Evaluation of Efficiency of a Finned Corrugation Basin in Inclined Basin-Type Solar Stills in Regulating the Water Supply of the CaspiCement Plant

Abstract

:1. Introduction

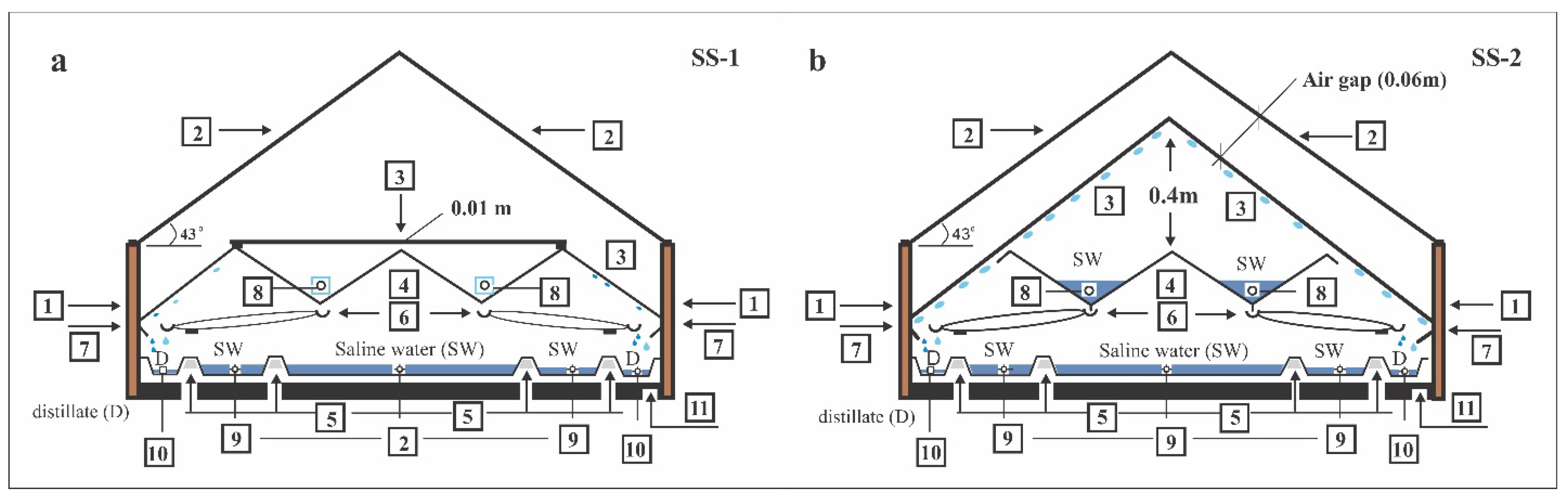

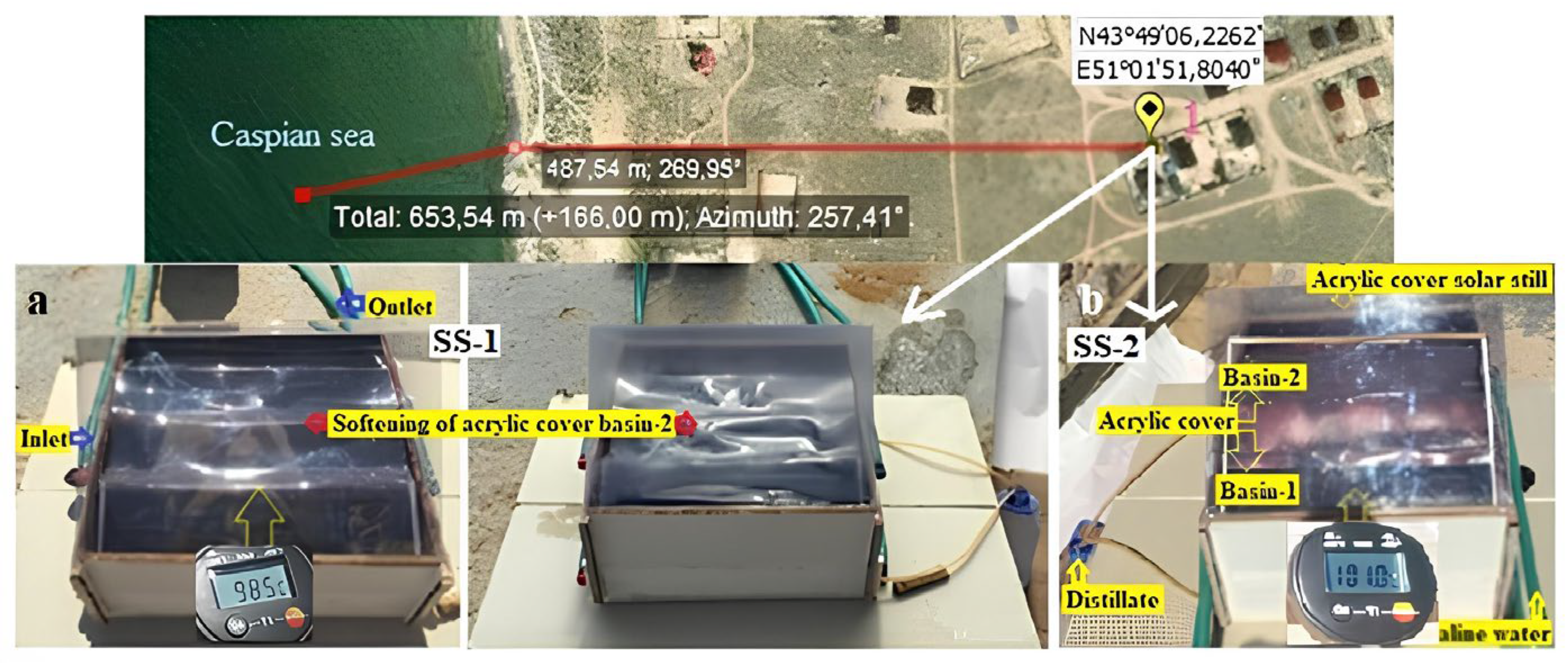

2. Materials and Methods

