Rheological Characterization of Chapatti (Roti) Enriched with Flour or Paste of House Crickets (Acheta domesticus)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Preparation of the Cricket Flour and Paste

2.3. Formulations

2.4. Particle Size Distribution

2.5. Rheological Properties of Flour

2.5.1. Farinograph Characteristics

2.5.2. Pasting Properties

2.6. Rheological Properties of Dough

2.6.1. Dough Preparation

2.6.2. Dynamic Oscillatory Measurements

2.6.3. Dough Extensibility

2.7. Chapatti Making

Chapatti Texture

2.8. Statistical Analysis

3. Results and Discussion

3.1. Particle Size Distribution

3.2. Rheological Properties of the Flour

3.2.1. Effect of Cricket Flour on Dough Mixing Properties

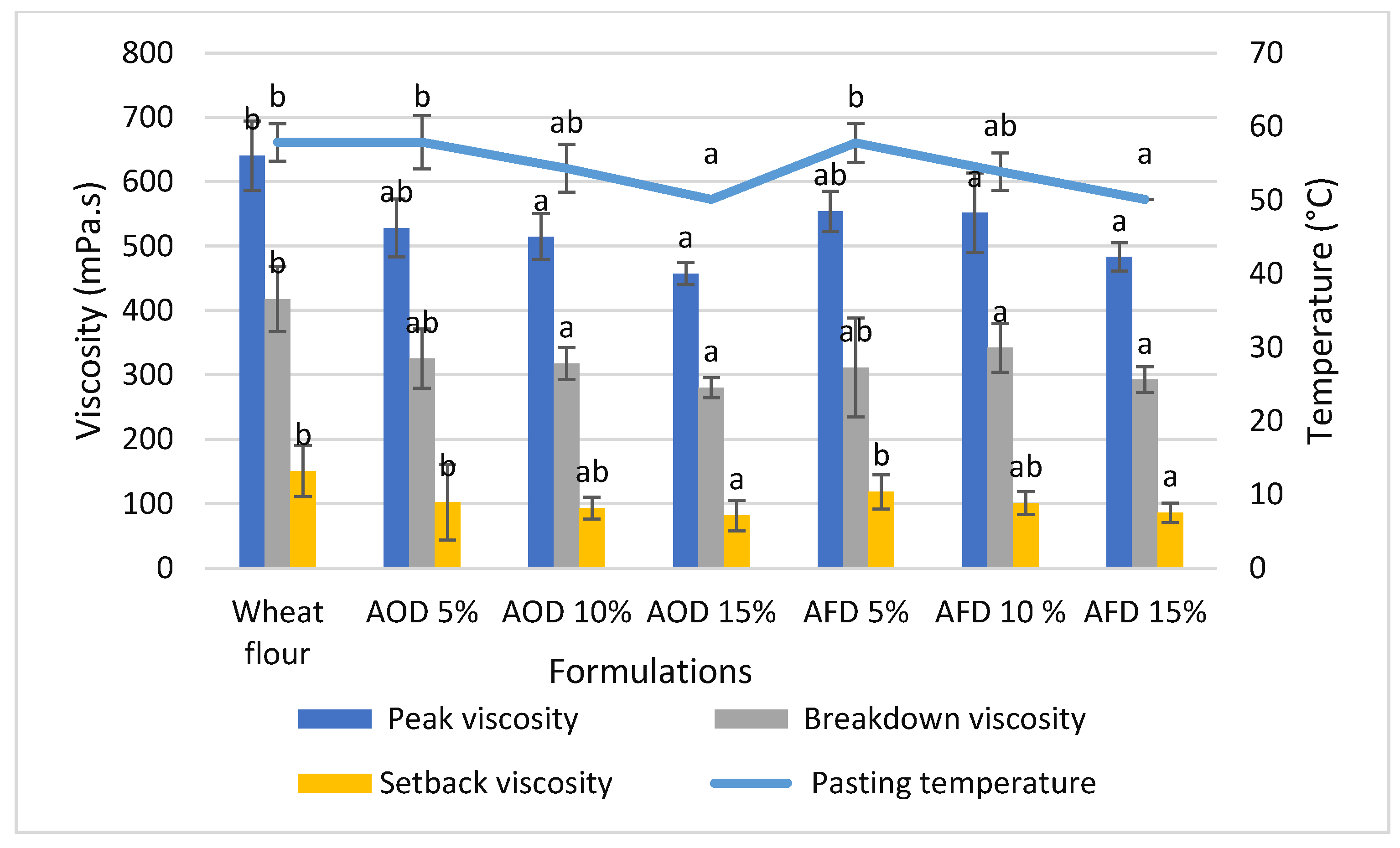

3.2.2. Effect of Cricket Flour on Pasting Properties of Wheat Flour and Cricket Flour Blends

3.3. Rheological Properties of Dough

3.3.1. Effects of Cricket Flour on Dynamic Moduli

3.3.2. Effects of Cricket Flour on Biaxial Extensibility

3.4. Effects of Cricket Flour on Uniaxial Extensibility of Baked Chapatti

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hemalatha, M.S.; Leelavathi, K.; Salimath, P.V.; Rao, U.J.S.P. Control of Chapati Staling upon Treatment of Dough with Amylases and Xylanase. Food Biosci. 2014, 5, 73–84. [Google Scholar] [CrossRef]

- Rehman, S.U.; Paterson, A.; Piggott, J.R. Chapatti Quality from British Wheat Cultivar Flours. LWT-Food Sci. Technol. 2007, 40, 775–784. [Google Scholar] [CrossRef]

- Banerji, A.; Ananthanarayan, L.; Lele, S. The Science and Technology of Chapatti and Other Indian Flatbreads; Taylor & Francis, CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Yadav, D.N.; Rajan, A.; Sharma, G.K.; Bawa, A.S. Effect of Fiber Incorporation on Rheological and Chapati Making Quality of Wheat Flour. J. Food Sci. Technol. 2010, 47, 166–173. [Google Scholar] [CrossRef] [Green Version]

