An All-Fiber FLRD System for SO2 Detection Based on Graphene-Coated Microfiber

Abstract

:1. Introduction

2. Analysis of Gas Sensing Mechanism

3. Experimental Platform Building

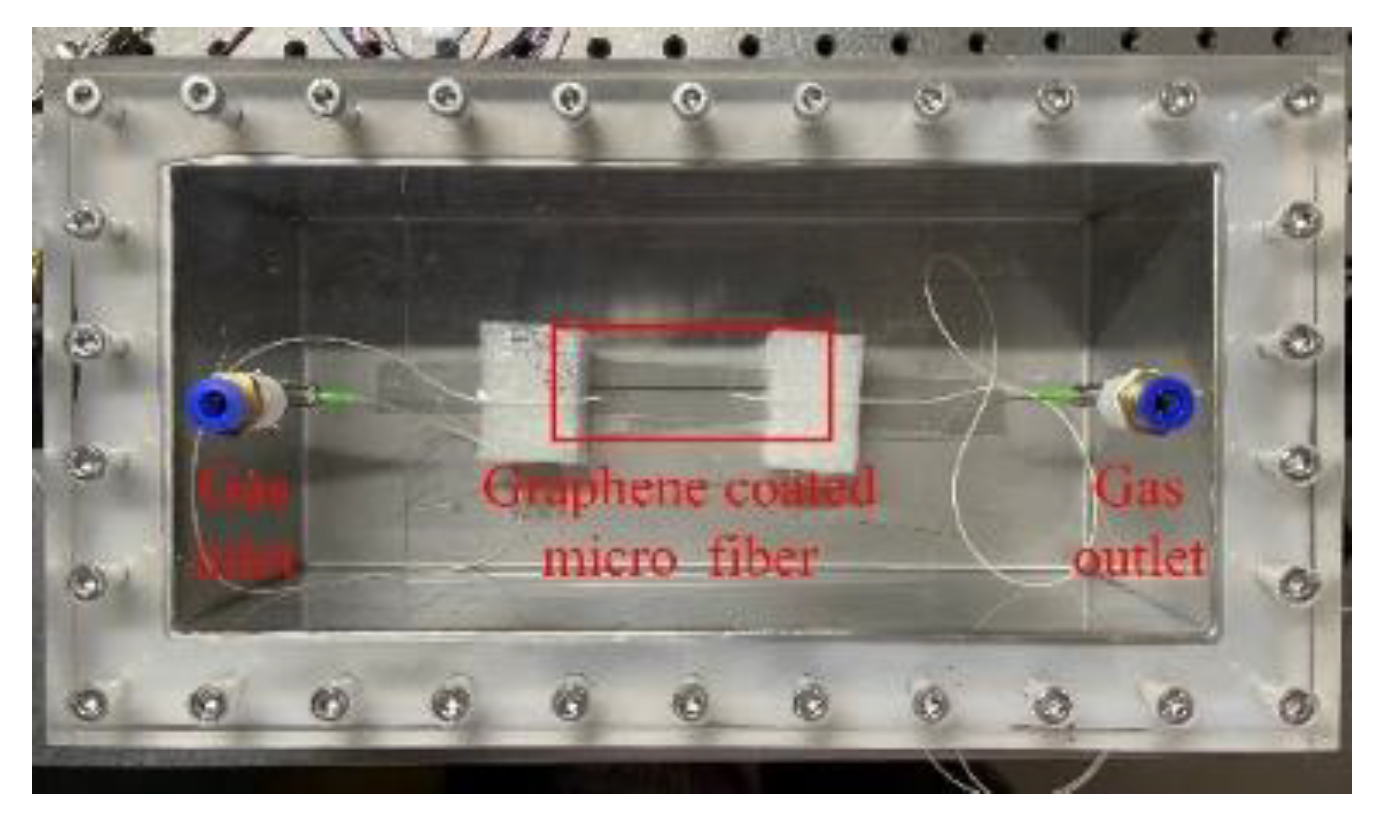

3.1. Sensor Preparation

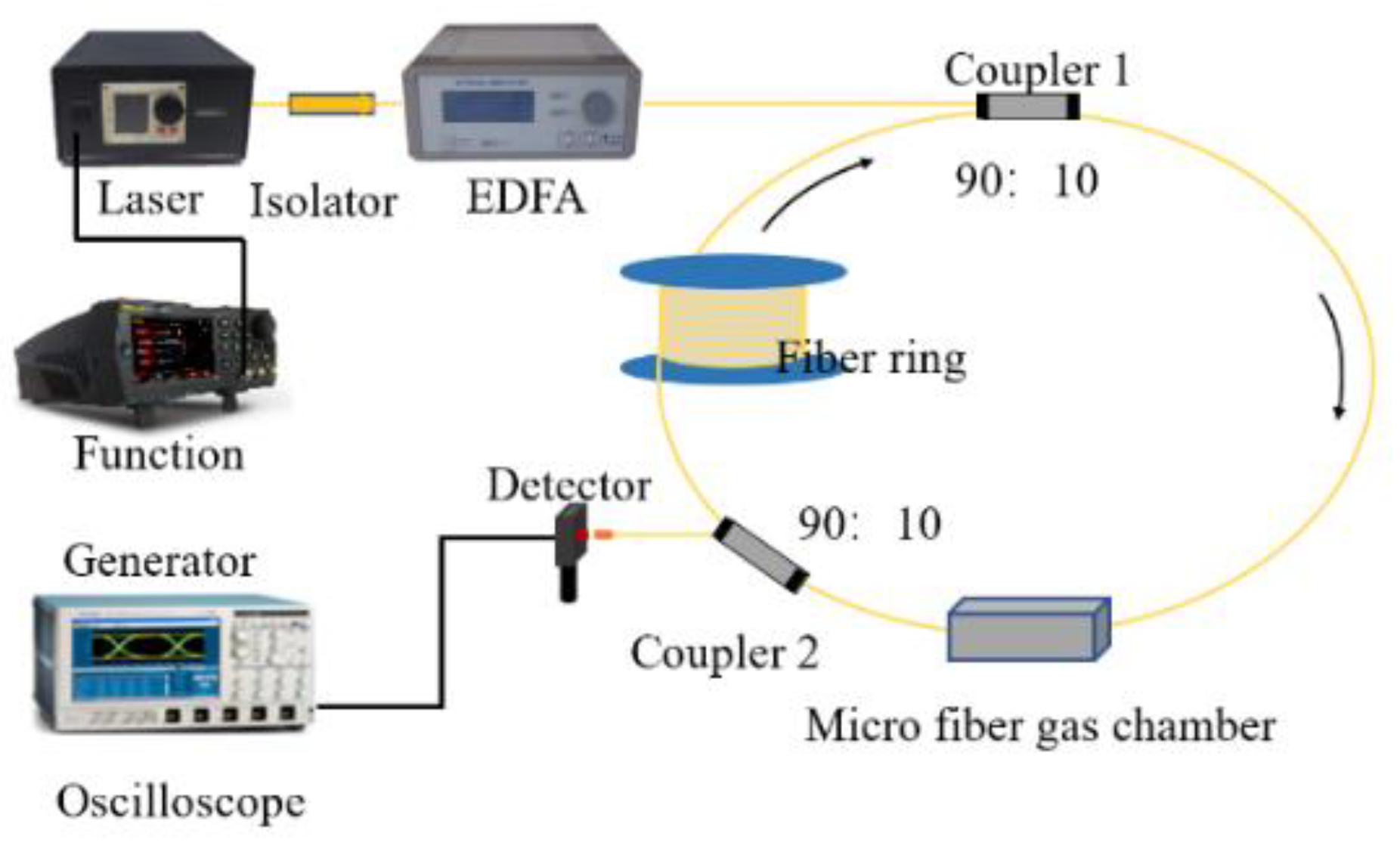

