Magnetic Technologies and Green Solvents in Extraction and Separation of Bioactive Molecules Together with Biochemical Objects: Current Opportunities and Challenges

Abstract

:1. Introduction

2. Roles of Magnetic Fields in Extraction and Separation

3. Magnetic Nanofluids and Ionic Liquids in Extraction and Separation

3.1. Magnetic Nanofluids

3.2. Magnetic Ionic Liquids

4. Magnetite Nanoparticles and Their Surface Modification

4.1. Surface Modification with Ionic Liquids and Other Inorganic Substances

4.2. Surface Modification with Small Organic Molecules

4.3. Surface Modification with Polymers

4.4. Surface Modification with Biomolecules

5. The Application of Magnetic Technology in Separation of Natural Products

5.1. Magnetic Solid-Phase Extraction

| Objects | Samples | Magnetic Materials | Separation Efficiency or Recovery | Ref. |

|---|---|---|---|---|

| Sesamol, sesamin, and sesamolin | Sesame oil | Graphene oxide-coated Fe3O4 | 84–86%, 82–92% and 83–94% | [99] |

| Cinnamic acid, ferulic acid and genistein | oilseeds | Graphene oxide-coated Fe3O4 | 84–98%, 94–95% and 83–109% | [100] |

| Aristolochic acid I and aristolochic acid II | Aristolochiae fructus and Asari radix et rhizome extrat | Adenine-coated magnetic multi-walled carbon nanotubes | 92.7–97.5% and 92.6–99.4% | [101] |

| Morin, quercetin, and kaempferol | Dark tea, dark chocolate and tomato | Fe3O4-agarose | 86–99%, 87–98% and 86–97% | [102] |

| Sudan dyes | Tomato sauce | Fe3O4-NH2-MOF (MIL-101) | 73–93% | [103] |

| Puerarin, daidzin, and daidzein | Pueraria lobata extrat | Fe3O4-SiO2-MOF (ZIF-8) | 98–101%, 94–102% and 97–104% | [104] |

| Rhodamine B | Chinese prickly ash extrat | Fe3O4-COF | 92–98% | [105] |

| α-asarone and β-asarone | Acorous Tatarinowii Rhizoma and Polygalae Radix extrat | Fe3O4-COF | 106–112% and 98–99% | [106] |

| Hydroxytyrosol | Chinese olive leaves extrat | MMIP | 97–98% | [107] |

| Harmaline | Peganum harmala extrat | MMIP | 96–105% | [108] |

| Hesperetin | The dried pericarp of Citrus reticulata Blanco extrat | MMIP | 91–97% | [109] |

5.2. Magnetic Nanofluid Extraction

5.3. Magnetic Ionic Liquid Extraction

5.4. Magnetic Field-Assisted Extraction

| Extract Objects | Solvent Systems | Magnetic Field Intensity | Time | Extraction Rate | Effect of Magnetic Field | Ref. |

|---|---|---|---|---|---|---|

| Scopolamine | Ethanol– water solution | 400 mT | 40 min (magnetization treatment), 60 min (ultrasonic extraction) | 0.135% | The magnetic field destroyed the hydrogen bond network of solvents molecules, the molecules became smaller and easier to penetrate into the plant cells and dissolve the target substance, so the magnetic field is beneficial to improve the extraction rate of scopolamine, shorten the extraction time and improve the production efficiency | [23] |

| Polyphenols, caffeine and mineral component K | Demineralized water | 100 mT, permanent magnetic field (PMF) and variable magnetic field (VMF) | 5 min | Polyphenols: 0.990 mg/mL (PMF), 1.103 mg/mL (VMF); caffeine: 241.2 mg/L (PMF), 283.7 mg/L (VMF); K: 162 mg/L (PMF), 380 mg/L (VMF) | PMF had no significant effect on the extraction rate of the three target substances, the extraction rate of caffeine and K increased by VMF, but the effect of VMF on polyphenols was less obvious | [24] |

| Peony seed oil | Petroleum ether | 720 mT | 60 min | 27.5% | Peony seed oil yield increased with the increase in magnetic induction intensity; when the magnetic induction intensity was 720 mT, the highest yield was achieved, and then the yield decreased with a further increase in magnetic induction intensity | [25] |

| Wolfberry flavonoids | Ethanol– water solution | 640 mT | 120 min (magnetization treatment), 60 min (reflux extraction) | 2.9081 mg/g | The extraction rate increased with the increase in magnetic field intensity at the beginning; when the magnetic field intensity was higher than 640 mT, the extraction rate decreased with the increase in the magnetic field intensity | [134] |

| Astaxanthin | Acetic ether | 18 mT | 50 min | 62.72% | A magnetic field was produced by a magnet, and the extraction yield of astaxanthin increased when the magnetic intensity increased from 0 to 15 mT, and then the extraction yield decreased | [135] |

| Stachyose | Magnetized water | 287.8 mT | 74.34 min (magnetization treatment), 1.96 h (extraction) | 28.2% | The extraction rate was 1.4 fold the rate when the solvent was unmagnetized water | [138] |

6. Immunomagnetic Beads in Separation of Biological Objects

6.1. Separation of Nucleic Acids

6.2. Separation of Cells

6.3. Adsorption and Immobilization of Enzyme or Protein

6.4. Enrichment and Trapping of Microorganism

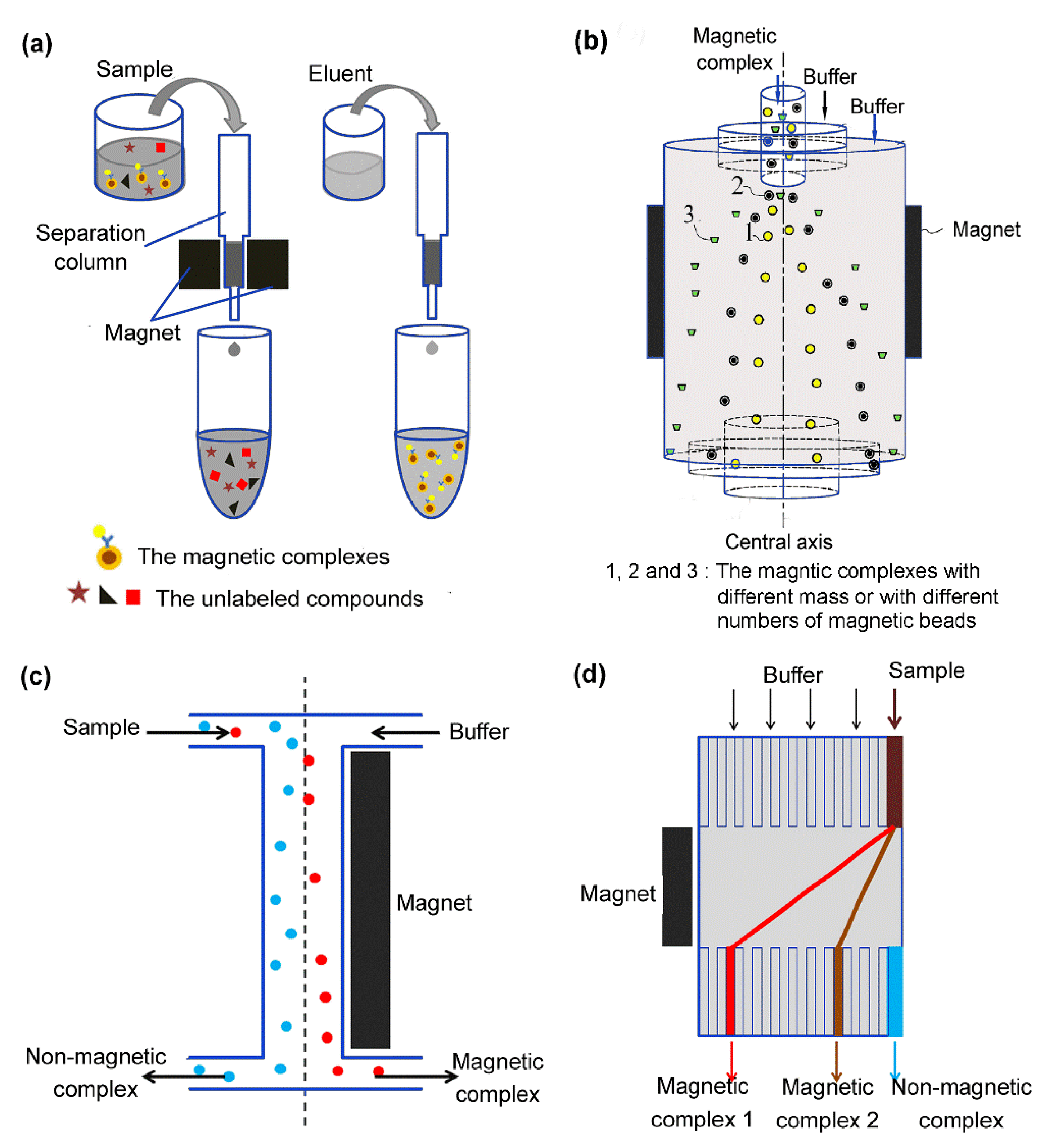

7. Magnetic Separators for Multi-Level Applications

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bobinaitė, R.; Kraujalis, P.; Tamkutė, L.; Urbonavičienė, D.; Viškelis, P.; Venskutonis, P.R. Recovery of bioactive substances from rowanberry pomace by consecutive extraction with supercritical carbon dioxide and pressurized solvents. J. Ind. Eng. Chem. 2020, 85, 152–160. [Google Scholar] [CrossRef]

