Physiochemical Responses of the Kernel Quality, Total Phenols and Antioxidant Enzymes of Walnut in Different Forms to the Low-Temperature Storage

Abstract

:1. Introduction

2. Materials and Methods

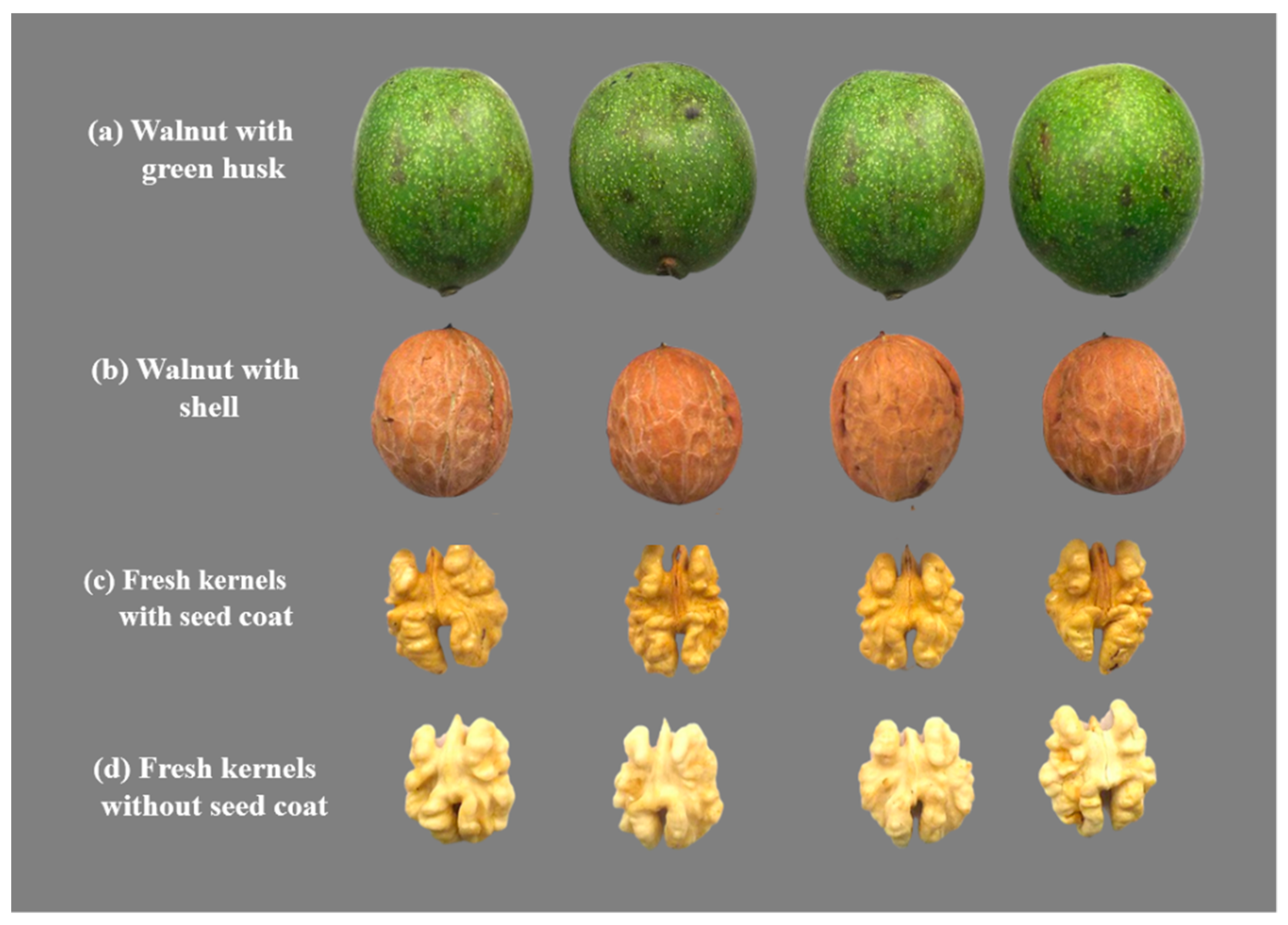

2.1. Plant Material and Treatments

2.2. Relative Electrical Conductivity (REC)

2.3. Total Phenol Analysis

2.4. Antioxidant Activity

2.4.1. Ferric Reducing Antioxidant Power (FRAP) Assay

2.4.2. DPPH Radical Scavenging Activity

2.5. Activities of Antioxidant Enzymes: CAT, SOD, and POD

2.6. Changes of O2−, H2O2, and MDA Contents in Walnut Kernels

2.7. Acid Value (AV) and Peroxide Value (PV)

2.8. Fatty Acids Composition

2.9. Statistical Analysis

3. Results and Discussion

3.1. Relative Electrical Conductivity (REC)

3.2. Total Phenols Content

3.3. Total Antioxidant Activity (TAC)

3.4. SOD, CAT, and POD Activity

3.5. MDA, H2O2, and O2− Production

3.6. Fatty Acid Composition

3.7. Total Fat Content, Acid Value, and Peroxide Value of Walnut Kernels

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- US Department of Agriculture. Available online: www.fdc.nal.usda.gov (accessed on 20th May 2018).

- Jahanbani, R.; Ghaffari, S.M.; Salami, M.; Vahdati, K.; Sepehri, H.; Sarvestani, N.N.; Sheibani, N.; Moosavi-Movahedi, A.A. Antioxidant and Anticancer Activities of Walnut (Juglans regia L.) Protein Hydrolysates Using Different Proteases. Plant Foods Hum. Nutr. 2016, 71, 402–409. [Google Scholar] [CrossRef] [Green Version]

