Abstract

High-power ultrasound (HPU) is an innovative cleaning method used in wineries for oak barrel sanitation and regeneration. The process is associated with hot water (HPUhw) to ensure microbial stabilization and has been proved to be highly effective in recent years. This study thus examines the impact of different cleaning treatments on the subsequent extraction of wood compounds in wine and their impact on organoleptic properties. Red wines aging in barrels treated (HPUhw and steam) in different years (1, 2, and 3 years) were examined during the first 12 months for chemical exchange from wood to wine. Specific analyses were realized on ellagitannins, the physicochemical composition, and oak wood volatile compounds. Only a small increase in some wood volatile compounds occurred in the case of HPUhw, including furfural, 5-methylfurfural, trans-whisky lactone, vanillin, and syringaldehyde. The sensory analysis carried out by a panel of experts showed that the impact on the organoleptic properties of wines is similar with both processes (HPUhw and steam). However, since HPUhw treatment requires lower energy for the same efficiency, it could be an interesting alternative to steam treatment, given the promising prior microbial results.

1. Introduction

Oak wood releases several specific compounds into wine. Extraction of phenolic compounds from oak barrels depends on the quantity of extractable compounds; contact time; wine composition; and toasting, aging, and sanitation procedures. Conversely, when aging takes place in wooden barrels, bacteria and yeast can penetrate the wood to the same depth as the wine (close to 8 mm) [1]. Consequently, a frequent problem occurring in wines aged in barrels is the potential presence of ethylphenols and ethylguaiacol. Brettanomyces bruxellensis spoilage can lead to organoleptic deviations due to the production of several undesirable compounds, such as 4-Ethylphenol and 4-Ethylguaiacol [2], molecules that can deteriorate the wine quality [3]. Organoleptic deviations, known as ‘Brett flavors’, may appear, corresponding to ‘stable’, ‘leather’, ‘manure’, or ‘horse sweat’. To avoid such deviations, several treatments can be adopted in wineries. Many types of treatment are applied to sanitize barrels, such as the use of chemical agents (sulfur dioxide, ozone, sodium percarbonate, peracetic acid, and peroxide-based compounds) or physical agents (barrel rejuvenation, dry ice blasting, UV radiation, hot water, microwaves, and ultrasounds). These practices show varying levels of efficiency and may induce potential organoleptic modifications [4]. Steam treatments are still the most commonly used in wineries for two reasons: high efficiency and low impact on oak barrels. Solis (2018) found that steam was required for at least 10 min to achieve temperatures above 57.5 °C (the temperature required to kill Brettanomyces bruxellensis) [5] at a depth of 8 mm in a barrel.

Several studies have recently been published on the use of high-power ultrasound (HPU) on an industrial scale [6]. In this process, electrical energy is converted into ultrasound (20 kHz–10 MHz) at frequencies higher than those audible to the human ear (16–20 kHz). High-power ultrasound has intensities over 1 W/cm2 and frequencies between 20 and 100 kHz [7,8,9]. When emitted in a liquid, the process forms high-energy microbubbles (acoustic cavitation phenomenon) [10]. These cavitation bubbles generate very high temperatures locally (close to 5000 °C) and high pressure (above 50 MPa) [8]. The microcavitation bubbles (diameters around 1 μm) act homogeneously throughout the fluid (Pascal’s law) and can penetrate deep into the pores. Piyasena et al. (2003) identified a large number of pathogenic microorganisms inhibited by the cavitation phenomenon generated by HPU [11].