- Yadav, D.N.; Singh, K.K.; Rehal, J. Studies on Fortification of Wheat Flour with Defatted Rice Bran for Chapati Making. J. Food Sci. Technol. 2012, 49, 96–102. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khan, M.A.; Mahesh, C.; Semwal, A.D.; Sharma, G.K. Effect of Spinach Powder on Physico-Chemical, Rheological, Nutritional and Sensory Characteristics of Chapati Premixes. J. Food Sci. Technol. 2015, 52, 2359–2365. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mehfooz, T.; Mohsin Ali, T.; Arif, S.; Hasnain, A. Effect of Barley Husk Addition on Rheological, Textural, Thermal and Sensory Characteristics of Traditional Flat Bread (Chapatti). J. Cereal Sci. 2018, 79, 376–382. [Google Scholar] [CrossRef]

- Kewuyemi, Y.O.; Kesa, H.; Chinma, C.E.; Adebo, O.A. Fermented Edible Insects for Promoting Food Security in Africa. Insects 2020, 11, 283. [Google Scholar] [CrossRef]

- Govorushko, S. Global Status of Insects as Food and Feed Source: A Review. Trends Food Sci. Technol. 2019, 91, 436–445. [Google Scholar] [CrossRef]

- Khatun, H.; Claes, J.; Smets, R.; De Winne, A.; Akhtaruzzaman, M.; Van Der Borght, M. Characterization of Freeze—Dried, Oven—Dried and Blanched House Crickets (Acheta domesticus) and Jamaican Field Crickets (Gryllus assimilis) by Means of Their Physicochemical Properties and Volatile Compounds. Eur. Food Res. Technol. 2021, 247, 1291–1305. [Google Scholar] [CrossRef]

- Ghosh, S.; Lee, S.M.; Jung, C.; Meyer-Rochow, V.B. Nutritional Composition of Five Commercial Edible Insects in South Korea. J. Asia. Pac. Entomol. 2017, 20, 686–694. [Google Scholar] [CrossRef]

- Meyer-Rochow, V.B. Can Insects Help to Ease the Problem of World Food Shortage? Search 1975, 6, 261–262. [Google Scholar]

- van Huis, A.; Oonincx, D.G.A.B. The Environmental Sustainability of Insects as Food and Feed. A Review. Agron. Sustain. Dev. 2017, 37, 43. [Google Scholar] [CrossRef] [Green Version]

- Jantzen da Silva Lucas, A.; Menegon de Oliveira, L.; da Rocha, M.; Prentice, C. Edible Insects: An Alternative of Nutritional, Functional and Bioactive Compounds. Food Chem. 2020, 311, 126022. [Google Scholar] [CrossRef] [PubMed]

