Preparation and Characterization of Pickering Emulsions with Modified Okara Insoluble Dietary Fiber

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Modified OIDF

2.3. Preparation of Pickering Emulsions with Modified Okara Insoluble Dietary Fiber

2.4. Particle Size and Zeta Potential Analysis

2.5. Contact Angle Measurement

2.6. Morphological Observation of OIDF-Pickering Emulsions

2.7. Croy-Scanning Electron Microscope (Croy-SEM)

2.8. Rheological Properties

2.9. Stability Analysis of OIDF-Pickering Emulsions

2.9.1. Storage Stability

2.9.2. Centrifugal Stability (Encapsulation Efficiency)

2.9.3. pH Value or Ionic Strength Stability

2.10. Statistical Analysis

3. Results

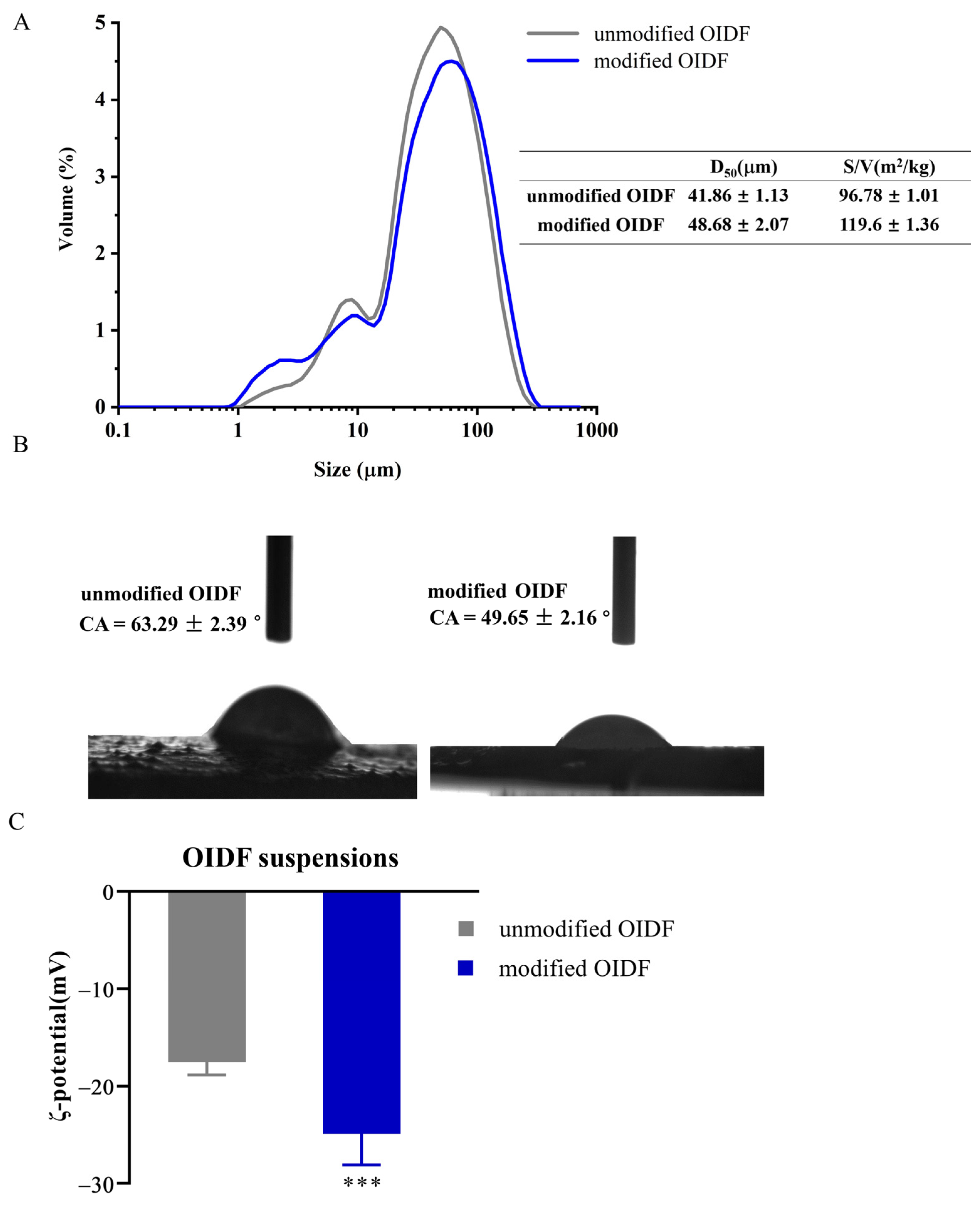

3.1. Basic Characteristics of OIDF

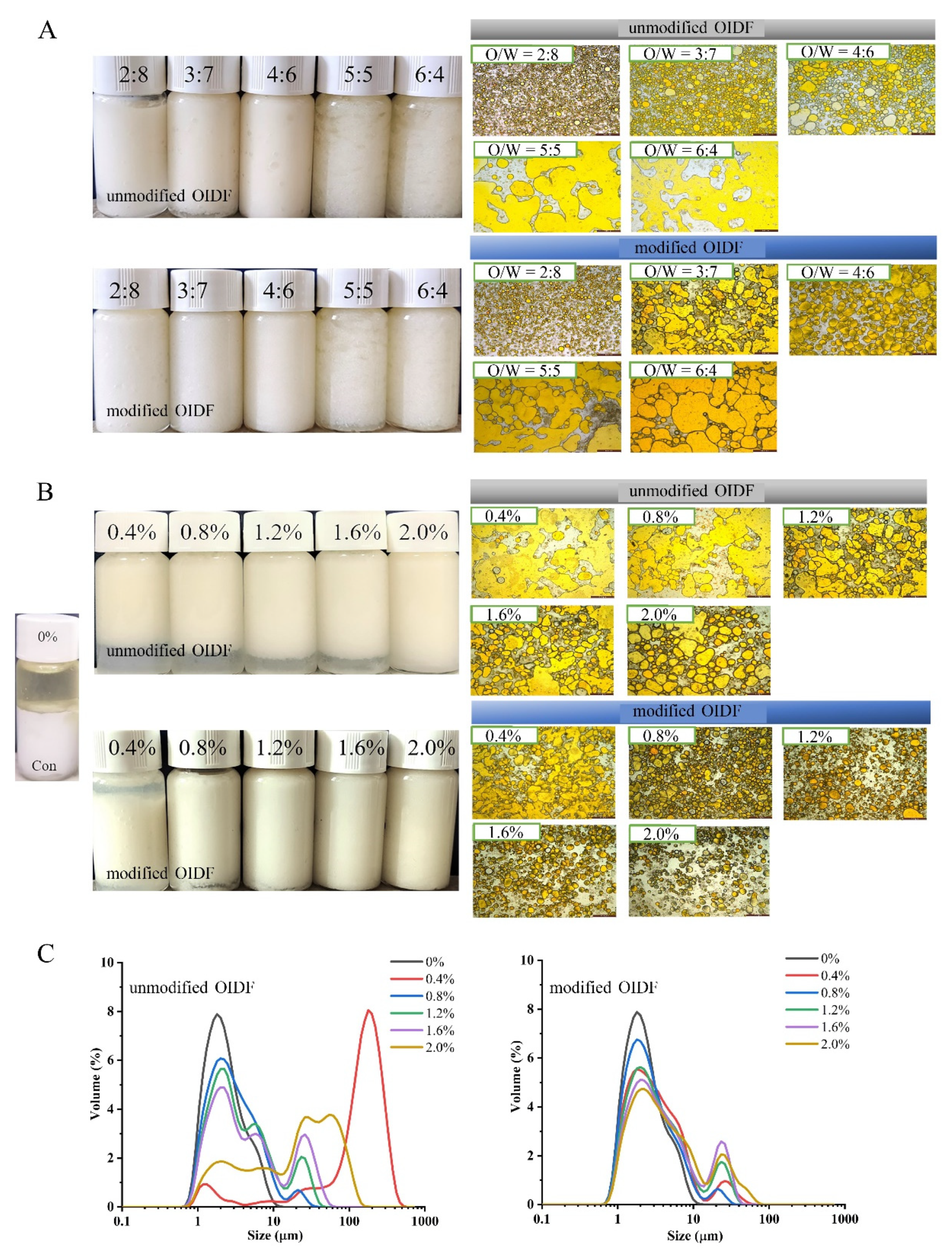

3.2. Effects of O/W and OIDF Concentration on the Formation of OIDF-Pickering Emulsions

3.3. Characteristics of OIDF-Pickering Emulsions

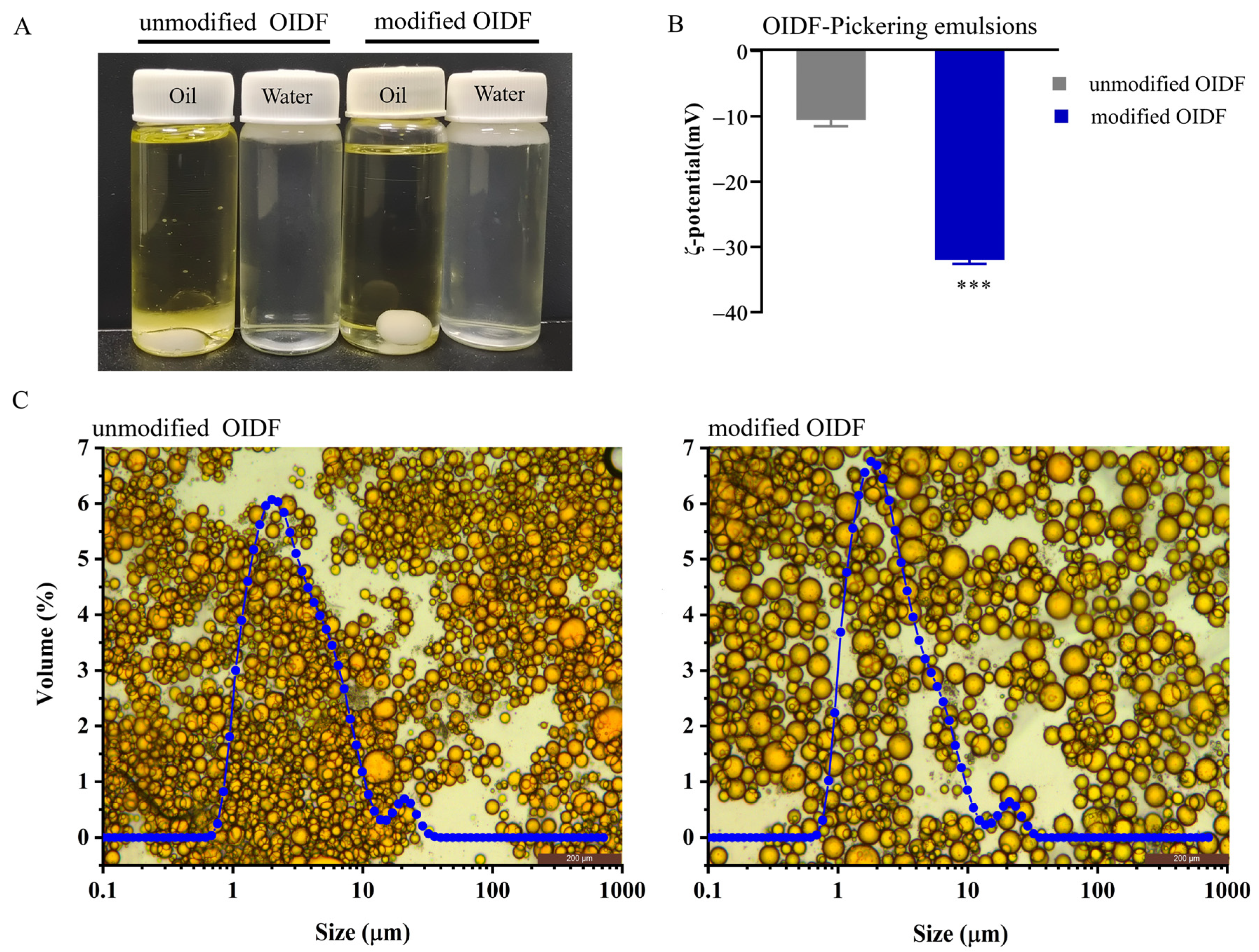

3.3.1. Basic Physical Characteristics of OIDF-Pickering Emulsions

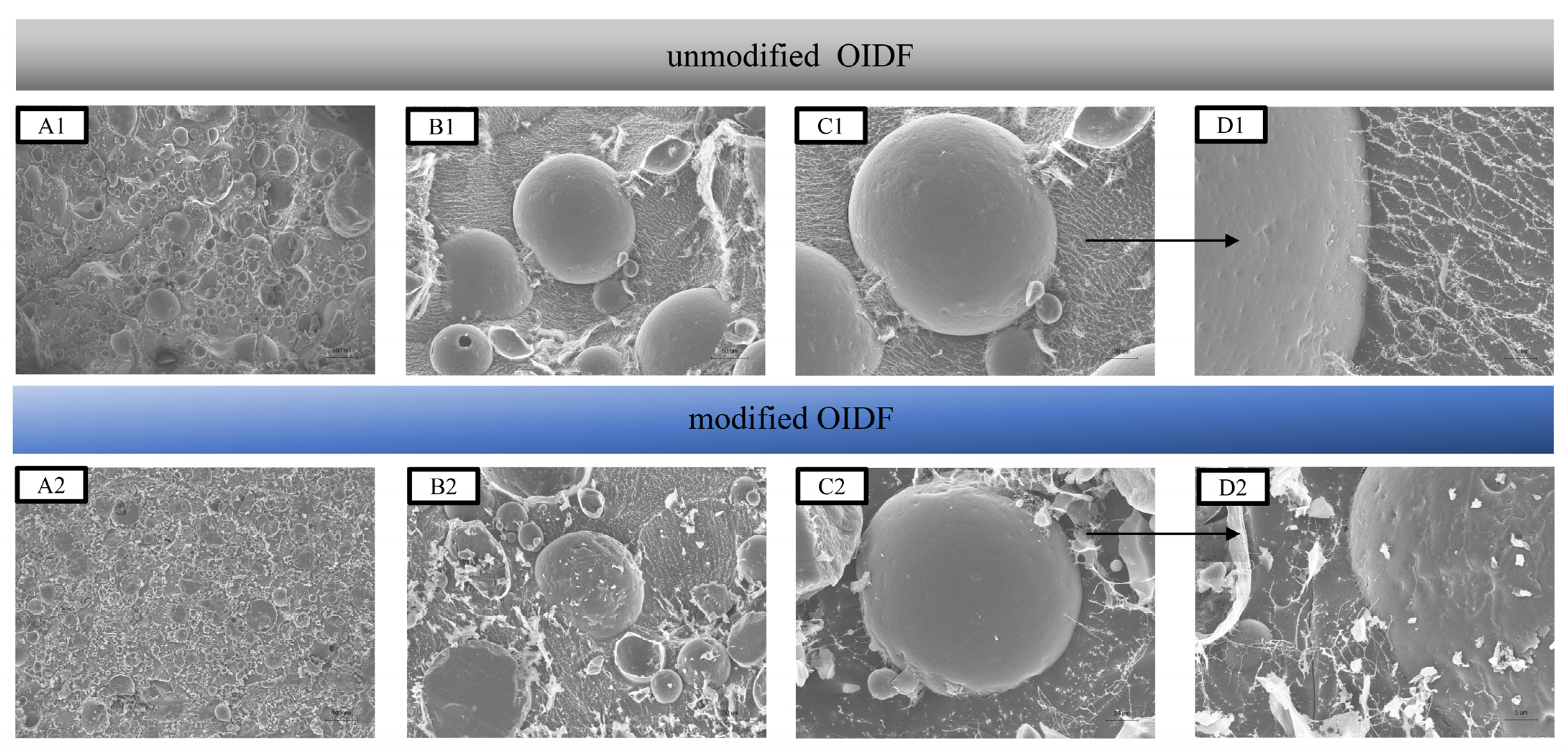

3.3.2. Croy-SEM of OIDF-Pickering Emulsions

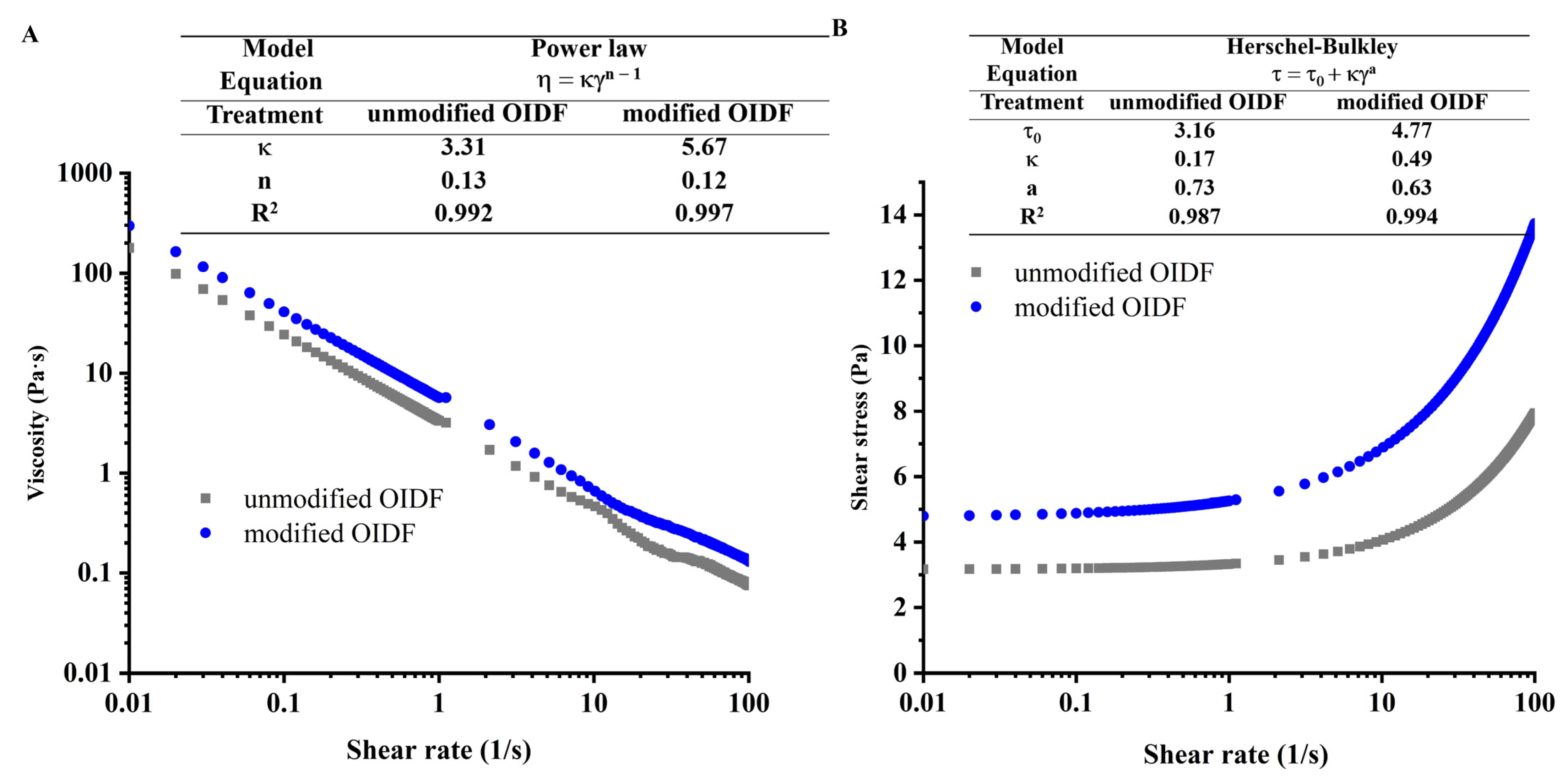

3.3.3. Rheological Properties of OIDF-Pickering Emulsions

