Effect of Different Black Quinoa Fractions (Seed, Flour and Wet-Milling Coproducts) upon Quality of Meat Patties during Freezing Storage

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Design

2.2. Plant Materials and Preparation of the Different Fractions of Quinoa

2.3. Meat Patties Processing, Freezing Preservation, Thawing and Cooking Conditions

2.4. Chemical Composition

2.5. Physicochemical Properties

2.6. Lipid Oxidation

2.7. Cooking Properties

2.8. Sensorial Analysis

2.9. Statistical Analysis

3. Results

3.1. Chemical Composition of Meat Patties with Different Black Quinoa Fractions (Seed, Flour and Wet-Milling Coproduct)

3.2. Effect of Freezing Storage on Physico-Chemical Parameters of Meat Patties with Different Black Quinoa Fractions

3.3. Effect of Freezing Storage on Texture Parameters of Patties with Different Black Quinoa Fractions (Seed, Flour and Wet-Milling Coproducts)

3.4. Effect of Freezing Storage on Lipid Oxidation of Patties with Different Black Quinoa Fractions (Seed, Flour and Wet-Milling Coproducts)

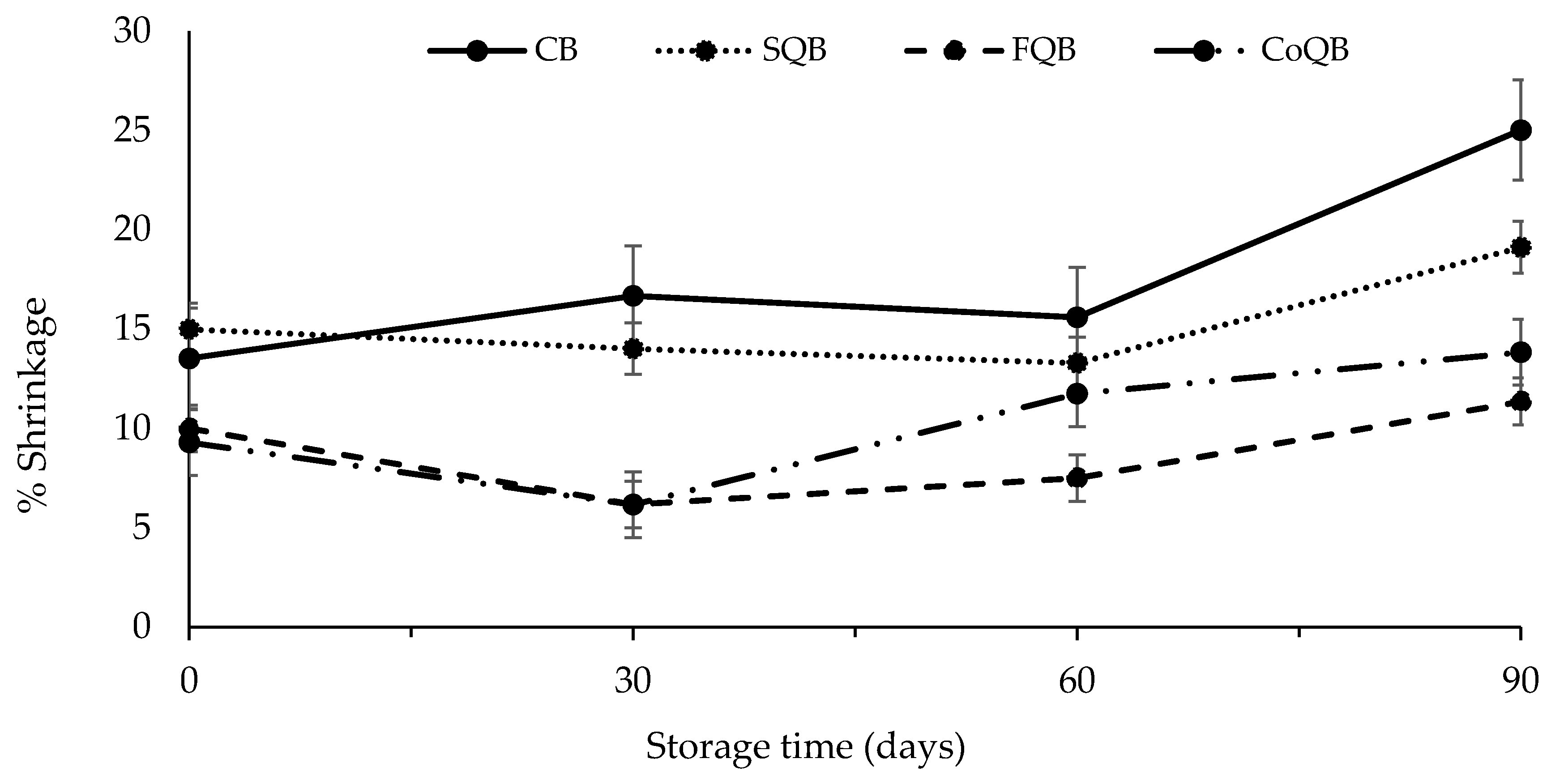

3.5. Effect of Freezing Storage on Cooking Properties of Meat Patties with Different Black Quinoa Fractions (Seed, Flour and Wet-Milling Coproducts)

3.6. Effect of Freezing Storage on Sensorial Characteristics of Patties with Different Black Quinoa Fractions (Seed, Flour and Wet-Milling Coproducts)

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nakat, Z.; Bou-Mitri, C. COVID-19 and the food industry: Readiness assessment. Food Control 2021, 121, 107661. [Google Scholar] [CrossRef]

- FAO. Sustainable Food and Agriculture. Available online: https://www.fao.org/sustainability/es/ (accessed on 12 September 2021).