- Li, P.F.; Qin, L.T.; Wang, T.; Dai, L.X.; Li, H.; Jiang, J.X.; Zhou, J.Y.; Li, H.; Cheng, X.Q.; Lei, F.H. Preparation and adsorption characteristics of rosin-based polymer microspheres for berberine hydrochloride and separation of total alkaloids from coptidis rhizome. Chem. Eng. J. 2020, 392, 123707. [Google Scholar] [CrossRef]

- He, Q.; Guo, Z.X.; Cao, Y.; Yang, M.; Yao, S. Selective separation of main flavonoids by combinational use of ionic liquid-loaded microcapsules from crude extract of Tartary buckwheat. Food Chem. 2021, 362, 130225. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.Y.; Li, Y.S.; Li, Z.C.; Yan, W.T.; Chen, P.; Yao, S. Extraction assisted by far infrared radiation and hot air circulation with deep eutectic solvent for bioactive polysaccharides from Poriacocos (Schw.) Wolf. Green Chem. 2021, 23, 7170–7192. [Google Scholar] [CrossRef]

- Tang, J.Y.; Cao, Y.; Wang, X.; Yan, W.T.; Yao, S. A targeted extraction with solvent-free pressurized method based on analyte-like oxonium salts: An example for simultaneous determination of bamboo-leaf flavonoids by ultra-performance liquid chromatography/ultraviolet detection. J Chromatogr. A 2021, 1658, 462595. [Google Scholar] [CrossRef]

- Andrade, T.A.; Hamerski, F.; Fetzer, D.E.L.; Roda-Serrat, M.C.; Corazza, M.L.; Norddahl, B.; Errico, M. Ultrasound-assisted pressurized liquid extraction of anthocyanins from Aronia melanocarpa pomace. Sep. Purif. Technol. 2021, 276, 119290. [Google Scholar] [CrossRef]

- Phakoukaki, Y.V.; O’Shaughnessy, P.; Angeli, P. Intensified liquid-liquid extraction of biomolecules using ionic liquids in small channels. Sep. Purif. Technol. 2022, 282, 120063. [Google Scholar] [CrossRef]

- Li, P.P.; Li, M.H.; Yuan, Z.J.; Jiang, X.B.; Yue, D.M.; Ye, B.; Zhao, Z.J.; Jiang, J.W.; Fan, Q.; Zhou, Z.C.; et al. 3D printed integrated separator with hybrid micro-structures for high throughput and magnetic-free nucleic acid separation from organism samples. Sep. Purif. Technol. 2021, 271, 118881. [Google Scholar] [CrossRef]

- Ghosh, R.; Hale, G.; Durocher, Y.; Gatt, P. Dry-compression packing of hydroxyapatite nanoparticles within a flat cuboid chromatography device and its use for fast protein separation. J Chromatogr. A 2022, 1667, 462881. [Google Scholar] [CrossRef]

- Song, Y.M.; Yang, Y.L.; Lin, X.; Zhao, Q.Z.; Li, Z.J.; Ma, G.H.; Su, Z.G.; Zhang, S.P. On-line separation and quantification of virus antigens of different serotypes in multivalent vaccines by capillary zone electrophoresis: A case study for quality control of foot-and-mouth disease virus vaccines. J Chromatogr. A 2021, 1637, 461834. [Google Scholar] [CrossRef]

- Zhao, L.C.; Lv, X.R.; Cao, X.; Zhang, J.F.; Gu, X.K.; Zeng, H.Y.; Wang, L. Improved quantitative detection of VBNC Vibrio parahaemolyticus using immunomagnetic separation and PMAxx-qPCR. Food Control 2020, 110, 106962. [Google Scholar] [CrossRef]

- Aslam, H.; Shukrullah, S.; Naz, M.Y.; Fatima, H.; Hussain, H.; Ullah, S.; Assiri, M.A. Current and future perspectives of multifunctional magnetic nanoparticles based controlled drug delivery systems. J. Drug Deliv. Sci. Tec. 2022, 67, 102946. [Google Scholar] [CrossRef]

- Haghighi, A.H.; Khorasani, M.T.; Faghih, Z.; Farjadian, F. Effects of different quantities of antibody conjugated with magnetic nanoparticles on cell separation efficiency. Heliyon 2020, 6, 03677. [Google Scholar] [CrossRef]

- Lee, G.; Song, J.; Han, H.; Kwon, D.; Park, J.; Jeon, S.; Jeong, S.; Kim, S. Zwitterion-coated colloidal magnetic nanoparticle clusters for reduced nonspecific adsorption of biomolecules. Bioconjugate Chem. 2021, 32, 1052–1057. [Google Scholar] [CrossRef]

- Cai, Y.; Zhang, S.S.; Dong, C.; Yang, J.C.; Ma, T.; Zhang, H.; Cui, Y.L.; Hui, W.L. Lateral flow immunoassay based on gold magnetic nanoparticles for the protein quantitative detection: Prostate-specific antigen. Anal. Biochem. 2021, 627, 114265. [Google Scholar] [CrossRef]

- Wang, Y.K.; Wei, H.N.; Li, Z.W. Effect of magnetic field on the physical properties of water. Results Phys. 2018, 8, 262–267. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, Z.; Deng, Q.J. Effects of pulsed magnetic field on freezing kinetics and physical properties of water and cucumber tissue fluid. J. Food Eng. 2021, 288, 110149. [Google Scholar] [CrossRef]

- Feng, D.D.; Gao, J.M.; Zhang, Y.; Li, H.Y.; Du, Q.; Wu, S.H. Mass transfer in ammonia-based CO2 absorption in bubbling reactor under static magnetic field. Chem. Eng. J. 2018, 338, 450–456. [Google Scholar] [CrossRef]

- Guo, K.; Lv, Y.L.; He, L.M.; Luo, X.M.; Yang, D.H. Separation characteristics of water-in-oil emulsion under the coupling of electric field and magnetic field. Energ. Fuel. 2019, 33, 2565–2574. [Google Scholar] [CrossRef]

- Guo, K.; Lv, Y.L.; He, L.M.; Luo, X.M.; Zhao, J. Experimental study on the effect of spatial distribution and action order of electric field and magnetic field on oil-water separation. Chem. Eng. Process. 2019, 145, 107658. [Google Scholar] [CrossRef]

- Bahrpaima, K.; Bijanzadeh, A.R.; Behzadi, M. Effect of magnetic field on the liquid-liquid equilibria of (water + acetic acid + organic solvent) ternary systems. Phys. Chem. Res. 2017, 5, 125–134. [Google Scholar]

- Cai, H.B.; Huang, L.H.; Qin, L.Q.; Jiang, L.X.; Huang, X.S. Extraction of active components from camellia oleifera tea by magnetized small molecules group water. J. Guilin Norm. Coll 2020, 34, 137–139. [Google Scholar]

- Wu, Z.Y.; Chen, P.P.; Zhang, W.C.; Chen, T.Y.; Hui, A.L.; Xu, K. A Method for Ultrasonic Synergistic Magnetic Field Enhanced Solvent Extraction and Liquid-Liquid Extraction and Separation of Scopolamine. CN Patent 201810722377.6, 25 December 2018. [Google Scholar]

- Zaguła, G.; Bajcar, M.; Saletnik, B.; Czernicka, M.; Puchalski, C.; Kapusta, I.; Oszmiański, J. Comparison of the effectiveness of water-based extraction of substances from dry tea leaves with the use of magnetic field assisted extraction techniques. Molecules 2017, 22, 1656. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, W.L.; Fu, L.D.; Liu, D.; Zhu, H.T.; Wang, X.J.; Bi, Y.P. Extraction of peony seed oil by magnetization technology. Coal Chem. Ind. 2015, 38, 33–34. [Google Scholar]

- Malek, F.H.; Alaridhee, T.; Hussein, A.A.; Al-Saeed, A.H.M. Effects of static magnetic field on dye extracted from Anchusa-ltalica through optimization the optoelectronic properties. Int. J. Nonlinear Anal. 2021, 12, 946–960. [Google Scholar]

- Upadhyaya, L.; Semsarilar, M.; Quemener, D.; Fernandez-Pacheco, R.; Martinez, G.; Coelhoso, I.M.; Nunes, S.P.; Crespo, J.G.; Mallada, R.; Portugal, C.A.M. Block copolymer-based magnetic mixed matrix membranes-Effect of magnetic field on protein permeation and membrane fouling. Membranes 2021, 11, 105. [Google Scholar] [CrossRef]

