1. Introduction

The development of transport services in previous decades has strongly affected mobility and accessibility [

1]. Air traffic connects remote areas and increases their accessibility by increasing the possibilities for people and goods to travel [

2].

The main characteristics of air traffic, which also represent its advantages, are fast transport service, the transfer of products with small volume and of high value, service from terminal to terminal, service cover on the locations with higher transport flows, short transport time, service flexibility and reliability, minimal losses, low probability of causing damage, a smaller necessity for the package and minimal supply costs. Air traffic is an important part of the international market, since it enables a faster response to its client’s needs, according to the aforementioned characteristics and advantages [

3]. International Civil Aviation Organization (ICAO) has defined three major groups of events which cause high risks for the development of disorders in air traffic, to provide safety in air traffic and to create global safety plans in aviation. Among them are the events on and in the surroundings of the area, meant for aircrafts landing and taking off (events of abnormal runway contact (ARC), runway excursion (RE), loss of control on the ground (LOC-G), etc.). Recent studies show that a large number of plane crashes happen when aircrafts take off and land [

4]. Therefore, the control over the events on and in the surroundings of the runways is key when providing safety and efficiency of air traffic. Well-maintained runways have an important role here as well. The authors [

5] emphasize that when a runway does not function or is not able to perform its function, i.e., planes taking off and landing, the flow of aircrafts in the airport can be diminished or interrupted, which negatively affects the operations on a national, regional or even international level. It is necessary to maintain the runways constantly in the optimal condition due to safety and economic reasons.

Non-efficient airport infrastructure and runways can infringe these advantages, or in the case of the closure of the runway, completely ruin them. The consequences are also shown in the delays of flights and can consequently affect the entire economy. The authors also show the importance of the time factor, suggesting the concept of time delay in maintenance as a way of reducing maintenance costs. Their study of a Brazilian airport may be adopted in other contexts after parameterization of the data for failures and runway consumption [

6]. Inefficient airport infrastructure is shown especially to jeopardize the safety, diminish the flexibility and reliability of the service, jeopardize the guarantee of minimal losses, jeopardize the insurance of a low probability of damage and lower the service’s level in general. The authors [

7] claim that the provision of a high service level at the airport is important for its successful functioning.

The decision-makers use various technical and economic analyses when creating maintenance strategies, which are implemented in the pavement management system (PMS) for adequate and timely maintenance of the road surface. Various information systems or the airport pavement management system (APMS) are used to create adequate maintenance strategies for the runways due to the specificity of the airports. They include procedures which help to evaluate and search for adequate maintenance strategies [

8]. Many airports around the world use APMS. The development of the PMS in APMS is a subject of many kinds of research. The APMS is an approach to monitoring the condition of pavements and determining the priorities for intervention, as well as planning and allocating resources [

9,

10,

11,

12,

13].

The phenomenon of the deformations presents a big problem on the runways, which can be abolished with early precautions when dealing with airport infrastructure. The automatized obtainment and spatial data processing of information about the deformations on the road surfaces and on the runways are the subject of many kinds of recent research [

14,

15,

16,

17,

18,

19,

20,

21,

22]. The authors of the research mostly analyze the recordings of the roadways and runways which are a product of remote sensing. The development of algorithms for automatic detection or extraction of the deformations (cracks, holes, etc.) from the recordings, determining the dimensions of the deformations (width and depth) and their classification, is common among the studies. The authors [

23] used infra-red thermal sensors with which the deformations on the surface of the runway were detected, and the ground penetrating radar (GPR) for structural density distribution with which the extent and depth of the deformations were detected.

The author of [

24] researched the detecting of the deformations of the runway and taxiway with non-destructive methods: GPR, ground load capacity measuring device, thermography and the sonic/seismic method. The authors of [

25] researched the condition of the runway by merging the data of the measurements obtained with the 3D-laser scanner, Heavy Weight Deflectometer and 3D-GPR. The authors of [

26] researched the condition of the runway with the GPR and [

27] used 3D-GPR (GSSI SIR-20) with a central frequency of 1 in 2 GHz for the measurements. The authors of [

28] researched the adequacy and applicability of various methods of the measuring of the shifts. They describe geodetic methods (trigonometric leveling, geometric leveling, Global Navigation Satellite System (GNSS) measuring methods, 3D-laser scanning and photogrammetry) and non-geodetic methods of data measuring (strain gauges). The use of geodetic methods in determining the vertical deviations and detecting the deformations on the surface of the runways and predicting the creation of new ones is not sufficiently researched yet. Research on this topic cannot be found in the accessible literature. Authors have researched the use of geodetic methods in deformational analyses. The authors of [

29,

30,

31,

32] researched the performances of modern electronic tachymeters and their incorporation into the monitoring of the deformations.

