Simulation Study of Utilizing X-ray Tube in Monitoring Systems of Liquid Petroleum Products

Abstract

:1. Introduction

2. Materials and Methods

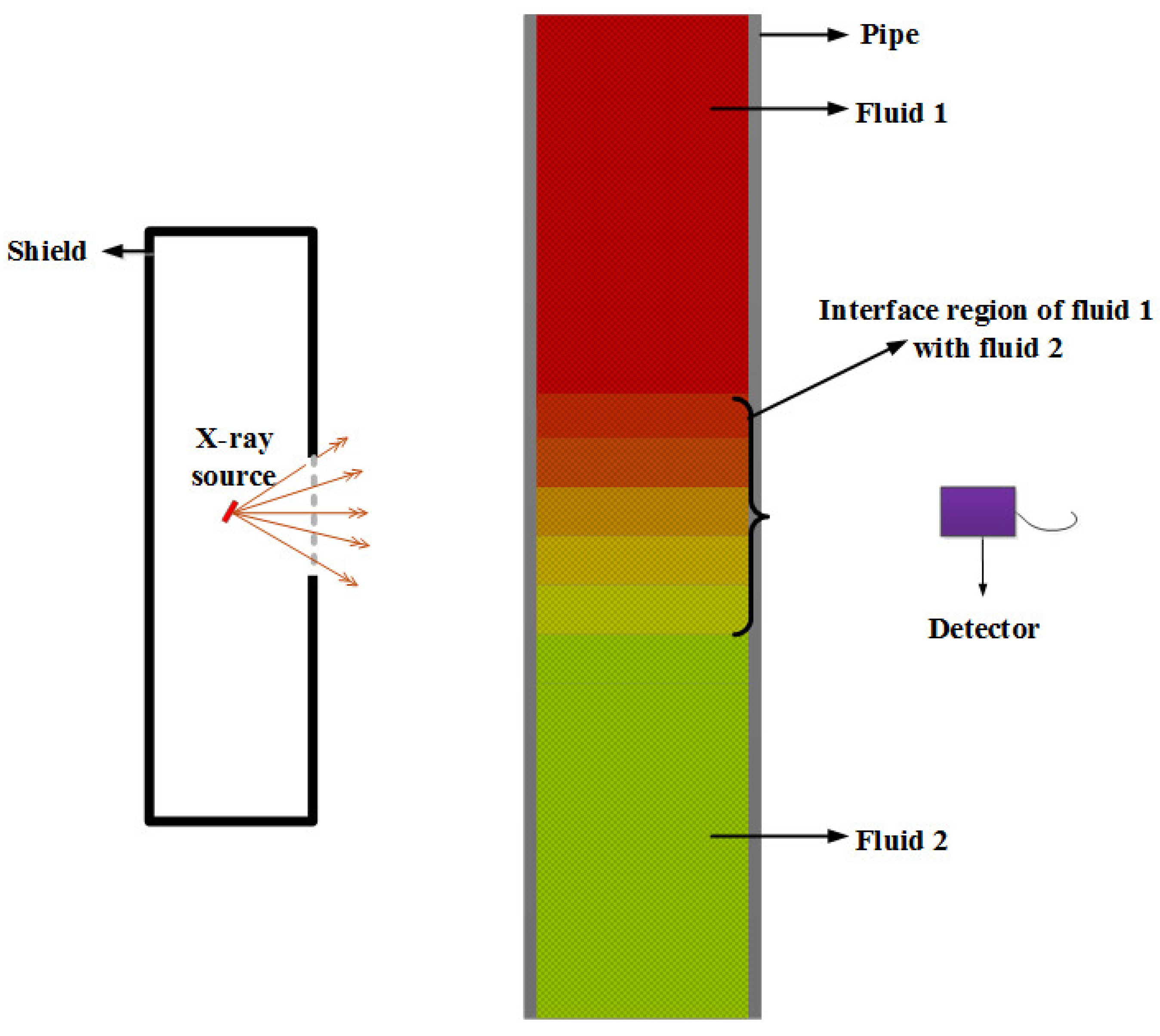

2.1. Modeling the Proposed System

2.2. Artificial Intelligence

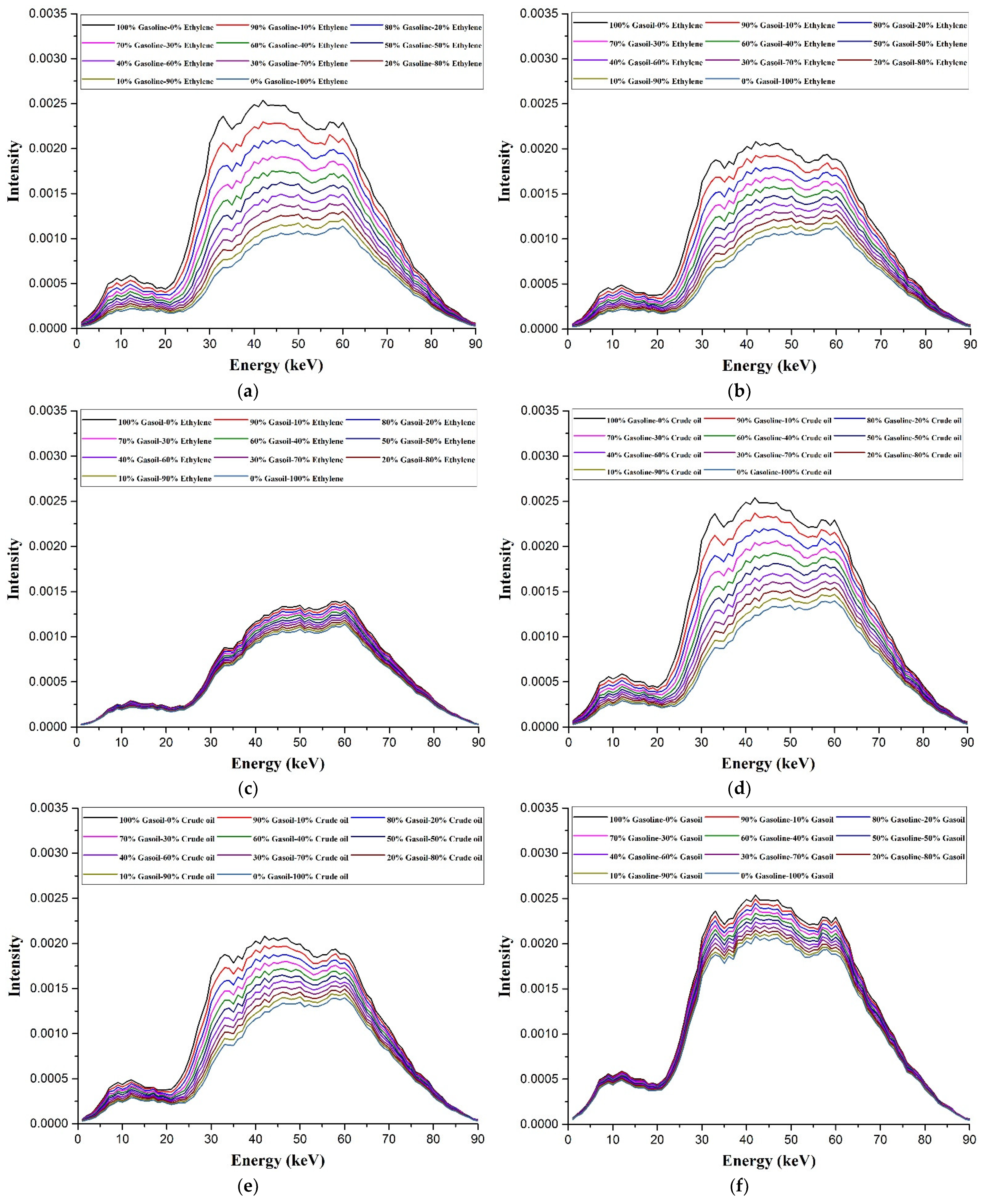

3. Result and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Salgado, C.M.; Brandão, L.E.B.; Conti, C.C.; Salgado, W.L. Density prediction for petroleum and derivatives by gamma-ray attenuation and artificial neural networks. Appl. Radiat. Isot. 2016, 116, 143–149. [Google Scholar] [CrossRef]