3.2. FLRD Platform

4. Analysis and Discussion

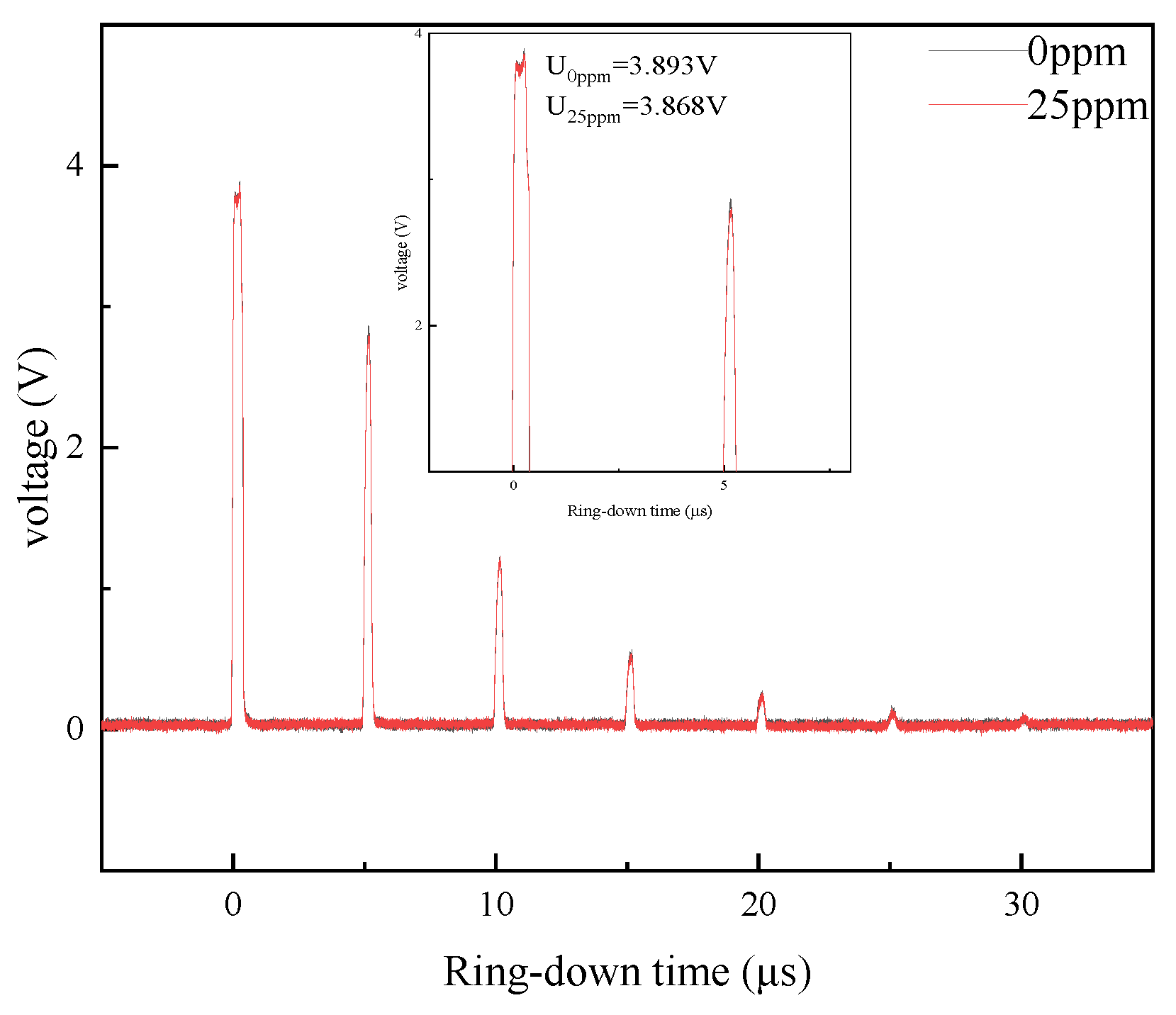

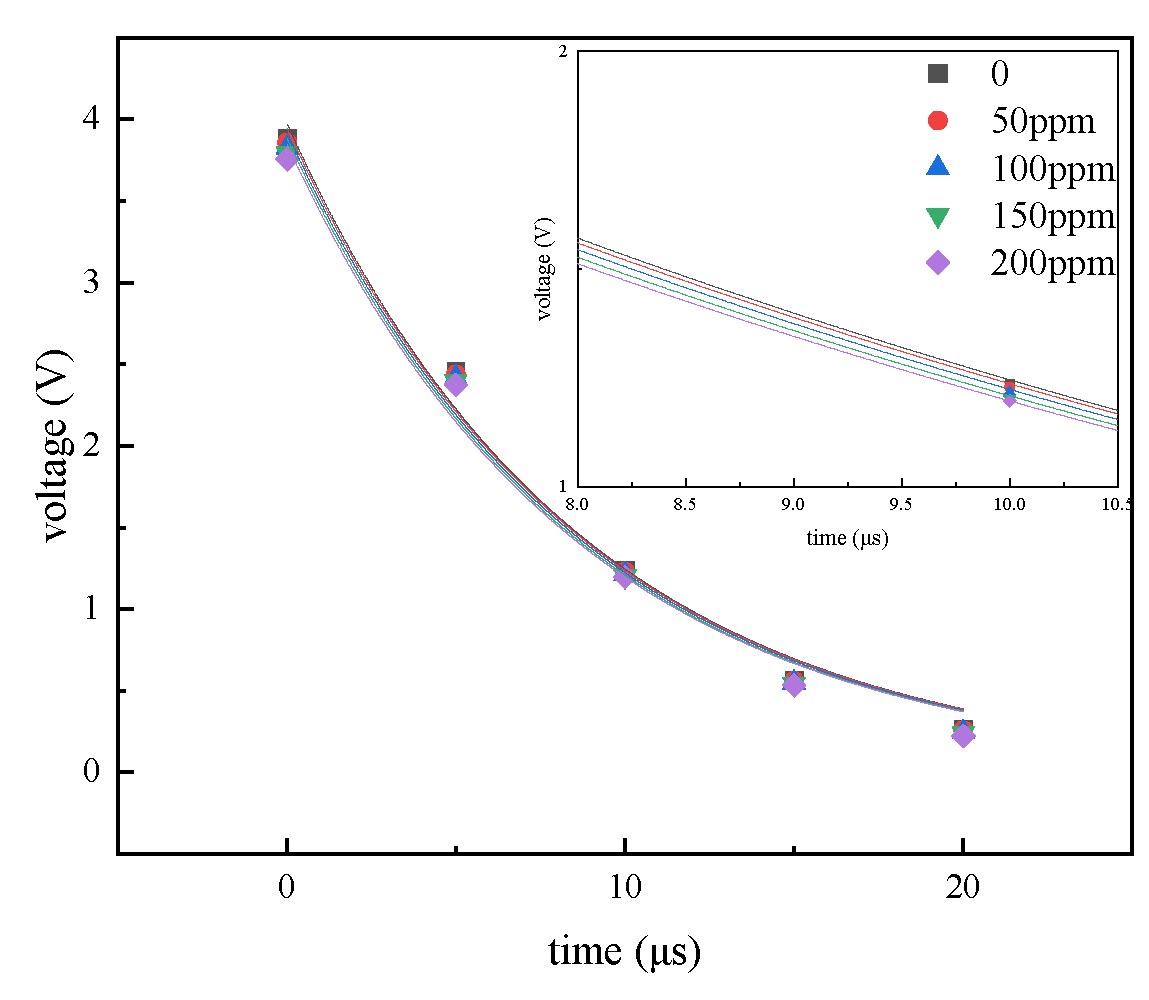

4.1. SO2 Gas Detection

