The Effect of Chitosan Incorporation on Physico-Mechanical and Biological Characteristics of a Calcium Silicate Filling Material

Abstract

1. Introduction

2. Materials and Methods

2.1. Setting Time

2.2. Solubility

2.3. Radiopacity

2.4. Compressive Strength

2.5. Microhardness

2.6. Surface Topography

2.7. Cell Proliferation

2.8. Statistical Analysis

3. Results

3.1. Setting Time

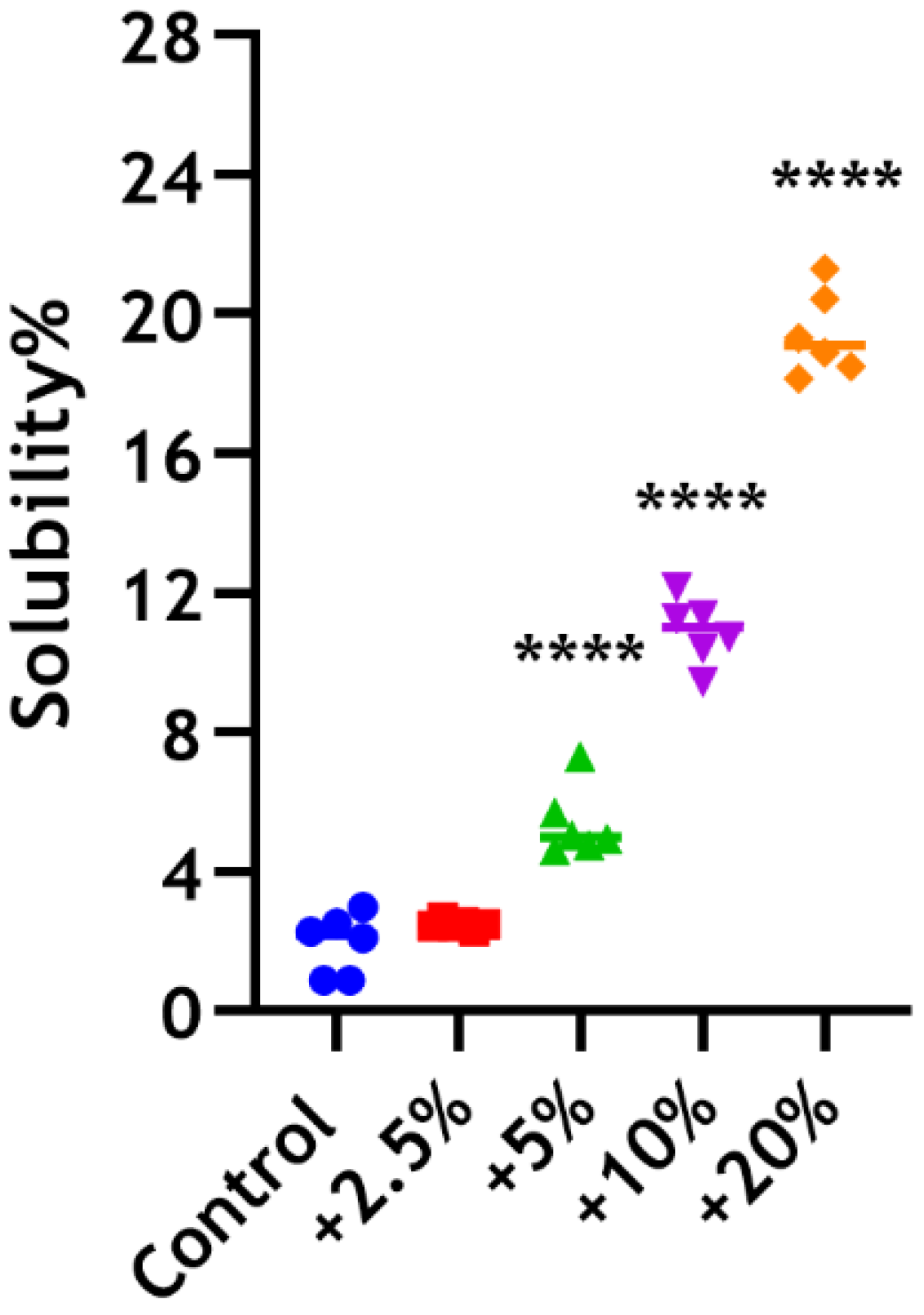

3.2. Solubility

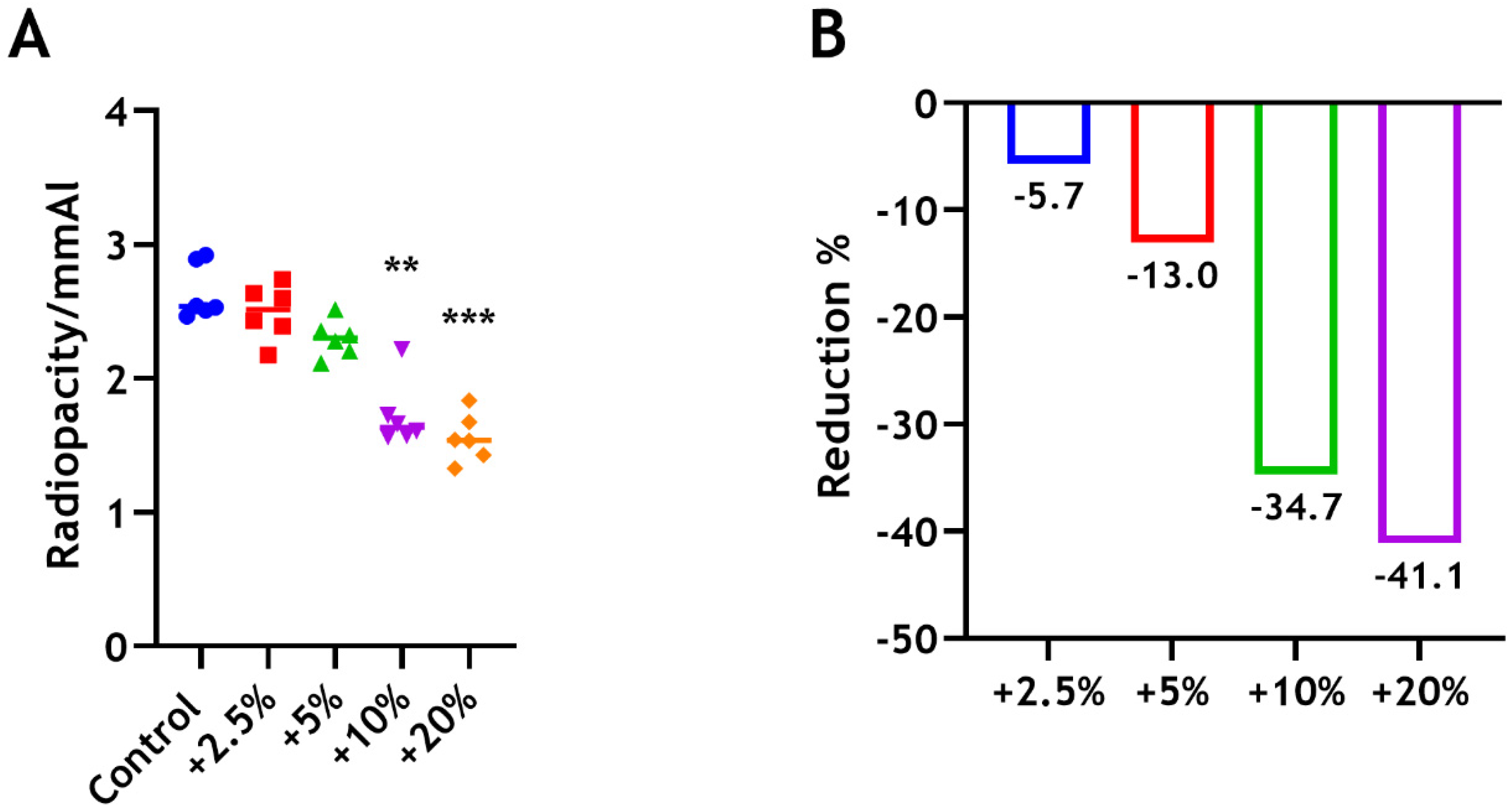

3.3. Radiopacity

3.4. Compressive Strength

3.5. Microhardness

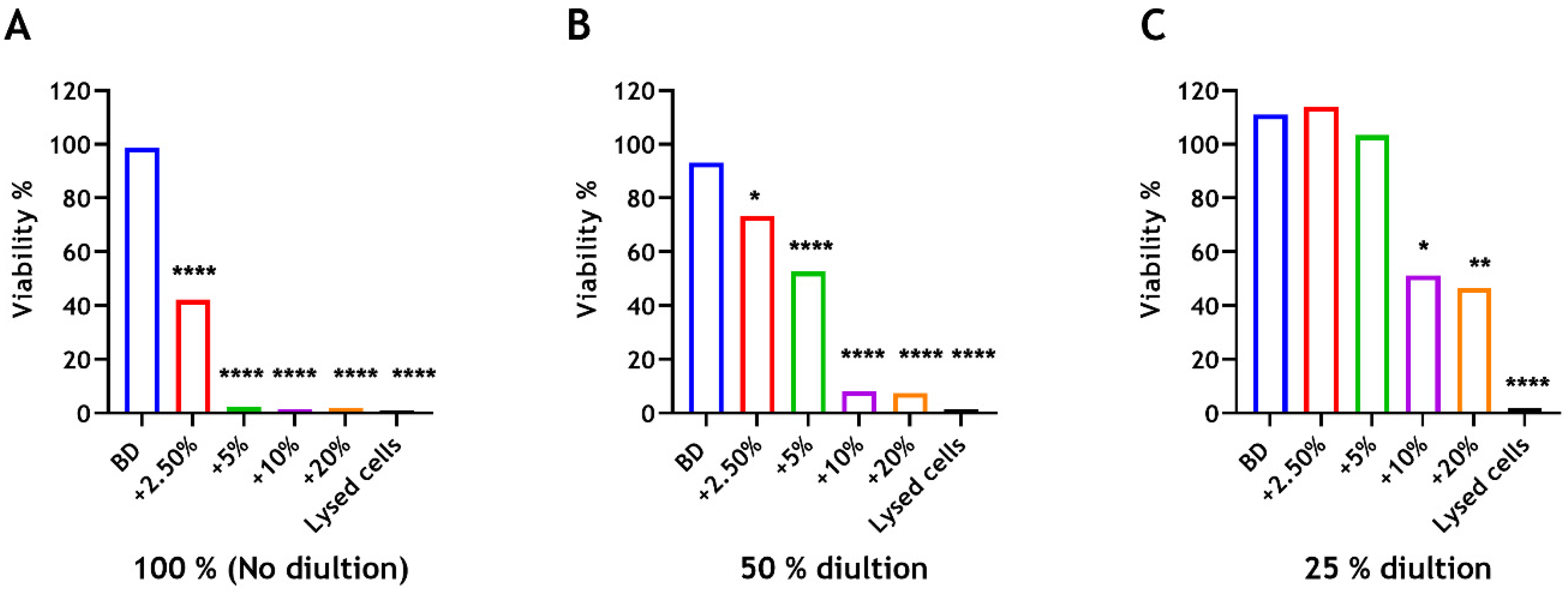

3.6. Cell Proliferation

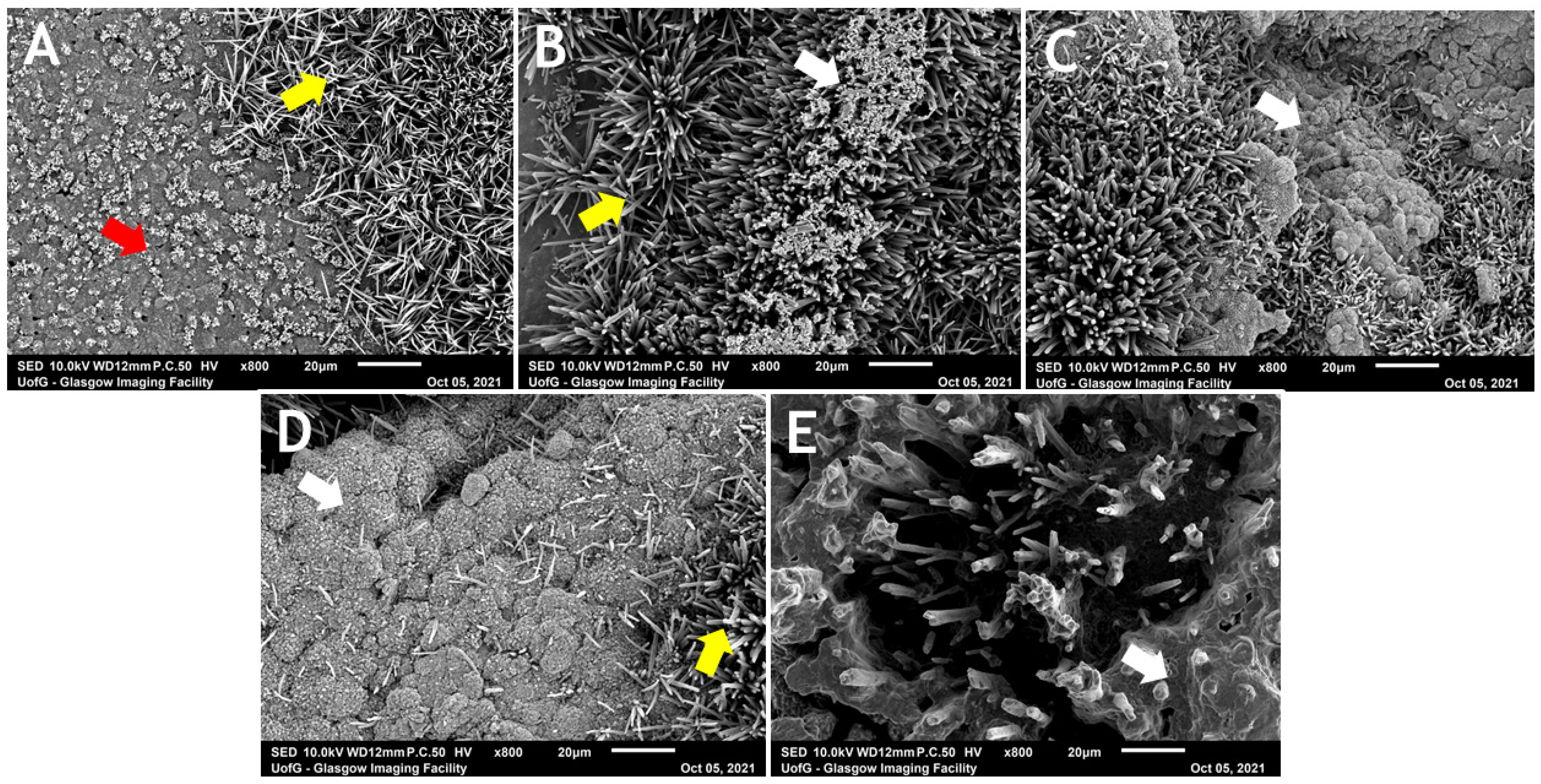

3.7. Surface Topography

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Widbiller, M.; Jeanneau, C.; Galler, K.M.; Laurent, P. Biocompatibility and Bioactive Properties of Biodentine TM. In Biodentine™; Springer: Berlin/Heidelberg, Germany, 2022; pp. 31–50. [Google Scholar]

