Abstract

Studies have reported the impact of frying on the nutritional and sensory properties of mackerel. However, no study has reviewed this topic. This study reviewed the effects of different frying processes on the nutritional and sensory characteristics of mackerel, with and without batter, marinade, and spice. MEDLINE, Web of Science, PubMed, and ScienceDirect were used as online databases to find relevant articles. We found that the nutritional, physicochemical, and sensory properties of fried mackerel without treatment were influenced by frying methods. Deep frying affected the oxidation of lipids and degradation of proteins, while air frying increased the overall acceptance score. Frying can reduce perfluorinated compounds (PFCs), eliminate some toxins, lower the trypsin inhibitor (TI), and increase the sensory parameters of mackerel with batter, marinade, and spice treatment. The different ingredients of minced mackerel products preserved their nutritional and sensory parameters after frying. Interestingly, vacuum frying resulted in lower oxidation and maintenance of nutritional and sensory parameters of fried mackerel (with or without treatment) and minced mackerel products. Further research is needed to reveal the effectiveness of vacuum frying in maintaining the nutritional and sensory properties of fried and minced mackerel products.

1. Introduction

Mackerel is a pelagic fish, belonging to the family Scombridae, which lives in the open ocean, including the Pacific, Indian, and Atlantic Oceans. According to Froese et al. [1], mackerel has a streamlined body, a silvery white belly, and a darker back, which is usually black mottled. The large eyes, long heads, and teeth in a large mouth are the main morphological characteristics of these fish. They also have two triangular fins on the dorsal side and some stabilizing fins along the caudal peduncle.

Mackerel is widely consumed worldwide because of its high nutritional value to humans, as it contains lipids, minerals, and proteins [2,3]. It also contains eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA), which can decrease the risk of prostate cancer and Alzheimer’s disease [4]. Mackerel can be processed by frying, with and without batter. Fried mackerel is simple to cook, highly nutritious, and has a high market demand.

Frying is the simplest and fastest method of processing mackerel. As one of the oldest methods of food preparation, it offers advantages such as ease, speed, and affordability. Fried products are reported to have good nutritional content, unique flavor, taste, and good sensory characteristics [5]. Frying is also known as an efficient cooking method because of the high temperature at normal atmospheric pressure and quick heat transfer that occurs during the process. These conditions result in the thermal destruction of microorganisms and enzymes and the reduction of water on the food surface.

Currently, three methods can be used to fry mackerel: deep, vacuum, and air frying. Deep frying is a simple and common method. Food is immersed in oil that has been heated to a temperature sufficiently high to brown the food’s surface, partially or completely cooking it. This frying process ensures that the food is tender and juicy inside and crisp on the outside.

Meanwhile, vacuum frying involves atmospheric pressure (<50 Torr). Under these conditions, the reduced moisture of fried products is obtained without excessive darkening or scorching [6]. This method has been used in several industries to fry and produce high-quality fried products. Vacuum frying maintains the nutrition of fried products with low oxidation [7,8,9,10]. Air frying is a method that circulates and utilizes hot air to fry food. Under these conditions, oil absorption in food can be minimized [11]; thus, it is claimed to be a healthier frying method. The fried products will have low calories, fat, and good color.

These frying methods can be used to produce high-quality mackerel products. Nonetheless, during the frying process, some reactions that affect nutritional quality may occur [12,13]. Lipid, fat, and minerals in fish can be affected. Moreover, some water-soluble proteins can be lost during the process.

Several studies have been conducted on the effects of deep [9,14,15,16,17,18,19,20,21,22,23], vacuum [9], and air frying [9] on mackerel, with and without batter [24,25]. Furthermore, studies on the effect of frying on minced mackerel products have also been conducted by Tolasa et al. [26], Albertos et al. [10], Chen et al. [27], and Lee et al. [28]. However, there are no review papers on this topic. Therefore, this article reviews studies conducted on the effects of different frying processes on mackerel (with and without batter) and minced mackerel products.

This study focuses on reviewing the current scientific literature on the effects of frying methods. Thus, the changes in the composition that occur during the frying process are discussed. Special emphasis has been placed on the nutritional and sensory characteristics of fried mackerel and minced mackerel products, as influenced by the different frying processes.

2. Materials and Methods

Existing literature was searched following systematic reviews and meta-analyses (PRISMA) guidelines in online databases (MEDLINE, Web of Science, PubMed, and ScienceDirect) [29]. “Mackerel,” “Frying,” “Nutritional,” “Sensory,” “Batter,” “Spice,” and “Marinate” were used as the keywords. The words “English language,” “nutritional,” and “sensory” were applied as filters.

3. Results

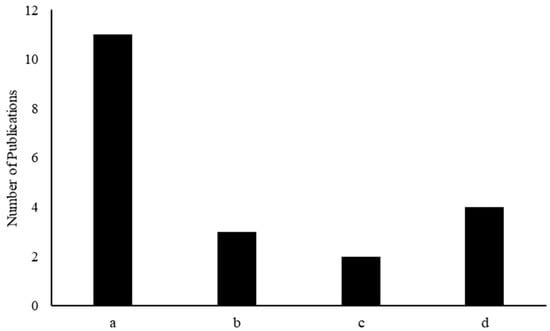

A total of 61 articles were found based on the keywords “Mackerel,” “Frying,” and “Nutritional.” After filtering the articles with several criteria, including “English language,” “nutritional,” and “sensory,” 20 articles were found to have examined the effect of frying on the nutritional and sensory characteristics of minced mackerel. Of the 20 articles, 11 discussed mackerel without battering, marinating, and spicing treatments; 4 discussed minced mackerel products; 3 discussed mackerel with marinade and spice; and 2 discussed mackerel with batter (Figure 1).

Figure 1.

The number of publications related to the effects of frying processes on the nutritional and sensory characteristics of mackerel (a), mackerel with marinade and spice (b), mackerel with batter (c), and minced mackerel products (d).