Porter et al. (2011) recently studied the effects of HPU treatment on porous materials and cleaning efficiency in American oak wine barrels using X-ray tomography. The authors demonstrated that industrial-scale high-power ultrasonic (4 kW/20 kHz) applications provide an efficient way to remove tartrate sediment from the surface of staves up to a depth of 2 mm, with a relatively short treatment time (12 min) and at quite low temperatures (40–60 °C) [12]. Oak wood consists of macromolecules, such as cellulose and hemicellulose, and extractive compounds, such as ellagitannins, lignin, and aromatic precursors. However, only a few studies have investigated the impact of these treatments on the release of oak wood non-volatile compounds. Breniaux et al. (2019) proved that the combined effect of HPU and heat treatment had a significant impact on wood sanitation, wood wettability, and its specific surface and oxygen transfer kinetics [13]. The authors showed that HPUhw treatment removed B. bruxellensis cells up to a depth of 9 mm, with processing parameters set at 60 °C/6 min at 3.8 kW. While the study characterized the oak wood ultrastructure, it did not take the impact of HPUhw on volatile and non-volatile compounds into consideration. Indeed, oak wood aging changes the wine composition as non-volatile and volatile compounds are extracted from the wood. The extraction phenomena depend on several factors, such as the wood’s geographic origin, the type of seasoning, toasting, and the length of contact between wine and wood [14,15,16]. During the aging process, the wine’s phenol composition is modified with the release of phenols like ellagitannins, increasing the wine’s astringency [17]. Finally, various volatile compounds are released from the wood during aging, such as cis and trans-whisky lactones (coconut notes); volatile phenols, such as guaiacol, 4-methylguaiacol and eugenol (spicy and smoky notes); aldehyde phenols like vanillin or acetovanillone (vanilla notes); or furfural derivatives (smoky and toasty notes) [18]. Nevertheless, according to a recent study [19], the mix of volatile compounds from wood at concentrations reflecting various toasting levels could have a masking effect on the fruity pool. Thus, the main challenge during barrel cleaning is not to leach the volatile and non-volatile compounds from the wood into the washing water. The final goal is thus to reuse them once or twice without microbial contamination while continuing to benefit from the wood.

Our study investigated the effect of HPU associated with hot water (HPUhw) and steam treatment for barrel cleaning and regeneration. Steam treatment was retained, as it is widely employed in wineries and has high microbial stabilization efficiency, while the HPUhw process can ensure complete microbial stabilization and avoid wine spoilage. The aim of the study was to examine whether aqueous steam or HPUhw has a significant effect on wine composition and perceptions of aroma according to the barrel’s age (1, 2, or 3 years). Taking these processes into consideration, we investigated (i) the extraction of oak volatile compounds, (ii) non-volatile compounds after one year of wine aging, and (iii) the impact on wine organoleptic properties by sensory analysis (olfactory and gustatory).

2. Materials and Methods

2.1. Experimental Setup

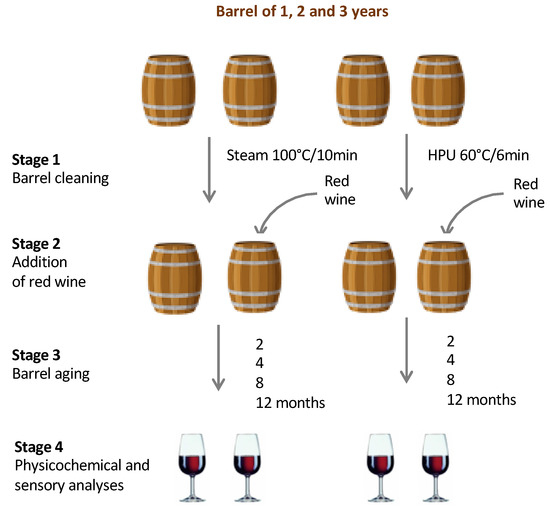

The French oak barrels used were 1, 2, or 3 years old, and the experimental setup was divided into 4 stages (Figure 1). For each modality, two barrels were first cleaned and regenerated by steam treatment (Barriclean®, Brive la Gaillarde, France) or by HPUhw as described in Section 2.2. Red wine was then introduced from two estates: Estate A and Estate B. Wine from Estate A was put in the 1- and 3-year-old barrels and wine from Estate B in the 2-year-old barrels. The wines were aged in the barrels for 2, 4, 8, and 12 months, and several physicochemical and sensory analyses were realized in the final stages and during the aging process. No filtration or fining agents were used in these cases.

Figure 1.

Experimental design of the study.

2.2. Barrel Treatment: High-Power Ultrasound (HPU) and Aqueous Steam Treatment

The HPUhw treatment process consisted of filling the barrel with water (heated to 60 °C by an autonomous system) and then introducing the sonotrode before the treatment modality was applied (partially allowing the ultrasound to be emitted) via the bung hole (Figure 2), thereby causing pressurization (0.3 bars). The treatment was applied for 6 min (frequency 20 kHz, 3.8 kW). The operating parameters had been optimized in earlier research [13].

Figure 2.

HPU apparatus.

