IAEA-Assisted Treatment of Liquid Radioactive Waste at the Saakadze Site in Georgia

Abstract

:1. Introduction

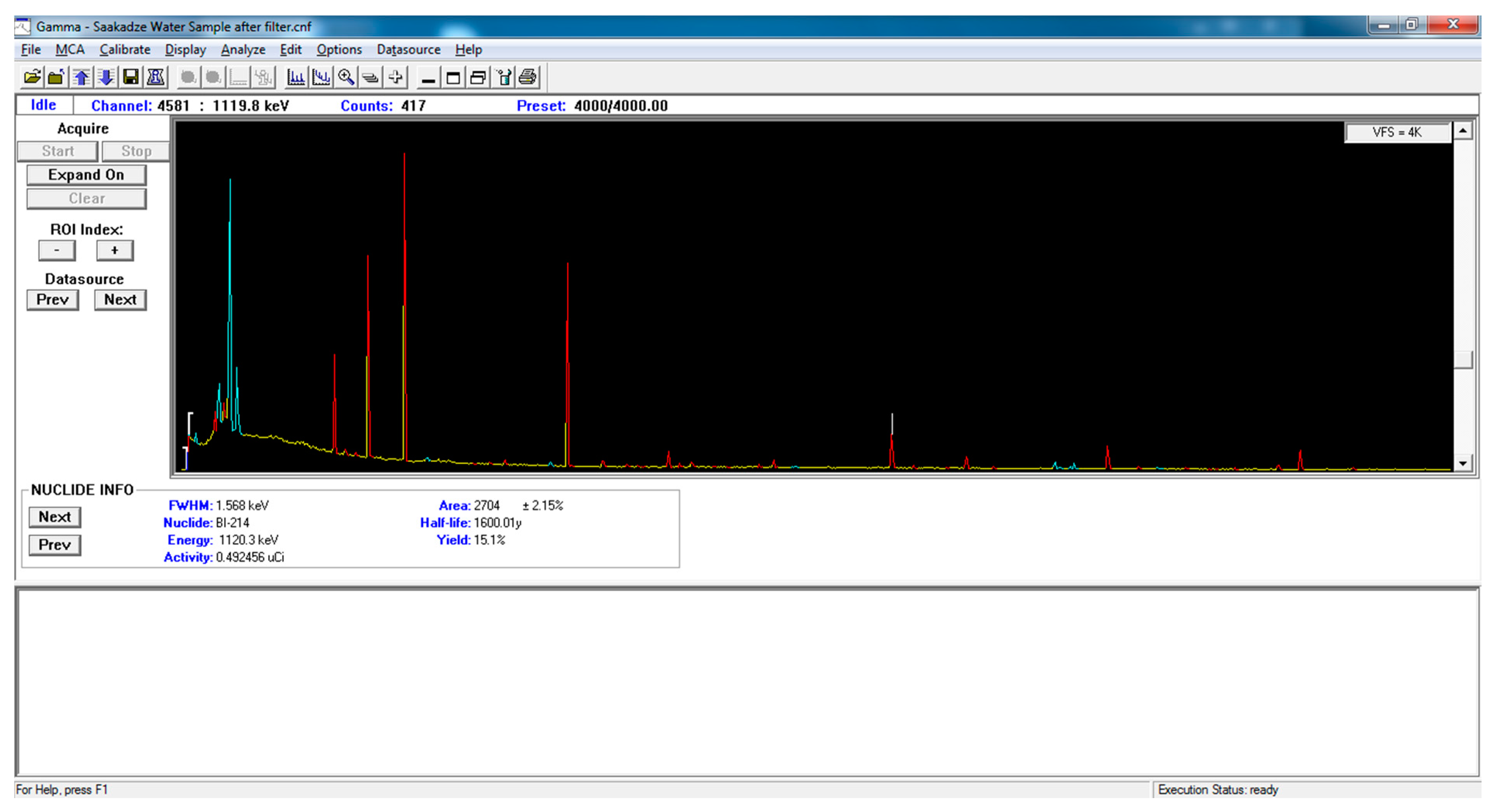