- Zhang, T.H.; Li, C.F.; Zhang, J.; Yu, Y.L. A process for enzymatic extraction of soybean oligosaccharide. CN Patent 202111019573.5, 26 November 2021. [Google Scholar]

- Wang, Z.Q. The mechanism of action of magnetic fields on molecules of liquid. J. China Univ. Pet. (Nat. Sci. Ed.) 1998, 04, 119–122. [Google Scholar]

- Du, J.; Feng, R.Y.; Zhao, J.; Yang, J.D. Research advance of the effect of magnetic field on physical and chemical properties of substances and their separation. Hebei Chem. Eng. Ind. 2006, 11, 21–24. [Google Scholar]

- Pareja-Rivera, C.; Cuellar-Cruz, M.; Esturau-Escofet, N.; Demitri, N.; Polentarutti, M.; Stojanoff, V.; Moreno, A. Recent advances in the understanding of the influence of electric and magnetic fields on protein crystal growth. Cryst. Growth Des. 2017, 17, 135–145. [Google Scholar] [CrossRef]

- Ryu, S.Y.; Oh, I.H.; Cho, S.J.; Kim, S.A.; Song, H.K. Enhancing protein crystallization under a magnetic field. Crystals 2020, 10, 821. [Google Scholar] [CrossRef]

- Numoto, N.; Shimizu, K.I.; Matsumoto, K.; Miki, K.; Kita, A. Observation of the orientation of membrane protein crystals grown in high magnetic force fields. J. Cryst. Growth 2013, 367, 53–56. [Google Scholar] [CrossRef] [Green Version]

- Nakamura, A.; Ohtsuka, J.; Miyazono, K.I.; Yamamura, A.; Kubota, K.; Hirose, R.; Hirota, N.; Ataka, M.; Sawano, Y.; Tanokura, M. Improvement in quality of protein crystals grown in a high magnetic field gradient. Cryst. Growth Des. 2012, 12, 1141–1150. [Google Scholar] [CrossRef]

- Wu, Z.Q.; Liu, Y.M.; Liu, C.; Chen, J.J.; Chen, L.L.; Zhang, T.D.; Zhou, R.B.; Yang, C.Q.; Shang, P.; Yin, D.C. A first attempt investigation on crystallization screening and crystal quality of lysozyme under different simulated gravities in a large-gradient magnetic field. CrystEngComm 2019, 26, 4001–4010. [Google Scholar] [CrossRef]

- Rodríguez-Romero, A.; Esturau-Escofet, N.; Pareja-Rivera, C.; Moreno, A. Crystal growth of high-quality protein crystals under the presence of an alternant electric field in pulse-wave mode, and a strong magnetic field with radio frequency pulses characterized by x-ray diffraction. Crystals 2017, 7, 179. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.H.; Hou, B.H.; Liu, C.H.; Ji, X.T.; Huang, Y.H.; Sui, J.C.; Liu, D.; Wang, N.; Hao, H.X. Mechanistic study on the effect of magnetic field on the crystallization of organic small molecules. Ind. Eng. Chem. Res. 2021, 60, 15741–15751. [Google Scholar] [CrossRef]

- Yuan, C.X.; Xu, Y.; Jin, R.S. Effect of a magnetic field on the crystallization time and quality of phytosterols. Sep. Eng. 2019, 52, 401–405. [Google Scholar]

- Cao, H.L.; Sun, L.H.; Li, J.; Tang, L.; Lu, H.M.; Guo, Y.Z.; He, J.; Liu, Y.M.; Xie, X.Z.; Shen, H.F.; et al. A quality comparison of protein crystals grown under containerless conditions generated by diamagnetic levitation. Acta Crystallogr. D 2013, 69, 1901–1910. [Google Scholar] [CrossRef]

- Hayashi, S.; Hamaguchi, H.O. Discovery of a magnetic ionic liquid [Bmim]FeCl4. Chem. Lett. 2004, 33, 1590–1591. [Google Scholar] [CrossRef]

- Singh, K.P.; Gupta, S.; Basant, N. Predicting toxicities of ionic liquids in multiple test species—An aid in designing green chemicals. RSC Adv. 2014, 4, 64443. [Google Scholar] [CrossRef]

- Peng, D.L.; Picchioni, F. Prediction of toxicity of Ionic Liquids based on GC-COSMO method. J. Hazard. Mater. 2020, 398, 122964. [Google Scholar] [CrossRef]

- Feng, X.T.; Zhang, W.; Zhang, T.H.; Yao, S. Systematic investigation for extraction and separation of polyphenols in tea leaves by magnetic ionic liquids. J. Sci. Food Agr. 2018, 98, 4550–4560. [Google Scholar] [CrossRef]

- Nie, L.R.; Yao, S.; Dong, B.; Li, X.L.; Song, H. Synthesis, characterization and physical properties of novel cholinium-based organic magnetic ionic liquids. J. Mol. Liq. 2017, 240, 152–161. [Google Scholar] [CrossRef]

- Yao, T.; Zang, H.M.; Yao, S.; Dai, X.Z.; Song, H. Measurement and correlation of phase equilibria in aqueous two-phase systems containing functionalized magnetic ionic liquids and potassium phosphate at different temperatures. J. Mol. Liq. 2018, 263, 72–80. [Google Scholar] [CrossRef]

- Yoshida, Y.; Tanaka, H.; Saito, G. Organic paramagnetic ionic liquids based on anion containing 2,2,6,6-tetramethyl-1-piperidinyloxyl radical moiety. Chem. Lett. 2007, 36, 1096–1097. [Google Scholar] [CrossRef]

- Xu, W.; Dai, Q.Z.; Wang, Y.Z.; Hu, X.J.; Xu, P.L.; Ni, R.; Meng, J.J. Creating magnetic ionic liquid-molecularly imprinted polymers for selective extraction of lysozyme. Rsc Adv. 2018, 8, 21850–21856. [Google Scholar] [CrossRef] [Green Version]

- Nie, L.R.; Song, H.; Yohannes, A.; Liang, S.W.; Yao, S. Extraction in cholinium-based magnetic ionic liquid aqueous two-phase system for the determination of berberine hydrochloride in Rhizoma coptidis. RSC Adv. 2018, 8, 25201–25209. [Google Scholar] [CrossRef] [Green Version]

- Crespo, P.; Litran, R.; Rojas, T.C.; Multigner, M.; De La Fuente, J.M.; Sanchez-Lopez, J.C.; Garcia, M.A.; Hernando, A.; Penades, S.; Fernandez, A. Permanent magnetism, magnetic anisotropy, and hysteresis of thiol-capped gold nanoparticles. Phys. Rev. Lett. 2004, 93, 087204. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Miura, T.; Teranishi, T.; Suzuki, M.; Kawamura, N.; Miyagawa, H.; Nakamura, T.; Kobayashi, K.; Hori, H. X-ray magnetic circular dichroism study of gold nanoparticles protected by polymer. J. Magn. Magn. Mater. 2004, 272, 1183–1184. [Google Scholar] [CrossRef]

- Li, H.Q.; Wang, Y.Z.; He, X.Y.; Chen, J.; Xu, F.T.; Liu, Z.W.; Zhou, Y.G. A green deep eutectic solvent modified magnetic titanium dioxide nanoparticles for the solid-phase extraction of chymotrypsin. Talanta 2021, 230, 122341. [Google Scholar] [CrossRef]

- Zhang, B.W.; Wang, Y.F.; Zhang, J.; Qiao, S.Y.; Fan, Z.Z.; Wan, J.Q.; Chen, K.Z. Well-defined 3-Aminopropyltriethoxysilane functionalized magnetite nanoparticles and their adsorption performance for partially hydrolyzed polyacrylamide from aqueous solution. Colloid. Surface. A 2020, 586, 124288. [Google Scholar] [CrossRef]

- Patil, S.S.; Rathod, V.K. Combined effect of enzyme co-immobilized magnetic nanoparticles (MNPs) and ultrasound for effective extraction and purification of curcuminoids from Curcuma longa. Ind. Crop. Prod. 2022, 177, 114385. [Google Scholar] [CrossRef]

- Zheng, M.; Huang, Z.; Ji, H.D.; Qiu, F.G.; Zhao, D.Y.; Bredar, A.R.C.; Farnum, B.H. Simultaneous control of soil erosion and arsenic leaching at disturbed land using polyacrylamide modified magnetite nanoparticles. Sci. Total Environ. 2020, 702, 134977. [Google Scholar] [CrossRef] [PubMed]

- Jiang, P.F.; Zhang, Y.X.; Zhu, C.N.; Zhang, W.J.; Mao, Z.W.; Gao, C.Y. Fe3O4/BSA particles induce osteogenic differentiation of mesenchymal stem cells under static magnetic field. Acta Biomater. 2016, 46, 141–150. [Google Scholar] [CrossRef]