4.2. Errors Analysis

4.3. Sensitivity Analysis

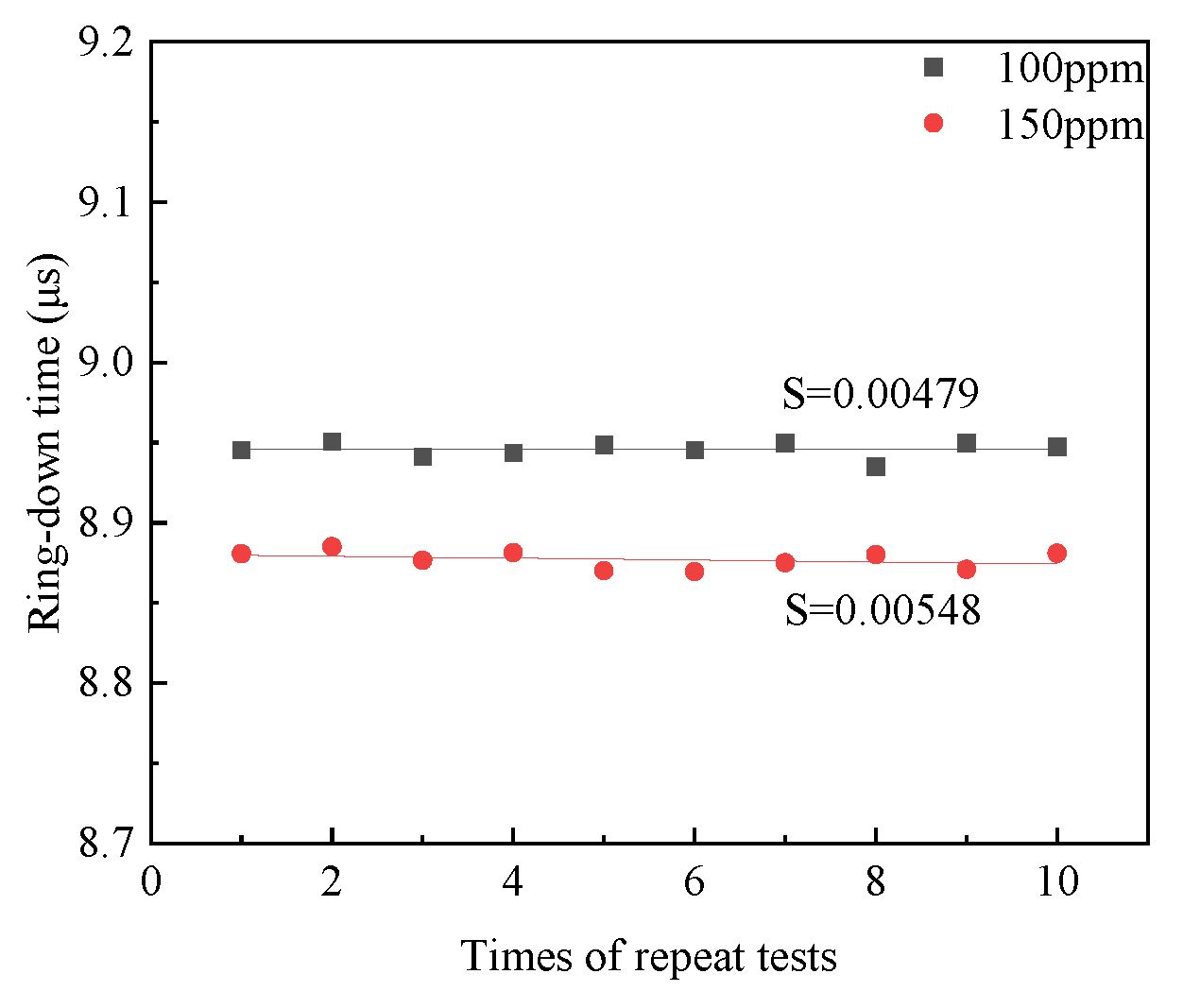

4.4. Stability Analysis

5. Conclusions

- (1)

