A Review of Composting Process Models of Organic Solid Waste with a Focus on the Fates of C, N, P, and K

Abstract

1. Introduction

- What are the key features of existing composting models that involve the fates of C, N, P, and K? (RQ1);

- How could the gaps between the existing model and the target model be well defined and presented? (RQ2).

2. Methods

2.1. Literature Screening

2.2. Data Extraction

2.3. Checklist for Model Assessment

3. Results

3.1. Overview of Reviewed Models

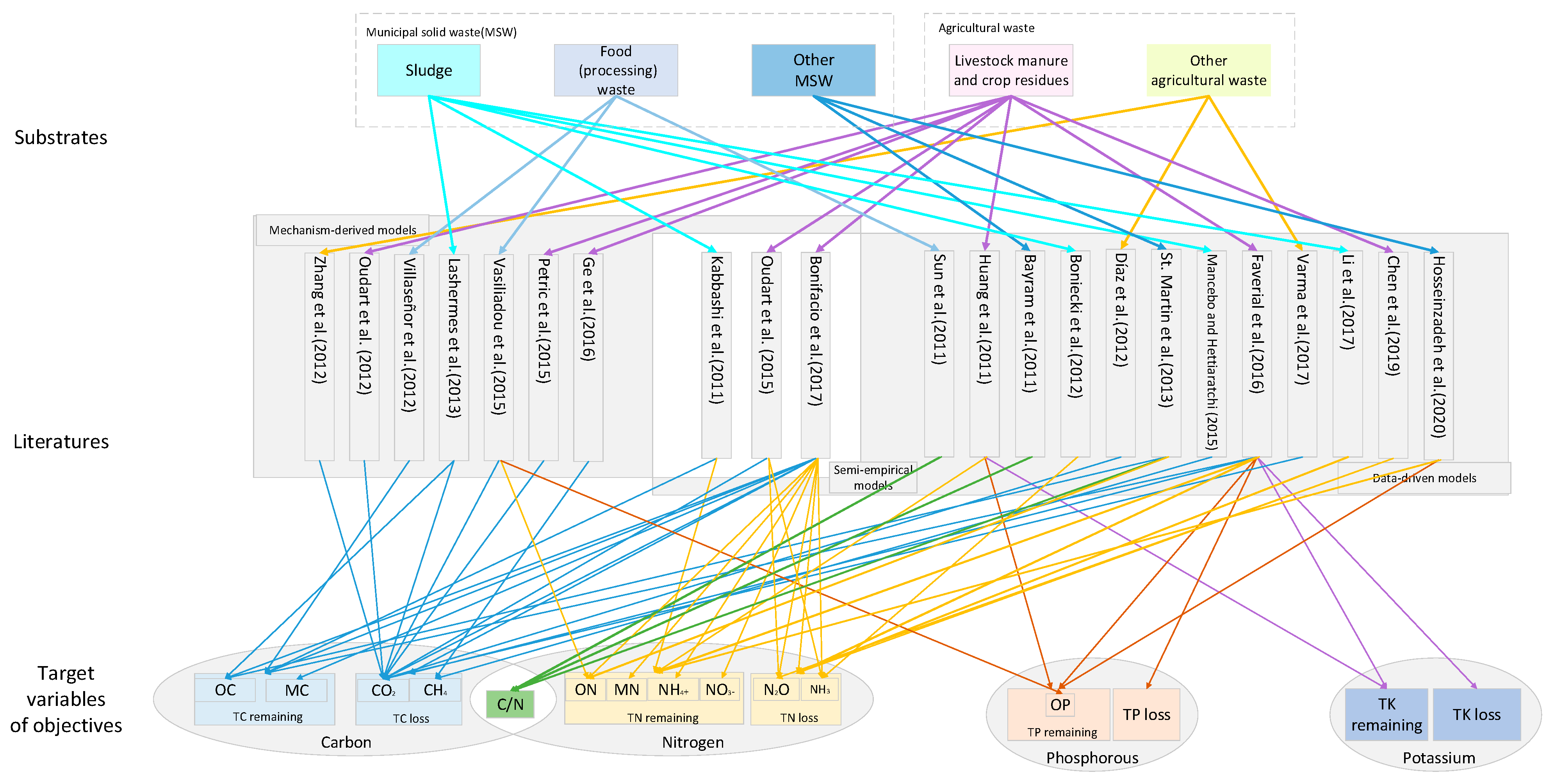

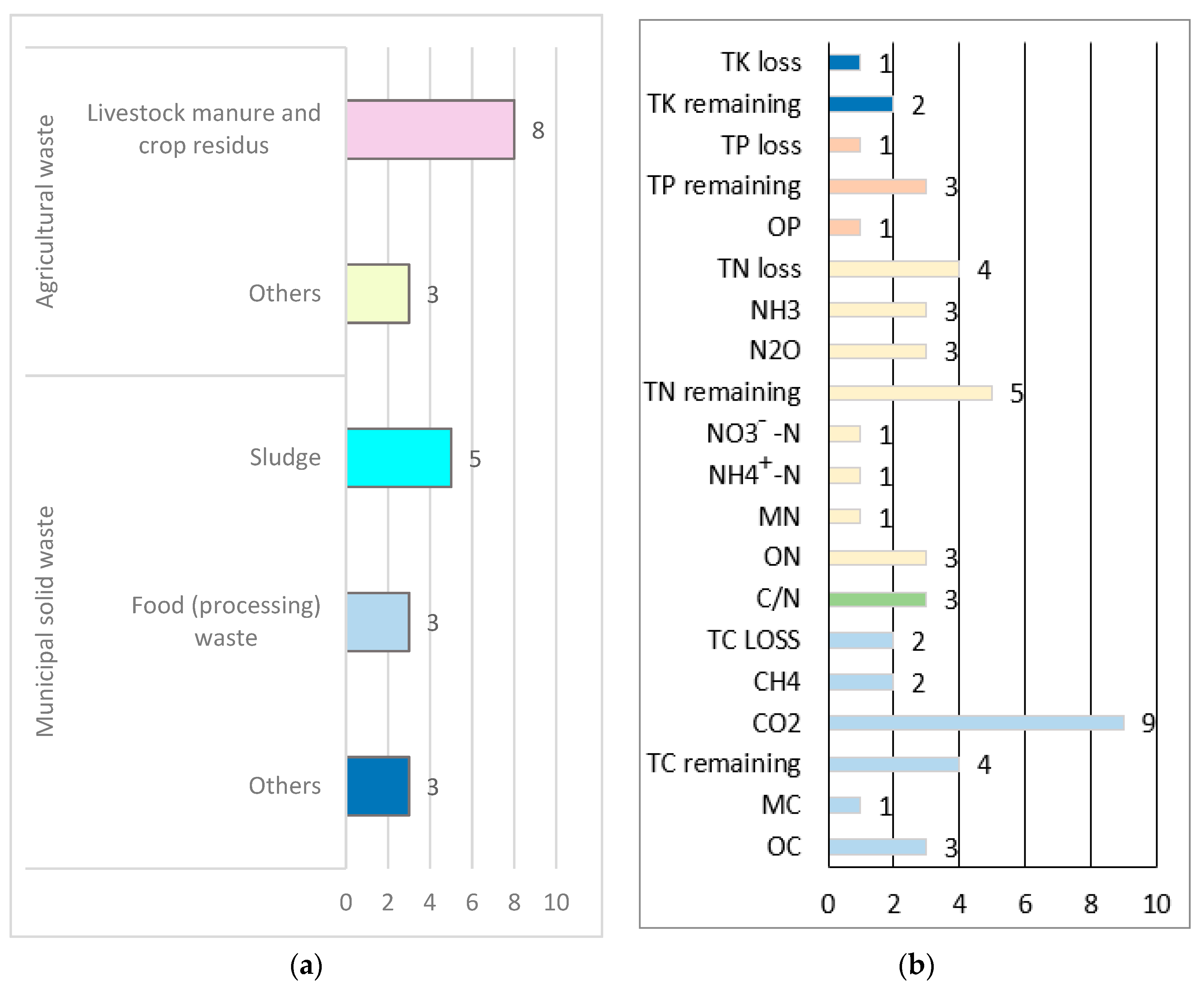

3.2. Composting Substrates and Target Variables

3.3. Modeling Approaches

3.3.1. Mechanism-Derived Models

3.3.2. Data-Driven Models

3.4. Application Scales

3.5. Sensitivity Analysis and Validation

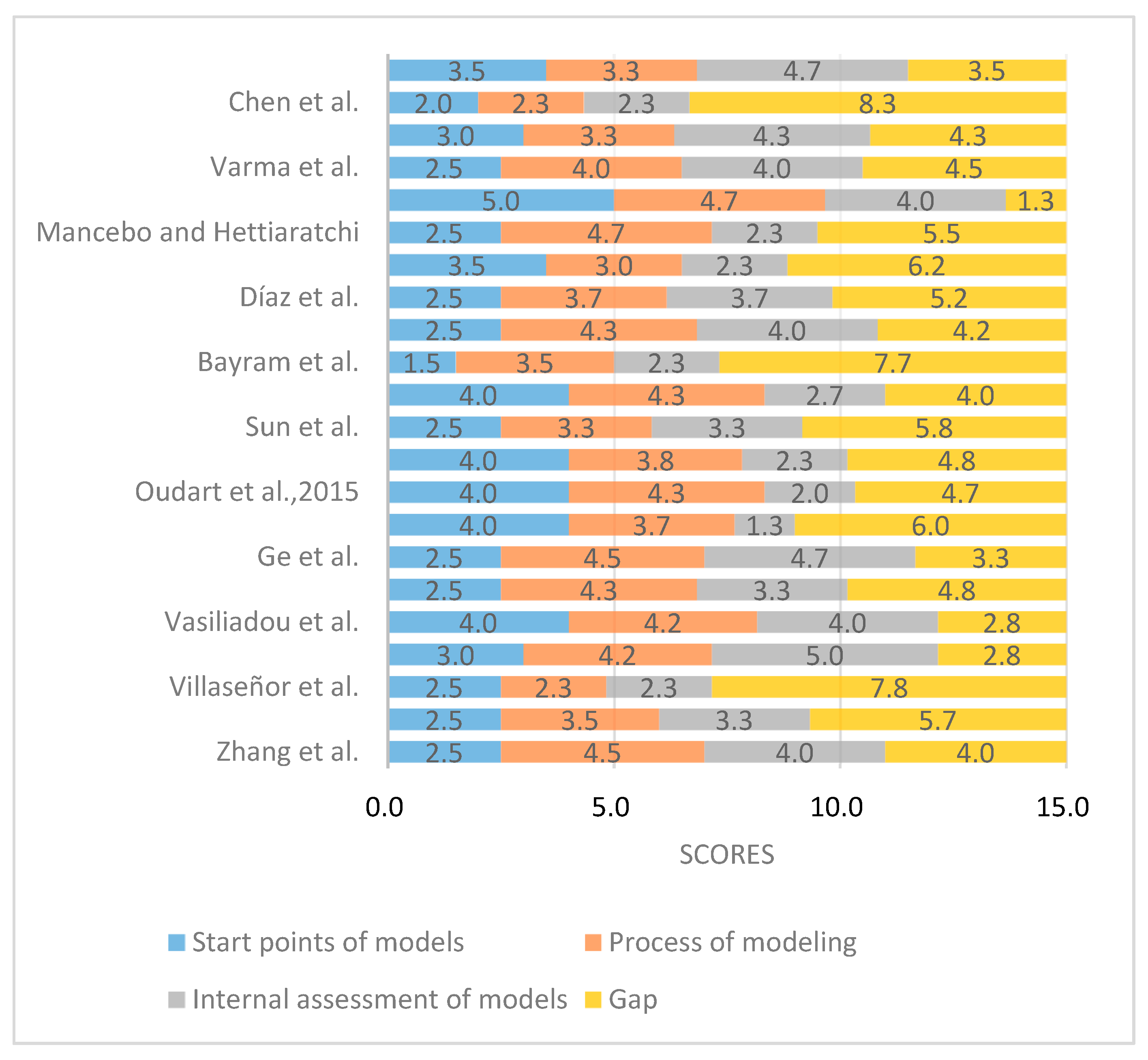

3.6. Gaps with the Target Models Reflected by the Checklist

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| AD | Anaerobic digestion |

| ADM1 | Anaerobic Digestion Model No. 1 |

| ANN | Artificial neural network |

| ANOVA | Adopting analysis of variance |

| BP | Backpropagation |

| BVS | Biodegradable volatile solids |

| C | Carbon |

| CH4 | Methane |

