A Novel Approach for Tuning the Physicochemical, Textural, and Sensory Characteristics of Plant-Based Meat Analogs with Different Levels of Methylcellulose Concentration

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

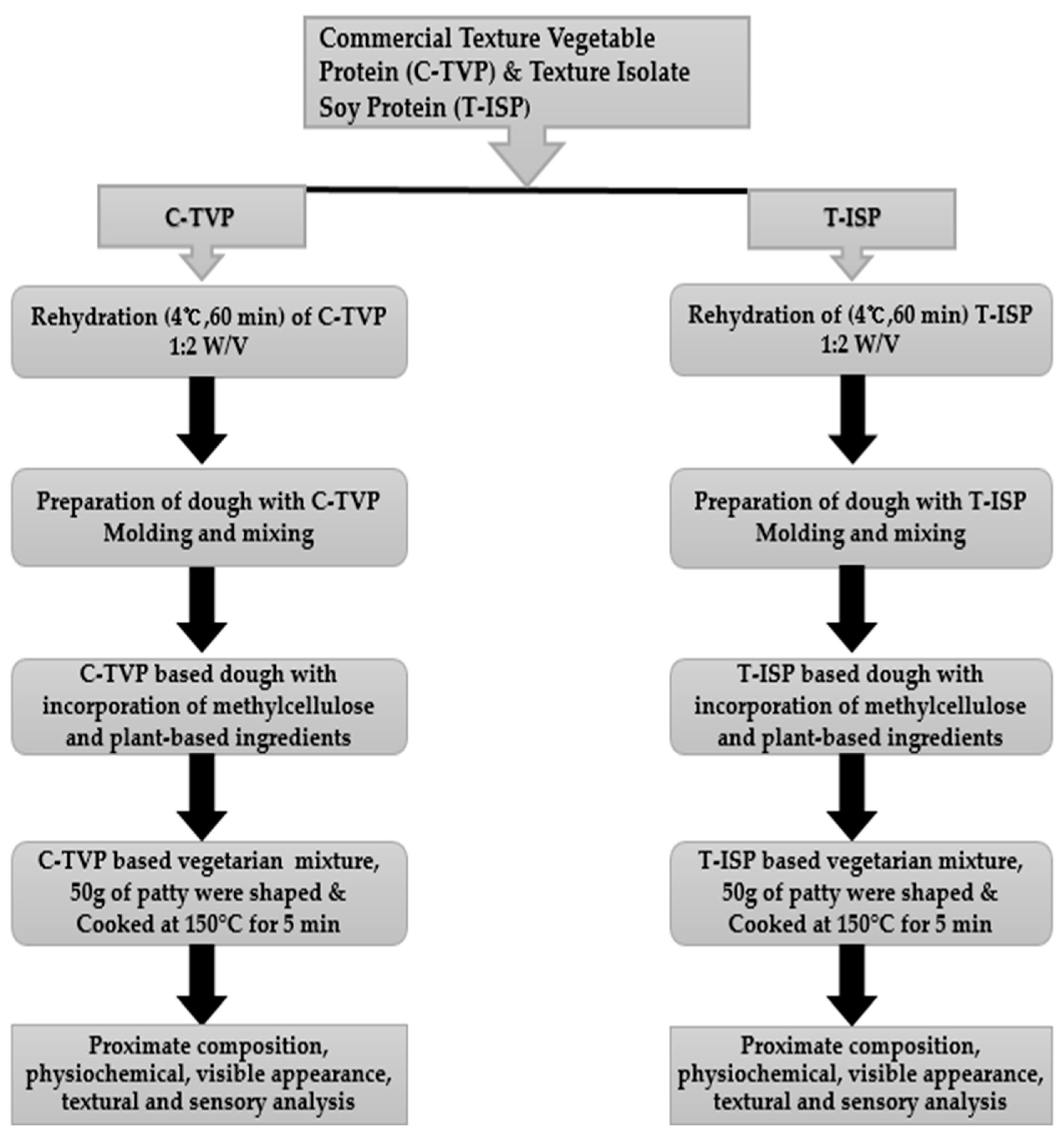

2.2. Sample Preparation and Processing

2.3. Proximate Analysis

2.4. Physicochemical Analysis

2.5. Visible Appearance

2.6. Texture Profile Analysis

2.7. Sensory Evaluation

2.8. Statistical Analysis

3. Results and Discussion

3.1. Proximate Analysis

3.2. Physicochemical Analysis

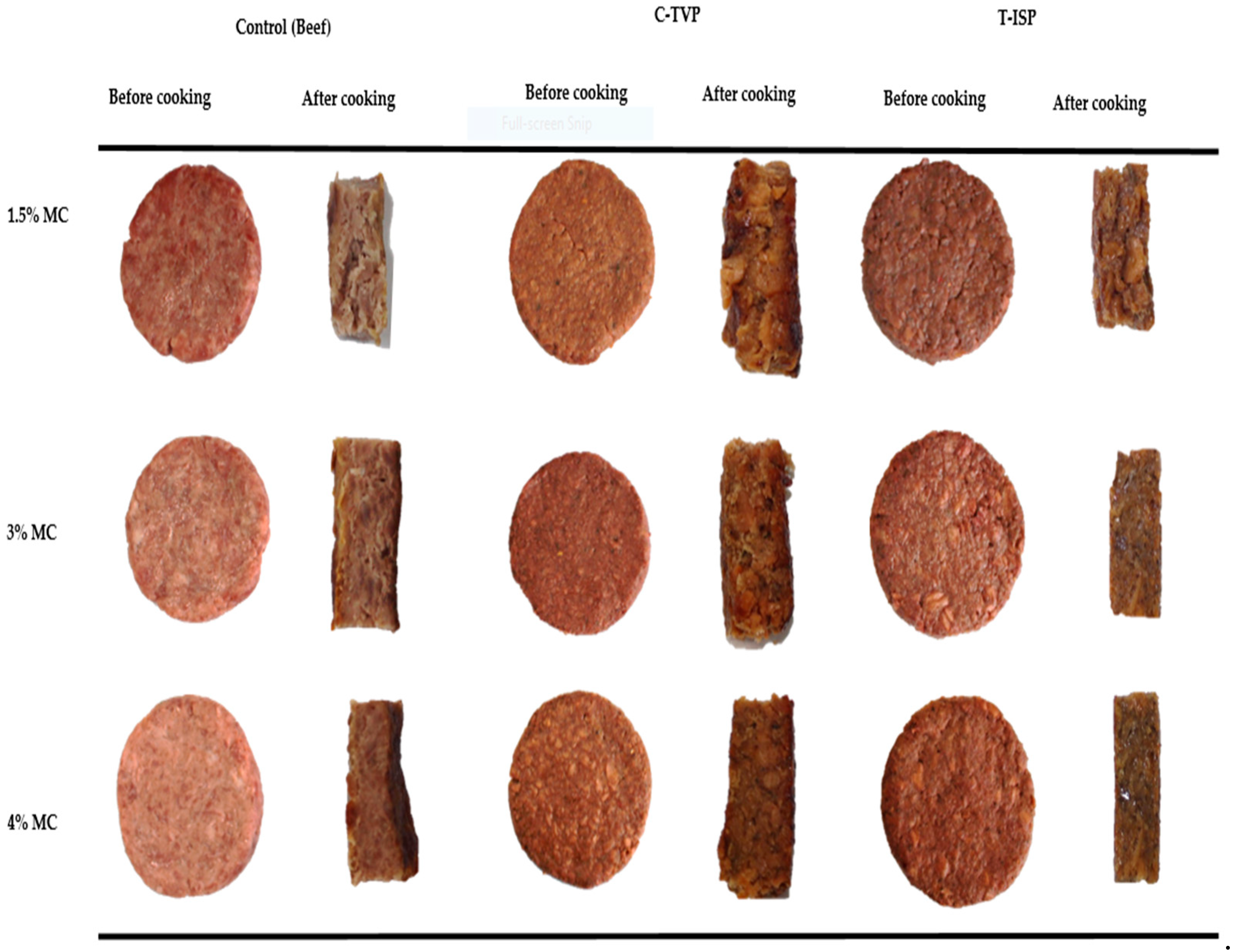

3.3. Visible Appearance

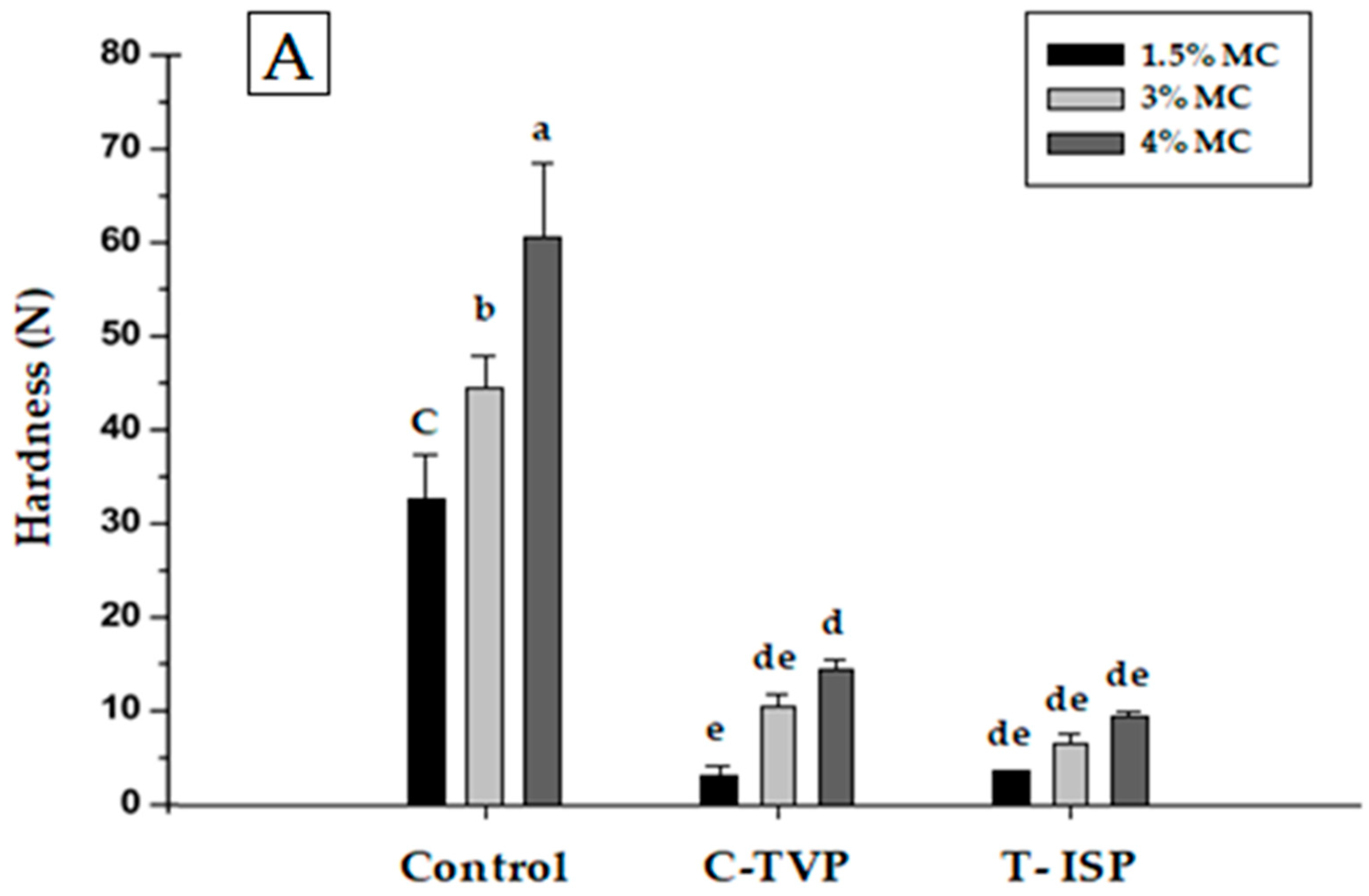

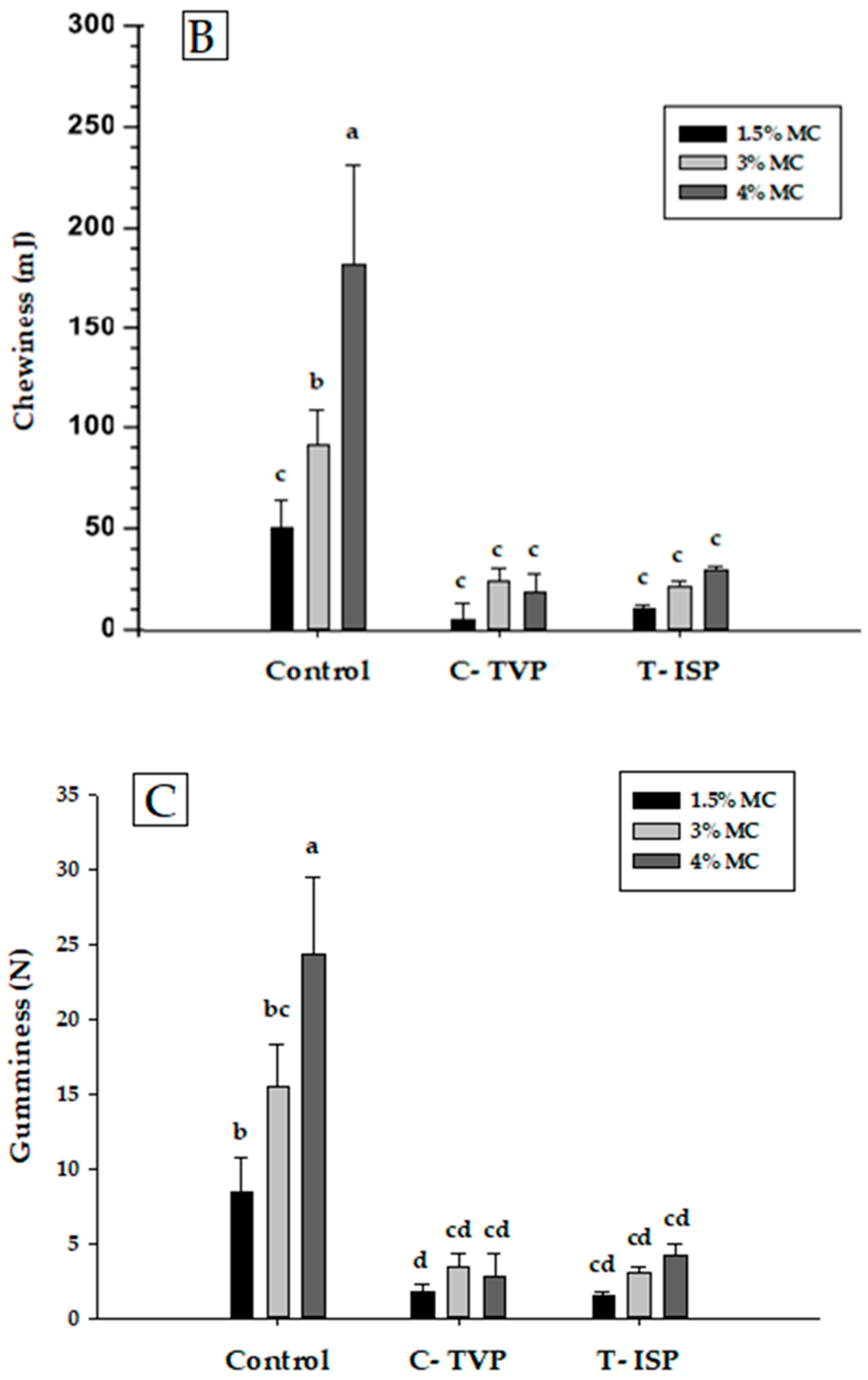

