Composting of Olive Mill Pomace, Agro-Industrial Sewage Sludge and Other Residues: Process Monitoring and Agronomic Use of the Resulting Composts

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Design

2.2. Greenhouse Design for Composting Operations

2.3. Compost Turning Machine

- -

- Main bearing frame, made of painted steel, with a drawbar for towing and a hinge for connecting the turning element, supported by two bearing wheels;

- -

- System for the hydraulic adjustment of the free height to the ground;

- -

- Counterweight on the bearing frame;

- -

- Turning device with a length of 1.4 m and a height of 0.8 m, equipped with turning hammers welded to the reel, having the shape of a double opposed helicoid;

- -

- Structure supporting the turning mechanism with a hinge for connection to the mainframe;

- -

- Metal roof and load-bearing lintel;

- -

- Double-acting hydraulic cylinder for overturning the turning element;

- -

- Gearbox for the deviation of the motion to the turning organ;

- -

- Cardan shaft for the connection between the P.T.O. tractor side and the P.T.O. operator side;

- -

- Complete hydraulic system for operating the lifting cylinder of the turning element;

- -

- System for the sprinkling of liquids with an external water connection.

2.4. Sampling and Analytical Methods

2.5. Composting Process

2.6. Microbiological Analyses

2.7. Qualitative and Quantitative Parameters of the Tomato and Durum Wheat Crops

2.8. Statistical Analysis

