1. Introduction

Global climate change and the unpredictable rain cycle cause uncertainty in the availability of water. However, water is commonly used in homes, agriculture, and industry. Currently, one of the basic problems in industries is the water level control system. The liquid level, which is an important process parameter, must be kept at the desired level for the process to run smoothly and to obtain better-quality products. All process industries, water treatment plants, and nuclear power plants depend on the level control of tank systems. Many engineers have designed controllers based on linearized models of real tank systems. However, due to the complexity and nonlinearity of real processes, it is difficult to improve the performance of these real systems using conventional control techniques [

1,

2,

3,

4,

5,

6]. Therefore, it is vital that the engineers working in these systems, especially the control and mechatronics engineers, have a good understanding of how tank level control systems work and how difficult it is to handle level control.

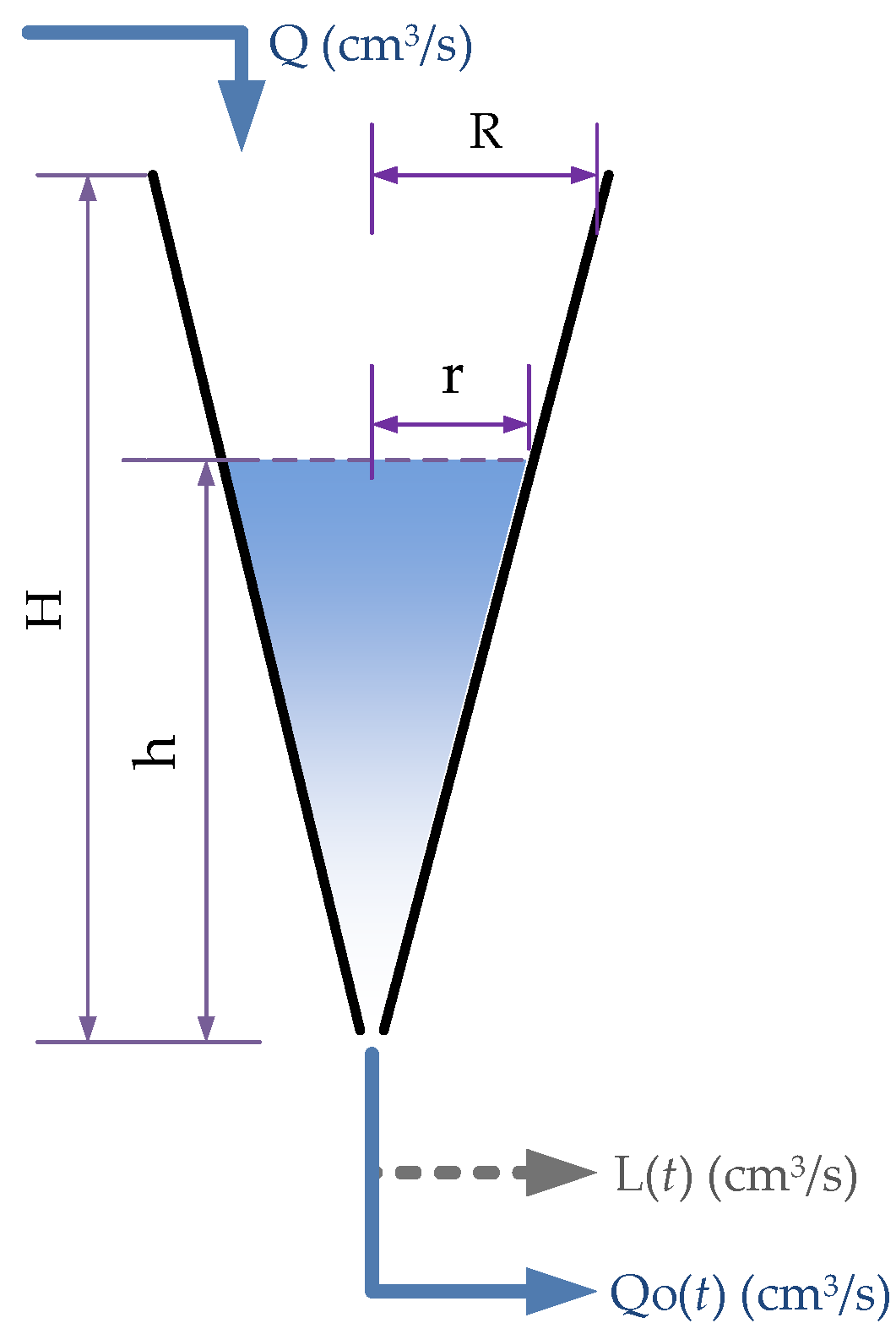

Level control in tanks is a widespread need in industries from all sectors. In industrial processes, liquid level control in conical tanks is a major problem. For example, a level well above the surface can upset the process reaction balances and damage equipment, but a level below the required setpoint can also cause serious problems [