- Roshani, G.H.; Feghhi, S.A.H.; Adineh-Vand, A.; Khorsandi, M. Application of adaptive neuro-fuzzy inference system in prediction of fluid density for a gamma ray densitometer in petroleum products monitoring. Measurement 2013, 46, 3276–3281. [Google Scholar] [CrossRef]

- Salgado, W.L.; Dam, R.S.D.F.; Barbosa, C.M.; da Silva, A.X.; Salgado, C.M. Monitoring system of oil by-products interface in pipelines using the gamma radiation attenuation. Appl. Radiat. Isot. 2020, 160, 109125. [Google Scholar] [CrossRef] [PubMed]

- Roshani, M.; Phan, G.; Faraj, R.H.; Phan, N.H.; Roshani, G.H.; Nazemi, B.; Corniani, E.; Nazemi, E. Proposing a gamma radiation based intelligent system for simultaneous analyzing and detecting type and amount of petroleum by-products. Nucl. Eng. Technol. 2021, 53, 1277–1283. [Google Scholar] [CrossRef]

- Roshani, M.; Sattari, M.A.; Ali, P.J.M.; Roshani, G.H.; Nazemi, B.; Corniani, E.; Nazemi, E. Application of GMDH neural network technique to improve measuring precision of a simplified photon attenuation based two-phase flowmeter. Flow Meas. Instrum. 2020, 75, 101804. [Google Scholar] [CrossRef]

- Vlasák, P.; Chára, Z.; Matoušek, V.; Konfršt, J.; Kesely, M. Experimental investigation of fine-grained settling slurry flow behaviour in inclined pipe sections. J. Hydrol. Hydromech. 2019, 67, 113–120. [Google Scholar] [CrossRef] [Green Version]

- Roshani, G.; Nazemi, E.; Feghhi, S. Investigation of using 60 Co source and one detector for determining the flow regime and void fraction in gas-liquid two-phase flows. Flow Meas. Instrum. 2016, 50, 73–79. [Google Scholar] [CrossRef]

- El Abd, A. Intercomparison of gamma ray scattering and transmission techniques for gas volume fraction measurements in two phase pipe flow. Nucl. Instrum. Methods Phys. Res. A 2014, 735, 260–266. [Google Scholar] [CrossRef]

- Roshani, G.H.; Nazemi, E.; Feghhi, S.A.; Setayeshi, S. Flow regime identification and void fraction prediction in two-phase flows based on gamma ray attenuation. Measurement 2015, 62, 25–32. [Google Scholar] [CrossRef]

- Nazemi, E.; Feghhi, S.A.H.; Roshani, G.H.; Peyvandi, R.G.; Setayeshi, S. Precise void fraction measurement in two-phase flows independent of the flow regime using gamma-ray attenuation. Nucl. Eng. Technol. 2016, 48, 64–71. [Google Scholar]

- Abro, E.; Johansen, G.A. Improved Void Fraction Determination by Means of Multibeam Gamma-Ray Attenuation Measurements. Flow Meas. Instrum. 1999, 10, 99–108. [Google Scholar]

- Nazemi, E.; Roshani, G.H.; Feghhi, S.A.H.; Setayeshi, S.; Zadeh, E.E.; Fatehi, A. Optimization of a method for identifying the flow regime and measuring void fraction in a broad beam gamma-ray attenuation technique. Int. J. Hydrog. Energy 2016, 41, 7438–7444. [Google Scholar] [CrossRef]

- Sattari, M.A.; Roshani, G.H.; Hanus, R.; Nazemi, E. Applicability of time-domain feature extraction methods and artificial intelligence in two-phase flow meters based on gamma-ray absorption technique. Measurement 2021, 168, 108474. [Google Scholar] [CrossRef]

- Zych, M. An analysis and interpretation of the signals in gamma-absorption measurements of liquid–gas intermittent flow. Acta Geophys. 2018. [Google Scholar] [CrossRef] [Green Version]

- Roshani, G.; Hanus, R.; Khazaei, A.; Zych, M.; Nazemi, E.; Mosorov, V. Density and velocity determination for single-phase flow based on radiotracer technique and neural networks. Flow Meas. Instrum. 2018, 61, 9–14. [Google Scholar] [CrossRef]

