Accelerating Aging of White and Red Wines by the Application of Hydrostatic High Pressure and Maceration with Holm Oak (Quercus ilex) Chips. Influence on Physicochemical and Sensory Characteristics

Abstract

:1. Introduction

2. Materials and Methods

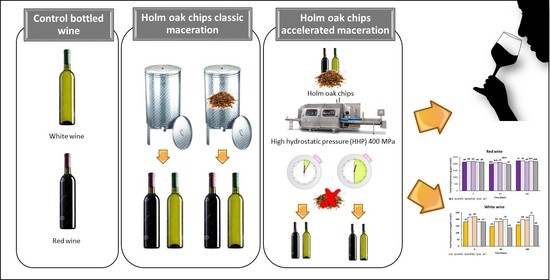

2.1. Samples

2.2. Holm Oak Chips

2.3. Hydrostatic High Pressure (HHP) Treatment

2.4. Experimental Design

2.5. Analytical Methods

2.5.1. General Oenological Parameters

2.5.2. Phenolic Compounds

2.5.3. Chromatic Characteristics

2.6. Sensorial Analysis

2.7. Statistical Analysis

3. Results and Discussion

3.1. White Wine

3.1.1. Effects of Treatments, Sampling Date and Their Interactions on Chemical Parameters Values

3.1.2. General Oenological Parameters

3.1.3. Phenolic Compounds

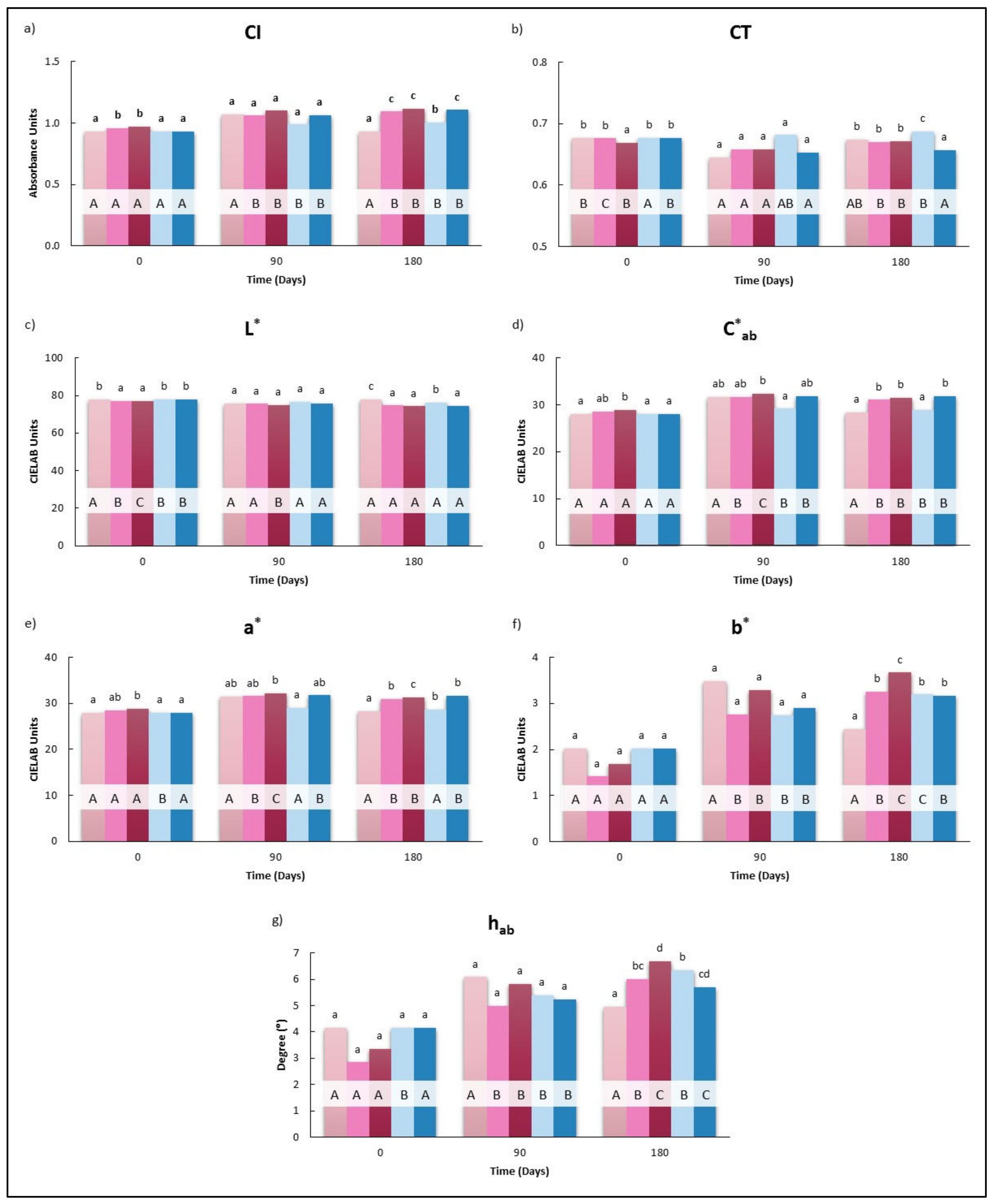

3.1.4. Chromatic Characteristics

3.2. Red Wine

3.2.1. Effects of Treatments, Sampling Date and Their Interactions on Chemical Parameters Values

3.2.2. General Oenological Parameters

3.2.3. Polyphenolic Compounds

3.2.4. Chromatic Characteristics

3.3. Sensory Analysis

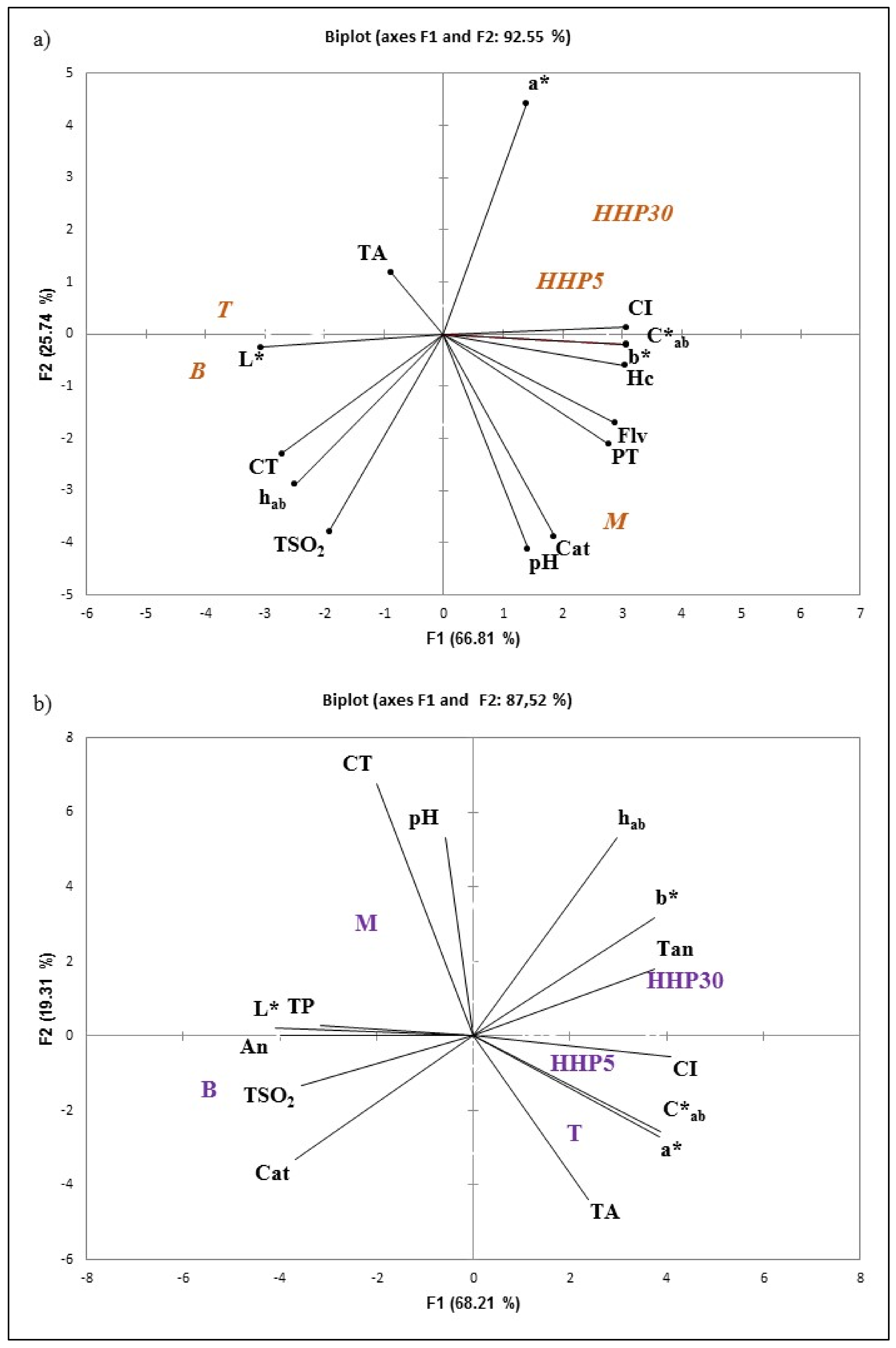

3.4. Principal Components Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Carpena, M.; Pereira, A.G.; Prieto, M.A.; Simal-Gandara, J. Wine Aging Technology: Fundamental Role of Wood Barrels. Foods 2020, 9, 1160. [Google Scholar] [CrossRef]