7,

8,

9,

10,

11,

12]. In particular, inverted conical tanks, the object of this study, exhibit significant operational advantages. For example, they allow for the reduction or elimination of sediments accumulated in the base of the tank, as well as the complete emptying of the same. However, the inherent nonlinearity of these tanks is considered a challenge for control systems [

13,

14,

15,

16,

17,

18].

Regarding level control in conical tanks, some studies introduce fractional-order internal model controllers, which have a fractional filter cascaded with an integer-order PID controller. In these cases, the linearization of the nonlinear systems includes the Lagrange remainder term to compensate for higher-order derivatives that are simulated using fractional-order PID and compared with classical PID and Gain-Scheduling PID [

19,

20]. In turn, different control techniques are used for the tank level controls, such as Backstepping, PI control by direct synthesis, and Gain Scheduling [

21,

22]. Some simulated comparisons between IMC, Model Predictive Control (MPC), and classical PID are presented in [

23,

24,

25]. Additionally, results using a mix of fuzzy control and neural network control are presented in [

26,

27,

28,

29]. Other techniques for level control include Passive-Based Control (PBC), Linear Parameter Variation (LPV), and Particle Swarm Optimization (PSO) [

7,

19,

30].

After reviewing the state of research on level control techniques for conical tanks, it has been found that in most publications, the level control is only simulated and/or implemented with changes in the reference, but without incorporating load variations or disturbances in the intake flow. Therefore, considering situations much closer to reality, load variations and disturbances are included in this work. To achieve this, four control strategies are designed, applied, and compared, namely classical PID, GS, IMC, and FL. To determine which of the designed control strategies are the most suitable for an inverted conical tank, a comparative study of the behavior of the system is carried out. With this purpose, a variety of scenarios, such as step responses, random input disturbances, and momentary load disturbances, are conducted. Additionally, performance indexes (error- and statistics-based) are calculated to assess the system’s response.

3. Research Design and Control Strategies Applied

After reviewing the state of research on level control techniques for conical tanks, it was found that in most publications, the level control is only simulated and/or implemented with changes in the reference, but without incorporating load or disturbance scenarios in the intake flow. Therefore, considering scenarios much closer to reality, both disturbances are included in this work. To achieve this, four control strategies are designed, applied, and compared, namely Classic PID, GS, IMC, and FL, which provide the following advantages:

PID control is the most widely used strategy in industrial applications due to its feasibility and easy implementation. The PID gains can be obtained based on system parameters and whether they can be accurately achieved or estimated. However, if the system parameters are unknown, the PID gains can be obtained based solely on the system tracking error and treated as a “black box.”

GS control facilitates process control when the gains and the time constants vary with the current value of the process variable. GS is particularly appropriate for processes that speed up or slow down as the process variable rises and falls.

IMC allows a feedback regulator under external disturbances to regain regulation and stability as long as a suitably duplicated model of the disturbance signal is fitted into the feedback path.

FL provides a high level of automation incorporating expert knowledge. It also offers robust nonlinear control and reduced development and maintenance time.

3.1. Classic PID Control

The PID controller is named after the three simultaneous control actions that it performs: proportional, integrative, and derivative. In today’s industrial control systems, more than half of the controllers in use are PID controllers. These controllers have demonstrated to provide satisfactory control, although in many specific situations, their performance is not optimal in terms of uploading and stabilization time, overshoot, oscillations, etc.

Regarding Laplace’s domains, the corresponding PID transfer functions are:

Feedback control by means of PID is shown in

Figure 4. The tuning procedure for a PID controller can be unexpectedly complex. Therefore, besides adaptive and/or heuristic tuning methods via computational algorithms, there are more than a dozen methods based on reaction curves, oscillatory characteristics, and plant model parameters. Among these methods, the most traditional ones are Ziegler–Nichols (Z–N) and Cohen–Coon. Other methods for tuning PID controllers are: Tyreus–Luyben (similar to Z–N in a closed loop), damped oscillation (a 1:4 relation between the first and second overshoot in a closed loop is sought), Chien–Hrones–Reswick, Fertick, Skögestad (based on IMC), Ciancone–Marlin, etc. This work used Tyreus–Luyben and Skögestad [

31].