3. Results and Discussion

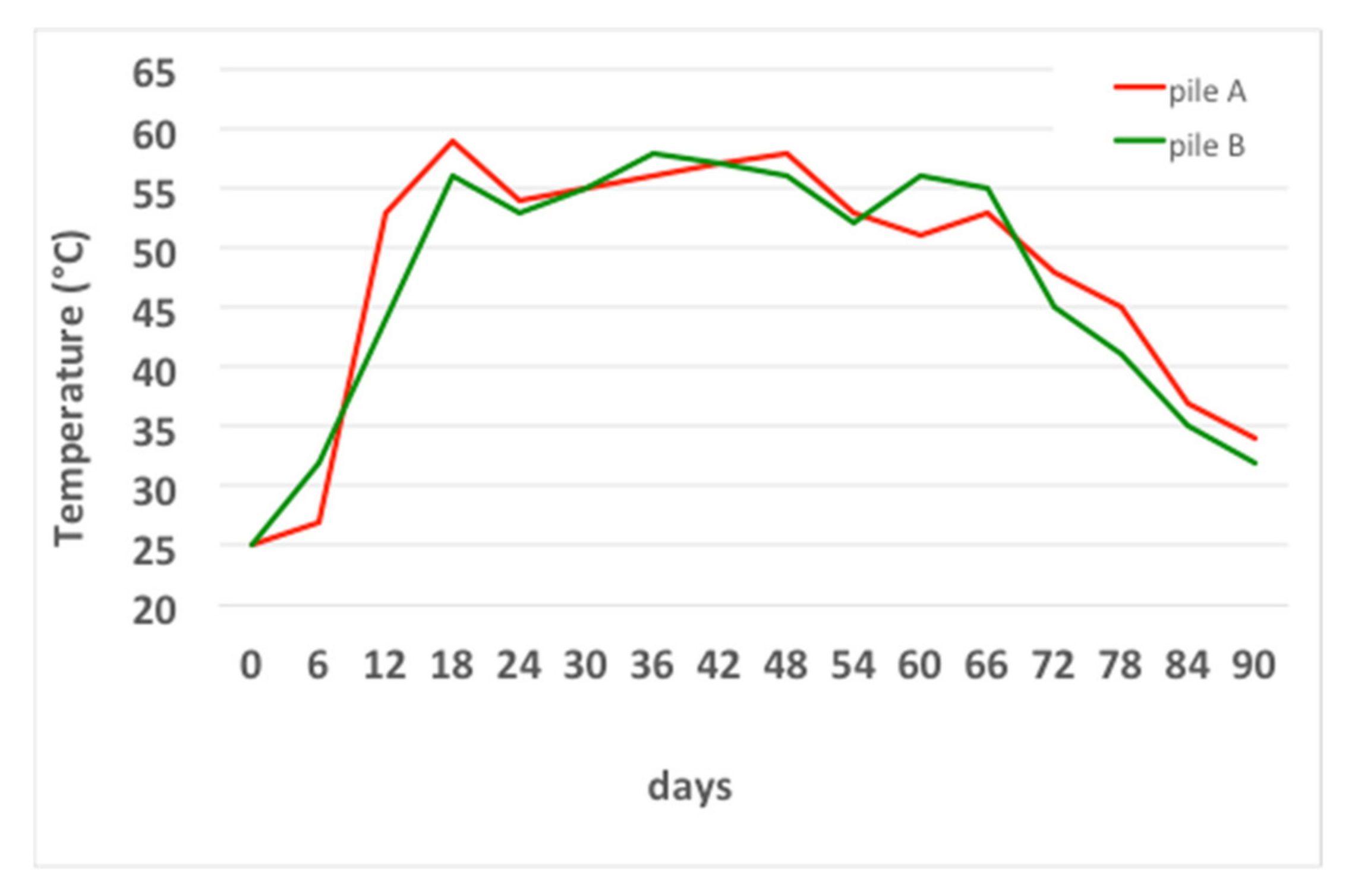

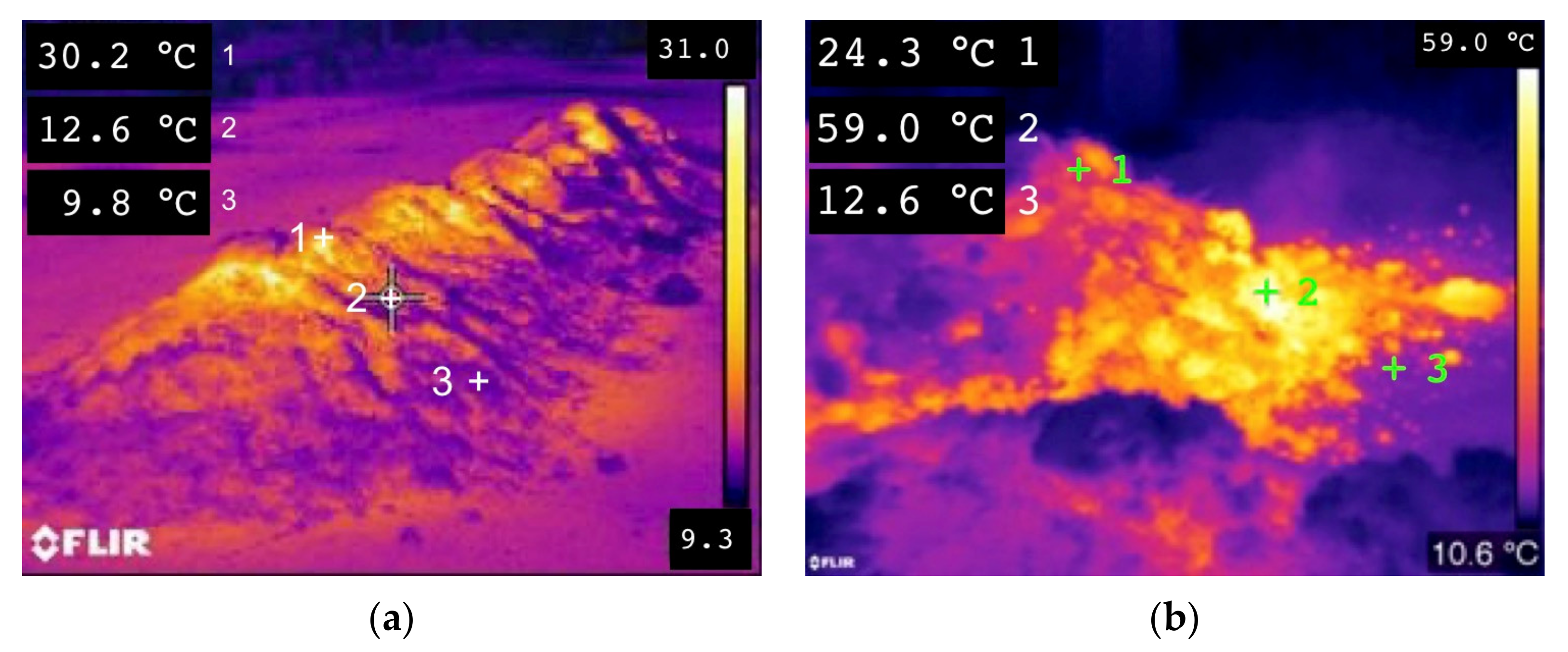

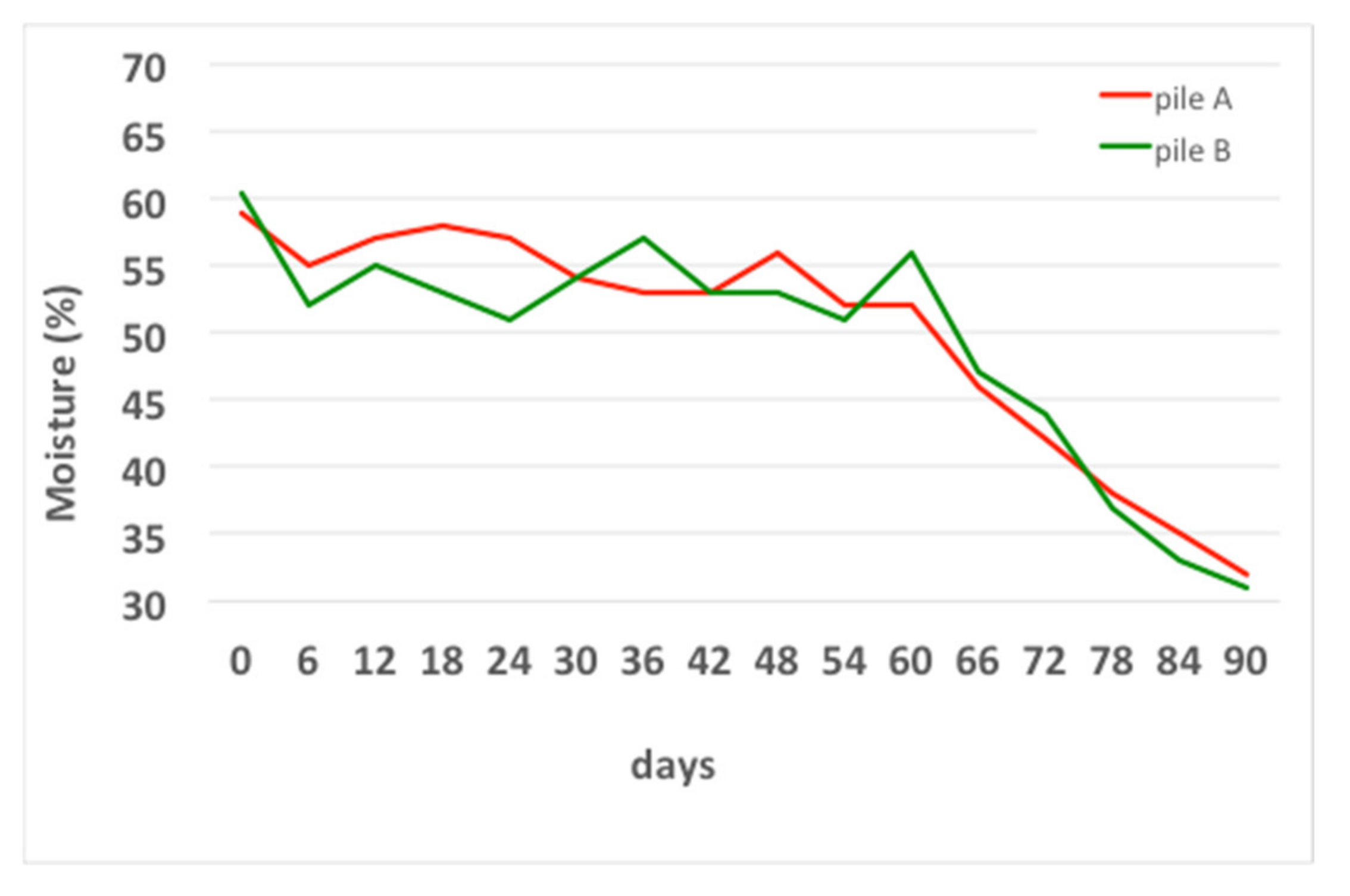

3.1. Temperature and Moisture Trends

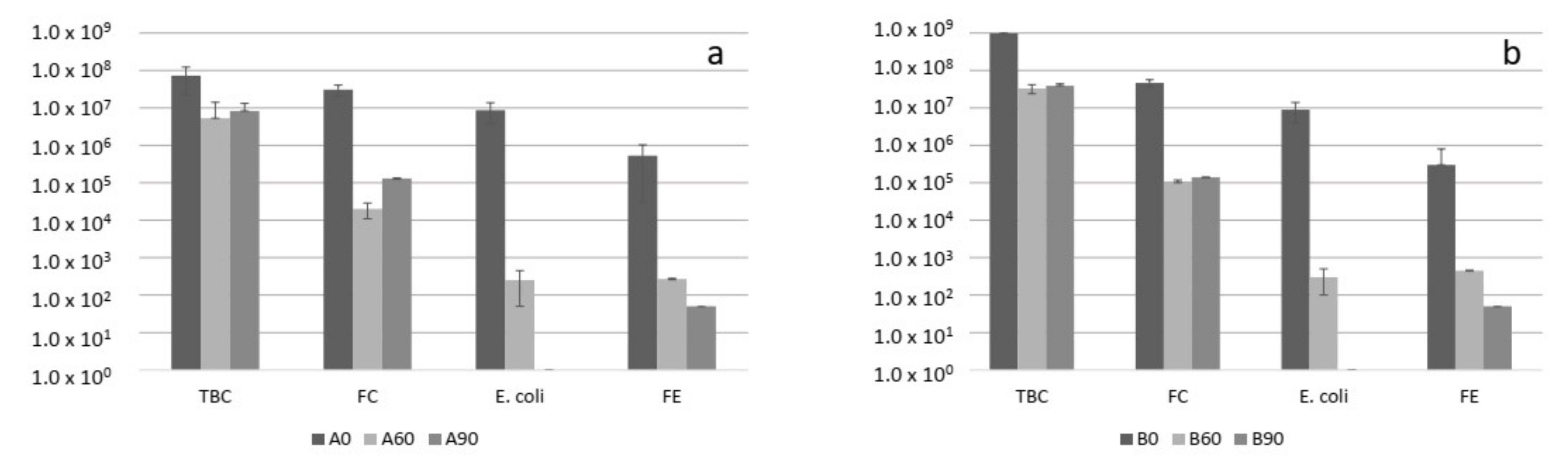

3.2. Microbial Quality of the Produced Compost

3.3. Agronomics Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Alburquerque, J.A.; Gonzálvez, J.; Tortosa, G.; Baddi, G.A.; Cegarra, J. Evaluation of “alperujo” composting based on organic matter degradation, humification and compost quality. Biodegradation 2009, 20, 257–270. [Google Scholar] [CrossRef]

- Bari, Q.; Koenig, A. Effect of air recirculation and reuse on composting of organic solid waste. Resour. Conserv. Recycl. 2001, 33, 93–111. [Google Scholar] [CrossRef]