- Regueiro, J.; Sánchez-González, C.; Vallverdú-Queralt, A.; Simal-Gándara, J.; Lamuela-Raventós, R.; Izquierdo-Pulido, M. Comprehensive identification of walnut polyphenols by liquid chromatography coupled to linear ion trap—Orbitrap mass spectrometry. Food Chem. 2014, 152, 340–348. [Google Scholar] [CrossRef]

- Sánchez-González, C.; Ciudad, C.; Noé, V.; Pulido, M.L.I. Health benefits of walnut polyphenols: An exploration beyond their lipid profile. Crit. Rev. Food Sci. Nutr. 2017, 57, 3373–3383. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Estruch, R.; Ros, E.; Salas-Salvadó, J.; Covas, M.-I.; Corella, D.; Arós, F.; Gómez-Gracia, E.; Ruiz-Gutiérrez, V.; Fiol, M.; Lapetra, J.; et al. Primary Prevention of Cardiovascular Disease with a Mediterranean Diet. N. Engl. J. Med. 2013, 368, 1279–1290. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.; Kim, Y.-S.; Lee, J.; Heo, S.; Lee, K.; Choi, S.-W.; Kim, Y. Walnut phenolic extract and its bioactive compounds suppress colon cancer cell growth by regulating colon cancer stemness. Nutrients 2016, 8, 439. [Google Scholar] [CrossRef]

- Shukitt Hale, B.; Thangthaeng, N.; Fisher, D.R.; Bielinski, D.E.; Poulose, S.M. Walnuts improve neuronal and behavioral function in aging. Presented at the Federation of European Nutrition Societies European Nutrition Conference, Boston, MA, USA, 2015. [Google Scholar]

- Ma, Y.; Lu, X.; Liu, X.; Ma, H. Effect of 60Coγ-irradiation doses on nutrients and sensory quality of fresh walnuts during storage. Postharvest Biol. Technol. 2013, 84, 36–42. [Google Scholar] [CrossRef]

- Wang, J.; Li, P.; Gong, B.; Ma, H. Phenol metabolism and preservation of fresh in-hull walnut stored in modified atmosphere packaging. J. Sci. Food Agric. 2017, 97, 5335–5342. [Google Scholar] [CrossRef]