| CO2 | Carbon dioxide |

| C/N | Carbon-to-nitrogen ratio |

| DM | Dry matter |

| EC | Electrical conductivity |

| IFSM | Integrated Farm System Model |

| K | Potassium |

| MC | Microbial carbon |

| MLP | Multilayer perceptron |

| MLR | Multiple linear regression |

| MN | Microbial nitrogen |

| MSW | Municipal solid waste |

| N | Nitrogen |

| NH3 | Ammonia |

| N2O | Nitrous oxide |

| NSE | Nash–Sutcliffe efficiency |

| OC | Organic carbon |

| ON | Organic nitrogen |

| P | Phosphorus |

| R2 | Determination coefficient |

| RBF | Radial basis functional |

| RMSE | Root-mean-square error |

| TC | Total carbon |

| TK | Total potassium |

| TKN | Total Kjeldahl nitrogen |

| TN | Total nitrogen |

| TOC | Total organic carbon |

| TP | Total phosphorus |

| VOC | Volatile organic compounds |

References

- Yalcinkaya, S. A spatial modeling approach for siting, sizing and economic assessment of centralized biogas plants in organic waste management. J. Clean. Prod. 2020, 255, 120040. [Google Scholar] [CrossRef]

- Dhanya, B.S.; Mishra, A.; Chandel, A.K.; Verma, M.L. Development of sustainable approaches for converting the organic waste to bioenergy. Sci. Total Environ. 2020, 723, 138109. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.-N.; Wu, S.-B.; Tian, Y.-J.; Zhang, J.; Liu, H.-T. Application of machine learning methods for the prediction of organic solid waste treatment and recycling processes: A review. Bioresour. Technol. 2021, 319, 124114. [Google Scholar] [CrossRef]

- Chen, T.; Zhang, S.; Yuan, Z. Adoption of solid organic waste composting products: A critical review. J. Clean. Prod. 2020, 272, 122712. [Google Scholar] [CrossRef]

- Mor, S.; Ravindra, K.; Dahiya, R.P.; Chandra, A. Leachate characterization and assessment of groundwater pollution near municipal solid waste landfill site. Environ. Monit. Assess. 2006, 118, 435–456. [Google Scholar] [CrossRef] [PubMed]

- Onwosi, C.O.; Igbokwe, V.C.; Odimba, J.N.; Eke, I.E.; Nwankwoala, M.O.; Iroh, I.N.; Ezeogu, L.I. Composting technology in waste stabilization: On the methods, challenges and future prospects. J. Environ. Manag. 2017, 190, 140–157. [Google Scholar] [CrossRef]

- Mayer, F.; Bhandari, R.; Gäth, S. Critical review on life cycle assessment of conventional and innovative waste-to-energy technologies. Sci. Total Environ. 2019, 672, 708–721. [Google Scholar] [CrossRef] [PubMed]

