New Method to Evaluate the Crosslinking Degree of Resin Finishing Agent with Cellulose Using Kjeldahl Method and Arrhenius Formula

Abstract

1. Introduction

2. Experimental

2.1. Materials and Chemicals

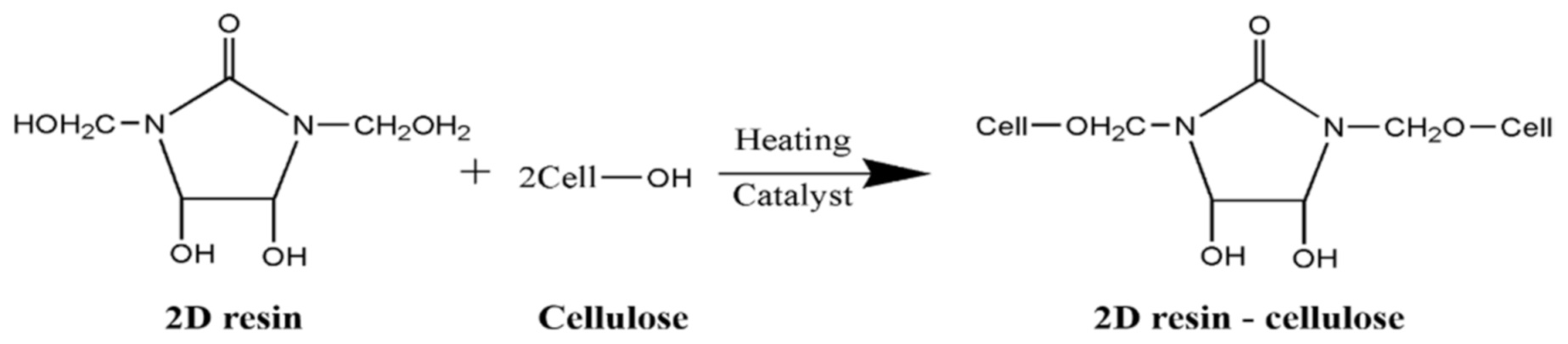

2.2. Finishing Process of 2D Resin

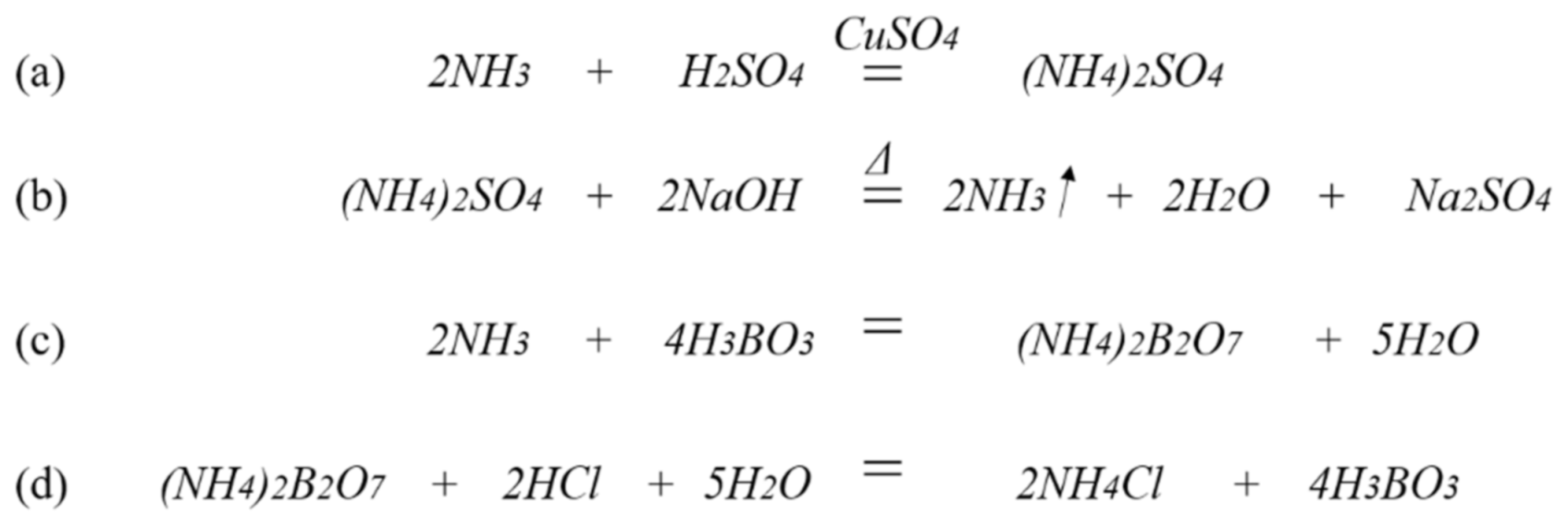

2.3. Nitrogen Content of Finished Fabric (Kjeldahl Method)

2.4. Wrinkle Recovery Angles (WRA)

3. Results and Discussion

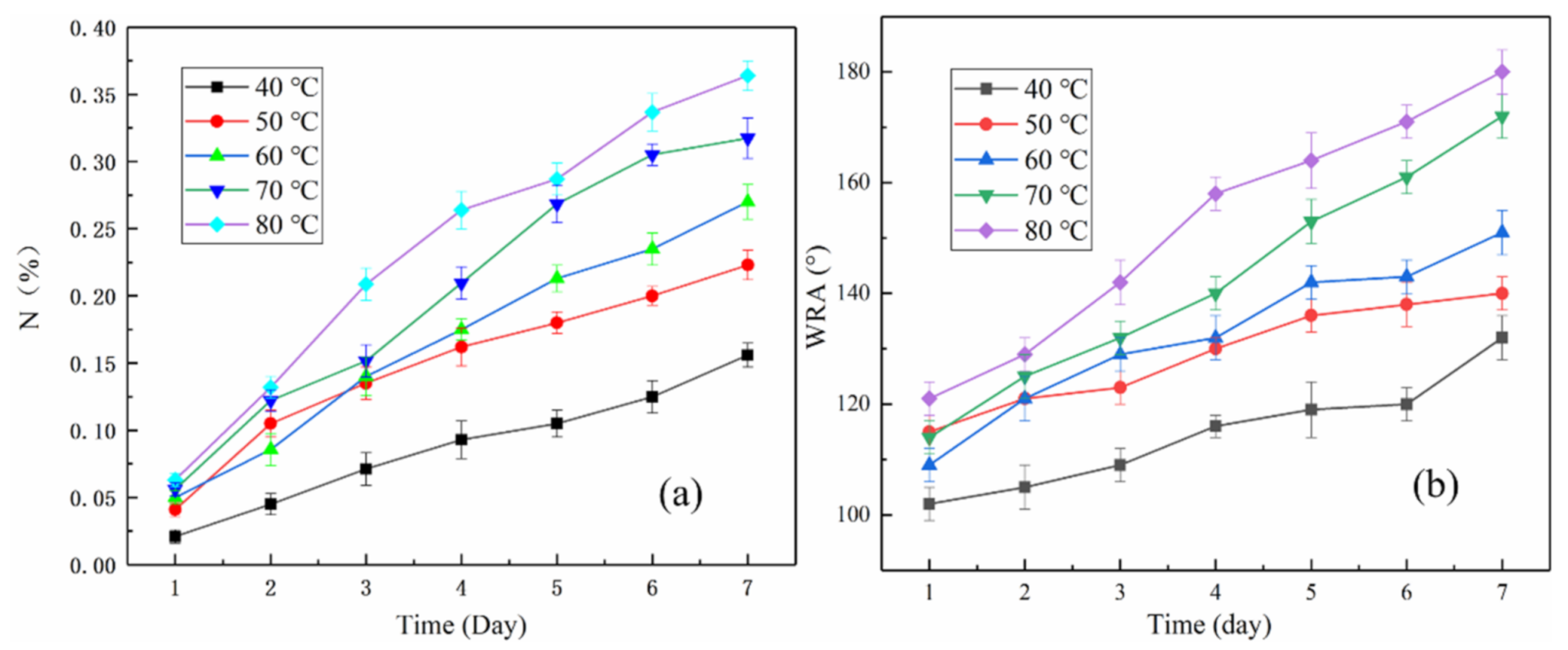

3.1. Nitrogen Content and WRA with Storage Time

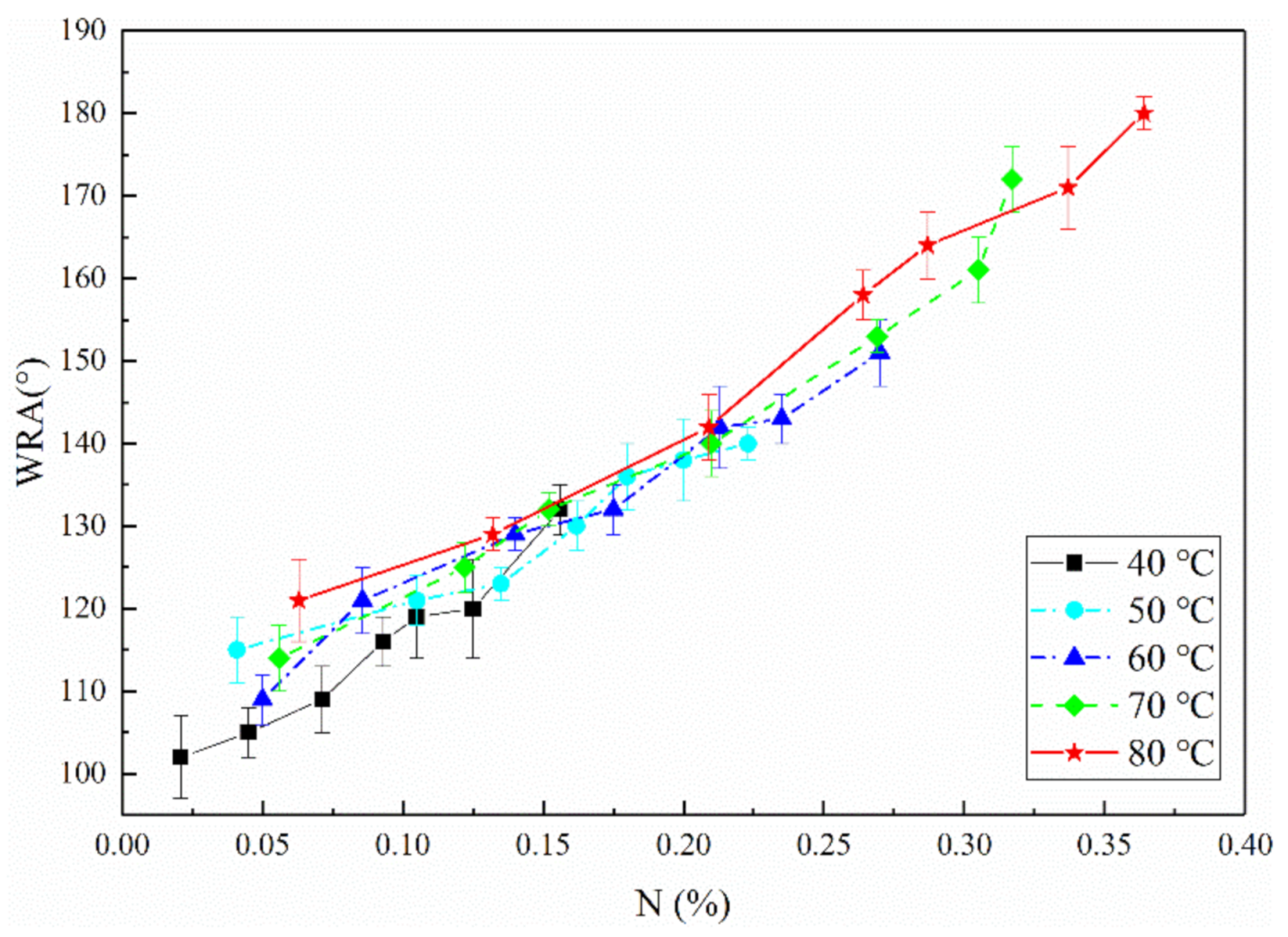