- Wang, J.; Liang, S.; Ma, H.; Zhang, P.; Shi, W. Effects of Ethephon on Fresh In-Husk Walnut Preservation and its Possible Relationship with Phenol Metabolism. J. Food Sci. 2016, 81, C1921–C1927. [Google Scholar] [CrossRef]

- Galetto, C.D.; Verdini, R.A.; Zorrilla, S.; Rubiolo, A.C. Freezing of strawberries by immersion in CaCl2 solutions. Food Chem. 2010, 123, 243–248. [Google Scholar] [CrossRef]

- Liang, D.; Lin, F.; Yang, G.; Yue, X.; Zhang, Q.; Zhang, Z.; Chen, H. Advantages of immersion freezing for quality preservation of litchi fruit during frozen storage. LWT Food Sci. Technol. 2015, 60, 948–956. [Google Scholar] [CrossRef]

- Xin, Y.; Zhang, M.; Adhikari, B. Ultrasound assisted immersion freezing of broccoli (Brassica oleracea L. var. botrytis L.). Ultrason. Sonochemistry 2014, 21, 1728–1735. [Google Scholar] [CrossRef] [PubMed]

- Celli, G.B.; Ghanem, A.; Brooks, M.S.-L. Influence of freezing process and frozen storage on the quality of fruits and fruit products. Food Rev. Int. 2015, 32, 280–304. [Google Scholar] [CrossRef]

- Cheng, L.; Sun, D.W.; Zhu, Z.; Zhang, Z. Emerging techniques for assisting and accelerating food freezing processes: A review of recent research progresses. Crit. Rev. Food Sci. Nutr. 2015, 57, 769–781. [Google Scholar] [CrossRef] [PubMed]

- Aydogdu, A.; Yildiz, E.; Aydogdu, Y.; Sumnu, G.; Sahin, S.; Ayhan, Z. Enhancing oxidative stability of walnuts by using gallic acid loaded lentil flour based electrospun nanofibers as active packaging material. Food Hydrocoll. 2019, 95, 245–255. [Google Scholar] [CrossRef]

- Wang, J.; Wang, J.; Ye, J.; Vanga, S.K.; Raghavan, V. Influence of high-intensity ultrasound on bioactive compounds of strawberry juice: Profiles of ascorbic acid, phenolics, antioxidant activity and microstructure. Food Control 2018, 96, 128–136. [Google Scholar] [CrossRef]

- Benzie, I.; Strain, J. The Ferric Reducing Ability of Plasma (FRAP) as a Measure of “Antioxidant Power”: The FRAP Assay. Anal. Biochem. 1996, 239, 70–76. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Jin, P.; Wang, J.; Gong, H.; Zhang, S.; Zheng, Y. Hot air treatment induces resistance against blue mold decay caused by Penicillium expansum in sweet cherry (Prunus cerasus L.) fruit. Sci. Hortic. 2015, 189, 74–80. [Google Scholar] [CrossRef]

- Lin, Y.; Lin, H.; Zhang, S.; Chen, Y.; Chen, M.; Lin, Y. The role of active oxygen metabolism in hydrogen per-oxide-induced pericarp browning of harvested longan fruit. Postharvest Biol. Technol. 2014, 96, 42–48. [Google Scholar] [CrossRef]

- Chen, H.; Gao, H.; Fang, X.; Ye, L.; Zhou, Y.; Yang, H. Effects of allyl isothiocyanate treatment on postharvest quality and the activities of antioxidant enzymes of mulberry fruit. Postharvest Biol. Technol. 2015, 108, 61–67. [Google Scholar] [CrossRef]

- National Health and Family Planning Commission of the People’s Republic of China. Food Safety National Standard-Determination of Acid in Food; GB/T 5009.229-2016a; Chinese Standard Publication House: Beijing, China, 2016. (In Chinese) [Google Scholar]