2. Liquid Radioactive Waste Characterization

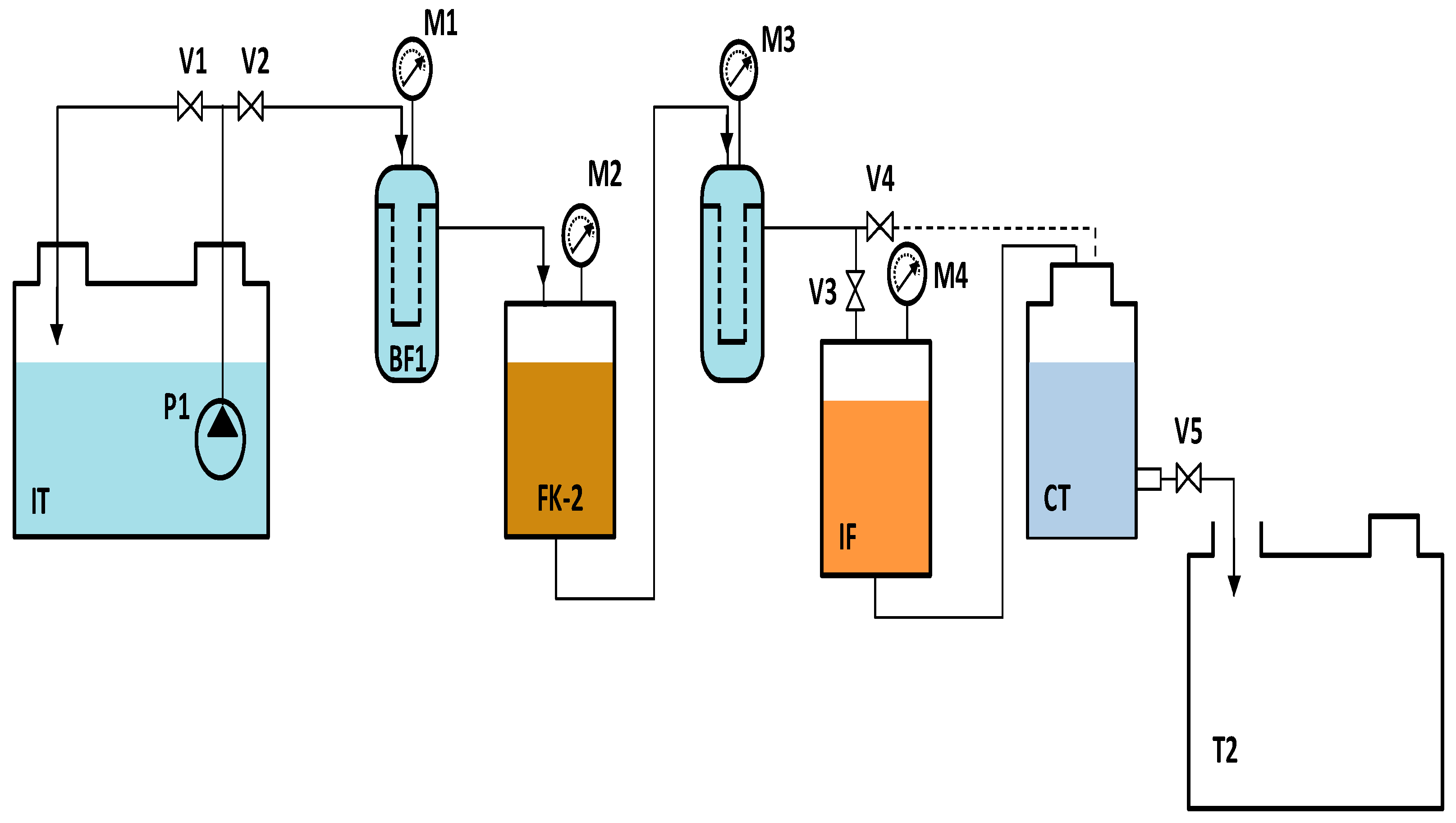

3. Treatment of Waste

- MDM—100–1000 bed (column) volumes;

- KU-2-8—50–200 bed (column) volumes.