3.2. Relationship between Nitrogen Content and WRA

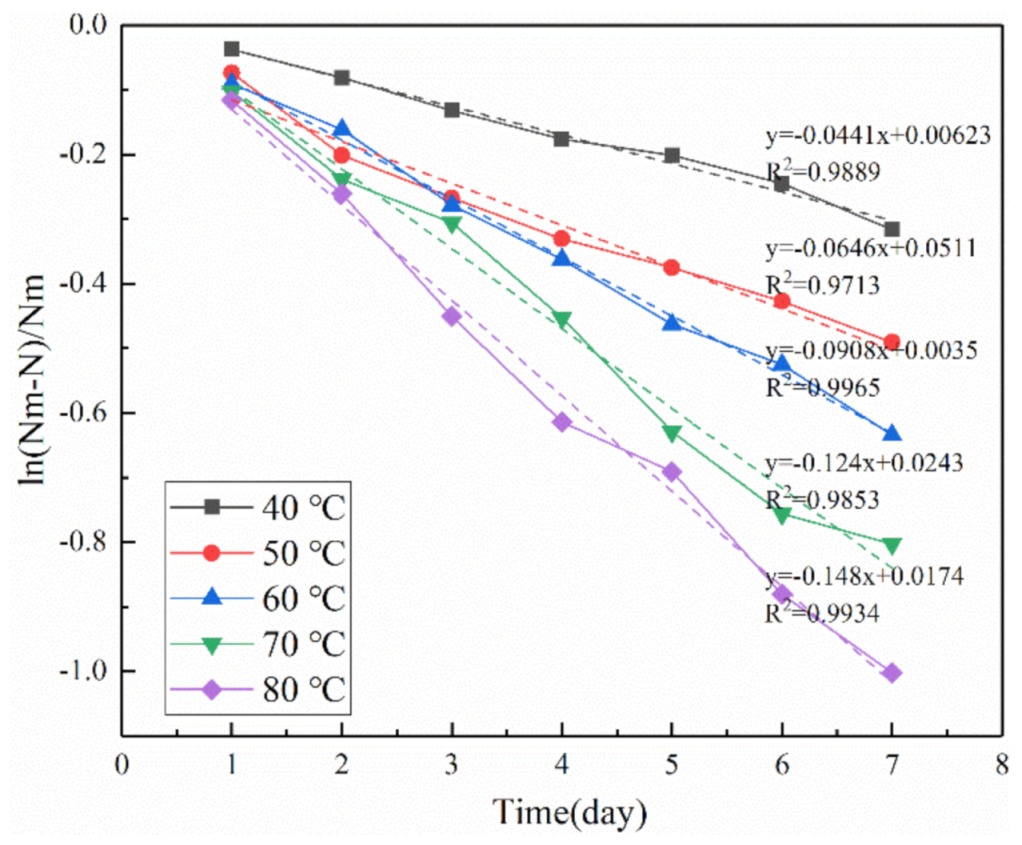

3.3. Calculation of Arrhenius Formula

3.4. Reaction Rate of under Different Storage Conditions

3.5. Accuracy of the Reaction Rate Evaluation Method

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Chakraborty, J.N.; Goyal, A.; Jain, S.; Jindal, C. Performance of durable press finish on cotton with modified DMDHEU, citric acid, BTCA and maleic acid. Tekstilec 2018, 61, 289–297. [Google Scholar] [CrossRef]

- Chang, H.-L.; Chen, C.-C. Crosslinking of Cotton with DMDMDHEU in the Presence of Sodium Chloride. Text. Res. J. 2016, 66, 803–809. [Google Scholar] [CrossRef]

