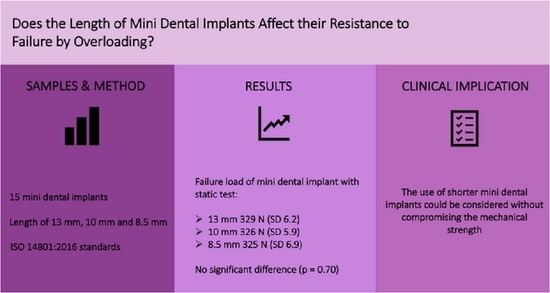

Does the Length of Mini Dental Implants Affect Their Resistance to Failure by Overloading?

Abstract

:1. Introduction

2. Materials and Methods

3. Results

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alshenaiber, R.; Cowan, C.; Barclay, C.; Silikas, N. Analysis of residual ridge morphology in a group of edentulous patients seeking NHS dental implant provision—Retrospective observational lateral cephalometric study. Diagnostics 2021, 11, 2348. [Google Scholar] [CrossRef] [PubMed]

- Cawood, J.; Howell, R. A classification of the edentulous jaws. Int. J. Oral Maxillofac. Surg. 1988, 17, 232–236. [Google Scholar] [CrossRef]

- Kheur, M.; Matani, J.; Latifi, M. Prediction of further residual ridge resorption by a simple biochemical and radiographic evaluation: A pilot study. J. Orofac. Sci. 2012, 4, 32–37. [Google Scholar]

- Khalifa, A.; Wada, M.; Ikebe, K.; Maeda, Y. To what extent residual alveolar ridge can be preserved by implant? A systematic review. Int. J. Implant. Dent. 2016, 2, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Renouard, F.; Nisand, D. Impact of implant length and diameter on survival rates. Clin. Oral Implant. Res. 2006, 17, 35–51. [Google Scholar] [CrossRef]

- Stellingsma, C.; Vissink, A.; Meijer, H.; Kuiper, C.; Raghoebar, G. Implantology and the severely resorbed edentulous mandible. Crit. Rev. Oral Biol. Med. 2004, 15, 240–248. [Google Scholar] [CrossRef] [Green Version]

- Bonfante, E.; Almeida, E.; Lorenzoni, F.; Coelho, P. Effects of implant diameter and prosthesis retention system on the reliability of single crowns. Int. J. Oral Maxillofac. Implant. 2015, 30, 95–101. [Google Scholar] [CrossRef] [Green Version]

- Barclay, C.; Jawad, S.; Foster, E. Mini dental implants in the management of the atrophic maxilla and mandible: A new implant design and preliminary results. Eur. J. Prosthodont. Restor. Dent. 2018, 26, 190–196. [Google Scholar]

- Marcello-Machado, R.; Faot, F.; Schuster, A.; Nascimento, G.; Del Bel Cury, A. Mini-implants and narrow diameter implants as mandibular overdenture retainers: A systematic review and meta-analysis of clinical and radiographic outcomes. J. Oral Rehabil. 2018, 45, 161–183. [Google Scholar] [CrossRef]

- Aunmeungtong, W.; Khongkhunthian, P.; Rungsiyakull, P. Stress and strain distribution in three different mini dental implant designs using in implant retained overdenture: A finite element analysis study. Oral Implantol. 2016, 9, 202–210. [Google Scholar]

- Catalán, A.; Martínez, A.; Marchesani, F.; González, U. Mandibular overdentures retained by two mini-implants: A seven-year retention and satisfaction study. J. Prosthodont. 2016, 25, 364–370. [Google Scholar] [CrossRef] [PubMed]

- Palacios, J.; Garcia, J.; Caramês, J.; Quirynen, M.; da Silva Marques, D. Short implants versus bone grafting and standard-length implants placement: A systematic review. Clin. Oral Investig. 2018, 22, 69–80. [Google Scholar] [CrossRef] [PubMed]

- Givol, N.; Chaushu, G.; Halamish-Shani, T.; Taicher, S. Emergency tracheostomy following life-threatening hemorrhage in the floor of the mouth during immediate implant placement in the mandibular canine region. J. Periodontol. 2000, 71, 1893–1895. [Google Scholar] [CrossRef] [PubMed]

