Methods Controlling Radiation Parameters of Mode-Locked All-Fiberized Lasers

Abstract

:1. Introduction

2. Mechanical Action on Fibre

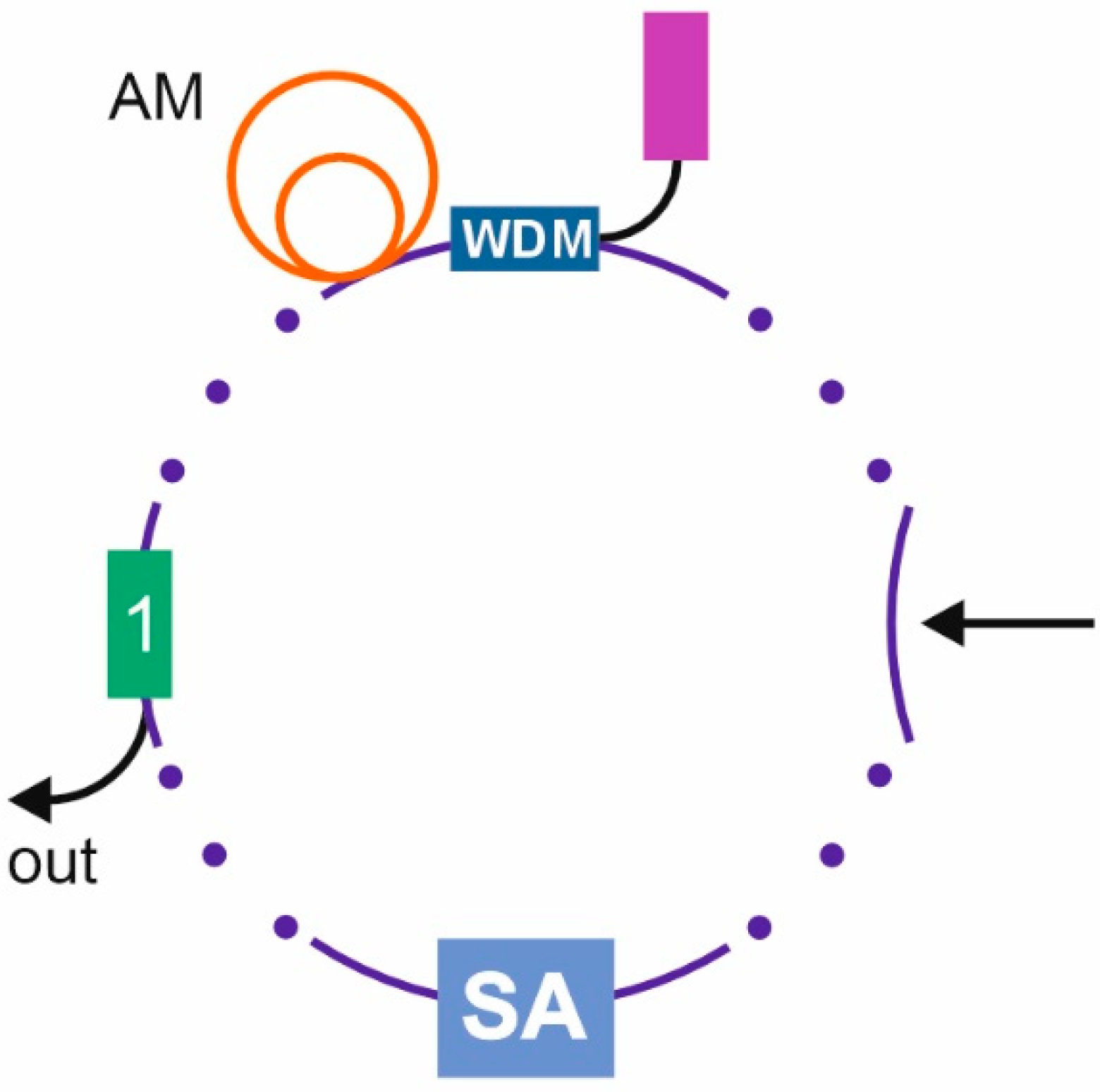

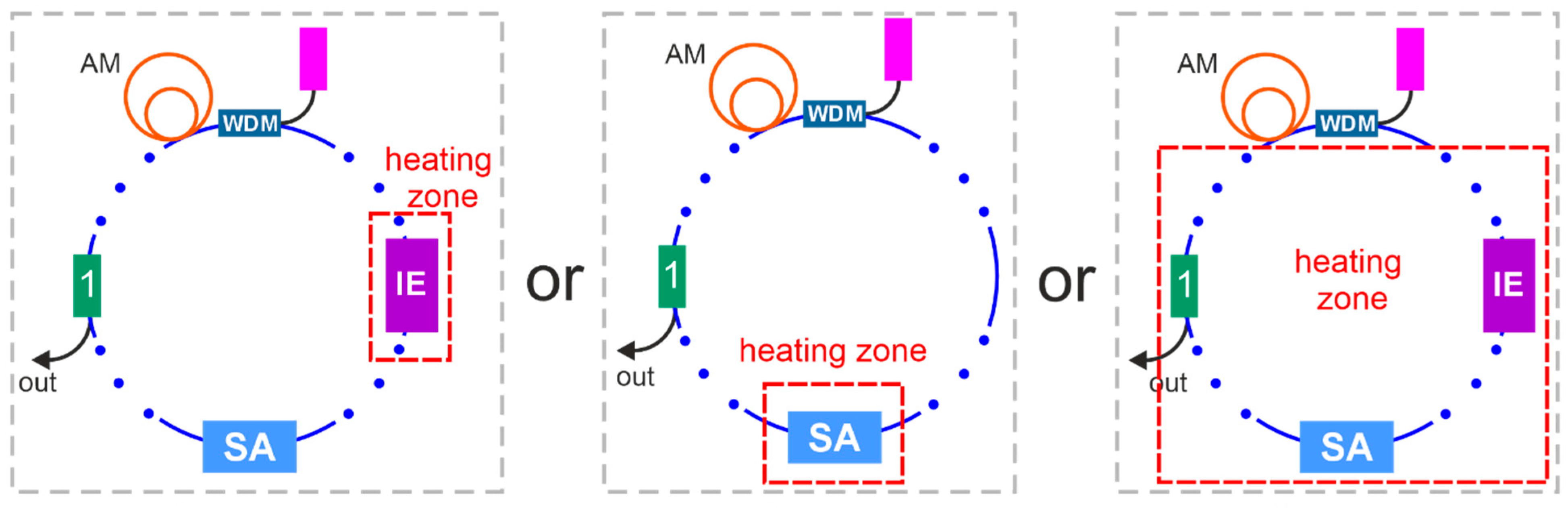

3. Temperature Adjustment of MLFL Cavity Elements

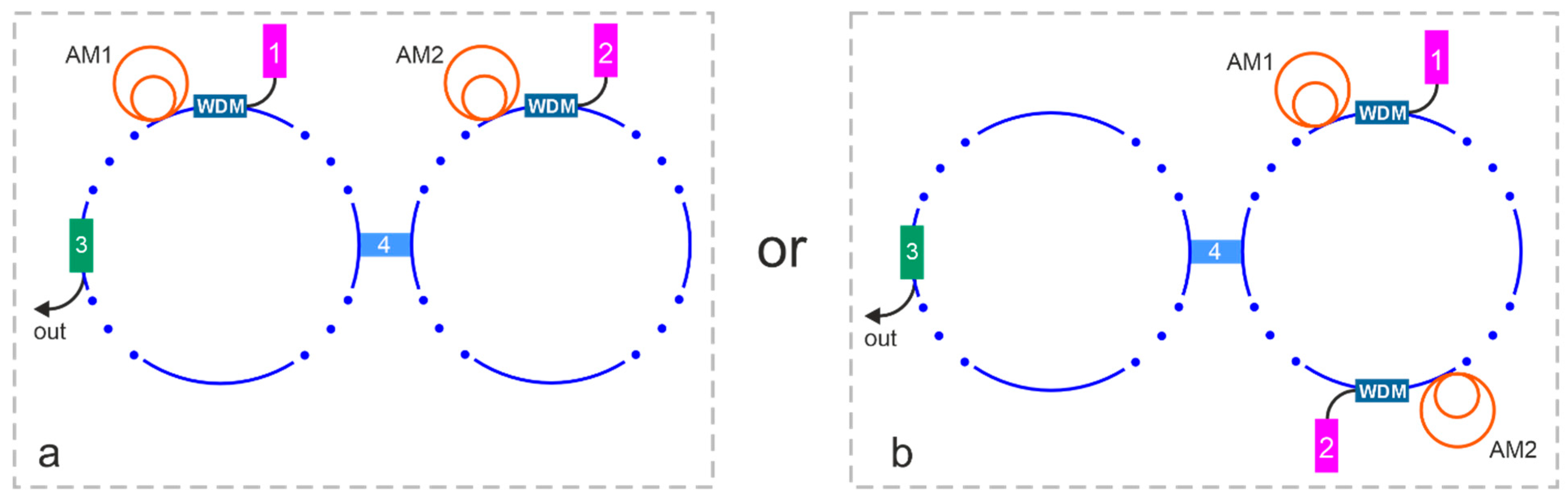

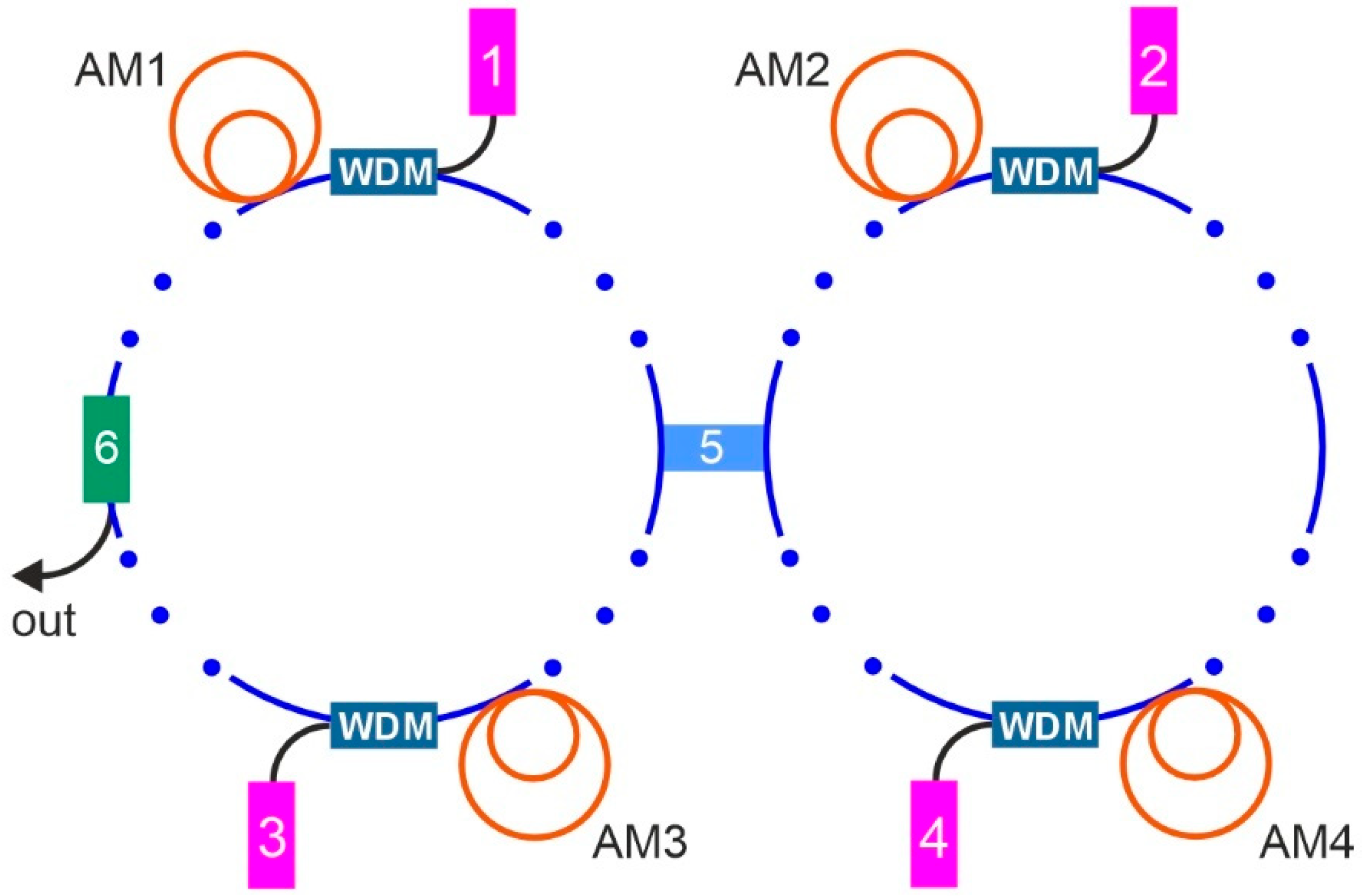