- Dehabadi, V.A.; Buschmann, H.J.; Gutmann, J.S. Durable press finishing of cotton fabrics: An overview. Text. Res. J. 2013, 83, 1974–1995. [Google Scholar] [CrossRef]

- Harifi, T.; Montazer, M. Past, present and future prospects of cotton cross-linking: New insight into nano particles. Carbohydr. Polym. 2012, 88, 1125–1140. [Google Scholar] [CrossRef]

- Yuan, H.; Zhou, X.; Zhang, Y.; Zhou, L. Application of non-formaldehyde reaction system to post cure durable press finish. Dye Finish. 2017, 43, 35–38. [Google Scholar]

- Yuan, H.; Zhou, X.; Zhang, Y.; Zhou, L. Storage conditions of sensitized fabrics for post cure durable press finish. Dye Finish. 2016, 16, 16–20. [Google Scholar]

- Lam, Y.L.; Kan, C.W.; Yuen, C.W. Wrinkle-resistant finishing with dimethyloldihydroxyethyleneurea (DMDHEU)—The effect of co-catalyst. Text. Res. J. 2011, 81, 1419–1426. [Google Scholar] [CrossRef]

- Li, B.; Dong, Y.; Wang, P.; Cui, G. Release behavior and kinetic evaluation of formaldehyde from cotton clothing fabrics finished with DMDHEU-based durable press agents in water and synthetic sweat solution. Text. Res. J. 2015, 86, 1738–1749. [Google Scholar] [CrossRef]