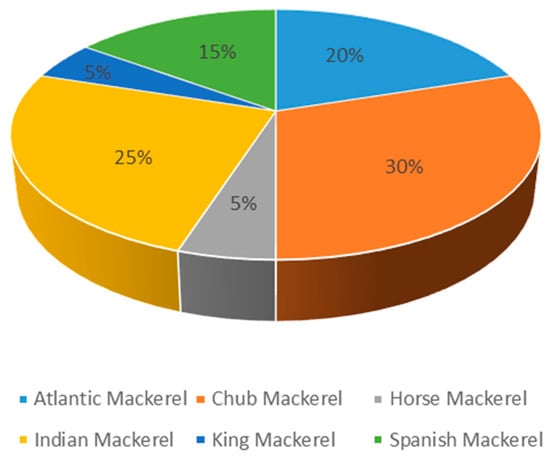

Six mackerel species are commonly used in this field of study. Among them, chub mackerel is the most commonly used (30%), followed by Indian mackerel (25%), Atlantic mackerel (20%), Spanish mackerel (15%), horse mackerel (5%), and king mackerel (5%) (Figure 2). The effects of different frying processes on the nutritional and sensory characteristics of mackerel and minced mackerel products are discussed below.

Figure 2.

Percentage of mackerel species used in the related studies.

4. Discussion

4.1. Fried Mackerel without Batter, Marinade, and Spice

Fried mackerel is a popular dish worldwide. Fried mackerel have been reported to contain high levels of omega-3 fatty acids, such as eicosapentaenoic (EPA) and docosahexaenoic (DHA) acid, as well as omega-6 fatty acids such as linoleic acid (LA). Amino acids have also been found in fried mackerel, such as glutamic acid, aspartic acid, lysine, leucine, and arginine [9,16,25]. They are cooked by frying under ideal conditions. Several studies have been conducted to determine the effects of frying methods on Atlantic [14,15], chub [9,16,17], Indian [18,19,20,21,22], and Spanish mackerel [23]. The frying process is known to have some effects on several aspects, including nutritional, physicochemical, and sensory properties. The effects of the frying process of mackerel are summarized in Table 1 and described specifically bellow.

Table 1.

Optimum conditions for frying mackerel without batter, marinade, and spice.

4.1.1. Effect of Frying on Fatty Acid Profile of Fried Mackerel without Batter, Marinade, and Spice

The frying process of mackerel affects its fatty acid profile. During the frying process, several factors are known to affect the fatty acid profile of mackerel, including the oxidative decomposition of unsaturated fatty acids, the migration of fatty acid compounds into the medium during the frying process, and the absorption of linoleic acid from oil. Moreover, the use of different oils as frying media is known to have some effects on the fatty acid profile [14,15,18,20,22].

Oxidative decomposition of unsaturated fatty acids of mackerel is influenced by high temperature during the frying process. At high temperatures, free radicals attack the double bonds of PUFAs. After heating, the amount of PUFA decreases significantly, most likely due to oxidative reactions. PUFAs are easily oxidized and incorporated into the chain mechanism of lipid peroxidation, and their levels tend to decrease as the temperature rises [30,31]. Furthermore, water loss during frying increases the lipid content in fried products. These conditions also affect the changes in fatty acids of Indian mackerel, especially EPA and DHA, after frying [20].

Moreover, the migration of fatty acid compounds into the medium during the frying process might cause decreased fatty acid content in Atlantic mackerel [14]. PUFA levels are also significantly affected by frying time, with longer exposure times producing a significantly higher reduction than shorter times. Further, the absorption of linoleic acid from oil affects the leaching of lipids into the frying medium, resulting in a reduction of essential fatty acids in Atlantic mackerel of 88% [15].

Oil absorption during the frying process occurs as a consequence of the loss of moisture. The size, shape, and surface of products influence oil absorption. The thinner the product, the more oil is absorbed. Moreover, the pretreatment before frying also affects the oil absorption. Pre-drying decreases oil uptake in fried products [32]. Moreover, Zhang et al. [33] found that oil absorption and the production of acrylamide as a result of the Maillard reaction are the primary changes in the nutrition of fried products caused by frying.

Furthermore, the use of different oils has been reported to decrease different fatty acids contained in fried Indian mackerel [18]. Similarly, Franscico et al. [34] reported that the use of sunflower and olive oil resulted in the loss of DHA and EPA in fried fish. Consequently, the amount of oleic acid in the oils increased after frying [35]. Additionally, the oxidation that occurs during the frying process might increase the loss of fatty acid content in fried mackerel, implying decreased fatty acid content and moisture loss in the mackerel. However, these conditions could increase the amount of fat from the oil that is absorbed into the fried mackerel. The different frying media potentially increased the number of peroxide values (PV), resulting in varied hydroperoxides in the fried product. This would affect the formation of cholesterol oxidation products (COPs) [20]. The same phenomenon was also reported by Gall et al. [23], who found that the absorption of soybean oil resulted in higher levels of the most prominent soybean oil fatty acids in fried Spanish mackerel. On a percentage composition basis, fatty acid levels in other major filets decreased. As the lipid content of the original filet increased, this effect diminished. If the original level in the filet is high, further absorption of soybean oil fatty acids appears to be inhibited.

4.1.2. Effect of Frying on Amino Acid Profile of Fried Mackerel without Batter, Marinade, and Spice

The frying process has also been known to influence the amino acids of fried mackerel. The Maillard reaction and the thermal decomposition of sensitive amino acids are two factors that affect the amino acid content in fried mackerel [21,36].

In fried Indian mackerel, alanine and lysine were the most reduced amino acids [21]. Both amino acids have a reactive role in the formation of the Maillard reaction. This reaction forms between reducing sugars and amino acid groups and causes the brown color in fried foods. Furthermore, in the study of García-Arias et al. [36], they confirmed that some amino acid losses, such as lysine, could be attributed to the formation of various Maillard products during heating.

The presence of a free amino group at the ε-carbon unit, which is readily available for reaction with reducing sugars, makes lysine the most susceptible amino acid in intact proteins. Two free amino groups give free lysine an even higher reactivity. The crash of disulfide bonds and the acquisition of sulfide ions and free sulfur are the two effects of the increasing temperature on serine and threonine due to the conversion of these amino acids [37]. Moreover, Sikorski [37] mentioned that an increase in temperature, the presence of oxygen, and the reduction of saccharides significantly increased the thermal decomposition of sensitive amino acids. The decrease in tryptophan after frying is also caused by thermal degradation [38].

