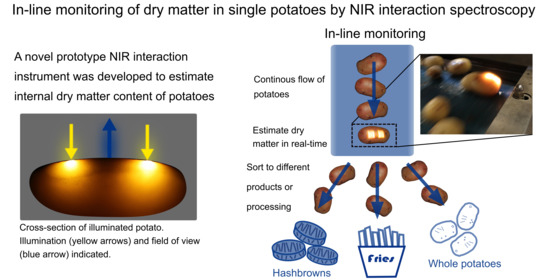

Optimization of Instrument Design for In-Line Monitoring of Dry Matter Content in Single Potatoes by NIR Interaction Spectroscopy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Calibration Set

2.1.2. Test Set

2.1.3. Process Monitoring

2.1.4. Study of Robustness

2.2. NIR System

2.3. Calibration Procedure

2.4. Process Monitoring

2.5. Study of Robustness

2.6. Study of Sampling Volume as Function of Distance between Illumination and Detection Region

2.7. Determination of Dry Matter

3. Results

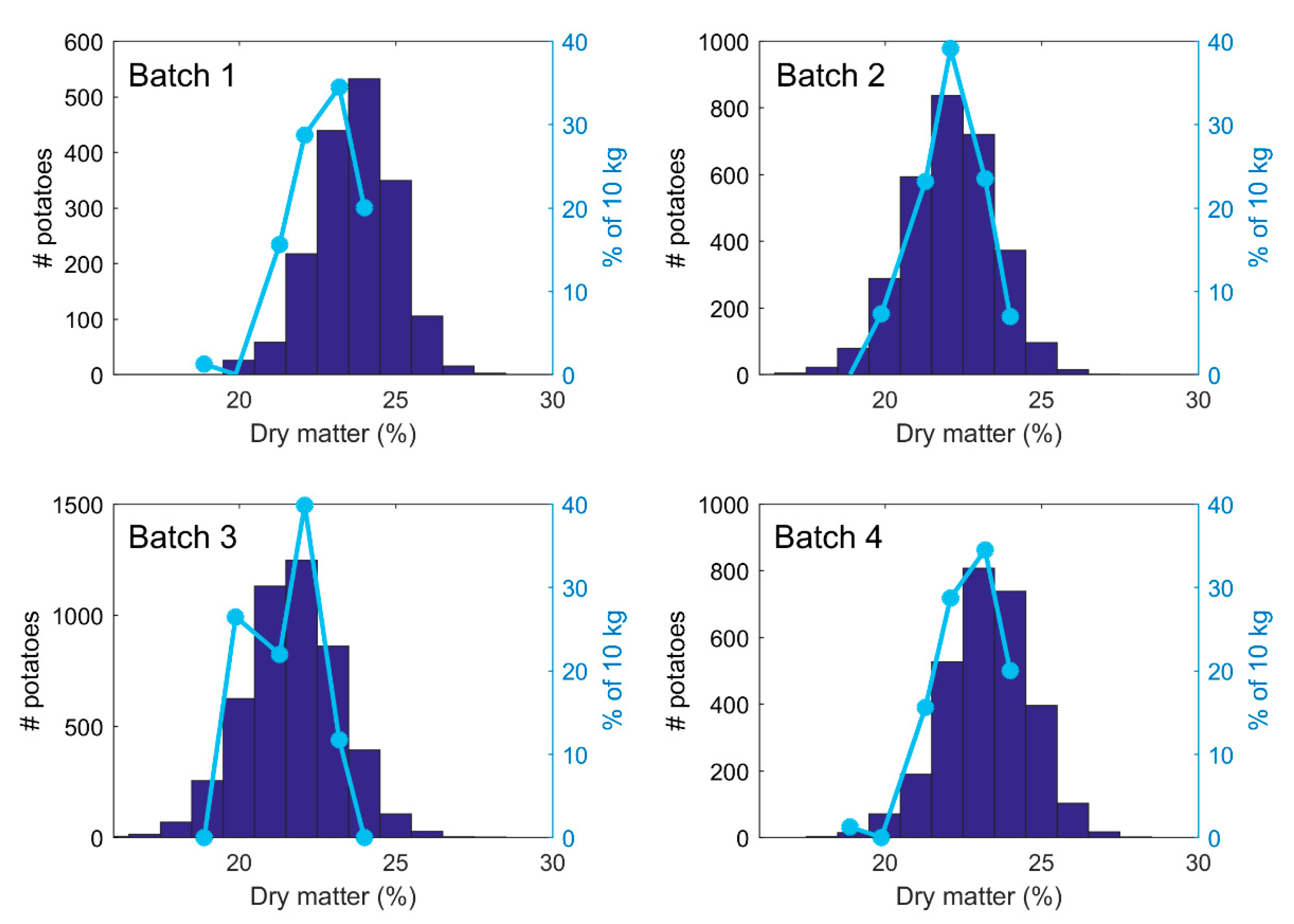

3.1. Dry Matter Contents

3.2. Spectroscopic Measurements

3.3. Calibration Results

3.4. Process Monitoring

3.5. Study of Robustness

4. Conclusions

- It can probe light that has travelled deeply enough into the potatoes, by suppressing the stronger light closer to the surface. This in turn enables sufficiently good DM estimates due to better sample representation. It has earlier been reported that depth of measurement is critical for this application [4].