- National Health and Family Planning Commission of the People’s Republic of China. Food Safety National Standard-Determination of Peroxide Value in Food; GB/T 5009.229-2016b; Chinese Standard Publication House: Beijing, China, 2016. (In Chinese) [Google Scholar]

- Esteki, M.; Farajmand, B.; Amanifar, S.; Barkhordari, R.; Ahadiyan, Z.; Dashtaki, E.; Vander Heyden, Y. Classification and authentication of Iranian walnuts according to their geographical origin based on gas chroma-tographic fatty acid fingerprint analysis using pattern recognition methods. Chemom. Intell. Lab. Syst. 2017, 171, 251–258. [Google Scholar] [CrossRef]

- Goneli, A.; Corrêa, P.; Resende, O.; Neto, S.R. Electrical Conductivity for Quality Evaluation of Popcorn Kernels subjected to Mechanical Damage. Biosyst. Eng. 2007, 96, 361–367. [Google Scholar] [CrossRef]

- Kaewtathip, T.; Charoenrein, S. Changes in volatile aroma compounds of pineapple (Ananas comosus) during freezing and thawing. Int. J. Food Sci. Technol. 2012, 47, 985–990. [Google Scholar] [CrossRef]

- Ghirardello, D.; Bertolino, M.; Belviso, S.; Dal Bello, B.; Giordano, M.; Rolle, L.; Gerbi, V.; Antonucci, M.; Spigolon, N.; Zeppa, G. Phenolic composition, antioxidant capacity and hexanal content of hazelnuts (Corylus avellana L.) as affected by different storage conditions. Postharvest Biol. Technol. 2016, 112, 95–104. [Google Scholar] [CrossRef] [Green Version]

- Hoang, N.T.; Golding, J.; Wilkes, M.A. The effect of postharvest 1-MCP treatment and storage atmosphere on ‘Cripps Pink’ apple phenolics and antioxidant activity. Food Chem. 2011, 127, 1249–1256. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.-H.; Cai, L.-Y.; Lu, X.-Y.; Han, X.-X.; Ying, T.-J. Effect of Postharvest UV-C Irradiation on Phenolic Compound Content and Antioxidant Activity of Tomato Fruit During Storage. J. Integr. Agric. 2012, 11, 159–165. [Google Scholar] [CrossRef]

- Palafox-Carlos, H.; Yahia, E.; Islas-Osuna, M.; Gutierrez-Martinez, P.; Robles-Sánchez, M.; González-Aguilar, G. Effect of ripeness stage of mango fruit (Mangifera indica L., cv. Ataulfo) on physiological parameters and antioxidant activity. Sci. Hortic. 2012, 135, 7–13. [Google Scholar] [CrossRef]

- Ighodaro, O.; Akinloye, O. First line defence antioxidants-superoxide dismutase (SOD), catalase (CAT) and glutathione peroxidase (GPX): Their fundamental role in the entire antioxidant defence grid. Alex. J. Med. 2018, 54, 287–293. [Google Scholar] [CrossRef] [Green Version]

- Jin, P.; Shang, H.; Chen, J.; Zhu, H.; Zhao, Y.; Zheng, Y. Effect of 1-Methylcyclopropene on Chilling Injury and Quality of Peach Fruit during Cold Storage. J. Food Sci. 2011, 76, S485–S491. [Google Scholar] [CrossRef] [PubMed]

- Song, H.; Yuan, W.; Jin, P.; Wang, W.; Wang, X.; Yang, L.; Zhang, Y. Effects of chitosan/nano-silica on post-harvest quality and antioxidant capacity of loquat fruit during cold storage. Postharvest Biol. Technol. 2016, 119, 41–48. [Google Scholar] [CrossRef]

- Scussel, V.M.; Giordano, B.N.; Simão, V.; Manfio, D.; Galvao, S.; Rodrigues, M.N.F. Effect of Oxygen-Reducing Atmospheres on the Safety of Packaged Shelled Brazil Nuts during Storage. Int. J. Anal. Chem. 2011, 2011, 813591. [Google Scholar] [CrossRef] [PubMed]