- Faustino, M.; Veiga, M.; Sousa, P.; Costa, E.M.; Silva, S.; Pintado, M. Agro-food byproducts as a new source of natural food additives. Molecules 2019, 24, 1056. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rodríguez-Barona, S.; Cuaspud, J.A.; Giraldo, G.I. Efecto del pretratamiento con deshidratación osmótica en la impregnación a vacío de láminas de banano para el desarrollo de un alimento funcional. Inf. Tecnol. 2019, 30, 51–58. [Google Scholar] [CrossRef] [Green Version]

- Olmedilla-Alonso, B.; Jiménez-Colmenero, F. Alimentos cárnicos funcionales: Desarrollo y evaluación de sus propiedades saludables. Nutr. Hosp. 2014, 29, 1197–1209. [Google Scholar] [CrossRef]

- Fernández-López, J.; Viuda-Martos, M.; Pérez-Alvarez, J.A. Quinoa and chia products as ingredients for healthier processed meat products: Technological strategies for their application and effects on the final product. Curr. Opin. Food Sci. 2021, 40, 26–32. [Google Scholar] [CrossRef]

- Föste, M.; Nordlohne, S.D.; Elgeti, D.; Linden, M.H.; Heinz, V.; Jekle, M.; Becker, T. Impact of quinoa bran on gluten-free dough and bread characteristis. Eur. Food Res. Technol. 2014, 239, 767–775. [Google Scholar] [CrossRef]

- Graf, B.L.; Rojas-Silva, P.; Rojo, L.E.; Delatorre-Herrera, J.; Baldeón, M.E.; Raskin, I. Innovations in health value and functional food development of quinoa (Chenopodium quinoa Willd.). Rev. Food. Sci. Food Saf. 2015, 14, 431–445. [Google Scholar] [CrossRef] [Green Version]

- Navruz-Varli, S.; Sanlier, N. Nutritional and health benefits of quinoa (Chenopodium quinoa Willd.). J. Cereal Sci. 2016, 69, 371–376. [Google Scholar] [CrossRef]

- Vilcacundo, R.; Hernández-Ledesma, B. Nutritional and biological value of quinoa (Chenopodium quinoa Willd.). Curr. Opin. Food Sci. 2017, 14, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Nowak, V.; Du, J.; Charrondière, U.R. Assessment of the nutritional composition of quinoa (Chenopodium quinoa Willd.). Food Chem. 2016, 193, 47–54. [Google Scholar] [CrossRef] [PubMed]