4. Discussion

5. Conditioning of Secondary Waste

- spent sorbents;

- spent ion exchange resins;

- spent filter elements;

- pump and piping.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IAEA. Selection of Technical Solutions for the Management of Radioactive Waste; IAEA TECDOC; International Atomic Energy Agency, Vienna International Centre: Vienna, Austria, 2017; Volume 1817, 112p, Available online: http://www-pub.iaea.org/books/IAEABooks/12217/Selection-of-Technical-Solutions-for-the-Management-of-Radioactive-Waste (accessed on 18 August 2021).

- IAEA. Disposal of Radioactive Waste; Specific Safety Requirements; International Atomic Energy Agency, Vienna International Centre: Vienna, Austria, 2011; Volume SSR-5, 62p, Available online: https://www.iaea.org/publications/8420/disposal-of-radioactive-waste (accessed on 18 August 2021).

- Ojovan, M.I.; Lee, W.E.; Kalmykov, S.N. An Introduction to Nuclear Waste Immobilisation, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2019; 498p. [Google Scholar]

- Chabashvili, M.; Japaridze, G.; Lordkipanidze, S.; Nabakhtiani, G.; Pataraia, T.; Rostomashvili, Z. Georgia’s Nuclear Odyssey: The Path from Soviet Atomic Legacy to Global Nonproliferation Regime; Civil Council of Defence and Security CCDS: Tbilisi, Georgia, 2013; 102p, ISBN 978-9941-0-6091-5. [Google Scholar]

- EU. Project G.4.01.08 Survey and Strategic Assessment of Georgian Radwaste Disposal and Interim Storage Sites, Technical Report 2.2: Results from the Environmental and Radiological Site Survey; European Union: Maastricht, The Netherlands, 2012. [Google Scholar]

- Georgian Technical Regulation No. 450—Radiation Safety Norms and Basic Requirements Related to Handling of Ionizing Radiation Sources; Parliament of Georgia: Tbilisi, Georgia, 2015; pp. 9–10.

- IAEA. Treatment of Low-and Intermediate-Level Liquid Radioactive Wastes; Technical Reports Series; International Atomic Energy Agency, Vienna International Centre: Vienna, Austria, 1984; Volume 236, Available online: https://www.iaea.org/publications/1337/treatment-of-low-and-intermediate-level-liquid-radioactive-wastes (accessed on 18 August 2021).

- IAEA. Chemical Precipitation Processes for the Treatment of Aqueous Radioactive Waste; Technical Reports Series; International Atomic Energy Agency, Vienna International Centre: Vienna, Austria, 1992; Volume 337, Available online: https://www.iaea.org/publications/1441/chemical-precipitation-processes-for-the-treatment-of-aqueous-radioactive-waste (accessed on 18 August 2021).

- IAEA. Advances in Technologies for the Treatment of Low and Intermediate Level Radioactive Liquid Waste; Technical Reports Series; International Atomic Energy Agency, Vienna International Centre: Vienna, Austria, 1994; Volume 370, 117p, Available online: https://inis.iaea.org/collection/NCLCollectionStore/_Public/26/038/26038193.pdf (accessed on 18 August 2021).

- IAEA. Handling and Processing of Radioactive Waste from Nuclear Applications; Technical Reports Series; International Atomic Energy Agency, Vienna International Centre: Vienna, Austria, 2001; Volume 402, 143p, Available online: https://www.iaea.org/publications/6006/handling-and-processing-of-radioactive-waste-from-nuclear-applications (accessed on 18 August 2021).

- IAEA. Application of Ion Exchange Processes for the Treatment of Radioactive Waste and Management of Spent Ion Exchangers; Technical Reports Series; International Atomic Energy Agency, Vienna International Centre: Vienna, Austria, 2002; Volume 408, 115p, Available online: https://www.iaea.org/publications/6221/application-of-ion-exchange-processes-for-treatment-of-radioactive-waste-and-management-of-spent-ion-exchangers (accessed on 18 August 2021).

- IAEA. Application of Membrane Technologies for Liquid Radioactive Waste Processing; Technical Reports Series; International Atomic Energy Agency, Vienna International Centre: Vienna, Austria, 2004; Volume 431, 145p, Available online: https://www.iaea.org/publications/7029/application-of-membrane-technologies-for-liquid-radioactive-waste-processing (accessed on 18 August 2021).