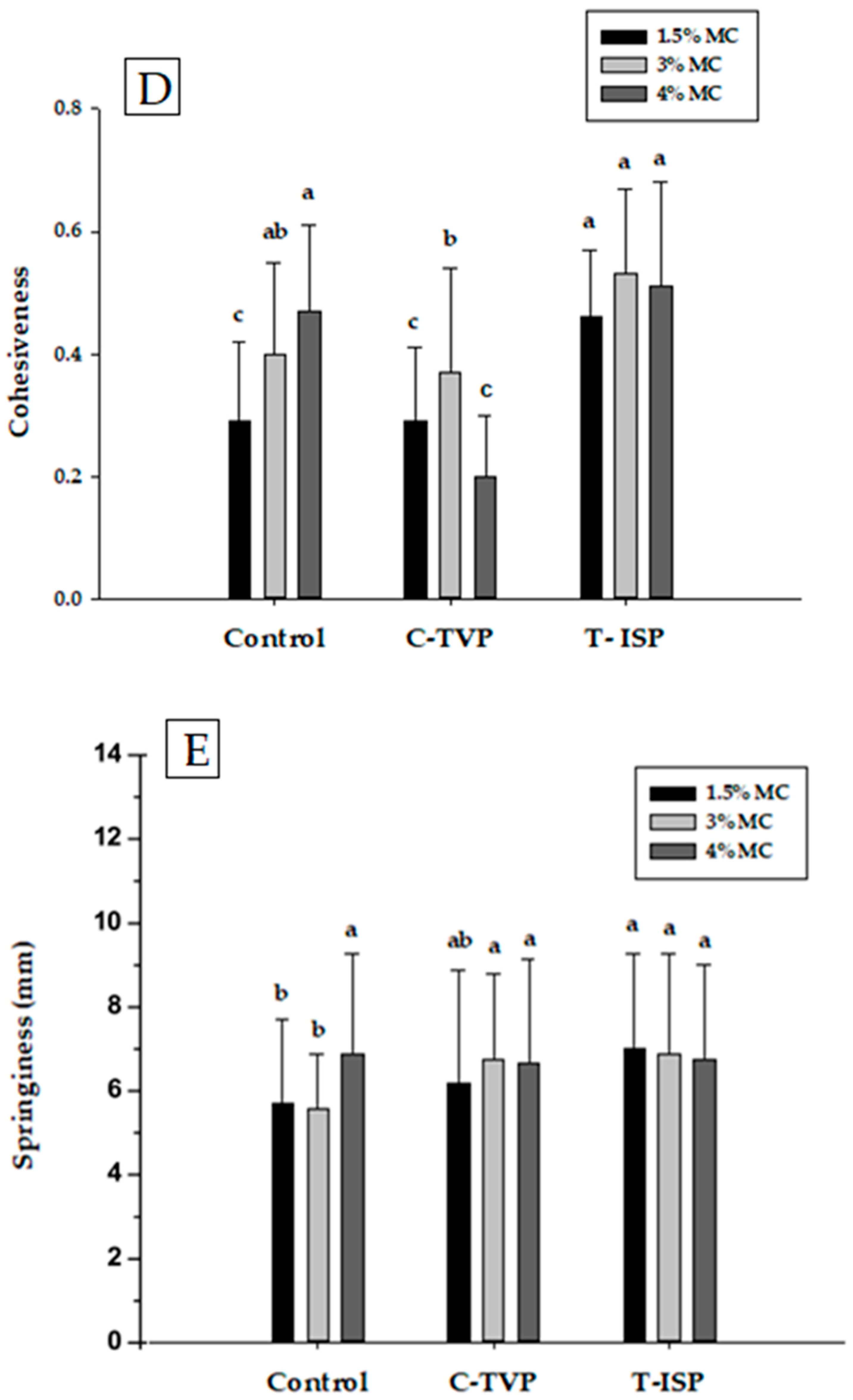

3.4. Texture Profile Analysis

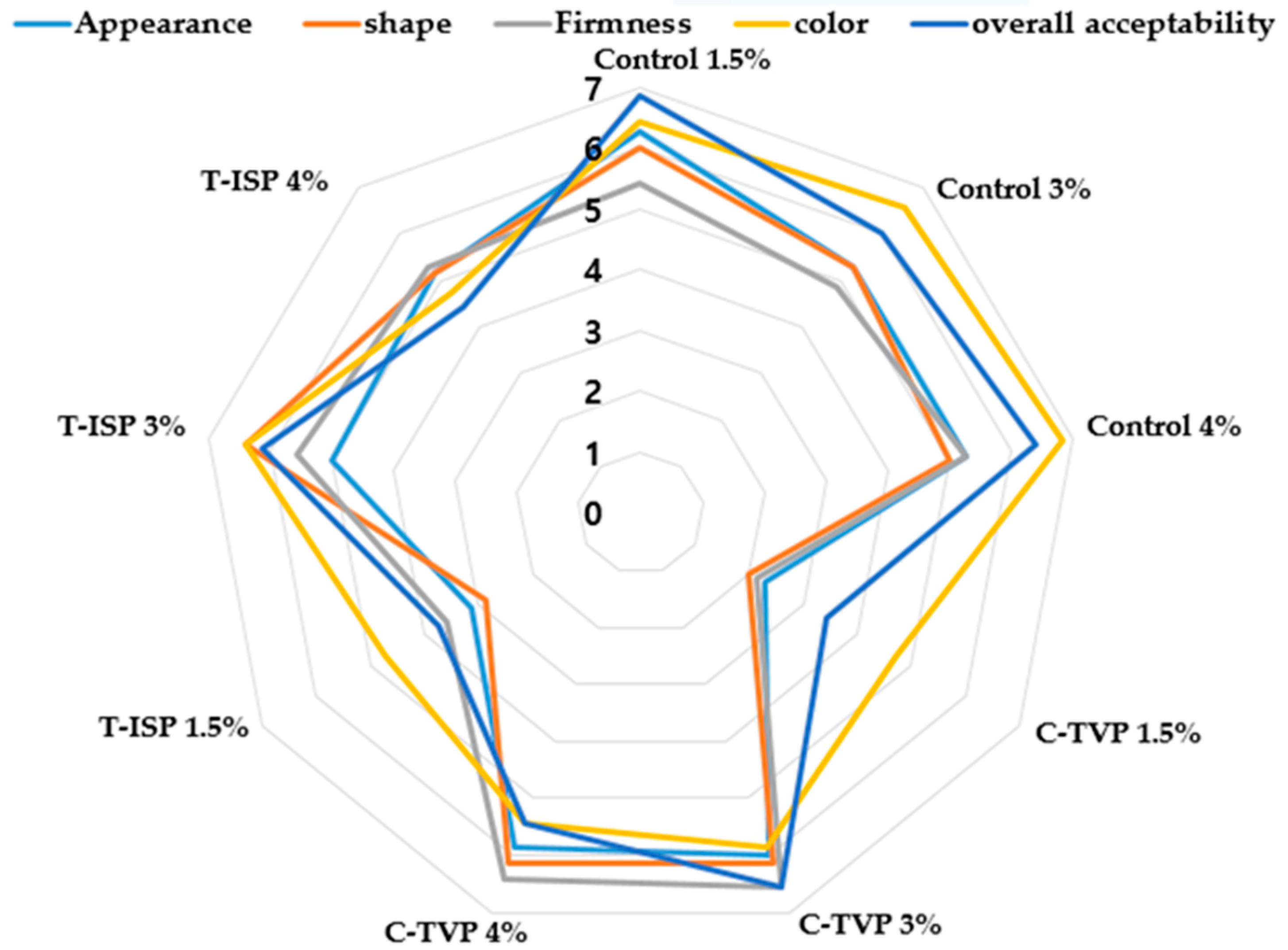

3.5. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ismail, I.; Hwang, Y.-H.; Joo, S.-T. Meat analog as future food: A review. J. Anim. Sci. Technol. 2020, 62, 111–120. [Google Scholar] [CrossRef] [Green Version]

- Wild, F. Manufacture of Meat Analogues through High Moisture Extrusion; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Arora, B.; Kamal, S.; Sharma, V. Effect of Binding Agents on Quality Characteristics of Mushroom Based Sausage Analogue. J. Food Process. 2017, 41, e13134. [Google Scholar] [CrossRef]

