole Ring. Acta Chim. Slov. 2015, 62, 652–661. [Google Scholar] [CrossRef] [Green Version]

- Boisaubert, P.; Kébir, N.; Schuller, A.-S.; Burel, F. Photo-crosslinked Non-Isocyanate Polyurethane Acrylate (NIPUA) coatings through a transurethane polycondensation approach. Polymer 2020, 206, 122855. [Google Scholar] [CrossRef]

- Peyton, J.; Avérous, L. Structure-properties relationships of cellular materials from biobased polyurethane foams. Mater. Sci. Eng. R 2021, 145, 100608. [Google Scholar] [CrossRef]

- Morales-Cerrada, R.; Tavernier, R.; Caillol, S. Fully Bio-Based Thermosetting Polyurethanes from Bio-Based Polyols and Isocyanates. Polymers 2021, 13, 1255. [Google Scholar] [CrossRef]

- Noreen, A.; Zia, K.M.; Zuber, M.; Tabasum, S.; Zahoor, A.F. Bio-based polyurethane: An efficient and environment friendly coating systems: A review. Prog. Org. Coat. 2016, 91, 25–32. [Google Scholar] [CrossRef]

- Llevot, A.; Meier, M. Perspective: Green polyurethane synthesis for coating applications. Polym. Int. 2019, 68, 826–831. [Google Scholar] [CrossRef]

- Bresolin, D.; Estrella, A.S.; da Silva, J.R.P.; Valério, A.; Sayer, C.; de Araújo, P.H.H.; de Oliveira, D. Synthesis of a green polyurethane foam from a biopolyol obtained by enzymatic glycerolysis and its use for immobilization of lipase NS-40116. Bioprocess Biosyst. Eng. 2019, 42, 213–222. [Google Scholar] [CrossRef]

- Isbell, T.A.; Lowery, B.A.; DeKeyser, S.S.; Winchell, M.L.; Cermak, S.C. Physical properties of triglyceride estolides from lesquerella and castor oils. Ind. Crop. Prod. 2006, 23, 256–263. [Google Scholar] [CrossRef]

- Petrović, Z.S. Polyurethanes from Vegetable Oils. Polym. Rev. 2008, 48, 109–155. [Google Scholar] [CrossRef]

- Bundjali, B.; Masykuri, M.; Hartantini, F.W.; Arcana, M. Poly(urethane-urea) synthetised from 9-ethoxy-1,10-octadecanediol obtained by modification of palm oil oleic acid. J. Math. Fund. Sci. 2018, 50, 13–27. [Google Scholar] [CrossRef]

- Mohammed, I.A.; Khadir, N.K.A.; Al-Murra, E.A.J. New polyurethane nanocomposites based on soya oil. J. Oleo Sci. 2014, 63, 193–200. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Zhang, J.; Huang, J.; Wang, H.; He, M.; Ding, L. Flame Retardant Modified Bio-Based Waterborne Polyurethane Dispersions Derived from Castor Oil and Soy Polyol. Eur. J. Lipid Sci. Technol. 2021, 123, 2000248. [Google Scholar] [CrossRef]

- Karimi, M.B.; Khanbabaeib, G.; Sadeghi, C.M.M. Vegetable oil-based polyurethane membrane for gas separation. J. Membr. Sci. 2017, 527, 198–206. [Google Scholar] [CrossRef]

- Kurth, T.M.; Kurth, R.A.; Turner, R.B.; Kreifels, L.P. Vegetable Oil-Based Coating and Method for Application. U.S. Patent 8575226, 4 December 2001. [Google Scholar]

- Aristri, M.A.; Lubis, M.A.R.; Yadav, S.M.; Antov, P.; Papadopoulos, A.N.; Pizzi, A.; Fatriasari, W.; Ismayati, M.; Iswanto, A.H. Recent Developments in Lignin- and Tannin-Based Non-Isocyanate Polyurethane Resins for Wood Adhesives—A Review. Appl. Sci. 2021, 11, 4242. [Google Scholar] [CrossRef]