4. Controlling Output Parameters of MLFLs with Two Pump Sources

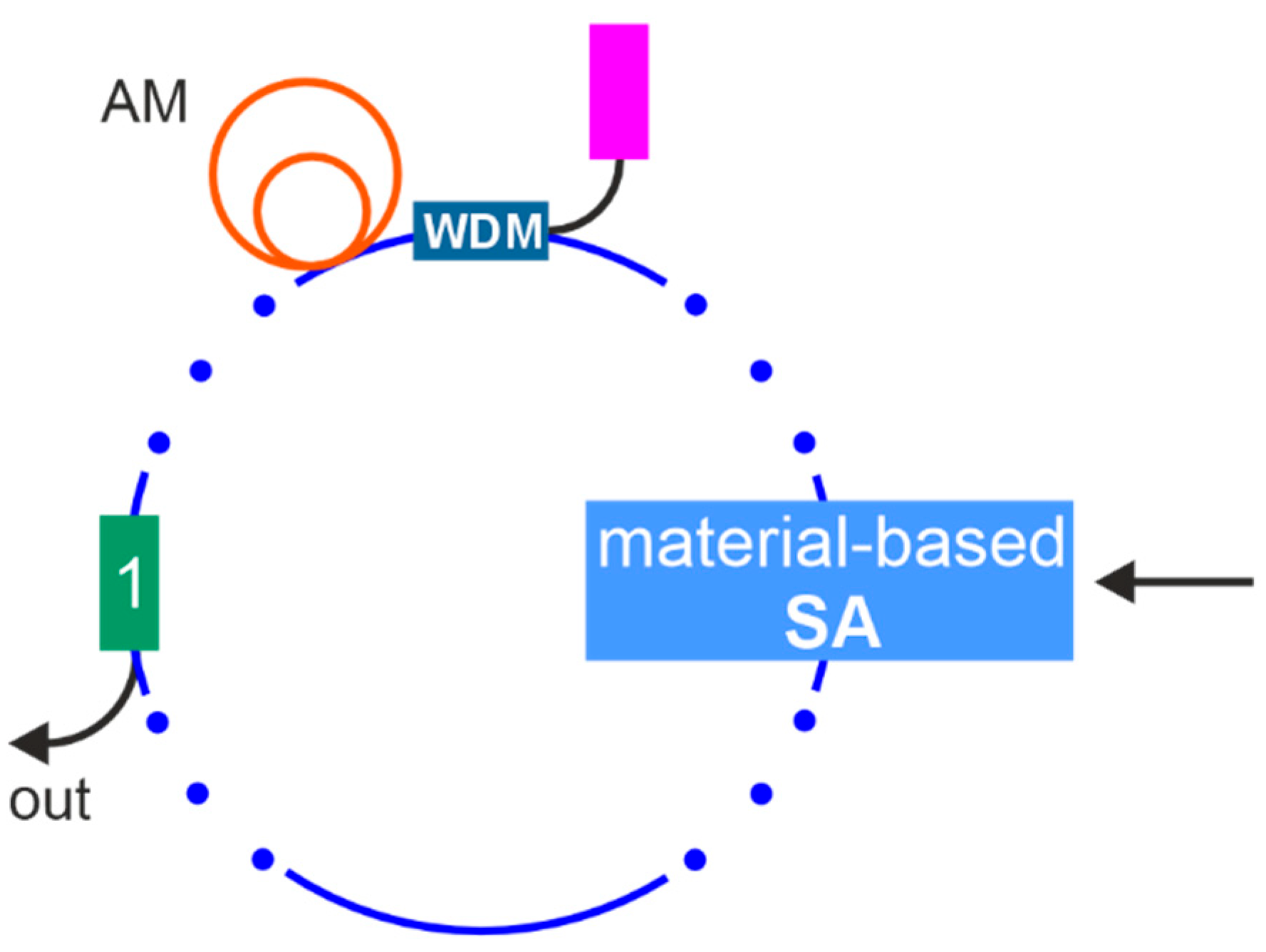

5. Controlling the Output Radiation Parameters of MLFLs through Adjustment of the Material-Based Absorbers

6. Controlling Output Parameters of MLFLs with Modified Fibres

7. Controlling Output Parameters of MLFLs by Radiation Selection: Spectral, Amplitude, Polarisational, and Temporal

8. Intellectual Technologies for Controlling MLFL Radiation Parameters

9. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dong, L.; Samson, B. Fiber Lasers: Basics, Technology, and Applications; CRC Press: Boca Raton, FL, USA, 2016; p. 340. ISBN 978-1-49872-554-5. [Google Scholar] [CrossRef]