- Apostolidis, C.; McLeay, F. Should we stop meating like this? Reducing meat consumption through substitution. Food Policy 2016, 65, 74–89. [Google Scholar] [CrossRef] [Green Version]

- Asgar, M.; Fazilah, A.; Huda, N.; Bhat, R.; Karim, A. Nonmeat protein alternatives as meat extenders and meat analogs. Compr. Rev. Food Sci. Food Saf. 2010, 9, 513–529. [Google Scholar] [CrossRef] [PubMed]

- Tubiello, F.; Salvatore, M.; Cóndor Golec, R.; Ferrara, A.; Rossi, S.; Biancalani, R.; Federici, S.; Jacobs, H.; Flammini, A. Agriculture, Forestry and Other Land Use Emissions by Sources and Removals by Sinks; FAO Statistics Devision: Rome, Italy, 2014. [Google Scholar]

- Sadler, M.J. Meat alternatives—market developments and health benefits. Trends Food Sci. Technol. 2004, 15, 250–260. [Google Scholar] [CrossRef]

- de Bakker, E.; Dagevos, H. Reducing meat consumption in today’s consumer society: Questioning the citizen-consumer gap. J. Agric. Environ. 2012, 25, 877–894. [Google Scholar] [CrossRef] [Green Version]

- Kyriakopoulou, K.; Dekkers, B.; van der Goot, A.J. Plant-based meat analogues. In Sustainable Meat Production and Processing; Elsevier: Amsterdam, The Netherlands, 2019; pp. 103–126. [Google Scholar]

- Ranasinghesagara, J.; Hsieh, F.H.; Yao, G. An image processing method for quantifying fiber formation in meat analogs under high moisture extrusion. J. Food Sci. 2005, 70, 450–454. [Google Scholar] [CrossRef]

- Malav, O.; Talukder, S.; Gokulakrishnan, P.; Chand, S. Meat analog: A review. Crit. Rev. Food Sci. Nutr. 2015, 55, 1241–1245. [Google Scholar] [CrossRef]

- Garcıa, M.; Dominguez, R.; Galvez, M.; Casas, C.; Selgas, M. Utilization of cereal and fruit fibres in low fat dry fermented sausages. Meat Sci. 2002, 60, 227–236. [Google Scholar] [CrossRef]

- Al-Tabakha, M.M. HPMC capsules: Current status and future prospects. J. Pharm. Pharm. Sci. 2010, 13, 428–442. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 16th ed.; Association of Official Analytical Chemists: Arlington, TX, USA, 2002. [Google Scholar]

- ANKOM. Crude Fiber Analysis in Feeds by Filter Bag Technique; ANKOM: Macedon, NY, USA, 2008. [Google Scholar]