- Klein, S.E.; Rumpf, J.; Alzagameem, A.; Rehahn, M.; Schulze, M. Antioxidant activity of unmodified kraft and organosolv lignins to be used as sustainable components for polyurethane coatings. J. Coat. Technol. Res. 2019, 16, 1543–1552. [Google Scholar] [CrossRef]

- Visco, A.; Nocita, D.; Giamporcaro, A.; Ronca, S.; Forte, G.; Pistone, A.; Espro, C. Effect of Ethyl Ester L-Lysine Triisocyanate addition to produce reactive PLA/PCL bio-polyester blends for biomedical applications. J. Mech. Behav. Biomed. Mater. 2017, 68, 308–317. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gu, R.; Sain, M. Biobased Polyurethanes in Handbook of Green Materials: Processing Technologies, Properties and Applications; Oksman, K., Mathew, A.P., Bismarck, A., Rojas, O., Sain, M., Eds.; World Scientific Publishing Company: Singapore, 2014; pp. 77–87. [Google Scholar]

- Da Silva, F.C.; Felgueiras, H.P.; Ladchumananandasivam, R.; Mendes, J.U.L.; de O Souto Silva, K.K.; Zille, A. Dog wool microparticles/polyurethane composite for thermal insulation. Polymers 2020, 12, 1098. [Google Scholar] [CrossRef] [PubMed]

- Alonso-Lerma, B.; Larraza, I.; Barandiaran, L.; Ugarte, L.; Saralegi, A.; Corcuera, M.A.; Perez-Jimenez, R.; Eceiza, A. Enzymatically produced cellulose nanocrystals as reinforcement for waterborne polyurethane and its applications. Carbohydr. Polym. 2021, 254, 117478. [Google Scholar] [CrossRef] [PubMed]

- Alma, M.H.; Salan, T.; Tozluoglu, A.; Gonultas, O.; Candan, Z. Green composite materials from liquefied biomass. In Green Composites: Materials, Manufacturing and Engineering; Davim, J.P., Ed.; Walter de Gruyter GmbH: Berlin, Germany; Boston, MA, USA, 2017; pp. 1–31. [Google Scholar]

- Silva Araújo, R.C.; Duarte Pasa, V.M.; Marriott, P.J.; Cardeal, Z.L. Analysis of volatile organic compounds in polyurethane coatings based on Eucalyptus sp. bio-oil pitch using comprehensive two-dimensional gas chromatography (GC×GC). J. Anal. Appl. Pyrolysis 2010, 88, 91–97. [Google Scholar] [CrossRef]

- Sarojini, S.K.; Indumathi, M.P.; Rajarajeswari, G.R. Mahua oil-based polyurethane/chitosan/nano ZnO composite films for biodegradable food packaging applications. Int. J. Biol. Macromol. 2019, 124, 163–174. [Google Scholar]

- Ghasemlou, M.; Daver, E.; Ivanova, E.P.; Brkljaca, R.; Adhikari, B. Assessment of interfacial interactions between starch and non-isocyanate polyurethanes in their hybrids. Carbohydr. Polym. 2020, 246, 116656. [Google Scholar] [CrossRef] [PubMed]

- Ghasemlou, M.; Daver, E.; Ivanova, E.P.; Brkljaca, R.; Adhikari, B. Synthesis of green hybrid materials using starch and non-isocyanate polyurethanes. Carbohyd. Polym. 2020, 229, 115535. [Google Scholar] [CrossRef]

- Kiss, G.; Rusu, G.; Bandur, G.; Hulka, I.; Romecki, D.; Péter, F. Advances in Low-Density Flexible Polyurethane Foams by Optimized Incorporation of High Amount of Recycled Polyol. Polymers 2021, 13, 1736. [Google Scholar] [CrossRef]