The treatment by aqueous steam was carried out using an autonomous boiler (Barriclean®, 18 kW), which supplied pressurized hot water inside the barrel for 10 min (1 bar, 100 °C). Steam modalities were only used to compare the results with HPUhw treatment (a reference modality that can ensure complete microbiological stabilization). Total energy consumption was 0.38 kWh for HPU and 3 kWh for aqueous steam, which is 7.89 times lower.

2.3. Physicochemical Parameters

The anthocyanin, tannin, colour intensity (CI), modified colour intensity (MCI), and total polyphenol index (TPI) values were determined by spectrophotometry methods using a Lambda 25 UV/Vis Spectrophotometer (Perkin Elmer, Waltham, MA, USA). TPI was measured at 280 nm after wine dilution (1/100), CI is the sum of optical density at 420 and 520 nm, and MCI is the sum of optical density at 420, 520, and 620 nm. The other physicochemical parameters of wines, such as pH, ethanol content (% vol.), and total and volatile acidity, were determined by Fourier transform infrared spectroscopy using an OenoFoss™ (Foss electric, Hilleroed, Denmark) that was previously calibrated with wine samples in accordance with OIV methods. Free SO2 was measured with a Y15 enzymatic auto analyzer (Biosystems, S.A., Barcelona, Spain). The Y15 equipment was calibrated using the external standards provided in every kit by Biosystems. Free SO2 was performed using the appropriate kits from Biosystems S.A. (Barcelona, Spain).

2.4. Search for Brettanomyces in Wine

Serial dilutions of wine samples were plated on solid YPG (yeast extract 10 g/L; bacto-peptone 10 g/L; glucose 20 g/L; agar 20 g/L; adjusted to pH 5), supplemented with antibiotics to limit the growth of bacteria, molds, and yeast of the Saccharomyces genus (0.1 g/L chloramphenicol; 0.15 g/L biphenyl; 0.5 g/L cycloheximide). Brettanomyces yeast colonies were counted after 7 days of incubation at 30 °C. All of the assays were performed in triplicate.

2.5. Determination of Volatile Wood Compounds

A quantitative determination of the volatile compounds extracted from oak wood was based on an adaptation of the method developed by Barbe and Bertrand (1962) [20]. We spiked 50 mL wines with a solution of dodecan-1-ol (200 µL) as an internal standard. Then, 3 liquid/liquid extractions were performed using 4, 2, and 2 mL of dichloromethane. The organic fractions were dried using sodium sulfate anhydrous and then concentrated to 250 µL under a nitrogen flush. All of the samples were analyzed in duplicate.

An Agilent HP 7890 GC (Les Ulis, France) was coupled with a mass spectrometer (HP 5975, electronic impact 70 eV, eMV = 2 kV). The quantitative determination was made in SIM mode, selecting ions of m/z = 99 for trans-3-methyloctano-4-lactone and cis-3-methyloctano-4-lactone (oak lactone), m/z = 96 for furfural, m/z = 110 for 5-methylfurfural, m/z = 109 for guaiacol, m/z =164 for eugenol and isoeugenol, m/z = 154 for syringol, m/z = 194 for allylsyringol, m/z =152 for vanillin, m/z = 166 for acetovanillone, m/z = 182 for syringaldehyde, m/z =196 for acetosyringol, and m/z = 83 for the internal standard (dodecan-1-ol). The column was BP21 (SGE) (50 m, 0.32 mm, 0.25 mm); the carrier gas was helium 5.5 (Linde, France, pressure: 70 kPa); temperatures were injector, 250 °C; detector, 280 °C; oven, 60 °C for 1 min programmed at 3 °C/min to 220 °C. The final step lasted 40 min; the split-less time was 30 s with a split flow of 30 mL/min.

2.6. Determination of Ellagitannins

Determination of total ellagitannins was realized as previously noted [21]. Each sample was analyzed in triplicate, and each reaction mixture was subjected to HPLC-UV using a Lichrospher100 RP 18 column, 250 × 4.6 mm, 5 μm. The apparatus used for the HPLC analysis was composed of a Finnigan Surveyor UV–Vis detector (UV–Vis 200), a Finnigan autosampler, and a Finnigan ternary pump. The mobile phases employed were solvent A (water/formic acid (99.9/0.1)) and solvent B (methanol/formic acid (99.9/0.1)), and the gradient elution was 0–35% of B in 5 min, 35–4% of B in 25 min, and 45–100% of B in 5 min. The flow rate was established at 1 mL/min, with detection set at 370 and 280 nm.

