Preliminary Evaluation of a Novel Microwave-Assisted Induction Heating (MAIH) System on White Shrimp Cooking

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

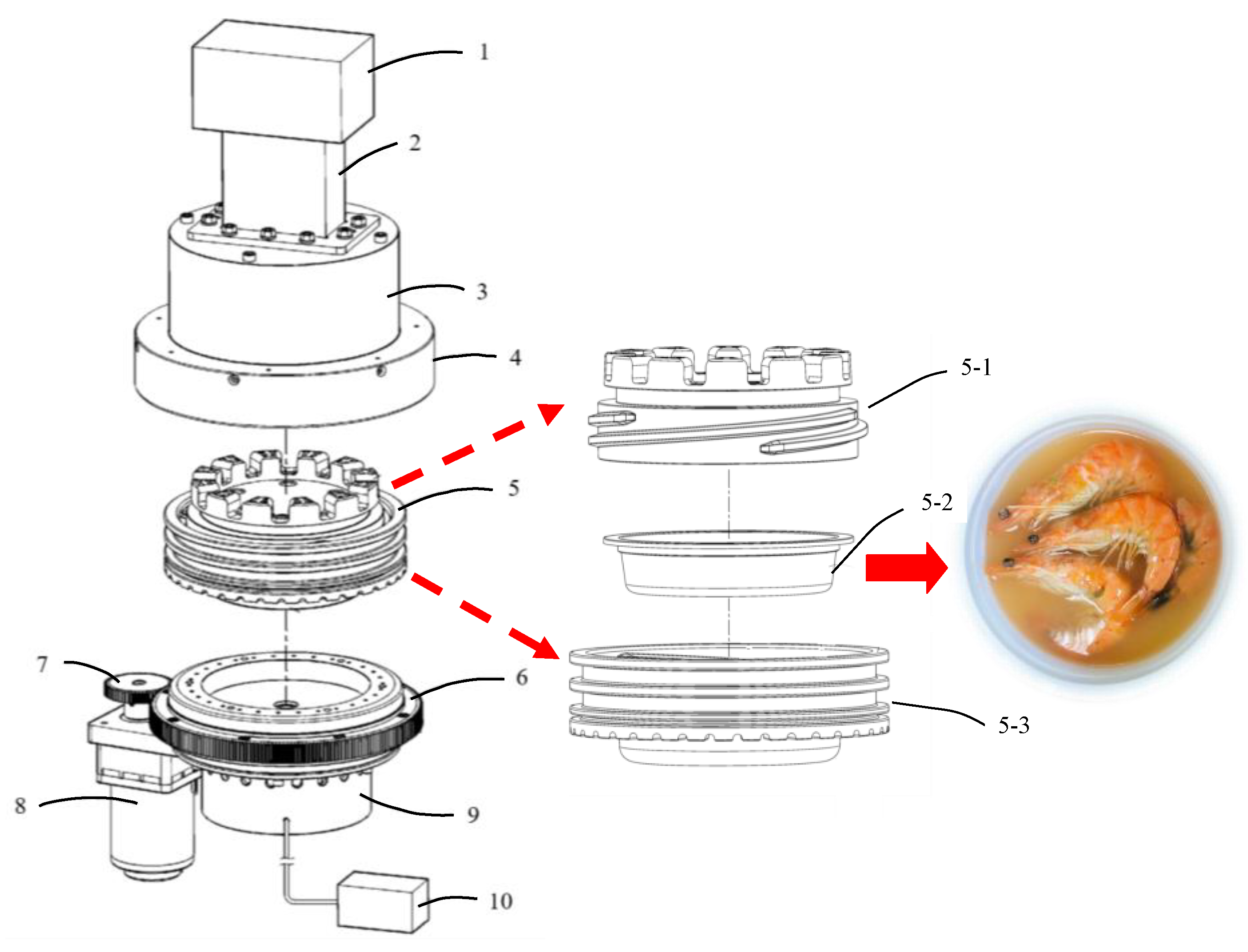

2.2. MAIH Processing

2.3. Cook Loss Measurement

2.4. Determination of Aerobic Plate Count (APC)

2.5. Appearance and Color Measurement

2.6. Texture Measurement

2.7. Sensory Evaluation

2.8. Statistical Analysis

3. Results and Discussion

3.1. Appearance of Shrimp after Heating in MAIH System

3.2. APC and Cook Loss of Shrimp Heated in MAIH System

3.3. Color of Shrimp Heated in MAIH System

3.4. Texture of Shrimp Heated in MAIH System

3.5. Sensory Properties of Cooked White Shrimp with MAIH Treatments

4. Conclusion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Soni, A.; Smith, J.; Thompson, A.; Brightwell, G. Microwave-induced thermal sterilization—A review on history, technical progress, advantages and challenges as compared to the conventional methods. Trends Food Sci. Technol. 2020, 97, 433–442. [Google Scholar] [CrossRef]

- Tang, Z.; Mikhaylenko, G.; Liu, F.; Mah, J.H.; Pandit, R.; Younce, F.; Tang, J. Microwave sterilization of sliced beef in gravy in 7-oz trays. J. Food Eng. 2008, 89, 375–383. [Google Scholar] [CrossRef]

- Guo, Q.; Sun, D.W.; Cheng, J.H.; Han, Z. Microwave processing techniques and their recent applications in the food industry. Trends Food Sci. Technol. 2017, 67, 236–247. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Ramanathan, S.; Basak, T. Microwave food processing—A review. Food Res. Int. 2013, 52, 243–261. [Google Scholar] [CrossRef]

- Vadivambal, R.; Jayas, D.S. Non-uniform temperature distribution during microwave heating of food materials—A review. Food Bioprocess Technol. 2010, 3, 161–171. [Google Scholar] [CrossRef]