3.4. Stability Analysis of OIDF-Pickering Emulsions

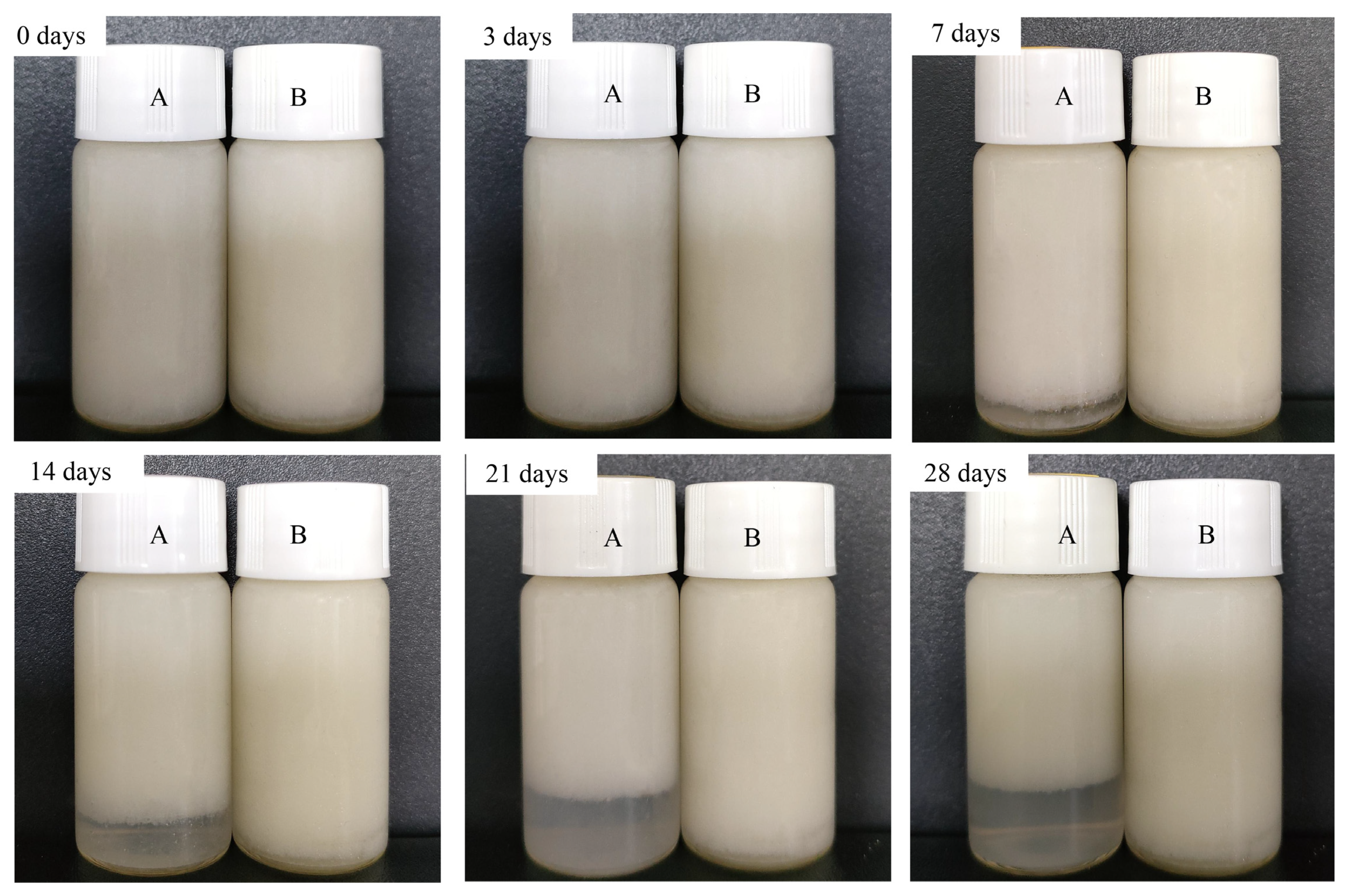

3.4.1. Storage Stability

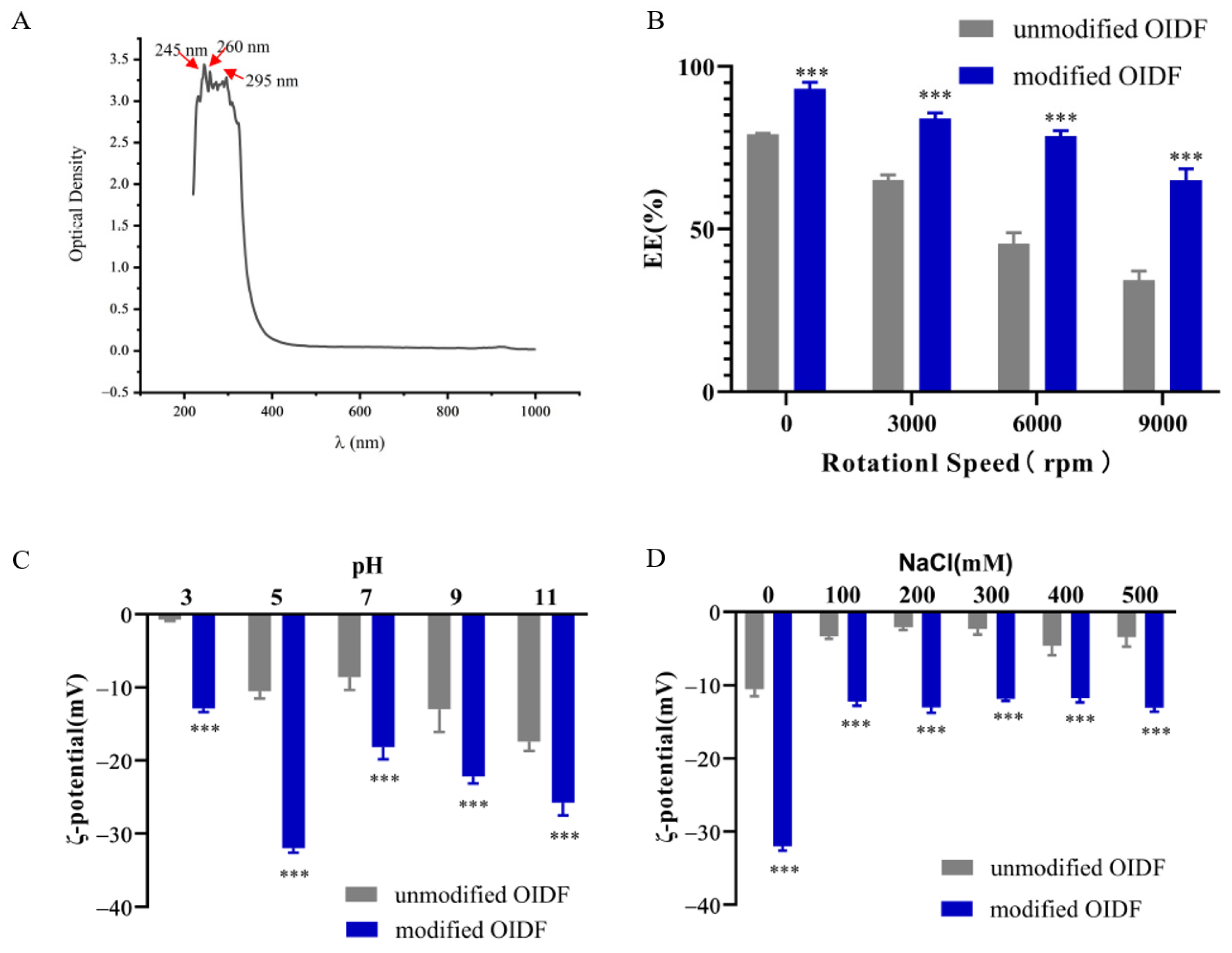

3.4.2. Centrifugal Stability (Encapsulation Efficiency)

3.4.3. pH and Ionic Strength (NaCl) Stability

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, T.; Yang, J.; Hua, S.; Hong, Y.; Gu, Z.; Cheng, L.; Li, Z.; Li, C. Characteristics of starch-based Pickering emulsions from the interface perspective. Trends Food Sci. Technol. 2020, 105, 334–346. [Google Scholar] [CrossRef]