- Yasin, S.; Behary, N.; Perwuelz, A.; Guan, J.P.; Chen, G.Q. Degradation Kinetics of Organophosphorus Flame Retardant from Cotton Fabric. Appl. Mech. Mater. 2017, 864, 54–58. [Google Scholar] [CrossRef]

- Ziifle, H.M.; Benerito, R.R.; Gonzales, E.J.; Berni, R.J. Kinetics of the Reactions of Ethyleneurea Derivatives with Cotton Cellulose. Text. Res. J. 2016, 38, 925–930. [Google Scholar] [CrossRef]

- Welo, L.A.; Ziifle, H.M.; Loeb, L. Swelling Capacities of Fibers in Water. Text. Res. J. 2016, 22, 254–261. [Google Scholar] [CrossRef]

- Reeves, W.A.; Drake, G.L., Jr.; McMillan, O.J., Jr.; Guthrie, J.D. Insolubility in Cuprammonium Hydroxide as a Means of Detecting Crosslinking in Chemically Modified Cotton. Text. Res. J. 2016, 25, 41–46. [Google Scholar] [CrossRef]

- Li, S.; Freeman, H.S.; Boyter, H. One-Step Pad Dyeing and DP Finishing of Cotton: Part 2. Mechanism of Dye Fixation Using DMDHEU. Aatcc J. Res. 2015, 2, 13–20. [Google Scholar] [CrossRef]

- Mohsin, M.; Rasheed, A.; Farooq, A.; Ashraf, M.; Shah, A. Environment friendly finishing of sulphur, vat, direct and reactive dyed cotton fabric. J. Clean. Prod. 2013, 53, 341–347. [Google Scholar] [CrossRef]

- Terrero, M.A.; Faz, N.; Ondoo, S.; Muoz, M.n. Impacts of Raw and Purified Pig Slurry on Carbon and Nitrogen Contents in Mediterranean Agricultural Soil—ScienceDirect. Soil Manag. Clim. Chang. 2018, 207–219. [Google Scholar]

- Kavvadias, V.; Papadopoulou, M.; Vavoulidou, E.; Theocharopoulos, S.; Psarras, G. Effects of Carbon Inputs on Chemical and Microbial Properties of Soil in Irrigated and Rainfed Olive Groves. Soil Manag. Clim. Chang. 2018, 137–150. [Google Scholar]

- Fadeeva, V.; Tikhova, V.; Nikulicheva, O. Elemental analysis of organic compounds with the use of automated CHNS analyzers. J. Anal. Chem. 2008, 63, 1094–1106. [Google Scholar] [CrossRef]

- Poon, C.; Kan, C. Optimization Of Wrinkle Resistant Finishing With Dimethyloldihydroxyethyleneurea (Dmdheu) Using Titanium Dioxide As Co-Catalyst. Cellul. Chem. Technol. 2016, 50, 889–894. [Google Scholar]

- Meyer, U.; Müller, K.; Zollinger, H. The Temperature Dependence of the Rate of Crosslinking with Formaldehyde and of the Hydrolysis of Cotton Cellulose. Text. Res. J. 1976, 46, 880–886. [Google Scholar] [CrossRef]

- Madan, G.; Patel, S.; Baddi, N.; Mehta, P. Physical Chemistry of Crosslinking: Part I: Thermodynamics of Cellulose in Aqueous Solution of Crosslinking Agents. Text. Res. J. 1976, 46, 329–342. [Google Scholar] [CrossRef]

- Haule, L.V.; Carr, C.M.; Rigout, M. Investigation into the removal of an easy-care crosslinking agent from cotton and the subsequent regeneration of lyocell-type fibres. Cellulose 2014, 21, 2147–2156. [Google Scholar] [CrossRef]

- Ellery, A.J.; Simpson, M.J.; Mccue, S.W.; Baker, R.E. Characterizing transport through a crowded environment with different obstacle sizes. J. Chem. Phys. 2014, 140, 054108. [Google Scholar] [CrossRef]

- Fu, Y.; Michopoulos, J.; Song, J.H. Coarse-grained molecular dynamics simulations of epoxy resin during the curing process. Comput. Mater. Sci. 2015, 107, 24–32. [Google Scholar] [CrossRef]

- Fu, Y.; Song, J.H. Heat flux expressions that satisfy the conservation laws in atomistic system involving multibody potentials. J. Comput. Phys. 2015, 294, 191–207. [Google Scholar] [CrossRef]