- Wainaina, S.; Awasthi, M.K.; Sarsaiya, S.; Chen, H.; Singh, E.; Kumar, A.; Ravindran, B.; Awasthi, S.K.; Liu, T.; Duan, Y.; et al. Resource recovery and circular economy from organic solid waste using aerobic and anaerobic digestion technologies. Bioresour. Technol. 2020, 301, 122778. [Google Scholar] [CrossRef] [PubMed]

- Aguelmous, A.; El Fels, L.; Souabi, S.; Zamama, M.; Hafidi, M. The fate of total petroleum hydrocarbons during oily sludge composting: A critical review. Rev. Environ. Sci. Biotechnol. 2019, 18, 473–493. [Google Scholar] [CrossRef]

- Kulkarni, M.B.; Ghanegaonkar, P.M. Biogas generation from floral waste using different techniques. Glob. J. Environ. Sci. Manag. 2019, 5, 17–30. [Google Scholar] [CrossRef]

- Fernandez-Bayo, J.D.; Yazdani, R.; Simmons, C.W.; VanderGheynst, J.S. Comparison of thermophilic anaerobic and aerobic treatment processes for stabilization of green and food wastes and production of soil amendments. Waste Manag. 2018, 77, 555–564. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, X.; Wang, F.; Bai, Z.; Chadwick, D.; Misselbrook, T.; Ma, L. The progress of composting technologies from static heap to intelligent reactor: Benefits and limitations. J. Clean. Prod. 2020, 122328. [Google Scholar] [CrossRef]

- Cerda, A.; Artola, A.; Font, X.; Barrena, R.; Gea, T.; Sánchez, A. Composting of food wastes: Status and challenges. Bioresour. Technol. 2018, 248, 57–67. [Google Scholar] [CrossRef]

- Li, H.; Chen, Z.; Fu, D.; Wang, Y.; Zheng, Y.; Li, Q. Improved ADM1 for modelling C, N, P fates in anaerobic digestion process of pig manure and optimization approaches to biogas production. Renew. Energy 2020, 146, 2330–2336. [Google Scholar] [CrossRef]

- Faverial, J.; Cornet, D.; Paul, J.; Sierra, J. Multivariate Analysis of the Determinants of the End-Product Quality of Manure-Based Composts and Vermicomposts Using Bayesian Network Modelling. PLoS ONE 2016, 11, e0157884. [Google Scholar] [CrossRef] [PubMed]

- Galvez-Sola, L.; Morales, J.; Mayoral, A.M.; Marhuenda-Egea, F.C.; Martinez-Sabater, E.; Perez-Murcia, M.D.; Bustamante, M.A.; Paredes, C.; Moral, R. Estimation of phosphorus content and dynamics during composting: Use of near infrared spectroscopy. Chemosphere 2010, 78, 13–21. [Google Scholar] [CrossRef] [PubMed]

- Tiquia, S.M.; Richard, T.L.; Honeyman, M.S. Carbon, nutrient, and mass loss during composting. Nutr. Cycl. Agroecosyst. 2002, 62, 15–24. [Google Scholar] [CrossRef]

- Eghball, B.; Power, J.F.; Gilley, J.E.; Doran, J.W. Nutrient, Carbon, and Mass Loss during Composting of Beef Cattle Feedlot Manure. J. Environ. Qual. 1997, 26, 189–193. [Google Scholar] [CrossRef]

- Zhao, S.; Schmidt, S.; Qin, W.; Li, J.; Li, G.; Zhang, W. Towards the circular nitrogen economy—A global meta-analysis of composting technologies reveals much potential for mitigating nitrogen losses. Sci. Total Environ. 2020, 704, 135401. [Google Scholar] [CrossRef]

- Qu, J.; Zhang, L.; Zhang, X.; Gao, L.; Tian, Y. Biochar combined with gypsum reduces both nitrogen and carbon losses during agricultural waste composting and enhances overall compost quality by regulating microbial activities and functions. Bioresour. Technol. 2020, 314, 123781. [Google Scholar] [CrossRef]

- Abdel-Shafy, H.I.; Mansour, M.S.M. Solid waste issue: Sources, composition, disposal, recycling, and valorization. Egypt. J. Pet. 2018, 27, 1275–1290. [Google Scholar] [CrossRef]

- Oladele, S.O.; Adetunji, A.T. Agro-residue biochar and N fertilizer addition mitigates CO2-C emission and stabilized soil organic carbon pools in a rain-fed agricultural cropland. Int. Soil Water Conserv. Res. 2020. [Google Scholar] [CrossRef]

- Petric, I.; Selimbašić, V. Development and validation of mathematical model for aerobic composting process. Chem. Eng. J. 2008, 139, 304–317. [Google Scholar] [CrossRef]

- Mason, I.G. Mathematical modelling of the composting process: A review. Waste Manag. 2006, 26, 3–21. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Niu, W.; Ai, P. Assessing thermal conductivity of composting reactor with attention on varying thermal resistance between compost and the inner surface. Waste Manag. 2016, 58, 144–151. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Ai, P.; Cao, H.; Liu, Z. Prediction of moisture variation during composting process: A comparison of mathematical models. Bioresour. Technol. 2015, 193, 200–205. [Google Scholar] [CrossRef] [PubMed]

- Ma, S.; Sun, X.; Fang, C.; He, X.; Han, L.; Huang, G. Exploring the mechanisms of decreased methane during pig manure and wheat straw aerobic composting covered with a semi-permeable membrane. Waste Manag. 2018, 78, 393–400. [Google Scholar] [CrossRef]