- Taylor, H. Bending effects in optical fibers. J. Lightwave Technol. 1984, 2, 617–628. [Google Scholar] [CrossRef]

- Collett, E. Polarized Light in Fiber Optics; SPIE Press: St Bellingham, WA, USA, 2003; p. 540. ISBN 978-0-81945-761-5. [Google Scholar]

- Matsas, V.; Newson, T.; Richardson, D.; Payne, D. Selfstarting passively mode-locked fibre ring soliton laser exploiting nonlinear polarisation rotation. Electron. Lett. 1992, 28, 1391–1393. [Google Scholar] [CrossRef]

- Li, Z.; Li, M.; Hou, X.; Du, L.; Xiao, L.; Wang, T.; Ma, W. Generation of mode-locked states of conventional solitons and bright-dark solitons in graphene mode-locked fiber laser. Front. Optoelectron. 2023, 16, 12. [Google Scholar] [CrossRef] [PubMed]

- Kobtsev, S. Methods of radiation wavelength tuning in short-pulsed fibre lasers. Photonics 2024, 11, 28. [Google Scholar] [CrossRef]

- Abdullina, S.R.; Babin, S.A.; Vlasov, A.A.; Kablukov, S.I. Tunable Bragg gratings for fiber lasers. Opt. Spectrosc. 2007, 103, 1007–1011. [Google Scholar] [CrossRef]

- Hisham, H.K. Fiber Bragg Grating Sensors: Development and Applications; CRC Press: Boca Raton, FL, USA, 2019; p. 136. [Google Scholar] [CrossRef]

- Crunteanu, A.; Bouyge, D.; Sabourdy, D.; Blondy, P.; Couderc, V.; Grossard, L.; Pioger, P.H.; Barthélemy, A. Deformable micro-electro-mechanical mirror integration in a fibre laser Q-switch system. J. Opt. A Pure Appl. Opt. 2006, 8, S347–S351. [Google Scholar] [CrossRef]

- Hatton, W.; Nishimura, M. Temperature dependence of chromatic dispersion in single mode fibers. J. Lightwave Technol. 1986, 4, 1552–1555. [Google Scholar] [CrossRef]

- Ghosh, G.; Endo, M.; Iwasaki, T. Temperature-dependent Sellmeier coefficients and chromatic dispersions for some optical fiber glasses. J. Lightwave Technol. 1994, 12, 1338–1342. [Google Scholar] [CrossRef]

- Kato, T.; Koyano, Y.; Nishimura, M. Temperature dependence of chromatic dispersion in various types of optical fiber. Opt. Lett. 2000, 25, 1156–1158. [Google Scholar] [CrossRef]

- Hamp, M.; Wright, J.; Hubbard, M.; Brimacombe, B. Investigation into the temperature dependence of chromatic dispersion in optical fiber. IEEE Photon Technol. Lett. 2002, 14, 1524–1526. [Google Scholar] [CrossRef]

- Andre, P.; Pinto, A.; Pinto, J. Effect of temperature on the single mode fibers chromatic dispersion. J. Microw. Optoelectron. 2004, 3, 64–70. [Google Scholar]

- Stepniewski, G.; Kasztelanic, R.; Pysz, D.; Stepien, R.; Klimczak, M.; Buczynski, R. Temperature sensitivity of chromatic dispersion in nonlinear silica and heavy metal oxide glass photonic crystal fibers. Opt. Mater. Express 2016, 6, 2689–2703. [Google Scholar] [CrossRef]

- Hashimoto, D.; Shimizu, K. Cooling an optical fiber to 4.5 K by indirect thermal contact with a liquid-helium flow and spectroscopic temperature measurements. Rev. Sci. Instrum. 2008, 79, 093102. [Google Scholar] [CrossRef]

- Kashyap, R. Fiber Bragg Gratings; Academic Press: Cambridge, MA, USA, 2010; p. 614. [Google Scholar] [CrossRef]

- Othonos, A.; Kalli, K.; Kohnke, G.E. Fiber Bragg Gratings: Fundamentals and Applications in Telecommunications and Sensing; Artech House: Norwood, MA, USA, 1999; p. 433. ISBN 978-0-89006-344-6. [Google Scholar]

- Rosman, N.A.; Rashidi, C.B.M.; Aljunid, S.A.; Endut, R. Temperature monitoring system using fiber Bragg grating (FBG) approach. In Proceedings of the 2nd International Conference on Applied Photonics and Electronics 2019 (Incape 2019), Putrajaya, Malaysia, 22 August 2019; Volume 34, p. 085122. [Google Scholar] [CrossRef]

- Khan, R.Y.M.; Ullah, R.; Faisal, M. Design and development of cost-effective fiber Bragg grating temperature sensor package. Meas. Sci. Technol. 2023, 34, 085122. [Google Scholar] [CrossRef]

- Lin, G.-C.; Wang, L.; Yang, C.; Shih, M.; Chuang, T. Thermal performance of metal-clad fiber Bragg grating sensors. IEEE Photon Technol. Lett. 1998, 10, 406–408. [Google Scholar] [CrossRef]

- Kersey, A.; Davis, M.; Patrick, H.; LeBlanc, M.; Koo, K.; Askins, C.; Putnam, M.; Friebele, E. Fiber grating sensors. J. Lightwave Technol. 1997, 15, 1442–1463. [Google Scholar] [CrossRef]

- Farries, M.; Rogers, A. Temperature dependence of the Kerr effect in a silica optical fibre. Electron. Lett. 1983, 19, 890–891. [Google Scholar] [CrossRef]