- Chen, Z.Q.; Wang, X.M.; Chen, Y.; Xue, Z.H.; Guo, Q.W.; Ma, Q.Q.; Chen, H.X. Preparation and characterization of a novel nanocomposite with double enzymes immobilized on magnetic Fe3O4-chitosan-sodium tripolyphosphate. Colloids Surf. B 2018, 169, 280–288. [Google Scholar] [CrossRef]

- Wei, X.X.; Wang, Y.Z.; Chen, J.; Xu, P.L.; Zhou, Y.G. Preparation of ionic liquid modified magnetic metal-organic frameworks composites for the solid-phase extraction of [alpha]-chymotrypsin. Talanta 2018, 182, 484. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, J.S.; Liu, Z.K.; Xu, H.Y.; Zheng, Y.H.; Zhong, J.S.; Yang, Q.L.; Tian, H.F.; Shi, Z.Q.; Yao, J.L.; et al. Facile fabrication of Fe3O4 nanoparticle/carbon nanofiber aerogel from Fe-ion cross-linked cellulose nanofibrils as anode for lithium-ion battery with superhigh capacity. J. Alloy. Compd. 2020, 829, 154541. [Google Scholar] [CrossRef]

- Ognjanović, M.; Stanković, D.M.; Jaćimović, Ž.K.; Kosović-Perutović, M.; Dojčinović, B.; Antić, B. The effect of surface-modifier of magnetite nanoparticles on electrochemical detection of dopamine and heating efficiency in magnetic hyperthermia. J. Alloy. Compd. 2021, 884, 161075. [Google Scholar] [CrossRef]

- Nasrollahzadeh, M.; Issaabadi, Z. Reduction of Cr(VI) and 4-nitrophenol in aqueous media using N-heterocyclic palladium complex immobilized on the nano Fe3O4@SiO2 as a magnetically recyclable catalyst. Sep. Purif. Technol. 2019, 211, 809–815. [Google Scholar] [CrossRef]

- Ding, J.; Cheng, L.G. Core-shell Fe3O4@SiO2@PANI composite: Preparation, characterization, and applications in microwave absorption. J. Alloy. Compd. 2021, 881, 160574. [Google Scholar] [CrossRef]

- Stöber, W.; Fink, A.; Bohn, E. Controlled growth of monodisperse silica spheres in the micron size range. J. Colloid Interf. Sci. 1968, 26, 62–69. [Google Scholar] [CrossRef]

- Da Silva, T.L.; Da Silva, A.M.H.; Assaf, J.M. Preparation of core-shell Pt@Fe3O4@SiO2 nanostructures by oxidation of core-shell FePt@SiO2 nanoflowers and their performance in preferential CO oxidation reaction. Mater. Res. Express 2019, 6, 015042. [Google Scholar] [CrossRef]

- Lee, J.S.; Hong, S.K.; Hur, N.J.; Seo, W.S.; Hwang, H.J. Fabrication of spherical silica aerogel/magnetite nanocomposite particle. Mater. Lett. 2013, 112, 153–157. [Google Scholar]

- Xu, H.; Tong, N.; Cui, L.; Liu, Y.; Gu, H. Preparation of hydrophilic magnetic nanospheres with high saturation magnetization. J. Magn. Magn. Mater. 2017, 311, 125–130. [Google Scholar] [CrossRef]

- Liu, X.D.; Feng, J.N.; Li, Y. Preparation of carbon-functionalized magnetic graphene/mesoporous silica composites for selec-tive extraction of miglitol and voglibose in rat plasma. Talanta 2018, 182, 405–413. [Google Scholar] [CrossRef]

- Nistler, A.; Hartmann, C.; Rümenapp, C.; Opel, M.; Gleich, B.; Ivleva, N.P.; Niessner, R.; Seidel, M. Production and characterization of long-term stable superparamagnetic iron oxide-shell silica-core nanocomposites. J. Magn. Magn. Mater. 2017, 442, 497–503. [Google Scholar] [CrossRef]

- Gang, Q.; Akhtar, M.N.; Boudaghi, R. Development of high-efficient double layer microwave absorber based on Fe3O4/carbon fiber and Fe3O4/Rgo. J. Magn. Magn. Mater. 2021, 537, 168181. [Google Scholar] [CrossRef]

- Wu, Q.J.; Mo, Z.L.; Guo, R.B.; Wang, B.; Li, L.; Liu, H.D.; Qi, L. Preparation and properties of C@Fe3O4 magnetic micro porous spheres. J. Synth. Cryst. 2016, 45, 2655–2660. [Google Scholar]

- Nikolića, V.N.; Tadića, M.; Jovanovićbc, S.; Pasojevića, V.S. Tracking of the electronic re-ordering in Fe3O4/OA nanoparticles using magnetometry. Ceram. Int. 2019, 45, 17429–17437. [Google Scholar] [CrossRef]

- Yue, T.T.; Huang, H.T.; Chang, Y.; Jia, J.C.; Jia, M.L. Controlled assembly of nitrogen-doped iron carbide nanoparticles on reduced graphene oxide for electrochemical reduction of carbon dioxide to syngas. J. Colloid. Interf. Sci. 2021, 601, 877–885. [Google Scholar] [CrossRef]

- Lobato, N.C.C.; Ferreira, A.D.; Mansur, M.B. Evaluation of magnetic nanoparticles coated by oleic acid applied to solvent extraction processes. Sep. Purif. Technol. 2016, 168, 93–100. [Google Scholar] [CrossRef]

- Yuan, Z.; Li, X.L.; Gao, Y.W.; Yan, F. Preparation and characterization of hydrophobic superparamagnetic magnetite nanoparticles. Guangdong Chem. Ind. 2015, 42, 144–145. [Google Scholar]

- Zhang, L.J.; Liu, Y.J. Preparation and characterization of the epoxy silane modified magnetic nanoparticles. J. Suzhou Univ. Sci. Tech. (Nat. Sci.) 2013, 30, 45–49. [Google Scholar]

- Klein, S.; Harreiβ, C.; Menter, C.; Hümmer, J.; Distel, L.V.R.; Meyer, K.; Hock, R.; Kryschi, C. NOBF4-functionalized Au–Fe3O4 nanoheterodimers for radiation therapy: Synergy effect due to simultaneous reactive oxygen and nitrogen species formation. ACS Appl. Mater. Interfaces 2018, 10, 17071–17080. [Google Scholar] [CrossRef]

- Yachi, T.; Matsubara, M.; Shen, C.; Asami, S.; Milbrandt, N.B.; Ju, M.; Wickramasinghe, S.; Samia, A.C.S.; Muramatsu, A.; Kanie, K. Water-dispersible Fe3O4 nanoparticles modified with controlled numbers of carboxyl moieties for magnetic induction heating. ACS Appl. Nano Mater. 2021, 4, 7395–7403. [Google Scholar] [CrossRef]

- Dong, A.G.; Ye, X.C.; Chen, J.; Kang, Y.J.; Gordon, T.; Kikkawa, J.M.; Murray, C.B. A generalized ligand-exchange strategy enabling sequential surface functionalization of colloidal nanocrystals. J. Am. Chem. Soc. 2011, 133, 998–1006. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, Z.; Peng, Y.Z.; Feng, L.; Li, X.H.; Zhao, C.L.; Sarfaraz, K. Novel cationic polymer modified magnetic chitosan beads for efficient adsorption of heavy metals and dyes over a wide pH range. Int. J. Biol. Macromol. 2020, 156, 289–301. [Google Scholar] [CrossRef]

- Ning, J.H.; Chen, D.E.; Liu, Y.L.; Huang, S.E.; Wang, F.X.; Wei, R.; Hu, Q.C.; Wei, J.Q.; Sun, C. Efficient adsorption removal and adsorption mechanism of basic fuchsin by recyclable Fe3O4@CD magnetic microspheres. J. Cent. South Univ. 2021, 28, 3666–3680. [Google Scholar] [CrossRef]

- Micurova, A.; Kluknavsky, M.; Liskova, S.; Balis, P.; Skratek, M.; Okruhlicova, L.; Manka, J.; Bernatova, I. Differences in distribution and biological effects of Fe3O4@PEG nanoparticles in normotensive and hypertensive rats-focus on vascular function and liver. Biomedicines 2021, 9, 1855. [Google Scholar] [CrossRef]

- Ezzat, A.O.; Tawfeek, A.M.; Rajabathar, J.R.; Al-Lohedan, H.A. Synthesis of new hybrid structured magnetite crosslinked poly ionic liquid for efficient removal of coomassie brilliant blue R-250 dye in aqueous medium. Molecules 2022, 27, 441. [Google Scholar] [CrossRef]

- Bide, Y.; Shokrollahzadeh, S. Toward tailoring of a new draw solute for forward osmosis process: Branched poly (deep eutectic solvent)-decorated magnetic nanoparticles. J. Mol. Liq. 2020, 320, 114409. [Google Scholar] [CrossRef]

- Cryz, H.; Gabon, M.I.; Salehin, S.; Seviour, T.; Laycock, B.; Pikaar, I. Magnetic poly(acrylic acid)-based hydrogels for rapid ammonium sorption and efficient sorbent separation from sewage. Environ. Sci. Ecotechnol. 2021, 6, 100097. [Google Scholar] [CrossRef] [PubMed]