- Solanki, N.P.; Venkappa, K.K.; Shah, N.C. Biocompatibility and sealing ability of mineral trioxide aggregate and biodentine as root-end filling material: A systematic review. J. Conserv. Dent. 2018, 21, 10–15. [Google Scholar] [PubMed]

- Pradeep, P.; Randhya, R.; Shanavas Palliyal, M.K.; Hima, S. An in vitro comparative evaluation of shear bond strength of biodentine and MTA. Int. J. Appl. Dent. Sci. 2018, 4, 1–3. [Google Scholar]

- Rahimi, S.; Shahi, S.; Torabi, Z.; Rezaie, Y.; Ghasemi, N.; Abolhasani, S. The effect of a mineralized bone graft on the surface microhardness of mineral trioxide aggregate and biodentine. Iran. Endod. J. 2018, 13, 83–87. [Google Scholar] [PubMed]

- Septodont. Biodentine Active Biosilicate Technology: Scientific File; Septodont: Saint-Maur-des-Fossés, France, 2010. [Google Scholar]

- Dammaschke, T. Biodentine™ a New Bioactive Cement for Direct Pulp Capping. Septodont Case Studies Collection, March (2012). Available online: https://issuu.com/coadental/docs/collection_1 (accessed on 5 March 2024).

- Esteki, P.; Jahromi, M.Z.; Tahmourespour, A. In vitro antimicrobial activity of mineral trioxide aggregate, Biodentine, and calcium-enriched mixture cement against Enterococcus faecalis, Streptococcus mutans, and Candida albicans using the agar diffusion technique. Dent. Res. J. 2021, 18, 3. [Google Scholar]

- Çırakoğlu, S.; Baddal, B.; İslam, A. The effectiveness of laser-activated irrigation on the apical microleakage qualities of MTA repair HP and NeoMTA plus in simulated immature teeth: A comparative study. Materials 2020, 13, 3287. [Google Scholar] [CrossRef] [PubMed]

- Fathy, S.M.; El-Aziz, A.M.A.; Labah, D.A. Cellular interaction and antibacterial efficacy of two hydraulic calcium silicate-based cements: Cell-dependent model. J. Conserv. Dent. 2019, 22, 17–22. [Google Scholar]

- Hiremath, G.S.; Kulkarni, R.D.; Naik, B.D. Evaluation of minimal inhibitory concentration of two new materials using tube dilution method: An in vitro study. J. Conserv. Dent. 2015, 18, 159–162. [Google Scholar] [CrossRef] [PubMed]