Therefore, the maintenance of the runways must be managed with precautions, so they are kept in the best condition and, with the use of APMS, with minimal costs [

11,

33]. Thus, the risks, caused by inadequate maintenance, and consequently, the closure or limited function of the runway are diminished [

6]. The authors of [

6] claim that, along with the regular runway check-ups, it is necessary to provide the use of methods to evaluate the condition of the runway. Therefore, it can be concluded that the development of adequate monitoring is necessary and recommended. Despite the mentioned facts, the maintenance politics in some airports is still determined in compliance with the experiences and priorities of the managers, which are connected also with not enough means meant for the maintenance.

Based on the overview of the literature, it is possible to detect the necessity of the development of a monitoring model which would enable relatively faster and easier data collection about the damages on the runways, and would at the same time present a relevant basis for more adequate and more timely decision-making about the method and extent of the execution of the maintenance or renovation works.

A novelty of our research is an optimized model for the implementation of deformation monitoring at small airports. We ask the research questions, how can measurements at the airport be performed without having to close the airport and thus not cause financial losses, and how can we establish an optimized model that will allow us to quickly and qualitatively determine the location and degree of deformations?

The added value of this research to this community is the prototyping of a runway model for management and maintenance with the ability to determine the degree of runway damage.

Research Framework

In the article, we focused on the overview of previous research and the models´ development. From the research, it was concluded that the used and described models are appropriate only for big and well-equipped airports. Here, we refer to the use of an information system for detecting the deformations and rate of runway damage. In the research, we used geodetic and other methods with which the deformations were located, and the cause of the deformations was detected. The significant part of the research was the production of an information process system with which the results of the measurements are valued, the mutual correlation is detected and, based on the analysis, the rate and the location of the runway damage are given. This system will enable the manager to more easily manage the runway, especially in terms of runway maintenance.

2. Methodology—Geodetic Measurements

The research was executed in the Maribor Edvard Rusjan Airport before the opening of the airport, which is between 6.30 and 8.30, after the agreement of the management of the airport. The airport is the second biggest in Slovenia and is among smaller airports in the international air traffic. Due to the strict regulations, the research of the airport´s function and the execution of the measurements at the airport is very difficult. The runway which enabled wide data collection with the use of various methods, was not congested which would cause additional vibrations between measurements and was adequate in terms of location was chosen for the execution of the experiment.

The Phases of the Execution of the Measurements

The research was executed in three phases. The geodetic measurements were executed in the first and second phase, and the supplementary measurements were executed in the third phase. In the first phase, the test of the measuring equipment was executed; the geodetic (zero) net was established which materialized a stable and homogenous coordinate system, and perpendicular grid (hereinafter: GRID) were measured as well. GRID served as the starting point in the comparative analysis of the first, second and third measurements of the runway with a trailer and when calculating the vertical deviations between them. In the second phase, the measurements with an especially made trailer for this measurement were executed. Three measurements were executed: the first in the winter, the second in the spring and the third in the summer.

Non-horizontality of the surface was detected with geodetic instrument Leica RTS TS50 with 0.5-s accuracy. Ten readings per second were executed with automatic monitoring through the GeoCOM protocol. The Topcon 360° prism was placed on the specially made non-spring and stiff trailer with other stationary measuring technology as seen in

Figure 1.

Five longitudinal profiles were driven with the equal minimal speed of 6 km/h, with which the whole width of the runway was contained, and 8700 points were recorded. The GNSS Topcon Hyper Pro equipment was placed on the trailer, as well as on the GPR, which served for the positioning of the vehicle and GPR and placing the measured values on the comparative plane which was recorded as classically geodetic with a density of points 2.5 m × 2.5 m. Used measuring equipment is seen in

Figure 1 and

Figure 2.

3. Methodology—The Development of the Process Decision-Making Maintenance Model and Innovative Model for the Continuous Monitoring of Deformations on the Runways

The aim is to create a logistics information system which will support processes in smaller airports. Therefore, it is necessary to establish the APMS, which will be used mainly in smaller airports and will enable collecting, storage, maintenance and execution of the analyses and a search of the correlations of certain types of measuring data.

The maintenance model APMS-MB was developed for smaller airports which may have limited means. The APMS-MB maintenance model contains the monitoring model that, along with regular runway check-ups, includes the geodetic and supplementary methods. This model is called the innovative model of the runway (IMR) and IMR_all model.

The IMR and IMR_all models enable us to obtain data about the condition of the runway easily, quickly and with minimal costs, which is essential for the quality of planes’ landing and taking off.