- Shabzendedar, S.; Modarresi-Alam, A.R.; Noroozifar, M.; Kerman, K. Core-shell nanocomposite of superparamagnetic Fe3O4 nanoparticles with poly(m-aminobenzenesulfonic acid) for polymer solar cells. Org. Electron. 2020, 77, 105462. [Google Scholar] [CrossRef]

- Yao, J.; Gao, F.; Liang, X.Q.; Li, Y.X.; Mi, Y.F.; Qi, Q.; Yao, J.; Cao, Z.H. Efficient preparation of carboxyl-functionalized magnetic polymer/Fe3O4 nanocomposite particles in one-pot miniemulsion systems. Colloid. Surface. A 2019, 570, 449–461. [Google Scholar] [CrossRef]

- Resende, G.; Gutra, G.V.S.; Neta, M.S.B.; Araujo, O.A.; Chaves, S.B.; Machado, F. Well defined poly(methyl methacrylate)-Fe3O4/poly(vinyl pivalate) core-shell superparamagnetic nanoparticles: Design and evaluation of in vitro cytotoxicity activity against cancer cells. Polymers 2020, 12, 2868. [Google Scholar] [CrossRef]

- Wu, J.M.; Cheng, X.; Li, Y.L.; Yang, G.S. Constructing biodegradable nanochitin-contained chitosan hydrogel beads for fast and efficient removal of Cu(II) from aqueous solution. Carbohyd. Polym. 2019, 211, 152–160. [Google Scholar] [CrossRef]

- Chen, P.F.; Song, H.; Zhou, L.; Chen, J.; Liu, J.; Yao, S. Magnetic solid-phase extraction based on ferro ferric oxide nanoparticles doubly coated with chitosan and -cyclodextrin in layer-by-layer mode for the separation of ibuprofen. RSC Adv. 2016, 6, 56240–56248. [Google Scholar] [CrossRef]

- Rashid, Z.; Shokri, F.; Abbasi, A.; Khoobi, M.; Zarnani, A.H. Surface modification and bioconjugation of anti-CD4 monoclonal antibody to magnetic nanoparticles as a highly efficient affinity adsorbent for positive selection of peripheral blood T CD4+ lymphocytes. Int. J. Biol. Macromol. 2020, 161, 729–737. [Google Scholar] [CrossRef]

- Fayazi, R.; Habibi-Rezaei, M.; Heiat, M.; Javadi-Zarnaghi, F.; Taheri, R.A. Glycated albumin precipitation using aptamer conjugated magnetic nanoparticles. Sci. Rep. 2020, 10, 10716. [Google Scholar] [CrossRef]

- Ilyas, S.; Ullah, N.K.; Ilyas, M.; Wennhold, K.; Iqbal, M.; Schlößer, H.A.; Hussain, M.S.; Mathur, S. Mediating the fate of cancer cell uptake: Dual-targeted magnetic nanovectors with biotin and folate surface ligands. ACS Biomater. Sci. Eng. 2020, 6, 6138–6147. [Google Scholar] [CrossRef]

- Sanli, S.; Ghorbani-Zamani, F.; Moulahoum, H.; Gumus, Z.P.; Coskunol, H.; Odaci Demirkol, D.; Timur, S. Application of biofunctionalized magnetic nanoparticles based-sensing in abused drugs diagnostics. Anal. Chem. 2020, 92, 1033–1040. [Google Scholar] [CrossRef]

- Zhu, X.L.; Lu, N.; Zhou, Y.; Xuan, S.Y.; Zhang, J.J.; Giampieri, F.; Zhang, Y.P.; Yang, F.F.; Yu, R.S.; Battino, M.; et al. Targeting pancreatic cancer cells with peptide-functionalized polymeric magnetic nanoparticles. Int. J. Mol. Sci. 2019, 20, 2988. [Google Scholar] [CrossRef] [PubMed]

- Kecili, R.; Ghorbani-Bidkorbeh, F.; Dolak, I.; Canpolat, G.; Karabork, M.; Hussain, C.M. Functionalized magnetic nanoparticles as powerful sorbents and stationary phases for the extraction and chromatographic applications. TrAC-Trend. Anal. Chem. 2021, 143, 116380. [Google Scholar] [CrossRef]

- Yin, S.J.; Zhao, J.; Yang, F.Q. Recent applications of magnetic solid phase extraction in sample preparation for phytochemical analysis. J. Pharmaceut. Biomed. 2021, 192, 113675. [Google Scholar] [CrossRef]

- Yuan, H.; Wan, H.; Hu, Y.K.; Ayeni, E.A.; Chang, Q.; Ma, C.; Liao, X. Fishing of alpha-glucosidase’s ligands from aloe vera by alpha-glucosidase functionalized magnetic nanoparticles. Molecules 2021, 26, 5840. [Google Scholar] [CrossRef]

- Cao, Y.H.; Zhao, C.X.; Tan, Q.T.; Gao, M.K.; Chen, G.; Zhai, R.Q.; Huang, X.D.; Xu, X.M.; Liu, G.Y.; Wang, J.; et al. Ternary magnetic Fe3O4@C3N4@covalent organic framework for facile extraction and determination of organophosphorus pesticides in fruit. Microchem. J. 2022, 174, 107103. [Google Scholar]

- Yamini, Y.; Tahmasebi, E.; Ranjbar, L. Magnetic nanoparticle-based solid-phase extraction of vitamin B12 from pharmaceutical formulations. Biol. Trace Elem. Res. 2012, 147, 378–385. [Google Scholar] [CrossRef]

- Wu, L.X.; Yu, L.; Ding, X.X.; Li, P.W.; Dai, X.H.; Chen, X.M.; Zhou, H.Y.; Bai, Y.Z.; Ding, J. Magnetic solid-phase extraction based on graphene oxide for the determination of lignans in sesame oil. Food Chem. 2017, 217, 320–325. [Google Scholar] [CrossRef]

- Lang, H.H.; Yang, R.N.; Dou, X.J.; Wang, D.D.; Zhang, L.X.; Li, J.; Li, P.W. Simultaneous determination of 19 phenolic compounds in oilseeds using magnetic solid phase extraction and LC-MS/MS. LWT 2019, 107, 221–227. [Google Scholar] [CrossRef]

- Shu, H.; Chen, G.N.; Wang, L.; Cui, X.; Wang, Q.; Li, W.; Chang, C.; Guo, Q.; Luo, Z.M.; Fu, Q. Adenine-coated magnetic multiwalled carbon nanotubes for the selective extraction of aristolochic acids based on multiple interactions. J. Chromatogr. A 2020, 1627, 461382. [Google Scholar] [CrossRef]

- Majidi, S.M.; Hadjmohammadi, M.R. Development of magnetic dispersive micro-solid phase extraction based on magnetic agarose nanoparticles and deep eutectic solvents for the isolation and pre-concentration of three flavonoids in edible natural samples. Talanta 2021, 222, 121649. [Google Scholar] [CrossRef]

- Shi, X.R.; Chen, X.L.; Hao, Y.L.; Li, L.; Xu, H.J.; Wang, M.M. Magnetic metal-organic frameworks for fast and efficient solid-phase extraction of six Sudan dyes in tomato sauce. J. Chromatogr. B 2018, 1086, 146–152. [Google Scholar] [CrossRef]

- Zhu, J.Q.; Cheng, H.; Zhou, M.L.; Li, S.Y.; Tang, T.F.; Feng, J. Determining three isoflavones from Pueraria lobata using magnetic ZIF-8 nanoparticle-based solid-phase extraction and pressurized capillary electrochromatography. Microchem. J. 2022, 212, 114592. [Google Scholar] [CrossRef]

- Liu, Q.L.; Xu, Q.; Sun, W. Facile preparation of core-shell magnetic organic covalent framework via self-polymerization of two-in-one strategy as a magnetic solid-phase extraction adsorbent for determination of Rhodamine B in food samples. J. Chromatogr. A 2021, 1657, 462566. [Google Scholar] [CrossRef]

- Wei, W.; Han, Q.; Tian, S.; Wang, Y.P.; Zhang, H.Y.; Wang, H.B.; Liang, Q.L. Effective separation of α-asarone and β-asarone in TCM by covalent organic framework modified magnetic solid phase extraction. Microchem. J. 2022, 175, 107015. [Google Scholar] [CrossRef]

- Yu, Q.Q.; Gan, H.X.; Feng, N.; Li, Y.F.; Han, Y.P. Hydroxytyrosol magnetic molecularly imprinted polymers as the sorbent for solid-phase extraction for selective recognition of hydroxytyrosol from Chinese olive leaves. Mater. Today Commun. 2021, 29, 102992. [Google Scholar] [CrossRef]