- Huang, G.F.; Wu, Q.T.; Wong, J.W.C.; Nagar, B.B. Transformation of organic matter during co-composting of pig manure with sawdust. Bioresour. Technol. 2006, 97, 1834–1842. [Google Scholar] [CrossRef]

- Komilis, D.P.; Tziouvaras, I.S. A statistical analysis to assess the maturity and stability of six composts. J. Waste Manag. 2009, 29, 1504–1513. [Google Scholar] [CrossRef]

- Massa, D.; Malorgio, F.; Lazzereschi, S.; Carmassi, G.; Prisa, D.; Burchi, G. Evaluation of two green composts for peat substitution in geranium (Pelargonium zonale L.) cultivation: Effect on plant growth, quality, nutrition, and photosynthesis. Sci. Hortic-Amst. 2018, 228, 213–221. [Google Scholar] [CrossRef]

- Leone, A.; Romaniello, R.; Peri, G.; Tamborrino, A. Development of a new model of olives de-stoner machine: Evaluation of electric consumption and kernel characterization. Biomass Bioenergy 2015, 81, 108–116. [Google Scholar] [CrossRef]

- Karaouzas, I. Spatial and temporal e ects of olive mill wastewaters to stream macroinvertebrates and aquatic ecosystems status. Water Res. 2011, 45, 6334–6346. [Google Scholar] [CrossRef] [PubMed]

- Gil, A.; Toledo, M.; Siles, J.A.; Martín, M.A. Multivariate analysis and biodegrad- ability test to evaluate different organic wastes for biological treatments: Anaerobic co-digestion and co-composting. J. Waste Manag. 2018, 78, 819–828. [Google Scholar] [CrossRef] [PubMed]

- Toledo, M.; Gutiérrez, M.C.; Peña, A.; Siles, J.A.; Martín, M.A. Co-composting of chicken manure, alperujo, olive leaves/pruning, and cereal straw at full-scale: Compost quality assessment and odour emission. Process. Saf. Environ. Prot. 2020, 139, 362–370. [Google Scholar] [CrossRef]

- Khan, N.; Clark, I.; Sánchez-Monedero, M.A.; Shea, S.; Meier, S.; Bolan, N. Matu- rity indices in co-composting of chicken manure and sawdust with biochar. Bioresour. Technol. 2014, 168, 245–251. [Google Scholar] [CrossRef] [PubMed]

- Janczak, D.; Malińska, K.; Czekała, W.; Cáceres, R.; Lewicki, A.; Dach, J. Biochar to reduce ammonia emissions in gaseous and liquid phase during composting of poultry manure with wheat straw. J. Waste Manag. 2017, 66, 36–45. [Google Scholar] [CrossRef] [PubMed]

- Altieri, R.; Esposito, A. Evaluation of the fertilizing effect of olive mill waste compost in short-term crops. Int. Biodeterior. Biodegrad. 2010, 64, 124–128. [Google Scholar] [CrossRef]

- Hachicha, R.; Hachicha, S.; Trabelsi, I.; Woodward, S.; Mechichi, T. Evolution of the fatty fraction during co-composting of olive oil industry wastes with animal manure: Maturity assessment of the end product. Chemosphere 2009, 75, 1382–1386. [Google Scholar] [CrossRef]

- Canet, R.; Pomares, F.; Cabot, B.; Chaves, C.; Ferrer, E.; Ribó, M.; Albiach, M.R. Composting olive mill pomace and other residues from rural southeastern Spain. J. Waste Manag. 2008, 28, 2585–2592. [Google Scholar] [CrossRef]

- Cayuela, M.L.; Sanchez-Monedero, M.A.; Roig, A. Evaluation of two different aeration systems for composting two-phase olive mill wastes. Process. Biochem. 2006, 41, 616–623. [Google Scholar] [CrossRef]

- Asses, N.; Farhat, A.; Cherif, S.; Hamdi, M.; Bouallagui, H. Comparative study of sewage sludge co-composting with olive mill wastes or green residues: Process monitoring and agriculture value of the resulting composts. Process. Saf. Environ. Prot. 2018, 114, 25–35. [Google Scholar] [CrossRef]

- Hachicha, R.; Rekik, O.; Hachicha, S.; Ferchichi, M.; Woodward, S.; Moncef, N.; Cegarra, J.; Mechichi, T. Co-composting of spent coffee ground with olive mill wastewater sludge and poultry manure and effect of Trametes versicolor inoculation on the compost maturity. Chemosphere 2012, 88, 677–682. [Google Scholar] [CrossRef]

- Hachicha, S.; Cegarra, J.; Sellami, F.; Hachicha, R.; Drira, N.; Medhioub, K.; Ammar, E. Elimination of polyphenols toxicity from olive mill wastewater sludge by its co-composting with sesame bark. J. Hazard. Mater. 2009, 161, 1131–1139. [Google Scholar] [CrossRef]

- Aparicio, I.; Santos, J.L.; Alonso, E. Limitation of the concentration of organic pollutants in sewage sludge for agricultural purposes: A case study in South Spain. J. Waste Manag. 2009, 29, 1747–1753. [Google Scholar] [CrossRef]