- Abusrewil, S.; Brown, J.L.; Delaney, C.; Butcher, M.C.; Tiba, M.; Scott, J.A.; Ramage, G.; McLean, W. Chitosan Enhances the Anti-Biofilm Activity of Biodentine against an Interkingdom Biofilm Model. Antibiotics 2021, 10, 1317. [Google Scholar] [CrossRef] [PubMed]

- Jardine, A.P.; Montagner, F.; Quintana, R.M.; Zaccara, I.M.; Kopper, P.M.P. Antimicrobial effect of bioceramic cements on multispecies microcosm biofilm: A confocal laser microscopy study. Clin. Oral Investig. 2019, 23, 1367–1372. [Google Scholar] [CrossRef] [PubMed]

- Farrugia, C.; Lung, C.Y.; Wismayer, P.S.; Arias-Moliz, M.T.; Camilleri, J. The relationship of surface characteristics and antimicrobial performance of pulp capping materials. J. Endod. 2018, 44, 1115–1120. [Google Scholar] [CrossRef] [PubMed]

- Rahman, B.; Goswami, M. Comparative evaluation of indirect pulp therapy in young permanent teeth using biodentine and theracal: A randomized clinical trial. J. Clin. Pediatr. Dent. 2021, 45, 158–164. [Google Scholar] [CrossRef] [PubMed]

