Suitability Assessment of PLA Bottles for High-Pressure Processing of Apple Juice

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Samples Preparation and High-Pressure Processing

2.3. Microbiological Analyses

2.4. Headspace Gas Composition Analysis

2.4.1. Conventional Approach by Gas-Chromatography

2.4.2. Non-Destructive Determination by Laser Spectroscopy

2.5. Colorimetric Analysis

2.6. Statistical Analysis

3. Results and Discussion

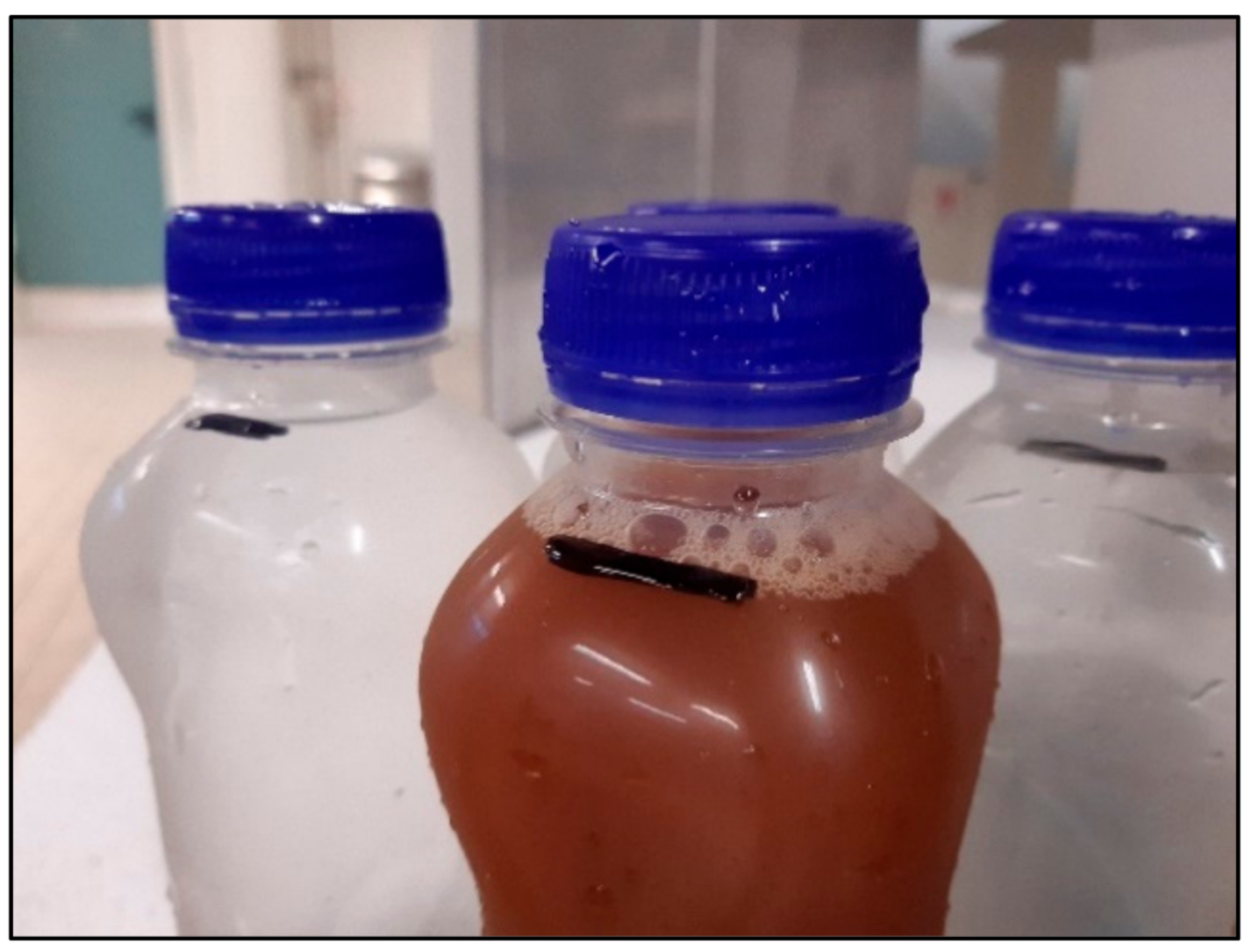

3.1. Visual Appearance and Deformation Test of Bottles after HPP Treatment

3.2. Microbiological Analyses

3.3. Headspace Gas Composition

3.4. Color Parameters

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Buerman, E.C.; Worobo, R.W.; Padilla-Zakour, O.I. High pressure processing of heat and pressure resistant fungi as affected by pH, water activity, sulfites, and dimethyl dicarbonate in a diluted apple juice concentrate. Food Control 2021, 120, 107551. [Google Scholar] [CrossRef]

- Uchida, R.; Silva, F.V.M. Alicyclobacillus acidoterrestris spore inactivation by high pressure combined with mild heat: Modeling the effects of temperature and soluble solids. Food Control 2017, 73, 426–432. [Google Scholar] [CrossRef]

- Farkas, D.F.; Hoover, D.G. High pressure processing. J. Food Sci. 2000, 65, 47–64. [Google Scholar] [CrossRef]

- Elamin, W.M.; Endan, J.B.; Yosuf, Y.A.; Shamsudin, R.; Ahmedov, A. High pressure processing technology and equipment evolution: A review. J. Eng. Sci. Technol. Rev. 2015, 8, 75–83. [Google Scholar] [CrossRef]