- Silva, P.; Cardoso, H.; Geros, H. Studies on the wine spoilage capacity of Brettanomyces/Dekkera spp. Am. J. Enol. Vitic. 2004, 55, 65–72. [Google Scholar]

- Garde-Cerdán, T.; Ancín-Azpilicueta, C. Review of quality factors on wine ageing in oak barrels. Trends Food Sci. Technol. 2006, 17, 438–447. [Google Scholar] [CrossRef]

- García, R.; Soares, B.; Dias, C.B.; Costa-Freitas, A.M.C.; Cabrita, M.J. Phenolic and furanic compounds of Portuguese chestnut and French, American and Portuguese oak wood chips. Eur. Food Res. Technol. 2012, 235, 457–467. [Google Scholar] [CrossRef]

- Martínez-Gil, A.M.; del Alamo-Sanza, M.; Nevares, I.; Sánchez-Gómez, R.; Gallego, L. Effect of size, seasoning and toasting level of Quercus pyrenaica Willd. wood on wine phenolic composition during maturation process with micro-oxygenation. Food Res. Int. 2020, 128, 108703. [Google Scholar] [CrossRef] [PubMed]

- Natali, N.; Chinnici, F.; Riponi, C. Characterization of Volatiles in Extracts from Oak Chips Obtained by Accelerated Solvent Extraction (ASE). J. Agric. Food Chem. 2006, 54, 8190–8198. [Google Scholar] [CrossRef] [PubMed]

- De Simón, B.F.; Cadahía, E.; Muiño, I.; del Álamo, M.; Nevares, I. Volatile composition of toasted oak chips and staves and of red wine aged with them. Am. J. Enol. Vitic. 2010, 61, 157–165. [Google Scholar]

- Goncalves, F.J.; Jordao, A.M. Changes in antioxidant activity and the proanthocyanidin fraction of red wine aged in contact with portuguese (Quercus pyrenaica Willd.) and American (Quercus alba L.) oak wood chips. Ital. J. Food Sci. 2009, 21, 51–64. [Google Scholar]

