Solving a Real-Life Distributor’s Pallet Loading Problem

Abstract

:1. Introduction

- stability: that is, the property of a layer to sustain other layers, possibly with a larger area;

- weight limit: the sum of the weights of all boxes loaded on a pallet, which must not be greater than a certain limit given by the company;

- compression limit: capacity of a layer of boxes to support the weight of the boxes above it.

2. Materials and Methods

- c1.

- Numerosity constraint: all boxes in must be packed;

- c2.

- Height constraint: the sum of the heights of all layers loaded on a pallet must not exceed H;

- c3.

- Stackability constraint: each layer, except the top one of each pallet, must be composed by boxes satisfying (1);

- c4.

- c5.

- Compression constraint: the total weight of all boxes in the layers loaded over a layer l cannot exceed the compression factor .

2.1. Creating 2D Layers

| Algorithm 1: Algorithm for creating the layers. |

| Algorithm BuildLayers() input: boxes and their types , pallets’ sizes 1. Sort the box types in by non decreasing heights (i.e., ) 2. ; 3. for to do 4. () = CreateFamilies(f); 5. for to f do 6. for to do 7. pack the boxes in with heuristic - giving layers L 8. ; 9. endfor 10. endfor 11. endfor return |

| Algorithm 2: Procedure for creating the box types families. |

| Procedure CreateFamilies(number of families f) 1. Let 2. Choose randomly 3. for do let Random 4. with 5. for to do 6. with 7. endfor 8. with 9. for to do 10. if then 11. 12. endif 13. endfor 14. foreach do 15. if then 16. assign i to the set with nearest pivot height 17. endif 18. endfor return() |

- MaxRectBL: maximal rectangle with bottom-left strategy (place each rectangle in the position where the y-coordinate of the top side of the rectangle is the smallest, and if there are several such valid positions, pick the one that has the smallest x-coordinate value);

- MaxRectBLR: maximal rectangle with bottom-left strategy and rotation allowed;

- MaxRectBssfR: maximal rectangles best short side fit strategy chooses to pack the current rectangle into the free rectangle, which minimizes the differences between the dimensions of the rectangle and the free one;

- SkylineBlWm: skyline with bottom-left and waste map strategy;

- SkylineBlWmR: skyline with bottom-left and waste map strategy with rotation allowed;

- SkylineMwfWm: skyline with min waste fit with low profile heuristic, minimizing the area wasted below the rectangle; at the same time, it tries to keep the height minimal;

- SkylineMwfWmR: skyline with min waste fit with low profile heuristic and rotation allowed.

2.2. A Mathematical Model for Loading Layers

3. Results

Author Contributions

Funding

Conflicts of Interest

References

- Hu, H.; Zhang, X.; Yan, X.; Wang, L.; Xu, Y. Solving a new 3D bin packing problem with deep reinforcement learning method. arXiv 2017, arXiv:1708.05930. [Google Scholar]

- Maarouf, W.; Barbar, A.; Owayjan, M. A new heuristic algorithm for the 3D bin packing problem. In Innovations and Advanced Techniques in Systems, Computing Sciences and Software Engineering; Springer: Dordrecht, The Netherlands, 2008; pp. 342–345. [Google Scholar]

- Martello, S.; Pisinger, D.; Vigo, D.; Boef, E.; Korst, J. Algorithm 864: General and robot-packable variants of the three-dimensional bin packing problem. ACM Trans. Math. Softw. 2007, 33, 7-es. [Google Scholar] [CrossRef]

- Paquay, C.; Schyns, M.; Limbourg, S. A mixed integer programming formulation for the three-dimensional bin packing problem deriving from an air cargo application. Int. Trans. Oper. Res. 2016, 23, 187–213. [Google Scholar] [CrossRef] [Green Version]

- Garey, M.R.; Johnson, D.S. Computers and Intractability: A Guide to the Theory of NP-Completeness; W. H. Freeman & Co.: New York, NY, USA, 1979. [Google Scholar]

- Korte, B.; Vygen, J. “Bin-Packing”. In Combinatorial Optimization: Theory and Algorithms. Algorithms and Combinatorics; Springer: Berlin/Heidelberg, Germany, 2006; Volume 21, pp. 426–441. [Google Scholar]

- Gilmore, R.; Gomory, R. A Linear Programming Approach to the Cutting Stock Problem. Oper. Res. 1961, 9, 849–859. [Google Scholar] [CrossRef] [Green Version]

- Gilmore, P.; Gomory, R. Multi-stage cutting stock problems of two or more dimensions. Oper. Res. 1965, 13. [Google Scholar] [CrossRef]