- Zych, M.; Hanus, R.; Wilk, B.; Petryka, L.; Świsulski, D. Comparison of noise reduction methods in radiometric correlation measurements of two-phase liquid-gas flows. Measurement 2018, 129, 288–295. [Google Scholar] [CrossRef]

- Roshani, G.; Nazemi, E.; Roshani, M. Identification of flow regime and estimation of volume fraction independent of liquid phase density in gas-liquid two-phase flow. Prog. Nucl. Energy 2017, 98, 29–37. [Google Scholar] [CrossRef]

- Roshani, G.; Nazemi, E. Intelligent densitometry of petroleum products in stratified regime of two phase flows using gamma ray and neural network. Flow Meas. Instrum. 2017, 58, 6–11. [Google Scholar] [CrossRef]

- Roshani, G.H.; Feghhi, S.A.; Mahmoudi-Aznaveh, A.; Nazemi, E.; Adineh-Vand, A. Precise volume fraction prediction in oil–water–gas multiphase flows by means of gamma-ray attenuation and artificial neural networks using one detector. Measurement 2014, 51, 34–41. [Google Scholar] [CrossRef]

- Roshani, G.H.; Roshani, S.; Nazemi, E.; Roshani, S. Online measuring density of oil products in annular regime of gas-liquid two phase flows. Measurement 2018, 129, 296–301. [Google Scholar] [CrossRef]

- Roshani, G.H.; Nazemi, E.; Roshani, M.M. Intelligent recognition of gas-oil-water three-phase flow regime and determination of volume fraction using radial basis function. Flow Meas. Instrum. 2017, 54, 39–45. [Google Scholar] [CrossRef]

- Roshani, M.; Phan, G.; Roshani, G.H.; Hanus, R.; Nazemi, B.; Corniani, E.; Nazemi, E. Combination of X-ray tube and GMDH neural network as a nondestructive and potential technique for measuring characteristics of gas-oil-water three phase flows. Measurement 2021, 168, 108427. [Google Scholar] [CrossRef]

- Salgado, C.M.; Pereira, C.M.; Schirru, R.; Brandão, L.E. Flow regime identification and volume fraction prediction in multiphase flows by means of gamma-ray attenuation and artificial neural networks. Prog. Nucl. Energy. 2010, 52, 555–562. [Google Scholar] [CrossRef]

- Roshani, G.H.; Nazemi, E.; Roshani, M.M. Flow regime independent volume fraction estimation in three-phase flows using dual-energy broad beam technique and artificial neural network. Neural Comput. Appl. 2016, 28, 1265–1274. [Google Scholar] [CrossRef]

- Karami, A.; Roshani, G.H.; Khazaei, A.; Nazemi, E.; Fallahi, M. Investigation of different sources in order to optimize the nuclear metering system of gas–oil–water annular flows. Neural Comput. Appl. 2018, 32, 3619–3631. [Google Scholar] [CrossRef]

- Salgado, C.M.; Brandão, L.E.; Pereira, C.M.; Salgado, W.L. Salinity independent volume fraction prediction in annular and stratified (water-gas-oil) multiphase flows using artificial neural networks. Prog. Nucl. Energy 2014, 76, 17–23. [Google Scholar] [CrossRef]

- Karami, A.; Roshani, G.H.; Nazemi, E.; Roshani, S. Enhancing the performance of a dual-energy gamma ray based three-phase flow meter with the help of grey wolf optimization algorithm. Flow Meas. Instrum. 2018, 64, 164–172. [Google Scholar] [CrossRef]

- Roshani, G.; Nazemi, E.; Roshani, M. Usage of two transmitted detectors with optimized orientation in order to three phase flow metering. Measurement 2017, 100, 122–130. [Google Scholar] [CrossRef]

- Salgado, W.L.; Dam, R.S.D.F.; Teixeira, T.P.; Conti, C.C.; Salgado, C.M. Application of artificial intelligence in scale thickness prediction on offshore petroleum using a gamma-ray densitometer. Radiat. Phys. Chem. 2020, 168, 108549. [Google Scholar] [CrossRef]

- Roshani, M.; Phan, G.T.; Ali, P.J.M.; Roshani, G.H.; Hanus, R.; Duong, T.; Corniani, E.; Nazemi, E.; Kalmoun, E.M. Evaluation of flow pattern recognition and void fraction measurement in two phase flow independent of oil pipeline’s scale layer thickness. Alex. Eng. J. 2021, 60, 1955–1966. [Google Scholar] [CrossRef]

- Pelowitz, D.B. MCNP-X TM User’s Manual, Version 2.5.0. LA-CP-05e0369; Los Alamos National Laboratory: New Mexico, NM, USA, 2005.