- Jordão, A.M.; Costa, F.; Fontes, L.; Correia, A.C.; Miljić, U.; Puškaš, V.; Nunes, F.; Cosme, F. Impact of the contact time of different oak wood chips on red wine phenolic composition evolution after bottling. BIO Web Conf. 2019, 15, 02019. [Google Scholar] [CrossRef]

- Costa, M.; Fontes, L.; Correia, A.C.; Miljić, U.; Jordão, A.M. Impact of oak (Q. pyrenaica and Q. pubescens) and cherry (P. avium) wood chip contact on phenolic composition and sensory profile evolution of red wines during bottle storage. OENO One 2020, 54, 1159–1181. [Google Scholar] [CrossRef]

- Martins, N.; Garcia, R.; Gomes da Silva, M.; Cabrita, M.J. Volatile compounds from oak, cherry, chestnut and acacia chips: Influence of toasting level. Ciência Téc. Vitiv. 2012, 27, 49–57. [Google Scholar]

- Sevenich, R.; Rauh, C.; Knorr, D. A scientific and interdisciplinary approach for high pressure processing as a future toolbox for safe and high quality products: A review. Innov. Food Sci. Emerg. Technol. 2016, 38, 65–75. [Google Scholar] [CrossRef]

- Buzrul, S. High hydrostatic pressure treatment of beer and wine: A review. Innov. Food Sci. Emerg. Technol. 2012, 13, 1–12. [Google Scholar] [CrossRef]

- Huang, H.-W.; Wu, S.-J.; Lu, J.-K.; Shyu, Y.-T.; Wang, C.-Y. Current status and future trends of high-pressure processing in food industry. Food Control. 2017, 72, 1–8. [Google Scholar] [CrossRef]