These data in the foregoing maintenance process present the basis for decision-making about the method and extent of the execution of the maintenance or renovation works. The APMS-MB maintenance model presents the integrational component of the airport management system (AMS) or, more widely, the transport management system (TMS). According to Article 158 of the Aviation Act, maintenance is one of the needed components for public airports to run. The integration of APMS-MB with AMS and more widely with the TMS is shown in

Figure 3.

The suggested processual decision-making maintenance model was tested at Maribor Edvard Rusjan Airport. The model consists of the main processed model (APMS-MB) and sub-process (IMR) or expanded sub-process (IMR_all). The emphasis is on the development of sub-process monitoring models or an innovative model for the continuous monitoring of the deformations of the airport runways, which contains the production of the work processes model, containing of measuring data, processing of the measuring data, the calculation of vertical deviations and determining the damages of the runway.

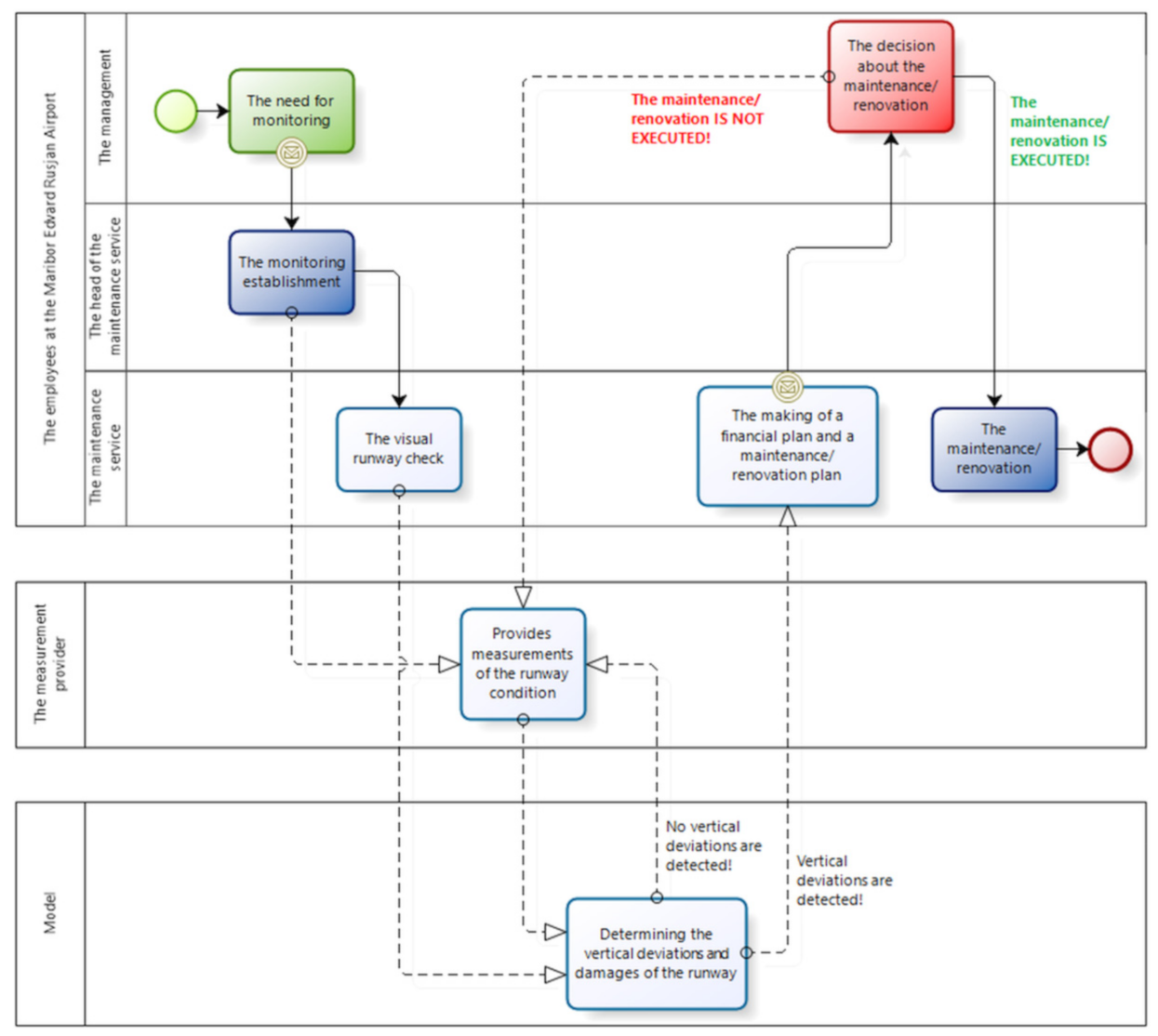

3.1. Process Decision-Making Maintenance Model

Process models must be transferable within and between organizations and connectable to other models, so it is recommended to use standardized notations when designing them. The most commonly used are business process model and notation (BPMN notation) (latest version BPMN 2.0) and general purpose modeling language unified modeling language (UML). UML is object-oriented and is primarily intended for software development. BPMN is process-oriented and therefore more suitable for business process modeling. At the same time, BPMN enables the conversion of models into execution languages such as XML process definition language (XPDL) and business process modeling language (BPEL), which are based on extensible markup language (XML).