2.7. Sensory Analysis

The impact of both processes on the olfactory and gustatory level was evaluated with a trained panel by sensory analysis. The samples were evaluated in individual booths in an appropriate sensory analysis room [22] with controlled temperature, lighting, and humidity, using black glasses [23] containing 50 mL of liquid, coded with random three-digit numbers, and with repetitions of tasting combinations. Before the tastings, the wine bottles were taken out of the room at 10 °C and left to rest to reach optimal room temperature. The sensory panels consisted of at least 24 trained individuals. All the panelists were research laboratory staff at ISVV, University of Bordeaux, selected for their experience. Descriptive sensory analyses were conducted of the red wine aged for 12 months in barrels of 1, 2, and 3 years treated with HPU or steam, employing scale descriptors graduating from 0 (low intensity) to 7 (high intensity). The intensity level of each descriptor was then expressed as the mean value of all the panelists.

2.8. Statistical Analysis

The statistical significance of the differences was determined via the Student test (p = 0.05). The XLSTAT program was used for data processing.

The results of all the triangular tests were statistically analyzed according to tables derived from the literature based on the binomial law corresponding to the distribution of answers in the test [24].

3. Results

3.1. Oenological Parameters

We analyzed two different wines aged in barrels of 1, 2, and 3 years treated with steam or HPU to evaluate the potential changes in the physicochemical and microbial properties of these wines before and after 12 months.

Comparisons of the impact of HPUhw/steam and aging realized before and after treatment for both processes showed no evident changes in terms of colour, free SO2, pH, total acidity, volatile acidity, or micro-organism content (Table 1). However, a significant increase in TPI was observed after one year of aging for both treatments and all modalities (1-, 2- and 3-year-old barrels for both estates). The increase in TPI before aging in oak barrels and after one year was the same in the case of steam and HPUhw treatments. The release of phenolic compounds was very similar for HPUhw and steam treatment in both cases (Estate A and Estate B). In addition, there were no significant differences in terms of classical chromatic characteristics (MCI and CI) between either modality during aging. Titratable acidity, volatile acidity, pH, and ethanol content did not change significantly following the two treatments. These results were expected, as neither barrel aging process affects such components in wine. However, oak volatile extraction is affected by pH and ethanol, and it was essential to measure these parameters. No significant differences were found, and the extraction of phenolic oak wood compounds appeared similar and led to no differences in terms of color. The results thus confirmed that the wine was homogenous upon filling, and that differences in wine composition should not have had a significant effect on the extraction of oak-related compounds in the different experiments. Finally, we noted no Brettanomyces contamination before or after aging in either modality.

Table 1.

Physicochemical and microbial properties of wines detected before and after 12 months of aging.