- Chizoba Ekezie, F.G.; Sun, D.W.; Han, Z.; Cheng, J.H. Microwave-assisted food processing technologies for enhancing product quality and process efficiency: A review of recent developments. Trends Food Sci. Technol. 2017, 67, 58–69. [Google Scholar] [CrossRef]

- Tang, J. Unlocking potentials of microwaves for food safety and quality. J. Food Sci. 2015, 80, E1776–E1793. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Barbosa-Cánovas, G.V.; Medina-Meza, I.; Candoğan, K.; Bermúdez-Aguirre, D. Advanced retorting, microwave assisted thermal sterilization (MATS), and pressure assisted thermal sterilization (PATS) to process meat products. Meat Sci. 2014, 98, 420–434. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Tang, Z.; Rasco, B.; Tang, J.; Sablani, S.S. Shelf-life modeling of microwave-assisted thermal sterilized mashed potato in polymeric pounches of different gas barrier properties. J. Food Eng. 2016, 183, 65–73. [Google Scholar] [CrossRef] [Green Version]

- Auksornsri, T.; Bornhorst, E.R.; Tang, J.; Tang, Z. Developing model food systems with rice based products for microwave assisted thermal sterilization. LWT Food Sci. Technol. 2018, 96, 551–559. [Google Scholar] [CrossRef]

- Chang, H.I.; Chin, K.T.; Yu, Y.C.; Hsieh, J.K.; Lin, C.H. Cavity Detachable Modular Composite Microwave Heating System. Taiwan Patent I614457, 2 November 2018. [Google Scholar]

- Alfaro-Montoya, J.; Braga, A.; Umaña-Castro, R. Research frontiers in penaeid shrimp reproduction: Future trends to improve commercial production. Aquaculture 2019, 503, 70–87. [Google Scholar] [CrossRef]

- FDA. Bacteriological Analytical Manual; AOAC International: Arlington, VA, USA, 1998. [Google Scholar]

- Ovissipour, M.; Rasco, B.; Tang, J.; Sablani, S.S. Kinetics of quality changes in whole blue mussel (Mytilus edulis) during pasteurization. Food Res. Int. 2013, 53, 141–148. [Google Scholar] [CrossRef]