- He, X.; Han, L.; Ge, J.; Huang, G. Modelling for reactor-style aerobic composting based on coupling theory of mass-heat-momentum transport and Contois equation. Bioresour. Technol. 2018, 253, 165–174. [Google Scholar] [CrossRef] [PubMed]

- Zambra, C.E.; Moraga, N.O.; Escudey, M. Heat and mass transfer in unsaturated porous media: Moisture effects in compost piles self-heating. Int. J. Heat Mass Transf. 2011, 54, 2801–2810. [Google Scholar] [CrossRef]

- Zambra, C.E.; Rosales, C.; Moraga, N.O.; Ragazzi, M. Self-heating in a bioreactor: Coupling of heat and mass transfer with turbulent convection. Int. J. Heat Mass Transf. 2011, 54, 5077–5086. [Google Scholar] [CrossRef]

- Alavi, N.; Sarmadi, K.; Goudarzi, G.; Babaei, A.A.; Bakhshoodeh, R.; Paydary, P. Attenuation of tetracyclines during chicken manure and bagasse co-composting: Degradation, kinetics, and artificial neural network modeling. J. Environ. Manag. 2019, 231, 1203–1210. [Google Scholar] [CrossRef] [PubMed]

- Fernandez-Mena, H.; MacDonald, G.K.; Pellerin, S.; Nesme, T. Co-benefits and Trade-Offs from Agro-Food System Redesign for Circularity: A Case Study With the FAN Agent-Based Model. Front. Sustain. Food Syst. 2020, 4, 41. [Google Scholar] [CrossRef]

- Bonifacio, H.F.; Rotz, C.A.; Richard, T.L. A Process-Based Model for Cattle Manure Compost Windrows: Part 1. Model Description. Trans. ASABE 2017, 60, 877–892. [Google Scholar] [CrossRef]

- Lauwers, J.; Appels, L.; Thompson, I.P.; Degrève, J.; van Impe, J.F.; Dewil, R. Mathematical modelling of anaerobic digestion of biomass and waste: Power and limitations. Prog. Energy Combust. Sci. 2013, 39, 383–402. [Google Scholar] [CrossRef]

- Walling, E.; Trémier, A.; Vaneeckhaute, C. A review of mathematical models for composting. Waste Manag. 2020, 113, 379–394. [Google Scholar] [CrossRef]

- Li, S.; Fang, Y.; Wu, X. A systematic review of lean construction in Mainland China. J. Clean. Prod. 2020, 257, 120581. [Google Scholar] [CrossRef]

- Heyman, A.; Law, S.; Berghauser Pont, M. How is Location Measured in Housing Valuation? A Systematic Review of Accessibility Specifications in Hedonic Price Models. Urban Sci. 2019, 3, 3. [Google Scholar] [CrossRef]

- Jia, F.; Peng, S.; Green, J.; Koh, L.; Chen, X. Soybean supply chain management and sustainability: A systematic literature review. J. Clean. Prod. 2020, 255, 120254. [Google Scholar] [CrossRef]

- Wijewardhana, U.A.; Meyer, D.; Jayawardana, M. Statistical models for the persistence of threatened birds using citizen science data: A systematic review. Glob. Ecol. Conserv. 2020, 21, e00821. [Google Scholar] [CrossRef]

- Harris, R.C.; Sumner, T.; Knight, G.M.; White, R.G. Systematic review of mathematical models exploring the epidemiological impact of future TB vaccines. Hum. Vaccin. Immunother. 2016, 12, 2813–2832. [Google Scholar] [CrossRef] [PubMed]

- Downs, S.H.; Black, N. The feasibility of creating a checklist for the assessment of the methodological quality both of randomised and non-randomised studies of health care interventions. J. Epidemiol. Community Health 1998, 52, 377. [Google Scholar] [CrossRef]

- Shiflet, A.B.; Shiflet, G.W. Introduction to Computational Science: Modeling and Simulation for the Sciences, 2nd ed.; Princeton University Press: Princeton, NJ, USA, 2014; ISBN 9781400850556. [Google Scholar]

- Lin, Y.P.; Huang, G.H.; Lu, H.W.; He, L. Modeling of substrate degradation and oxygen consumption in waste composting processes. Waste Manag. 2008, 28, 1375–1385. [Google Scholar] [CrossRef]

- Oudart, D.; Robin, P.; Paillat, J.M.; Paul, E. Modelling nitrogen and carbon interactions in composting of animal manure in naturally aerated piles. Waste Manag. 2015, 46, 588–598. [Google Scholar] [CrossRef]

- Calisti, R.; Regni, L.; Proietti, P. Compost-recipe: A new calculation model and a novel software tool to make the composting mixture. J. Clean. Prod. 2020, 122427. [Google Scholar] [CrossRef]

- Douglas, P.; Tyrrel, S.F.; Kinnersley, R.P.; Whelan, M.; Longhurst, P.J.; Walsh, K.; Pollard, S.J.T.; Drew, G.H. Sensitivity of predicted bioaerosol exposure from open windrow composting facilities to ADMS dispersion model parameters. J. Environ. Manag. 2016, 184, 448–455. [Google Scholar] [CrossRef] [PubMed]