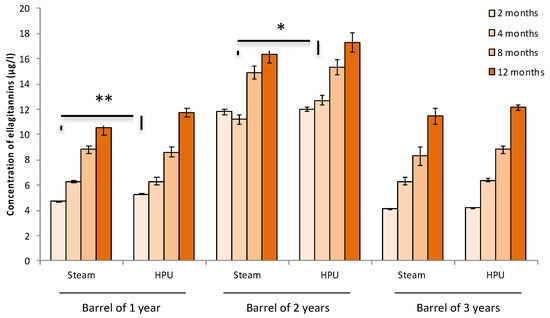

3.2. Oak Wood Non-Volatile Compounds: Ellagitanins

The increase in ellagitannin content during the wine aging process in oak barrels can be very interesting with regard to improving wine quality. In this study, HPUhw was used to step up the mass transfer of phenolics and was then compared to steam treatment. The comparison is interesting given the positive effect of temperature on the release of phenolics. This is in accordance with thermodynamic law, since the rising temperature can increase the diffusivity and solubility coefficient [25]. Heat is also employed for HPUhw, but the temperature is lower (60 °C), and time treatment is shorter (6 min). Here, a comparative study was realized by examining total ellagitannin content to evaluate if the acoustic cavitation phenomenon could have an influence on extraction of oak wood compounds. Our results show that the total of ellagitannins released for HPUhw was comparable to that obtained with steam treatment (Figure 3), apart from a significant improvement for HPUhw treatment in a barrel of 1 year after 2 months of aging and in a barrel of 2 years after 4 months of aging. Otherwise, while there is a tendency towards higher extraction in the case of HPUhw, the statistical analysis did not reveal a significant difference. Furthermore, with regard to the mechanism of mass transfer of phenolics in wine following ultrasonic field and steam treatment, the release of total phenolics was very similar. We can assume that alcohol contact time is mainly responsible for ellagitannin desorption in both cases. Thus, the accessibility and diffusivity of phenolic compounds remain the same in these treatments after 12 months of aging.

Figure 3.

Total ellagitannins concentration of red wine aging for 2, 4, and 8 months in barrels of 1, 2, or 3 years cleaned with HPUhw or steam. (*) significant at p < 0.05; (**) significant at p < 0.01.

These findings are in line with previous studies, confirming that the treatment induced no surface modification [13]. Furthermore, we can note that in the case of 2-year barrels, similar results were obtained in terms of TPI, CI, and MCI for HPU and steam treatment for Estate B.

3.3. Oak Wood Volatile Compounds

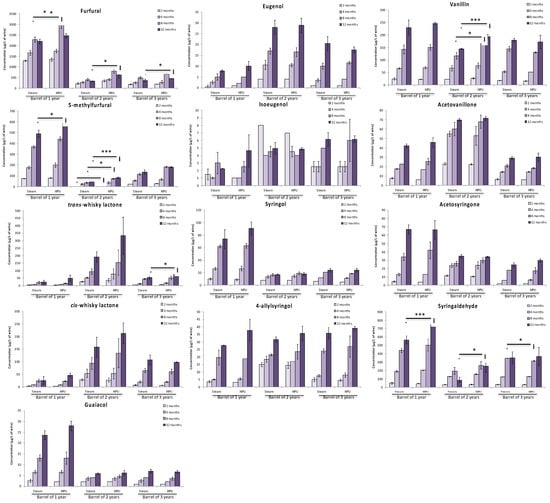

Oak barrels contain a high concentration of volatile compounds that positively impact a wine’s aroma. The main volatile compounds susceptible to desorb from oak wood to wine are the cis and trans-whisky lactones; volatile phenols, such as eugenol, guaiacol, furfural, and its derived compounds; and phenolic aldehydes, such as vanillin and syringaldehyde.

In our case, the results show that there are some significant differences between the volatiles from the oak wood composition of wines aged in barrels treated with HPUhw compared to those treated with steam (Figure 4). Indeed, the concentration of furfural was higher in the case of HPUhw treatment at 8 months of aging (barrels of 1 year) and 12 months of aging (barrels of 2 and 3 years), with the concentration increasing between 18.8 and 92.6% compared to steam. For the 5-methylfurfural, the concentration was significantly higher for HPUhw treatment for barrels of 1 year (12 months of aging) and 2 years (2, 8, and 12 months of aging) with an increase between 20.5 and 97%. Regarding the whisky lactone diastereoisomers, the trans-whisky lactone was significantly higher for barrels of 3 years treated with HPUhw after 12 months of aging with a concentration at 75.2 ± 5.6 μg/L, resulting in an increase of 46.9% compared to steam. This appears to also be a trend for barrels of 1 and 2 years. On the other hand, for cis-whisky lactone, there was no significant difference between steam and HPUhw treatments.

Figure 4.

Oak wood volatile composition of red wines aging for 2, 4, 8, and 12 months in barrels of 1, 2, or 3 years cleaned with HPUhw or steam. (*) significant at p < 0.05; (**) significant at p < 0.01; (***) significant at p < 0.001.

For syringaldehyde, the concentration was significantly higher for barrels of 1 and 2 years (12 months of aging) treated with HPUhw, with an increase of between 32.9 and 194.9% compared to steam. For barrels of 3 years (8 months of aging), we noticed a slight decrease in synringaldehyde concentration in the case of HPUhw treatment (8.7%) compared to steam. Finally, the concentration of vanillin was higher for barrels of 2 years treated with HPUhw after 8 and 12 months of aging, with an increase of 42.2 and 34%, respectively. There were no significant differences for eugenol, syringol, iso eugenol, 4-Allylsyringol, acetovanillone, acetosyringone, and guaiacol compounds.