- Alonso-Miravalles, L.; O’Mahony, J.A. Composition, Protein Profile and Rheological Properties of Pseudocereal-Based Protein-Rich Ingredients. Foods 2018, 7, 73. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lucas-González, R.; Fernández-López, J.; Pérez-Álvarez, J.A.; Viuda-Martos, M. Effect of Drying Processes in the Chemical, Physico-Chemical, Techno-Functional and Antioxidant Properties of Flours Obtained from House Cricket (Acheta domesticus). Eur. Food Res. Technol. 2019, 245, 1451–1458. [Google Scholar] [CrossRef]

- Osimani, A.; Milanović, V.; Cardinali, F.; Roncolini, A.; Garofalo, C.; Clementi, F.; Pasquini, M.; Mozzon, M.; Foligni, R.; Raffaelli, N.; et al. Bread Enriched with Cricket Powder (Acheta domesticus): A Technological, Microbiological and Nutritional Evaluation. Innov. Food Sci. Emerg. Technol. 2018, 48, 150–163. [Google Scholar] [CrossRef]

- Cappelli, A.; Oliva, N.; Bonaccorsi, G.; Lorini, C.; Cini, E. Assessment of the Rheological Properties and Bread Characteristics Obtained by Innovative Protein Sources (Cicer arietinum, Acheta domesticus, Tenebrio molitor): Novel Food or Potential Improvers for Wheat Flour? Lwt 2020, 118, 108867. [Google Scholar] [CrossRef]

- de Oliveira, L.M.; da Silva Lucas, A.J.; Cadaval, C.L.; Mellado, M.S. Bread Enriched with Flour from Cinereous Cockroach (Nauphoeta cinerea). Innov. Food Sci. Emerg. Technol. 2017, 44, 30–35. [Google Scholar] [CrossRef]

- González, C.M.; Garzón, R.; Rosell, C.M. Insects as Ingredients for Bakery Goods. A Comparison Study of H. Illucens, A. Domestica and T. Molitor Flours. Innov. Food Sci. Emerg. Technol. 2019, 51, 205–210. [Google Scholar] [CrossRef]

- Roncolini, A.; Milanovi, V.; Cardinali, F.; Id, A.O.; Garofalo, C.; Sabbatini, R.; Clementi, F.; Pasquini, M.; Mozzon, M.; Foligni, R.; et al. Protein Fortification with Mealworm (Tenebrio molitor L.) Powder: Effect on Textural, Microbiological, Nutritional and Sensory Features of Bread. PLoS ONE 2019, 14, e0211747. [Google Scholar] [CrossRef] [Green Version]

- Kumar, P.; Kaur, C.; Jambh, H.K. Rheological Textural and Technological Modifications in Wheat Unleavened Flatbread Substituted with Extruded Finger Millet. J. Texture Stud. 2021, 52, 400–409. [Google Scholar] [CrossRef] [PubMed]

- Thakur, S.; Singh, N.; Kaur, A. Characteristics of Normal and Waxy Corn: Physicochemical, Protein Secondary Structure, Dough Rheology and Chapatti Making Properties. J. Food Sci. Technol. 2017, 54, 3285–3296. [Google Scholar] [CrossRef]

- Ahmed, J.; Al-Attar, H.; Arfat, Y.A. Effect of Particle Size on Compositional, Functional, Pasting and Rheological Properties of Commercial Water Chestnut Flour. Food Hydrocoll. 2016, 52, 888–895. [Google Scholar] [CrossRef]

- Simoni, R.C.; Lemes, G.F.; Fialho, S.; Gonçalves, O.H.; Gozzo, A.M.; Chiaradia, V.; Sayer, C.; Shirai, M.A.; Leimann, F.V. Effect of Drying Method on Mechanical, Thermal and Water Absorption Properties of Enzymatically Crosslinked Gelatin Hydrogels. An. Acad. Bras. Cienc. 2017, 89, 745–755. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Strange, E.D.; Onwulata, C.I. Effect of Particle Size on the Water Sorption Properties of Cereal Fibers. J. Food Qual. 2002, 25, 63–73. [Google Scholar] [CrossRef]

- Mohammed, I.; Ahmed, A.R.; Senge, B. Dough Rheology and Bread Quality of Wheat-Chickpea Flour Blends. Ind. Crops Prod. 2012, 36, 196–202. [Google Scholar] [CrossRef]