- Sadegh, N.; Asfaram, A.; Javadian, H.; Haddadi, H.; Sharifpour, E. Ultrasound-assisted solid phase microextraction-HPLC method based on Fe3O4@SiO2-NH2-molecularly imprinted polymer magnetic nano-sorbent for rapid and efficient extraction of harmaline from Peganum harmala extract. J. Chromatogr. B 2021, 1171, 122640. [Google Scholar] [CrossRef]

- Wang, D.D.; Gao, D.; Xu, W.J.; Li, F.; Yin, M.N.; Fu, Q.F.; Xia, Z.N. Magnetic molecularly imprinted polymer for the selective extraction of hesperetin from the dried pericarp of Citrus reticulata Blanco. Talanta 2018, 184, 307–315. [Google Scholar] [CrossRef]

- Tang, W.W.; Zeng, G.M.; Gong, J.L.; Liu, Y.; Wang, X.Y.; Liu, Y.Y.; Liu, Z.F.; Chen, L.; Zhang, X.R.; Tu, D.Z. Simultaneous adsorption of atrazine and Cu(II) from wastewater by magnetic multi-walled carbon nanotube. Chem. Eng. J. 2012, 211, 470–478. [Google Scholar] [CrossRef]

- Rahimi, A.; Zanjanchi, M.A.; Bakhtiari, S.; Dehsaraei, M. Selective determination of caffeine in foods with 3D-graphene based ultrasound-assisted magnetic solid phase extraction. Food Chem. 2018, 262, 206–214. [Google Scholar] [CrossRef]

- Xiao, D.L.; Yuan, D.H.; He, H.; Pham-Huy, C.; Dai, H.; Wang, C.X.; Zhang, C. Mixed hemimicelle solid-phase extraction based on magnetic carbon nanotubes and ionic liquids for the determination of flavonoids. Carbon 2014, 72, 274–286. [Google Scholar] [CrossRef]

- Su, X.; Li, X.; Li, J.; Liu, M.; Lei, F.; Tan, X.; Li, P.; Luo, W. Synthesis and characterization of core–shell magnetic molecularly imprinted polymers for solid-phase extraction and determination of Rhodamine B in food. Food Chem. 2015, 171, 292–297. [Google Scholar] [CrossRef]

- Ma, R.T.; Shi, Y.P. Magnetic molecularly imprinted polymer for the selective extraction of quercetagetin from Calendula officinalis extract. Talanta 2015, 134, 650–656. [Google Scholar] [CrossRef]

- Xiao, Y.R.; Ying, X.; Jian, L.; Li, S.D.; Xun, L. Selective extraction of flavonoids from Ginkgo biloba leaves using human serum albumin functionalized magnetic nanoparticles. Chin. Chem. Lett. 2013, 24, 1099–1102. [Google Scholar]

- Qing, L.S.; Shan, X.Q.; Xu, X.M.; Xue, Y.; Deng, W.L.; Li, B.G.; Wang, X.L.; Liao, X. Rapid probe and isolation of bioactive compounds from Dioscorea panthaica using human serum albumin functionalized magnetic nano-particles (HAS-MNPs)-based ligand fishing coupled with electrospray ionization mass spectrometr. Rapid Commun. Mass Sp. 2010, 24, 3335–3339. [Google Scholar] [CrossRef] [PubMed]

- Qinga, L.S.; Xue, Y.; Zheng, Y.; Xiong, J.; Liao, X.; Ding, L.S.; Li, B.G.; Liu, Y.M. Ligand fishing from Dioscorea nipponica extract using human serum albumin functionalized magnetic nanoparticles. J. Chromatogr. A 2010, 1217, 4663–4668. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xiong, J.; Ren, X.; Ding, L.; Xie, J.; Liao, X. Ligand fishing from rheum palmatum extract using human serum albumin functionalized magnetic nanoparticles. Chin. J. Appli. Environ. Biol. 2013, 19, 164–167. [Google Scholar] [CrossRef]

- Shen, Y.P.; Wang, M.; Zhou, J.W.; Chen, Y.F.; Wu, M.R.; Yang, Z.Z.; Yang, C.Y.; Xia, G.H.; Tam, J.P.; Zhou, C.S.; et al. Construction of Fe3O4@α-glucosidase magnetic nanoparticles for ligand fishing of α-glucosidase inhibitors from a natural tonic Epimedii Folium. Int. J. Biol. Macromol. 2020, 165, 1361–1372. [Google Scholar] [CrossRef]

- Zhang, F.; Li, S.H.; Liu, C.; Fang, K.; Jiang, Y.M.; Zhang, J.Y.; Lan, J.; Zhu, L.; Pang, H.Q.; Wang, G. Rapid screening for acetylcholinesterase inhibitors in Selaginella doederleinii Hieron by using functionalized magnetic Fe3O4 nanoparticles. Talanta 2022, 243, 123284. [Google Scholar] [CrossRef]

- Jiang, X.L.; Yuan, Y.C.; Chen, L.B.; Liu, Y.M.; Xiao, M.W.; Hu, Y.D.; Chun, Z.; Liao, X. Monoamine oxidase B immobilized on magnetic nanoparticles for screening of the enzyme’s inhibitors from herbal extracts. Microchem. J. 2019, 146, 1181–1189. [Google Scholar] [CrossRef]

- Guo, H.; Chen, Y.F.; Song, N.; Yang, X.Y.; Yao, S.; Qian, J.Q. Screening of lipase inhibitors from bamboo leaves based on the magnetic ligand fishing combined with HPLC/MS. Microchem. J. 2020, 153, 104497. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Nie, M.K.; Shi, S.Y.; You, Q.P.; Guo, J.F.; Liu, L.L. Integration of magnetic solid phase fishing and off-line two-dimensional high-performance liquid chromatography–diode array detector–mass spectrometry for screening and identification of human serum albumin binders from Radix Astragali. Food Chem. 2014, 146, 56–64. [Google Scholar] [CrossRef]

- Liu, L.L.; Ma, Y.J.; Chen, X.Q.; Xiong, X.; Shi, S.Y. Screening and identification of BSA bound ligands from Puerariae lobata flower by BSA functionalized Fe3O4 magnetic nanoparticles coupled with HPLC–MS/MS. J. Chromatogr. B 2012, 887–888, 55–60. [Google Scholar] [CrossRef]

- Chen, M.; Liu, L.L.; Chen, X.Q. Rapid screening and analysis of alcohol dehydrogenase binders from Glycyrrhiza uralensis root extract using functionalized magnetic nanoparticles coupled with HPLC−MS/MS. Can. J. Chem. 2013, 91, 1147–1154. [Google Scholar] [CrossRef]

- Zhao, Y.M.; Wang, L.H.; Luo, S.F.; Wang, Q.Q.; Moaddel, R.; Zhang, T.T.; Jiang, Z.J. Magnetic beads-based neuraminidase enzyme microreactor as a drug discovery tool for screening inhibitors from compound libraries and fishing ligands from natural products. J. Chromatogr. A 2018, 1568, 123–130. [Google Scholar] [CrossRef] [PubMed]

- Megías, C.; Pedroche, J.; Del Mar Yust, M.; Alaiz, M.; Girón-Calle, J.; Millán, F.; Vioque, J. Immobilization of angiotensin-converting enzyme on glyoxyl-agarose. J. Agr. Food Chem. 2006, 54, 4641–4645. [Google Scholar] [CrossRef]

- Yuan, L.; Xu, P.L.; Zeng, Q.; Liu, Y.M.; Ding, L.S.; Liao, X. Preparation of ds-DNA functionalized magnetic nanobaits for screening of bioactive compounds from medicinal plant. Mater. Sci. Eng. C 2015, 56, 401–408. [Google Scholar] [CrossRef]

- Rastbood, S.; Hadjmohammadi, M.R.; Majidi, S.M. Development of a magnetic dispersive micro-solid-phase extraction method based on a deep eutectic solvent as a carrier for the rapid determination of meloxicam in biological samples. Anal. Methods 2020, 12, 2331–2337. [Google Scholar] [CrossRef]

- Kabeer, M.; Hakami, Y.; Asif, M.; Alrefaei, T.; Sajid, M. Modern solutions in magnetic analytical extractions of metals: A review. TrAC Trends Anal. Chem. 2020, 130, 115987. [Google Scholar] [CrossRef]

- Majidi, S.M.; Hadjmohammadi, M.R. Alcohol-based deep eutectic solvent as a carrier of SiO2@Fe3O4 for the development of magnetic dispersive micro-solid-phase extraction method: Application for the preconcentration and determination of morin in apple and grape juices, diluted and acidic extract of dried onion and green tea infusion samples. J. Sep. Sci. 2019, 42, 2842–2850. [Google Scholar]

- Li, Q.; Wu, S.G.; Wang, C.Y.; Yi, Y.J.; Zhou, W.L.; Wang, H.Y.; Li, F.F.; Tan, Z.J. Ultrasonic-assisted extraction of sinomenine from Sinomenium acutum using magnetic ionic liquids coupled with further purification by reversed micellar extraction. Process Biochem. 2017, 58, 282–288. [Google Scholar] [CrossRef]

- Zhou, M.Q.; Gao, Y. Extraction of active substances from citrus peel under magnetic field. Feed Husb. 2009, 10, 47–49. [Google Scholar]