4.1.3. Effect of Frying on Proximate of Fried Mackerel without Batter, Marinade, and Spice

The frying process has been recorded to increase minerals and to oxidase the protein and lipids of fried mackerel products [9,23]. The absorption of some minerals from the frying medium might be caused by the increasing of fried mackerel, while the high temperatures involved during the frying process have also contributed to oxidase protein and lipids.

In the study of Gall et al. [23], frying Spanish mackerel at 177 °C for three minutes also increased some minerals, such as sodium, potassium, phosphorus, magnesium, calcium, zinc, iron, copper, and manganese. It appears as though some minerals from the Spanish mackerel were not lost during the frying process, and minerals from the frying medium could be absorbed.

For the oxidation of proteins and lipids, Negara et al. [9] reported that frying chub mackerel increased VBN and TBARS for deep, vacuum, and air frying compared with uncooked treatment. However, they mentioned that the increase in VBN and TBARS was lowest for vacuum frying, compared with deep and air frying. This condition indicates that deep and air frying impact the oxidation of proteins and lipids [9]. These findings suggest that vacuum frying can maintain physicochemical and nutritional qualities.

4.1.4. Effect of Frying on Sensory Evaluation of Fried Mackerel without Batter, Marinade, and Spice

In spite of the nutritional quality, the frying process was reported to affect the sensory parameters of fried mackerel. Several sensory parameters such as taste, color, and overall acceptance were influenced by the frying process [9,17]. Temperature, frying time, and the changing of fat might be influenced the sensorial parameters [9,17,19].

The high temperatures during frying process could increase the rate of heat penetration [19]. The rate of heat penetration to the center of the Indian mackerel at 160 °C was faster than that at 120 °C. At 160 °C, the temperature at the center of the mackerel reaches 89.3 °C in four minutes. Zaisev et al. [39] mentioned that during the frying process, the temperature in the center of the mackerel is always below 100 °C. Further, increasing the temperature and frying time increases the loss of moisture and weight. The thickness and fat content of the fish meat also contributed to this. In some cases, the same frying time resulted in low moisture, followed by an increase in temperature.

The low moisture was also reported by Negara et al. [9] which affected the score for the overall acceptance of chub mackerel after deep, vacuum, and air frying. The score of overall acceptance was “like slightly” to “like very much.” They mentioned that the overall acceptance score was influenced by moisture. Lower moisture content resulted in dried and crispy products. Moreover, the optimization of frying conditions, such as temperature and frying time, would affect the overall acceptance. The uncooked and overcooked products had low overall acceptance scores.

Moreover, the frying time would affect the taste of fried chub mackerel [17]. The longer frying time resulted in less oily tasting mackerel. The alteration of fat might cause a change in the taste of fried mackerel. Under these conditions, the exchange of fatty acids between mackerel and the oil might have occurred and impacted the test. During this process, gadoleic acid and EPA in the mackerel were taken up by frying oil, while linoleic and oleic acids from the frying oil were absorbed by the mackerel. Additionally, the texture of fried mackerel also changed after frying due to the dehydration or transformation of the tissue.

Frying not only changes the nutrition and sensorial aspects of fried mackerel, but also can reduce perfluorinated compounds (PFCs). According to the results of Kim et al. [16], the frying method successfully reduced the PFCs of fried chub mackerel. Frying at 160 °C for five minutes decreased 58% of PFC. The findings of this study also revealed that the combination of pre-treatment and frying of mackerel could decrease some environmental pollutants contained in raw mackerel. Using high temperature heating and edible oil effectively reduces PFCs with high polarity in food [40,41].

To conclude, it is known that frying methods can affect the nutritional, physicochemical, and sensory properties of mackerel. However, studies on the frying of Atlantic, Indian, and Spanish mackerel only used deep frying methods. To the best of our knowledge, studies of these mackerel species using different frying methods, such as vacuum and air frying, have not been conducted. These fry methods have been reported to produce high-quality fried products. Vacuum frying can also potentially be applied in fishery industries to produce high-quality fried mackerel. The low oxygen and temperature involved in vacuum frying results in low lipid oxidation and peroxide formation. Therefore, the effects of other frying methods on the nutritional, physicochemical, and sensory properties of Atlantic, Indian, and Spanish mackerel should be further investigated.

4.2. Fried Mackerel with Marinade and Spice

The marinating and spicing treatment before frying influenced the physicochemical [40] and sensory parameters [41,42] of the fried mackerel. The effects of frying on the mackerel with marinade and spice treatments are displayed in Table 2.

Table 2.

Optimum condition for frying mackerel with marinade and spice.

Before the frying process, marinating is the common treatment that is applied to mackerel. This pre-treatment was reported as influencing the physicochemical characteristics of fried mackerel such as TBARS and trypsin inhibitor activity [42].

The uses of sodium chloride to marinate chub mackerel increased TBARS levels after frying at 180 °C for ten minutes [42]. The high temperature and presence of oxygen are two main factors that lead to the rate of oxidation in the frying process. Nevertheless, salt can act as a pro-oxidant agent in fish, increasing oxidation and reducing nutrition. Additionally, oxidative changes can result in altered water-binding capacity and protein hydration, as well as the formation of protein−lipid complexes. However, marinating chub mackerel with sodium chloride resulted in the lowering of the trypsin inhibitor (TI) level. The inactivation of these enzyme inhibitors by the heating process may cause a decrease in the TI level. The duration of frying also affected the level of reduced TI activity.

The pre-treatments of marinating and spicing also impacted the sensory characteristic of fried mackerel. The uses of different marinating and spicing ingredients were known to influence the sensory characteristics of fried mackerel [43,44].

Pre-treatment of Spanish mackerel with polyethylene glycol (PEG) 200, butylated hydroxyl anisole (BHA), and sorbic acid before frying resulted in lower water activity compared to the untreated one [43]. The treatment also affected the color of the fried mackerel. Mackerel frying for three minutes using deep frying resulted in an orange-red color, while frying for five minutes resulted in a reddish-brown color, losing much of their yellow coloration. These conditions led to the moderate overall acceptability of the fried mackerel.