- Meilgaard, M.C.; Civille, G.V.; Carr, B.T. Sensory Evaluation Techniques; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Erdogdu, F.; Balaban, M.O.; Otwell, W.S.; Garrido, L. Cook-related yield loss for pacific white (Penaeus vannamei) shrimp previously treated with phosphates: Effects of shrimp size and internal temperature distribution. J. Food Eng. 2004, 64, 297–300. [Google Scholar] [CrossRef]

- Kong, F.; Tang, J.; Rasco, B.; Crapo, C. Kinetics of salmon quality changes during thermal processing. J. Food Eng. 2007, 83, 510–520. [Google Scholar] [CrossRef]

- Kong, F.; Tang, J.; Rasco, B.; Crapo, C.; Smiley, S. Quality changes of salmon (Oncorhynchus gorbuscha) muscle during thermal processing. J. Food Sci. 2007, 72, S103–S111. [Google Scholar] [CrossRef] [PubMed]

- Sreenat, P.G.; Abhilash, S.; Ravishankar, C.N.; Gopal, T.K.S. Standardization of process parameters for ready-to-eat shrimp curry in tin-free steel cans. J. Food Process. Preserv. 2008, 32, 247–269. [Google Scholar] [CrossRef]

- Niamnuy, C.; Devahastin, S.; Soponronnarit, S. Quality changes of shrimp during boiling in salt solution. J. Food Sci. 2007, 75, S289–S297. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharya, S.; Choudhury, G.S.; Studebaker, S. Hydrothermal processing of pacific Chum Salmon: Effects on texture and in-vitro digestibility. J. Food Qual. 1993, 16, 243–251. [Google Scholar] [CrossRef]

- Yagiz, Y.; Kristinsson, H.; Balaban, M.O.; Welt, B.A.; Ralat, M.; Marshall, M.R. Effect of high pressure processing and cooking treatment on the quality of Atlantic salmon. Food Chem. 2009, 116, 828–835. [Google Scholar] [CrossRef]

- Fan, H.; Fan, D.; Huang, J.; Zhao, J.; Yan, B.; Ma, S.; Zhou, W.; Zhang, H. Cooking evaluation of crayfish (Procambarus clarkia) subjected to microwave and conduction heating: A visualized strategy to understand the heat-induced quality changes of food. Innov. Food Sci. Emerg. Technol. 2020, 62, 102368. [Google Scholar] [CrossRef]

| Temperature | First Stage Heating (s) | Second Stage Heating (s) | Total Heating Time (s) |

|---|---|---|---|

| MW + IH | IH | ||

| 130 °C | 30 | 30 | 60 |

| 40 | 30 | 70 | |

| 50 | 30 | 80 | |

| 60 | 30 | 90 | |

| 70 | 30 | 100 | |

| 90 °C | 30 | 30 | 60 |

| 40 | 30 | 70 | |

| 50 | 30 | 80 | |

| 60 | 30 | 90 | |

| 70 | 30 | 100 | |

| 90 | 30 | 120 |

| Treatments | Heating Time (s) | APC (log CFU/g) | Cook Loss (%) |

|---|---|---|---|

| Raw shrimp | 6.24 ± 0.02 a | 0 | |

| 130 °C | 60 | 3.47 ± 0.18 c | 1.15 ± 0.07 de |

| 70 | 3.23 ± 0.12 c | 1.35 ± 0.07 de | |

| 80 | <2.0 e | 2.55 ± 0.21c | |

| 90 | <2.0 e | 3.45 ± 0.49 b | |

| 100 | <2.0 e | 4.90 ± 0.42 a | |

| 90 °C | 60 | 4.28 ± 0.06 b | 0.80 ± 0.14 e |

| 70 | 4.16 ± 0.09 b | 1.50 ± 0.28 d | |

| 80 | 3.30 ± 0.18 c | 2.20 ± 0.14 c | |

| 90 | 2.65 ± 0.07 d | 2.65 ± 0.21 c | |

| 100 | <2.0 e | 3.35 ± 0.07 b | |

| 120 | <2.0 e | 3.90 ± 0.28 b |

| Treatments | Heating Time(s) | L* | a* | b* | W |

|---|---|---|---|---|---|

| Peeled raw shrimp | 25.23 ± 0.60 i | 1.90 ± 0.12 g | −1.06±0.04 a | 25.20±0.58i | |