- Martins, I.B.A.; Oliveira, D.; Rosenthal, A.; Ares, G.; Deliza, R. Brazilian consumer’s perception of food processing technologies: A case study with fruit juice. Food Res. Int. 2019, 125, 108555. [Google Scholar] [CrossRef] [PubMed]

- Daher, D.; Le Gourrierec, S.; Pérez-Lamela, C. Effect of high pressure processing on the microbial inactivation in fruit preparations and other vegetable based beverages. Agriculture 2017, 7, 72. [Google Scholar] [CrossRef]

- Daryaei, H.; Yousef, A.E.; Balasubramaniam, V.M. Microbiological aspects of high-pressure processing of food: Inactivation of microbial vegetative cells and spores. In High Pressure Processing of Food; Food Engineering Series; Balasubramaniam, V., Barbosa-Cánovas, G., Lelieveld, H., Eds.; Springer LLC: New York, NY, USA, 2016; pp. 271–294. ISBN 9781493932344. [Google Scholar]

- Zhang, H.; Mittal, G.S. Effects of High-pressure Processing (HPP) on bacterial spores: An overview. Food Rev. Int. 2008, 24, 330–351. [Google Scholar] [CrossRef]

- Terefe, N.S.; Buckow, R.; Versteeg, C. Quality-related enzymes in fruit and vegetable products: Effects of novel food processing technologies, Part 1: High-Pressure Processing. Crit. Rev. Food Sci. Nutr. 2014, 54, 24–63. [Google Scholar] [CrossRef]

- Marangoni Júnior, L.; Cristianini, M.; Padula, M.; Anjos, C.A.R. Effect of high-pressure processing on characteristics of flexible packaging for foods and beverages. Food Res. Int. 2019, 119, 920–930. [Google Scholar] [CrossRef]

- Sansone, L.; Aldi, A.; Musto, P.; Di Maio, E.; Amendola, E.; Mensitieri, G. Assessing the suitability of polylactic acid flexible films for high pressure pasteurization and sterilization of packaged foodstuff. J. Food Eng. 2012, 111, 34–45. [Google Scholar] [CrossRef]