Moreover, the pre-treatment of spicing Spanish mackerel with shallot, red chilies, turmeric powder, ginger, garlic, salt, and MSG resulted in a good score for the sensory parameters [44]. The color of fried Spanish mackerel treated with some spices was scored as 6.4. For rancidity, moldiness, texture, and overall acceptability, panelists were scored as 7.3, 8.6, 6.0, and 6.4, respectively. The score of the sensory parameter was categorized from “like slightly” to “like very much,” based on the hedonic score. In this study, they mentioned that the application of spices before frying affected the sensory parameters and prolonged shelf-life in combination with polypropylene (PP) and high-density polyethylene (HDPE) packaging. The sensory evaluation of fried Spanish mackerel treated with spices and packaging in PP and HDPE was acceptable for up to eight weeks.

It is well known that the marination and spicing of fried mackerel before frying affects the sensory characteristics and oxidation of lipids. However, research on the effects of marinating and spicing fried mackerel only studied chub and Spanish mackerel and used only the deep-fried method. Therefore, future research should investigate the effects of marinating and spicing on Atlantic, Indian, horse, and king mackerel to produce high-quality fried mackerel with high nutrition and sensory scores.

4.3. Fried Mackerel with Batter

The effects of frying on fried mackerel with batter have been reported by Lee et al. [24] and Tirtawijaya et al. [25] and summarized in Table 3. Battering before frying affected the maintenance of the physicochemical, nutritional, and sensory parameters of fried mackerel.

Table 3.

Optimum condition for frying mackerel with batter.

The use of wheat flour, water, NaCl, potassium sorbate, and red pepper as ingredients of the batter successfully coated the fried chub mackerel and prevented nutritional loss during frying. The batter also stabilized the water activity, moisture, pH, and VBN of fried chub mackerel [24]. Furthermore, fried chub mackerel with batter in vacuum frying produced higher protein, lipid, DHA, and EPA levels, as well as better sensory properties than deep frying. Lipid atherogenic (AI), thrombogenic (TI), and hypocholesterolemic/hypercholesterolemic (h/H) indices of the vacuum-fried product showed better values suitable for human health. Moreover, lower AI and TI values are considered to be healthy conditions for preventing cardiovascular disease [25].

For sensory analysis, the scores for taste, flavor, texture, and colors of fried chub mackerel with batter that contain wheat flour, water, NaCl, potassium sorbate, and red pepper were 4.5–5, based on five hedonic scales. These sensory parameters were categorized from “good” to “very good” products [24]. Notably, the sensory property scores of the fried mackerel with batter in vacuum fry samples were higher than those of the deep fry samples, although all the samples were scored above the “like very much” category [25].

These studies revealed that frying mackerel with batter can increase sensory parameters. The nutritional and physicochemical properties of fried mackerel with batter can be maintained adequately with proper frying methods. However, research on the effect of frying on the mackerel with batter only studied chub mackerel. No research has been conducted on this topic for Atlantic, Indian, horse, Spanish, and king mackerel. Therefore, the effects of the frying method on these mackerel with batter should be further researched to produce high-quality fried mackerel with batter that contains high nutrition and sensory scores.

4.4. Minced Mackerel Products

Minced mackerel can be processed as nuggets, burgers, and croquette products. Processing mackerel into mackerel-based products is an alternative way to utilize mackerel, maintain nutrition, and extend shelf-life. Several studies have focused on the processing of minced mackerel as a good mackerel-based product, as shown in Table 4. The effects of ingredients and the frying process of these products are discussed below.

Table 4.

Optimum conditions for minced mackerel products.

4.4.1. Nugget

Mackerel-based nuggets are fishery products that contain mackerel mince, wheat flour, corn starch, leavening, and salt. During the production of mackerel-based nuggets, several aspects should be considered to produce high nutrition, prolong shelf-life, and taste products. Problems often arise in the production of mackerel-based nuggets, such as oxidation and unstable emulsions, which affect nutrition loss, moisture, texture, and sensory parameters.

Studies on the effect of different ingredients of mackerel-based nugget have been conducted by Tolasa et al. [26], Chen et al. [27], Lee et al. [28], and Fatimah et al. [45]. They mentioned that the different ingredients affected the appearance and nutritional and sensory analysis of mackerel-based nuggets products.

Regarding nutritional characteristics, 4% of milk protein concentrates (MPC) added to minced Atlantic mackerel nugget protected it against lipid oxidation [26]. MPC can prevent lipid oxidation during the preparation of nuggets. Nonetheless, the number of EPA and DHA in mackerel-based nuggets decreased after deep frying at 160 °C for one minute. This might be caused by the thermal degradation of heat-labile EPA and DHA and the release of fish oil during frying. Moreover, MPC significantly reduced lipid oxidation in fish mince based on TBARS values during the storage of mackerel nuggets. In the development of value-added high ω-3 seafood products from fish mince, it is critical not to have oxidative deterioration, leading to a reduction in ω-3 fatty acid levels.

In the sensory analysis, the addition of onion and mushroom as moisture-releasing ingredients improved the moistness and softness of king mackerel nuggets [28]. After deep frying at 160 °C for two minutes, the mackerel-based nuggets containing onions and mushrooms resulted in better moistness and softness. These conditions might be caused by the onions and mushrooms that formed stable liquid cells upon cooking—they retained the water and allowed moisture release. Moreover, the high moisture retention capacity of mushrooms also contributes to the release of more fluid in the mackerel nugget. Vegetables were effective in forming and making the cooked product moist with less liquid added by holding moisture release during forming and liquid cells after cooking.

Furthermore, according to the results of Fatimah et al. [45], mackerel-based nuggets containing 0.5% carrageenan flour resulted in the highest scores for appearance, aroma, texture, and taste. At this concentration, the appearance got a higher score from panelists due to the color of carrageenan; the other ingredients of mackerel-based nuggets (tapioca flour and surimi) were white. This resulted in a good level of preference for appearance. Carrageenan flour has a neutral and odorless aroma that does not affect the aroma of the product. As carrageenan is known to contain 25–30% of sulfate esters as a gelling agent, a high concentration of carrageenan can form a gel and decrease the texture of mackerel-based nuggets.