- Awawdeh, L.; Al-Qudah, A.; Hamouri, H.; Chakra, R.J. Outcomes of vital pulp therapy using mineral trioxide aggregate or Biodentine: A prospective randomized clinical trial. J. Endod. 2018, 44, 1603–1609. [Google Scholar] [CrossRef] [PubMed]

- Nagas, E.; Cehreli, Z.C.; Uyanik, O.; Vallittu, P.K.; Lassila, L.V. Reinforcing Effect of Glass Fiber–incorporated ProRoot MTA and Biodentine as Intraorifice Barriers. J. Endod. 2016, 42, 1673–1676. [Google Scholar] [CrossRef] [PubMed]

- Aidaros, N.H.; Niazy, M.A.; El-yassaky, M.A. The Effect of Incorporating Nanocalcium Phosphate Particles into Biodentine on Pulpal Tissue Response (In Vitro Study). Al-Azhar Dent. J. Girls 2018, 5, 181–186. [Google Scholar] [CrossRef][Green Version]

- Gad El-Rab, S.M.; Ashour, A.A.; Basha, S.; Alyamani, A.A.; Felemban, N.H.; Enan, E.T. Well-Orientation Strategy Biosynthesis of Cefuroxime-Silver Nanoantibiotic for Reinforced Biodentine™ and Its Dental Application against Streptococcus mutans. Molecules 2021, 26, 6832. [Google Scholar] [CrossRef] [PubMed]

- Austin, P.; Brine, C.; Castle, J.; Zikakis, J. Chitin: New facets of research. Science 1981, 212, 749–753. [Google Scholar] [CrossRef] [PubMed]

- MubarakAli, D.; LewisOscar, F.; Gopinath, V.; Alharbi, N.S.; Alharbi, S.A.; Thajuddin, N. An inhibitory action of chitosan nanoparticles against pathogenic bacteria and fungi and their potential applications as biocompatible antioxidants. Microb. Pathog. 2018, 114, 323–327. [Google Scholar] [CrossRef] [PubMed]

- Beck, B.H.; Yildirim-Aksoy, M.; Shoemaker, C.A.; Fuller, S.A.; Peatman, E. Antimicrobial activity of the biopolymer chitosan against Streptococcus iniae. J. Fish Dis. 2019, 42, 371–377. [Google Scholar] [CrossRef] [PubMed]

- Kong, M.; Chen, X.G.; Xing, K.; Park, H.J. Antimicrobial properties of chitosan and mode of action: A state of the art review. Int. J. Food Microbiol. 2010, 144, 51–63. [Google Scholar] [CrossRef] [PubMed]

- Kaczmarek, M.B.; Struszczyk-Swita, K.; Li, X.; Szczęsna-Antczak, M.; Daroch, M. Enzymatic modifications of chitin, chitosan, and chitooligosaccharides. Front. Bioeng. Biotechnol. 2019, 7, 243. [Google Scholar] [CrossRef] [PubMed]

- Kumar, M.R.; Muzzarelli, R.A.; Muzzarelli, C.; Sashiwa, H.; Domb, A. Chitosan Chemistry and Pharmaceutical Perspectives. Chem. Rev. 2004, 104, 6017–6084. [Google Scholar] [CrossRef] [PubMed]

- Abusrewil, S.M. The endodontic biofilm: Effects of chitosan as a novel antimicrobial agent. Ph.D. Thesis, University of Glasgow, Glasgow, UK, 2023. [Google Scholar]

- ISO 6876:2012; Dentistry—Root Canal Sealing Materials. International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO 9917–1:2007; Dentistry—Water-Based Cements—Part 1: Powder/Liquid Acid-Base Cements. International Organization for Standardization: Geneva, Switzerland, 2007.

- ISO 6507–1:2018; Metallic Materials—Vickers Hardness Test—Part 1: Test Method. International Organization for Standardization: Geneva, Switzerland, 2018.

- Simmons, N.L. A cultured human renal epithelioid cell line responsive to vasoactive intestinal peptide. Exp. Physiol. 1990, 75, 309–319. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.-M.; Shen, Y.; Wang, Z.-j.; Li, L.; Zheng, Y.-f.; Häkkinen, L.; Haapasalo, M. In vitro cytotoxicity evaluation of a novel root repair material. J. Endod. 2013, 39, 478–483. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Peng, B.; Yang, Y.; Ma, J.; Haapasalo, M. What do different tests tell about the mechanical and biological properties of bioceramic materials? Endod. Top. 2015, 32, 47–85. [Google Scholar] [CrossRef]

- Careddu, R.; Duncan, H. How does the pulpal response to Biodentine and ProRoot mineral trioxide aggregate compare in the laboratory and clinic? Br. Dent. J. 2018, 225, 743–749. [Google Scholar] [CrossRef] [PubMed]