- Koo, J.; Kim, J.; Lee, J.H. A Thermo-optically controllable saturable absorber for switchable operation of a fiber laser between Q-switching and harmonic mode-locking. J. Lumin. 2019, 205, 30–36. [Google Scholar] [CrossRef]

- Shi, J.; Xu, W.; Xu, D.; Wang, Y.; Zhang, C.; Yan, C.; Yan, D.; He, Y.; Tang, L.; Zhang, W.; et al. Humidity sensor based on intracavity sensing of fiber ring laser. J. Phys. D Appl. Phys. 2017, 50, 425105. [Google Scholar] [CrossRef]

- Guo, K.; He, J.; Li, H.; Xu, X.; Du, B.; Liu, S.; Chen, Y.; Ma, D.; Xu, G.; Wang, Y. Polarimetric fiber laser for relative humidity sensing based on graphene oxide-coated D-shaped fiber and beat frequency demodulation. Opt. Express 2022, 30, 15998–16008. [Google Scholar] [CrossRef]

- Zhang, Z.; Gong, H.; Yu, C.; Ni, K.; Zhao, C. An optical fiber humidity sensor based on femtosecond laser micromachining Fabry-Perot cavity with composite film. Opt. Laser Technol. 2022, 150, 107949. [Google Scholar] [CrossRef]

- Wang, J.; Kou, Y.; Wang, A.; Hao, J.; Niu, C.; Jiang, H.; Meng, H.; Sun, W.; Geng, T. Lab-on-fiber: Laser-induced micro-cavity for a relative humidity measurement. Opt. Lett. 2023, 48, 5261–5264. [Google Scholar] [CrossRef] [PubMed]

- Deng, M.; Liu, D.; Huang, W.; Zhu, T. Highly-sensitive magnetic field sensor based on fiber ring laser. Opt. Express 2016, 24, 645–651. [Google Scholar] [CrossRef] [PubMed]

- Bohnert, K.M.; Nehring, J. Fiber-optic sensing of electric field components. Appl. Opt. 1988, 27, 4814–4818. [Google Scholar] [CrossRef] [PubMed]

- Kobtsev, S.M. Artificial saturable absorbers for ultrafast fibre lasers. Opt. Fiber Technol. 2022, 68, 102764. [Google Scholar] [CrossRef]

- Doran, N.J.; Wood, D. Nonlinear-optical loop mirror. Opt. Lett. 1988, 13, 56–58. [Google Scholar] [CrossRef]

- Fermann, M.E.; Haberl, F.; Hofer, M.; Hochreiter, H. Nonlinear amplifying loop mirror. Opt. Lett. 1990, 15, 752–754. [Google Scholar] [CrossRef] [PubMed]

- Kokhanovskiy, A.; Kobtsev, S.; Ivanenko, A.; Smirnov, S. Properties of artificial saturable absorbers based on NALM with two pumped active fibres. Laser Phys. Lett. 2018, 15, 125101. [Google Scholar] [CrossRef]

- Smirnov, S.; Kobtsev, S.; Ivanenko, A.; Kokhanovskiy, A.; Kemmer, A.; Gervaziev, M. Layout of NALM fiber laser with adjustable peak power of generated pulses. Opt. Lett. 2017, 42, 1732–1735. [Google Scholar] [CrossRef]

- Kokhanovskiy, A.; Kuprikov, E.; Ivanenko, A.; Kobtsev, S. All-polarisation-maintaining modified figure-of-8 fibre laser as a source of soliton molecules. Laser Phys. Lett. 2020, 17, 085101. [Google Scholar] [CrossRef]

- Horowitz, M.; Barad, Y.; Silberberg, Y. Noiselike pulses with a broadband spectrum generated from an erbium-doped fiber laser. Opt. Lett. 1997, 22, 799–801. [Google Scholar] [CrossRef] [PubMed]

- Kobtsev, S.; Kukarin, S.; Smirnov, S.; Turitsyn, S.; Latkin, A. Generation of double-scale femto/pico-second optical lumps in mode-locked fiber lasers. Opt. Express 2009, 17, 20707–20713. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Rafailov, E.U.; Livshits, D.; Turchinovich, D. Quantum well saturable absorber mirror with electrical control of modulation depth. Appl. Phys. Lett. 2010, 97, 051103. [Google Scholar] [CrossRef]

- Zolotovskaya, S.A.; Butkus, M.; Häring, R.; Able, A.; Kaenders, W.; Krestnikov, I.L.; Livshits, D.A.; Rafailov, E.U. P-i-n junction quantum dot saturable absorber mirror: Electrical control of ultrafast dynamics. Opt. Express 2012, 20, 9038–9045. [Google Scholar] [CrossRef] [PubMed]

- Baylam, I.; Cizmeciyan, M.N.; Ozharar, S.; Polat, E.O.; Kocabas, C.; Sennaroglu, A. Femtosecond pulse generation with voltage-controlled graphene saturable absorber. Opt. Lett. 2014, 39, 5180–5183. [Google Scholar] [CrossRef] [PubMed]

- Baylam, I.; Balci, O.; Kakenov, N.; Kocabas, C.; Sennaroglu, A. Graphene-gold supercapacitor as a voltage controlled saturable absorber for femtosecond pulse generation. Opt. Lett. 2016, 41, 910–913. [Google Scholar] [CrossRef] [PubMed]

- Baylam, I.; Ozharar, S.; Kakenov, N.; Kocabas, C.; Sennaroglu, A. Femtosecond pulse generation from a Ti3+:sapphire laser near 800 nm with voltage reconfigurable graphene saturable absorbers. Opt. Lett. 2017, 42, 1404–1407. [Google Scholar] [CrossRef]