- Phaiphan, A.; Panichakool, P.; Jinawan, S.; Penjumras, P. Effects of heat and shallot (Allium ascalonicum L.) supplementation on nutritional quality and enzymatic browning of apple juice. J. Food Sci. Technol. 2019, 56, 4121–4128. [Google Scholar] [CrossRef] [PubMed]

- Abdullah, S.; Pradhan, R.C.; Pradhan, D.; Mishra, S. Modeling and optimization of pectinase-assisted low-temperature extraction of cashew apple juice using artificial neural network coupled with genetic algorithm. Food Chem. 2021, 339, 127862. [Google Scholar] [CrossRef] [PubMed]

- Du, G.; Zhu, Y.; Wang, X.; Zhang, J.; Tian, C.; Liu, L.; Meng, Y.; Guo, Y. Phenolic composition of apple products and by-products based on cold pressing technology. J. Food Sci. Technol. 2019, 56, 1389–1397. [Google Scholar] [CrossRef] [PubMed]

- Davis, M.A.; Bynum, J.P.W.; Sirovich, B.E. Association between apple consumption and physician visits: Appealing the conventional wisdom that an apple a day keeps the doctor away. JAMA Intern. Med. 2015, 175, 777–783. [Google Scholar] [CrossRef] [PubMed]

- Sanchez-Vega, R.; Mujica-Paz, H.; Marquez-Melendez, R.; Ngadi, M.O.; Ortega-Rivas, E. Enzyme inactivation on apple juice treated by ultrapasteurization and pulsed electric fields technology. J. Food Process. Preserv. 2009, 33, 486–499. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, X.; Ma, Y.; Zhao, X.; Zhang, C. Effect of ultrahigh temperature treatment on qualities of watermelon juice. Food Sci. Nutr. 2018, 6, 594–601. [Google Scholar] [CrossRef]

- Dars, A.G.; Hu, K.; Liu, Q.; Abbas, A.; Xie, B.; Sun, Z. Effect of thermo-sonication and ultra-high pressure on the quality and phenolic profile of mango juice. Foods 2019, 8, 298. [Google Scholar] [CrossRef]

- Licciardello, F. Packaging, blessing in disguise. Review on its diverse contribution to food sustainability. Trends Food Sci. Technol. 2017, 65, 32–39. [Google Scholar] [CrossRef]

- Amienyo, D.; Gujba, H.; Stichnothe, H.; Azapagic, A. Life cycle environmental impacts of carbonated soft drinks. Int. J. Life Cycle Assess. 2013, 18, 77–92. [Google Scholar] [CrossRef]

- Licciardello, F.; Piergiovanni, L. Packaging and food sustainability. In The Interaction of Food Industry and Environment; Galanakis, C., Ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2020; pp. 191–222. ISBN 9780128164495. [Google Scholar]

- Haghighi, H.; Gullo, M.; La China, S.; Pfeifer, F.; Siesler, H.W.; Licciardello, F.; Pulvirenti, A. Characterization of bio-nanocomposite films based on gelatin/polyvinyl alcohol blend reinforced with bacterial cellulose nanowhiskers for food packaging applications. Food Hydrocoll. 2020, 113, 106454. [Google Scholar] [CrossRef]

- Haghighi, H.; Licciardello, F.; Fava, P.; Siesler, H.W.; Pulvirenti, A. Recent advances on chitosan-based films for sustainable food packaging applications. Food Packag. Shelf Life 2020, 26, 100551. [Google Scholar] [CrossRef]

- Tawakkal, I.S.M.A.; Cran, M.J.; Miltz, J.; Bigger, S.W. A review of poly(lactic acid)-based materials for antimicrobial packaging. J. Food Sci. 2014, 79. [Google Scholar] [CrossRef] [PubMed]

- Auras, R.; Singh, P.; Singh, J. Evaluation of OPLA polymers with existing PET and OPS for fresh food service containers. Packag. Technol. Sci. 2005, 18, 207–216. [Google Scholar]