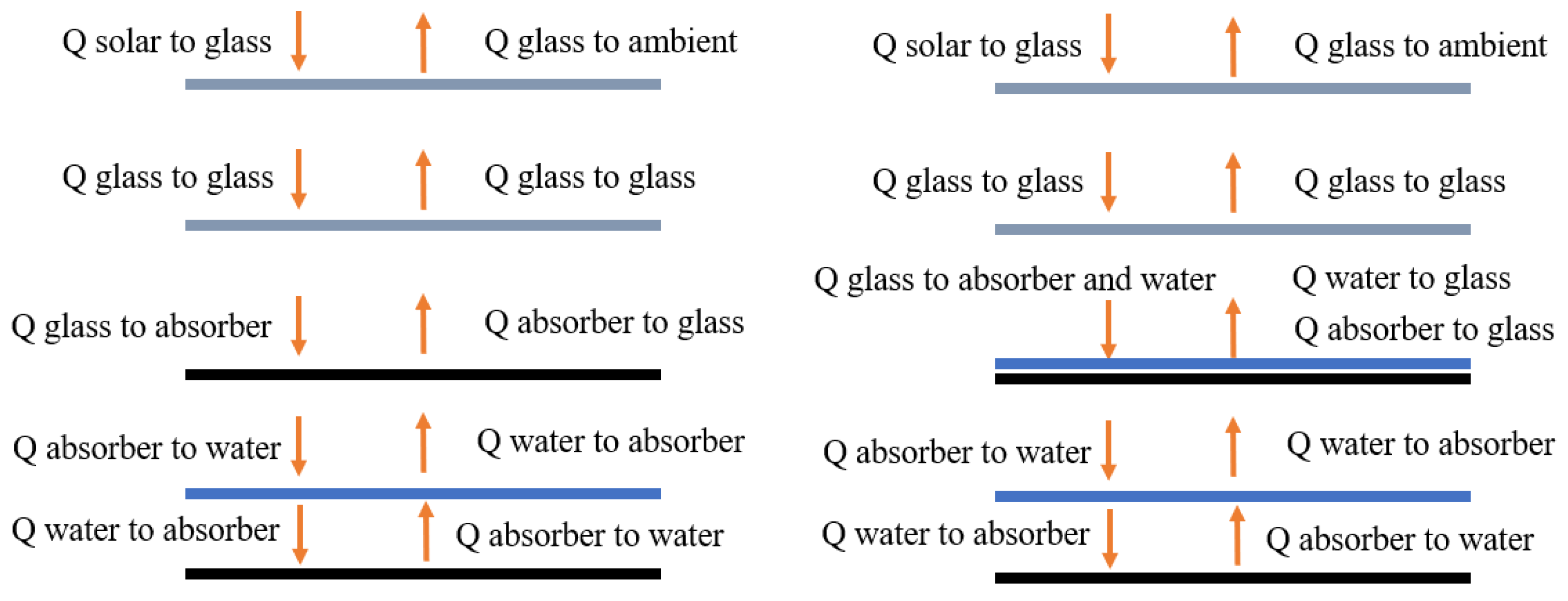

3. Mathematical Model of a Solar Still Thermal Process

Heat Balance Equations for the Capacity of a Basin-Type Still

4. Results and Discussion

Efficiency of the Basin-2 in a Double-Basin Distiller on 1 August 2023. SS-1: The Upper Basin-2 as an Air Heater (Water Free)