- Winuprasith, T.; Suphantharika, M. Microfibrillated cellulose from mangosteen (Garcinia mangostana L.) rind: Preparation, characterization, and evaluation as an emulsion stabilizer. Food Hydrocoll. 2013, 32, 383–394. [Google Scholar] [CrossRef]

- Liu, C.; Fan, L.; Yang, Y.; Jiang, Q.; Xu, Y.; Xia, W. Characterization of surimi particles stabilized novel pickering emulsions: Effect of particles concentration, pH and NaCl levels. Food Hydrocoll. 2021, 117, 106731. [Google Scholar] [CrossRef]

- Ren, Z.; Chen, Z.; Zhang, Y.; Lin, X.; Li, Z.; Weng, W.; Yang, H.; Li, B. Effect of heat-treated tea water-insoluble protein nanoparticles on the characteristics of Pickering emulsions. LWT 2021, 149, 111999. [Google Scholar] [CrossRef]

- Sun, Y.; Ma, L.; Fu, Y.; Dai, H.; Zhang, Y. Fabrication and characterization of myofibrillar microgel particles as novel Pickering stabilizers: Effect of particle size and wettability on emulsifying capacity. LWT 2021, 151, 112002. [Google Scholar] [CrossRef]

- Chen, Q.-H.; Zheng, J.; Xu, Y.-T.; Yin, S.-W.; Liu, F.; Tang, C.-H. Surface modification improves fabrication of pickering high internal phase emulsions stabilized by cellulose nanocrystals. Food Hydrocoll. 2018, 75, 125–130. [Google Scholar] [CrossRef]

- Lu, H.; Tian, Y. Nanostarch: Preparation, Modification, and Application in Pickering Emulsions. J. Agric. Food Chem. 2021, 69, 6929–6942. [Google Scholar] [CrossRef]

- Costa, A.L.R.; Gomes, A.; Tibolla, H.; Menegalli, F.C.; Cunha, R.L. Cellulose nanofibers from banana peels as a Pickering emulsifier: High-energy emulsification processes. Carbohydr. Polym. 2018, 194, 122–131. [Google Scholar] [CrossRef]

- Chen, B.; Cai, Y.; Liu, T.; Huang, L.; Deng, X.; Zhao, Q.; Zhao, M. Improvements in physicochemical and emulsifying properties of insoluble soybean fiber by physical-chemical treatments. Food Hydrocoll. 2019, 93, 167–175. [Google Scholar] [CrossRef]