Nevertheless, we noted that for all significant differences in volatile compounds, the concentrations were below the detection thresholds reported in Table 2. However, despite their high detection thresholds, they can contribute to the ‘toasty’ notes of wines and also increase the overall intensity of the woody character [18]. Moreover, Cameleyre et al. (2019) recently described the indirect impact of some volatile oak compounds at infra-threshold levels on the perception of panels [19]. Omission tests revealed the important role of vanillin and coniferaldehyde as, when omitted alone or with other compounds from the same family, their absence was significantly perceived, even under the detection threshold. The results are compelling since these compounds are widely sought by winemakers and can improve the organoleptic properties of wine. Increasing the extraction of these positive compounds by HPUhw treatment is very interesting and may be explained by the preservation of the wood structure following treatment [13].

Table 2.

Volatile compounds present in oak wood and their detection threshold [19,26,27,28,29].

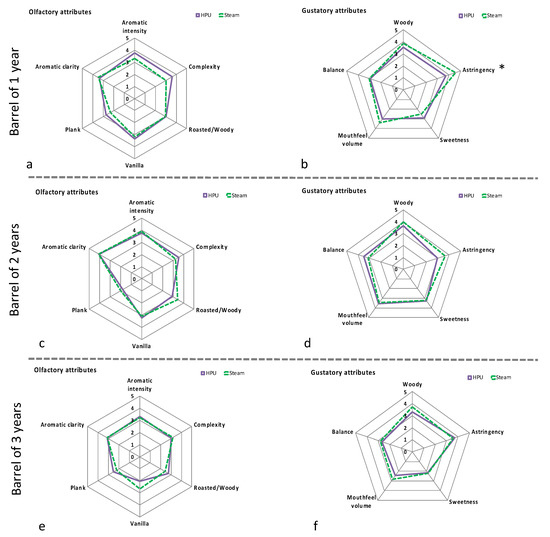

3.4. Sensory Evaluation of Wines

Spider web diagrams obtained from average values of olfactory and gustative descriptors from a sensory analysis of wines after 12 months of aging for each modality are presented in Figure 5. All of the treated wines were characterized, with no significant difference (p < 0.05) found for any of the olfactory descriptors (aromatic clarity and intensity, complexity, roasted/woody, vanilla and plank). The olfactory profile of all the wines was very similar. The focus on the roasted/woody descriptor revealed no significant difference, even though some volatile compounds from wood were extracted to a greater degree in the case of HPUhw treatment. Increased extraction of furfural and 5-methylfurfural as well as syringaldehyde by HPUhw was not detected by the panel, as they were below the detection threshold (Table 2). We noted the same trend in the case of the vanilla descriptor, despite finding a significant increase in vanillin for barrels of 2 years. The concentration differences of volatile compounds from wood between HPUhw and steam were insufficient to be detected by the panel.

Figure 5.

Sensory evaluation (olfactory and gustatory) of red wine aging for 12 months in barrels of 1 (a,b), 2 (c,d), or 3 years old (e,f) cleaned with HPUhw or steam. (*) significant at p < 0.05.

In addition, for gustatory attributes, we only noted a significant increase (p < 0.05) in astringency for barrels of one year treated with steam. The other attributes were not impacted.

Thus, it appears that the HPUhw and steam treatments have a similar impact on the organoleptic properties of wine.

4. Conclusions and Perspectives

The study investigated the impact of using high-power ultrasounds associated with hot water or steam treatment on barrels containing a red wine aging in a barrel of different years with respect to (i) the chemical composition of the wine, (ii) the extraction of volatile compounds from oak, and (iii) ellagitannins over the course of one year, evaluated by sensory analysis (olfactory and gustatory).

In winemaking, the traditional steam treatment is widely acknowledged to provide complete sanitation, even though removing tartrate deposits is not complete at the porous surface. Application of HPU with hot water (60 °C) ensures complete removal of tartrate deposits and can also remove microorganisms in the depths of the wood. In this study on whole oak barrels, specific analyses proved that these treatments do not change the accessibility or diffusivity of phenolic compounds.