- Auras, R.; Harte, B.; Selke, S. An overview of polylactides as packaging materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef] [PubMed]

- Mauricio-Iglesias, M.; Jansana, S.; Peyron, S.; Gontard, N.; Guillard, V. Effect of high-pressure/temperature (HP/T) treatments of in-package food on additive migration from conventional and bio-sourced materials. Food Addit. Contam. Part A Chem. Anal. Control. Expo. Risk Assess. 2010, 27, 118–127. [Google Scholar] [CrossRef]

- Mauricio-Iglesias, M.; Peyron, S.; Chalier, P.; Gontard, N. Scalping of four aroma compounds by one common (LDPE) and one biosourced (PLA) packaging materials during high pressure treatments. J. Food Eng. 2011, 102, 9–15. [Google Scholar] [CrossRef]

- Sulaiman, A.; Farid, M.; Silva, F.V.M. Quality stability and sensory attributes of apple juice processed by thermosonication, pulsed electric field and thermal processing. Food Sci. Technol. Int. 2017, 23, 265–276. [Google Scholar] [CrossRef]

- Francis, F.J.; Clydesdale, F.M. Food Colorimetry: Theory and Applications; The Avi Publishing Company, Inc.: Westport, CT, USA, 1975; ISBN 0870551833. [Google Scholar]

- Houska, M.; Marques da Silva, F.V. (Eds.) High Pressure Processing of Fruit and Vegetable Products, 1st ed.; CRC Press: Boca Raton, FL, USA, 2017; ISBN 9781315121123. [Google Scholar]

- Barba, F.J.; Esteve, M.J.; Frigola, A. Physicochemical and nutritional characteristics of blueberry juice after high pressure processing. Food Res. Int. 2013, 50, 545–549. [Google Scholar] [CrossRef]

- Lee, S.Y.; Chung, H.J.; Kang, D.H. Combined treatment of high pressure and heat on killing spores of Alicyclobacillus acidoterrestris in apple juice concentrate. J. Food Prot. 2006, 69, 1056–1060. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Dougherty, R.H.; Kaang, D.-H. Inhibitory effects of high pressure and heat on Alicyclobacillus acidoterrestris spores in apple juice. Appl. Environ. Microbiol. 2002, 68, 4158–4161. [Google Scholar] [CrossRef]

- Evelyn; Kim, H.J.; Silva, F.V.M. Modeling the inactivation of Neosartorya fischeri ascospores in apple juice by high pressure, power ultrasound and thermal processing. Food Control 2016, 59, 530–537. [Google Scholar] [CrossRef]

- Suárez-Jacobo, Á.; Gervilla, R.; Guamis, B.; Roig-Sagués, A.X.; Saldo, J. Effect of UHPH on indigenous microbiota of apple juice. A preliminary study of microbial shelf-life. Int. J. Food Microbiol. 2010, 136, 261–267. [Google Scholar] [CrossRef] [PubMed]

- Tiwari, B.K.; O’Donnell, C.P.; Cullen, P.J. Effect of non thermal processing technologies on the anthocyanin content of fruit juices. Trends Food Sci. Technol. 2009, 20, 137–145. [Google Scholar] [CrossRef]

- Jiménez-Sánchez, C.; Lozano-Sánchez, J.; Segura-Carretero, A.; Fernández-Gutiérrez, A. Alternatives to conventional thermal treatments in fruit-juice processing. Part 1: Techniques and applications. Crit. Rev. Food Sci. Nutr. 2017, 57, 501–523. [Google Scholar] [CrossRef]

- El-Mesery, H.S.; Mao, H.; Abomohra, A.E.F. Applications of non-destructive technologies for agricultural and food products quality inspection. Sensors (Switz.) 2019, 19, 846. [Google Scholar] [CrossRef]

- Vidal, J.C.; Moutounet, M. Monitoring of oxygen in the gas and liquid phases of bottles of wine at bottling and during storage. J. Int. Des. Sci. la Vigne du Vin 2006, 40, 35–45. [Google Scholar] [CrossRef]