- Karlin, Y.V.; Dmitriev, S.A.; Iljin, V.A.; Ojovan, M.I. Elaboration of not large mobile modular installations “Aqua-Express” (300 L/h) for LWR cleaning. In Proceedings of the WM’03 Conference, Tucson, Arizona, 23–27 February 2003; p. 8. [Google Scholar]

- Karlin, Y.V.; Chujkov, V.Y.; Adamovich, D.V. Liquid radioactive waste (LRW) reprocessing by means of modular mobile plants. At. Energy 2001, 90, 65–69. [Google Scholar] [CrossRef]

- Karlin, Y.V.; Chuikov, V.Y.; Adamovich, D.V.; Slastennikov, Y.T.; Il’in, V.A.; Sumenko, A.V.; Flit, V.Y.; Dmitriev, S.A.; Sobolev, I.A. Reprocessing of liquid radioactive wastes using mobile modular systems. At. Energy 2001, 90, 74–79. [Google Scholar] [CrossRef]

- Savkin, A.E.; Karlin, Y.V.; Maryakhin, M.A. Development and trials of an improved process for decontamination of liquid radioactive wastes from Radon Moscow Research and Production Association. Radiochemistry 2011, 53, 559–562. [Google Scholar] [CrossRef]

- Hung, Y.-T.; Aziz, H.A.; Al-Khatib, I.A.; Abdel Rahman, R.O.; Cora-Hernandez, M.G.R. Water quality engineering and wastewater treatment. Water 2021, 13, 330. [Google Scholar] [CrossRef]

- Abdel Rahman, R.O.; Ibrahium, H.A.; Hung, Y.T. Liquid Radioactive Wastes Treatment: A Review. Water 2011, 3, 551–565. [Google Scholar] [CrossRef] [Green Version]

- Abdel-Rahman, R.O.; El-Kamash, A.M.; Ali, H.F.; Hung, Y.T. Overview on recent trends and developments in radioactive liquid waste treatment part 1: Sorption/Ion Exchange Technique. Int. J. Environ. Eng. Sci. 2011, 2, 1–16. [Google Scholar]

- Savkin, A.E.; Karlin, Y.V. Processing of liquid radioactive waste accumulated in Georgia. In Proceedings of the 1st Scientific Practical Conference “Environmental Protection and Radioactive Waste Management of Scientific and Industrial Centers” (FSUE “RADON”), Moscow, Russia, 24–26 April 2019; pp. 12–18. [Google Scholar]

- Dmitriev, S.A.; Adamovich, D.V.; Gelis, V.M.; Milyutin, V.V. Development of a selective sorbent for liquid radioactive waste decontamination from strontium. In Proceedings of the International Conference WM’2005, Tucson, AZ, USA, 27 February–3 March 2005. [Google Scholar]

- Giorgadze, I.; Nabakhtiani, G.; Kotetishvili, K.; Chelidze, L. Site Selection for Radioactive Waste Management Facilities in Georgia. Adv. Ecol. Environ. Res. 2020, 5, 276–283. [Google Scholar]

- Abdel Rahman, R.O.; Rahimov, R.Z.; Rahimova, V.; Ojovan, M.I. Cementitious Materials for Nuclear Waste Immobilization; Wiley: Chichester, UK, 2015; 232p, ISBN 978-1-118-51200-5. [Google Scholar]

| Radionuclide | Activity, Bq/kg | Measurement Error, % |

|---|---|---|

| 22Na | 3.1 | 43 |

| 46Sc | 16.5 | 49 |

| 140La | 5.3 | 66 |

| 155Eu | 16.0 | 61 |

| 214Pb | 37.8 | 1.1 |

| 207Bi | 1.7 | 110 |

| 214Bi | 8.8 | 1.4 |

| 226Ra | 1215 | 5.2 |

| Method | Features | Limitations |

|---|---|---|

| Filtration | Removal of suspended solids. Use as polishing step after chemical treatment. Use upstream of ion exchanger. Backwash is possible. | Not suitable for colloids. Need to replace filter media. |

| Evaporation | High DF 1 > 103. Well established technology—many different designs. High volume reduction factor. Concentrate can be directly immobilized or dried to produce a salt cake. Utilized mostly as batch process. Condensate may require polishing depending on the activity. | Not suitable for small volumes of aqueous waste generation. Process limitations (scaling, foaming, corrosion, volatility of certain radionuclides). High capital and operating cost with high energy consumption. |