- Morata, A.; Loira, I.; Vejarano, R.; González, C.; Callejo, M.J.; Suárez-Lepe, J.A. Emerging preservation technologies in grapes for winemaking. Trends Food Sci. Technol. 2017, 67, 36–43. [Google Scholar] [CrossRef]

- Santos, M.C.; Nunes, C.; Rocha, M.A.M.; Rodrigues, A.J.; Rocha, S.M.; Saraiva, J.A.; Coimbra, M.A. High pressure treatments accelerate changes in volatile composition of sulphur dioxide-free wine during bottle storage. Food Chem. 2015, 188, 406–414. [Google Scholar] [CrossRef]

- Santos, M.C.; Nunes, C.; Jourdes, M.; Teissedre, P.-L.; Rodrigues, A.; Amado, O.; Saraiva, J.A.; Coimbra, M.A. Evaluation of the potential of high pressure technology as an enological practice for red wines. Innov. Food Sci. Emerg. Technol. 2016, 33, 76–83. [Google Scholar] [CrossRef]

- Sun, X.; Li, L.; Ma, T.; Zhao, F.; Yu, D.; Huang, W.; Zhan, J. High hydrostatic pressure treatment: An artificial accelerating aging method which did not change the region and variety non-colored phenolic characteristic of red wine. Innov. Food Sci. Emerg. Technol. 2016, 33, 123–134. [Google Scholar] [CrossRef]

- Guo, X.; Han, D.; Xi, H.; Rao, L.; Liao, X.; Hu, X.; Wu, J. Extraction of pectin from navel orange peel assisted by ultra-high pressure, microwave or traditional heating: A comparison. Carbohydr. Polym. 2012, 88, 441–448. [Google Scholar] [CrossRef]

- Jun, X. Caffeine extraction from green tea leaves assisted by high pressure processing. J. Food Eng. 2009, 94, 105–109. [Google Scholar] [CrossRef]

- Tao, Y.; Sun, D.-W.; Górecki, A.; Błaszczak, W.; Lamparski, G.; Amarowicz, R.; Fornal, J.; Jeliński, T. A preliminary study about the influence of high hydrostatic pressure processing in parallel with oak chip maceration on the physicochemical and sensory properties of a young red wine. Food Chem. 2016, 194, 545–554. [Google Scholar] [CrossRef] [PubMed]

- Del Galdo, V.; Correia, A.C.; Jordão, A.M.; Ricardo-da-Silva, J.M. Blends of wood chips from oak and cherry: Impact on the general phenolic parameters and sensory profile of a white wine during the aging process. Vitis 2019, 58, 159–169. [Google Scholar] [CrossRef]

- Delia, L.; Jordão, A.M.; Ricardo-da-Silva, J.M. Influence of different wood chips species (oak, acacia and cherry) used in a short period of aging on the quality of ’encruzado’ white wines. Mitt. Klosterneubg. 2017, 67, 84–96. [Google Scholar]

- Organisation Internationale de la Vigne et du Vin OIV. Recueil des Méthodes Internationales d’Analyse des Vins et des Moûts; OIV: Paris, France, 1990; Volume II. [Google Scholar]

- Blouin, J. Techniques d’Analyses des Moûts et des Vins; Dujardin-Salleron: Paris, France, 1992. [Google Scholar]

- Singleton, V.L.; Rossi, J.A. Colorimetry of total phenolics with phosphomolybdic–phosphotungstic acid reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar]

- Broadhurst, R.B.; Jones, W.T. Analysis of condensed tannins using acidified vanillin. J. Sci. Food Agric. 1978, 29, 788–794. [Google Scholar] [CrossRef]

- Iland, P.; Ewart, A.; Markides, A.; Sitters, J.; Bruer, N. Techniques for Chemical Analysis and Quality Monitoring during Winemaking; Patrick Iland Wine Promotions: Campbelltown, Australia, 2000; pp. 88–91. [Google Scholar]

- Di Stefano, R.; Cravero, M.C.; Gentilini, N. Metodi per lo studio dei polifenoli dei vini. L’Enotecnico 1989, 25, 83–89. [Google Scholar]

- Sarneckis, C.; Dambergs, R.; Jones, P.; Mercurio, M.; Herderich, M.; Smith, P. Quantification of condensed tannins by precipitation with methyl cellulose: Development and validation of an optimised tool for grape and wine analysis. Aust. J. Grape Wine Res. 2006, 12, 39–49. [Google Scholar] [CrossRef]

- Boulton, R. The copigmentation of anthocyanins and its role in the color of red wine. A critical review. Am. J. Enol. Vitic. 2001, 52, 67–87. [Google Scholar]

- Ayala, F.; Echávarri, J.F.; Negueruela, A.I. A new simplified method for measuring the color of wines. I. Red and rose wines. Am. J. Enol. Vitic. 1997, 48, 357–363. [Google Scholar]

- Ayala, F.; Echávarri, J.F.; Negueruela, A.I. MSCVes.zip. Available online: http://www.unizar.es/negueruela/MSCV.es (accessed on 2 October 2001).