- Shokry, A.M. The usage of quinoa flour as a potential ingredient in production of meat burger with functional properties. Middle East J. Appl. Sci. 2016, 6, 1128–1137. [Google Scholar]

- Özer, C.O.; Seçen, S.M. Effects of quinoa flour on lipid and protein oxidation in raw and cooked beef burger during long term frozen storage. Food Sci. Technol. 2018, 38, 221–227. [Google Scholar] [CrossRef] [Green Version]

- Bağdatli, A. The influence of quinoa (Chenopodium quinoa Willd.) Flour on the pshycochmical, textural and sensorial properties of beef meatball. Ital. J. Food Sci. 2018, 30, 280–288. [Google Scholar]

- Fernández-López, J.; Lucas-González, R.; Viuda-Martos, M.; Sayas-Barberá, E.; Ballester-Sánchez, J.; Haros, C.M.; Martínez-Mayoral, A.; Pérez-Álvarez, J.A. Chemical and technological properties of bologna-type sausages with added black quinoa wet-milling coproducts as binder replacer. Food Chem. 2020, 310, 125936. [Google Scholar] [CrossRef]

- Ballester-Sánchez, J.; Fernández-Espinar, M.T.; Haros, C.M. Isolation of red quinoa fibre by wet and dry milling and application as a potential functional bakery ingredient. Food Hydrocoll. 2020, 101, 105513. [Google Scholar] [CrossRef]

- Jimenez, D.; Miraballes, M.; Gámbaro, A.; Lobo, M.; Samman, N. Baby purees elaborated with andean crops. Influence of germination and oils in physico-chemical and sensory characteristics. LWT-Food Sci. Technol. 2020, 124, 108901. [Google Scholar] [CrossRef]

- Park, J.H.; Lee, Y.J.; Lim, J.G.; Jeon, J.H.; Yoon, K.S. Effect of Quinoa (Chenopodium quinoa Willd.) Starch and Seeds on the Physicochemical and Textural and Sensory Properties of Chicken Meatballs during Frozen Storage. Foods 2021, 10, 1601. [Google Scholar] [CrossRef] [PubMed]

- Pellegrini, M.; Lucas-Gonzales, R.; Ricci, A.; Fontecha, J.; Fernández-López, J.; Pérez-Álvarez, J.A.; Viuda-Martos, M. Chemical, fatty acid, polyphenolic profile, techno-functional and antioxidant properties of flours obtained from quinoa (Chenopodium quinoa Willd) seeds. Ind. Crops Prod. 2018, 111, 38–46. [Google Scholar] [CrossRef]

- Roldán Verdú, A. Caracterización Tecnofuncional, Acondicionamiento y Aplicación a Matrices Cárnicas del Coproducto de la Quínoa Negra (Chenopodium quinoa W.). Master’s Thesis, Universidad Miguel Hernández, Alicante, Spain, 2019. [Google Scholar]

- Ballester-Sánchez, J.; Gil, J.V.; Fernández-Espinar, M.T.; Haros, C.M. Quinoa wet-milling: Effect of steeping conditions on starch recovery and quality. Food Hydrocoll. 2019, 89, 837–843. [Google Scholar] [CrossRef] [Green Version]

- Association of Official Analytical Chemists. Official Methods of Analysis, 18th ed.; AOAC: Washington, DC, USA, 2010. [Google Scholar]

- American Meat Science Association. Meat Color Measurement Guidelines; AMSA: Champaign, IL, USA, 2012. [Google Scholar]

- Bourne, M.C. Food Texture and Viscosity Concept and Measurement, 2nd ed.; Academic Press: Cambridge, MA, USA, 2002. [Google Scholar]