- Singh, H.; Kaur, M.; Markan, S.; Kapoor, P. Biodentine: A promising dentin substitute. J. Interdiscip. Med. Dent. Sci. 2014, 2, 2. [Google Scholar]

- Grech, L.; Mallia, B.; Camilleri, J. Investigation of the physical properties of tricalcium silicate cement-based root-end filling materials. Dent. Mater. 2013, 29, e20–e28. [Google Scholar] [CrossRef] [PubMed]

- Elsaka, S.E.; Elnaghy, A.M.; Mandorah, A.; Elshazli, A.H. Effect of titanium tetrafluoride addition on the physicochemical and antibacterial properties of Biodentine as intraorfice barrier. Dent. Mater. 2019, 35, 185–193. [Google Scholar] [CrossRef]

- Kaup, M.; Schäfer, E.; Dammaschke, T. An in vitro study of different material properties of Biodentine compared to ProRoot MTA. Head Face Med. 2015, 11, 16. [Google Scholar] [CrossRef]

- Pires, M.D.; Cordeiro, J.; Vasconcelos, I.; Alves, M.; Quaresma, S.A.; Ginjeira, A.; Camilleri, J. Effect of different manipulations on the physical, chemical and microstructural characteristics of Biodentine. Dent. Mater. 2021, 37, e399–e406. [Google Scholar] [CrossRef] [PubMed]

- Camilleri, J. Hydration characteristics of Biodentine and Theracal used as pulp capping materials. Dent. Mater. 2014, 30, 709–715. [Google Scholar] [CrossRef] [PubMed]

- Nomoto, R.; McCabe, J. A simple acid erosion test for dental water-based cements. Dent. Mater. 2001, 17, 53–59. [Google Scholar] [CrossRef] [PubMed]

- Alazrag, M.; Abu-Seida, A.M.; El-Batouty, K.M.; El Ashry, S.H. Marginal adaptation, solubility and biocompatibility of TheraCal LC compared with MTA-angelus and biodentine as a furcation perforation repair material. BMC Oral Health 2020, 20, 298. [Google Scholar] [CrossRef] [PubMed]

- Silva, E.J.; Cardoso, M.L.; Rodrigues, J.P.; De-Deus, G.; Fidalgo, T.K.d.S. Solubility of bioceramic-and epoxy resin-based root canal sealers: A systematic review and meta-analysis. Aust. Endod. J. 2021, 47, 690–702. [Google Scholar] [CrossRef]

- Chybowski, E.A.; Glickman, G.N.; Patel, Y.; Fleury, A.; Solomon, E.; He, J. Clinical outcome of non-surgical root canal treatment using a single-cone technique with endosequence bioceramic sealer: A retrospective analysis. J. Endod. 2018, 44, 941–945. [Google Scholar] [CrossRef] [PubMed]

- Pekkan, G. Radiopacity of dental materials: An overview. Avicenna J. Dent. Res. 2016, 8, 8. [Google Scholar] [CrossRef]

- Williams, J.; Billington, R. A new technique for measuring the radiopacity of natural tooth substance and restorative materials. J. Oral Rehabil. 1987, 14, 267–269. [Google Scholar] [CrossRef] [PubMed]

- Devito, K.L.; Ortega, A.I.; Haiter-Neto, F. Radiopacity of calcium hydroxide cement compared with human tooth structure. J. Appl. Oral Sci. 2004, 12, 290–293. [Google Scholar] [CrossRef] [PubMed]

- Tanalp, J.; Karapınar-Kazandağ, M.; Dölekoğlu, S.; Kayahan, M.B. Comparison of the radiopacities of different root-end filling and repair materials. Sci. World J. 2013, 2013, 594950. [Google Scholar] [CrossRef] [PubMed]

- Milutinović-Smiljanić, S.; Ilić, D.; Danilović, V.; Antonijević, Đ. The advantages and disadvantages of biodentine: Satisfactory mechanical properties and radiopacity not meeting ISO standard. Vojnosanit. Pregl. 2021, 78, 973–980. [Google Scholar] [CrossRef]

- Corral, C.; Negrete, P.; Estay, J.; Osorio, S.; Covarrubias, C.; de Oliveira Junior, O.B.; Barud, H.; Corral, C.; Negrete, P.; Estay, J. Radiopacity and chemical assessment of new commercial calcium silicate-based cements. Int. J. Odontostomatol. 2018, 12, 262–268. [Google Scholar] [CrossRef][Green Version]

- El-Din, N.G.; El-Helbawy, D. Evaluation of radiopacity changes of Biodentine as a root-end filling material within soft and hard tissue simulation using digital radiography. ENDO 2016, 10, 77–82. [Google Scholar]