- Lee, E.J.; Choi, S.Y.; Jeong, H.; Park, N.H.; Yim, W.; Kim, M.H.; Park, J.-K.; Son, S.; Bae, S.; Kim, S.J.; et al. Active control of all-fibre graphene devices with electrical gating. Nat. Commun. 2015, 6, 6851. [Google Scholar] [CrossRef]

- Kovalchuk, O.; Uddin, S.; Lee, S.; Song, Y.-W. Graphene capacitor-based electrical switching of mode-locking in all-fiberized femtosecond lasers. ACS Appl. Mater. Interfaces 2020, 12, 54005–54011. [Google Scholar] [CrossRef]

- Gene, J.; Park, N.H.; Jeong, H.; Choi, S.Y.; Rotermund, F.; Yeom, D.-I.; Kim, B.Y. Optically controlled in-line graphene saturable absorber for the manipulation of pulsed fiber laser operation. Opt. Express 2016, 24, 21301–21307. [Google Scholar] [CrossRef]

- Wilson, M.; Aboites, V.; Pisarchik, A.; Pinto, V.; Barmenkov, Y. Controlling a laser output through an active saturable absorber. Rev. Mex. Fis. 2011, 57, 250–254. Available online: https://www.scielo.org.mx/pdf/rmf/v57n3/v57n3a13.pdf (accessed on 1 June 2024).

- Gladush, Y.; Mkrtchyan, A.; Nyushkov, B.; Ivanenko, A.; Kokhanovskiy, A.; Kobtsev, S.M.; Nasibulin, A.G. Electro-optically gated in-line saturable absorbers for fibre lasers. In Proceedings of the AOPC 2019: Advanced Laser Materials and Laser Technology, Beijing, China, 7–9 July 2019; Volume 11333, p. 113331M. [Google Scholar] [CrossRef]

- Gladush, Y.; Mkrtchyan, A.A.; Kopylova, D.S.; Ivanenko, A.; Nyushkov, B.; Kobtsev, S.; Kokhanovskiy, A.; Khegai, A.; Melkumov, M.; Burdanova, M.; et al. Ionic Liquid Gated Carbon Nanotube Saturable Absorber for Switchable Pulse Generation. Nano Lett. 2019, 19, 5836–5843. [Google Scholar] [CrossRef] [PubMed]

- Kokhanovskiy, A.; Kuprikov, E.; Serebrennikov, K.; Mkrtchyan, A.; Davletkhanov, A.; Bunkov, A.; Krasnikov, D.; Shashkov, M.; Nasibulin, A.; Gladush, Y. Multistability manipulation by reinforcement learning algorithm inside mode-locked fiber laser. Nanophotonics 2024, 13. [Google Scholar] [CrossRef]

- Viskontas, K.; Regelskis, K.; Rusteika, N. Slow and fast optical degradation of the SESAM for fiber laser mode-locking at 1 μm. Lith. J. Phys. 2014, 54, 127–135. [Google Scholar] [CrossRef]

- Ryu, S.Y.; Kim, K.-S.; Kim, J.; Kim, S. Degradation of optical properties of a film-type single-wall carbon nanotubes saturable absorber (SWNT-SA) with an Er-doped all-fiber laser. Opt. Express 2012, 20, 12966–12974. [Google Scholar] [CrossRef] [PubMed]

- Stępień, W.; Szczepanek, J.; Kardaś, T.; Nejbauer, M.; Radzewicz, C.; Stepanenko, Y. Study on parameters of fiber loop mirrors as artificial saturable absorbers. Proc. SPIE 2017, 10094, 100941N. [Google Scholar] [CrossRef]

- Tseng, S.-M.; Chen, C.-L. Side-polished fibers. Appl. Opt. 1992, 31, 3438–3447. [Google Scholar] [CrossRef] [PubMed]

- Lacroix, S.; Black, R.J.; Veilleux, C.; Lapierre, J. Tapered single-mode fibers: External refractive-index dependence. Appl. Opt. 1986, 25, 2468–2469. [Google Scholar] [CrossRef] [PubMed]

- Falciai, R.; Scheggi, A.M. Biconical fibers as mode and wavelength filters. Appl. Opt. 1989, 28, 1309–1311. [Google Scholar] [CrossRef]

- Tang, J.; Zhou, J.; Guan, J.; Long, S. Fabrication of side-polished single mode-multimode-single mode fiber and its characteristics of refractive index sensing. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 238–245. [Google Scholar] [CrossRef]

- Zhuo, L.; Tang, J.; Zhu, W.; Zheng, H.; Guan, H.; Lu, H.; Chen, Y.; Luo, Y.; Zhang, J.; Zhong, Y.; et al. Side polished fiber: A versatile platform for compact fiber devices and sensors. Photon. Sens. 2023, 13, 230120. [Google Scholar] [CrossRef]

- Markos, D.J.; Ipson, B.L.; Smith, K.H.; Schultz, S.M.; Selfridge, R.H.; Monte, T.D.; Dyott, R.B.; Miller, G. Controlled core removal from a D-shaped optical fiber. Appl. Opt. 2003, 42, 7121–7125. [Google Scholar] [CrossRef]

- Fan, S.; Healy, N. CO2 laser-based side-polishing of silica optical fibers. Opt. Lett. 2020, 45, 4128–4131. [Google Scholar] [CrossRef]

- Hu, C.; Ma, X.; Wang, C.; Zhou, S.; Wu, H.; Sun, K. High-quality rapid fabrication method of a D-shaped optical fiber based on a CO2 laser. Opt. Mater. Express 2021, 11, 2025–2036. [Google Scholar] [CrossRef]

- Pan, Y.Z.; Liu, W.J.; Tian, Z.S.; Wang, S.S.; Su, X.H.; Liu, Y.; Qu, S.L. Fabrication of a D-shaped fiber by femtosecond laser-induced water breakdown for carbon nanotubes’ evanescent field interaction mode-locking of a double-clad fiber laser. Laser Phys. 2013, 23, 85110. [Google Scholar] [CrossRef]