3.2. Gain Scheduling PID Control

The Gain Scheduling control technique is widely used for the control of nonlinear processes. The objective is to identify several operation points in the stationary curve of the process. Then, the adequate parameters of the controller are tuned for each operation point. These parameters will be valid in the corresponding segments of the stationary curve. The set of parameters are introduced into the controller as tables that are read, and optionally interpolated, by the same controller during the process execution. This dynamic change is governed by one or more scheduling variables, which, in general, correspond to the output variables of the process.

Although, theoretically speaking, applying Gain Scheduling to any controller is feasible, a popular and effective method is to combine Gain Scheduling and PID control; hereinafter, GSPID [

19,

32,

33,

34,

35,

36,

37,

38]. In a traditional PID controller, the

Kp,

Ki, and

Kd gains are invariable for all the operation range, which causes overshoot and oscillations when changing the operation point considered in the first tuning. An effective solution for this problem is to divide the operation range into several segments (in this case, three) and input these gains (obtained from tuning) into a table for each segment. Afterward, the PID controller will change its gains dynamically by reading them from the table, according to the water level.

3.2.1. Division of Level Range into Segments

Considering the type of tank under study, the tank’s volumetric capacity was divided into three segments of approximately 17 cm each: low, medium, and high (see

Table 3). After settling the limits of these segments, the operation points

for each were located in the middle of each level segment. GSPID tuning was conducted on these operation points.

3.2.2. GSPID Parameter Tuning

A PID controller was tuned for each segment by means of computational simulations and subsequent sharper tuning according to the parameters of the linearized plant in the corresponding operation point

. To compare the performance of the GSPID controllers, a classic PID controller was tuned in a fourth operation point, in

cm, denominated “nominal point.” Subsequently, through computational simulations, the PID controller gains were searched for in each operation point using the Tyreus–Luyben and Skögestad methods. A lower overshoot, shorter rise time, and less oscillation were preferred, as presented in

Table 3.

3.3. IMC Controller

Internal Model Control is a relatively recent control technique, as opposed to traditional control techniques with decades of history such as PID control. Internal Model Control establishes that control can be conducted only if the control system “encapsulates, either implicitly or explicitly, some representation of the process to be controlled” [

25,

39]. Therefore, the process model in the open loop is embedded in the controller. Regarding other controllers, the IMC type is easier to tune, as the only tuning parameter is the coefficient parameter

.

In general, IMC is considered to have good tracking of reference and load changes and good rejection of disturbances. To design an IMC associated with a plant

, either linear or nonlinear, a model

of the plant is necessary, as shown in

Figure 5.

For

to be physically achievable, the poles

must belong to the left half of the imaginary plane (stability criterion), and the transfer function

must be semiproper or proper. For the tank under study, the linearized transfer function

at a stationary level

, is

. For this plant, the function

that satisfies the criteria above is:

where

corresponds to a first-order filter function, and

is the reversible part of the plant model, that is:

. With this, we have:

3.4. Fuzzy Logic Control

Fuzzy Logic was originally proposed by Zadeh in 1965. This theory is based on fuzzy sets with degrees of membership ranging between 0 and 1, challenging the traditional set theory. In 1974, Mamdani developed the first fuzzy control applied to a steam engine. The miniaturization and power of digital electronics nowadays allow for the implementation of Fuzzy Logic in compact and reliable controllers. In general, a fuzzy controller consists of the following stages:

Input fuzzification that assigns degrees of membership to the input membership functions.

Interaction between the inference engine and a set of linguistic rules, which generates a number of output fuzzy sets.

Defuzzification of the output set. This generates one or more real numbers (controller outputs) that constitute the control action, whose most used method is the centroid one.

3.4.1. Implementation of Fuzzy Controller in Simulink

The following inputs and output were set for the controller:

Input 1: Error, e(t); difference between the reference and the current level of the tank.

Input 2: Derivative dh/dt of the tank’s level (the “dnivel” variable), which allows for more precise control of the system by rapid anticipation of changes.

Output: Relative control action, c(t) (the “valve” output variable), which acts on a modulating valve.

The other characteristics of the designed and simulated fuzzy controller were set as below:

3.4.2. Linguistic Rules of the Controller

Five rules with unity weights were defined for the five fuzzy output functions as in the following Simulink toolkit syntax:

If (error is ok) then (valve is no change).

If (error is neg) then (valve is close fast).

If (error is pos) then (valve is open fast).

If (error is ok) and (dnivel is neg) then (valve is open).

If (error is ok) and (dnivel is pos) then (valve is close).