- Rosmini, M.R.; Perlo, F.; Pérez-Álvarez, J.A.; Pagán-Moreno, M.J.; Gago-Gago, A.; López-Santoveña, F.; Aranda-Catalá, V. TBA test by an extractive method applied to ‘paté’. Meat Sci. 1996, 42, 103–110. [Google Scholar] [CrossRef]

- American Meat Science Association. Research Guidelines for Cookery, Sensory Evaluation, and Instrumental Tenderness Measurements of Meat; AMSA: Champaign, IL, USA, 2015. [Google Scholar]

- Sánchez-Zapata, E.; Muñoz, C.M.; Fuentes, E.; Fernández-López, J.; Sendra, E.; Sayas, E.; Navarro, C.; Pérez-Alvarez, J.A. Effect of tiger nut fibre on quality characteristics of pork burger. Meat Sci. 2010, 85, 70–76. [Google Scholar] [CrossRef] [PubMed]

- Bis-Souza, C.V.; Henck, J.M.M.; Barretto, A.C.D.S. Performance of low-fat beef burger with added soluble and insoluble dietary fibers. Food Sci. Technol. 2018, 38, 522–529. [Google Scholar] [CrossRef] [Green Version]

- Bahmanyar, F.; Hosseini, S.M.; Mirmoghtadaie, L.; Shojaee-Aliabadi, S. Effects of replacing soy protein and bread crumb with quinoa and buckwheat flour in functional beef burger formulation. Meat Sci. 2021, 172, 108305. [Google Scholar] [CrossRef]

- Sayas-Barberá, E.; Quesada, J.; Sánchez-Zapata, E.; Viuda-Martos, M.; Fernández-López, F.; Pérez-Álvarez, J.A.; Sendra, E. Effect of the molecular weight and concentration of chitosan in pork model burgers. Meat Sci. 2011, 88, 740–749. [Google Scholar] [CrossRef] [PubMed]

- Holman, B.W.B.; Coombs, C.E.O.; Morris, S.; Kerr, M.J.; Hopkins, D.L. Effect of long term chilled (up to 5 weeks) then frozen (up to 12 months) storage at two different sub-zero holding temperatures on beef: 1. Meat quality and microbial loads. Meat Sci. 2017, 133, 133–142. [Google Scholar] [CrossRef] [PubMed]

- Leygonie, C.; Britz, T.J.; Hoffman, L.C. Impact of freezing and thawing on the quality of meat. Meat Sci. 2012, 91, 93–98. [Google Scholar] [CrossRef]

- Utrera, M.; Morcuende, D.; Estévez, M. Temperature of frozen storage affects the nature and consequences of protein oxidation in beef patties. Meat Sci. 2014, 96, 1250–1257. [Google Scholar] [CrossRef]

- Fernández-López, J.; Jiménez, S.; Sayas-Barberá, E.; Sendra, E.; Pérez-Álvarez, J.A. Quality characteristics of ostrich (Struthio camelus) burgers. Meat Sci. 2006, 73, 295–303. [Google Scholar] [CrossRef]

- Angiolillo, L.; Conte, A.; Del Nobile, M.A. Technological strategies to produce functional meat burgers. LWT-Food Sci. Technol. 2015, 62, 697–703. [Google Scholar] [CrossRef]

- Hashemi Gahruie, H.; Hosseini, S.M.H.; Taghavifard, M.H.; Eskandari, M.H.; Golmakani, M.T.; Shad, E. Lipid oxidation, color changes, and microbiological quality of frozen beef burgers incorporated with shirazi thyme, cinnamon, and rosemary extracts. J. Food Qual. 2017. [Google Scholar] [CrossRef]

- Hamzaoui, A.; Ghariani, M.; Sellem, I.; Hamdi, M.; Feki, A.; Jaballi, I.; Nasri, M.; Amara, I.B. Extraction, characterization and biological properties of polysaccharide derived from green seaweed “Chaetomorpha linum” and its potential application in Tunisian beef sausages. Int. J. Biol. Macromol. 2020, 148, 1156–1168. [Google Scholar] [CrossRef]