- Bacigalupi, C.; Lemaistre, M.H.; Boutroy, N.; Bunel, C.; Peyron, S.; Guillard, V.; Chalier, P. Changes in nutritional and sensory properties of orange juice packed in PET bottles: An experimental and modelling approach. Food Chem. 2013, 141, 3827–3836. [Google Scholar] [CrossRef]

- Van Bree, I.; Baetens, J.M.; Samapundo, S.; Devlieghere, F.; Laleman, R.; Vandekinderen, I.; Noseda, B.; Xhaferi, R.; De Baets, B.; De Meulenaer, B. Modelling the degradation kinetics of vitamin C in fruit juice in relation to the initial headspace oxygen concentration. Food Chem. 2012, 134, 207–214. [Google Scholar] [CrossRef]

- Pathare, P.B.; Opara, U.L.; Al-Said, F.A.J. Colour measurement and analysis in fresh and processed foods: A review. Food Bioprocess Technol. 2013, 6, 36–60. [Google Scholar] [CrossRef]

- Fundo, J.F.; Miller, F.A.; Mandro, G.F.; Tremarin, A.; Brandão, T.R.S.; Silva, C.L.M. UV-C light processing of Cantaloupe melon juice: Evaluation of the impact on microbiological, and some quality characteristics, during refrigerated storage. LWT Food Sci. Technol. J. 2019, 103, 247–252. [Google Scholar] [CrossRef]

- Croak, S.; Corredig, M. The role of pectin in orange juice stabilization: Effect of pectin methylesterase and pectinase activity on the size of cloud particles. Food Hydrocoll. 2006, 20, 961–965. [Google Scholar] [CrossRef]

- Paciulli, M.; Medina Meza, I.G.; Rinaldi, M.; Ganino, T.; Pugliese, A.; Rodolfi, M.; Barbanti, D.; Morbarigazzi, M.; Chiavaro, E. Improved physicochemical and structural properties of blueberries by high hydrostatic pressure processing. Foods 2019, 8, 272. [Google Scholar] [CrossRef] [PubMed]

- Chakraborty, S.; Kaushik, N.; Rao, P.S.; Mishra, H.N. High-pressure inactivation of enzymes: A review on its recent applications on fruit purees and juices. Compr. Rev. Food Sci. Food Saf. 2014, 13, 578–596. [Google Scholar] [CrossRef]

- Klimczak, I.; Gliszczyńska-Świgło, A. Green tea extract as an anti-browning agent for cloudy apple juice. J. Sci. Food Agric. 2017, 97, 1420–1426. [Google Scholar] [CrossRef] [PubMed]

- Wibowo, S.; Vervoort, L.; Tomic, J.; Santiago, J.S.; Lemmens, L.; Panozzo, A.; Grauwet, T.; Hendrickx, M.; Van Loey, A. Colour and carotenoid changes of pasteurised orange juice during storage. Food Chem. 2015, 171, 330–340. [Google Scholar] [CrossRef]