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Syrlybekkyzy, S.; Kenzhetaev, G.Z.; Permyakov, V.N.; Nurbayeva, F.K. Investigation into the Physico-Chemical Properties of Soils of Caspian Sea Coastal Area in Mangystau Province. Orient. J. Chem. 2014, 30, 1631–1638. [Google Scholar] [CrossRef]

- Zhidebayeva, A.; Kenzhetayev, G.; Syrlybekkyzy, S.; Aitimova, A. Studying state of soils in South shetpe chalk deposit. EEC EM Ecol. Environ. Conserv. 2018, 24, 1065–1068. [Google Scholar]

- Serikbayeva, A.; Taizhanova, L.; Suleimenova, B.; Altybayeva, Z.; Seidalieva, L. Intensification of the Wastewater Treatment Process of a Bitumen Plant with the Production of Recycled Water. J. Ecol. Eng. 2023, 24, 295–301. [Google Scholar] [CrossRef] [PubMed]

- Kenzhetaev, G.Z.; Koibakova, S.E.; Syrlybekkyzy, S.; Zhidebaeva, A.E.; Aitimova, A.M.; Kenzhetaev, G.Z. Method and Device for Desalination of Sea Water. Patent No. 33969, 20 December 2019. [Google Scholar]

- Sangeetha, A.; Shanmugan, S.; Alrubaie, A.J.; Jaber, M.M.; Panchal, H.; Attia, M.E.H.; Elsheikh, A.H.; Mevada, D.; Essa, F.A. A review on PCM and nanofluid for various productivity enhancement methods for double slope solar still: Future challenge and current water issues. Desalination 2023, 551, 116367. [Google Scholar] [CrossRef]

- Stiubiener, U.; de Freitas, A.G.; dos Santos, G.P.; Fuser, I. Solar channels as an innovative energy approach for large water transposition projects. Solar Energy 2023, 265, 112090. [Google Scholar] [CrossRef]

- Dev, R.; Tiwari, G.N. Characteristic equation of the inverted absorber solar still. Eureka Mag Biomedical Library. Desalination 2011, 269, 67–77. [Google Scholar] [CrossRef]

- Selvakumar, P. Performance Studies on Solar Air Heater with Staggered Open Channel Aluminium Turbulators. J. Inst. Eng. Ser. C 2021, 102, 1261–1265. [Google Scholar] [CrossRef]

- Tanaka, H. Tilted wick solar still with flat plate bottom reflector. Desalination 2011, 273, 405–413. [Google Scholar] [CrossRef]

- Yadav, Y.P.; Raut, B. Parametric studies on a double-exposure single-basin solar still. Int. J. Ambient. Energy 2011, 27, 203–220. [Google Scholar] [CrossRef]

- Khan, M.Z.; Nawaz, I.; Tiwari, G.N. Effect of wind velocity on active and passive solar still. Int. J. Curr. Res. 2016, 8, 28398–28402. [Google Scholar]

- Patel, M.; Panchal, H.; Patel, C. Performance analysis of conventional triple basin solar still with evacuated heat pipes, corrugated sheets and storage materials. Groundw. Sustain. Dev. 2020, 11, 100387. [Google Scholar] [CrossRef]

- Douani, M.; Tahri, T.; Abdul-Wahab, S.A.; Bettahar, A.; Hinai, A. Modeling heat exchange in the condenser of a seawater greenhouse in Oman. Chem. Eng. Commun. 2011, 198, 1579–1593. [Google Scholar] [CrossRef]

- Dev, R.; Singh, H.N.; Tiwari, G.N. Characteristic equation of double slope passive solar still. Desalination 2011, 267, 261–266. [Google Scholar] [CrossRef]

- Aburideh, H.; Deliou, A.; Abbad, B.; Alaoui, F.; Tassalit, D.; Tigrine, Z. An Experimental Study of a Solar Still: Application on the sea water desalination of Fouka. Procedia Eng. 2012, 33, 475–484. [Google Scholar] [CrossRef]