- Nikulin, M.; Švedas, V. Prospects of Using Biocatalysis for the Synthesis and Modification of Polymers. Molecules 2021, 26, 2750. [Google Scholar] [CrossRef] [PubMed]

- Bresolin, D.; Hawerroth, B.; de Oliveira Romera, C.; Sayer, C.; de Araújo, P.H.H.; de Oliveira, D. Immobilization of lipase Eversa Transform 2.0 on poly(urea–urethane) nanoparticles obtained using a biopolyol from enzymatic glycerolysis. Bioprocess Biosyst. Eng. 2020, 43, 1279–1286. [Google Scholar] [CrossRef]

- de Lima, A.P.D.; Aschenbrenner, E.M.; Oliveira, S.N.; Doucet, J.B.; Weiss, C.K.; Ziener, U.; Fonseca, L.P.; Ricardo, N.M.P.S.; de Freitas, L.L.; Petzhold, C.L.; et al. Towards regioselective enzymatic hydrolysis and glycerolysis of tricaprylin in miniemulsion and the direct preparation of polyurethane from the hydrolysis products. J. Mol. Catal. B Enzym. 2013, 98, 127–137. [Google Scholar] [CrossRef]

- Baraldi, S.; Fantin, G.; Di Carmine, G.; Ragno, D.; Brandolese, A.; Massi, A.; Bortolini, O.; Marchetti, N.; Giovannini, P.P. Enzymatic synthesis of biobased aliphatic–aromatic oligoesters using 5,5′-bis(hydroxymethyl) furoin as a building block. RSC Adv. 2019, 9, 29044–29050. [Google Scholar] [CrossRef] [Green Version]

- Arrieta, M.P.; Barrera Rivera, K.A.; Salgado, C.; Richa, A.M.; López, D.; Peponi, L. Degradation under composting conditions of lysine-modified polyurethane based on PCL obtained by lipase biocatalysis. Polym. Degrad. Stab. 2018, 152, 139–146. [Google Scholar] [CrossRef]

- Hayashi, H.; Yanagishita, Y.; Matsumura, S. Chemoenzymatic Synthesis and Chemical Recycling of Poly(ester-urethane)s. Int. J. Mol. Sci. 2011, 12, 5490–5507. [Google Scholar] [CrossRef]

- Skoczinski, P.; Espinoza Cangahuala, M.K.; Maniar, D.; Loos, K. Enzymatic transesterification of urethane-bond containing ester Enzymatic transesterification of urethane-bond containing ester. Colloid Polym. Sci. 2021, 299, 561–573. [Google Scholar] [CrossRef]

- Moentamaria, D.; Dewajani, H.; Chumaidi, A.; Nurmahdi, H.; Sinduwati, C. Heterogeneous biocatalyst: Polyurethane foam coating technique with co-immobilized lipase for bio-flavor production. Mat. Sci. Eng. 2020, 732, 012003. [Google Scholar] [CrossRef]

- Cipolatti, E.P.; Valério, A.; Henriques, R.O.; Pinto, M.C.C.; Lorente, G.F.; Manoel, E.A.; Guisán, J.M.; Ninowa, J.L.; de Oliveira, D.; Pessela, B.C. Production of new nanobiocatalysts via immobilization of lipase B from C. antarctica on polyurethane nanosupports for application on food and pharmaceutical industries. Int. J. Biol. Macromol. 2020, 165, 2957–2963. [Google Scholar] [CrossRef] [PubMed]

- Quezada, M.A.; Carballeira, J.D.; Sinisterra, J.V. Monascus kaoliang CBS 302.78 immobilized in polyurethane foam using iso-propanol as co-substrate: Optimized immobilization conditions of a fungus as biocatalyst for the reduction of ketones. Bioresour. Technol. 2009, 100, 2018–2025. [Google Scholar] [CrossRef] [PubMed]