- Oudart, D.; Paul, E.; Robin, P.; Paillat, J.M. Modeling organic matter stabilization during windrow composting of livestock effluents. Environ. Technol. 2012, 33, 2235–2243. [Google Scholar] [CrossRef] [PubMed]

- Ge, J.; Huang, G.; Huang, J.; Zeng, J.; Han, L. Particle-Scale Modeling of Methane Emission during Pig Manure/Wheat Straw Aerobic Composting. Environ. Sci. Technol. 2016, 50, 4374–4383. [Google Scholar] [CrossRef] [PubMed]

- Vasiliadou, I.A.; Muktadirul Bari Chowdhury, A.K.M.; Akratos, C.S.; Tekerlekopoulou, A.G.; Pavlou, S.; Vayenas, D.V. Mathematical modeling of olive mill waste composting process. Waste Manag. 2015, 43, 61–71. [Google Scholar] [CrossRef]

- Villaseñor, J.; Rodríguez Mayor, L.; Rodríguez Romero, L.; Fernández, F.J. Simulation of carbon degradation in a rotary drum pilot scale composting process. J. Environ. Manag. 2012, 108, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Lashermes, G.; Houot, S.; Doublet, J.; Steyer, J.P.; Zhu, Y.G.; Barriuso, E.; Garnier, P. Modelling of organic matter dynamics during the composting process. Waste Manag. 2012, 32, 19–30. [Google Scholar] [CrossRef] [PubMed]

- Lashermes, G.; Zhang, Y.; Houot, S.; Steyer, J.P.; Patureau, D.; Barriuso, E.; Garnier, P. Simulation of Organic Matter and Pollutant Evolution during Composting: The COP-Compost Model. J. Environ. Qual. 2013, 42, 361–372. [Google Scholar] [CrossRef]

- St Martin, C.C.G.; Bekele, I.; Eudoxie, G.D.; Bristol, D.; Brathwaite, R.A.I.; Campo, K.-R. Modelling response patterns of physico-chemical indicators during high-rate composting of green waste for suppression of Pythium ultimum. Environ. Technol. 2014, 35, 590–601. [Google Scholar] [CrossRef]

- Li, W.; Wu, C.; Wang, K.; Meng, L.; Lv, L. Nitrogen loss reduction by adding sucrose and beet pulp in sewage sludge composting. Int. Biodeterior. Biodegrad. 2017, 124, 297–303. [Google Scholar] [CrossRef]

- Huang, G.; Wang, X.; Han, L. Rapid estimation of nutrients in chicken manure during plant-field composting using physicochemical properties. Bioresour. Technol. 2011, 102, 1455–1461. [Google Scholar] [CrossRef]

- Petric, I.; Mustafić, N. Dynamic modeling the composting process of the mixture of poultry manure and wheat straw. J. Environ. Manag. 2015, 161, 392–401. [Google Scholar] [CrossRef]

- Li, Z.; Lu, H.; Ren, L.; He, L. Experimental and modeling approaches for food waste composting: A review. Chemosphere 2013, 93, 1247–1257. [Google Scholar] [CrossRef] [PubMed]

- Kabbashi, N. Sewage sludge composting simulation as carbon/nitrogen concentration change. J. Environ. Sci. 2011, 23, 1925–1928. [Google Scholar] [CrossRef]

- Boniecki, P.; Dach, J.; Pilarski, K.; Piekarska-Boniecka, H. Artificial neural networks for modeling ammonia emissions released from sewage sludge composting. Atmos. Environ. 2012, 57, 49–54. [Google Scholar] [CrossRef]

- Haug, R.T. The Practical Handbook of Compost Engineering; Lewis Publishers: Boca Raton, FL, USA, 1993; ISBN 0873713737. [Google Scholar]

- Wang, Y.; Huang, G.; Zhang, A.; Han, L.; Ge, J. Estimating thermal balance during composting of swine manure and wheat straw: A simulation method. Int. J. Heat Mass Transf. 2014, 75, 362–367. [Google Scholar] [CrossRef]

- Hamelers, H.V.M. A Mathematical Model for Composting Kinetics; Rulkens, W.H., van Straten, G., Eds.; Wageningen University: Wageningen, The Netherlands, 2001; ISBN 90-5808-445-0. [Google Scholar]

- Hamelers, H.V.M. Modeling composting kinetics: A review of approaches. Rev. Environ. Sci. Biotechnol. 2004, 3, 331–342. [Google Scholar] [CrossRef]

- Bonifacio, H.F.; Rotz, C.A.; Richard, T.L. A Process-Based Model for Cattle Manure Compost Windrows: Part 2. Model Performance and Application. Trans. ASABE 2017, 60, 893–913. [Google Scholar] [CrossRef]

- Sun, W.; Huang, G.H.; Zeng, G.; Qin, X.; Yu, H. Quantitative effects of composting state variables on C/N ratio through GA-aided multivariate analysis. Sci. Total Environ. 2011, 409, 1243–1254. [Google Scholar] [CrossRef]

- Bayram, A.; Kankal, M.; Ozsahin, T.; Saka, F. Estimation of the carbon to nitrogen (C:N) ratio in compostable solid waste using artificial neural networks. Fresenius Environ. Bull. 2011, 20, 3250–3257. [Google Scholar]