Moreover, in the study by Chen et al. [27], the addition of hydroxypropyl methylcellulose (HPMC) to minced horse mackerel resulted in brown color and a good level of crust crispness after deep frying at 180 °C for two minutes. The presence of reducing sugars in batters affects the browning rate [46]. Wheat flour, which is used as an ingredient, also contains sugar and can caramelize during frying. These conditions contribute to the color of mackerel-based nuggets. Furthermore, the addition of proteins accelerates the browning process of the batter during frying and impacts the brown color caused by an increase in amino clusters involved in Maillard reactions [47].

HMPC acts as a moisture barrier by retaining the evaporated molecules within the fish meat. The water barrier effect of HPMC successfully reduced the number of water molecules diffusing into the crust, allowing the crust’s crispness to be preserved. HPMC can also reduce oil absorption in both the surface layer [48] and core regions [49] of nuggets and other fried battered products, compared with products without HPMC. During the frying process, HPMC can sufficiently dehydrate the polymer, causing polymer-to-polymer interactions to create an oil barrier effect when temperatures rise and the gel point is reached.

The different ingredients of mackerel-based nuggets are well known to impact the protection of nutrition loss, moisture, texture, and sensory parameters after frying. These conditions improve the quality of mackerel-based nuggets. However, to the best of our knowledge, the processing of minced mackerel as a nugget only utilizes Atlantic, horse, and king mackerel. The processing of minced chub, Indian, and Spanish mackerel as nuggets has not been researched. Moreover, the frying process of mackerel-based nuggets uses only the deep-frying method. Alternative frying methods, such as vacuum and air frying, have not been performed. Although vacuum and air frying can also maintain the nutritional and sensory characteristics of fried products, no study has evaluated the effect of different frying methods and conditions on the nutritional and sensory parameters of mackerel-based nuggets. Therefore, further studies should confirm these.

4.4.2. Burger

Mackerel-based burgers are an alternative way to process and prolong the shelf-life of mackerels. As mackerel contains many nucleic, high-quality amino, and polyunsaturated fatty acids, there is an urgent need for the development of processing technology for more efficient use. A study on the effect of frying on mackerel-based burgers was conducted by Albertos et al. [10]; furthermore, studies on the processing of mackerel as a burger have been reported by Quadros et al. [50], Ozogul and Ucar [51], and Ucak et al. [52]. Frying and the ingredients of mackerel-based burgers have been reported to affect product quality.

According to the results of Albertos et al. [10], vacuum frying significantly enhanced the nutritional and organoleptic properties of Atlantic mackerel burger. The degradation of EPA and DHA was prevented during the frying process. Moreover, the polyene index was reduced, and the ω6/ω3 fatty acid ratio was maintained after frying. The formation of peroxides and carbonyl derivatives was also reduced. For the sensory parameters, vacuum frying successfully prevented color changes and improved the juiciness of the Atlantic mackerel burger.

Quadros et al. [50] reported that Spanish mackerel burgers prepared with whole minced mackerel resulted in high scores for appearance, aroma, flavor, and acceptance. The presence of pigments and volatile nitrogen compounds in whole minced Spanish mackerel, with unwashed treatment, gives a fish aroma and pink color to mackerel-based burgers. These conditions produce a mackerel-based burger with a high score. Meanwhile, during the washing process of raw mackerel, the loss of blood pigments, lipids, and soluble nitrogen compounds resulted in weaker flavor and aroma, as well as discoloration [53].

According to Ozogul and Ucar [51], the addition of natural antioxidants, such as oregano, green tea, sage, and laurel extracts, to a chub mackerel burger has effects on the control of biochemical and biological aspects of the product during storage and prolongs shelf-life. After grinding at 350 °C for three minutes, the natural extracts improved the sensory quality of the mackerel-based burgers. However, storage of the product for a long time decreased the sensory parameters. The panelist rejected the product with green tea after nine months of storage; sage and laurel groups were rejected after eight months of storage. As oregano and laurel have a strong flavor and taste, these conditions were mentioned by the panelists. Furthermore, the combination of rosemary extract and vacuum packing affected the growth of bacteria and biochemical aspects and prolonged its shelf-life [52]. Natural antioxidants do not change the taste of the end products. Moreover, the addition of natural antioxidants lowered rancidity and reduced the microbial count. Phytochemical compounds present in natural antioxidants are believed to act as preservative agents that prevent oxidation.

Based on the results of their study, the frying process and the ingredients of mackerel-based burgers affected their nutritional, sensory, and biochemical properties. The shelf-life of mackerel-based burgers is also influenced by the basic ingredients of the product. However, studies on the processing of minced mackerel as burgers only utilized Atlantic, chub, and Spanish mackerel. The processing of minced Indian, horse, and king mackerel as burgers has not been studied. Considering the nutritional value of these fish, studies on the processing of these mackerel fish as burgers and the effects of frying and ingredients should be studied further. This can contribute positively to the promotion of good products with high nutrition.

4.4.3. Croquette

Croquette is a popular fish product produced by applying coated technology during production. Currently, the demand for this product is increasing daily. Fish-based croquettes were produced by two steps of coating: first with batter and then with breadcrumbs. Fish-based croquettes were marketed as frozen products by manufacturers [54]. As frozen foods are known to have a long shelf-life, fish-based croquettes have a long shelf-life with high nutrition [55].

The fish-based croquette was produced by mixing fish mince with ingredients and spices, such as wheat flour, wheat starch, corn flour, dried garlic, dried onion, white pepper, cilantro, salt, dried coconut, black pepper, and breadcrumbs. Fish with high nutrition are used as ingredients in fish-based croquettes. Çankırılıgil and Berik [56] and Fuchsa et al. [55] produced a sardine-based croquette with high nutrition and long shelf-life. As a frozen food product, fish-based croquettes should be deep-fried before being served. Deep frying, however, will change the nutritional, chemical, and sensory properties of fried fish-based croquettes.

In the report by Çankırılıgil and Berik [56], deep frying at 180 °C for two minutes increases the crude fat and ash and decreases the water content and crude protein of sardine-based croquettes. Amino acids, such as leucine, isoleucine, lysine, phenylalanine, and threonine, were observed to decrease after frying. The frying process also decreased the total saturated fatty acid content and increased the unsaturated fatty acid content.