- Stepniewski, G.; Filipkowski, A.; Pysz, D.; Warszewski, J.; Buczynski, R.; Smietana, M.; Kasztelanic, R. From D-shaped to D-shape optical fiber—A universal solution for sensing and biosensing applications: Drawn D-shape fiber and its sensing applications. Measurement 2023, 222, 113642. [Google Scholar] [CrossRef]

- Ahmad, H.; Sadafi, N.; Yusoff, N.; Samion, M.; Ismail, M.; Chong, W. Arc-shaped fiber coated with Ta2AlC MAX phase as mode-locker for pulse laser generation in thulium/holmium doped fiber laser. Optik 2022, 252, 168508. [Google Scholar] [CrossRef]

- Chen, K.; Herman, P.; Taylor, R.; Hnatovsky, C. Vacuum-ultraviolet laser-induced refractive-index change and birefringence in standard optical fibers. J. Lightwave Technol. 2003, 21, 1969–1977. [Google Scholar] [CrossRef]

- Meltz, G.; Morey, W.W.; Glenn, W.H. Formation of Bragg gratings in optical fibers by a transverse holographic method. Opt. Lett. 1989, 14, 823–825. [Google Scholar] [CrossRef]

- Salter, P.S.; Woolley, M.J.; Morris, S.M.; Booth, M.J.; Fells, J.A.J. Femtosecond fiber Bragg grating fabrication with adaptive optics aberration compensation. Opt. Lett. 2018, 43, 5993–5996. [Google Scholar] [CrossRef]

- Yang, F.; Wang, D.N.; Wang, Z.; Li, L.; Zhao, C.-L.; Xu, B.; Jin, S.; Cao, S.-Y.; Fang, Z.-J. Saturable absorber based on a single mode fiber—Graded index fiber—Single mode fiber structure with inner micro-cavity. Opt. Express 2018, 26, 927–934. [Google Scholar] [CrossRef]

- Hideur, A.; Chartier, T.; Özkul, C.; Sanchez, F. All-fiber tunable ytterbium-doped double-clad fiber ring laser. Opt. Lett. 2001, 26, 1054–1056. [Google Scholar] [CrossRef] [PubMed]

- Nyushkov, B.N.; Kobtsev, S.M.; Ivanenko, A.V.; Smirnov, S.V. Programmable optical waveform generation in a mode-locked gain-modulated SOA-fiber laser. J. Opt. Soc. Am. B 2019, 36, 3133–3138. [Google Scholar] [CrossRef]

- Nyushkov, B.N.; Ivanenko, A.V.; Smirnov, S.V. Control of the regimes and parameters of lasing in mode-locked fiber lasers: Opportunities and prospects. Optoelectron. Instrum. Data Process. 2021, 57, 569–583. [Google Scholar] [CrossRef]

- Lam, H.Q.; Li, R.; Lee, K.E.K.; Wong, V.; Shum, P. Mode locking of an erbium-doped fiber laser with intra-cavity polarization modulation. Opt. Commun. 2011, 284, 1026–1028. [Google Scholar] [CrossRef]

- Winters, D.G.; Backus, S.; Kirchner, M.S. Electronic control of nonlinear polarization evolution modelocking in a fiber laser. In Proceedings of the Nonlinear Optics, OSA Technical Digest (Online), Waikoloa, HI, USA, 17–21 July 2017; paper NTh3A.5. Optica Publishing Group: Washington, DC, USA, 2017. [Google Scholar] [CrossRef]

- Nikodem, M.; Krzempek, K.; Zygadlo, K.; Dudzik, G.; Waz, A.; Abramski, K.; Komorowska, K. Intracavity polarization control in mode-locked Er-doped fibre lasers using liquid crystals. Opto-Electronics Rev. 2014, 22, 113–117. [Google Scholar] [CrossRef]

- Iegorov, R.; Ilday, F. Spectral sculpting a fiber laser via intracavity spatial light modulator. In Proceedings of the 2015 European Conference on Lasers and Electro-Optics—European Quantum Electronics Conference, Munich, Germany, 21–25 June 2015; paper CJ_2_3. Optica Publishing Group: Washington, DC, USA, 2015. Available online: https://opg.optica.org/abstract.cfm?URI=CLEO_Europe-2015-CJ_2_3 (accessed on 1 June 2024).

- Reber, M.; Cooper, N.; Ta, U. Spectral shaping of an ultrafast ytterbium fiber laser via a passive intracavity optical filter: A simple and reliable route to sub-45 fs pulses. Appl. Opt. 2023, 62, 2195–2199. [Google Scholar] [CrossRef] [PubMed]

- Yun, S.H.; Hwang, I.K.; Kim, B.Y. All-fiber tunable filter and laser based on two-mode fiber. Opt. Lett. 1996, 21, 27–29. [Google Scholar] [CrossRef] [PubMed]

- Jeon, M.-Y.; Lee, H.K.; Kim, K.H.; Lee, E.-H.; Yun, S.H.; Kim, B.Y.; Koh, Y.W. An electronically wavelength-tunable mode-locked fiber laser using an all-fiber acoustooptic tunable filter. IEEE Photon. Technol. Lett. 1996, 8, 1618–1620. [Google Scholar] [CrossRef] [PubMed]

- Jiang, H.; Chu, H. Bandpass filter tuned wavelength-variable mode-locked PM fiber laser at 1.06 μm. Optik 2019, 188, 87–90. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, A.P.; Shen, Y.H.; Tam, H.-Y.; Wai, P.K.A. Widely tunable mode-locked fiber laser using carbon nanotube and LPG W-shaped filter. Opt. Lett. 2015, 40, 4329–4332. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Yao, M.; Hu, C.; Zhang, A.P.; Shen, Y.; Tam, H.-Y.; Wai, P.K.A. Optofluidic tunable mode-locked fiber laser using a long-period grating integrated microfluidic chip. Opt. Lett. 2017, 42, 1117–1120. [Google Scholar] [CrossRef] [PubMed]