Few effects were observed on oak volatile compounds extraction in wine stored in HPUhw-treated barrels. The concentration of furfural/5-methylfurfural, trans-whisky lactone, syringaldehyde, and vanillin could be extracted to a greater degree in the case of HPUhw treatment for barrels of 2 and 3 years. In the case of a younger barrel (one year), syringaldehyde could also be extracted to a greater degree as well as furfural and 5-methylfurfural. However, differences between the steam and the HPUhw wines were not significant in the sensorial analyses and could be explained by the high detection threshold of volatile compounds from wood. Further investigation on various wines, especially white wines, is required to complete these initial findings.

Author Contributions

P.R. and R.G. conceived the experimental design; P.R. realized HPUhw and steam treatment and conducted all of the analyses; P.R. and R.G. supervised the experiments; P.R. and M.B. treated the results; M.B. wrote the paper: R.G. and P.R. reviewed the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Region Aquitaine, France.

Acknowledgments

The authors would like to thank Hancock Hutton Langues Services for the English corrections. We would like to thank Dyogena for the financial support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Malfeito-Ferreira, M.; Laureano, P.; Barata, A.; D’Antuono, I.; Stender, H.; Loureiro, V. Effect of Different Barrique Sanitation Procedures on Yeasts Isolated from the Inner Layers of Wood. Am. J. Enol. Vitic. 2004, 55, 304A. [Google Scholar]

- Chatonnet, P.; Dubourdie, D.; Boidron, J.; Pons, M. The Origin of Ethylphenols in Wines. J. Sci. Food Agric. 1992, 60, 165–178. [Google Scholar] [CrossRef]

- Coulon, J.; Perello, M.C.; Lonvaud-Funel, A.; Revel, G.D.; Renouf, V. Brettanomyces Bruxellensis Evolution and Volatile Phenols Production in Red Wines during Storage in Bottles. J. Appl. Microbiol. 2010, 108, 1450–1458. [Google Scholar] [CrossRef] [PubMed]

- Stadler, E.; Fischer, U. Sanitization of Oak Barrels for Wine—A Review. J. Agric. Food Chem. 2020, 68, 5283–5295. [Google Scholar] [CrossRef] [PubMed]

- Solis, A. Thermal Inactivation of Wine Spoilage Yeasts to Validate Steam Sanitation Protocols in Wineries. Food Safety Mag. 2018, 60, 70. [Google Scholar]

- Patist, A.; Bates, D. Ultrasonic Innovations in the Food Industry: From the Laboratory to Commercial Production. Innov. Food Sci. Emerg. 2008, 9, 147–154. [Google Scholar] [CrossRef]

- McClements, D.J. Advances in the Application of Ultrasound in Food Analysis and Processing. Trends Food Sci. Technol. 1995, 6, 293–299. [Google Scholar] [CrossRef]

- Leighton, T.G. What Is Ultrasound? Prog. Biophys. Mol. Biol. 2007, 93, 3–83. [Google Scholar] [CrossRef]

- Villamiel, M.; de Jong, P. Influence of High-Intensity Ultrasound and Heat Treatment in Continuous Flow on Fat, Proteins, and Native Enzymes of Milk. J. Agric. Food Chem. 2000, 48, 472–478. [Google Scholar] [CrossRef]

- Maisonhaute, E.; Prado, C.; White, P.C.; Compton, R.G. Surface Acoustic Cavitation Understood via Nanosecond Electrochemistry. Part III: Shear Stress in Ultrasonic Cleaning. Ultrason Sonochem. 2002, 9, 297–303. [Google Scholar] [CrossRef]

- Piyasena, P.; Mohareb, E.; McKellar, R.C. Inactivation of Microbes Using Ultrasound: A Review. Int. J. Food Microbiol. 2003, 87, 207–216. [Google Scholar] [CrossRef]

- Porter, G.W.; Lewis, A.; Barnes, M.; Williams, R. Evaluation of High Power Ultrasound Porous Cleaning Efficacy in American Oak Wine Barrels Using X-Ray Tomography. Innov. Food Sci. Emerg. 2011, 12, 509–514. [Google Scholar] [CrossRef]

- Breniaux, M.; Renault, P.; Meunier, F.; Ghidossi, R. Study of High Power Ultrasound for Oak Wood Barrel Regeneration: Impact on Wood Properties and Sanitation Effect. Beverages 2019, 5, 10. [Google Scholar] [CrossRef]