- Joo, S.T. Determination of water-holding capacity of porcine musculature based on released water method using optimal load. Korean J. Food Sci. An. 2018, 38, 823–828. [Google Scholar]

- Biswas, S.; Chakraborty, A.; Sarkar, S. Comparison Among the Qualities of Patties Prepared from Chicken Broiler, Spent Hen and Duck Meats. J. Poult. Sci. 2006, 43, 180–186. [Google Scholar] [CrossRef]

- AMSA. Research Guidelines for Cookery; American Meat Science Association in Cooperation with National Live Stock and Meat Board: Chicago, IL, USA, 1995; p. 8. [Google Scholar]

- Ismail, I.; Hwang, Y.-H.; Joo, S.-T. Interventions of two-stage thermal sous-vide cooking on the toughness of beef semitendinosus. Meat Sci. 2019, 157, 107882. [Google Scholar] [CrossRef]

- Lawless, H.T.; Heymann, H. Sensory Evaluation of Food: Principles and Practices; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Rahman, M.S.; Seo, J.-K.; Zahid, M.A.; Park, J.-Y.; Choi, S.-G.; Yang, H.-S. Physicochemical properties, sensory traits and storage stability of reduced-fat frankfurters formulated by replacing beef tallow with defatted bovine heart. Meat Sci. 2019, 151, 89–97. [Google Scholar] [CrossRef] [PubMed]

- Amboon, W.; Tulyathan, V.; Tattiyakul, J. Effect of hydroxypropyl methylcellulose on rheological properties, coating pickup, and oil content of rice flour-based batters. Food Bioprocess Tech. 2012, 5, 601–608. [Google Scholar] [CrossRef]

- Sarkar, N. Thermal gelation properties of methyl and hydroxypropyl methylcellulose. J. Appl. Polym. Sci. 1979, 24, 1073–1087. [Google Scholar] [CrossRef]

- Sarkar, N.; Walker, L. Hydration—Dehydration properties of methylcellulose and hydroxypropylmethylcellulose. Carbohydr. Polym. 1995, 27, 177–185. [Google Scholar] [CrossRef]

- Walstra, P. Physical Chemistry of Foods; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Ismail, B.P.; Senaratne-Lenagala, L.; Stube, A.; Brackenridge, A. Protein demand: Review of plant and animal proteins used in alternative protein product development and production. Anim. Front. 2020, 10, 53–63. [Google Scholar] [CrossRef]

- Bohrer, B.M. An investigation of the formulation and nutritional composition of modern meat analogue products. Food Sci. Hum. Well. 2019, 8, 320–329. [Google Scholar] [CrossRef]

- Ahirwar, R.; Jayathilakan, K.; Reddy, K.; Pandey, M.; Batra, H. Development of mushroom and wheat gluten based meat analogue by using response surface methodology. IJAR 2015, 3, 923–930. [Google Scholar]

- Trowell, H. Dietary fibre, ischaemic heart disease and diabetes mellitus. Proc. Nutr. Soc. 1973, 32, 151–157. [Google Scholar] [CrossRef] [Green Version]

- Chauhan, S.S.; LeMaster, M.N.; Clark, D.L.; Foster, M.K.; Miller, C.E.; England, E.M. Glycolysis and pH Decline Terminate Prematurely in Oxidative Muscles despite the Presence of Excess Glycogen. Meat Muscle Biol. 2019, 3. [Google Scholar] [CrossRef]

- Anjum, F.M.; Naeem, A.; Khan, M.I.; Nadeem, M.; Amir, R.M. Development of texturized vegetable protein using indigenous sources. Pak. J. Food Sci. 2011, 21, 33–44. [Google Scholar]

- Bell, W.; Shelef, L. Availability and microbial stability of retail beef-soy blends. J. Food Sci. 1978, 43, 315–333. [Google Scholar] [CrossRef]

- Ahmad, S.; Rizawi, J.; Srivastava, P. Effect of soy protein isolate incorporation on quality characteristics and shelf-life of buffalo meat emulsion sausage. J. Food Sci. Technol. 2010, 47, 290–294. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Deliza, R.; SALDIVAR, S.S.; Germani, R.; Benassi, V.; Cabral, L. The effects of colored textured soybean protein (TSP) on sensory and physical attributes of ground beef patties. J. Sens. Stud. 2002, 17, 121–132. [Google Scholar] [CrossRef]

- Hidayat, B.; Wea, A.; Andriat, N. Physicochemical, sensory attributes and protein profile by SDS-PAGE of beef sausage substituted with texturized vegetable proteins. Food Res. 2018, 2, 20–31. [Google Scholar] [CrossRef]

- Barbut, S.; Marangoni, A. Organogels use in meat processing–Effects of fat/oil type and heating rate. Meat Sci. 2019, 149, 9–13. [Google Scholar] [CrossRef]

- Sen, A.R.; Naveena, B.M.; Muthukumar, M.; Vaithiyanathan, S. Colour, myoglobin denaturation and storage stability of raw and cooked mutton chops at different end point cooking temperature. J. Food Sci. Technol. 2014, 51, 970–975. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hill, S.; Prusa, K. Physical and sensory properties of lean ground beef patties containing methylcellulose and hydroxypropyl methylcellulose. J. Food Qual. 1988, 11, 331–337. [Google Scholar] [CrossRef]

- de Huidobro, F.R.; Martínez, V.C.; Gómez, S.L.; Velasco, S.; Pérez, C.; Onega, E. Sensory characterization of meat texture in sucking lamb: Methodology. Investig. Agrar. Prod. Sanid. Anim. 2001, 16, 245–256. [Google Scholar]