- García, M.L.; Caceres, E.; Selgas, M.D. Utilisation of fruit fibres in conventional and reduced-fat cooked-meat sausages. J. Sci. Food Agric. 2007, 87, 624–631. [Google Scholar] [CrossRef]

- López-Vargas, J.H.; Fernández-López, J.; Pérez-Álvarez, J.Á.; Viuda-Martos, M. Quality characteristics of pork burger added with albedo-fiber powder obtained from yellow passion fruit (Passiflora edulis var. flavicarpa) co-products. Meat Sci. 2014, 97, 270–276. [Google Scholar] [CrossRef]

- Aidani, E.; Aghamohammadi, B.; Akbarian, M.; Morshedi, A.; Hadidi, M.; Ghasemkhani, N.; Akbarian, A. Effect of chilling, freezing and thawing on meat quality: A review. Int. J. Biosci. 2014, 5, 159–169. [Google Scholar] [CrossRef]

- Domínguez, R.; Pateiro, M.; Gagaoua, M.; Barba, F.J.; Zhang, W.; Lorenzo, J.M. A comprehensive review on lipid oxidation in meat and meat products. Antioxidants 2019, 8, 429. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Castro, W.F.; Mariutti, L.R.B.; Bragagnolo, N. The effects of colourifico on lipid oxidation, colour and vitamin E in raw and grilled chicken patties during frozen storage. Food Chem. 2011, 124, 126–131. [Google Scholar] [CrossRef]

- Barbera, S.; Tassone, S. Meat cooking shrinkage: Measurement of a new meat quality parameter. Meat Sci. 2006, 73, 467–474. [Google Scholar] [CrossRef] [PubMed]

- Baioumy, A.A.; Bobreneva, I.V.; Tvorogova, A.A.; Shobanova, T.V. Possibility of using quinoa seeds (Chenopodium quinoa) in meat products and its impact on nutritional and organoleptic characteristics. Biosci. Res. 2018, 15, 3307–3315. [Google Scholar]

- Saldaña, E.; Merlo, T.C.; Patinho, I.; Rios-Mera, J.D.; Contreras-Castillo, C.J.; Selani, M.M. Use of sensory science for the development of healthier processed meat products: A critical opinion. Curr. Opin. Food Sci. 2021, 40, 13–19. [Google Scholar] [CrossRef]

- Mancini, R.A.; Hunt, M. Current research in meat color. Meat Sci. 2005, 71, 100–121. [Google Scholar] [CrossRef]

| Samples | ||||

|---|---|---|---|---|

| CB | SQB | FQB | CoQB | |

| Moisture (%) | 72.92 ± 0.86 a | 67.39 ± 1.21 b | 64.13 ± 0.49 c | 66.88 ± 0.93 b |

| Ashes (%) | 2.33 ± 0.26 a | 2.51 ± 0.41 a | 2.33 ± 0.08 a | 2.40 ± 0.17 a |

| Proteins (%) | 20.10 ± 0.65 a | 20.83 ± 0.79 a | 19.80 ± 0.17 a | 19.70 ± 0.93 a |

| Fat (%) | 3.72 ± 1.01 a | 3.28 ± 0.71 a | 4.28 ± 0.63 a | 3.75 ± 0.40 a |

| Parameters | Batch | Storage Time at −20 °C (Days) | |||

|---|---|---|---|---|---|

| Day 0 | Day 30 | Day 60 | Day 90 | ||

| pH | CB | 5.70 ± 0.02 Aa | 5.92 ± 0.08 Ba | 5.80 ± 0.0 Ba | 5.89 ± 0.05 Ba |

| SQB | 5.63 ± 0.08 Aa | 5.88 ± 0.02 Ba | 5.85 ± 0.03 Ba | 5.86 ± 0.04 Ba | |

| FQB | 5.65 ± 0.05 Aa | 5.87 ± 0.05 Ba | 5.84 ± 0.03 Ba | 5.92 ± 0.02 Ba | |

| CoQB | 5.60 ± 0.03 Aa | 5.90 ± 0.02 Ba | 5.87 ± 0.04 Ba | 5.91 ± 0.04 Ba | |

| Water activity (aw) | CB | 0.959 ± 0.01 Aa | 0.951 ± 0.01 Aa | 0.976 ± 0.01 Ba | 0.956 ± 0.01 Aa |