- Guo, Y.T.; Rene, E.R.; Wang, J.J.; Ma, W.F. Biodegradation of polyaromatic hydrocarbons and the in uence of environmental factors during the co-composting of sewage sludge and green forest waste. Bioresour. Technol. 2020, 297, 122434. [Google Scholar] [CrossRef]

- Mantovia, P.; Baldonib, G.; Toderib, G. Reuse of liquid, dewatered, and composted sewage sludge on agricultural land: Effects of long-term application on soil and crop. Water Res. 2005, 39, 289–296. [Google Scholar] [CrossRef] [PubMed]

- Benitez, E.; Romero, M.; Gomez, M.; Gallardolaro, F.; Nogales, R. Biosolid and biosolid ash as sources of heavy metals in plant–soil system. Water Air Soil Pollut. 2001, 132, 75–87. [Google Scholar] [CrossRef]

- Aggelides, S.M.; Londra, P.A. Effect of compost produced from town wastes and sewage sludge on the physical properties of a loamy and a clay soil. Bioresour. Technol. 2000, 71, 253–259. [Google Scholar] [CrossRef]

- Akrivos, J.; Mamais, D.; Katsara, K.; Andredakis, A.D. Agricultural utilization of lime treated sewage sludge. Water Sci. Technol. 2000, 42, 203–210. [Google Scholar] [CrossRef]

- Du Preez, L.A.; Van der Merwe, W.; Terblanche, J.S. Biosolid management at 18 wastewater treatment plants in South Africa-optimization strategies. Water Sci. Technol. 2000, 42, 7–12. [Google Scholar] [CrossRef]

- Vasseur, L.; Shipley, W.; Ansseau, C. Potential for municipal sewage sludge application on agricultural lands in Southern Quebec. Water Pollut. Res. J. Can. 1999, 34, 469–480. [Google Scholar] [CrossRef]

- Marx, D.H.; Berry, C.R.; Kormanik, P.P. Application of municipal sewage sludge in forest and degraded land. ASA 1995, 38, 275–295. [Google Scholar]

- Dubey, M.; Mohapatra, S.; Tyagi, V.K.; Suthar, S.; Kazmi, A.A. Occurrence, fate, and persistence of emerging micropollutants in sewage sludge treatment. Environ. Pollut. 2021, 273, 116515. [Google Scholar] [CrossRef]

- Patureau, D.; Mailler, R.; Delgenes, N.; Danel, A.; Vulliet, E.; Deshayes, S.; Moilleron, R.; Rocher, V.; Gasperi, J. Fate of emerging and priority micropollutants during the sewage sludge treatment—Part 2: Mass balances of organic contaminants on sludge treatments are challenging. J. Waste Manag. 2021, 125, 122–131. [Google Scholar] [CrossRef]

- Hendrickx, T.L.G.; Elissen, H.J.H.; Buisman, C.J.N. Aquatic worms eating waste sludge in a continuous system. Bioresour. Technol. 2009, 100, 4642–4648. [Google Scholar] [CrossRef]

- Regulation (EU) 2019/1009 of the European Parliament and of the Council of 5 June 2019 laying down rules on the making available on the market of EU fertilising products and amending Regulations (EC) No 1069/2009 and (EC) No 1107/2009 and repealing Regulation (EC) No 2003/2003. Off. J. Eur. Union 2019, 62, L170.

- Alfano, G.; Belli, C.; Lustrato, G.; Ranalli, G. Pile composting of two-phase centrifuged olive husk residues: Technical solutions and quality of cured compost. Bioresour. Technol. 2008, 99, 4694–4701. [Google Scholar] [CrossRef] [PubMed]

- Tomati, U.; Madejon, E.; Galli, E. Evolution of humic add molecular weight as an index of compost stability. Compos. Sci. Util. 2000, 8, 108–115. [Google Scholar] [CrossRef]

- US-EPA Method 3050 B. Risk Assessment Guidance for Superfund; EPA/540/1-89/002, OSWER; EPA: Washington, DC, USA, 1989. [Google Scholar]

- Gatta, G.; Libutti, A.; Gagliardi, A.; Beneduce, L.; Brusetti, L.; Borruso, L.; Disciglio, G.; Tarantino, E. Treated agro-industrial wastewater irrigation of tomato crop: Effects on qualitative/quantitative characteristics of production and microbiological properties of the soil. Agric. Water Manag. 2015, 149, 33–43. [Google Scholar] [CrossRef] [Green Version]

- APAT (Italian Agency for the Environmental Protection). Microbiological Methods for the Analysis of Compost. Manual and Guidelines 20/2013; Laraia, R., Ed.; APAT: Roma, Italy, 2013; ISBN 88-448-0102-7. Available online: https://www.isprambiente.gov.it/contentfiles/00003500/3544-manuali-2003-20.pdf/ (accessed on 24 August 2021).