Regarding these rules, it should be noted that the “fast” control action aims to open or close the simulated valve (by means of the output variable) more than its “nonfast” counterparts.

4. Results Based on Performance Indexes

To assess the performance of the four controllers described above, computational simulations were conducted in parallel, considering identical situations, i.e., the same nonlinear tank, as well as reference changes and disturbances. The following performance indexes were employed [

40,

41]:

For performance indexes with the integral of error, the incoming signal e(t) of each controller was used. For statistical performance indexes, the reference level and the output level were employed as predicted value sets (pi) and observed value sets (oi), respectively. Additionally, to evaluate the performance of the four controllers more accurately, the following criteria were considered:

Rising time (considering from 0% to 90% of the reference step’s height).

Overshoot (% of the reference step’s height).

Stabilization time (considering a 2% proportional band centered on the desired stationary value).

Stationary-State Error (% based on the reference level value).

These criteria were organized as parameters in

Table 4.

Test scenarios for simulation were the following:

Step at the reference level (from 35 to 45 cm) for 90 and 400 s simulation times (see

Table 4 and

Figure 10).

Random disturbance of input flow with constant reference (see

Figure 11).

Transitory load disturbance at the tank level with constant reference (see

Figure 12).

The results of the computational simulations of controller performance in the three test scenarios are detailed below.

4.1. Step at the Reference Level

Table 5 contains results based on the tank water level in the stationary state, maximum water level, error, etc., for a 90 s simulation time.

Table 6 presents the results of the performance indexes obtained for the same interval. IMC and fuzzy controllers offer the best performance scores. In addition, overshoot and settling times for these controllers are shorter than those of their PID. In particular, IAE and ITAE indexes tend to punish the high overshoot of PID controllers, with statistical indexes showing clearly a lower dispersion between reference (predicted level) and output (observed level) in IMC and fuzzy controllers. In the 400 s simulations (see

Table 7), these controllers exhibit better results in ISE, RMS, and RSD. The slower response of the IMC controller leads to high values in ITAE, while the fuzzy controller delivers a higher IAE index value higher and, noticeably, an ITAE value almost 10 times higher than PID GSPID. This is because the stationary error is below 1%, but not 0, which is amplified in the integral component due to the longer time passed.

It must be noted that, as expected, the ISE, RMS, and RSD values were lower when using IMC and fuzzy control for the two simulation intervals, whereas the values of the IAE and ITAE indexes (especially the latter) increased for the longer time interval. Nonetheless, for this particular test scenario, these two performance indexes did not provide relevant information that allowed us to choose either of them.

The ITAE index and, to a lesser extent, IAE, mistakenly indicate that IMC and fuzzy controllers do not have good performance, which is in contradiction with the graphs obtained, response times, stabilization, low or inexistent overshoot, etc.

4.2. Random Disturbance on Input Flow

After the first 300 s, a random disturbance is introduced into the tank input flow, representing an unstable flow condition, which is simulated as an arithmetic addition to the input variable in an 800 s computational simulation interval and for a 40 cm level, as shown in

Figure 11. As a result, controller performance indexes that delivered the best results are those with PID components, both integrative and statistical, probably due to its integrative component, as shown in

Table 8.

From

Figure 11, we can conclude that PID controllers are able to handle disturbances with minimum errors in the tank water level. Furthermore, IMC and fuzzy controllers do not perform better than PID.

4.3. Transitory Load Disturbance at the Tank Level

This test lasts 800 s and begins with equal initial and reference water levels of 40 cm. Then, a load disturbance is applied between 200 and 450 s, simulated as a lowering of the water level (

, as shown in

Figure 12. In a real-life scenario, such transitory lowering could be achieved by means of the tank’s auxiliary “L” output. Results are presented in the same figure in order to compare the response of controllers to the disturbance having time as a reference. It is noteworthy that PID and GSPID controllers show an almost identical behavior.

According to

Table 9, the fuzzy controller offers the best ISE, RMS, and RSD indexes (by a slim margin). Apparently, IMC would not be a good choice if we compare it to the performance of the PID and GSPID controllers. Nevertheless, the table does not reflect the sudden decrease of PID controllers before 500 s, which is clearly evident in the graph in

Figure 12. As expected, controllers with PID components offer the best IAE and ITAE values, confirming once more that these types of indexes are the most suitable for these controllers, as they allow the system input variable to stabilize quickly and make its error tend to zero in the stationary state.

The only time period when none of the controllers reduces overshoot occurs between 430 and 450 s, as the disturbance starts decreasing. In terms of transitory response, at both the beginning of simulation and t = 200 s, the fuzzy controller again shows superiority in performance, with a stationary-state error practically inexistent.