- Escudero-Gilete, M.; González-Miret, M.L.; Heredia, F.J. Implications of blending wines on the relationships between the colour and the anthocyanic composition. Food Res. Int. 2010, 43, 745–752. [Google Scholar] [CrossRef]

- Roessler, E.B.; Warren, J.; Guymon, J.F. Significance in triangular taste tests. J. Food Sci. 1948, 13, 503–505. [Google Scholar] [CrossRef] [PubMed]

- Valdes, E.; Vilanova, M.; Sabio, E.; Benalte, M. Clarifying agents effect on the nitrogen composition in must and wine during fermentation. Food Chem. 2011, 125, 430–437. [Google Scholar] [CrossRef]

- Briones-Labarca, V.; Perez-Wom, M.; Habib, G.; Giovagnoli-Vicuña, C.; Cañas-Sarazua, R.; Tabilo-Munizaga, G.; Salazar, F.N. Oenological and Quality Characteristic on Young White Wines (Sauvignon Blanc): Effects of High Hydrostatic Pressure Processing. J. Food Qual. 2017, 2017, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Santos, M.C.; Nunes, C.; Saraiva, J.A.; Coimbra, M.A. Chemical and physical methodologies for the replacement/reduction of sulfur dioxide use during winemaking: Review of their potentialities and limitations. Eur. Food Res. Technol. 2012, 234, 1–12. [Google Scholar] [CrossRef]

- Santos, M.C.; Nunes, C.; Cappelle, J.; Gonçalves, F.J.; Rodrigues, A.; Saraiva, J.; Coimbra, M.A. Effect of high pressure treatments on the physicochemical properties of a sulphur dioxide-free red wine. Food Chem. 2013, 141, 2558–2566. [Google Scholar] [CrossRef]

- Lukić, K.; Tomašević, M.; Ćurko, N.; Sivrić, A.; Ružman, E.; Kovačević Ganić, K.K. Influence of non-thermal processing techniques on sulfur dioxide and oxygen concentrations in young and aged wines. Hrvatski Časopis za Prehrambenu Tehnologiju, Biotehnologiju i Nutricionizam 2020, 14, 65–75. [Google Scholar] [CrossRef] [Green Version]

- Del Alamo, M.; Nevares, I. Wine aging in bottle from artificial systems (staves and chips) and oak woods: Anthocyanin composition. Anal. Chim. Acta. 2006, 563, 255–263. [Google Scholar] [CrossRef]

- Gallego, L.; del Alamo, M.; Nevares, I.; Fernández, J.A.; de Simón, B.F.; Cadahía, E. Phenolic compounds and sensorial characterization of wines aged with alternative to barrel products made of Spanish oak wood (Quercus pyrenaica Willd.). Food Sci. Technol. Int. 2012, 18, 151–165. [Google Scholar] [CrossRef] [PubMed]

- Corcho-Corral, B.; Olivares-Marín, M.; Valdes-Sánchez, E.; Fernández-González, C.; Macias-Garcia, A.; Gómez-Serrano, V. Development of Activated Carbon Using Vine Shoots (Vitis Vinifera) and Its Use for Wine Treatment. J. Agric. Food Chem. 2005, 53, 644–650. [Google Scholar] [CrossRef]

- Martínez, J.A.; Melgosa, M.; Pérez, M.M.; Hita, E.; Negueruela, A.I. Note. Visual and Instrumental Color Evaluation in Red Wines. Food Sci. Technol. Int. 2001, 7, 439–444. [Google Scholar] [CrossRef]

- Valdés, M.E.; Moreno, D.; Gamero, E.; Uriarte, D.; Prieto, M.D.H.; Manzano, R.; Picón, J.; Intrigliolo, D.S. Effects of cluster thinning and irrigation amount on water relations, growth, yield and fruit and wine composition of Tempranillo grapes in Extemadura (Spain). OENO One 2009, 43, 67–76. [Google Scholar] [CrossRef]