- Beneduce, L.; Gatta, G.; Bevilacqua, A.; Libutti, A.; Tarantino, E.; Bellucci, M.; Troiano, E.; Spano, G. Impact of the reusing of food manufacturing wastewater for irrigation in a closed system on the microbiological quality of the food crops. Int. J. Food Microbiol. 2017, 260, 51–58. [Google Scholar] [CrossRef]

- AOAC (Official Method of and Analysis). Official Methods of Analysis; Association of Official Analytical Chemists: Washington, DC, USA, 1995. [Google Scholar]

- AOAC (Official Method of and Analysis). Official Method of Analysis; Association of Official Analytical Chemists: Washington, DC, USA, 1990. [Google Scholar]

- Francis, F.J.; Clydesdale, F.M. Food Colorimetry: Theory and Applications; AVI Publishing Co.: Westport, CT, USA, 1975. [Google Scholar]

- Renna, M.; Gonnella, M.; Giannino, D.; Santamaria, P. Quality evaluation of cook-chilled chicory stems (Cichorium intybus L.; Catalogna group) by conventional and sous vide cooking methods. J. Sci. Food Agric. 2014, 94, 656–665. [Google Scholar] [CrossRef]

- Michailides, M.; Christou, G.; Akratos, C.S.; Tekerlekopoulou, A.G.; Vayenas, D.V. Composting of olive leaves and pomace from a three-phase olive mill plant. Int. Biodeterior. Biodegrad. 2011, 65, 560–564. [Google Scholar] [CrossRef]

- Hachicha, S.; Sallemi, F.; Medhioub, K.; Hachicha, R.; Ammar, E. Quality assessment of composts prepared with olive mill wastewater and agricultural wastes. J. Waste Manag. 2008, 28, 2593–2603. [Google Scholar] [CrossRef]

- Baeta-Hall, L.; Sàágua, M.C.; Bartolomev, M.L.; Anselmo, A.M.; Rosa, M.F. Biodegradation of olive oil husks in composting aerated piles. Bioresour. Technol. 2005, 96, 69–78. [Google Scholar] [CrossRef]

- Cayuela, M.L.; Bernal, M.P.; Roig, A. Composting olive mill waste and sheep manure for orchard use. Compos. Sci. Util. 2004, 12, 130–136. [Google Scholar] [CrossRef]

- Gatta, G.; Gagliardi, A.; Disciglio, G.; Lonigro, A.; Francavilla, M.; Tarantino, E.; Giuliani, M.M. Irrigation with treated municipal wastewater on artichoke crop: Assessment of soil and yield heavy metal content and human risk. Water 2018, 10, 255. [Google Scholar] [CrossRef] [Green Version]

- Fernández, F.J.; Sánchez-Arias, V.; Rodríguez, L.; Villaseñor, J. Feasibility of composting combinations of sewage sludge, olive mill waste and winery waste in a rotary drum reactor. J. Waste Manag. 2010, 30, 1948–1956. [Google Scholar] [CrossRef] [PubMed]

- Nartey, E.G.; Amoah, P.; Ofosu-Budu, G.K.; Muspratt, A.; Pradhan, S. Effects of co-composting of faecal sludge and agricultural wastes on tomato transplant and growth. Int. J. Recycl. Org. Waste Agric. 2017, 6, 23–36. [Google Scholar] [CrossRef]

- Joshua, B.; Gurtler, M.P.; Doyle, M.C.; Erickson, X.J.; Patricia Millner, M.S. Composting to Inactivate Foodborne Pathogens for Crop Soil Application: A Review. J. Food Prot. 2018, 81, 1821–1837. [Google Scholar] [CrossRef]

- Manga, M.; Camargo-Valero, M.A.; Anthonj, C.; Evans, B.E. Fate of faecal pathogen indicators during faecal sludge composting with different bulking agents in tropical climate. Int. J. Hyg. Environ. Health 2021, 232, 113670. [Google Scholar] [CrossRef] [PubMed]

- Arshad, M.; Khalid, A.; Mahmood, M.H.; Zahir, Z.A. Potential of nitrogen and L-tryptophan enriched compost for improving growth and yield of hybrid maize. Pak. J. Agric. Sci. 2004, 41, 16–24. [Google Scholar]

- Kindred, D.R.; Verhoeven, T.M.O.; Weightman, R.M.; Swanston, J.S.; Agu, R.C.; Brosnan, J.M.; Sylvester-Bradley, R. Effects of variety and fertiliser nitrogen on alcohol yield, grain yield, starch and protein content, and protein composition of winter wheat. J. Cereal Sci. 2008, 48, 46–57. [Google Scholar] [CrossRef]

- Johansson, E.; Prieto-Linde, M.L.; Svensson, G. Influence of nitrogen application rate and timing on grain protein composition and gluten strength in Swedish wheat cultivars. J. Plant Nutr. Soil Sci. 2004, 167, 345–350. [Google Scholar] [CrossRef]

- Johansson, E.; Kuktaite, R.; Andersson, A.; Prieto-Linde, M.L. Protein polymer build-up during wheat grain development: Influences of temperature and nitrogen timing. J. Sci. Food Agric. 2005, 85, 473–479. [Google Scholar] [CrossRef]

- Cheuk, W.; Lo, K.V.; Fraser, B. Use of composted greenhouse waste as a growing medium component will contribute to a sustainable waste management solution for vegetable greenhouses. Biol. Agric. Hortic. 2003, 21, 321–335. [Google Scholar] [CrossRef]