- Dai, L.; Huang, Z.; Huang, Q.; Al Araimi, M.; Rozhin, A.; Liang, X.; Mou, C. Microfiber assisted bidirectional wavelength-locked ultrafast erbium-doped fiber laser. Opt. Laser Technol. 2023, 162, 109219. [Google Scholar] [CrossRef]

- Pu, G.; Yi, L.; Zhang, L.; Hu, W. Intelligent programmable mode-locked fiber laser with a human-like algorithm. Optica 2019, 6, 362–369. [Google Scholar] [CrossRef]

- Genty, G.; Salmela, L.; Dudley, J.M.; Brunner, D.; Kokhanovskiy, A.; Kobtsev, S.; Turitsyn, S.K. Machine learning and applications in ultrafast photonics. Nat. Photon. 2021, 15, 91–101. [Google Scholar] [CrossRef]

- Kobtsev, S.M. Perspective paper: Can machine learning become a universal method of laser photonics? Opt. Fiber Technol. 2021, 65, 102626. [Google Scholar] [CrossRef]

- Zheng, P.-Z.; Li, T.-J.; Xia, H.-D.; Feng, M.-J.; Liu, M.; Ye, B.-L.; Luo, A.-P.; Xu, W.-C.; Luo, Z.-C. Autosetting soliton pulsation in a fiber laser by an improved depth-first search algorithm. Opt. Express 2021, 29, 34684–34694. [Google Scholar] [CrossRef] [PubMed]

- Ma, Q.; Yu, H. Artificial Intelligence-Enabled Mode-Locked Fiber Laser: A Review. Nanomanuf. Metrol. 2023, 6, 36. [Google Scholar] [CrossRef]

- Freire, P.; Manuylovich, E.; Prilepsky, J.E.; Turitsyn, S.K. Artificial neural networks for photonic applications—From algorithms to implementation: Tutorial. Adv. Opt. Photon. 2023, 15, 739–834. [Google Scholar] [CrossRef]

- Yan, Q.; Tian, Y.; Zhang, T.; Lv, C.; Meng, F.; Jia, Z.; Qin, W.; Qin, G. Machine learning based automatic mode-locking of a dual-wavelength soliton fiber laser. Photonics 2024, 11, 47. [Google Scholar] [CrossRef]

- Jiang, X.; Zhang, M.; Song, Y.; Chen, H.; Huang, D.; Wang, D. Predicting ultrafast nonlinear dynamics in fiber optics by enhanced physics-informed neural network. J. Lightwave Technol. 2024, 42, 1381–1394. [Google Scholar] [CrossRef]

- Smirnov, S.; Kobtsev, S.; Kukarin, S.; Ivanenko, A. Three key regimes of single pulse generation per round trip of all-normal-dispersion fiber lasers mode-locked with nonlinear polarization rotation. Opt. Express 2012, 20, 27447–27453. [Google Scholar] [CrossRef]

- Kobtsev, S.; Smirnov, S.; Kukarin, S.; Turitsyn, S. Mode-locked fiber lasers with significant variability of generation regimes. Opt. Fiber Technol. 2014, 20, 615–620. [Google Scholar] [CrossRef]

- Ye, G.; Liu, B.; Dai, M.; Ma, Y.; Shirahata, T.; Yamashita, S.; Set, S.Y. Pump-power-controlled L-band wavelength-tunable mode-locked fiber laser utilizing nonlinear polarization evolution in all-polarization-maintaining fibers. Opt. Lett. 2024, 49, 2433–2436. [Google Scholar] [CrossRef]

| № | Control Method | Advantages | Disadvantages |

|---|---|---|---|

| 1 | Mechanical action on fibre | Simplicity, possibility of implementation in practically any conditions | Slow response time, repeatability problems, possible lack of parameter reproducibility due to plastic deformation of the fibre |

| 2 | Temperature adjustment of MLFL cavity elements | Simplicity, possibility of electronic control | Slow response time, need of thermally isolated spaces |

| 3 | Controlling output parameters of MLFL with two pump sources | Fast response time, possibility of electronic control | Desired pulse parameters may be only reachable at pumping powers below the maximum |

| 4 | Controlling the output radiation parameters of MLFL through adjustment of material-based absorbers | Certain types of material-based saturable absorbers allow electrical control of their properties | Limited lifetime of material-based absorbers, difficulties in controlling the properties of absorbers |

| 5 | Controlling output parameters of MLFL with modified fibres | Great variety of methods, possibility of electronic control in rare cases | Methods, in their majority, do not allow dynamic control over output radiation parameters |

| 6 | Controlling output parameters of MLFL by radiation selection: spectral, amplitude, polarisational, and temporal | Fast response time, use of components adapted to the all-fibre format | Needs intracavity elements allowing adjustment (electronic or manual) of their parameters. |

| 7 | Intellectual technologies for controlling MLFL radiation parameters | Many laser tuning functions may be automated | Acquisition of the output radiation parameters requires complex measurement equipment |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kobtsev, S. Methods Controlling Radiation Parameters of Mode-Locked All-Fiberized Lasers. Photonics 2024, 11, 552. https://doi.org/10.3390/photonics11060552

Kobtsev S. Methods Controlling Radiation Parameters of Mode-Locked All-Fiberized Lasers. Photonics. 2024; 11(6):552. https://doi.org/10.3390/photonics11060552

Chicago/Turabian StyleKobtsev, Sergey. 2024. "Methods Controlling Radiation Parameters of Mode-Locked All-Fiberized Lasers" Photonics 11, no. 6: 552. https://doi.org/10.3390/photonics11060552