- Laakkonen, E.; Wellington, G.; Sherbon, J. Low-temperature, long-time heating of bovine muscle 1. Changes in tenderness, water-binding capacity, pH and amount of water-soluble components. J. Food Sci. 1970, 35, 175–177. [Google Scholar] [CrossRef]

- Danowska-Oziewicz, M. Effect of soy protein isolate on physicochemical properties, lipid oxidation and sensory quality of low-fat pork patties stored in vacuum, MAP and frozen state. J. Food Process. 2014, 38, 641–654. [Google Scholar] [CrossRef]

- Gujral, H.S.; Kaur, A.; Singh, N.; Sodhi, N.S. Effect of liquid whole egg, fat and textured soy protein on the textural and cooking properties of raw and baked patties from goat meat. J. Food Eng. 2002, 53, 377–385. [Google Scholar] [CrossRef]

- Sanz, T.; Fernández, M.; Salvador, A.; Munoz, J.; Fiszman, S. Thermogelation properties of methylcellulose (MC) and their effect on a batter formula. Food Hydrocoll. 2005, 19, 141–147. [Google Scholar] [CrossRef]

- Ayadi, M.; Kechaou, A.; Makni, I.; Attia, H. Influence of carrageenan addition on turkey meat sausages properties. J. Food Eng. 2009, 93, 278–283. [Google Scholar] [CrossRef]

- Oh, I.; Lee, J.; Lee, H.G.; Lee, S. Feasibility of hydroxypropyl methylcellulose oleogel as an animal fat replacer for meat patties. Food Res. Int. 2019, 122, 566–572. [Google Scholar] [CrossRef]

- Raharjo, S.; Sofos, J.; Schmidt, G. Performance of Methylcellulose and Hydroxypropyl-methylcellulose as Moisture Retention and Gelling Additives in Low-Fat Ground Beef Patties. Indones. Food Nutr. Prog. 1996, 3, 1. [Google Scholar]

| Ingredients % Concentration (MC) | Treatments | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Control (Beef) | C-TVP | T-ISP | |||||||

| 1.5% | 3% | 4% | 1.5% | 3% | 4% | 1.5% | 3% | 4% | |

| Lean beef C-TVP T-ISP | 82.1 | 80.82 | 80.00 | 76.08 | 74.90 | 74.13 | 70.08 | 74.90 | 74.13 |

| Methylcellulose | 1.5 | 3.00 | 4.00 | 1.50 | 3.00 | 4.00 | 1.50 | 3.00 | 4.00 |

| Garlic powder | 2.28 | 2.25 | 2.22 | 2.28 | 2.25 | 2.22 | |||

| Yeast extract | 2.28 | 2.25 | 2.22 | 2.28 | 2.25 | 2.22 | |||

| Black pepper | 1.52 | 1.50 | 1.49 | 1.52 | 1.50 | 1.49 | |||

| Mushroom | 2.28 | 2.25 | 2.22 | 2.28 | 2.25 | 2.22 | |||

| Salt | 1.14 | 1.11 | 1.11 | 1.14 | 1.11 | 1.11 | |||

| Beef back fat | 16.4 | 16.18 | 16.00 | ||||||

| Coconut oil Canola oil | 3.80 3.80 | 3.75 3.75 | 3.71 3.71 | 3.80 3.80 | 3.75 3.75 | 3.71 3.71 | |||

| Beet juice | 3.04 | 3.00 | 2.96 | 3.04 | 3.00 | 2.96 | |||

| Molasses | 1.52 | 1.50 | 1.49 | 1.52 | 1.50 | 1.49 | |||

| Umami seasoning | 0.76 | 0.74 | 0.74 | 0.76 | 0.74 | 0.74 | |||

| Ingredient | Beef (Control) | C-TVP | T-ISP | SEM | P Ingredient | P Concentration | P ing * P Conc. | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Concentration | 1.5% | 3% | 4% | 1.5% | 3% | 4% | 1.5% | 3% | 4% | ||||

| Moisture | 57.49 b,c,d | 59.46 a,b | 62.64 a | 57.43 b,c,d | 51.54 e,f | 48.32 f | 57.80 b,c | 53.77 d,e | 54.28 c,d,e | 1.21 | <0.001 | 0.026 | <0.001 |

| Protein | 20.56 b | 21.19 b | 21.18 b | 16.48 b | 16.77 b | 16.93 b | 16.96 b | 16.95 b | 16.07 b | 0.71 | 0.079 | 0.650 | 0.345 |

| Fat | 18.38 a | 19.12 a | 18.85 a | 14.28 a | 15.05 a | 15.83 a | 17.25 a | 16.13 a | 15.28 a | 2.17 | 0.126 | 0.997 | 0.945 |

| Ash | 2.92 a,b | 2.22 b | 2.64 a,b | 3.11 a | 3.24 a | 2.84 a,b | 2.65 a,b | 2.83 a,b | 2.65 a,b | 0.25 | <0.001 | 0.857 | 0.831 |

| Crude fibre | 1.38 c | 1.56 c | 1.69 c | 6.04a b | 6.87 a | 7.82 a | 3.15 c | 3.66 bc | 3.70 b,c | 0.90 | <0.001 | 0.499 | 0.932 |