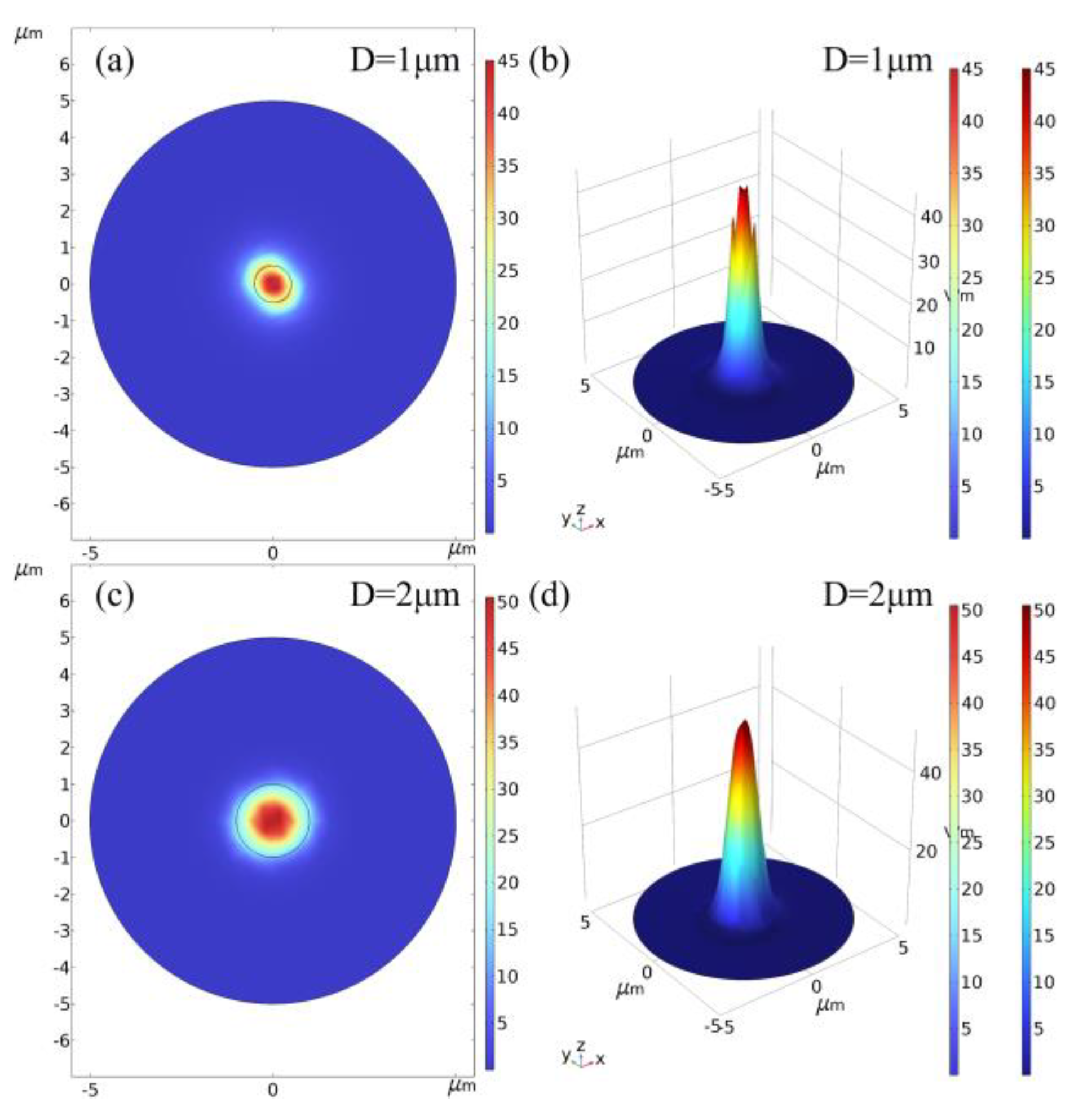

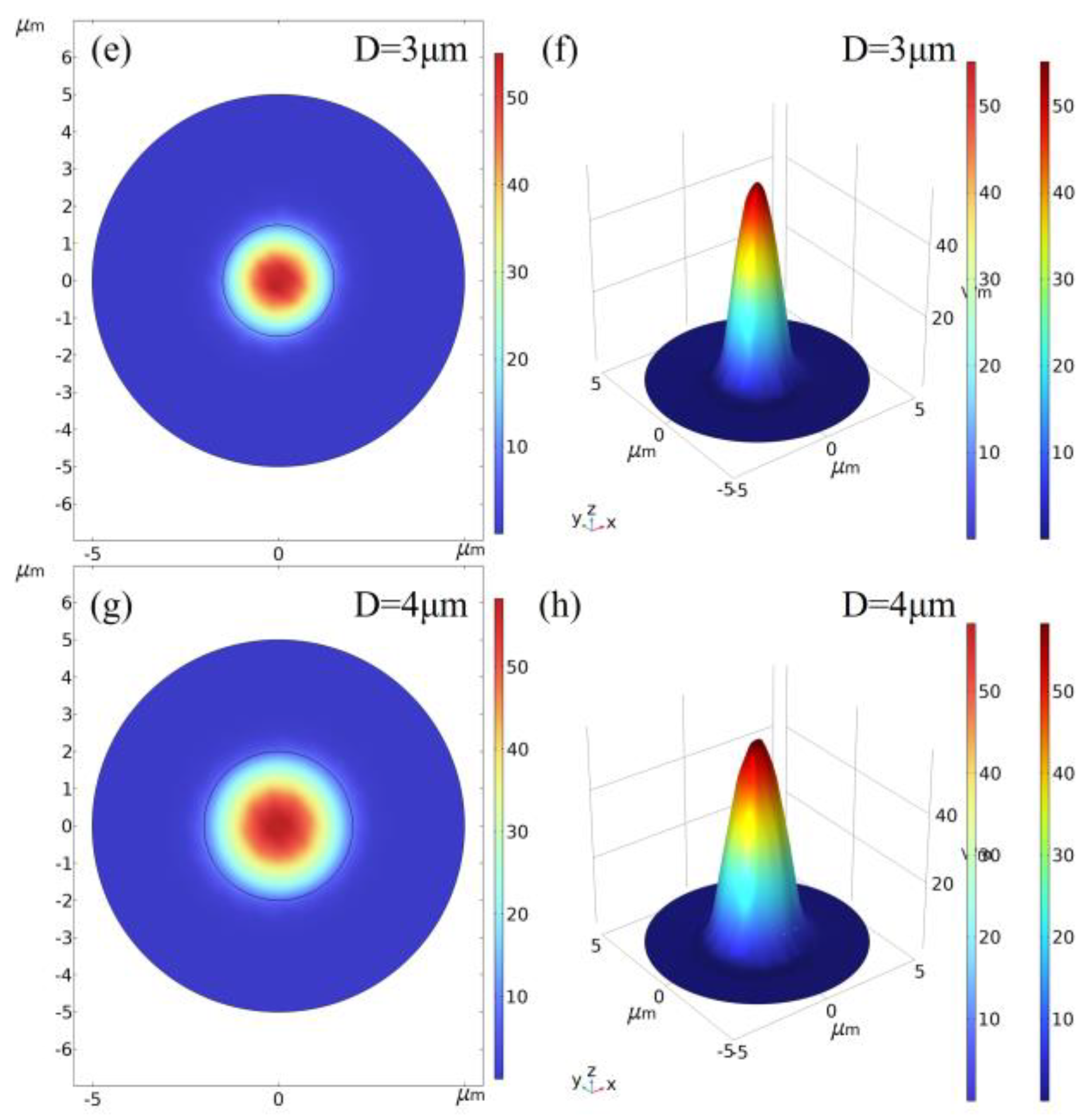

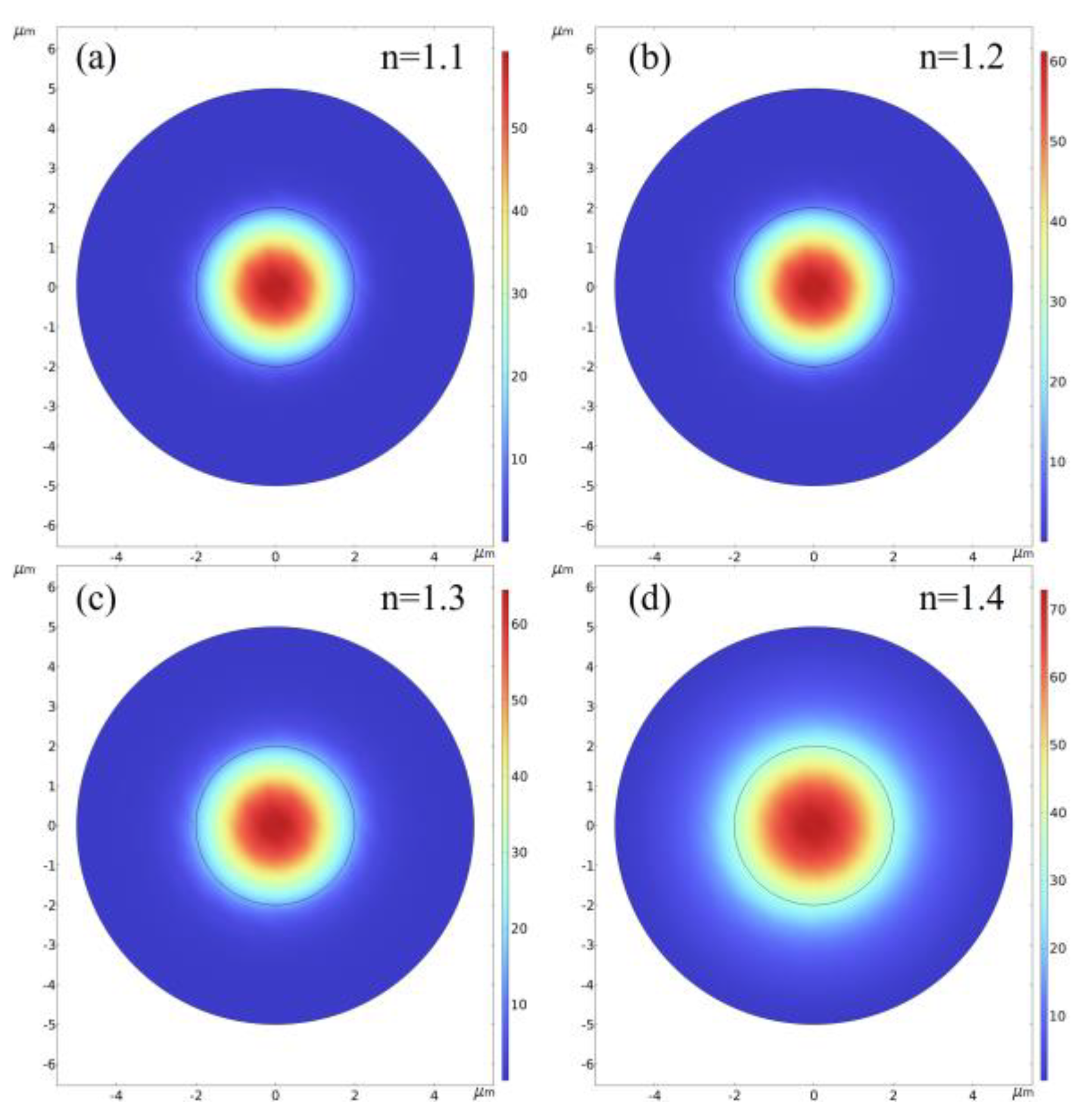

- Microfibers with smaller diameters or larger external refractive indices contain less optical field energy in the core and a stronger evanescent field on the fiber surface.

- (2)

- The graphene-coated microfiber is sensitive to SO2 gas, and the optical loss of the graphene-coated microfiber increases as the SO2 concentration increases, which decreased the FLRD system ring-down time. There is a good linear relationship between the ring-down time and SO2 concentration, with an R2 of 0.994.

- (3)

- The FLRD gas detection system based on graphene-coated microfiber has a good detection performance for SO2, with a maximum error of 4.76% in the concentration inversion and a sensitivity of 1.24 ns/ppm within the range of 0~200 ppm.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, D.; Tang, J.; Zeng, F.; Yang, X.; Yao, Q.; Miao, Y.; Chen, L. Correlation characteristics between SF6 decomposition process and partial discharge quantity under negative DC condition initiated by free metal particle defect. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 574–583. [Google Scholar] [CrossRef]