| SQB | 0.963 ± 0.01 Ab | 0.953 ± 0.01 Aa | 0.973 ± 0.01 Ba | 0.959 ± 0.01 Aa | |

| FQB | 0.961 ± 0.01 Ab | 0.954 ± 0.01 Aa | 0.973 ± 0.01 Ba | 0.949 ± 0.01 Aa | |

| CoQB | 0.966 ± 0.01 Ab | 0.954 ± 0.01 Aa | 0.973 ± 0.01 Ba | 0.955 ± 0.01 Aa | |

| Lightness (L*) | CB | 37.45 ± 2.09 Bb | 36.77 ± 3.69 Ab | 35.75 ± 4.74 Aa | 35.12 ± 3.57 Aa |

| SQB | 35.08 ± 1.9 Ba | 33.32 ± 3.03 Aa | 33.69 ± 2.26 Aa | 33.26 ± 2.85 Aa | |

| FQB | 39.17 ± 1.98 Ac | 39.51 ± 2.24 Ac | 40.38 ± 3.26 Ab | 38.81 ± 2.03 Ab | |

| CoQB | 34.44 ± 1.78 Aa | 30.70 ± 2.12 Aa | 31.63 ± 2.05 Aa | 33.77 ± 2.02 ABa | |

| Redness (a*) | CB | 7.16 ± 0.98 Bc | 7.24± 1.56 Bb | 7.85 ± 1.56 Bb | 5.27 ± 1.65 Ab |

| SQB | 5.30 ± 1.25 Bb | 6.03 ± 1.98 Bb | 5.38 ± 1.46 Bb | 2.52 ± 0.83 Aa | |

| FQB | 5.79 ± 1.65 Ab | 5.42 ± 0.85 bA | 4.65 ± 0.98 Ab | 4.84 ± 1.41 Ab | |

| CoQB | 2.88 ± 1.00 Aa | 3.91 ± 0.66 Aa | 3.2 ± 0.65 Aa | 4.85 ± 1.67 Bb | |

| Yellowness (b*) | CB | 5.72 ± 1.03 Abc | 7.49 ± 1.41 Bb | 8.98 ± 1.34 Bc | 5.51 ± 1.55 Aa |

| SQB | 4.65 ± 0.84 Aab | 7.61 ± 1.08 Bb | 7.45 ± 2.01 Bb | 4.48 ± 1.88 Aa | |

| FQB | 6.63 ± 0.96 Ac | 9.28 ± 1.05 Bc | 9.02 ± 1.44 Bd | 7.41 ± 1.23 Ab | |

| CoQB | 3.25 ± 1.25 Aa | 5.73 ± 0.70 Ba | 5.31 ± 1.29 Ba | 5.83 ± 2.00 Ba | |

| Parameters | Sample | Storage Time at −20 °C (Days) | |||

|---|---|---|---|---|---|

| Day 0 | Day 30 | Day 60 | Day 90 | ||

| Hardness | CB | 6.72 ± 2.34 Ba | 3.57 ± 1.24 Aa | 4.367 ± 1.46 Aa | 6.85 ± 2.01 Bb |

| (kg) | SQB | 8.99 ± 0.66 Bb | 4.78 ± 1.12 Aa | 7.96 ± 0.30 Bb | 8.95 ± 1.62 Bb |

| FQB | 5.79 ± 1.11 Ba | 4.05 ± 0.72 Aa | 6.22 ± 1.32 Bb | 4.77± 0.65 ABa | |

| CoQB | 13.63 ± 1.7 Ab | 11.50 ± 1.60 Ab | 12.94 ±1.11 Ac | 12.19 ±2.94 Ac | |

| Springiness | CB | 0.28 ± 0.03 Ba | 0.21 ± 0.04 Aa | 0.30 ± 0.06 Ba | 0.33 ± 0.06 Ba |