5. Conclusions

In this paper, the water level control of an inverted conical tank system was presented. To determine which of the designed control strategies are the most suitable for an inverted conical tank, a comparative study of the behavior of the system was carried out. With this purpose, and considering situations much closer to reality, a variety of scenarios, such as step responses, random input disturbances, and momentary load disturbances, are conducted.

First, for each applied control strategy, and then, for the measured performance indices, it is concluded that:

PID Control. This controller performs an excellent job in controlling water levels in the vicinity of the operation point for which it was tuned, even tolerating small leaps in the reference, with more than acceptable overshoot and oscillation. Its tendency to eliminate error from the stationary state relatively quickly in comparison with other controllers, as well as its rejection to random disturbances in the input, are definitely strong points in favor of this classic controller. Nonetheless, as evidenced in this study, when attempting to take the level to points farther from the original tuning, excessive overshoot or oscillation appears. These phenomena are compensated for by modern controllers with more efficacy. Moreover, the rejection of load disturbances is not a scenario that favors traditional PID controllers, according to the results of the scenarios researched. Finally, the tuning of a PID controller is challenging and can take many hours of theoretical and practical experiments. Therefore, it can be concluded that this controller is ideal for tanks in which the reference level will not suffer important fluctuations, which will not require retuning, and where there is no possibility of failure in the supply of input flow. As demonstrated in this study, the PID controller compensated for this simulated failure scenario in a satisfactory way.

GSPID. When Gain Scheduling is combined with PID components, it creates PID control, with the advantages already described, along the full operation range of the system. This is achieved through the dynamic commutation/interpolation of gains. The larger the number of segments into which the operation range is divided, the sharper the control over the total system. This partly mitigates excessive overshoot and oscillation, although the natural disadvantages of PID components remain the same. Gain Scheduling offers a huge potential of adaptability to all types of controllers and, in fact, has been successfully used in critical scenarios such as aeronautic control.

IMC. This type of control is relatively recent and has a very interesting conceptual and mathematical approach. Although the need to know the process to be controlled to obtain the internalized model of the controller may be a disadvantage, in practice, the systems to which IMC is applied are well known, and their models have been determined rather accurately. Compared to PID controllers, IMC did not evidence considerable overshooting or oscillation. In addition, the simplicity of its tuning is another point in its favor. Despite its slow response, IMC can be adapted to farther operation points without having to reformulate the internal model. The only significant disadvantages of this controller are its slow response and the single parameter tuning, which, in spite of simplifying the process, impede the controller’s response from adapting to more specific control requirements. In this sense, the PID controller is much more flexible because of its three tunable parameters. Additionally, the capacity of rejecting input flow disturbances is not an outstanding feature in this controller.

Fuzzy control. Results were impressive: low overshoot, minimum oscillation, quick response time for abrupt increases and decreases in the reference, and rapid stabilization in the vicinity of the desired operation point. The only goal that was not achieved with this controller, albeit several attempts, was to eliminate the stationary-state error completely, although this error did not exceed 0.7%. Nonetheless, this result is not considered critical for the tank’s operation. Thus, the fuzzy controller delivers the best results in the scenarios tested in this study.

Performance indexes. The following performance indexes were considered:

Graphs: as fast visual indicators of the controlled variable behavior.

Overshoot and times: increase and stabilization.

Integrative error indexes: IAE, ITAE, ISE.

Statistical error indexes: RMS, RSD.

In the control of the tank level, excessive overshooting is definitely unwanted, as the content of the tank can leak out. This is a phenomenon that occurs easily when using PID control, and to a lesser extent with GSPID.

PID controllers offer better values in the IAE and ITAE indexes, even with high overshooting. Thus, on their own, these values cannot be taken into account to select the most suitable controller in a specific scenario.

In another vein, controllers that offer better responses than PID, such as IMC and fuzzy controllers, see their performance impaired by these indexes due to their relatively slow response speed (in the case of IMC), or due to stationary-state errors (in the case of fuzzy control). This problem is noticeably heightened in the ITAE index, which calls into question whether these indexes are associated with other controllers different from PID.

The ISE index, and especially the RMS and RSD indexes, allow for a more useful and coherent view of controller performance, as they do not give excessive importance to transitory error or stationary error. When analyzing the tables obtained in this study, it is noticed that these three indexes favor, by a narrow margin, in some cases, controllers without PID components, which is consistent with the graphs obtained and the constraints imposed.