The purpose of BPMN is to provide a standardized record of activities in the process that will be understandable to all users: decision makers, analysts, programmers, contractors, etc. Using a standardized set of graphic elements, it enables a visual presentation of the process.

The process modeling technique BPMN was used for modeling the work processes, related to the maintenance at Maribor Edvard Rusjan Airport. The business process diagrams (BPD) wholly present the business or the work process. The software for modeling of business processes, Bizagi Modeler, version 3.6.0.044, was used to produce BPDs.

The first step in the modeling process was the production of a conceptual model which presents basic characteristics of the system and provides a high-level view of the system. The high-level diagram of cooperation LetMB was made (

Figure 4) for this purpose. This type of diagram provides a basic presentation of the process, a presentation of the actors in the process and their cooperation.

As shown in

Figure 4, the maintenance process begins with the problem identification, i.e., with the acknowledgement that a runway is an object, liable to the outer influences, and that, for the optimal assurance of its function, i.e., safe aircraft taking off and landing, the regular monitoring of the runway and maintenance on time are needed. Thus, the service, which is obligated to assure the optimal function of the runway, is enabled to establish the monitoring of the runway. The monitoring consists of providing data about the condition of the runway, determining the vertical deviations, determining the areas of vertical deviations and deformations and determining the damages of the runway. The data about the runway is provided by the service, which is obligated to carry out a daily visual runway check-up, and providers of geodetic and supplementary measurements. The vertical deviations, the areas of vertical deviations and deformations and damages of the runways are determined based on the measuring data and with the algorithm, which was presented in the articles by [

34,

35]. The results of the algorithm are the basis for evaluating various maintenance alternatives, the preparation of maintenance plans and hereinafter, for the selection of the optimal alternative or decision-making about whether the maintenance or renovation is necessary, and if so, to what extent it should be executed.

Hereinafter, the conceptual model was upgraded and completed with detailed presentations and descriptions of work processes.

Figure 5 shows the deck level or the mass of work processes in runway maintenance procedures. The process, shown in

Figure 5, shows actors in the process, connections between the actors, their activities and results of individual activities, which are stored in the central database of the information system of the airport governance (CB-LetMB).

3.2. The Innovative Model for the Continuous Monitoring of the Deformations of the Runways

The monitoring (IMR), which was built as a subprocess in the maintenance process (APMS-MB), was, hereinafter, defined in detail (

Figure 6 and

Figure 7). The more detailed BPD was made, which describes the monitoring, in which, along with the daily visual runway check-ups, the measurement with the use of geodetic methods is intended. The geodetic measurements provider is included in the monitoring process as an outer actor who, according to the estimated plan, executes measurements and writes the measurement results into the central database (CB-LetMB) or forwards them into the model in which the vertical deviations are calculated and areas of vertical deviations and deformations are determined. The monitoring result (IMR) contains calculated vertical deviations and determined areas of vertical deviations, which are a combination of findings that are based on the visual runway check-up and the results of the used geodetic method.

3.3. The Expanded Innovative Model for the Continuous Monitoring of the Deformations on the Runways

The monitoring (IMR) was, hereinafter, expanded with new actors since the incorporation of additional supplementary measurements with which deformations on the runway can be detected or confirmed is intended. Thus, the expanded BDP monitoring (IMR_all) (

Figure 8,

Figure 9 and

Figure 10), in which the geodetic measurement provider and supplementary measurement provider are included as outer actors, was created.

In the present research and also in [

36,

37], we have, with the help of newly established models for measuring and assessing the airport infrastructure, and with the help of the made prototype for the runway management maintenance, examined the possibility to consider the already established and the ICAO regulated safety demands. They are based on the physical testing of the runway state and those demanded methods cannot be uniquely used in the computer environment.

To upgrade the obsolete evaluation system, it is suggested that, as the base to evaluate the runway state, the value of estimated vertical deviations is used (level of damage), obtained based on the executed measurements and the analysis as it suggested with the adapted method for monitoring the runway state.