| Sorption/Ion exchange (organics) | DF high on low salt content (102). High DF also possible for high salt content by use of specific resins. Regeneration of resins possible. | Some colloidal particles and resin fines may pass straight through to the treated water. Limited radiation, thermal and chemical stability of the resins. Resins cost. May require some chemical treatment before conditioning. |

| Sorption/Ion exchange (inorganics) | 10 < DF < 104. Chemical, thermal and radiation stability better than organic ion exchangers. Relatively easy immobilization. Mostly used as once through cycle. | Some colloidal particles and sorbent fines may pass straight through to the treated water. Possible high cost for specific sorbents. |

| Microfiltration | Removal of fine particulates. Pore sizes range from 0.05 and 5 μm. Low pressure operation (100–150 kPa). High recovery (99%). Low fouling when air backwash is employed. Mostly used as the first step in treatment. | Used for suspended fine particles, but not colloidal matter. Backwash frequency depends on solids content of waste stream. Short lifetime of organic membranes. Inorganic membranes exhibit greater mechanical durability than polymeric membranes. High cost of inorganic membranes. |

| Ultrafiltration | Removal of colloidal materials and large dissolved molecules. Pore sizes range from 0.001–0.01 μm. Pressure < 1 MPa. DFs in the region of 103 for α and 102 for β and γ emitters. High volume reduction factor can be achieved. Good chemical and radiation stability for inorganic membranes. | Fouling—need for chemical cleaning and backflushing. Organic membranes subject to radiation damage. Short lifetime of organic membranes. Inorganic membranes exhibit greater mechanical durability than polymeric membranes. High cost of inorganic membranes. |

| Nanofiltration | Separation of salts with charge differences and separation of high molecular weight organics from high concentration monovalent salt solutions. Pore sizes between 0.001 and 0.01 μm. Pressure from 0.3 to 1.4 MPa. Functions between ultrafiltration and reverse osmosis, and is often termed ‘loose reverse osmosis’. | Organic membranes subject to radiation damage. Short lifetime of organic membranes. |

| Reverse osmosis | Removes dissolved ions and small molecules that contaminate aqueous solutions. 10 < DF < 102. Well established for large scale operations. Compete with other separation processes (such as evaporation). Suitable for waste streams with complex radiochemical compositions. | High pressure system, limited by osmotic pressure. Non-back-washable, subject to fouling. |

| Radionuclide | Activity, Bq/kg | Measurement Error, % |

|---|---|---|

| 22Na | 1.1 | 43 |

| 40K | 15.1 | 95 |

| 46Sc | 12.9 | 19 |

| 109Cd | 98.8 | 22 |

| 134Cs | 1.3 | 39 |

| 140Ba | 3.1 | 60 |

| 140La | 2.5 | 25 |

| 143Ce | 5.7 | 49 |

| 155Eu | 13.9 | 19 |

| 237Np | 7.0 | 98 |

| 226Ra | <23.1 | - 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nabakhtiani, G.; Giorgadze, I.; Ojovan, M.I. IAEA-Assisted Treatment of Liquid Radioactive Waste at the Saakadze Site in Georgia. Processes 2021, 9, 1679. https://doi.org/10.3390/pr9091679

Nabakhtiani G, Giorgadze I, Ojovan MI. IAEA-Assisted Treatment of Liquid Radioactive Waste at the Saakadze Site in Georgia. Processes. 2021; 9(9):1679. https://doi.org/10.3390/pr9091679

Chicago/Turabian StyleNabakhtiani, Giorgi, Irma Giorgadze, and Michael I. Ojovan. 2021. "IAEA-Assisted Treatment of Liquid Radioactive Waste at the Saakadze Site in Georgia" Processes 9, no. 9: 1679. https://doi.org/10.3390/pr9091679

APA StyleNabakhtiani, G., Giorgadze, I., & Ojovan, M. I. (2021). IAEA-Assisted Treatment of Liquid Radioactive Waste at the Saakadze Site in Georgia. Processes, 9(9), 1679. https://doi.org/10.3390/pr9091679