- Sudha, M.L.; Vetrimani, R.; Leelavathi, K. Influence of Fibre from Different Cereals on the Rheological Characteristics of Wheat Flour Dough and on Biscuit Quality. Food Chem. 2007, 100, 1365–1370. [Google Scholar] [CrossRef]

- Dhinda, F.; Lakshmi A., J.; Prakash, J.; Dasappa, I. Effect of Ingredients on Rheological, Nutritional and Quality Characteristics of High Protein, High Fibre and Low Carbohydrate Bread. Food Bioprocess Technol. 2012, 5, 2998–3006. [Google Scholar] [CrossRef]

- Rosell, C.M.; Collar, C.; Haros, M. Assessment of Hydrocolloid Effects on the Thermo-Mechanical Properties of Wheat Using the Mixolab. Food Hydrocoll. 2007, 21, 452–462. [Google Scholar] [CrossRef]

- Kundu, M.; Khatkar, B.S.; Gulia, N. Assessment of Chapatti Quality of Wheat Varieties Based on Physicochemical, Rheological and Sensory Traits. Food Chem. 2017, 226, 95–101. [Google Scholar] [CrossRef] [PubMed]

- Liang, X.; King, J.M. Pasting and Crystalline Property Differences of Commercial and Isolated Rice Starch with Added Amino Acids. J. Food Sci. 2003, 68, 832–838. [Google Scholar] [CrossRef]

- Devi, A.; Sindhu, R.; Khatkar, B.S. Effect of Fats and Oils on Pasting and Textural Properties of Wheat Flour. J. Food Sci. Technol. 2020, 57, 3836–3842. [Google Scholar] [CrossRef] [PubMed]

- Indriani, S.; Bin Ab Karim, M.S.; Nalinanon, S.; Karnjanapratum, S. Quality Characteristics of Protein-Enriched Brown Rice Flour and Cake Affected by Bombay Locust (Patanga succincta L.) Powder Fortification. LWT 2020, 119, 108876. [Google Scholar] [CrossRef]

- Villanueva, M.; Pérez-Quirce, S.; Collar, C.; Ronda, F. Impact of Acidification and Protein Fortification on Rheological and Thermal Properties of Wheat, Corn, Potato and Tapioca Starch-Based Gluten-Free Bread Doughs. LWT 2018, 96, 446–454. [Google Scholar] [CrossRef] [Green Version]

- Larsson, K. Some Effects of Lipids on the Structure of Foods. Food Struct. 1982, 1, 55–62. [Google Scholar]

- Dreese, P.C.; Hoseney, R.C. Baking properties of the bran fraction from brewer’s spent grain. Cereal Chem. 1982, 59, 89–91. [Google Scholar]

- Peressini, D.; Sensidoni, A. Effect of Soluble Dietary Fibre Addition on Rheological and Breadmaking Properties of Wheat Doughs. J. Cereal Sci. 2009, 49, 190–201. [Google Scholar] [CrossRef]

- Gómez, M.; Ronda, F.; Blanco, C.A.; Caballero, P.A.; Apesteguía, A. Effect of Dietary Fibre on Dough Rheology and Bread Quality. Eur. Food Res. Technol. 2003, 216, 51–56. [Google Scholar] [CrossRef]

- Hu, X.; Tang, Y.; Wang, Q.; Li, Y.; Yang, J.; Du, Y.; Kennedy, J.F. Rheological Behaviour of Chitin in NaOH/Urea Aqueous Solution. Carbohydr. Polym. 2011, 83, 1128–1133. [Google Scholar] [CrossRef]

- Petrova, V.A.; Elokhovskiy, V.Y.; Raik, S.V.; Poshina, D.N.; Romanov, D.P.; Skorik, Y.A. Alginate Gel Reinforcement with Chitin Nanowhiskers Modulates Rheological Properties and Drug Release Profile. Biomolecules 2019, 9, 291. [Google Scholar] [CrossRef] [Green Version]

- Crockett, R.; Ie, P.; Vodovotz, Y. How Do Xanthan and Hydroxypropyl Methylcellulose Individually Affect the Physicochemical Properties in a Model Gluten-Free Dough? J. Food Sci. 2011, 76, E274–E282. [Google Scholar] [CrossRef] [PubMed]