- Ochoa-Rodríguez, V.M.; Tanomaru-Filho, M.; Rodrigues, E.M.; Guerreiro-Tanomaru, J.M.; Spin-Neto, R.; Faria, G. Addition of zirconium oxide to Biodentine increases radiopacity and does not alter its physicochemical and biological properties. J. Appl. Oral Sci. 2019, 27, e20180429. [Google Scholar] [CrossRef] [PubMed]

- Camilleri, J.; Sorrentino, F.; Damidot, D. Investigation of the hydration and bioactivity of radiopacified tricalcium silicate cement, Biodentine and MTA Angelus. Dent. Mater. 2013, 29, 580–593. [Google Scholar] [CrossRef] [PubMed]

- Bachoo, I.; Seymour, D.; Brunton, P. Clinical case reports using a novel calcium-based cement. Br. Dent. J. 2013, 214, 61–64. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Butt, N.; Talwar, S.; Chaudhry, S.; Nawal, R.R.; Yadav, S.; Bali, A. Comparison of physical and mechanical properties of mineral trioxide aggregate and Biodentine. Indian J. Dent. Res. 2014, 25, 692–697. [Google Scholar] [CrossRef] [PubMed]

- Camilleri, J.; Grech, L.; Galea, K.; Keir, D.; Fenech, M.; Formosa, L.; Damidot, D.; Mallia, B. Assessment of porosity and sealing ability of tricalcium silicate-based root-end filling materials. Clin. Oral Investig. 2014, 18, 1437–1446. [Google Scholar] [CrossRef]

- Luković, M.; Schlangen, E.; Ye, G. Combined experimental and numerical study of fracture behaviour of cement paste at the microlevel. Cem. Concr. Res. 2015, 73, 123–135. [Google Scholar] [CrossRef]

- Ouyang, X.; Koleva, D.; Ye, G.; Van Breugel, K. Understanding the adhesion mechanisms between CSH and fillers. Cem. Concr. Res. 2017, 100, 275–283. [Google Scholar] [CrossRef]

- Ezz, A.A.; Shaban, A.; Abdalla, M.M.; Abbas, M. Bonding ability and mechanical strength of recently formulated glass ionomer cements. Al-Azhar J. Dent. Sci. 2018, 21, 147–154. [Google Scholar] [CrossRef]

- Torabinejad, M.; Hong, C.; McDonald, F.; Ford, T.P. Physical and chemical properties of a new root-end filling material. J. Endod. 1995, 21, 349–353. [Google Scholar] [CrossRef] [PubMed]

- Elnaghy, A.M. Influence of QMix irrigant on the micropush-out bond strength of Biodentine and white mineral trioxide aggregate. J. Adhes. Dent. 2014, 16, 277–283. [Google Scholar] [PubMed]

- Elnaghy, A.M. Influence of acidic environment on properties of biodentine and white mineral trioxide aggregate: A comparative study. J. Endod. 2014, 40, 953–957. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.-L.; Lee, B.-S.; Lin, F.-H.; Lin, A.Y.; Lan, W.-H.; Lin, C.-P. Effects of physiological environments on the hydration behavior of mineral trioxide aggregate. Biomaterials 2004, 25, 787–793. [Google Scholar] [CrossRef] [PubMed]

- Schmalz, G.; Arenholt-Bindslev, D. Basic aspects. In Biocompatibility of Dental Materials; Springer: Berlin/Heidelberg, Germany, 2009; pp. 1–12. [Google Scholar]

- Kulshrestha, S.; Khan, S.; Hasan, S.; Khan, M.E.; Misba, L.; Khan, A.U. Calcium fluoride nanoparticles induced suppression of Streptococcus mutans biofilm: An in vitro and in vivo approach. Appl. Microbiol. Biotechnol. 2016, 100, 1901–1914. [Google Scholar] [CrossRef] [PubMed]

- Barma, M.D.; Muthupandiyan, I.; Samuel, S.R.; Amaechi, B.T. Inhibition of Streptococcus mutans, antioxidant property and cytotoxicity of novel nano-zinc oxide varnish. Arch. Oral Biol. 2021, 126, 105132. [Google Scholar] [CrossRef] [PubMed]

- Vistica, D.T.; Skehan, P.; Scudiero, D.; Monks, A.; Pittman, A.; Boyd, M.R. Tetrazolium-based assays for cellular viability: A critical examination of selected parameters affecting formazan production. Cancer Res. 1991, 51, 2515–2520. [Google Scholar] [PubMed]

- Margunato, S.; Taşlı, P.N.; Aydın, S.; Kazandağ, M.K.; Şahin, F. In vitro evaluation of ProRoot MTA, Biodentine, and MM-MTA on human alveolar bone marrow stem cells in terms of biocompatibility and mineralization. J. Endod. 2015, 41, 1646–1652. [Google Scholar] [CrossRef] [PubMed]

- Escobar-García, D.M.; Aguirre-López, E.; Méndez-González, V.; Pozos-Guillén, A. Cytotoxicity and Initial Biocompatibility of Endodontic Biomaterials (MTA and Biodentine™) Used as Root-End Filling Materials. BioMed Res. Int. 2016, 2016, 7926961. [Google Scholar] [CrossRef] [PubMed]