The airport logistics infrastructure maintenance strategy for smaller regional airports is determined as [

36]:

- –

The execution of basic measurements (the zero-net establishment, the first time dimension), the establishment (upgrade) of the airport logistics infrastructure maintenance information system in smaller regional airports (IMR)—basic condition for the maintenance system to function;

- –

The level of runway condition (the level of damage Manuscript ID: processes-09-00833):

- ○

0 = great: no deepening larger than 1 mm and no risings of the runway surface larger than 1 cm are detected;

- ○

1 = good: no deepening larger than 2 mm and no risings of the runway surface larger than 2 cm are detected, the »0 = great« is exceeded;

- ○

2 = satisfactory: no deepening larger than 3 mm and no risings of the runway surface larger than 3 cm are detected, the »1 = good« is exceeded;

- ○

3 = bad: no deepening larger than 4 mm and no risings of the runway surface larger than 5 cm are detected, the »2 = satisfactory« is exceeded;

- ○

4 = very bad: no deepening larger than 5 mm and no risings of the runway surface larger than 7 cm are detected, »3 = bad« is exceeded;

- ○

5 = inappropriate: deepening larger than 5 mm and risings of the runway surface larger than 7 cm are detected, 4 = very bad« is exceeded.

4. The Monitoring Results

The monitoring results (IMR_all) are determined areas of vertical deviations, which are a combination of findings based on the visual runway check-up, the results of the used geodetic method and the results of the supplementary method, which is shown in

Figure 11. Areas of the deformations can be shown as 2D contours of the plane of deviations from the regression plane, as a 3D plane of deviations from the regression plane or on a plate in a real space.

5. Discussion

The runways are liable to various factors which affect their deformations. This primarily refers to the weight of the aircrafts and weather conditions, as well as the function of the forces under the runway. It is due to these factors, for the safety of people, cargo and aircrafts, that the runway must be regularly checked, and the level of damage must be determined. Only a well-maintained runway enables a good logistics system, and with-it, related activities. Smaller airports, among which is also the airport in Maribor, have a weakly developed information system for detecting the deformations. The research aimed to create an innovative model for monitoring the deformations on the runways for smaller and less frequent airports based on geodetic measurements.

Deformed and insufficiently maintained tracks directly affect safety. Longer and more extensive remediation results in higher costs [

38] and longer runway closures. The researchers in [

39] state that aviation disruptions have a major impact on the aviation industry. Undetected deformations on the runways are also considered to be disturbances that cause delays in air traffic. These cause delays that are similar in duration to those resulting from aircraft damages. The authors of [

39] also state that in 2016, there were a total of approximately 59 million minutes of delays in passenger air travel at airports in the United States. Costs due to delays are increasing every year and in 2019 amounted to 74.24 US dollars per minute [

40].

The maintenance process begins with problem identification, i.e., acknowledgement that a runway is an object liable to outer influences. The regular monitoring of the condition of the runway and maintenance on time is needed for the optimal provision of its function, among which is the safe taking off and landing of the aircrafts.

The monitoring, which was executed, is based as a sub-process in the maintenance process in which all measuring methods are included. Other actors, whose results are written in the central database and are forwarded into a model in which vertical deviations are calculated, can be included in this part of the process as well. The result of the innovative model is calculated vertical deviations and determined areas of these deviations, which are a combination of findings based on the visual runway check-up, results of the used geodetic method and results of the supplementary method. The emphasis was on the development of the sub-process models for the monitoring or the innovative model for the continuous monitoring of the deformations of the runways, which contains the production of the work processes model, containing the measuring data, measuring data processing, calculation of vertical deviations, determining the areas of vertical deviations and deformations and determining the damage of the runway.

The presented process model of maintenance and narrower process model of monitoring is developed in a way that is useful for smaller and less congested airports, and enables the inclusion of several types of measurement data. With this research we come to the conclusion that the geodetic method is suitable for inclusion in the monitoring model, and at the same time we find that by using only geodetic observations we can detect deformations or determine the areas of vertical deviations on the surface of the runways, as well as determine them as in [

34], but we do not need to determine the causes of their formation and predict their spread.

The biggest advantage of the innovative model, which is useable for all types of driving constructions, is mainly the fast data collection, which is very important at runways since the measurements can be done outside the running of the airport. We needed thirty minutes for one data collection for the executed research at the airport.