- Wei, Y.; Guo, A.; Liu, Z.; Mao, L.; Yuan, F.; Gao, Y.; Mackie, A. Structural design of zein-cellulose nanocrystals core-shell microparticles for delivery of curcumin. Food Chem. 2021, 357, 129849. [Google Scholar] [CrossRef]

- Geng, S.; Liu, X.; Ma, H.; Liu, B.; Liang, G. Multi-scale stabilization mechanism of pickering emulsion gels based on dihydromyricetin/high-amylose corn starch composite particles. Food Chem. 2021, 355, 129660. [Google Scholar] [CrossRef]

- Guimarães, R.M.; Silva, T.E.; Lemes, A.C.; Boldrin, M.C.F.; da Silva, M.A.P.; Silva, F.G.; Egea, M.B. Okara: A soybean by-product as an alternative to enrich vegetable paste. LWT 2018, 92, 593–599. [Google Scholar] [CrossRef]

- Vong, W.C.; Liu, S.-Q. Biovalorisation of okara (soybean residue) for food and nutrition. Trends Food Sci. Technol. 2016, 52, 139–147. [Google Scholar] [CrossRef]

- Hu, Y.; Piao, C.; Chen, Y.; Zhou, Y.; Wang, D.; Yu, H.; Xu, B. Soybean residue (okara) fermentation with the yeast Kluyveromyces marxianus. Food Biosci. 2019, 31, 100439. [Google Scholar] [CrossRef]

- Yang, T.; Liu, T.-X.; Li, X.-T.; Tang, C.-H. Novel nanoparticles from insoluble soybean polysaccharides of Okara as unique Pickering stabilizers for oil-in-water emulsions. Food Hydrocoll. 2019, 94, 255–267. [Google Scholar] [CrossRef]

- Cai, Y.; Huang, L.; Chen, B.; Zhao, X.; Zhao, M.; Zhao, Q.; Van der Meeren, P. Effect of alkaline pH on the physicochemical properties of insoluble soybean fiber (ISF), formation and stability of ISF-emulsions. Food Hydrocoll. 2020, 111, 106188. [Google Scholar] [CrossRef]

- Ullah, I.; Yin, T.; Xiong, S.; Zhang, J.; Din, Z.-u.; Zhang, M. Structural characteristics and physicochemical properties of okara (soybean residue) insoluble dietary fiber modified by high-energy wet media milling. LWT Food Sci. Technol. 2017, 82, 15–22. [Google Scholar] [CrossRef]

- Karim, A.; Gerliani, N.; Aider, M. Kluyveromyces marxianus: An emerging yeast cell factory for applications in food and biotechnology. Int. J. Food Microbiol. 2020, 333, 108818. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Y.; Li, Y.; Yu, H.; Wang, Y.; Piao, C. Insoluble dietary fibre from okara (soybean residue) modified by yeast Kluyveromyces marxianus. LWT 2020, 134, 110252. [Google Scholar] [CrossRef]

- Capron, I.; Cathala, B. Surfactant-free high internal phase emulsions stabilized by cellulose nanocrystals. Biomacromolecules 2013, 14, 291–296. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Li, J.; Ge, L.; Xie, W.; Wu, D. Pickering emulsion stabilized with fibrous nanocelluloses: Insight into fiber flexibility-emulsifying capacity relations. Carbohydr. Polym. 2021, 255, 117483. [Google Scholar] [CrossRef]

- Yuan, Y.; Kong, Z.-Y.; Sun, Y.-E.; Zeng, Q.-Z.; Yang, X.-Q. Complex coacervation of soy protein with chitosan: Constructing antioxidant microcapsule for algal oil delivery. LWT 2017, 75, 171–179. [Google Scholar] [CrossRef]

- Huang, L.; Cai, Y.; Liu, T.; Zhao, X.; Chen, B.; Long, Z.; Zhao, M.; Deng, X.; Zhao, Q. Stability of emulsion stabilized by low-concentration soybean protein isolate: Effects of insoluble soybean fiber. Food Hydrocoll. 2019, 97, 105232. [Google Scholar] [CrossRef]

- Yu, H.; Huang, G.; Ma, Y.; Liu, Y.; Huang, X.; Zheng, Q.; Yue, P.; Yang, M. Cellulose nanocrystals based clove oil Pickering emulsion for enhanced antibacterial activity. Int. J. Biol. Macromol. 2021, 170, 24–32. [Google Scholar] [CrossRef]

- Ni, Y.; Li, J.; Fan, L. Production of nanocellulose with different length from ginkgo seed shells and applications for oil in water Pickering emulsions. Int. J. Biol. Macromol. 2020, 149, 617–626. [Google Scholar] [CrossRef] [PubMed]

- Dickinson, E. Food emulsions and foams: Stabilization by particles. Curr. Opin. Colloid Interface Sci. 2010, 15, 40–49. [Google Scholar] [CrossRef]

- Dickinson, E. Use of nanoparticles and microparticles in the formation and stabilization of food emulsions. Trends Food Sci. Technol. 2012, 24, 4–12. [Google Scholar] [CrossRef]