- Cranley, K.; Gilmore, B.J.; Fogarty, G.W.A.; Desponds, L. IPEM Report 78: Catalogue of Diagnostic X-ray Spectra and Other Data (CD-Rom Edition 1997) (Electronic Version Prepared by D Sutton); The Institute of Physics and Engineering in Medicine (IPEM): York, UK, 1997. [Google Scholar]

- Ranganathan, A. The levenberg-marquardt algorithm. Tutoral LM Algorithm 2004, 11, 101–110. [Google Scholar]

| Data Number | Real Percentage of Ethylene Glycol | Measured Percentage of Ethylene Glycol | Differences between Real and Measured Data | Real Percentage of Crude Oil | Measured Percentage of Crude Oil | Differences between Real and Measured Data | Real Percentage of Gasoline | Measured Percentage of Gasoline | Differences between Real and Measured Data |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 100 | 93.99 | 6.00 | 0 | 4.38 | 4.38 | 0 | 0.79 | 0.79 |

| 2 | 5 | −0.01 | 5.01 | 95 | 90.41 | 4.58 | 0 | −2.07 | 2.07 |

| 3 | 25 | 22.65 | 2.34 | 75 | 84.28 | 9.28 | 0 | −0.04 | 0.04 |

| 4 | 45 | 47.69 | 2.69 | 55 | 52.84 | 2.15 | 0 | 0.08 | 0.08 |

| 5 | 60 | 63.82 | 3.82 | 40 | 35.83 | 4.16 | 0 | 0.14 | 0.14 |

| 6 | 75 | 78.37 | 3.37 | 25 | 27.55 | 2.55 | 0 | 5.29 | 5.29 |

| 7 | 95 | 93.03 | 1.96 | 5 | 4.93 | 0.06 | 0 | −0.15 | 0.15 |

| 8 | 15 | 7.86 | 7.13 | 0 | 5.57 | 5.57 | 0 | −1.08 | 1.0 |

| 9 | 30 | 28.60 | 1.39 | 0 | −0.10 | 0.10 | 0 | −1.82 | 1.82 |

| 10 | 50 | 42.83 | 7.16 | 0 | 1.04 | 1.04 | 0 | −1.019 | 1.01 |

| 11 | 70 | 72.23 | 2.23 | 0 | 0.39 | 0.39 | 0 | −2.13 | 2.13 |

| 12 | 90 | 94.48 | 4.48 | 0 | 1.26 | 1.26 | 0 | 2.12 | 2.12 |

| 13 | 15 | 10.00 | 4.99 | 0 | 2.60 | 2.60 | 85 | 86.81 | 1.81 |

| 14 | 30 | 30.01 | 0.01 | 0 | −0.06 | 0.06 | 70 | 70.74 | 0.74 |

| 15 | 50 | 51.05 | 1.05 | 0 | 0.73 | 0.73 | 50 | 45.80 | 4.19 |

| 16 | 70 | 72.32 | 2.32 | 0 | −1.07 | 1.07 | 30 | 35.05 | 5.05 |

| 17 | 85 | 92.67 | 7.67 | 0 | −0.18 | 0.18 | 15 | 8.54 | 6.45 |

| 18 | 0 | −5.08 × 10−5 | 5.08 × 10−5 | 5 | 6.62 | 1.62 | 0 | 1.45 | 1.45 |

| 19 | 0 | 0.45 | 0.45 | 20 | 14.32 | 5.67 | 0 | 9.47 | 9.47 |

| 20 | 0 | −3.28 × 10−5 | 3.28 × 10−5 | 40 | 31.03 | 8.96 | 0 | 8.62 | 8.62 |

| 21 | 0 | 0.00 | 0.00 | 50 | 47.60 | 2.39 | 0 | 5.29 | 5.29 |

| 22 | 0 | −8.19 × 10−5 | 8.19 × 10−5 | 65 | 64.91 | 0.08 | 0 | −5.98 | 5.98 |

| 23 | 0 | −0.00 | 0.00 | 80 | 79.80 | 0.19 | 0 | 0.31 | 0.31 |

| 24 | 0 | −0.03 | 0.03 | 95 | 93.77 | 1.22 | 0 | 2.82 | 2.82 |