Fish-based croquettes can be an alternative for fishery products that can appease people’s desire for easy and healthy food. However, studies on fish-based croquettes are limited to the utilization of sardines. To the best of our knowledge, there are no studies on mackerel-based croquettes. As mackerel is known to contain high levels of nutrients, such as DHA and EPA, a mackerel-based croquette can be developed. Therefore, the effect of frying on the nutritional properties of mackerel-based croquettes should be further studied.

5. Conclusions

Our study revealed that frying mackerel without batter, marinade, and spice treatment influences the nutritional, physicochemical, and sensory properties of the food. The reduction of PFCs during the process resulted in the elimination of some toxins and affected the oxidation of lipids and degradation of proteins. This resulted in an increase in VBN and TBARS in fried mackerel compared to uncooked mackerel. Conversely, vacuum frying resulted in a low oxidation rate. Moreover, water loss during the frying process impacted the proximate contents, while the mineral content of fried mackerel was influenced by the absorption of oil. Several factors, including the absorption of linoleic acid from oil, oxidative decomposition, and water loss, may influence the fatty acid profile of fried mackerel. The thermal decomposition of sensitive amino acids was significantly increased by the rise in temperature, the presence of oxygen, and the reduction of saccharides. Regarding sensory parameters, the frying process influenced taste, color, and overall acceptance.

A marinating and spicing treatment before frying affected the oxidation and sensory parameters of fried mackerel. Marination with sodium chloride successfully decreased the TI level after frying, while the spicing treatment increased sensory parameters such as color, rancidity, moldiness, texture, and overall acceptability of the fried mackerel. Battering is also known to maintain the sensory, nutritional, and physicochemical parameters of fried mackerel after frying.

The nutritional and sensory parameters of minced mackerel products, such as nuggets and burgers, were impacted by the ingredients of the products. The frying process also contributed to the sensory parameters of minced mackerel products. Interestingly, the use of the vacuum frying method successfully maintained the nutritional and sensory parameters. This frying method can prevent the degradation of EPA, DHA, and color changes.

Alternative methods, such as vacuum and air frying, might be used to fry mackerel and minced mackerel products. These frying methods can minimize nutritional loss and produce high-quality fried products. Further studies on these fields are needed to confirm the effectiveness of vacuum and air frying in maintaining the nutritional and sensory properties of mackerel and minced mackerel products.

Author Contributions

Conceptualization, J.-S.C.; methodology, B.F.S.P.N., D.H., W.-H.C.; formal analysis, J.-H.S.; data curation, J.-H.S.; writing—original draft preparation, B.F.S.P.N., G.T.; writing—review and editing, J.-S.C.; visualization, J.-S.K.; supervision, J.-S.C., J.-S.K. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by the Ministry of Oceans and Fisheries, Korea, under the project no. PJT200885 entitled “Development and commercialization of traditional seafood products based on the Korean coastal marine resources.”

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data supporting reported results are available upon request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Froese, R.; Coro, G.; Kleisner, K.; Demirel, N. Revisiting safe biological limits in fisheries. Fish Fish. 2016, 17, 193–209. [Google Scholar] [CrossRef]

- Lee, D.; Son, S.; Kim, W.; Park, J.; Joo, H.; Lee, S. Spatio-Temporal Variability of the Habitat Suitability Index for Chub Mackerel (Scomber japonicus) in the East/Japan Sea and the South Sea of South Korea. Remote Sens. 2018, 10, 938. [Google Scholar] [CrossRef] [Green Version]

- Shulgina, L.V.; Davletshina, T.A.; Pavlovsky, A.M.; Solodova, E.A.; Pavel, K.G. Composition of lipids and fatty acids in muscle tissue of chub mackerel Scomber japonicus. Izv. TINRO 2019, 196, 193–203. [Google Scholar] [CrossRef]

- Huang, T.L.; Zandi, P.P.; Tucker, K.L.; Fitzpatrick, A.L.; Kuller, L.H.; Fried, L.P.; Burke, G.L.; Carlson, M.C. Benefits of fatty fish on dementia risk are stronger for those without APOE epsilon4. Neurology 2005, 65, 1409–1414. [Google Scholar] [CrossRef]

- Ziaiifar, A.M.; Achir, N.; Courtois, F.; Trezzani, I.; Trystram, G. Review of mechanisms, conditions, and factors involved in the oil uptake phenomenon during the deepfat frying process. Int. J. Food Sci. Technol. 2008, 43, 1410–1423. [Google Scholar] [CrossRef]

- Moreira, R.G. Vacuum frying versus conventional frying—An overview. EUR J LIPID SCI TECH 2014, 116, 723–734. [Google Scholar] [CrossRef]

- Shyu, S.L.; Hwang, L.S. Effects of processing conditions on the quality of vacuum fried apple chips. Food Res. Int. 2001, 34, 133–142. [Google Scholar] [CrossRef]

- Dueik, V.; Moreno, M.C.; Bouchon, P. Microstructural approach to understand oil absorption during vacuum and atmospheric frying. J. Food Eng. 2012, 111, 528–536. [Google Scholar] [CrossRef]

- Negara, B.F.S.P.; Lee, M.-J.; Tirtawijaya, G.; Cho, W.-H.; Sohn, J.-H.; Kim, J.-S.; Choi, J.-S. Application of Deep, Vacuum, and Air Frying Methods to Fry Chub Mackerel (Scomber japonicus). Processes 2021, 9, 1225. [Google Scholar] [CrossRef]

- Albertos, I.; Martin-Diana, A.B.; Jaime, I.; Diez, A.M.; Rico, D. Protective role of vacuum vs. atmospheric frying on PUFA balance and lipid oxidation. Innov. Food Sci. 2016, 36, 336–342. [Google Scholar]

- Ferreira, F.S.; Sampaio, G.R.; Keller, L.M.; Sawaya, A.C.H.F.; Chavez, D.W.H.; Torres, E.A.F.S.; Saldanha, T. Impact of Air Frying on Cholesterol and Fatty Acids Oxidation in Sardines: Protective Effects of Aromatic Herbs. J. Food Sci. 2017, 82, 2823–2831. [Google Scholar] [CrossRef] [PubMed]

- Ans, V.G.; Mattos, E.S.; Jorge, N. Quality assessment of frying oils used in restaurants and similar. Ciênc. Tecnol. Alim. 1999, 19, 413–419. [Google Scholar] [CrossRef]