- Bai, L.; Xiang, W.; Huan, S.; Rojas, O.J. Formulation and Stabilization of Concentrated Edible Oil-in-Water Emulsions Based on Electrostatic Complexes of a Food-Grade Cationic Surfactant (Ethyl Lauroyl Arginate) and Cellulose Nanocrystals. Biomacromolecules 2018, 19, 1674–1685. [Google Scholar] [CrossRef] [Green Version]

- Liu, L.; Kerr, W.L.; Kong, F. Characterization of lipid emulsions during in vitro digestion in the presence of three types of nanocellulose. J. Colloid Interface Sci. 2019, 545, 317–329. [Google Scholar] [CrossRef]

- Bai, L.; Lv, S.; Xiang, W.; Huan, S.; McClements, D.J.; Rojas, O.J. Oil-in-water Pickering emulsions via microfluidization with cellulose nanocrystals: 2. In vitro lipid digestion. Food Hydrocoll. 2019, 96, 709–716. [Google Scholar] [CrossRef]

- Long, B.; Huan, S.; Xiang, W.; Rojas, O.J. Pickering emulsions by combining cellulose nanofibrils and nanocrystals: Phase behavior and depletion stabilization. Green Chem. 2018, 20, 1571–1582. [Google Scholar]

- Yuan, T.; Zeng, J.; Wang, B.; Cheng, Z.; Chen, K. Pickering emulsion stabilized by cellulosic fibers: Morphological properties-interfacial stabilization-rheological behavior relationships. Carbohydr. Polym. 2021, 269, 118339. [Google Scholar] [CrossRef] [PubMed]

- Adachi, Y.; Xiao, J. Initial stage of bridging flocculation of PSL particles induced by an addition of polyelectrolyte under high ionic strength. Colloids Surf. A Physicochem. Eng. Asp. 2013, 435, 127–131. [Google Scholar] [CrossRef] [Green Version]

- Lu, Y.; Qian, X.; Xie, W.; Zhang, W.; Huang, J.; Wu, D. Rheology of the sesame oil-in-water emulsions stabilized by cellulose nanofibers. Food Hydrocoll. 2019, 94, 114–127. [Google Scholar] [CrossRef]

- Seo, H.M.; Seo, M.; Shin, K.; Choi, S.; Kim, J.W. Bacterial cellulose nanofibrils-armored Pickering emulsions with limited influx of metal ions. Carbohydr. Polym. 2021, 258, 117730. [Google Scholar] [CrossRef]

- Yuan, T.; Zeng, J.; Wang, B.; Cheng, Z.; Chen, K. Lignin containing cellulose nanofibers (LCNFs): Lignin content-morphology-rheology relationships. Carbohydr. Polym. 2021, 254, 117441. [Google Scholar] [CrossRef] [PubMed]

| Treatment | Soybean Oil (mL) | OIDF Suspensions (mL) |

|---|---|---|

| 1 | 20 | 80 (1.0 wt%) |

| 2 | 30 | 70 (1.0 wt%) |

| 3 | 40 | 60 (1.0 wt%) |

| 4 | 50 | 50 (1.0 wt%) |

| 5 | 60 | 40 (1.0 wt%) |

| 6 | 40 | 60 (0 wt%) |

| 7 | 40 | 60 (0.4 wt%) |

| 8 | 40 | 60 (0.8 wt%) |

| 9 | 40 | 60 (1.2 wt%) |

| 10 | 40 | 60 (1.6 wt%) |

| 11 | 40 | 60 (2.0 wt%) |

| Sample | EPVF (%) | Emulsion Feature after 28 Days | |||||

|---|---|---|---|---|---|---|---|

| 0 Days | 7 Days | 14 Days | 21 Days | 28 Days | Upper Phase | Bottom Phase | |

| UnmodifiedOIDF | 100 ± 0.0 | 91.77 ± 4.6 | 87.01 ± 3.6 | 81.3 ± 2.2 | 78.75 ± 1.0 | Gel-like emulsion | Aqueous phase |

| Modified OIDF | 100 ± 0.0 | 100 ± 0.0 | 98.98 ± 2.3 | 97.44 ± 3.1 | 95.33 ± 3.9 | Gel-like emulsion | Gel-like emulsion |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bao, Y.; Xue, H.; Yue, Y.; Wang, X.; Yu, H.; Piao, C. Preparation and Characterization of Pickering Emulsions with Modified Okara Insoluble Dietary Fiber. Foods 2021, 10, 2982. https://doi.org/10.3390/foods10122982

Bao Y, Xue H, Yue Y, Wang X, Yu H, Piao C. Preparation and Characterization of Pickering Emulsions with Modified Okara Insoluble Dietary Fiber. Foods. 2021; 10(12):2982. https://doi.org/10.3390/foods10122982

Chicago/Turabian StyleBao, Yue, Hanyu Xue, Yang Yue, Xiujuan Wang, Hansong Yu, and Chunhong Piao. 2021. "Preparation and Characterization of Pickering Emulsions with Modified Okara Insoluble Dietary Fiber" Foods 10, no. 12: 2982. https://doi.org/10.3390/foods10122982

APA StyleBao, Y., Xue, H., Yue, Y., Wang, X., Yu, H., & Piao, C. (2021). Preparation and Characterization of Pickering Emulsions with Modified Okara Insoluble Dietary Fiber. Foods, 10(12), 2982. https://doi.org/10.3390/foods10122982