| Time (days) | TMB (CFU/mL) | YM (CFU/mL) | |

|---|---|---|---|

| Control (untreated) | 1.18 ± 0.29 × 104 | 6.00 ± 0.97 × 103 | |

| 0 | n.d. | n.d. | |

| 7 | 4.55 ± 0.00 | n.d. | |

| PET | 14 | n.d. | 1.50 ± 0.71 |

| 21 | n.d. | n.d. | |

| 28 | n.d. | n.d. | |

| 0 | n.d. | n.d. | |

| 7 | 2.27 ± 3.21 | n.d. | |

| PLA | 14 | 1.00 ± 1.41 | n.d. |

| 21 | 1.00 ± 1.41 | n.d. | |

| 28 | 1.50 ± 0.71 | n.d. |

| Time (days) | CO2 (%) | O2 (%) | |

|---|---|---|---|

| PET | 0 | 0.6 ± 0.8 B | 2.8 ± 0.4 A |

| 7 | 2.0 ± 0.6 A | 3.0 ± 0.8 A | |

| 14 | 1.7 ± 0.0 AB | 1.7 ± 0.0 A | |

| 21 | 1.6 ± 0.4 AB | 2.8 ± 0.8 A | |

| 28 | 1.7 ± 0.0 AB | 2.0 ± 0.1 A | |

| PLA | 0 | 0.6 ± 0.7 B | 2.8 ± 0.4 A |

| 7 | 1.6 ± 0.3 AB | 1.4 ± 0.4 B | |

| 14 | 1.8 ± 0.2 A | 2.7 ± 0.6 A | |

| 21 | 1.5 ± 0.0 AB | 2.2 ± 0.4 AB | |

| 28 | 1.5 ± 0.2 AB | 2.8 ± 0.3 A |

| Time (days) | L* | a* | b* | YI | |

|---|---|---|---|---|---|

| PET | 0 | 22.30 ± 0.23 a E | 2.56 ± 0.04 a B | 3.90 ± 0.08 a B | 24.98 ± 0.91 a D |

| 7 | 22.72 ± 0.26 a D | 2.83 ± 0.06 a A | 4.36 ± 0.12 a A | 27.42 ± 1.03 a E | |

| 14 | 25.29 ± 0.15 a C | 1.98 ± 0.07 b C | 2.66 ± 0.12 b A | 15.03 ± 0.75 a A | |

| 21 | 25.90 ± 0.21 b B | 2.61 ± 0.04 b B | 3.43 ± 0.07 b C | 18.92 ± 0.54 a B | |

| 28 | 26.43 ± 0.25 a A | 2.65 ± 0.05 a B | 3.90 ± 0.11a B | 21.09 ± 0.80 a C | |

| PLA | 0 | 22.30 ± 0.23 a E | 2.56 ± 0.04 a B | 3.90 ± 0.08 a B | 24.98 ± 0.91 a C |

| 7 | 22.22 ± 0.39 a C | 2.71 ± 0.07 a A | 3.64 ± 0.11 b B | 23.40 ± 1.09 a BC | |

| 14 | 25.11 ± 0.19 a B | 2.23 ± 0.12 a C | 3.32 ± 0.13 a C | 18.89 ± 0.89 a A | |

| 21 | 26.40 ± 0.01 a A | 2.77 ± 0.06 a A | 3.73 ± 0.03 a B | 20.18 ± 0.15 a A | |

| 28 | 26.31 ± 0.53 a A | 2.69 ± 0.08 a AB | 4.15 ± 0.28 a A | 22.53 ± 1.96 a B |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cubeddu, A.; Fava, P.; Pulvirenti, A.; Haghighi, H.; Licciardello, F. Suitability Assessment of PLA Bottles for High-Pressure Processing of Apple Juice. Foods 2021, 10, 295. https://doi.org/10.3390/foods10020295

Cubeddu A, Fava P, Pulvirenti A, Haghighi H, Licciardello F. Suitability Assessment of PLA Bottles for High-Pressure Processing of Apple Juice. Foods. 2021; 10(2):295. https://doi.org/10.3390/foods10020295

Chicago/Turabian StyleCubeddu, Arianna, Patrizia Fava, Andrea Pulvirenti, Hossein Haghighi, and Fabio Licciardello. 2021. "Suitability Assessment of PLA Bottles for High-Pressure Processing of Apple Juice" Foods 10, no. 2: 295. https://doi.org/10.3390/foods10020295

APA StyleCubeddu, A., Fava, P., Pulvirenti, A., Haghighi, H., & Licciardello, F. (2021). Suitability Assessment of PLA Bottles for High-Pressure Processing of Apple Juice. Foods, 10(2), 295. https://doi.org/10.3390/foods10020295