The findings of the authors and the findings of this research allow us to predict the spread of deformations and further the development of the model, which will include algorithms for predicting the formation and spread of deformations or areas of vertical deviations. The suggested maintenance model (APMS-MB), in which, as a subprocess, the suggested runway deformation and vertical deviation detection model (IMR ali IMR_all), is an autonomous process that includes the capture and processing of the captured data, the calculation of vertical deviations, preparation of the analyses, the evaluation of various alternatives and the decision-making of further activities in runway maintenance. The construction of the maintenance model and its integration with the airport management system is foreseen. It is necessary to research how the maintenance system (suggested model), to the greatest extent possible and in a reasonable manner, can be integrated with the airport maintenance system.

6. Conclusions

Monitoring the condition of the runway is critical for the safe taking off and landing of the aircrafts. For this purpose, the innovative model for monitoring the deformations on the runways for smaller and less frequent airports was created. The reason was, based on the research on the concerned airport, that smaller airports do not have an automatized system for monitoring of the runway. The late discovery of deformations can cause the closure of the runway or the airport and consequently to divert of transport to the nearby airport, which can cause big financial issues. This is why the methods, which provide qualitative and fast results and are usable in any weather or at any time, were researched.

The innovative model is thus based on geodetic measurements with modern methods and supplementary methods, with which the cause of the deformity is discovered. The innovative model is easy to use, and as a final result gives us the evaluation of the level of damage of the runway. The result of the innovative model is a display of areas of vertical deviations which are a combination of results from the used geodetic and supplementary methods.

The processes and sub-processes with which various geo-data were obtained and analyzed in the suggested decision-making maintenance model were described. The results of the model are key for decision-making about the maintenance execution at the airport, mainly the runways´ maintenance, taxiways and platforms. The inventory and description of the processes given in this paper gives a transparent view of the monitoring and maintenance process. The results of the model are very welcome in making decisions on the implementation of maintenance at the airport, especially the maintenance of runways.

The model is usable for other driving constructions as well, where the assessment of the condition is extremely necessary. The suggested process of assessing the damage of the runway is usable for all surfaces which are liable to deformations. The measurements can be executed in any weather and at any time. It is believed that the suggested process will enable the fast and reliable control of the conditions of construction, mainly of the runways.

The data obtained with the suggested model or suggested monitoring, graphically and with numbers, present the runway’s state to the decision-makers. We think that this data, especially their visual on-screen presentation or in interaction with the real world, are key in decision-making about the manner and extent of the execution of maintenance or regenerative works. In the analysis results, a question about the further monitoring and demanded cyclicality of the execution of individual measurements has also appeared. The monitoring data maintenance and the execution of the next measurements will be within the competence of the maintenance service, which will also be the main user of the data, and at the same time, these data will be the source of information necessary for the management in maintenance decision-making. We think that monitoring needs to be performed periodically, in which the measurements of the vertical deviations and deformity on the surface must be performed more often. When, with these measurements, the repeated larger vertical deviations and deformities are detected, and if they are detected on the new areas of the runway, it is necessary to also perform geomechanical and geophysical measurements which can also explain the causes for their creation.

Author Contributions

Conceptualization, B.K., D.D. and D.T.; methodology, B.K. and D.D.; software, D.D.; validation, B.K., D.D. and D.T.; formal analysis, B.K., D.D. and D.T.; investigation, B.K., D.D. and D.T.; resources, B.K., D.D. and D.T.; data curation, B.K., D.D. and D.T.; writing—original draft preparation, B.K., D.D. and D.T.; writing—review and editing, B.K.; visualization, D.D.; supervision, B.K. and D.T.; project administration, D.D.; funding acquisition, B.K., D.D. and D.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available. The data were obtained on the basis of own research within the doctoral dissertation of Damjan Doler at the Faculty of Logistics, University of Maribor.

Acknowledgments

The authors of the article thank the airport staff for allowing them to conduct the research.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Arbues, P.G.; Baños, J.F.; Mayor, M.; Suárez, P. Determinants of ground transport modal choice in long-distance trips in Spain. Transp. Res. Part A Policy Pract. 2016, 84, 131–143. [Google Scholar] [CrossRef] [Green Version]

- Román, C.; Martín, J.C. Integration of HSR and air transport: Understanding passengers’ preferences. Transp. Res. Part E Logist. Transp. Rev. 2014, 71, 129–141. [Google Scholar] [CrossRef]

- Larrodé, E.; Muerza, V.; Villagrasa, V. Analysis model to quantify potential factors in the growth of air cargo logistics in airports. Transp. Res. Procedia 2018, 33, 339–346. [Google Scholar] [CrossRef]

- Distefano, N.; Leonardi, S. Aircraft runway excursion features: A multiple correspondence analysis. Aircr. Eng. Aerosp. Technol. 2018, 91, 197–203. [Google Scholar] [CrossRef]