- Dowsland, K.A.; Dowsland, W.B. Packing problems. Eur. J. Oper. Res. 1992, 56, 2–14. [Google Scholar] [CrossRef]

- Egeblad, J. Heuristics for Multidimensional Packing Problems. Ph.D. Thesis, Department of Computer Science, University of Copenhagen, Copenhagen, Denmark, 2008. [Google Scholar]

- Bortfeldt, A.; Wascher, G. Constraints in container loading a state-of-the-art review. Eur. J. Oper. Res. 2013, 229, 1–20. [Google Scholar] [CrossRef]

- Morabito, R.; Morales, S. A simple and effective recursive procedure for the manufacturer’s pallet loading problem. J. Oper. Res. Soc. 1998, 49, 819–828. [Google Scholar] [CrossRef]

- Silva, E.; Oliveira, J.F.; Wascher, G. The pallet loading problem: A review of solution methods and computational experiments. Int. Trans. Oper. Res. 2016, 23, 147–172. [Google Scholar] [CrossRef]

- Ancora, G.; Palli, G.; Melchiorri, C. A hybrid genetic algorithm for pallet loading in real-world applications. IFAC-PapersOnLine 2020, 53, 10006–10010. [Google Scholar] [CrossRef]

- Bischoff, E.E.; Ratcliff, M.S.W. Loading multiple pallets. J. Oper. Res. Soc. 1995, 46, 1322–1336. [Google Scholar] [CrossRef]

- Bischoff, E.E.; Janetz, F.; Ratcliff, M.S.W. Loading pallets with non-identical items. Eur. J. Oper. Res. 1995, 84, 681–692. [Google Scholar] [CrossRef]

- Piyachayawat, T.; Mungwattana, A. A hybrid algorithm application for the multi-size pallet loading problem case study: Lamp and lighting factory. In Proceedings of the 4th International Conference on Industrial Engineering and Applications (ICIEA), Nagoya, Japan, 21–23 April 2017; pp. 100–105. [Google Scholar]

- Scheithauer, G.; Terno, J. A heuristic approach for solving the multi-pallet packing problem. In Decision Making under Conditions of Uncertainty (Cutting–Packing Problems); Mukhacheva, E.A., Ed.; Ufa State Aviation Technical University: Ufa, Ruassia, 1997; pp. 140–154. [Google Scholar]

- Gzara, F.; Elhedhli, S.; Yildiz, B.C. The pallet loading problem: Three-dimensional bin packing with practical constraints. Eur. J. Oper. Res. 2020, 287, 1062–1074. [Google Scholar] [CrossRef]

- Moura, A.; Oliveira, J.F. A GRASP approach to the container-loading problem. IEEE Intell. Syst. 2005, 20, 50–57. [Google Scholar] [CrossRef] [Green Version]

- Saraiva, R.D.; Nepomuceno, N.; Pinheiro, P.-R. A layer-building algorithm for the three-dimensional multiple bin packing problem: A case study in an automotive company. IFAC-PapersOnLine 2015, 48, 490–495. [Google Scholar] [CrossRef]

- Singh, M.; Almasarwah, N.; Suer, G. A two-phase algorithm to solve a 3-dimensional pallet loading problem. Procedia Manuf. 2019, 39, 1474–1481. [Google Scholar] [CrossRef]

- Alonso, M.T.; Alvarez-Valdes, R.; Iori, M.; Parreño, F. Mathematical models for multi container loading problems with practical constraints. Comput. Ind. Eng. 2019, 127, 722–733. [Google Scholar] [CrossRef]

- Alonso, M.T.; Alvarez-Valdes, R.; Parreño, F.; Tamarit, J.M. Algorithms for pallet building and truck loading in an interdepot transportation problem. Math. Probl. Eng. 2016, 2016, 3264214. [Google Scholar] [CrossRef] [Green Version]

- Alvarez Martinez, D.; Alvarez-Valdes, R.; Parreno, F. A GRASP algorithm for the container loading problem. Pesqui. Oper. 2015, 35, 1–24. [Google Scholar] [CrossRef]

- Ranck Júnior, R.; Yanasse, H.H.; Morabito, R.; Junqueira, L. A hybrid approach for a multi-compartment container loading problem. Expert Syst. Appl. 2019, 137, 471–492. [Google Scholar] [CrossRef]

- Jens, E.; Garavelli, C.; Lisi, S.; Pisinger, D. Heuristics for container loading of furniture. Eur. J. Oper. Res. 2010, 3, 881–892. [Google Scholar]