| Ingredient | Beef (Control) | C-TVP | T-ISP | SEM | P Ingredient | P Concentration | P ing * P Conc. | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Concentration | 1.5% | 3% | 4% | 1.5% | 3% | 4% | 1.5% | 3% | 4% | ||||

| pH before | 5.54 d | 5.35 d | 5.52 d | 6.34 c | 6.50 b,c | 6.35 c | 6.28 c | 6.68 b | 7.08 a | 0.08 | <0.001 | 0.002 | <0.001 |

| pH after | 5.71 e | 5.63 e,f | 5.51 f | 6.43 c | 6.20 d | 6.77 a,b | 6.15 d | 6.61 b | 6.88 a | 0.05 | <0.001 | <0.001 | <0.001 |

| L before | 46.47 a | 47.83 a | 46.93 a | 45.91 a | 39.95 b | 38.88 b,c | 34.70 d | 36.63 c,d | 40.16 b | 0.85 | <0.001 | 0.456 | <0.001 |

| a before | 17.83 a | 16.05 b | 16.25 b | 12.39 d | 14.09 c | 11.68 d,e | 12.94 c,d | 10.83 e,f | 9.90 f | 0.41 | <0.001 | <0.001 | 0.001 |

| b before | 11.87 c,d | 11.24 d | 11.55 d | 17.50 a | 13.37 b,c | 13.76 b | 12.04 c,d | 11.02 d | 11.85 c,d | 0.54 | <0.001 | 0.001 | 0.011 |

| L after | 38.48 a | 35.46 a,b | 32.20 b,c,d | 29.15 d | 31.15 c,d | 30.45 c,d | 31.33 c,d | 30.71 c,d | 32.93 b,c | 1.10 | <0.001 | 0.470 | 0.009 |

| a after | 8.59 b,c | 8.73 b,c | 7.75 c | 10.08 a,b | 9.77 a,b | 10.01 a,b | 10.62 a | 9.60 a,b | 8.52 b,c | 0.53 | 0.004 | 0.089 | 0.359 |

| b after | 11.36 a,b | 12.34 a,b | 10.19 a,b | 14.30 a,b | 12.89 a,b | 11.49 a,b | 15.61 a,b | 12.60 a,b | 15.56 a,b | 1.57 | 0.061 | 0.539 | 0.476 |

| Ingredient | Beef (Control) | C-TVP | T-ISP | SEM | P Ingredient | P Concentration | P ing * P Conc. | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Concentration | 1.5% | 3% | 4% | 1.5% | 3% | 4% | 1.5% | 3% | 4% | ||||

| Release water (%) | 3.9 a | 1.8b c,d | 1.8 b,c,d | 4.06 a | 2.21 b,c | 1.44 c,d | 3.47 a | 2.43 b | 1.77 d | 0.20 | 0.980 | <0.001 | 0.044 |

| Cooking loss (%) | 7.91 c,d | 6.55 d,e,f | 5.36 f | 9.98 b | 8.69 b,c | 7.12d e | 12.01 a | 7.30 c,d,e | 6.11 e,f | 0.48 | <0.001 | <0.001 | 0005 |

| WBSF (N) | 3.6 b,c | 3.80 b | 4.26 a | 2.14 f,g | 2.74 e | 3.20 d | 2.41 e,f | 2.41 e,f | 3.29 c,d | 0.12 | <0.001 | <0.001 | 0.044 |

| Diameter before | 14.99 a,b | 15.83 a,b | 15.52 a,b | 16.63 a,b | 15.47 a,b | 15.83 a,b | 16.30 a,b | 15.37 a,b | 15.70 a,b | 0.38 | 0.256 | 0.406 | 0.121 |

| Diameter after | 11.59 d | 12.30 c,d | 12.81 c,d | 14.96 a | 13.57 b,c | 15.16 a | 15.08 a | 14.29 a,b | 14.81 a,b | 0.41 | <0.001 | 0.308 | 0.038 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bakhsh, A.; Lee, S.-J.; Lee, E.-Y.; Sabikun, N.; Hwang, Y.-H.; Joo, S.-T. A Novel Approach for Tuning the Physicochemical, Textural, and Sensory Characteristics of Plant-Based Meat Analogs with Different Levels of Methylcellulose Concentration. Foods 2021, 10, 560. https://doi.org/10.3390/foods10030560

Bakhsh A, Lee S-J, Lee E-Y, Sabikun N, Hwang Y-H, Joo S-T. A Novel Approach for Tuning the Physicochemical, Textural, and Sensory Characteristics of Plant-Based Meat Analogs with Different Levels of Methylcellulose Concentration. Foods. 2021; 10(3):560. https://doi.org/10.3390/foods10030560

Chicago/Turabian StyleBakhsh, Allah, Se-Jin Lee, Eun-Yeong Lee, Nahar Sabikun, Young-Hwa Hwang, and Seon-Tea Joo. 2021. "A Novel Approach for Tuning the Physicochemical, Textural, and Sensory Characteristics of Plant-Based Meat Analogs with Different Levels of Methylcellulose Concentration" Foods 10, no. 3: 560. https://doi.org/10.3390/foods10030560

APA StyleBakhsh, A., Lee, S.-J., Lee, E.-Y., Sabikun, N., Hwang, Y.-H., & Joo, S.-T. (2021). A Novel Approach for Tuning the Physicochemical, Textural, and Sensory Characteristics of Plant-Based Meat Analogs with Different Levels of Methylcellulose Concentration. Foods, 10(3), 560. https://doi.org/10.3390/foods10030560