- Price, J.C.; Forrest, J.S. Practical Airport Operations, Safety, and Emergency Management: Protocols for Today and the Future, Butterworth-Heinemann; Elsevier: New York, NY, USA, 2016. [Google Scholar]

- De Souza, N.M.; Filho, A.T.D.A. A systematic airport runway maintenance and inspection policy based on a delay time modeling approach. Autom. Constr. 2020, 110, 103039. [Google Scholar] [CrossRef]

- Borille, G.M.R.; Correia, A.R. A method for evaluating the level of service arrival components at airports. J. Air Transp. Manag. 2013, 27, 5–10. [Google Scholar] [CrossRef]

- Chen, Y.-H.; Chou, C.-P. Effects of Airport Pavement-Profile Wavelength on Aircraft Vertical Responses. Transp. Res. Rec. J. Transp. Res. Board 2004, 1889, 83–93. [Google Scholar] [CrossRef]

- De Luca, M.; Dell’Acqua, G. Touchdown Remaining Lift on the Wings and Dynamic Vertical Force Transmitted to the Runway. Period. Polytech. Civ. Eng. 2018, 62, 590–595. [Google Scholar] [CrossRef] [Green Version]

- Biancardo, S.A.; Abbondati, F.; Russo, F.; Veropalumbo, R.; Dell’Acqua, G. A Broad-Based Decision-Making Procedure for Runway Friction Decay Analysis in Maintenance Operations. Sustainability 2020, 12, 3516. [Google Scholar] [CrossRef]

- Di Mascio, P.; Moretti, L. Implementation of a pavement management system for maintenance and rehabilitation of airport surfaces. Case Stud. Constr. Mater. 2019, 11, e00251. [Google Scholar] [CrossRef]

- Bazlamit, S.M.; Ahmad, H.S.; Obaidat, T.I.A.-S. Pavement Maintenance Applications Using Geographic Information Systems. Procedia Eng. 2017, 182, 83–90. [Google Scholar] [CrossRef]

- Gendreau, M.; Soriano, P. Airport pavement management systems: An appraisal of existing methodologies. Transp. Res. Part A Policy Pract. 1998, 32, 3. [Google Scholar] [CrossRef]

- Oliveira, H.; Correia, P.L. Automatic Road Crack Detection and Characterization. IEEE Trans. Intell. Transp. Syst. 2013, 14, 155–168. [Google Scholar] [CrossRef]

- Mokhtari, S.; Wu, L.; Yun, H.-B. Comparison of Supervised Classification Techniques for Vision-Based Pavement Crack Detection. Transp. Res. Rec. J. Transp. Res. Board 2016, 2595, 119–127. [Google Scholar] [CrossRef]

- Shi, Y.; Cui, L.; Qi, Z.; Meng, F.; Chen, Z. Automatic Road Crack Detection Using Random Structured Forests. IEEE Trans. Intell. Transp. Syst. 2016, 17, 3434–3445. [Google Scholar] [CrossRef]

- Wang, P.; Hu, Y.; Dai, Y.; Tian, M. Asphalt Pavement Pothole Detection and Segmentation Based on Wavelet Energy Field. Math. Probl. Eng. 2017, 2017, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Peng, L.; Chao, W.; Shuangmiao, L.; Baocai, F. Research on Crack Detection Method of Airport Runway Based on Twice-Threshold Segmentation. In Proceedings of the 2015 Fifth International Conference on Instrumentation and Measurement, Computer, Communication and Control (IMCCC), Qinhuangdao, China, 18–20 September 2015; pp. 1716–1720. [Google Scholar]

- Fernández, A.C.; Rodriguez-Lozano, F.J.; Villatoro, R.; Olivares, J.; Palomares, J.M. Efficient pavement crack detection and classification. EURASIP J. Image Video Process. 2017, 2017, 39. [Google Scholar] [CrossRef]

- Li, W.; Deng, R.; Zhang, Y.; Sun, Z.; Hao, X.; Huyan, J. Three-Dimensional Asphalt Pavement Crack Detection Based on Fruit Fly Optimisation Density Peak Clustering. Math. Probl. Eng. 2019, 2019, 1–15. [Google Scholar] [CrossRef]

- Jiaying, C.; Binshuang, Z.; Xi, C.; Runmin, Z.; Xiaoming, H. Acquisition method of asphalt pavement texture information based on the CPR Technology. MATEC Web Conf. 2019, 275, 04003. [Google Scholar] [CrossRef]

- Wang, W.; Wang, M.; Li, H.; Zhao, H.; Wang, K.; He, C.; Wang, J.; Zheng, S.; Chen, J. Pavement crack image acquisition methods and crack extraction algorithms: A review. J. Traffic Transp. Eng. 2019, 6, 535–556. [Google Scholar] [CrossRef]