- Olsson, J. Solving a Highly Constrained Multi-Level Container Loading Problem from Practice. Bachelor’s Thesis, Linköping University, Linköping, Sweden, 2017. [Google Scholar]

- Zhao, X.; Bennell, J.A.; Bektaş, T.; Dowsland, K. A comparative review of 3D container loading algorithms. Int. Trans. Oper. Res. 2016, 23, 287–320. [Google Scholar] [CrossRef] [Green Version]

- Iori, M.; Locatelli, M.; Moreira, M.C.; Silveira, T. Reactive GRASP-based algorithm for pallet building problem with visibility and contiguity constraints. In Proceedings of the 11th International Conference on Computational Logistics, Enschede, The Netherlands, 28–30 September 2020. [Google Scholar]

- Jylanki, J. A Thousand Ways to Pack the Bin—A Practical Approach to Two-Dimensional Rectangle Bin Packing. 2010. Available online: http://clb.demon.fi/files/RectangleBinPack.pdf (accessed on 15 July 2021).

- Wei, L.; Zhang, D.; Chen, Q. A least wasted first heuristic algorithm for the rectangular packing problem. Comput. Oper. Res. 2009, 36, 1608–1614. [Google Scholar] [CrossRef]

| Instance | N° Items | N° Items Type | Tot. Weight | Min. Compr. | Max. Height | Min. Height |