- Talaverano, I.; Valdés, E.; Moreno, D.; Gamero, E.; Ramírez, L.M.; Vilanova, M. The combined effect of water status and crop level on Tempranillo wine volatiles. J. Sci. Food Agric. 2017, 97, 1533–1542. [Google Scholar] [CrossRef] [PubMed]

- Tulyathan, V.; Boulton, R.B.; Singleton, V.L. Oxygen uptake by gallic acid as a model for similar reactions in wines. J. Agric. Food Chem. 1989, 37, 844–849. [Google Scholar] [CrossRef]

- Clarke, R.; Bakker, J. Chapter 3: Basic Taste and Stimulant Component. In Wine Flavour Chemistry; Clarke, R., Bakker, J., Eds.; Blackwell Publishing: Oxford, UK, 2004; pp. 66–119. [Google Scholar] [CrossRef]

- Peynaud, E. The Taste of Wine: The Art and Science of Wine Appreciation, 2nd ed.; John Wiley and Sons: New York, NY, USA, 1996. [Google Scholar]

- Tao, Y.; Sun, D.-W.; Górecki, A.; Błaszczak, W.; Lamparski, G.; Amarowicz, R.; Fornal, J.; Jeliński, T. Effects of high hydrostatic pressure processing on the physicochemical and sensorial properties of a red wine. Innov. Food Sci. Emerg. Technol. 2012, 16, 409–416. [Google Scholar] [CrossRef]

- Christofi, S.; Malliaris, D.; Katsaros, G.; Panagou, E.; Kallithraka, S. Limit SO2 content of wines by applying High Hydrostatic Pressure. Innov. Food Sci. Emerg. Technol. 2020, 62, 102342. [Google Scholar] [CrossRef]

- Bolumar, T.; Skibsted, L.H.; Orlien, V. Kinetics of the formation of radicals in meat during high pressure processing. Food Chem. 2012, 134, 2114–2120. [Google Scholar] [CrossRef]

- Barba, F.J.; Esteve, M.J.; Frigola, A. Physicochemical and nutritional characteristics of blueberry juice after high pressure processing. Food Res. Int. 2013, 50, 545–549. [Google Scholar] [CrossRef]

- Barrett, D.M.; Lloyd, B. Advanced preservation methods and nutrient retention in fruits and vegetables. J. Sci. Food Agric. 2011, 92, 7–22. [Google Scholar] [CrossRef]

- Ferrari, G.; Maresca, P.; Ciccarone, R. The application of high hydrostatic pressure for the stabilization of functional foods: Pomegranate juice. J. Food Eng. 2010, 100, 245–253. [Google Scholar] [CrossRef]

- González-Cebrino, F.; Durán, R.; Delgado-Adámez, J.; Contador, R.; Ramírez, R. Changes after high-pressure processing on physicochemical parameters, bioactive compounds, and polyphenol oxidase activity of red flesh and peel plum purée. Innov. Food Sci. Emerg. Technol. 2013, 20, 34–41. [Google Scholar] [CrossRef]

- Tavares, M.; Jordão, A.M.; Ricardo-Da-Silva, J.M. Impact of cherry, acacia and oak chips on red wine phenolic parameters and sensory profile. Oeno One 2017, 51, 329–342. [Google Scholar] [CrossRef] [Green Version]

- Chinnici, F.; Natali, N.; Bellachioma, A.; Versari, A.; Riponi, C. Changes in phenolic composition of red wines aged in cherry wood. LWT 2015, 60, 977–984. [Google Scholar] [CrossRef]

- Monagas, M.; Martín-Álvarez, P.J.; Bartolomé, B.; Gómez-Cordovés, C. Statistical interpretation of the color parameters of red wines in function of their phenolic composition during aging in bottle. Eur. Food Res. Technol. 2005, 222, 702–709. [Google Scholar] [CrossRef]

- Gamero, E.; Espinosa, F.; Moreno, D.; Uriarte, M.H.P.D.; Prieto, M.H.; Garrido, I.; Valdés, M.E. Convenience of Applying of Viticulture Technique as a Function of the Water Status of the Vine-Stock. In Grapes and Wines—Advances in Production, Processing, Analysis and Valorization; Jordão, A.M., Cosme, F., Eds.; IntechOpen: London, UK, 2018; pp. 91–115. [Google Scholar]

- Jordão, A.M.; Lozano, V.; Correia, A.C.; González-Sanjosé, M.L. Impact of different wood chip species (oak, acacia and cherry) on evolution of individual anthocyanins, chromatic characteristics and antioxidant capacity in model wine solutions. Bio Web Conf. 2017, 9, 2013. [Google Scholar] [CrossRef] [Green Version]