- Hosseinzadeh, A.; Baziar, M.; Alidadi, H.; Zhou, J.L.; Altaee, A.; Najafpoor, A.A.; Jafarpour, S. Application of artificial neural network and multiple linear regression in modeling nutrient recovery in vermicompost under different conditions. Bioresour. Technol. 2020, 303, 122926. [Google Scholar] [CrossRef]

- Díaz, M.J.; Eugenio, M.E.; López, F.; García, J.C.; Yañez, R. Neural Models for Optimizing Lignocellulosic Residues Composting Process. Waste Biomass Valor 2012, 3, 319–331. [Google Scholar] [CrossRef]

- Mancebo, U.; Hettiaratchi, J.P.A. Rapid assessment of methanotrophic capacity of compost-based materials considering the effects of air-filled porosity, water content and dissolved organic carbon. Bioresour. Technol. 2015, 177, 125–133. [Google Scholar] [CrossRef] [PubMed]

- Varma, V.S.; Kalamdhad, A.S.; Kumar, B. Optimization of waste combinations during in-vessel composting of agricultural waste. Waste Manag. Res. 2017, 35, 101–109. [Google Scholar] [CrossRef]

- Chen, H.; Sun, S.; Zhang, B. Forecasting N 2 O emission and nitrogen loss from swine manure composting based on BP neural network. MATEC Web Conf. 2019, 277, 1010. [Google Scholar] [CrossRef]

- Abdallah, M.; Abu Talib, M.; Feroz, S.; Nasir, Q.; Abdalla, H.; Mahfood, B. Artificial intelligence applications in solid waste management: A systematic research review. Waste Manag. 2020, 109, 231–246. [Google Scholar] [CrossRef] [PubMed]

- Solle, D.; Hitzmann, B.; Herwig, C.; Pereira Remelhe, M.; Ulonska, S.; Wuerth, L.; Prata, A.; Steckenreiter, T. Between the Poles of Data-Driven and Mechanistic Modeling for Process Operation. Chem. Ing. Tech. 2017, 89, 542–561. [Google Scholar] [CrossRef]

- Roy, D.; Azaïs, A.; Benkaraache, S.; Drogui, P.; Tyagi, R.D. Composting leachate: Characterization, treatment, and future perspectives. Rev. Environ. Sci. Biotechnol. 2018, 17, 323–349. [Google Scholar] [CrossRef]

- Fernandez-Mena, H.; Gaudou, B.; Pellerin, S.; MacDonald, G.K.; Nesme, T. Flows in Agro-food Networks (FAN): An agent-based model to simulate local agricultural material flows. Agric. Syst. 2020, 180, 102718. [Google Scholar] [CrossRef]

- Rotz, C.A.; Corson, M.; Chianese, D.; Coiner, C. The Integrated Farm System Model; Pasture Systems and Watershed Management Research Unit Agricultural Research Service United States Department of Agriculture: Washington, DC, USA, 2012.

| Category | Items | References | |

|---|---|---|---|

| Start points of models | Were the target variables of modeling clearly described? (1 point) | [39,40] | |

| Do the research objectives fit our review scope (C, N, P, and K)? (3 points) (1 point will be calculated for only one of C, N, P, and K involved in modeling; 2 points will be calculated for 2 or 3 of C, N, P, and K involved in modeling; 3 points will be calculated for all of C, N, P, and K involved in modeling. If partially involved in each related element only, such as CO2 or C/N, 0.5 points will be calculated.) | |||

| Were the substrates of the study clearly described? (1 point) | [43,45] | ||

| Process of modeling | Mechanism-derived models | Data-driven models | |

| Does the selection equation in the model clearly list the reference basis? (1 point) | Does the study identify the sources of the data and describe how the data were collected clearly? (1 point) | [39,41,42] | |

| Were the assumptions about the model clearly described? (1 point) | Was the modeling approach used clearly described? Does it include the reasons for adopting this approach (1 point) | [39,40,42] | |

| Was the basis for the selection of relevant parameters clearly described? (1 point) | Was the basis for the selection of variables clearly described? (1 point) | [24,40] | |

| How about the complexity of the models? (1 point, 0.5 points, or 0 will be calculated for Not complicated, Complicated, and Very complicated, respectively) | How well does the model reflect the composting process? (1 point, 0.5 points, or 0 will be calculated for Well reflect, Partly reflect, and Not reflect, respectively) | [42,44] | |

| Was the platform/software clearly described to solve/simulate the model? (1 point) | [42] | ||

| Internal assessment of models | Was the sensitivity analysis conducted? (1 point) | [40,46] | |

| Were experiments conducted to compare the models? (1 point) | [39] | ||

| Was the accuracy evaluation method of the models clearly described? (1 point) | [34,42] | ||

| How about the accuracy of the models? (2 points, 1 point, or 0 will be calculated for Very accurate, Relatively accurate, and Not accurate or not mentioned, respectively) | [42] | ||

| No. | References | Mechanism-Derived Model Type Involved | Related Modeling Objectives |

|---|---|---|---|

| 1 | Zhang et al., 2012 [51] | Monod kinetics model First-order kinetics model Mass balance model | CO2 corresponding to mineralization (% of initial total organic carbon) |