|---|---|---|---|---|---|---|

| A | 332 | 53 | 2967.58 | 87.5 | 305 | 150 |

| B | 136 | 22 | 1564.56 | 87.5 | 305 | 150 |

| C | 349 | 70 | 3272.756 | 87.5 | 305 | 150 |

| D | 669 | 68 | 6901.96 | 87.5 | 305 | 150 |

| E | 83 | 14 | 464.83 | 75 | 265 | 150 |

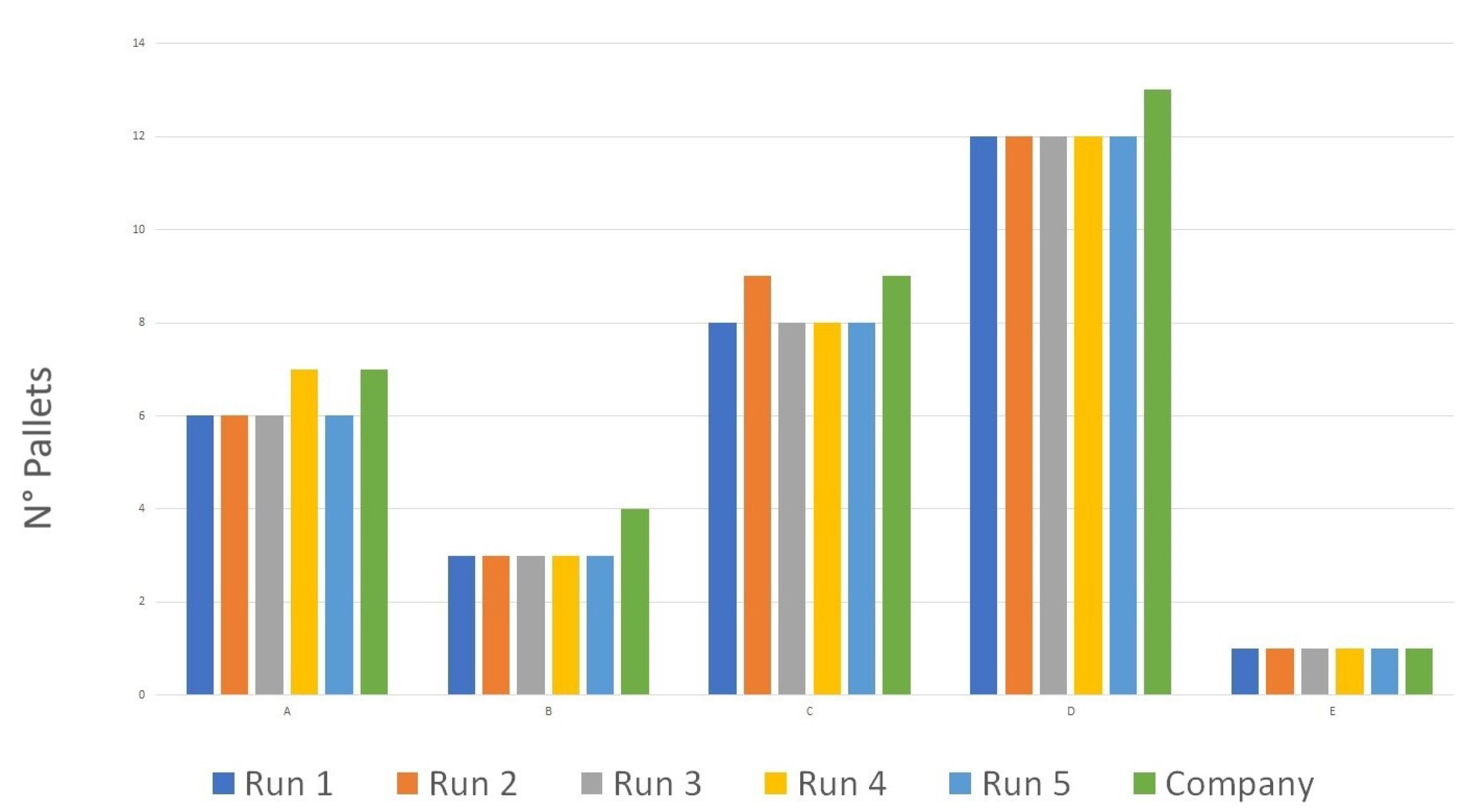

| Instance | Best Bound | Best Solution | Comp. Solution | Time (min) | |

|---|---|---|---|---|---|

| A | 139 | 5 | 6 | 7 | 120 |

| B | 65 | 3 | 3 | 4 | 3 |

| C | 180 | 7 | 8 | 8 | 120 |

| D | 220 | 11 | 12 | 13 | 120 |

| E | 34 | 1 | 1 | 2 | 2 |

| Instance | Best Bound | Best Solution | Comp. Solution | Time (min) | |

|---|---|---|---|---|---|

| A | 141 | 5 | 6 | 7 | 120 |

| B | 68 | 3 | 3 | 4 | 4 |

| C | 174 | 7 | 9 | 8 | 120 |

| D | 228 | 11 | 12 | 13 | 120 |

| E | 34 | 1 | 1 | 2 | 2 |

| Instance | Best Bound | Best Solution | Comp. Solution | Time (min) | |

|---|---|---|---|---|---|

| A | 136 | 5 | 6 | 7 | 120 |

| B | 67 | 3 | 3 | 4 | 3 |

| C | 178 | 7 | 8 | 8 | 120 |

| D | 222 | 11 | 12 | 13 | 120 |

| E | 32 | 1 | 1 | 2 | 2 |

| Instance | Best Bound | Best Solution | Comp. Solution | Time (min) | |

|---|---|---|---|---|---|

| A | 132 | 5 | 7 | 7 | 120 |

| B | 66 | 3 | 3 | 4 | 3 |

| C | 174 | 7 | 8 | 8 | 120 |

| D | 229 | 11 | 12 | 13 | 120 |

| E | 33 | 1 | 1 | 2 | 2 |

| Instance | Best Bound | Best Solution | Comp. Solution | Time (min) | |

|---|---|---|---|---|---|

| A | 137 | 5 | 6 | 7 | 120 |

| B | 64 | 3 | 3 | 4 | 3 |

| C | 174 | 7 | 8 | 8 | 120 |

| D | 231 | 11 | 12 | 13 | 120 |

| E | 32 | 1 | 1 | 2 | 2 |

| Instance | Best Bound | Best Solution | Comp. Solution | Time (min) | |

|---|---|---|---|---|---|

| A | 137 | 5 | 6 | 7 | 120 |

| B | 66 | 3 | 3 | 4 | 3 |

| C | 176 | 7 | 8 | 8 | 120 |

| D | 226 | 11 | 12 | 13 | 120 |

| E | 33 | 1 | 1 | 2 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dell’Amico, M.; Magnani, M. Solving a Real-Life Distributor’s Pallet Loading Problem. Math. Comput. Appl. 2021, 26, 53. https://doi.org/10.3390/mca26030053

Dell’Amico M, Magnani M. Solving a Real-Life Distributor’s Pallet Loading Problem. Mathematical and Computational Applications. 2021; 26(3):53. https://doi.org/10.3390/mca26030053

Chicago/Turabian StyleDell’Amico, Mauro, and Matteo Magnani. 2021. "Solving a Real-Life Distributor’s Pallet Loading Problem" Mathematical and Computational Applications 26, no. 3: 53. https://doi.org/10.3390/mca26030053

APA StyleDell’Amico, M., & Magnani, M. (2021). Solving a Real-Life Distributor’s Pallet Loading Problem. Mathematical and Computational Applications, 26(3), 53. https://doi.org/10.3390/mca26030053