- Li, J.; Han, X.; Liu, Z.; Yao, X. A Novel GIS Partial Discharge Detection Sensor with Integrated Optical and UHF Methods. IEEE Trans. Power Deliv. 2018, 33, 2047–2049. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, G.; Zhang, X.; Tian, H.; Lu, C.; Liu, J.; Zhang, Y. PD Flexible Built-In High-Sensitivity Elliptical Monopole Antenna Sensor. Sensors 2022, 22, 4982. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Ding, D.; Wang, Y.; Zhou, C.; Lu, H.; Zhang, X. Defect recognition and condition assessment of epoxy insulators in gas insulated switchgear based on multi-information fusion. Measurement 2022, 190, 110701. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Y.; Tang, J.; Cui, Z.; Li, Y.; Zhou, H.; Zhang, G.; Yang, J. Optical technology for detecting the decomposition products of SF6: A review. Opt. Eng. 2018, 57, 110901. [Google Scholar] [CrossRef]

- Cao, W.; Gui, Y.; Chen, T.; Xu, L.; Ding, Z. Adsorption and gas-sensing properties of Pt2–GaNNTs for SF6 decomposition products. Appl. Surf. Sci. 2020, 524, 146570. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, Q.; Zeng, W. Competitive adsorption of SF6 decompositions on Ni-doped ZnO (100) surface: Computational and experimental study. Appl. Surf. Sci. 2019, 479, 185–197. [Google Scholar] [CrossRef]