- Sarwar, G.; Hussain, N.; Schmeisky, H.; Muhammad, S. Use of compost an environment friendly technology for enhancing rice-wheat production in Pakistan. Pak. J. Bot. 2007, 39, 1553–1558. [Google Scholar]

- Abedi, T.; Alemzadeh, A.; Kazemeini, S.A. Effect of organic and inorganic fertilizers on grain yield and protein banding pattern of wheat. Aust. J. Crop Sci. 2010, 4, 384–389. [Google Scholar]

- Carucci, F.; Gatta, G.; Gagliardi, A.; De Vita, P.; Giuliani, M.M. Strobilurin effects on nitrogen use efficiency for the yield and protein in durum wheat grown under rainfed mediterranean conditions. J. Agron. 2020, 10, 1508. [Google Scholar] [CrossRef]

- Gagliardi, A.; Carucci, F.; Masci, S.; Flagella, Z.; Gatta, G.; Giuliani, M.M. Effects of genotype, growing season and nitrogen level on gluten protein assembly of durum wheat grown under Mediterranean conditions. J. Agron. 2020, 10, 755. [Google Scholar] [CrossRef]

| Parameter | Value (m) |

|---|---|

| Eaves Height | 2.50 |

| Ridge height | 4.50 |

| Distance between the pillars | 1.50 |

| Width | 8.00 |

| Length | 19.50 |

| Analytical and Calculated Characteristics | OMP | SS | AR | WS |

|---|---|---|---|---|

| MOISTURE % | 65.0 | 84.0 | 82.1 | 7.0 |

| TOTAL ORGANIC CARBON (TOC) (%) | 47.2 | 27.1 | 2.2 | 44.0 |

| TOTAL NITROGEN (TN) (%) | 0.87 | 4.7 | 40.4 | 0.5 |

| C/N RATIO | 54.25 | 5.7 | 19.4 | 88.0 |

| Matrix | Pile A | Pile B |

|---|---|---|

| OLIVE MILL POMACE (OMP) | 50.0% | 60.0% |

| SEWAGE SLUDGE (SS) | 40.0% | 25.0% |

| ARTICHOKE RESIDUES (AR) | 8.5% | 13.5% |

| WHEAT STRAW (WS) | 1.5% | 1.5% |

| TOTAL WEIGHT OF THE PILE (KG) | 4400 | 4200 |

| Analytical and Calculated Characteristics | Pile A | Pile B |

|---|---|---|

| PH (1:25) | 6.9 | 6.6 |

| MOISTURE % | 58.8 | 60.4 |

| C/N RATIO | 21.4 | 28.2 |

| HA + FA | 14.3 | 16.1 |

| TR1 | TR2 | TR3 | TR4 | TR5 |

|---|---|---|---|---|

| processing tomato | ||||

| Control (unfertilized) | Compost A 1.5 kg/m2 | Compost B 1.5 kg/m2 | Compost A (0.75 kg/m2) + Mineral fertilization (8.0 g N/m2; 16.0 g P2O5/m2) | Mineral fertilization (16.0 g N/m2; 16.0 g P2O5/m2) |

| durum wheat | ||||

| Control (unfertilized) | Compost A (0.78 kg/m2) | Compost B (1.25 kg/m2) | Compost A (0.38 kg/m2) + Mineral fertilization (5.3 g N/m2; 4.6 g P2O5/m2) | Mineral fertilization (10.6 g N/m2; 9.2 g P2O5/m2) |