| (mm) | SQB | 0.29 ± 0.03 Ba | 0.22 ± 0.04 Aa | 0.29 ± 0.04 Ba | 0.33 ± 0.04 Ba |

| FQB | 0.29 ± 0.04 Aa | 0.30 ± 0.06 Ab | 0.36 ± 0.03 Ab | 0.36 ± 0.03 Aa | |

| CoQB | 0.35 ± 0.04 Ab | 0.38 ± 0.05 Ab | 0.39 ± 0.04 Ab | 0.41 ± 0.06 Ab | |

| Cohesiveness | CB | 0.75 ± 0.06 Cd | 0.77 ± 0.04 Cc | 0.70 ± 0.03 Bc | 0.64 ± 0.06 Ac |

| SQB | 0.68 ± 0.04 Bc | 0.73 ± 0.03 Cc | 0.68 ± 0.03 Bc | 0.61 ± 0.03 Ac | |

| FQB | 0.40 ± 0.03 Aa | 0.38 ± 0.03 Aa | 0.36 ± 0.05 Aa | 0.36 ± 0.05 Aa | |

| CoQB | 0.58 ± 0.06 Ab | 0.54 ± 0.05 Ab | 0.56 ± 0.03 Ab | 0.58 ± 0.05 Ab | |

| Chewiness | CB | 1.42 ± 0.57 Bb | 0.61 ± 0.27 Ab | 0.92 ± 0.38 Aa | 1.50 ± 0.47 Bb |

| (kg) | SQB | 1.76 ± 0.56 Bb | 0.77 ± 0.22 Ab | 1.58 ± 0.37 Bb | 1.79 ± 0.16 Bb |

| FQB | 0.66 ± 0.21 Aa | 0.48 ± 0.16 Aa | 0.84 ± 0.33 Aa | 0.63 ± 0.16 Aa | |

| CoQB | 3.05 ± 0.56 Ac | 2.40 ± 0.45 Ac | 2.79 ± 0.34 Ac | 2.89 ± 0.26 Ac | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sayas-Barberá, E.; Valero-Asencio, M.M.; Navarro Rodríguez-Vera, C.; Fernández-López, J.; Haros, C.M.; Pérez-Álvarez, J.Á.; Viuda-Martos, M. Effect of Different Black Quinoa Fractions (Seed, Flour and Wet-Milling Coproducts) upon Quality of Meat Patties during Freezing Storage. Foods 2021, 10, 3080. https://doi.org/10.3390/foods10123080

Sayas-Barberá E, Valero-Asencio MM, Navarro Rodríguez-Vera C, Fernández-López J, Haros CM, Pérez-Álvarez JÁ, Viuda-Martos M. Effect of Different Black Quinoa Fractions (Seed, Flour and Wet-Milling Coproducts) upon Quality of Meat Patties during Freezing Storage. Foods. 2021; 10(12):3080. https://doi.org/10.3390/foods10123080

Chicago/Turabian StyleSayas-Barberá, Estrella, María Maite Valero-Asencio, Casilda Navarro Rodríguez-Vera, Juana Fernández-López, Claudia Monika Haros, José Ángel Pérez-Álvarez, and Manuel Viuda-Martos. 2021. "Effect of Different Black Quinoa Fractions (Seed, Flour and Wet-Milling Coproducts) upon Quality of Meat Patties during Freezing Storage" Foods 10, no. 12: 3080. https://doi.org/10.3390/foods10123080

APA StyleSayas-Barberá, E., Valero-Asencio, M. M., Navarro Rodríguez-Vera, C., Fernández-López, J., Haros, C. M., Pérez-Álvarez, J. Á., & Viuda-Martos, M. (2021). Effect of Different Black Quinoa Fractions (Seed, Flour and Wet-Milling Coproducts) upon Quality of Meat Patties during Freezing Storage. Foods, 10(12), 3080. https://doi.org/10.3390/foods10123080