- Aragoneses-Fenoll, L.; Montes-Casado, M.; Ojeda, G.; García-Paredes, L.; Arimura, Y.; Yagi, J.; Dianzani, U.; Portolés, P.; Rojo, J.M. Role of endocytosis and trans-endocytosis in ICOS costimulator-induced downmodulation of the ICOS Ligand. J. Leukoc. Biol. 2021, 110, 867–884. [Google Scholar] [CrossRef]

- Tian, J.; Zhao, G.; Fleisher, A.J.; Ma, W.; Jia, S. Optical feedback linear cavity enhanced absorption spectroscopy. Opt. Express 2021, 29, 26831–26840. [Google Scholar] [CrossRef]

- Rao, K.S.; Razdan, A.K.; Tyaki, A.; Chaudhary, A.K. Temperature dependent time resolved mid-IR photoacoustic spectroscopy of a nerve gas simulant DMMP. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2018, 204, 696–701. [Google Scholar] [CrossRef]

- Hanf, S.; Keiner, R.; Yan, D.; Popp, J.; Frosch, T. Fiber-Enhanced Raman Multigas Spectroscopy: A Versatile Tool for Environmental Gas Sensing and Breath Analysis. Anal. Chem. 2014, 86, 5278–5285. [Google Scholar] [CrossRef] [PubMed]

- Ge, H.; Kong, W.; Wang, R.; Zhao, G.; Ma, W.; Chen, W.; Wan, F. A novel and simple technique of coupling a diode laser into a linear power build-up cavity for Raman gas sensing. Opt. Lett. 2023, 48, 2186–2189. [Google Scholar] [CrossRef]