- Corissin, M.S.; Jorge, N. Oxidative changes in oils from cottonseed, sunflower and palm oil used for frying frozen cassava. Alim. Nutr. 2005, 17, 25–34. [Google Scholar]

- Sébédio, J.L.; Ratnayake, W.M.N.; Ackman, R.G.; Prevost, J. Stability of polyunsaturated omega-3 fatty acids during deep fat frying of Atlantic mackerel (Scomber scombrus L.). Food Res. Int. 1993, 26, 163–172. [Google Scholar] [CrossRef]

- Okogeri, O.; Obelebe, E.A. Nutritional Properties of Atlantic Mackerel and Salmon as Affected by Traditional Cooking Methods. IOSR j. Biotechnol. Biochem. 2019, 5, 23–27. [Google Scholar]

- Kim, M.J.; Park, J.; Luo, L.; Min, J.; Kim, J.H.; Yang, H.D.; Kho, Y.; Kang, G.J.; Chung, M.S.; Shin, S.; et al. Effect of washing, soaking, and cooking methods on perfluorinated compounds in mackerel (Scomber japonicus). Food Sci. Nutr. 2020, 8, 4399–4408. [Google Scholar] [CrossRef]

- Ikegami, S.; Murata, Y.; Chokki, A.; Kunisaki, N. Plain or Without-batter Frying of Fat-rich Fish. J. Home Econ. Jpn. 1973, 24, 376–383. [Google Scholar]

- Laly, S.J.; Venketeswarlu, G. Effect of Culinary Oil on Changes in Lipid Quality and Physical Properties of Fried Indian Mackerel (Rastrelliger kanagurta) Steaks. Fish Technol. 2016, 53, 211–219. [Google Scholar]

- Chand, B.K.; Dora, K.C.; Sarkar, S.; Maragal, M.M. Changes during frying of mackerel at different temperature. Fish Technol. 2001, 38, 87–91. [Google Scholar]

- Nurjanah, N.; Nurilmala, M.; Hidayat, T.; Azri, R.Y.I. Fatty Acid Composition and Cholesterol Indian Mackerel (Rastrelliger kanagurta) Due Frying Process. Int. J. Mater. Chem. Phys. 2016, 2, 54–61. [Google Scholar]

- Nurjanah, N.; Nurilmala, M.; Hidayat, T.; Ginanjar, T.M.G. Amino Acid and Taurine Changes of Indian Mackarel Due to Frying Process. Int. J. Chem. Biomol. Sci. 2015, 1, 163–166. [Google Scholar]

- Ismail, A.; Ikram, E.H.K. Effects of cooking practices (boiling and frying) on the protein and amino acids contents of four selected fishes. Nutr. Food Sci. 2004, 34, 54–59. [Google Scholar] [CrossRef]

- Gall, K.L.; Otwell, W.S.; Koburger, J.A.; Appledorf, H. Effects of Four Cooking Methods on the Proximate, Mineral and Fatty Acid Composition of Fish Fillets. J. Food Sci. 1983, 48, 1068–1074. [Google Scholar] [CrossRef]

- Lee, E.H.; Chung, S.H.; Cho, S.Y.; Cha, Y.J.; Kim, S.K. Storage stability of intermediate moisture deep-fried mackerel. Korean J. Food Sci. Technol. 1983, 15, 353–358. [Google Scholar]

- Tirtawijaya, G.; Lee, M.-J.; Negara, B.F.S.P.; Cho, W.-H.; Sohn, J.-H.; Kim, J.-S.; Choi, J.-S. Effects of Vacuum Frying on the Preparation of Ready-to-Heat Batter-Fried and Sauced Chub Mackerel (Scomber japonicus). Foods 2021, 10, 1962. [Google Scholar] [CrossRef]

- Tolasa, S.; Lee, C.M.; Calki, S. Lipid oxidation and omega-3 fatty acid retention in salmon and mackerel nuggets during frozen storage. J. Aquat. Food Prod. Technol. 2011, 20, 172–182. [Google Scholar] [CrossRef]

- Chen, C.L.; Li, P.Y.; Hu, W.H.; Lan, M.H.; Chen, M.J.; Chen, H.H. Using HPMC to improve crust crispness in microwave-reheated battered mackerel nuggets: Water barrier effect of HPMC. Food Hydrocoll. 2008, 22, 1337–1344. [Google Scholar] [CrossRef]

- Lee, K.H.; Joaquin, H.; Lee, C.M. Improvement of Moistness and Texture of High Omega-3 Fatty Acid Mackerel Nuggets by Inclusion of Moisture-Releasing Ingredients. J. Food Sci. 2007, 72, S119–S124. [Google Scholar] [CrossRef]

- Liberati, A.; Altman, D.G.; Tetzlaff, J.; Mulrow, C.; Gøtzsche, P.C.; Ioannidis, J.P.; Clarke, M.; Devereaux, P.J.; Kleijnen, J.; Moher, D. The PRISMA statement for reporting systematic reviews and meta-analyses of studies that evaluate health care interventions: Explanation and elaboration. PLoS Med. 2009, 6, e1000100. [Google Scholar] [CrossRef]

- Hsieh, R.J.; Kinsella, J.E. Oxidation of polyunsaturated fatty acids: Mechanisms, products, and inhibition with emphasis on fish. Adv. Food Nutr. Res. 1989, 33, 233–341. [Google Scholar]

- Saldanha, T.; Bragagnolo, N. Relation between types of packaging, frozen storage and grilling on cholesterol and fatty acids oxidation in Atlantic hake fillets (Merluccius hubbsi). Food Chem 2008, 106, 619–627. [Google Scholar] [CrossRef]

- Asokapandian, S.; Swamy, G.J.; Hajjul, H. Deep fat frying of foods: A critical review on process and product parameters. Crit. Rev. Food Sci. Nutr. 2019. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Zhanga, M.; Adhikaric, B. Recent developments in frying technologies applied to fresh foods. Trends Food Sci. Technol. 2020, 98, 68–81. [Google Scholar] [CrossRef]