- Bai, S.H.; Nevenimo, T.; Hannet, G.; Hannet, D.; Jones, K.; Trueman, S.; Grant, E.; Walton, D.; Randall, B.; Wallace, H. Freezing, roasting and salt dipping impacts on peroxide value, free fatty acid and fatty acid concentrations of nut kernels. Acta Hortic. 2019, 1256, 71–76. [Google Scholar] [CrossRef]

- Krause, A.J.; Miracle, R.E.; Sanders, T.H.; Dean, L.L.; Drake, M.A. The Effect of Refrigerated and Frozen Storage on Butter Flavor and Texture. J. Dairy Sci. 2008, 91, 455–465. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiang, L.; Feng, W.; Li, F.; Xu, J.; Ma, Y.; Ma, H. Effect of One-methylcyclopropene (1-MCP) and chlorine dioxide (ClO2) on preservation of green walnut fruit and kernel traits. J. Food Sci. Technol. 2013, 52, 267–275. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ma, Y.; Li, P.; Watkins, C.B.; Ye, N.; Jing, N.; Ma, H.; Zhang, T. Chlorine dioxide and sodium diacetate treatments in controlled atmospheres retard mold incidence and maintain quality of fresh walnuts during cold storage. Postharvest Biol. Technol. 2020, 161, 111063. [Google Scholar] [CrossRef]

| Storage Time (Month) | Total Phenols (mg/100 g FW) | FRAP (mmol/g FW) | DPPH (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Fresh Kernel | Walnut with Shell | Walnut with Husk | Walnut Kernel | Walnut with Shell | Walnut with Husk | Fresh Kernel | Walnut with Shell | Walnut with Husk | ||

| 0 °C | 0 | 44.23 ± 0.62Ab | 44.23 ± 0.62Ac | 44.23 ± 0.62Ac | 2.92 ± 0.26Ab | 2.92 ± 0.26Ac | 2.92 ± 0.26Ab | 16.09 ± 1.25Ab | 16.09 ±1.25 Ab | 16.09 ± 1.25Ab |

| 1 | 48.55 ± 0.55Ba | 35.77 ± 1.02Cd | 59.62 ± 0.73Ab | 5.67 ± 0.24Aa | 4.31 ± 0.16Aa | 4.16 ± 0.22Aa | 16.68 ± 0.85Bb | 17.48 ± 1.13Bb | 22.42 ± 0.45Aa | |

| 2 | 46.24 ± 1.32ab | 51.35 ± 1.51b | 57.52 ± 0.94Abc | 4.06 ± 0.33Aab | 3.66 ± 0.10Aab | 2.92 ± 0.13Ab | 21.31 ± 1.14Aa | 21.67 ± 1.24Aa | 14.30 ± 1.83Bb | |

| 3 | Na | 65.44 ± 2.11Ba | 72.82 ± 0.88Aa | Na | 4.71 ± 0.11Aa | 4.90 ± 0.15Aa | Na | 20.94 ± 0.70Aa | 23.48 ± 0.77Aa | |

| −20 °C | 1 | 55.00 ± 1.51Bb | 77.43 ± 1.77Aa | 53.00 ± 0.88Bc | 3.94±0.41Aa | 3.97 ± 0.29Aa | 2.57±0.35Ab | 21.29 ± 0.79Aab | 16.27 ± 0.75Ac | 18.46 ± 1.72Ab |

| 2 | 85.36 ± 1.85Aa | 55.98 ± 1.56Bc | 53.84 ± 1.26Bc | 3.73 ± 0.23Aa | 2.94 ± 0.28Ab | 3.21 ± 0.10Aa | 11.44 ± 1.19Bc | 21.04 ± 0.19Ab | 10.83 ± 0.69Bc | |

| 3 | 56.99 ± 1.57Bb | 72.85 ± 2.02Aa | 49.89 ± 2.05Bc | 3.62 ± 0.38Aa | 4.15 ± 0.17Aa | 3.16 ± 0.15Aa | 23.69 ± 0.44Aa | 26.39 ± 0.50Aa | 21.66 ± 0.24Ab | |