- It produces spectra with sufficient signal to noise ratios, enabling robust calibration models for DM, with acceptable accuracy.

- Measurements are done without physical contact, with a distance of approximately 20 cm between the instrument and potatoes.

- It can operate at high speed, capturing NIR spectra from single potatoes within 0.02 s.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nissen, M. The weight of potatoes in water. Am. Potato J. 1955, 32, 332–339. [Google Scholar] [CrossRef]

- Saini, G.R. Determination of dry matter in potatoes. Am. Potato J. 1964, 41, 123–125. [Google Scholar] [CrossRef]

- Cole, C.S. Variation in dry matter between and within potato tubers. Potato Res. 1975, 18, 28–37. [Google Scholar] [CrossRef]

- Helgerud, T.; Segtnan, V.H.; Wold, J.P.; Balance, S.; Knutsen, S.H.; Rukke, E.O.; Afseth, N.K. Near-infrared spectroscopy for rapid estimation of dry matter content in whole unpeeled potato tubers. J. Food Res. 2012, 1, 55–65. [Google Scholar] [CrossRef] [Green Version]

- Haase, N. Prediction of potato processing quality by near infrared reflectance spectroscopy of ground raw tubers. J. Near Infrared Spectrosc. 2011, 19, 37–45. [Google Scholar] [CrossRef]

- Dull, G.; Birth, G.; Leffler, R. Use of near infrared analysis for the nondestructive measurement of dry matter in potatoes. Am. Potato J. 1989, 66, 215–225. [Google Scholar] [CrossRef]

- Peiris, K.H.S.; Dull, G.G.; Leffler, R.G.; Kays, S.J. Spatial variability of soluble solids or dry-matter content within individual fruits, bulbs, or tubers: Implications for the development and use of NIR spectrometric techniques. Hortscience 1999, 34, 114–118. [Google Scholar] [CrossRef] [Green Version]

- Subedi, P.; Walsh, K. Assessment of potato dry matter concentration using short-wave near-infrared spectroscopy. Potato Res. 2009, 52, 67–77. [Google Scholar] [CrossRef]

- Chen, J.Y.; Zhang, H.; Miao, Y.L.; Matsunaga, R. NIR measurement of specific gravity of potato. Food Sci. Technol. Res. 2005, 11, 26–31. [Google Scholar] [CrossRef] [Green Version]

- Helgerud, T.; Wold, J.P.; Pedersen, J.; Liland, K.H.; Ballance, S.; Knutsen, S.; Rukke, E.O.; Afseth, N.K. Towards on-line determination of dry matter content in whole unpeeled potato tubers using Near-Infrared spectroscopy. Talanta 2015, 143, 138–144. [Google Scholar] [CrossRef]

- Wold, J.P.; Kermit, M.; Woll, A. Rapid nondestructive determination of edible meat content in crabs (Cancer Pagurus) by Near-Infrared Imaging spectroscopy. Appl. Spectrosc. 2010, 64, 691–699. [Google Scholar] [CrossRef] [PubMed]

- Wold, J.P.; O’Farrel, M.; Høy, M.; Tschudi, J. On-line determination and control of fat content in batches of beef trimmings by NIR imaging spectroscopy. Meat Sci. 2011, 89, 317–324. [Google Scholar] [CrossRef] [PubMed]

- Wold, J.P.; Veiseth-Kent, E.; Høst, V.; Løvland, A. Rapid on-line detection and grading of wooden breast myopathy in chicken fillets by near-infrared spectroscopy. PLoS ONE 2017, 12, e0173384. [Google Scholar] [CrossRef]

- Cortés, V.; Blasco, J.; Aleixos, N.; Cubero, S.; Talens, P. Monitoring strategies for quality control of agricultural products using visible and near-infrared spectroscopy: A review. Trends Food Sci. Technol. 2019, 85, 138–148. [Google Scholar] [CrossRef]

- Porep, J.U.; Kammerer, D.R.; Carle, R. On-line application of near infrared (NIR) spectroscopy in food production. Trends Food Sci. Technol. 2015, 46, 211–230. [Google Scholar] [CrossRef]

- Grassi, S.; Alamprese, C. Advances in NIR spectroscopy applied to process analytical technology in food industries. Curr. Opin. Food Sci. 2018, 22, 17–21. [Google Scholar] [CrossRef]

- Wold, J.P.; O’Farrell, M.; Tschudi, J.; Eskildsen, C.E.; Andersen, P.V.; Ottestad, S. In-line and non-destructive monitoring of core temperature in sausages during industrial heat treatment by NIR interaction spectroscopy. J. Food Eng. 2020, 277, 1–8. [Google Scholar] [CrossRef]

- Barnes, R.J.; Dhanoa, M.S.; Lister, S.J. Standard Normal Variate Transformation and De-trending of Near-Infrared Diffuse Reflectance Spectra. Appl. Spectrosc. 1989, 43, 772–777. [Google Scholar] [CrossRef]