| 130 °C | 60 | 41.53 ± 0.91 f | 6.44 ± 0.50 d | −1.45 ± 0.18 bc | 41.15 ± 0.89 f |

| 70 | 45.45 ± 1.08 e | 6.67 ± 0.47 d | −1.94 ± 0.19 d | 45.01 ± 1.09 e | |

| 80 | 49.49 ± 0.58 c | 10.28 ± 0.44 c | −2.38 ± 0.23 e | 48.40 ± 0.55 cd | |

| 90 | 49.65 ± 0.48 c | 10.45 ± 0.45 c | −2.54 ± 0.46 e | 48.51 ± 0.45 cd | |

| 100 | 52.01 ± 1.44 ab | 11.73 ± 1.12 b | −2.55 ± 0.30 e | 50.52 ± 1.23 b | |

| 90 °C | 60 | 28.22 ± 0.85 h | 2.71 ± 0.37 f | −1.01 ± 0.71 a | 28.16 ± 0.84 h |

| 70 | 37.55 ± 1.06 g | 3.97 ± 0.10 e | −1.37 ± 0.13 b | 37.40 ± 1.06 g | |

| 80 | 42.07 ± 0.65 f | 4.41 ± 0.28 e | −1.66 ± 0.25 cd | 41.87 ± 0.64 f | |

| 90 | 48.27 ± 1.06 d | 6.41 ± 0.69 d | −1.84 ± 0.10 d | 47.83 ± 1.06 d | |

| 100 | 51.49 ± 0.85 b | 15.46 ± 0.56 a | −1.35 ± 0.08 b | 49.07 ± 0.89 c | |

| 120 | 52.57 ± 0.78 a | 10.73 ± 0.44 c | −1.86 ± 0.06 d | 51.33 ± 0.73 a |

| Treatments | Color | Odor | Texture | Flavor | Taste | Overall Acceptance |

|---|---|---|---|---|---|---|

| Boiling water | 7.85 ± 0.96 a | 7.83 ± 0.69 a | 7.78 ± 0.79 a | 7.43 ± 0.77 a | 7.38 ± 0.83 a | 7.60 ± 0.79 a |

| MAIH 130 °C | 7.71 ± 0.90 a | 7.95 ± 0.84 a | 7.74 ± 0.93 a | 7.58 ± 0.90 a | 7.34 ± 0.96 a | 7.52 ± 0.83 a |

| MAIH 90 °C | 7.78 ± 0.88 a | 7.79 ± 0.98 a | 7.73 ± 0.99 a | 7.55 ± 0.81a | 7.42 ± 0.91 a | 7.53 ± 0.92 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, Y.-C.; Lin, C.-Y.; Wei, C.-I.; Tung, H.-N.; Chiu, K.; Tsai, Y.-H. Preliminary Evaluation of a Novel Microwave-Assisted Induction Heating (MAIH) System on White Shrimp Cooking. Foods 2021, 10, 545. https://doi.org/10.3390/foods10030545

Lee Y-C, Lin C-Y, Wei C-I, Tung H-N, Chiu K, Tsai Y-H. Preliminary Evaluation of a Novel Microwave-Assisted Induction Heating (MAIH) System on White Shrimp Cooking. Foods. 2021; 10(3):545. https://doi.org/10.3390/foods10030545

Chicago/Turabian StyleLee, Yi-Chen, Chih-Ying Lin, Cheng-I Wei, Hung-Nan Tung, Kuohsun Chiu, and Yung-Hsiang Tsai. 2021. "Preliminary Evaluation of a Novel Microwave-Assisted Induction Heating (MAIH) System on White Shrimp Cooking" Foods 10, no. 3: 545. https://doi.org/10.3390/foods10030545

APA StyleLee, Y.-C., Lin, C.-Y., Wei, C.-I., Tung, H.-N., Chiu, K., & Tsai, Y.-H. (2021). Preliminary Evaluation of a Novel Microwave-Assisted Induction Heating (MAIH) System on White Shrimp Cooking. Foods, 10(3), 545. https://doi.org/10.3390/foods10030545