- Scurria, M.; Morgan, Z.; Guckes, A.; Li, S.; Koch, G. Prognostic variables associated with implant failure: A retrospective effectiveness study. Int. J. Oral Maxillofac. Implant. 1998, 13, 400–406. [Google Scholar]

- Himmlova, L.; Kácovský, A.; Konvičková, S. Influence of implant length and diameter on stress distribution: A finite element analysis. J. Prosthet. Dent. 2004, 91, 20–25. [Google Scholar] [CrossRef]

- Allum, S.; Tomlinson, R.; Joshi, R. The impact of loads on standard diameter, small diameter and mini implants: A comparative laboratory study. Clin. Oral Implant. Res. 2008, 19, 553–559. [Google Scholar] [CrossRef] [Green Version]

- Bourauel, C.; Aitlahrach, M.; Heinemann, F.; Hasan, I. Biomechanical finite element analysis of small diameter and short dental implants: Extensive study of commercial implants. Biomed. Technik. Biomed. Eng. 2012, 57, 21–32. [Google Scholar] [CrossRef]

- Jawad, S.; Clarke, P. Survival of mini dental implants used to retain mandibular complete overdentures: Systematic review. Int. J. Oral Maxillofac. Implant. 2019, 34, 343–356. [Google Scholar] [CrossRef]

- BS ISO 14801; Dentistry—Implants—Dynamic Loading Test for Endosseous Dental Implants. British Standards Institute: London, UK, 2016.

- Tawil, G.; Younan, R. Clinical evaluation of short, machined-surface implants followed for 12 to 92 months. Int. J. Oral Maxillofac. Implant. 2003, 18, 894–901. [Google Scholar] [CrossRef]

- Lemos, C.; Ferro-Alves, M.; Okamoto, R.; Mendonça, M.; Pellizzer, E. Short dental implants versus standard dental implants placed in the posterior jaws: A systematic review and meta-analysis. J. Dent. 2016, 47, 8–17. [Google Scholar] [CrossRef] [Green Version]

- Arsalanloo, Z.; Telchi, R.; Osgouie, K. Optimum selection of the dental implants according to length and diameter parameters by FE method in the anterior position. Int. J. Biosci. Biochem. Bioinform. 2014, 4, 265–288. [Google Scholar] [CrossRef] [Green Version]

- Tomasi, C.; Idmyr, B.; Wennström, J. Patient satisfaction with mini-implant stabilised full dentures. A 1-year prospective study. J. Oral Rehabil. 2013, 40, 526–534. [Google Scholar] [CrossRef] [PubMed]

- Shiffler, K.; Lee, D.; Rowan, M.; Aghaloo, T.; Pi-Anfruns, J.; Moy, P. Effect of length, diameter, intraoral location on implant stability. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. 2016, 122, e193–e198. [Google Scholar] [CrossRef] [PubMed]

- Stellingsina, C.; Meijer, H.; Raghoebar, G. Use of short endosseous implants and an overdenture in the extremely resorbed mandible: A five-year retrospective study. J. Oral Maxillofac. Surg. 2000, 58, 382–387. [Google Scholar] [CrossRef]

- Higuchi, K.; Folmer, T.; Kultje, C. Implant survival rates in partially edentulous patients: A 3-year prospective multicenter study. J. Oral Maxillofac. Surg. 1995, 53, 264–268. [Google Scholar] [CrossRef]

- Naert, I.; Quirynen, M.; Van Steenberghe, D.; Darius, P. A six-year prosthodontic study of 509 consecutively inserted implants for the treatment of partial edentulism. J. Prosthet. Dent. 1992, 67, 236–245. [Google Scholar] [CrossRef]

- Gentile, M.; Chuang, S.; Dodson, T. Survival estimates and risk factors for failure with 6 × 5.7-mm implants. Int. J. Oral Maxillofac. Implant. 2005, 20, 930–937. [Google Scholar]

- Misch, C. Wide-diameter implants: Surgical, loading and prosthetic considerations. Dent. Today 2006, 25, 66–71. [Google Scholar]

- Shemtov-Yona, K.; Rittel, D. On the mechanical integrity of retrieved dental implants. J. Mech. Behav. Biomed. Mater. 2015, 49, 290–299. [Google Scholar] [CrossRef]