- Zhou, Y.; Zhang, Z.; Zhang, S.G.; Bi, Y.; Zhang, P.; Pang, C.; Hu, W.; Liu, Z.B.; Zhou, L.; Xia, X. Using orthogonal array design to optimize the extraction of wolfberry flavonoids by magnetic field treatment. Food Sci. 2012, 33, 98–101. [Google Scholar]

- Zhao, X.Y.; Fu, L.D.; Liu, D.; Zhu, H.T.; Wang, X.J.; Bi, Y.P. Assisted extraction of astaxanthin from Haematococcus pluvialis, journal of food processing and preservation. J. Food Process. Pres. 2016, 40, 463–472. [Google Scholar] [CrossRef]

- Xiao, K.J.; Chen, J.; Li, Q.L.; Li, L.; Ruan, T.E. Intensified extraction of pectin from orange peel in an electromagnetis fiebl of super-high frequency. Food Sci. 2001, 1, 50–52. [Google Scholar]

- Tarapatskyy, M.; Zaguła, G.; Bajcar, M.; Puchalski, C.; Saletnik, B. Field extraction techniques in preparing high-quality tea infusions. Appl. Sci. 2018, 8, 1876. [Google Scholar] [CrossRef] [Green Version]

- Chu, L.N.; Lu, J.J.; Ma, S.; Gao, J.Y.; Du, L.F. Extraction of stachyose from radix rahmanniae by magnetization technology. Mod. Food Sci. Technol. 2009, 10, 1186–1189. [Google Scholar]

- Jing, X.L.; Zhang, J.Q.; Zhang, L.P. Extraction process of oat bran protein by magnetized water. Cereal Feed Ind. 2014, 12, 32–35. [Google Scholar]

- Zhao, H.X.; Liu, K.; Zhao, Z.L.; He, G.Y.; Zhang, L.P. Optimization of extraction for oat bran polysaccharides using magnetized water by response surface methodology. Food Sci. 2015, 36, 37–43. [Google Scholar]

- Elkin, C.; Kapur, H.; Smith, T.; Humphries, D.; Pollard, M.; Hammon, N.; Hawkins, T. Magnetic bead purification of labeled DNA fragments for high-throughput capillary electrophoresis sequencing. Biotechniques 2002, 32, 1296, 1298–1300. [Google Scholar] [CrossRef]

- Saiyed, Z.M.; Ramchand, C.N.; Telang, S.D. Isolation of genomic DNA using magnetic nanoparticles as a solid-phase support. J. Phys. Condensed. Mat. 2008, 20, 204153. [Google Scholar] [CrossRef] [PubMed]

- Bandyopadhyay, A.; Chatterjee, S.; Sarkar, K. Rapid isolation of genomic DNA from E. coli XL1 Blue strain approaching bare magnetic nanoparticles. Curr. Sci. 2011, 101, 210–214. [Google Scholar]

- Li, P.P.; Li, M.H.; Zhang, F.; Wu, M.Y.; Jiang, X.B.; Ye, B.; Zhao, Z.J.; Yue, D.M.; Fan, Q.; Chen, H.X. High-efficient nucleic acid separation from animal tissue samples via surface modified magnetic nanoparticles. Sep. Purif. Technol. 2021, 262, 118348. [Google Scholar] [CrossRef]

- Aziz, N.; Novotny, J.; Brezinova, J.; Oborna, I. The effectiveness of different magnetic activated cell sorting columns and automated separation programs in depleting apoptotic sperm cells. Fertil. Steril. 2016, 106, 306. [Google Scholar] [CrossRef] [Green Version]

- Chen, W.; Zhang, W.W.; Shi, C.; Lian, X.; Yi, S.; Yang, T. Enrichment of epidermal stem cells of rats by Vario magnetic activated cell sorting system. Vitr. Cell. Dev. An. 2013, 49, 583–588. [Google Scholar] [CrossRef] [PubMed]

- Bie, Y.C.; Xu, Q.X.; Zhang, Z.Y. Isolation of dendritic cells from umbilical cord blood using magnetic activated cell sorting or adherence. Oncol. Lett. 2015, 10, 67–70. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jia, Z.; Liang, Y.; Xu, X.; Li, X.; Liu, Q.; Ou, Y.; Duan, L.; Zhu, W.; Lu, W.; Xiong, J.; et al. Isolation and characterization of human mesenchymal stem cells derived from synovial fluid by magnetic-activated cell sorting (MACS). Cell Biol. Int. 2018, 42, 262–271. [Google Scholar] [CrossRef]

- Jia, Z.; Liang, Y.; Li, X.; Xu, X.; Xiong, J.; Wang, D.; Duan, L. Magnetic-activated cell sorting strategies to isolate and purify synovial fluid-derived mesenchymal stem cells from a rabbit model. J. Vis. Exp. 2018, 138, 57466. [Google Scholar] [CrossRef]

- Zhang, Q.; Yin, T.; Xu, R.; Gao, W.; Zhao, H.; Shapter, J.G.; Wang, K.; Shen, Y.; Huang, P.; Gao, G.; et al. Large-scale immuno-magnetic cell sorting of T cells based on a self-designed high-throughput system for potential clinical application. Nanoscale 2017, 9, 13592–13599. [Google Scholar] [CrossRef] [Green Version]

- Naseri, M.G.; Saion, E.B.; Ahangar, H.A.; Hashim, M.; Shaari, A.H. Simple preparation and characterization of nickel ferrite nanocrystals by a thermal treatment method. Powder Technol. 2011, 212, 80–88. [Google Scholar] [CrossRef]

- Bahrami, A.; Hejazi, P. Electrostatic immobilization of pectinase on negatively charged AOT-Fe3O4 nanoparticles. J. Mol. Catal. B Enzym. 2013, 93, 1–7. [Google Scholar] [CrossRef]

- Saravanakumar, T.; Palvannan, T.; Kim, D.H.; Park, S.M. Optimized immobilization of peracetic acid producing recombinant acetyl xylan esterase on chitosan coated-Fe3O4 magnetic nanoparticles. Process Biochem. 2014, 49, 1920–1928. [Google Scholar] [CrossRef]

- Sui, Y.; Cui, Y.; Nie, Y.; Xia, G.M.; Sun, G.X.; Han, J.T. Surface modification of magnetite nanoparticles using gluconic acid and their application in immobilized lipase. Colloids Surf. B Biointerfaces 2012, 93, 24–28. [Google Scholar] [CrossRef]

- Cui, Y.; Li, Y.; Yang, Y.; Liu, X.; Lei, L.; Zhou, L.; Pan, F. Facile synthesis of amino-silane modified superparamagnetic Fe3O4 nanoparticles and application for lipase immobilization. J. Biotechnol. 2010, 150, 171–174. [Google Scholar] [CrossRef]

- Li, J.; Qin, X.M.; Ding, H.P.; Chen, W.; Shen, H.B.; Li, X.Y. Magnetic nanometer particle separate the protein from Chinese herb medicine. Biomagnetism 2005, 5, 1–4. [Google Scholar]

- Ma, Y.H.; Chen, G.; Zhao, J. Preparation and characterization of chitosan coated magnetic nanoparticles and their bsa adsorption properties. Acta Polym. Sin. 2013, 13, 1369–1375. [Google Scholar]

- Reza, E.K.; Hossein, B.; Zeinab, A.; Hooman, A.M.A.; Milad, S.B.; Athar, N.; Farahnaz, D.; Behnam, T.; Farnoush, A.; Fateme, R.; et al. Functionalized magnetic nanoparticles for the separation and purification of proteins and peptides. TrAC Trend. Anal. Chem. 2021, 141, 116291. [Google Scholar]

- Wu, X.M.; Zhang, L.P.; Ma, X.Z.; Zhao, Y.; Gao, J.M.; Hu, K.X. Integrating immunomagnetic bead enrichment with immunochromatography for the detection of in-fluenza A virus. Chin. J. Microbiol. Immunol. 2016, 36, 310–315. [Google Scholar]

- Gao, T.; Zhang, L.P.; Wei, W.; Wu, Y.P.; Yang, H.F.; Zhang, K.J.; Chen, Z.X. Immunomagnetic enrichment real-time fluorescent PCR technology in the application of food borne pathogenic bacteria monitoring. J. Med. Pest Contrl. 2017, 33, 18–20. [Google Scholar]

- Parham, N.; Spencer, J.; Taylor, D.; Ternent, H.; Innocent, G.; Mellor, D.; Roberts, M.; Williams, A. An adapted immunomagnetic cell separation method for use in quantification of Escherichia coli O157:H7 from bovine faeces. J. Microbiol. Meth. 2003, 53, 1–9. [Google Scholar] [CrossRef]

- Srinivasa, M.S.; William, B.J.; Shankar, C.; Kumar, T.A.; Joseph, D.T.A.; Vishwas, I.M. Systems and Methods for Magnetic Separation of Biological Materials. U.S. Patent 2012/0135494 A1, 31 May 2012. [Google Scholar]