- Moropoulou, A.; Avdelidis, N.P.; Koui, M.; Aggelopoulos, A.; Karmis, P. Infrared thermography and ground penetrating radar for airport pavements assessment. Nondestruct. Test. Eval. 2002, 18, 37–42. [Google Scholar] [CrossRef]

- Celaya, M. Evaluation of Nondestructive Technologies to Assess Presence and Extent of Delamination of Hot Mix Asphalt Air-Field Pavements. Ph.D. Thesis, The University of Texas at El Paso, El Paso, TX, USA, 2011. [Google Scholar]

- Dominguez-Santos, D.; Ballesteros-Perez, P.; Mora-Melia, D. Structural Resistance of Reinforced Concrete Buildings in Areas of Moderate Seismicity and Assessment of Strategies for Structural Improvement. Buildings 2017, 7, 89. [Google Scholar] [CrossRef] [Green Version]

- Slabej, M.; Grinč, M.; Kováč, M.; Decký, M.; Šedivý, Š. Non-invasive diagnostic methods for investigating the quality of Žilina airport’s runway. Contrib. Geophys. Geod. 2016, 45, 3. [Google Scholar] [CrossRef] [Green Version]

- Grinč, M. 3D GPR investigation of pavement using 1 GHz and 2 GHz horn type antenna—comparison of the results. Contrib. Geophys. Geod. 2015, 45, 25–39. [Google Scholar] [CrossRef] [Green Version]

- Kovačič, B.; Kamnik, R.; Bieliatynskyi, A. The Different Methods of Displacement Monitoring at Loading Tests of Bridges or Different Structures. MATEC Web Conf. 2016, 53, 1048. [Google Scholar] [CrossRef] [Green Version]

- Woźniak, M. Investigation of using total station with ATR system in monitoring of displacements. Rep. Geod. 2006, 1/76, 221–226. [Google Scholar]

- Kirschner, H.; Stempfhuber, W. The Kinematic Potential of Modern Tracking Total Stations: Stations. In Proceedings of the 1st International Conference on Machine Control and Guidance, Zürich, Switzerland, 24–26 June 2008. [Google Scholar] [CrossRef]

- Gamse, S. Uporaba Kalmanovega filtra pri Kinematičnih Geodetskih Meritvah. Ph.D. Thesis, University of Ljubljana, Ljubljana, Slovenia, 2010. [Google Scholar]

- Woźniak, A.P.M.; Odziemczyk, P.D.W. Investigation of Stability of Precise Geodetic Instruments Used in Deformation Monitoring. Rep. Geodesy Geoinform. 2017, 104, 79–90. [Google Scholar] [CrossRef] [Green Version]

- Shahin, M.Y. Pavement Management for Airports, Roads, and Parking Lots; Springer: New York, NY, USA, 2005. [Google Scholar]

- Doler, D.; Kovačič, B. Improved Decision-Making Geo-Information System for Continuous Monitoring of Deformations on Airport Infrastructure. ISPRS Int. J. Geo-Inf. 2018, 8, 1. [Google Scholar] [CrossRef] [Green Version]

- Kovačič, B.; Želodec, D.; Doler, D. Prototype of the Runway Monitoring Process at Smaller Airports: Edvard Rusjan Airport Maribor. Processes 2020, 8, 1689. [Google Scholar] [CrossRef]

- Kovačič, B.; Doler, D.; Sever, D. The Innovative Model of Runway Sustainable Management on Smaller Regional Airports. Sustainability 2021, 13, 652. [Google Scholar] [CrossRef]

- Kovačič, B.; Doler, D.; Sever, D. Innovative Business Model for the Management of Airports in Purpose to Identify Runway Damage in Time. Sustainability 2021, 13, 613. [Google Scholar] [CrossRef]

- Ong, G.P. (Raymond); Nantung, T.; Sinha, K. Indiana Pavement Preservation Program. Joint Transportation Research Program; Indiana Department of Transportation and Purdue University: West Lafayette, Indiana, 2010. [Google Scholar]

- Liang, Z.; Xiao, F.; Qian, X.; Zhou, L.; Jin, X.; Lu, X.; Karichery, S. A column generation-based heuristic for aircraft recovery problem with airport capacity constraints and maintenance flexibility. Transp. Res. Part B Methodol. 2018, 113, 70–90. [Google Scholar] [CrossRef]

- Airlines for America. U. S. Passenger Carrier Delay Costs. 2018. Available online: https://www.airlines.org/dataset/per-minute-cost-of-delays-to-u-s-airlines/ (accessed on 28 October 2020).

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).