| 6 | 47.35 ± 1.47Cc | 66.29 ± 1.73Ab | 52.44 ± 1.54Bc | 3.68 ± 0.46Aa | 3.84 ± 0.29Aab | 2.27 ± 0.29Ab | 24.62 ± 0.46Aa | 21.26 ± 0.06Ab | 18.09 ± 0.36Ab | |

| 8 | 47.48 ± 2.25Cc | 75.89 ± 2.65Ba | 96.10 ± 2.10Aa | 2.99 ± 0.46Aab | 3.19 ± 0.46Ab | 3.12 ± 0.13Aa | 16.68 ± 0.29Ab | 20.72 ± 0.35Ab | 19.96 ± 0.18Ab | |

| 10 | 30.55 ± 1.31Cd | 51.37 ± 1.31Bc | 115.98 ± 0.77Aa | 2.41 ± 0.25Ab | 3.34 ± 0.48Ab | 2.44 ± 0.17Ab | 24.13 ± 1.49Aa | 23.38 ± 0.41Aab | 26.78 ± 1.30Aa | |

| Fatty Acid | Storage Time (Month) | Fatty Acid Composition (%) | ||

|---|---|---|---|---|

| Fresh Kernel | Walnut with Shell | Walnut with Green Husk | ||

| Palmitic acid (16:0) | 0 | 9.21 ± 0.01Aa | 9.21 ± 0.01Aa | 9.21 ± 0.01Aa |

| 3 | 7.86 ± 0.01Ab | 8.62 ± 0.06Aab | 7.46 ± 0.62Ab | |

| 8 | 7.29 ± 0.78Ab | 7.76 ± 0.85Ac | 7.30 ± 0.78Ab | |

| Stearic acid (18:0) | 0 | 2.42 ± 0.16Aa | 2.42 ± 0.16Aa | 2.42 ± 0.16Aa |

| 3 | 2.52 ± 0.01Aa | 2.54 ± 0.14Aa | 2.41 ± 0.04Aa | |

| 8 | 2.08 ± 0.01Aa | 2.03 ± 0.11Aa | 2.18 ± 0.36Aa | |

| Oleic acid (18:1) | 0 | 13.04 ± 0.38Aa | 13.04 ± 0.38Aa | 13.04 ± 0.38Aa |

| 3 | 12.69 ± 0.05Aa | 11.18 ± 0.26Aa | 13.10 ± 0.48Aa | |

| 8 | 13.44 ± 0.62Aa | 14.54 ± 0.28Aa | 13.58 ± 0.62Aa | |

| Linoleic acid (18:2) | 0 | 66.90 ± 0.39Aa | 66.90 ± 0.39Aa | 66.90 ± 0.39Aa |

| 3 | 68.20 ± 0.11Aa | 67.93 ± 0.08Aa | 68.32 ± 0.11Aa | |

| 8 | 68.74 ± 0.03Aa | 67.35 ± 0.93Aa | 67.86 ± 0.45Aa | |

| Linolenic acid (18:3) | 0 | 8.44 ± 0.15Aa | 8.44 ± 0.15Aa | 8.44 ± 0.15Aa |

| 3 | 8.74 ± 0.17Aa | 9.73 ± 0.14Aa | 8.73 ± 0.31Aa | |

| 8 | 8.45 ± 0.01Aa | 8.32 ± 0.26Aa | 9.09 ± 0.01Aa | |

| Polyunsaturated fat (PUFA) | 0 | 75.33 ± 0.92Aa | 75.33 ± 0.92Aa | 75.33 ± 0.92Aa |

| 3 | 76.93 ± 0.48Aa | 77.66 ± 0.69Aa | 77.05 ± 0.18Aa | |

| 8 | 77.19 ± 0.38Aa | 75.66 ± 0.41Aa | 76.95 ± 0.35Aa | |

| Unsaturated fatty acid (UFA) | 0 | 88.37 ± 0.92Aa | 88.37 ± 0.92Aa | 88.37 ± 0.92Aa |