- Luna, G.C.; Martin-Gonzalez, F.S.; Mauer, L.J.; Liceaga, A.M. Cricket (Acheta domesticus) Protein Hydrolysates’ Impact on the Physicochemical, Structural and Sensory Properties of Tortillas and Tortilla Chips. J. Insects Food Feed 2021, 7, 109–120. [Google Scholar] [CrossRef]

- Zhou, Y.; Dhital, S.; Zhao, C.; Ye, F.; Chen, J.; Zhao, G. Dietary Fiber-Gluten Protein Interaction in Wheat Flour Dough: Analysis, Consequences and Proposed Mechanisms. Food Hydrocoll. 2021, 111, 106203. [Google Scholar] [CrossRef]

- Chaudhary, N.; Dangi, P.; Khatkar, B.S. Assessment of Molecular Weight Distribution of Wheat Gluten Proteins for Chapatti Quality. Food Chem. 2016, 199, 28–35. [Google Scholar] [CrossRef] [PubMed]

- da Rosa Machado, C.; Thys, R.C.S. Cricket Powder (Gryllus assimilis) as a New Alternative Protein Source for Gluten-Free Breads. Innov. Food Sci. Emerg. Technol. 2019, 56, 102180. [Google Scholar] [CrossRef]

- Brennan, C.S.; Cleary, L.J. Utilisation Glucagel Ò in the b -Glucan Enrichment of Breads: A Physicochemical and Nutritional Evaluation. Food Res. Int. 2007, 40, 291–296. [Google Scholar] [CrossRef]

| Samples | Particle Size µm < Volume * | ||

|---|---|---|---|

| 10D | 50D | 90D | |

| Wheat flour | 16.00 ± 0.30 | 74.74 ± 0.09 | 156.03 ± 0.29 |

| AOD | 101.77 ± 1.44 | 424.06 ± 7.78 | 1050.58 ± 82.16 |

| AFD | 65.58 ± 0.49 | 344.04 ± 0.15 | 855.58 ± 0.15 |

| APT | Nd ** | ||

| Samples | Water Absorption (%) | Dough Development Time (min) | Dough Stability (min) |

|---|---|---|---|

| Wheat flour | 51.23 ± 0.12 a | 1.83 ± 0.15 a | 8.83 ± 0.15 c |

| AOD 5% | 51.30 ± 0.00 a | 1.90 ± 0.26 a | 9.17 ± 0.42 c |

| AOD 10% | 52.30 ± 0.00 b | 5.20 ± 0.20 bc | 6.73 ± 0.31 b |

| AOD 15% | 53.60 ± 0.00 c | 5.27 ± 0.46 bc | 4.00 ± 0.95 a |

| AFD 5% | 52.46 ± 0.81 b | 3.00 ± 0.70 ab | 6.37 ± 0.57 b |

| AFD 10% | 53.40 ± 0.00 c | 4.23 ± 0.40 b | 5.77 ± 0.12 b |

| AFD 15% | 55.10 ± 0.00 d | 4.57 ± 0.55 b | 5.40 ± 0.26 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khatun, H.; Van Der Borght, M.; Akhtaruzzaman, M.; Claes, J. Rheological Characterization of Chapatti (Roti) Enriched with Flour or Paste of House Crickets (Acheta domesticus). Foods 2021, 10, 2750. https://doi.org/10.3390/foods10112750

Khatun H, Van Der Borght M, Akhtaruzzaman M, Claes J. Rheological Characterization of Chapatti (Roti) Enriched with Flour or Paste of House Crickets (Acheta domesticus). Foods. 2021; 10(11):2750. https://doi.org/10.3390/foods10112750

Chicago/Turabian StyleKhatun, Habiba, Mik Van Der Borght, Mohammad Akhtaruzzaman, and Johan Claes. 2021. "Rheological Characterization of Chapatti (Roti) Enriched with Flour or Paste of House Crickets (Acheta domesticus)" Foods 10, no. 11: 2750. https://doi.org/10.3390/foods10112750

APA StyleKhatun, H., Van Der Borght, M., Akhtaruzzaman, M., & Claes, J. (2021). Rheological Characterization of Chapatti (Roti) Enriched with Flour or Paste of House Crickets (Acheta domesticus). Foods, 10(11), 2750. https://doi.org/10.3390/foods10112750