- Kalidasa Murugavel, K.; Chockalingam, K.K.S.K.; Srithar, K. An experimental study on single basin double slope simulation solar still with thin layer of water in the basin. Desalination 2008, 220, 687–693. [Google Scholar] [CrossRef]

- Rajamanickam, M.R.; Ragupathy, A. Influence of Water Depth on Internal Heat and Mass Transfer in a Double Slope Solar Still. Energy Procedia 2012, 14, 1701–1708. [Google Scholar] [CrossRef]

- Abderachid, T.; Abdenacer, K. Effect of orientation on the performance of a symmetric solar still with a double effect solar still. Desalination 2013, 329, 68–77. [Google Scholar] [CrossRef]

- Zoori, H.A.; Tabrizi, F.F.; Sarhaddi, F.; Heshmatnezhad, F. Comparison between energy and exergy efficiencies in a weir type cascade solar still. Desalination 2013, 325, 113–121. [Google Scholar] [CrossRef]

- Sadineni, S.B.; Hurt, R.; Halford, C.K.; Boehm, R.F. Theory and experimental investigation of a weir-type inclined solar still. Energy 2008, 33, 71–80. [Google Scholar] [CrossRef]

- Mouhsin, N.; Bouzaid, M.; Taha-Janan, M. Experimental analysis of an improved cascade solar desalination still with modified absorber plate. E3S Web Conf. 2022, 336, 00023. [Google Scholar] [CrossRef]

- Rahim, N.H.A. New method to store heat energy in horizontal solar desalination still. Renew. Energy 2003, 28, 419–433. [Google Scholar] [CrossRef]

- Velmurugan, V.; Naveen Kumar, K.J.; Noorul Haq, T.; Srithar, K. Performance analysis in stepped solar still for effluent desalination. Energy 2009, 34, 1179–1186. [Google Scholar] [CrossRef]

- Badran, O.O. Experimental study of the enhancement parameters on a single slope solar still productivity. Desalination 2007, 209, 136–143. [Google Scholar] [CrossRef]

- Zhidebaeva, A.E.; Syrlybekkyzy, S. Solar Desalination Plant of the Basin Type. Patent No. 9128, 17 May 2024. [Google Scholar]

- Serikbayeva, A.K.; Taizhanova, L.S. Wastewater Treatment Method. Patent No. 8181, 16 June 2023. [Google Scholar]

- Kabeel, A.E.; Omara, Z.M.; Essa, F.A.; Abdullah, A.S. Solar still with condenser—A detailed review. Renew. Sustain. Energy Rev. 2016, 59, 839–857. [Google Scholar] [CrossRef]

- Velmurugan, V.; Pandiarajan, S.; Guruparan, P.; Subramanian, H.; David Prabaharan, C.; Srithar, K. Integrated performance of stepped and single basin solar stills with mini solar pond. Desalination 2009, 249, 902–909. [Google Scholar] [CrossRef]

- Tsilingiris, P.T. The glazing temperature measurement in solar stills—errors and implications on performance evaluation. Appl. Energy 2011, 88, 4936–4944. [Google Scholar] [CrossRef]

- Duffie, J.A.; Backman, W.A. Solar Engineering of Thermal Processes, 4th ed.; John Wiley & Sons, Inc.: New York, NY, USA, 2013; 910p. [Google Scholar]

- Torchia-Núñez, J.C.; Cervantes-de-Gortari, J.; Porta-Gándara, M.A. Thermodynamics of a Shallow Solar Still. Energy Power Eng. 2014, 6, 49573. [Google Scholar] [CrossRef]

- Suneesh, P.U.; Jayaprakash, R.; Namshad, T.; Kumar, S. Performance of Corrugated Wick in “V” Type Solar Still. Smart Grid Renew. Energy 2013, 4, 8. [Google Scholar] [CrossRef]

- Clark, J.A. The steady state performance of a solar still. Sol. Energy 1990, 44, 43–49. [Google Scholar] [CrossRef]

- Franco, A. Methods for the Sustainable Design of Solar Energy Systems for Industrial Process Heat. Sustainability 2020, 12, 5127. [Google Scholar] [CrossRef]

- Alahmer, A.; Lewkowicz, M.; Alsaqoor, S.; Borowski, G. Modeling and Optimization of Transparent Thermal Insulation Material. J. Sol. Energy Eng. 2018, 140, 054501. [Google Scholar]