- Martens, H.; Næs, T. Multivariate Calibration; Wiley: New York, NY, USA, 1989. [Google Scholar]

- Tauler, R. Multivariate curve resolution applied to second order data. Chemom. Intell. Lab. Syst. 1995, 30, 133–146. [Google Scholar] [CrossRef]

- Lammertyn, J.; Peirs, A.; De Baerdemaeker, J.; Nicolaï, B. Light penetration properties of NIR radiation in fruit with respect to non-destructive quality assessment. Postharvest Biol. Technol. 2000, 18, 121–132. [Google Scholar] [CrossRef]

- Wold, J.P. On-line and non-destructive measurements of core temperature in heat treated fish cakes by NIR hyperspectral imaging. Innov. Food Sci. Emerg. Technol. 2016, 33, 431–437. [Google Scholar] [CrossRef] [Green Version]

- Williams, P.; Norris, K. Qualitative applications of near-infrared reflectance spectroscopy. In Near-Infrared Technology en the Agricultural and Food Industries; Williams, P., Norris, K., Eds.; American Association of Cereal Chemists Inc.: Eagan, MN, USA, 1990; pp. 241–246. [Google Scholar]

- Walsh, K.B.; Blasco, J.; Zude-Sasse, M.; Sun, X. Visible-NIR ‘point’ spectroscopy in postharvest fruit and vegetable assessment: The science behind three decades of commercial use. Postharvest Biol. Technol. 2020, 168, 111246. [Google Scholar] [CrossRef]

- Nicolaï, B.M.; Beullens, K.; Bobelyn, E.; Peirs, A.; Saeys, W.; Theron, K.I.; Lammertyn, J. Nondestructive measurement of fruit and vegetable quality by means of NIR spectroscopy: A review. Postharvest Biol. Technol. 2007, 46, 99–118. [Google Scholar] [CrossRef]

| Variety | N a | Min | Max | Average | StDev b |

|---|---|---|---|---|---|

| Oleva (calibration) | 50 | 19.4 | 26.7 | 23.1 | 1.53 |

| Folva (calibration) | 50 | 14.9 | 23.4 | 19.1 | 1.48 |

| Innovator (calibration) | 63 | 18.9 | 28.4 | 23.0 | 2.68 |

| All calibration samples | 163 | 14.9 | 28.4 | 21.8 | 2.75 |

| Test set | 50 | 16.6 | 26.1 | 22.0 | 1.91 |

| Robustness test | 50 | 17.8 | 25.7 | 22.9 | 1.72 |

| Steady State | Scanning in Motion | Test In-Line | ||||||

|---|---|---|---|---|---|---|---|---|

| Dist | #LV a | R2 | RMSECVb (%) | #LV a | R2 | RMSECVb (%) | R2 | RMSEP b (%) |

| 1 | 7 | 0.76 | 1.35 | 5 | 0.83 | 1.11 | 0.52 | 1.30 |

| 2 | 7 | 0.79 | 1.25 | 7 | 0.87 | 0.91 | 0.72 | 1.00 |

| 3 | 5 | 0.81 | 1.17 | 7 | 0.89 | 0.89 | 0.74 | 0.94 |

| 4 | 5 | 0.84 | 1.10 | 7 | 0.91 | 0.78 | 0.77 | 0.88 |

| 5 | 5 | 0.82 | 1.14 | 7 | 0.87 | 0.98 | 0.63 | 1.14 |

| Calibration Set | RMSEP b (%) | |||||

|---|---|---|---|---|---|---|

| Dist | #LV a | R2 | RMSECVb (%) | Center | All | Off-Center |

| 1 | 6 | 0.85 | 0.65 | 0.74 | 0.86 | 0.89 |

| 2 | 6 | 0.90 | 0.53 | 0.70 | 0.79 | 0.83 |

| 3 | 5 | 0.90 | 0.51 | 0.83 | 0.98 | 1.04 |

| 4 | 5 | 0.85 | 0.65 | 1.26 | 1.35 | 1.44 |

| 5 | 4 | 0.81 | 0.74 | 1.49 | 1.61 | 1.66 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wold, J.P.; O’Farrell, M.; Andersen, P.V.; Tschudi, J. Optimization of Instrument Design for In-Line Monitoring of Dry Matter Content in Single Potatoes by NIR Interaction Spectroscopy. Foods 2021, 10, 828. https://doi.org/10.3390/foods10040828

Wold JP, O’Farrell M, Andersen PV, Tschudi J. Optimization of Instrument Design for In-Line Monitoring of Dry Matter Content in Single Potatoes by NIR Interaction Spectroscopy. Foods. 2021; 10(4):828. https://doi.org/10.3390/foods10040828

Chicago/Turabian StyleWold, Jens Petter, Marion O’Farrell, Petter Vejle Andersen, and Jon Tschudi. 2021. "Optimization of Instrument Design for In-Line Monitoring of Dry Matter Content in Single Potatoes by NIR Interaction Spectroscopy" Foods 10, no. 4: 828. https://doi.org/10.3390/foods10040828