| 3 | 89.62 ± 0.33Aa | 88.83 ± 0.43Aa | 90.14 ± 1.43Aa | |

| 8 | 90.63 ± 0.69Aa | 90.20 ± 1.66Aa | 90.52 ± 1.75Aa | |

| Parameters | Storage Time (Month) | 0 °C | −20 °C | ||||

|---|---|---|---|---|---|---|---|

| Fresh Kernel | Walnut with Shell | Walnut with Green Husk | Fresh Kernel | Walnut with Shell | Walnut with Green Husk | ||

| Fat content (%) | 0 | 54.04 ± 2.05A | 54.04 ± 2.05Aa | 54.04 ± 2.05Aa | 54.04 ± 2.05Aab | 54.04 ± 2.05Aa | 54.04 ± 2.05Aa |

| 3 | Na | 44.16± 2.42Ab | 44.22± 1.93Ab | 56.29 ± 0.86Aa | 48.29 ± 2.98Bb | 50.84 ± 1.05Ba | |

| 8 | 50.48 ± 3.66Ab | 49.50 ± 0.93Ab | 51.33 ± 4.10Aa | ||||

| Acid value (mg/g) | 0 | 0.57 ± 0.11A | 0.57 ± 0.11Ab | 0.57 ±0.11Aa | 0.57 ± 0.11Aa | 0.57 ± 0.11Ab | 0.57 ± 0.11Aa |

| 3 | Na | 0.76 ± 0.16Aa | 0.67 ± 0.03Aa | 0.59 ± 0.01Aa | 0.67 ± 0.20Ab | 0.60 ± 0.05Aa | |

| 8 | 0.61 ± 0.09Ba | 0.84 ± 0.08Aab | 0.68 ± 0.02ABa | ||||

| Peroxide value (mmol/kg) | 0 | 0.59 ± 0.06A | 0.59 ± 0.06Aa | 0.59 ± 0.06Aa | 0.59 ± 0.06Aab | 0.59 ± 0.06Ab | 0.59 ± 0.06Aab |

| 3 | Na | 0.55 ± 0.00Aa | 0.49 ± 0.01Aa | 0.79 ± 0.14Aa | 0.68 ± 0.09Aab | 0.84 ± 0.14Aa | |

| 8 | 0.37 ± 0.06Bb | 0.75 ± 0.10Aa | 0.44 ± 0.07Bb | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Wang, C.; Liu, C.; Tan, J.; Ma, H.; Wang, J. Physiochemical Responses of the Kernel Quality, Total Phenols and Antioxidant Enzymes of Walnut in Different Forms to the Low-Temperature Storage. Foods 2021, 10, 2027. https://doi.org/10.3390/foods10092027

Ma Y, Wang C, Liu C, Tan J, Ma H, Wang J. Physiochemical Responses of the Kernel Quality, Total Phenols and Antioxidant Enzymes of Walnut in Different Forms to the Low-Temperature Storage. Foods. 2021; 10(9):2027. https://doi.org/10.3390/foods10092027

Chicago/Turabian StyleMa, Yanping, Chaoye Wang, Chaobin Liu, Jiawei Tan, Huiling Ma, and Jin Wang. 2021. "Physiochemical Responses of the Kernel Quality, Total Phenols and Antioxidant Enzymes of Walnut in Different Forms to the Low-Temperature Storage" Foods 10, no. 9: 2027. https://doi.org/10.3390/foods10092027

APA StyleMa, Y., Wang, C., Liu, C., Tan, J., Ma, H., & Wang, J. (2021). Physiochemical Responses of the Kernel Quality, Total Phenols and Antioxidant Enzymes of Walnut in Different Forms to the Low-Temperature Storage. Foods, 10(9), 2027. https://doi.org/10.3390/foods10092027