- Sanchez-Muniz, F.J.; Viejo, J.M.; Medina, R. Deep-frying of sardines in different culinary fats, changes in the fatty acid composition of Sardines and frying fats. J. Agric. Food Chem. 1992, 40, 2252–2256. [Google Scholar] [CrossRef]

- Castrillon, A.M.; Navarro, P.; Alvarez-Pontes, E. Changes in chemical composition and nutritional quality of fried Sardine (Clupea pilchardus) produced by frozen storage and microwave reheating. J. Sci. Food Agric. 1997, 75, 125–132. [Google Scholar] [CrossRef]

- García-Arias, M.T.; Álvarez-Pontes, E.; García-Linares, M.C.; García-Fernández, M.C.; Sánchez-Muniz, F.J. Cooking-freezing-reheating (CFR) of sardine (Sardina pilchardus) fillets: Effect of different cooking and reheating procedures on the proximate and fatty acid compositions. Food Chem. 2003, 83, 349–356. [Google Scholar] [CrossRef]

- Sikorski, Z.E. Chemical and Functional Properties of Food Proteins; Technomic Publishing Co. Inc.: Lancaster, PA, USA, 2001; pp. 191–215. [Google Scholar]

- Rakowska, M.; Werner, J.; Szkilladziowa, W.; Nadolna, I.; Zielinska, Z. Comments on effect of heat treatment on the nutritive value of protein and the availability of amino acids in meat-vegetable canned foods. Zesz Probl. Postepow Nauk Roln. 1975, 167, 217–224. [Google Scholar]

- Zaitsev, V.; Kizevetter, I.; Lagunov, L.; Makarova, L.; Minder, L.; Podsevalov, V. In Siah Curing and Processing; Mir Publicationa: Moscow, Russia, 1969; 722p. [Google Scholar]

- Wu, D.; Li, X.K.; Zhang, J.X.; Chen, W.R.; Lu, P.; Tang, Y.M.; Li, L.S. Efficient PFOA degradation by persulfate-assisted photocatalytic ozonation. Sep Purif Technol. 2018, 207, 255–261. [Google Scholar] [CrossRef]

- Luo, L.; Kim, M.; Park, J.; Yang, H.; Kho, Y.; Chung, M.; Moon, B. Reduction of perfluorinated compound content in fish cake and swimming crab by different cooking methods. Appl. Biol. Chem. 2019, 62, 44–54. [Google Scholar] [CrossRef] [Green Version]

- Oduro, F.A.; Choi, N.D.; Ryu, H.S. Effects of cooking conditions on the protein quality of chub Mackerel Scomber japonicus. Fish Aquat. Sci. 2011, 14, 257–265. [Google Scholar] [CrossRef] [Green Version]

- Man, Y.; Atan, M. Some quality parameters of intermediate moisture, deep-fried mackerel (Scomberomorus commersoni, Lacepede). Pertanika 1984, 7, 115–119. [Google Scholar]

- Man, Y.B.C.; Bakar, J.; Mokri, A.A.K. Effect of packaging films on storage stability of intermediate-moisture deep-fried mackerel. Int. J. Food Sci. Technol. 1995, 30, 175–181. [Google Scholar] [CrossRef]

- Fatimah, S.S.; Pratama, R.I.; Liviawati, J.E. Addition of carrageenan fluor on preference level of mackerel nugget. World News Nat. Sci. 2019, 22, 180–189. [Google Scholar]

- Suderman, D.R. Selecting flavorings and seasonings for batter and breading systems. Cereal Food World 1993, 39, 689–694. [Google Scholar]

- Olewinik, M.; Kulp, K. Factors influencing wheat flour performance in batter system. Cereal Food World 1993, 39, 679–684. [Google Scholar]

- Balasubramaniam, V.M.; Chinnan, M.S.; Mallikarjunan, P.; Phillips, R.D. The effect of edible film on oil uptake and moisture retention of a deep-fat fried poultry product. J. Food Process Eng. 1997, 20, 17–29. [Google Scholar] [CrossRef]

- Sahin, S.; Sumnu, G.; Altunakar, B. Effects of batters containing different gum types on the quality of deep-fat fried chicken nuggets. J. Sci. Food Agric. 2005, 85, 2375–2379. [Google Scholar] [CrossRef]

- Quadros, D.A.; Rocha, I.F.O.; Ferreira, S.M.R.; Bolini, H.M.A. Low-sodium fish burgers: Sensory profile and drivers of liking. LWT Food Sci. Technol. 2015, 63, 236–242. [Google Scholar] [CrossRef]

- Ozogul, Y.; Uçar, Y. The Effects of Natural Extracts on the Quality Changes of Frozen Chub Mackerel (Scomber japonicus) Burgers. Food Bioprocess Technol. 2013, 6, 1550–1560. [Google Scholar] [CrossRef]

- Uçak, İ.; Özogul, Y.; Durmuş, M. The effects of rosemary extract combination with vacuum packing on the quality changes of Atlantic mackerel fish burgers. Int. J. Food Sci. Technol. 2011, 46, 1157–1163. [Google Scholar] [CrossRef]

- Alfaro, A.T.; Costa, C.S.; da Lanes, G.F.C.; Torres, L.; Soares, G.J.D.; Prentice, C.H. Processing parameters and acceptability of ham prepared from king weakfish (Macrodon ancylodon) surimi. Alimentos e Nutriçao 2004, 15, 259e265. [Google Scholar]

- Soto-Jover, S.; Boluda-Aguilar, M.; Esnoz-Nicuesa, A.; Iguaz-Gainza, A.; Lopez-Gomez, A. Texture, Oil Adsorption abd Safety of the european Style Crocuettes Manufactured at Industrial Scale. Food Eng. Rev. 2015, 8, 181–200. [Google Scholar] [CrossRef]

- Fuchs, R.H.B.; Ribeiro, R.P.; Matsushita, M.; Tanamati, A.A.C.; Canan, C.; Bona, E.; Marques, L.L.M.; Droval, A.A. Chemical, sensory and microbiological stability of freeze-dried Nile tilapia croquette mixtures. CyTA-J. Food 2015, 13, 556–562. [Google Scholar] [CrossRef] [Green Version]

- Çankırılıgil, E.C.; Berik, N. Effects of deep-frying to sardine croquettes’ chemical composition. EgeJFAS 2017, 34, 293–302. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).