- Sathish Kumar, T.R.; Raja Bharathi, B. Effect of Water Depth on Productivity of Solar Still with Thermal Energy Storage. Int. J. Sci. Res. 2013, 2, 413–417. [Google Scholar]

| Parameters | Glass Cover SS | Glass Cover of Basins | Basin-2 | Basin-1 | Water | |

|---|---|---|---|---|---|---|

| Basin-2 | Basin-1 | |||||

| —0.03 | —0.03 | —0.93 | —0.93 | 0.05 | 0.05 | |

| (m2) | 0.72 | 0.73 | 0.38 | 0.62 | 0.21 | 0.48 |

| 0.92 | 0.92 | - | - | 0.93 | 0.93 | |

| 0.88 | 0.88 | - | - | 0.94 | 0.94 | |

| (J/kg K) | 500 | 500 | 630 | 630 | 4190 | 4190 |

| (kg/m3) | 2500 | 2500 | 7850 | 7850 | 1010 | 1010 |

| Thickness, mm | 3.00 | 3.00 | 0.7 | 0.7 | 20-40-50 | 20-30 |

| Slope of glass, (°) | 38 | 38 | 38 | - | - | - |

| (Ambient Conditions) | 1 August 2023 | 2 August 2023 | ||

|---|---|---|---|---|

| Morning | Afternoon | Morning | Afternoon | |

| Sunrise time (hour) | 6:22 | - | 6:26 | - |

| Outdoor air temperature (°C) | 20.3 (7:00) | 32.0 (12:00) | 21.7 (7:00) | 31 (12:00) |

| Solar radiation intensity (W/m2) | 96.1 (7:00) | 795 (12:00) | 101 (7:00) | 840 (12:00) |

| Atmospheric pressure (mm Hg) | 759 | 758 | 756 | 756 |

| Wind speed, (m/s) | 3.4 (B) | 5.9 (Ю) | 2.1 (3) | 3.0 (C3) |

| Relative air humidity (%) | 75 | 39 | 51 | 41 |

| Precipitation amount (mm) | - | - | - | - |

| Cloudiness | Clear | Low | Clear | Clear |

| Time (hour) | (W/m2) | (°C) | (°C) | (°C) | (°C) | (°C) | (°C) | Distillate Output (b.1) (kg) |

|---|---|---|---|---|---|---|---|---|

| 7:00 a.m. | 96.10 | 21.3 | 18.6 | 21.0 | 18.4 | 18.7 | 19.5 | 0.00 |

| 8:00 a.m. | 155.00 | 22.8 | 34.6 | 33.2 | 21.4 | 23.7 | 24.8 | 0.00 |

| 9:00 a.m. | 220.17 | 24.1 | 43.3 | 41.0 | 27.0 | 29.5 | 32.3 | 0.014 |

| 10:00 a.m. | 390.51 | 27.2 | 54.0 | 50.3 | 31.3 | 37.1 | 40.5 | 0.071 |

| 11:00 a.m. | 590.70 | 29.3 | 64.1 | 61.3 | 42.1 | 44.7 | 49.3 | 0.128 |

| 12:00 a.m. | 795.00 | 32.0 | 76.1 | 73.5 | 40.7 | 57.3 | 61.1 | 0.293 |

| 1:00 p.m. | 781.33 | 31.4 | 85.0 | 81.2 | 43.0 | 45.8 | 49.4 | 0.173 |

| 2:00 p.m. | 776.40 | 31.1 | 96.8 | 91.1 | 51.4 | 53.1 | 57.3 | 0.270 |

| 3:00 p.m. | 713.51 | 30.6 | 101.6 | 98.5 | 53.1 | 58.3 | 61.1 | 0.337 |

| 4:00 p.m. | 681.70 | 30.2 | 97.3 | 92.4 | 49.2 | 54.6 | 58.0 | 0.283 |

| 5:00 p.m. | 635.50 | 29.0 | 93.6 | 89.3 | 45.0 | 50.1 | 55.3 | 0.219 |

| 6:00 p.m. | 593.00 | 28.5 | 88.1 | 84.0 | 39.3 | 45.2 | 48.9 | 0.121 |

| 7:00 p.m. | 475.30 | 28.1 | 81.6 | 77.5 | 31.4 | 39.6 | 44.7 | 0.088 |

| 8:00 p.m. | 189.65 | 27.0 | 76.0 | 71.3 | 28.0 | 36.0 | 40.3 | 0.052 |

| - | - | - | - | - | - | - | - | 2.049 |

| Time (hour) | (W/m2) | (°C) | (°C) | (°C) | (°C) | (°C) | (°C) | (°C) | Distillate Output, (kg) | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| (b.2) | (b.1) | ∑ (b.2 + b.1) | |||||||||