- Quezada, M.A.; Carballeira, J.D.; Sinisterra, J.V. Diplogelasinospora grovesii IMI 171018 immobilized in polyurethane foam. An efficient biocatalyst for stereoselective reduction of ketones. Bioresour. Technol. 2012, 112, 18–27. [Google Scholar] [CrossRef]

- Facin, B.R.; Valério, A.; de Oliveira, D.; Oliveira, J.V. Developing an immobilized low-cost biocatalyst for FAME synthesis. Biocatal. Agric. Biotechnol. 2020, 29, 101752. [Google Scholar] [CrossRef]

- Sultan, M.; Waheed, A.; Bibi, I.; Islam, A. Ecofriendly reduction of methylene blue with polyurethane catalyst. Int. J. Polym. Sci. 2019, 2019, 3168618. [Google Scholar] [CrossRef]

- Facin, B.R.; Valério, A.; Bresolin, D.; Centenaro, G.; de Oliveira, D.; Oliveira, V. Improving reuse cycles of Thermomyces lanuginosus lipase (NS-40116) by immobilization in flexible polyurethane. Biocatal. Biotransfor. 2018, 36, 372–380. [Google Scholar] [CrossRef]

- Magnin, A.; Pollet, E.; Phalip, V.; Avérous, L. Evaluation of biological degradation of polyurethanes. Biotech. Adv. 2020, 39, 107457. [Google Scholar] [CrossRef] [PubMed]

- Brzeska, J. Biodegradable polyurethanes cross-linked by multifunctional compounds. Curr. Org. Synth. 2017, 14, 778–784. [Google Scholar] [CrossRef]

- Ferris, C.; de Paz, M.V.; Zamora, F.; Galbis, J.A. Dithiothreitol-based polyurethanes. Synthesis and degradation studies. Polym. Degrad. Stab. 2010, 95, 1480–1487. [Google Scholar] [CrossRef]

- Álvarez-Barragán, J.; Domínguez-Malfavón, L.; Vargas-Suárez, M.; González-Hernández, R.; Aguilar-Osorio, G.; Loza-Tavera, H. Biodegradative Activities of Selected Environmental Fungi on a Polyester Polyurethane Varnish and Polyether Polyurethane Foams. Appl. Env. Microbiol. 2016, 82, 5225–5235. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, J.; He, J.; Xue, R.; Xu, B.; Qian, X.; Xin, F.; Blank, L.M.; Zhou, J.; Wei, R.; Dong, W.; et al. Biodegradation and up-cycling of polyurethanes: Progress, challenges, and prospects. Biotech. Adv. 2021, 48, 107730. [Google Scholar] [CrossRef]

- Tai, N.L.; Ghasemlou, M.; Adhikari, R.; Adhikari, B. Starch-based isocyanate- and non-isocyanate polyurethane hybrids: A review on synthesis, performance and biodegradation. Carbohyd. Polym. 2021, 265, 118029. [Google Scholar] [CrossRef] [PubMed]

- Park, H.; Gong, M.-S.; Knowles, J.C. Catalyst-free synthesis of high elongation degradable polyurethanes containing varying ratios of isosorbide and polycaprolactone: Physical properties and biocompatibility. J. Mater. Sci. Mater. Med. 2013, 24, 281–294. [Google Scholar] [CrossRef] [PubMed]

- Zia, K.M.; Bhatti, H.B.; Bhatti, I.A. Methods for polyurethane and polyurethane composites, recycling and recovery: A review. React. Funct. Polym. 2007, 67, 675–692. [Google Scholar] [CrossRef]

- Kang, J.J.; Lee, J.S.; Yang, W.S.; Park, S.W.; Alam, M.T.; Back, S.K.; Choi, H.S.; Seo, Y.C.; Yun, Y.S.; Gub, J.H.; et al. A study on environmental assessment of residue from gasification of polyurethane waste in e-waste recycling process. Procedia Environ. Sci. 2016, 35, 639–642. [Google Scholar] [CrossRef]

- Simón, D.; Borreguero, A.M.; de Lucas, A.; Rodríguez, J.F. Recycling of polyurethanes from laboratory to industry, a journey towards the sustainability. Waste Manag. 2018, 76, 147–171. [Google Scholar] [CrossRef]

- RAMPF Discover the Future. “Tailor-Made Recycled Polyols and Manufacturing Plants” by RAMPF Eco Solutions. Available online: https://www.rampf-group.com/en-us/company/rampf-core-competencies/eco-solutions/ (accessed on 21 October 2021).