- Boido, E.; Alcalde-Eon, C.; Carrau, F.; Dellacassa, E.; Rivas-Gonzalo, J.C. Aging Effect on the Pigment Composition and Color of Vitis vinifera L. Cv. Tannat Wines. Contribution of the Main Pigment Families to Wine Color. J. Agric. Food Chem. 2006, 54, 6692–6704. [Google Scholar] [CrossRef] [PubMed]

- Garcia Falcon, M.; Pérez-Lamela, C.P.; Martínez-Carballo, E.; Simal-Gandara, J. Determination of phenolic compounds in wines: Influence of bottle storage of young red wines on their evolution. Food Chem. 2007, 105, 248–259. [Google Scholar] [CrossRef]

| Parameter | Significance Level | ||

|---|---|---|---|

| Treatment | Time | Treatment × Time | |

| TrA | n.s. | *** | n.s. |

| pH | n.s. | *** | n.s. |

| TA | *** | *** | *** |

| VA | n.s. | *** | n.s. |

| FSO2 | *** | *** | ** |

| TSO2 | *** | *** | ** |

| Catechins | *** | *** | *** |

| Flavonoids | *** | *** | *** |

| Hidroxicinamics | *** | *** | *** |

| Total Polyphenols | *** | *** | *** |

| CI | *** | *** | *** |

| CT | *** | *** | n.s. |

| a* | n.s. | *** | * |

| b* | *** | *** | *** |

| Time (Days) | Treatment | TrA (g/L) | pH | TA (gTrA/L) | VA (g AcH/L) | FSO2 (mg/L) | TSO2 (mg/L) |

|---|---|---|---|---|---|---|---|

| 0 | B | 2.86A | 2.96aA*● | 5.25cC | 0.35aB | 33.50bC | 105.17bB |

| HHP5 | 2.93A | 2.98bA | 4.91bA | 0.36aC | 24.83aB | 98.33aB | |

| HHP30 | 2.96A | 2.98bA | 4.65aA | 0.37aC | 29.50abC | 101.17abC | |

| M | 2.86A | 2.96aA | 5.25cC | 0.35aB | 33.50bC | 105.17bC | |

| T | 2.86A | 2.96aA | 5.25cC | 0.35aC | 33.50bC | 105.17bC | |

| 90 | B | 1.67B | 3.58aB | 5.08bB | 0.26aA | 30.00bB | 109.67dC |

| HHP5 | 1.97B | 3.54aB | 4.85aA | 0.24aA | 18.50aAB | 92.33abB | |

| HHP30 | 1.94B | 3.54aB | 4.99abB | 0.24aA | 20.00aB | 90.00aB | |

| M | 1.97B | 3.56aB | 4.98abB | 0.24aA | 20.17aB | 98.50bcB | |

| T | 1.97B | 3.52aB | 5.06abB | 0.23aA | 22.50aB | 101.17cB | |

| 180 | B | 3.65aB | 4.64aA | 0.26aA | 14.00bA | 47.33cA | |

| HHP5 | 3.66aC | 4.73abA | 0.30aB | 12.00abA | 30.00aA | ||

| HHP30 | 3.65aC | 4.68aA | 0.30aB | 11.67aA | 26.00aA | ||

| M | 3.69aC | 4.68aA | 0.30aAB | 13.00abA | 43.67bcA | ||

| T | 3.66aC | 4.82bA | 0.29aB | 11.67aA | 40.00bA |

| Parameter | Significance Level | ||

|---|---|---|---|

| Treatment | Time | Treatment × Time | |

| TrA | n.s. | ** | n.s |

| pH | ** | *** | *** |

| TA | n.s. | *** | n.s. |

| VA | * | *** | n.s. |

| FSO2 | ** | n.s. | n.s. |

| TSO2 | ** | *** | n.s. |

| Anthocyanins | n.s. | *** | n.s. |

| Copigmented Anthocyanins | n.s. | *** | n.s. |

| Catechins | *** | *** | *** |

| Tannins | *** | *** | n.s. |

| Total Polyphenols | *** | *** | ** |

| CI | *** | *** | n.s. |

| CT | *** | *** | ** |

| a* | *** | *** | * |

| b* | n.s. | *** | n.s. |

| L* | ** | *** | n.s. |

| C*ab | ** | *** | * |

| hab | n.s. | *** | n.s. |

| Time (Days) | Treatment | TrA (g/L) | pH | TA (g TrA/L) | VA (g AcH/L) | FSO2 (mg/L) | TSO2 (mg/L) |