- Chen, C.; Feng, W. Intensity-modulated carbon monoxide gas sensor based on cerium dioxide-coated thin-core-fiber Mach-Zehnder interferometer. Opt. Laser Technol. 2022, 152, 108183. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.; Chen, X.; Meng, X.; Liu, X.; Yao, J. An optical fiber sensing method for partial discharge in the HVDC cable system. Int. J. Electr. Power Energy Syst. 2021, 128, 106749. [Google Scholar] [CrossRef]

- Wang, L.; Zhou, J.; Chen, Y.; Xiao, L.; Huang, G.; Huang, X.; Yang, X. An intensity modulated fiber-optic carbon monoxide sensor based on Ag/Co-MOF in-situ coated thin-core fiber. Z. Nat. 2021, 76, 881–889. [Google Scholar] [CrossRef]

- Cheng, H.; Zhang, X.; Tang, J.; Xiao, S.; Wang, T.; Luo, B.; Tian, S. The application of fluorescent optical fiber in partial discharge detection of Ring Main Unit. Measurement 2021, 174, 108979. [Google Scholar] [CrossRef]

- Zhang, L.; Tang, Y.; Tong, L. Micro-/nanofiber Optics: Merging Photonics and Material Science on Nanoscale for Advanced Sensing Technology. iScience 2020, 23, 100810. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Yu, L.; Wu, X.; Hu, W. Experimental Sensing and Density Functional Theory Study of H2S and SOF2 Adsorption on Au-Modified Graphene. Adv. Sci. 2015, 2, 1500101. [Google Scholar] [CrossRef]

- Zhang, L.; Gu, F.; Lou, J.; Yin, X.; Tong, L. Fast detection of humidity with a subwavelength-diameter fiber taper coated with gelatin film. Opt. Express 2008, 16, 13349–13353. [Google Scholar] [CrossRef]

- Jia, L.; Wu, Y.; Yao, B.; Yang, F.; Rao, Y. A Sensitivity Enhanced Gas Sensor Based on Carbon Nanotubes Around Microfiber. In Proceedings of the Third Asia Pacific Optical Sensors Conference, Sydney, Australia, 31 January–3 February 2012; Volume 8351, pp. 457–463. [Google Scholar]

- Fu, H.; Wang, Q.; Ding, J.; Zhu, Y.; Zhang, M.; Yang, C.; Wang, S. Fe2O3 nanotube coating micro-fiber interferometer for ammonia detection. Sens. Actuators B Chem. 2020, 303, 127186. [Google Scholar] [CrossRef]

- Yao, B.; Wu, Y.; Jia, L.; Rao, Y.; Gong, Y.; Jiang, C. Mode field distribution of optical transmission along microfiber affected by CNT films with complex refraction index. J. Opt. Soc. Am. B 2012, 29, 891–895. [Google Scholar] [CrossRef]

- Zhou, Z.; Xu, Y.; Qiao, C.; Liu, L.; Jia, Y. A novel low-cost gas sensor for CO2 detection using polymer-coated fiber Bragg grating. Sens. Actuators B Chem. 2021, 332, 129482. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, W.; Wang, D.; Zhuo, R.; Fu, M.; Zhang, X. Carbon Monoxide Detection Based on the Carbon Nanotube-Coated Fiber Gas Sensor. Photonics 2022, 9, 1001. [Google Scholar] [CrossRef]

- Chen, D.; Tang, J.; Zhang, X.; Wu, P.; Li, Y.; Xiao, B.; Miao, Q.; Liu, K. WS2 Nanostructure-Based Gas Sensor for SF6 Decomposition Products: Experimental and First-Principles Study. IEEE Sens. J. 2022, 22, 20171–20176. [Google Scholar] [CrossRef]

| Actual Concentration (ppm) | Inversion Concentration (ppm) | Relative Error (%) |

|---|---|---|

| 25 | 25.55 | 2.20 |

| 50 | 51.87 | 3.74 |

| 100 | 95.49 | 4.51 |

| 150 | 157.14 | 4.76 |

| 200 | 201.16 | 0.58 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Zhuo, R.; Zhang, Y.; Yu, W.; Huang, Z.; Fu, M.; Zhang, X. An All-Fiber FLRD System for SO2 Detection Based on Graphene-Coated Microfiber. Photonics 2023, 10, 863. https://doi.org/10.3390/photonics10080863

Wang D, Zhuo R, Zhang Y, Yu W, Huang Z, Fu M, Zhang X. An All-Fiber FLRD System for SO2 Detection Based on Graphene-Coated Microfiber. Photonics. 2023; 10(8):863. https://doi.org/10.3390/photonics10080863

Chicago/Turabian StyleWang, Dibo, Ran Zhuo, Yin Zhang, Wenwen Yu, Zhiming Huang, Mingli Fu, and Xiaoxing Zhang. 2023. "An All-Fiber FLRD System for SO2 Detection Based on Graphene-Coated Microfiber" Photonics 10, no. 8: 863. https://doi.org/10.3390/photonics10080863

APA StyleWang, D., Zhuo, R., Zhang, Y., Yu, W., Huang, Z., Fu, M., & Zhang, X. (2023). An All-Fiber FLRD System for SO2 Detection Based on Graphene-Coated Microfiber. Photonics, 10(8), 863. https://doi.org/10.3390/photonics10080863