- Kavanagh, D.M. Microfluidic Based Magnetic Separator for Biological Applications; Heriot-Watt University: Edinburgh, UK, 2013. [Google Scholar]

- Sun, X.L.; Zhu, J.M.; Wei, H.Y.; Liu, J.; Zhang, D.H.; Zhou, H.R.; Tian, J.G.; Ye, Q.; Mei, J.C.; Huang, H.L.; et al. A magnetic cell sorting method with adjustable magnetic field. CN Patent 201410680428.5, 4 March 2015. [Google Scholar]

- Wang, K.K.; Ding, R.R.; Ha, Y.P.; Jia, Y.N.; Liao, X.M.; Wang, S.S.; Li, R.J.; Shen, Z.H.; Xiong, H.; Guo, J.L.; et al. Hypoxia-stressed cardiomyocytes promote early cardiac differentiation of cardiac stem cells through HIF-1α/Jagged1/Notch1 signaling. Acta Pharm. Sin. B 2018, 8, 795–804. [Google Scholar] [CrossRef]

- Ravelo, K.M.; Andersen, N.D.; Monje, P.V. Magnetic-activated cell sorting for the fast and efficient separation of human and rodent schwann cells from mixed cell populations. Methods Mol. Biol. 2018, 1739, 87–109. [Google Scholar] [PubMed]

- Stimpfel, M.; Verdenik, I.; Zorn, B.; Virant-Klun, I. Magnetic-activated cell sorting of non-apoptotic spermatozoa improves the quality of embryos according to female age: A prospective sibling oocyte study. J. Assist. Reprod. Gen. 2018, 35, 1665–1674. [Google Scholar] [CrossRef] [PubMed]

- Oh, S.; Jung, S.H.; Seo, H.; Min, M.K.; Kim, B.; Hahn, Y.K.; Kang, J.H.; Choi, S. Magnetic activated cell sorting (MACS) pipette tip for immunomagnetic bacteria separation. Sensor. Actuat. B Chem. 2018, 272, 324–330. [Google Scholar] [CrossRef]

- Lin, S.J.; Zhi, X.; Chen, D.X.; Xia, F.F.; Shen, Y.H.; Niu, J.Q.; Huang, S.Y.; Song, J.; Miao, J.M.; Cui, D.X.; et al. A flyover style microfluidic chip for highly purified magnetic cell separation. Biosens. Bioelectron. 2019, 129, 175–181. [Google Scholar] [CrossRef]

| Methods | Preparation Conditions | Solvent | Advantages | Disadvantages |

|---|---|---|---|---|

| Coprecipitation method | Nitrogen or argon atmosphere | Water | Short reaction time, simple operation and high yield | Size of particles cannot be easily controlled |

| Hydrothermal method | High temperature and high pressure | Water | Good magnetism, uniform particle size distribution and adjustable particle size | Severe requirements for temperature and pressure |

| Solvothermal method | High temperature and high pressure | Organic solvent | Mesoporous or hollow particles with larger specific surface area, controllable particle size | Harsh preparation conditions; more dangerous than hydrothermal methods for VOCs |

| Pyrolysis method | High temperature | Organic solvent | Monodisperse, high crystallinity, adjustable particle size and shape, hollow nanoparticles | High reaction temperature, complex responsive process; hydrophobic MNPs produced mainly |

| Microemulsion method | Complex system and conditions | Water and organic solvent | Narrow particle size distribution, regular morphology and good dispersibility | High preparation cost; difficulty to remove the surfactant |

| Sol-gel method | High temperature, drying | Organic solvent | Narrow particle size distribution, small particle size, good dispersibility | High cost of raw materials and long reaction duration |

| Surface Modification | Composition | Methods | Purposes | Typical Applied Fields |

|---|---|---|---|---|

| Inorganic substance | Fe3O4-SiO2 | Stöber method, i.e., the hydrolyzed product of tetraethyl orthosilicate (TEOS) catalyzed by ammonia was coated on the surface of Fe3O4 nanoparticles and Fe3O4-SiO2 MNPs were prepared | Improve the chemical stability of MNPs, cover the surface of MNPs with hydroxyl groups | Catalysts in synthetic reactions, or used for further surface modification |

| Inorganic substance | Fe3O4-carbon | (1) Fe3O4-carbon can be obtained by adding glucose in the process of the preparation of Fe3O4 nanoparticles by solvothermal method; (2) the polymer was coated on the surface of Fe3O4 nanoparticles firstly, and then annealed to prepare Fe3O4-carbon | Make MNPs more stable and more dispersible | Adsorbing organic substances, such as dyes; magnetic pigments |

| Organic molecules | Fe3O4-C18, Fe3O4-APTES | Small molecules are added in the process of preparing Fe3O4 nanoparticles by pyrolysis method; ligand-exchange technology; (3) Fe3O4 nanoparticles are added to silane solution, and then react in autoclave after ultrasonic treatment | (1) Improve the water solubility and biocompatibility of MNPs; (2) provide sites for further grafting of other bioactive substances | Drug delivery system, or as magnetic solid-phase adsorbents to adsorb organic compounds |

| Polymers | Fe3O4-CS-TPP | Embedding method, i.e., Fe3O4 nanoparticles are dispersed in polymer solution, and cross-linking agents are added and then stirred; monomer polymerization method, i.e., Fe3O4 particles are dispersed in the solution of polymer monomers with functional groups, and then initiators and surfactants are added; (3) In situ synthesis, i.e., polymer microspheres are prepared and placed in the solution of Fe2+ and Fe3+. After the iron ions are inserted into the microspheres, they will be converted in Fe3O4 by the effect of alkali | Improve the stability and biocompatibility of MNPs, provide more binding sites | Immobilized enzymes, cells, proteins, separation of nucleic acids and other bioactive substances or environmental pollutants (organic dyes, drug residues, etc.), and magnetic targeted drug carrier |

| Biological macromolecules | Fe3O4-BSA | In general, a layer of organic small molecule or polymer is grafted onto the surface of Fe3O4 nanoparticles, and then the functional groups are used to graft biological molecules | Good biocompatibility | Biological fields such as separation, detection and biosensors |

| Metal-organic framework | Fe3O4-MOF | Fe3O4 nanoparticles are added in the preparation of MOF materials | Large specific surface area, magnetism | Biological fields such as separation, detection and biosensors |

| Samples | Magnetic Materials | Ligands | Ref. |

|---|---|---|---|

| Ginkgo biloba leaves extract | Human serum albumin-functionalized magnetic nanoparticles (HSA-MNPs) | Nine flavone glycosides | [115] |

| Dioscorea panthaica extrat | HSA-MNPs | Progenin II, progenin III, dioscin and gracillin | [116] |

| Dioscorea nipponica extract | HSA-MNPs | Three saponins (dioscin, gracillin, and pseudo-protodioscin) | [117,118] |

| Rhubarb extract | HSA-MNPs | Emodin and chrysophanol | |

| Epimedii Folium extract | α-glucosidase-functionalized magnetic nanoparticles | Eight flavonoid glycosides—baohuoside I, sagittatoside B, sagittatoside A, 2″-O-rhamnosyl icariside II, icariin, epimedin C, epimedin A, epimedin B | [119] |

| Selaginella doederleinii Hieron extract | Acetylcholinesterase-functionalized magnetic nanoparticles | Amentoflavone, robustaflavone, bilobetin and isoginkgetin | [120] |

| Pericarpium granati and Cortex fraxini extract | Monoamine oxidase B-functionalized magnetic nanoparticles | Calceolarioside B and ellagic acid | [121] |

| Bamboo leaf extract | Lipase-functionalized magnetic nanoparticles | Isoorientin, orientin, isovitexin | [122] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, X.; Song, H.; Zhang, T.; Yao, S.; Wang, Y. Magnetic Technologies and Green Solvents in Extraction and Separation of Bioactive Molecules Together with Biochemical Objects: Current Opportunities and Challenges. Separations 2022, 9, 346. https://doi.org/10.3390/separations9110346

Feng X, Song H, Zhang T, Yao S, Wang Y. Magnetic Technologies and Green Solvents in Extraction and Separation of Bioactive Molecules Together with Biochemical Objects: Current Opportunities and Challenges. Separations. 2022; 9(11):346. https://doi.org/10.3390/separations9110346

Chicago/Turabian StyleFeng, Xueting, Hang Song, Tenghe Zhang, Shun Yao, and Yan Wang. 2022. "Magnetic Technologies and Green Solvents in Extraction and Separation of Bioactive Molecules Together with Biochemical Objects: Current Opportunities and Challenges" Separations 9, no. 11: 346. https://doi.org/10.3390/separations9110346

APA StyleFeng, X., Song, H., Zhang, T., Yao, S., & Wang, Y. (2022). Magnetic Technologies and Green Solvents in Extraction and Separation of Bioactive Molecules Together with Biochemical Objects: Current Opportunities and Challenges. Separations, 9(11), 346. https://doi.org/10.3390/separations9110346