|---|---|---|---|---|---|---|---|

| 0 | B | 2.87aB | 3.47aA*● | 4.45aA | 0.43aB | 14.67cA | 54.50bA |

| HHP5 | 2.95aB | 3.57aA | 4.46aA | 0.43aB | 11.83bA | 49.33aB | |

| HHP30 | 3.03aB | 3.72bC | 4.44aA | 0.43aC | 9.17aA | 47.17aB | |

| M | 2.87aB | 3.47aA | 4.45aA | 0.43aB | 14.67cB | 54.50bC | |

| T | 2.87ab | 3.47aA | 4.45aA | 0.43aC | 14.67cB | 54.50bB | |

| 90 | B | 1.67aA | 3.58aB | 4.44aA | 0.29aA | 14.00aA | 41.50abA |

| HHP5 | 1.97aA | 3.54aA | 4.50abA | 0.41bB | 11.17aA | 34.33abA | |

| HHP30 | 1.94aA | 3.54aA | 4.49abA | 0.37bB | 10.50aB | 26.83aA | |

| M | 1.97aA | 3.56aB | 4.44abA | 0.38bB | 12.33aA | 50.17bB | |

| T | 1.97aA | 3.52aB | 4.51bA | 0.36abB | 12.33aAB | 46.83abAB | |

| 180 | B | 3.65aB | 4.64aA | 0.26aA | 14.00bA | 47.33cA | |

| HHP5 | 3.66aB | 4.73abA | 0.30aA | 12.00aB | 30.00aA | ||

| HHP30 | 3.65bC | 4.68abA | 0.30aA | 11.67abAB | 26.00bcA | ||

| M | 3.69aA | 4.68abA | 0.30aA | 13.00abA | 43.67aA | ||

| T | 3.66aC | 4.82bA | 0.29aA | 11.67aA | 40.00bA |

| Cayetana Wine | Tempranillo Wine | |||||

|---|---|---|---|---|---|---|

| Triangle Test | Correct Responses/Total Responses | d´ | p | Correct Responses/Total Responses | d´ | p |

| B vs. HHP5 | 14/14 | 10 | <0.0001 | 6/14 | 1.07 | n.s. |

| B vs. HHP30 | 11/12 | 4.24 | <0.0001 | 7/12 | 1.9 | n.s. |

| HHP5 vs. HHP30 | 8/14 | 2.2 | n.s. | 3/14 | >0.33 * | n.s. |

| M vs. HHP5 | 4/12 | >0.33 * | n.s. | 5/12 | 0.99 | n.s. |

| M vs. HHP30 | 5/13 | 0.77 | n.s. | 4/13 | >0.33 * | n.s. |

| M vs. T | 11/14 | 3.03 | 0.001 | 6/14 | >0.33 * | n.s. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valdés, M.E.; Ramírez, R.; Martínez-Cañas, M.A.; Frutos-Puerto, S.; Moreno, D. Accelerating Aging of White and Red Wines by the Application of Hydrostatic High Pressure and Maceration with Holm Oak (Quercus ilex) Chips. Influence on Physicochemical and Sensory Characteristics. Foods 2021, 10, 899. https://doi.org/10.3390/foods10040899

Valdés ME, Ramírez R, Martínez-Cañas MA, Frutos-Puerto S, Moreno D. Accelerating Aging of White and Red Wines by the Application of Hydrostatic High Pressure and Maceration with Holm Oak (Quercus ilex) Chips. Influence on Physicochemical and Sensory Characteristics. Foods. 2021; 10(4):899. https://doi.org/10.3390/foods10040899

Chicago/Turabian StyleValdés, María Esperanza, Rosario Ramírez, Manuel Alejandro Martínez-Cañas, Samuel Frutos-Puerto, and Daniel Moreno. 2021. "Accelerating Aging of White and Red Wines by the Application of Hydrostatic High Pressure and Maceration with Holm Oak (Quercus ilex) Chips. Influence on Physicochemical and Sensory Characteristics" Foods 10, no. 4: 899. https://doi.org/10.3390/foods10040899

APA StyleValdés, M. E., Ramírez, R., Martínez-Cañas, M. A., Frutos-Puerto, S., & Moreno, D. (2021). Accelerating Aging of White and Red Wines by the Application of Hydrostatic High Pressure and Maceration with Holm Oak (Quercus ilex) Chips. Influence on Physicochemical and Sensory Characteristics. Foods, 10(4), 899. https://doi.org/10.3390/foods10040899