| 25 | 0 | −5.13 × 10−5 | 5.13 × 10−5 | 15 | 4.92 | 10.07 | 85 | 86.19 | 1.19 |

| 26 | 0 | 0.00 | 0.00 | 30 | 21.94 | 8.05 | 70 | 70.81 | 0.81 |

| 27 | 0 | 0.00 | 0.00 | 50 | 41.01 | 8.98 | 50 | 54.84 | 4.84 |

| 28 | 0 | −4.70 × 10−5 | 4.7 × 10−5 | 65 | 65.13 | 0.13 | 35 | 31.24 | 3.75 |

| 29 | 0 | −0.00 | 0.00 | 80 | 79.27 | 0.72 | 20 | 16.44 | 3.55 |

| 30 | 0 | −0.05 | 0.05 | 95 | 99.52 | 4.52 | 5 | 4.96 | 0.03 |

| 31 | 0 | −5.11 × 10−5 | 5.11 × 10−5 | 0 | 1.18 | 1.18 | 85 | 84.32 | 0.67 |

| 32 | 0 | 3.15 × 10−5 | 3.15 × 10−5 | 0 | 0.07 | 0.07 | 70 | 67.53 | 2.46 |

| 33 | 0 | 0.012 | 0.012749 | 0 | −0.26 | 0.26 | 55 | 56.14 | 1.14 |

| 34 | 0 | −5.14 × 10−5 | 5.14 × 10−5 | 0 | −0.09 | 0.09 | 35 | 31.9 | 3.02 |

| 35 | 0 | −4.13 × 10−5 | 4.13 × 10−5 | 0 | −0.47 | 0.47 | 15 | 15.56 | 0.56 |

| ANN | MRE for Test Set | MAE for Test Set |

|---|---|---|

| Presented MLP-LM Model for Ethylene Glycol Percentage Measuring | 0.91 | 1.84 |

| Presented MLP-LM Model for Crude Oil Percentage Measuring | 1.70 | 2.72 |

| Presented MLP-LM Model for Gasoline Percentage Measuring | 0.03 | 2.61 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roshani, G.H.; Ali, P.J.M.; Mohammed, S.; Hanus, R.; Abdulkareem, L.; Alanezi, A.A.; Sattari, M.A.; Amiri, S.; Nazemi, E.; Eftekhari-Zadeh, E.; et al. Simulation Study of Utilizing X-ray Tube in Monitoring Systems of Liquid Petroleum Products. Processes 2021, 9, 828. https://doi.org/10.3390/pr9050828

Roshani GH, Ali PJM, Mohammed S, Hanus R, Abdulkareem L, Alanezi AA, Sattari MA, Amiri S, Nazemi E, Eftekhari-Zadeh E, et al. Simulation Study of Utilizing X-ray Tube in Monitoring Systems of Liquid Petroleum Products. Processes. 2021; 9(5):828. https://doi.org/10.3390/pr9050828

Chicago/Turabian StyleRoshani, Gholam Hossein, Peshawa Jammal Muhammad Ali, Shivan Mohammed, Robert Hanus, Lokman Abdulkareem, Adnan Alhathal Alanezi, Mohammad Amir Sattari, Saba Amiri, Ehsan Nazemi, Ehsan Eftekhari-Zadeh, and et al. 2021. "Simulation Study of Utilizing X-ray Tube in Monitoring Systems of Liquid Petroleum Products" Processes 9, no. 5: 828. https://doi.org/10.3390/pr9050828

APA StyleRoshani, G. H., Ali, P. J. M., Mohammed, S., Hanus, R., Abdulkareem, L., Alanezi, A. A., Sattari, M. A., Amiri, S., Nazemi, E., Eftekhari-Zadeh, E., & Kalmoun, E. M. (2021). Simulation Study of Utilizing X-ray Tube in Monitoring Systems of Liquid Petroleum Products. Processes, 9(5), 828. https://doi.org/10.3390/pr9050828