- Pierrisnard, L.; Renouard, F.; Renault, P.; Barquins, M. Influence of implant length and bicortical anchorage on implant stress distribution. Clin. Implant. Dent. Relat. Res. 2003, 5, 254–262. [Google Scholar] [CrossRef]

- Sannino, G.; Barlattani, A. Mechanical evaluation of an implant-abutment self-locking taper connection: Finite element analysis and experimental tests. Int. J. Oral Maxillofac. Implant. 2013, 28, 17–26. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huard, C.; Bessadet, M.; Nicolas, E.; Veyrune, J. Geriatric slim implants for complete denture wearers: Clinical aspects and perspectives. Clin. Cosmet. Investig. Dent. 2013, 5, 63–69. [Google Scholar] [PubMed] [Green Version]

- Reich, K.; Huber, C.; Lippnig, W.; Ulm, C.; Watzek, G.; Tangl, S. Atrophy of the residual alveolar ridge following tooth loss in an historical population. Oral Dis. 2011, 17, 33–44. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fontijn-Tekamp, F.; Slagter, A.; Van Der Bilt, A.; Van’T Hof, M.; Witter, D.; Kalk, W.; Jansen, J. Biting and chewing in overdentures, full dentures, and natural dentitions. J. Dent. Res. 2000, 79, 1519–1524. [Google Scholar] [CrossRef]

- Flanagan, D. Bite force and dental implant treatment: A short review. Med. Devices 2017, 10, 141–148. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jofré, J.; Hamada, T.; Nishimura, M.; Klattenhoff, C. The effect of maximum bite force on marginal bone loss of mini-implants supporting a mandibular overdenture: A randomized controlled trial. Clin. Oral Implant. Res. 2010, 21, 243–249. [Google Scholar] [CrossRef] [PubMed]

- Enkling, N.; Saftig, M.; Worni, A.; Mericske-Stern, R.; Schimmel, M. Chewing efficiency, bite force and oral health-related quality of life with narrow diameter implants-a prospective clinical study: Results after one year. Clin. Oral Implant. Res. 2017, 28, 476–482. [Google Scholar] [CrossRef]

- Hasan, I.; Madarlis, C.; Keilig, L.; Dirk, C.; Weber, A.; Bourauel, C.; Heinemann, F. Changes in biting forces with implant-supported overdenture in the lower jaw: A comparison between conventional and mini implants in a pilot study. Ann. Anat.-Anat. Anz. 2016, 208, 116–122. [Google Scholar] [CrossRef]

- Bonfante, E.; Coelho, P. A critical perspective on mechanical testing of implants and prostheses. Adv. Dent. Res. 2016, 28, 18–27. [Google Scholar] [CrossRef]

- Wiskott, H.; Nicholls, J.; Belser, U.; Wiskott, H.; Nicholls, J.; Belser, U. Stress fatigue: Basic principles and prosthodontic implications. Int. J. Prosthodont. 1995, 8, 105–116. [Google Scholar]

- Huang, H.; Tsai, C.; Chang, C.; Lin, C.; Lee, S. Evaluation of loading conditions on fatigue-failed implants by fracture surface analysis. Int. J. Oral Maxillofac. Implant. 2005, 20, 854–859. [Google Scholar]

- Sun, F.; Lv, L.; Cheng, W.; Zhang, J.; Ba, D.; Song, G.; Lin, Z. Effect of loading angles and implant lengths on the static and fatigue fractures of dental implants. Materials 2021, 14, 5542. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alshenaiber, R.; Silikas, N.; Barclay, C. Does the Length of Mini Dental Implants Affect Their Resistance to Failure by Overloading? Dent. J. 2022, 10, 117. https://doi.org/10.3390/dj10070117

Alshenaiber R, Silikas N, Barclay C. Does the Length of Mini Dental Implants Affect Their Resistance to Failure by Overloading? Dentistry Journal. 2022; 10(7):117. https://doi.org/10.3390/dj10070117

Chicago/Turabian StyleAlshenaiber, Rafif, Nick Silikas, and Craig Barclay. 2022. "Does the Length of Mini Dental Implants Affect Their Resistance to Failure by Overloading?" Dentistry Journal 10, no. 7: 117. https://doi.org/10.3390/dj10070117