- Widbiller, M.; Lindner, S.; Buchalla, W.; Eidt, A.; Hiller, K.-A.; Schmalz, G.; Galler, K. Three-dimensional culture of dental pulp stem cells in direct contact to tricalcium silicate cements. Clin. Oral Investig. 2016, 20, 237–246. [Google Scholar] [CrossRef] [PubMed]

- Yoshino, P.; Nishiyama, C.K.; Modena, K.C.d.S.; Santos, C.F.; Sipert, C.R. In vitro cytotoxicity of white MTA, MTA Fillapex® and Portland cement on human periodontal ligament fibroblasts. Braz. Dent. J. 2013, 24, 111–116. [Google Scholar] [CrossRef] [PubMed]

- Loh, J.W.; Yeoh, G.; Saunders, M.; Lim, L.-Y. Uptake and cytotoxicity of chitosan nanoparticles in human liver cells. Toxicol. Appl. Pharmacol. 2010, 249, 148–157. [Google Scholar] [CrossRef] [PubMed]

- Omar Zaki, S.S.; Ibrahim, M.N.; Katas, H. Particle size affects concentration-dependent cytotoxicity of chitosan nanoparticles towards mouse hematopoietic stem cells. J. Nanotechnol. 2015, 2015, 919658. [Google Scholar] [CrossRef]

| Powder | |

| Tricalcium silicate | Main core material |

| Dicalcium silicate | Second core material |

| Calcium carbonate and oxide | Filler |

| Iron oxide | Shade |

| Zirconium oxide | Radiopacifier |

| Liquid | |

| Calcium chloride | Accelerator |

| Hydrosoluble (water-soluble) polymer | Water reducing agent |

| Water | |

| Test Group | Setting Time (n = 7) | Solubility (n = 6) | Radiopacity (n = 6) | Compressive Strength (n = 10) | Microhardness (n = 5) |

|---|---|---|---|---|---|

| BD Control | 31.14 (±1.95 min) | 1.94 (±0.87%) | 2.64 (±0.21 mmAl) | 134.78 (±42.84 MPa) | 113.60 (±10.20 HV) |

| BD + 2.5 wt% CS | 23.14 (±1.95 min) | 2.47 (±0.13%) | 2.49 (±0.20 mmAl) | 60.56 (±9.43 MPa) | 77.60 (±9.42 HV) |

| BD + 5 wt% CS | 22.71 (±2.29 min) | 5.38 (±1.01%) | 2.30 (±0.14 mmAl) | 25.27 (±5.05 MPa) | 60.20 (±5.24 HV) |

| BD + 10 wt% CS | 44.43 (±1.99 min) | 10.88 (±0.93%) | 1.73 (±0.25 mmAl) | 13.48 (±3.60 MPa) | 55.40 (±6.85 HV) |

| BD + 20 wt% CS | 56.57 (±1.72 min) | 19.42 (±1.21%) | 1.56 (±0.18 mmAl) | 10.20 (±4.34 MPa) | 37.73 (±3.43 HV) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abusrewil, S.; Scott, J.A.; Alqahtani, S.S.; Butcher, M.C.; Tiba, M.; Kumar, C.; Mulvihill, D.M.; Ramage, G.; McLean, W. The Effect of Chitosan Incorporation on Physico-Mechanical and Biological Characteristics of a Calcium Silicate Filling Material. Dent. J. 2024, 12, 100. https://doi.org/10.3390/dj12040100

Abusrewil S, Scott JA, Alqahtani SS, Butcher MC, Tiba M, Kumar C, Mulvihill DM, Ramage G, McLean W. The Effect of Chitosan Incorporation on Physico-Mechanical and Biological Characteristics of a Calcium Silicate Filling Material. Dentistry Journal. 2024; 12(4):100. https://doi.org/10.3390/dj12040100

Chicago/Turabian StyleAbusrewil, Sumaya, J. Alun Scott, Saeed S. Alqahtani, Mark C. Butcher, Mohammed Tiba, Charchit Kumar, Daniel M. Mulvihill, Gordon Ramage, and William McLean. 2024. "The Effect of Chitosan Incorporation on Physico-Mechanical and Biological Characteristics of a Calcium Silicate Filling Material" Dentistry Journal 12, no. 4: 100. https://doi.org/10.3390/dj12040100

APA StyleAbusrewil, S., Scott, J. A., Alqahtani, S. S., Butcher, M. C., Tiba, M., Kumar, C., Mulvihill, D. M., Ramage, G., & McLean, W. (2024). The Effect of Chitosan Incorporation on Physico-Mechanical and Biological Characteristics of a Calcium Silicate Filling Material. Dentistry Journal, 12(4), 100. https://doi.org/10.3390/dj12040100