- Cadahía, E.; de Simón, B.F.; Jalocha, J. Volatile Compounds in Spanish, French, and American Oak Woods after Natural Seasoning and Toasting. J. Agric. Food Chem. 2003, 51, 5923–5932. [Google Scholar] [CrossRef] [PubMed]

- Spillman, P.J.; Sefton, M.A.; Gawel, R. The Contribution of Volatile Compounds Derived during Oak Barrel Maturation to the Aroma of a Chardonnay and Cabernet Sauvignon Wine. Aust. J. Grape Wine Res. 2004, 10, 227–235. [Google Scholar] [CrossRef]

- Arfelli, G.; Sartini, E.; Corzani, C.; Fabiani, A.; Natali, N. Impact of Wooden Barrel Storage on the Volatile Composition and Sensorial Profile of Red Wine. Food Sci. Technol. Int. 2007, 13, 293–299. [Google Scholar] [CrossRef]

- Ferrer-Gallego, R.; Brás, N.F.; García-Estévez, I.; Mateus, N.; Rivas-Gonzalo, J.C.; de Freitas, V.; Escribano-Bailón, M.T. Effect of Flavonols on Wine Astringency and Their Interaction with Human Saliva. Food Chem. 2016, 209, 358–364. [Google Scholar] [CrossRef] [PubMed]

- Andrei, P.; Pascal, C. Impact of Oak-Derived Compounds on the Olfactory Perception of Barrel-Aged Wines. Am. J. Enol. Vitic. 2010, 61, 408–413. [Google Scholar]

- Cameleyre, M.; Lytra, G.; Schütte, L.; Vicard, J.-C.; Barbe, J.-C. Oak Wood Volatiles Impact on Red Wine Fruity Aroma Perception in Various Matrices. J. Agric. Food Chem. 2020, 68, 13319–13330. [Google Scholar] [CrossRef]

- Barbe, J.C.; Bertrand, A. Quantitative Analysis of Volatile Compounds Stemming from Oak Wood. Applications to the Aging of Wines in Barrels. J. Des Sci. Et Tech. De La Tonnelerie De Fr. 1996, 2, 83–88. [Google Scholar]

- Chira, K.; Teissedre, P.-L. Chemical and Sensory Evaluation of Wine Matured in Oak Barrel: Effect of Oak Species Involved and Toasting Process. Eur. Food Res. Technol. 2015, 240, 533–547. [Google Scholar] [CrossRef]

- Association Française de Normalisation (AFNOR). Sensory Analysis–General Guidance for the Design of Test Rooms–ISO 8589; AFNOR: Paris, France, 1988. [Google Scholar]

- Association Française de Normalisation (AFNOR). Sensory Analysis–Apparatus–Wine-Tasting Glass–ISO 3591; AFNOR: Paris, France, 1997. [Google Scholar]

- Association Française de Normalisation (AFNOR). Sensory Analysis–Methodology–Triangle Test–ISO 4120; AFNOR: Paris, France, 2007. [Google Scholar]

- Tao, Y.; García, J.F.; Sun, D.-W. Advances in Wine Aging Technologies for Enhancing Wine Quality and Accelerating Wine Aging Process. Crit. Rev. Food Sci. 2013, 54, 817–835. [Google Scholar] [CrossRef] [PubMed]

- Slaghenaufi, D. Contribution à la Caractérisation des Précurseurs D’arôme Glycosylés du Bois de Chêne. Ph.D. Thesis, Université de Bordeaux, Bordeaux, France, 2012. [Google Scholar]

- Boidron, J.-N.; Chatonnet, P.; Pons, M. Influence Du Bois Sur Certaines Substances Odorantes Des Vins. OENO ONE 1988, 22, 275–294. [Google Scholar] [CrossRef]

- Chatonnet, P. Influence des Procédés de Tonnellerie et des Conditions D’élevage sur la Composition et la Qualité des Vins Élevés en Fûts de Chêne. Ph.D. Thesis, Université de Bordeaux, Bordeaux, France, 1995. [Google Scholar]

- Cameleyre, M.; Madrelle, V.; Lytra, G.; Barbe, J.-C. Impact of Whisky Lactone Diastereoisomers on Red Wine Fruity Aromatic Expression in Model Solution. J. Agric. Food Chem. 2020, 68, 10808–10814. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).