- Fu, Y.; Michopoulos, J.G.; Song, J.H. On Investigating the Thermomechanical Properties of Cross-linked Epoxy Via Molecular Dynamics Analysis. Microscale Thermophys. Eng. 2017, 21, 8–25. [Google Scholar] [CrossRef]

- Chen, J.C.; Chen, C.C. Crosslinking of Cotton Cellulose with Pre-reacted DMDMDHEU-AA. Part I: Physical Properties of Treated Fabrics. Text. Res. J. 2001, 71, 514–518. [Google Scholar] [CrossRef]

- Chen, J.C. Crosslinking of Cotton Cellulose with Pre-reacted DMDMDHEU-AA Part II: Reaction Kinetics. Text. Res. J. 2001, 71, 609–612. [Google Scholar] [CrossRef]

- Chen, J.C.; Yao, W.H.; Chen, C.H.; Chen, C.C. Dyeing kinetics from a finite bath of direct dyes on DMDHEU-AA crosslinked cotton. Text. Res. J. 2002, 72, 55–60. [Google Scholar]

- Chen, J.C.; Chiu, S.T.; Chen, C.C. Crosslinking of sulfonated cotton cellulose. III. Agent distribution and reaction kinetics. Text. Res. J. 2000, 70, 386–390. [Google Scholar] [CrossRef]

- Han, T.Y.; Chen, C.C. Crosslinking of Sulfonated Cotton Cellulose:Part I: Crosslinking and Physical Properties of DMDHEU-Treated Fabrics. Text. Res. J. 1998, 68, 115–120. [Google Scholar] [CrossRef]

- Chen, J.; Yao, W.; Chen, C.; Chen, C. Degree of crosslinked cotton cellulose with prereacted DMDHEU-AA. J. Appl. Polym. Sci. 2001, 82, 1580–1586. [Google Scholar] [CrossRef]

| Storage Conditions | Nitrogen Content (%) | Crosslinking Degree (%) | Relative Error (%) | WRA (°) | |||

|---|---|---|---|---|---|---|---|

| Calculated (CV) | Measured (MV) | Calculated (CV) | Measured (MV) | ||||

| 20 °C | 10 Days | 0.1019 | 0.0972 | 17.76 | 16.90 | −4.61 | 118 ± 5 |

| 15 Days | 0.1506 | 0.1574 | 26.19 | 27.37 | 4.52 | 130 ± 3 | |

| 20 Days | 0.1942 | 0.1887 | 33.77 | 32.82 | −2.83 | 140 ± 4 | |

| 30 Days | 0.2484 | 0.2542 | 43.20 | 44.21 | 2.33 | 145 ± 4 | |

| 30 °C | 10 Days | 0.1486 | 0.1534 | 25.84 | 26.68 | 3.23 | 127 ± 3 |

| 15 Days | 0.2140 | 0.2036 | 37.22 | 35.41 | −4.86 | 139 ± 6 | |

| 20 Days | 0.2693 | 0.2745 | 46.83 | 47.74 | 1.93 | 158 ± 4 | |

| 30 Days | 0.3559 | 0.3412 | 61.90 | 59.34 | −4.13 | 176 ± 5 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lou, J.; Zhang, J.; Xu, S.; Wang, D.; Fan, X. New Method to Evaluate the Crosslinking Degree of Resin Finishing Agent with Cellulose Using Kjeldahl Method and Arrhenius Formula. Processes 2021, 9, 767. https://doi.org/10.3390/pr9050767

Lou J, Zhang J, Xu S, Wang D, Fan X. New Method to Evaluate the Crosslinking Degree of Resin Finishing Agent with Cellulose Using Kjeldahl Method and Arrhenius Formula. Processes. 2021; 9(5):767. https://doi.org/10.3390/pr9050767

Chicago/Turabian StyleLou, Jiangfei, Jinfang Zhang, Shengxiang Xu, Dan Wang, and Xuerong Fan. 2021. "New Method to Evaluate the Crosslinking Degree of Resin Finishing Agent with Cellulose Using Kjeldahl Method and Arrhenius Formula" Processes 9, no. 5: 767. https://doi.org/10.3390/pr9050767

APA StyleLou, J., Zhang, J., Xu, S., Wang, D., & Fan, X. (2021). New Method to Evaluate the Crosslinking Degree of Resin Finishing Agent with Cellulose Using Kjeldahl Method and Arrhenius Formula. Processes, 9(5), 767. https://doi.org/10.3390/pr9050767