| 2 | Oudart et al., 2012 [47] | CO2 emission rate | |

| 3 | Lashermes et al., 2013 [52] | OC and CO2 corresponding to mineralization (% of initial total OC) | |

| 4 | Villaseñor et al., 2012 [50] | First-order kinetics model | C degradation (% of DM) |

| 5 | Vasiliadou et al., 2015 [49] | Monod kinetics model First-order kinetics model Mass balance model Heat (energy) balance model | Insoluble organic matter mass, insoluble N and P mass, and CO2 emission volume |

| 6 | Petric and Mustafić 2015 [56] | Monod kinetic model Mass balance model Heat (energy) balance model | CO2 mass |

| 7 | Ge et al., 2016 [48] | First-order kinetics model Michaelis−Menten kinetics model Energy balance model Mass balance model | CH4 emission rate |

| 8 | Kabbashi 2011 [58] | Semi-empirical model Multi-stage model | The remaining of TC and TN (% of DM) |

| 9 | Oudart et al., 2015 [44] | Semi-empirical model Process-based model | Production yield of CO2, N2O and NH3 |

| 10 | Bonifacio et al., 2017 [33,59] | OC, MC, ON, MN, NH4+, NO3− (% of DM), and emission rates of CO2, N2O and NH3 |

| No. | References | Modeling Type | Input Variables | Target Variables Related to Modeling Objects |

|---|---|---|---|---|

| 1 | Sun et al., 2011 [65] | Genetic algorithm aided by the stepwise cluster analysis method | NH4+ − N concentration, moisture content, ash content, mean temperature, and mesophilic bacteria biomass | C/N |

| 2 | Huang et al., 2011 [55] | Linear regression analysis | pH, EC, and DM content | The remaining TN, TP, and TK (% of DM) |

| 3 | Bayram et al., 2011 [66] | ANN model MLR model | Food and yard percentage, ash and scoria percentage, moisture content, fixed carbon content, the total proportion of organic matter, high, calorific value, and pH | C/N |

| 4 | Hosseinzadeh et al., 2020 [67] | pH, EC, C/N, NH4+/NO3−, water-soluble carbon, dehydrogenase enzyme, and total phosphorus | The remaining TN and TP (% of DM) | |

| 5 | Boniecki et al., 2012 [59] | ANN model | Time, temperature, pH, EC, DM concentration, C/N, NH4+ − N concentration | NH3 emissions (% of air released from bioreactor chamber) |

| 6 | Díaz et al., 2012 [68] | An adaptive network-based fuzzy inference system | Aeration rate, moisture content, particle size, and time | CO2 emission rate |

| 7 | St Martin et al., 2014 [53] | Critical exponential function Rectangular hyperbola function (Double) Fourier function MLR model | Composting formula, time and composting formula interacting through time | TOC and TKN (% of DM) |

| 8 | Faverial et al., 2016 [15] | Bayesian network model | Total C, N, lignin, P and K contents, pH, and loss of mass | The remaining, and loss of, TN, TP, and TK (% of DM) |

| 9 | Mancebo and Hettiaratchi 2015 [69] | Regression model | Air-filled porosity, moisture content, and dissolved OC content | CH4 emission rate |

| 10 | Li et al., 2017 [54] | Sucrose-adding ratio, adding time, sucrose concentration | The loss TN ration | |

| 11 | Varma et al., 2017 [70] | RBF neural network model | Moisture content, pH, EC, TOC, TKN, soluble biochemical oxygen demand, NH4+ − N concentration, available phosphorous, C/N, total phosphorous, oxygen uptake rate, Na, K, Ca | CO2 emission rate |

| 12 | Chen et al., 2019 [71] | Backpropagation neural network model Linear regression model | Moisture content, C/N, aeration rate, and superphosphate content | Proportion of N2O on TN |

| Applied Scales | Number of Reviewed Models | |

|---|---|---|

| Mechanism-Derived Models | Data-Driven Models | |

| Lab scale | 7 | 11 |

| Industrial plant scale | 1 | 1 |

| Farm scale | 2 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Muhayodin, F.; Larsen, O.C.; Miao, H.; Xue, B.; Rotter, V.S. A Review of Composting Process Models of Organic Solid Waste with a Focus on the Fates of C, N, P, and K. Processes 2021, 9, 473. https://doi.org/10.3390/pr9030473

Yang Z, Muhayodin F, Larsen OC, Miao H, Xue B, Rotter VS. A Review of Composting Process Models of Organic Solid Waste with a Focus on the Fates of C, N, P, and K. Processes. 2021; 9(3):473. https://doi.org/10.3390/pr9030473

Chicago/Turabian StyleYang, Zheng, Furqan Muhayodin, Oliver Christopher Larsen, Hong Miao, Bing Xue, and Vera Susanne Rotter. 2021. "A Review of Composting Process Models of Organic Solid Waste with a Focus on the Fates of C, N, P, and K" Processes 9, no. 3: 473. https://doi.org/10.3390/pr9030473

APA StyleYang, Z., Muhayodin, F., Larsen, O. C., Miao, H., Xue, B., & Rotter, V. S. (2021). A Review of Composting Process Models of Organic Solid Waste with a Focus on the Fates of C, N, P, and K. Processes, 9(3), 473. https://doi.org/10.3390/pr9030473