- C&EN Chemical & Engineering News. “BASF Advances Chemical Polyurethane Recycling” by Craig Bettenhausen. Available online: https://cen.acs.org/environment/recycling/BASF-advances-chemical-polyurethane-recycling/98/i26 (accessed on 21 October 2021).

- Magnin, A.; Entzmann, L.; Bazin, A.; Pollet, E.; Avérousm, L. Green Recycling Process for Polyurethane Foams by a Chem-Biotech Approach. ChemSusChem 2021, 14, 4234–4241. [Google Scholar] [CrossRef]

- Gendek, T. Bhopal—zapomniana katastrofa (in Polish). Kwart. Chem. 2019, 4, 38–41. [Google Scholar]

- European Parliament resolution on Bhopal. Official Journal of the European Union C 226 E/361, 16 December 2004. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52004IP0114 (accessed on 21 August 2021).

- McKenna, S.T.; Hullm, T.R. The fire toxicity of polyurethane foams. Fire Sci. Rev. 2016, 5, 3. [Google Scholar] [CrossRef] [Green Version]

- Cui, M.; Li, J.; Chen, X.; Hong, W.; Chen, Y.; Xiang, J.; Yan, J.; Fan, H. A halogen-free, flame retardant, waterborne polyurethane coating based on the synergistic effect of phosphorus and silicon. Prog. Org. Coat. 2021, 158, 106359. [Google Scholar] [CrossRef]

- Ren, L.; Tang, Z.; Du, J.; Chen, L.; Qiang, T. Recyclable polyurethane foam loaded with carboxymethyl chitosan for adsorption of methylene blue. J. Hazard. Mater. 2021, 417, 126130. [Google Scholar] [CrossRef] [PubMed]

- Piotrowska-Kirschling, A.; Szelągowska-Rudzka, K.; Karczewski, J.; Brzeska, J. Application of shrimp waste for the synthesis of polyurethane–chitosan materials with potential use in sorption of oil micro-spills in water treatment. Sustainability 2021, 13, 5098. [Google Scholar] [CrossRef]

- Fan, C.-J.; Huang, Z.-C.; Li, B.; Xiao, W.-X.; Zheng, E.; Yang, K.K.; Wang, Y.Z. A robust self-healing polyurethane elastomer: From H-bonds and stacking interactions to well-defined microphase morphology. Sci. China Mater. 2019, 62, 1188–1198. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brzeska, J.; Piotrowska-Kirschling, A. A Brief Introduction to the Polyurethanes According to the Principles of Green Chemistry. Processes 2021, 9, 1929. https://doi.org/10.3390/pr9111929

Brzeska J, Piotrowska-Kirschling A. A Brief Introduction to the Polyurethanes According to the Principles of Green Chemistry. Processes. 2021; 9(11):1929. https://doi.org/10.3390/pr9111929

Chicago/Turabian StyleBrzeska, Joanna, and Agnieszka Piotrowska-Kirschling. 2021. "A Brief Introduction to the Polyurethanes According to the Principles of Green Chemistry" Processes 9, no. 11: 1929. https://doi.org/10.3390/pr9111929

APA StyleBrzeska, J., & Piotrowska-Kirschling, A. (2021). A Brief Introduction to the Polyurethanes According to the Principles of Green Chemistry. Processes, 9(11), 1929. https://doi.org/10.3390/pr9111929