| 7:00 a.m. | 101.5 | 21.7 | 19.3 | 19.8 | 22.0 | 19.0 | 19.7 | 20.0 | 0.000 | 0.000 | 0.000 |

| 8:00 a.m. | 160.19 | 22.4 | 21.7 | 32.5 | 36.0 | 20.3 | 25.6 | 26.4 | 0.031 | 0.000 | 0.031 |

| 9:00 a.m. | 225.07 | 26.0 | 23.6 | 40.8 | 45.1 | 22.5 | 31.8 | 35.0 | 0.114 | 0.026 | 0.14 |

| 10:00 a.m. | 379.00 | 29.6 | 27.0 | 47.0 | 54.8 | 25.0 | 38.5 | 42.8 | 0.216 | 0.040 | 0.256 |

| 11:00 a.m. | 580.13 | 30.1 | 32.3 | 61.3 | 67.1 | 28.3 | 46.0 | 50.8 | 0.410 | 0.186 | 0.596 |

| 12:00 a.m. | 840.00 | 31.5 | 38.7 | 69.3 | 76.0 | 32.7 | 55.3 | 61.1 | 0.452 | 0.271 | 0.723 |

| 1:00 p.m. | 811.36 | 31.2 | 46.4 | 76.2 | 84.5 | 38.0 | 63.1 | 69.0 | 0.475 | 0.421 | 0.896 |

| 2:00 p.m. | 792.16 | 31.0 | 56.5 | 87.0 | 96.1 | 43.1 | 73.4 | 79.0 | 0.513 | 0.448 | 0.961 |

| 3:00 p.m. | 731.41 | 30.6 | 64.8 | 95.4 | 101.0 | 48.8 | 81.0 | 88.3 | 0.621 | 0.493 | 1.114 |

| 4:00 p.m. | 698.62 | 30.4 | 61.2 | 89.6 | 94.3 | 43.7 | 75.3 | 82.7 | 0.527 | 0.413 | 0.940 |

| 5:00 p.m. | 730.09 | 29.8 | 57.9 | 85.4 | 90.7 | 38.0 | 70.0 | 76.1 | 0.493 | 0.436 | 0.929 |

| 6:00 p.m. | 583.10 | 29.0 | 53.3 | 78.2 | 81.4 | 32.7 | 62.3 | 71.5 | 0.481 | 0.410 | 0.891 |

| 7:00 p.m. | 481.00 | 28.5 | 49.7 | 69.0 | 76.1 | 28.4 | 56.1 | 65.0 | 0.450 | 0.267 | 0.717 |

| 8:00 p.m. | 124.83 | 28.3 | 43.5 | 61.8 | 69.3 | 23.1 | 49.2 | 58.6 | 0.415 | 0.108 | 0.523 |

| - | - | - | - | - | - | - | - | - | 5.198 | 3.519 | 8.717 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kirvel, I.; Zhidebayeva, A.; Taizhanova, L.; Aitimova, A.; Syrlybekkyzy, S.; Serikbayeva, A.; Jumasheva, K.; Koibakova, S. Evaluation of Efficiency of a Finned Corrugation Basin in Inclined Basin-Type Solar Stills in Regulating the Water Supply of the CaspiCement Plant. Limnol. Rev. 2024, 24, 150-163. https://doi.org/10.3390/limnolrev24020008

Kirvel I, Zhidebayeva A, Taizhanova L, Aitimova A, Syrlybekkyzy S, Serikbayeva A, Jumasheva K, Koibakova S. Evaluation of Efficiency of a Finned Corrugation Basin in Inclined Basin-Type Solar Stills in Regulating the Water Supply of the CaspiCement Plant. Limnological Review. 2024; 24(2):150-163. https://doi.org/10.3390/limnolrev24020008

Chicago/Turabian StyleKirvel, Ivan, Ainur Zhidebayeva, Lyailim Taizhanova, Ainazhan Aitimova, Samal Syrlybekkyzy, Akmaral Serikbayeva, Kamshat Jumasheva, and Symbat Koibakova. 2024. "Evaluation of Efficiency of a Finned Corrugation Basin in Inclined Basin-Type Solar Stills in Regulating the Water Supply of the CaspiCement Plant" Limnological Review 24, no. 2: 150-163. https://doi.org/10.3390/limnolrev24020008