| Parameter | Pile A | Pile B | ||||

|---|---|---|---|---|---|---|

| Day 1 | Day 60 | Day 90 | Day 1 | Day 60 | Day 90 | |

| Physical parameters | ||||||

| pH (1:25) | 6.9 | 8.2 | 7.7 | 6.6 | 7.9 | 7.3 |

| Temperature (°C) | 25.1 | 56.5 | 34.2 | 25.3 | 58.7 | 32.1 |

| Moisture (%, w/w) | 58.8 | 53.7 | 32.4 | 60.4 | 57.2 | 31.6 |

| C/N ratio (-) | 21.4 | 18.5 | 12.9 | 28.2 | 21.6 | 15.1 |

| HA + FA (% of organic matter) | 14.3 | 19.2 | 20.4 | 16.1 | 23.2 | 24.1 |

| Macro-micronutrients† | ||||||

| P2O5 (mg/kg dw) †† | 301 | 189 | ||||

| N-NO3 (mg/kg dw) | 189.2 | 168.0 | ||||

| N-NH4 (mg/kg dw) | 50.0 | 39.2 | ||||

| N total (g/100 g dw) | 2.4 | 2.1 | ||||

| K (g/100 g dw) | 1214.9 | 816.4 | ||||

| Ca (g/100 g dw) | 1609.3 | 1980.6 | ||||

| Mg (g/100 g dw) | 357.5 | 334.5 | ||||

| Na (g/100 g dw) | 1990.7 | 1405.8 | ||||

| Heavy metal† | ||||||

| Cd (g/100 g dw) | nd | nd | ||||

| Cr (g/100 g dw) | nd | nd | ||||

| Ni (g/100 g dw) | 3.5 | 1.8 | ||||

| Pb (g/100 g dw) | 7.2 | 3.3 | ||||

| Cu (g/100 g dw) | 41.5 | 20.1 | ||||

| Zn (g/100 g dw) | 80.3 | 60.4 | ||||

| Compost Pile | Day 0 | Day 60 | Day 90 | |||

|---|---|---|---|---|---|---|

| A | B | A | B | A | B | |

| Salmonella spp. | + | + | - | - | - | - |

| Listeria monocytogenes | + | + | - | - | - | - |

| E. coli O157:H7 | - | - | - | - | - | - |

| Parameter | Fertilization Treatment | ||||

|---|---|---|---|---|---|

| TR1 | TR2 | TR3 | TR4 | TR5 | |

| Total yield (kg/plant) | 1.71 b | 1.89 b | 1.88 b | 2.51 a | 2.73 a |

| Marketable yield (kg/plant) | 1.45 c | 1.74 bc | 1.77 bc | 2.32 ab | 2.48 a |

| Discarded yield (kg/plant) | 0.25 a | 0.15 bc | 0.11 c | 0.19 abc | 0.21 ab |

| Production Parameter | Compared Theses | ||||

|---|---|---|---|---|---|

| TR1 | TR2 | TR3 | TR4 | TR5 | |

| Dry matter (% fw) † | 5.78 a | 5.51 a | 5.81 a | 5.97 a | 6.00 a |

| Mean weight (g) | 64.20 b | 64.66 b | 68.10 ab | 70.34 ab | 73.67 a |

| Polar diameter (mm) | 61.00 b | 65.00 b | 67.33 ab | 69.32 ab | 70.10 a |

| Equatorial diameter (mm) | 30.76 c | 33.00 bc | 35.66 abc | 39.00 ab | 42.00 a |

| pH (-) | 4.20 a | 4.07 a | 4.40 a | 4.36 a | 4.60 a |

| Soluble Solid Content (°Brix) | 4.78 a | 4.89 a | 4.96 a | 5.02 a | 5.10 a |

| Titratable acidity (g citric acid 100 mL−1 fresh juice) | 0.30 a | 0.28 a | 0.32 a | 0.31 a | 0.33 a |

| Color index (a/b) †† | 0.90 b | 1.08 a | 1.02 a | 1.15 a | 1.17 a |

| Treatment | Plant Height (cm) | Ear Length (cm) | Spiklet (n) | Kernel/Ear (n) | Thousand Kernel Weight (g) |

|---|---|---|---|---|---|

| TR1 | 50.8 b | 5.2 b | 11.0 b | 16.6 b | 43.9 a |

| TR2 | 57.6 ab | 6.1 b | 11.6 b | 23.6 ab | 46.7 a |

| TR3 | 53.8 b | 6.2 b | 12.3 b | 23.7 ab | 50.9 a |

| TR4 | 63.4 ab | 6.5 ab | 12.3 b | 24.3 ab | 43.5 a |

| TR5 | 69.2 a | 7.6 a | 16.0 a | 31.3 a | 44.5 a |

| Treatment | Proteins | Calcium | Potassium | Magnesium | Sodium |

|---|---|---|---|---|---|

| % dw † | [mg/kg fw ††] | [mg/kg fw ††] | [mg/kg fw ††] | [mg/kg fw ††] | |

| TR1 | 9.1 c | 453.5 a | 3651.2 a | 589.9 a | 134.6 a |

| TR2 | 9.7 b | 419.7 a | 4077.2 a | 610.1 a | 193.7 a |

| TR3 | 10.2 b | 403.1 a | 3323.7 a | 597.7 a | 156.7 a |

| TR4 | 11.9 ab | 347.7 a | 3259.0 a | 654.3 a | 152.8 a |

| TR5 | 12.1 a | 664.6 a | 3946.1 a | 724.0 a | 169.8 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leone, A.; Romaniello, R.; Tamborrino, A.; Beneduce, L.; Gagliardi, A.; Giuliani, M.; Gatta, G. Composting of Olive Mill Pomace, Agro-Industrial Sewage Sludge and Other Residues: Process Monitoring and Agronomic Use of the Resulting Composts. Foods 2021, 10, 2143. https://doi.org/10.3390/foods10092143

Leone A, Romaniello R, Tamborrino A, Beneduce L, Gagliardi A, Giuliani M, Gatta G. Composting of Olive Mill Pomace, Agro-Industrial Sewage Sludge and Other Residues: Process Monitoring and Agronomic Use of the Resulting Composts. Foods. 2021; 10(9):2143. https://doi.org/10.3390/foods10092143

Chicago/Turabian StyleLeone, Alessandro, Roberto Romaniello, Antonia Tamborrino, Luciano Beneduce, Anna Gagliardi, Marcella Giuliani, and Giuseppe Gatta. 2021. "Composting of Olive Mill Pomace, Agro-Industrial Sewage Sludge and Other Residues: Process Monitoring and Agronomic Use of the Resulting Composts" Foods 10, no. 9: 2143. https://doi.org/10.3390/foods10092143

APA StyleLeone, A., Romaniello, R., Tamborrino, A., Beneduce, L., Gagliardi, A., Giuliani, M., & Gatta, G. (2021). Composting of Olive Mill Pomace, Agro-Industrial Sewage Sludge and Other Residues: Process Monitoring and Agronomic Use of the Resulting Composts. Foods, 10(9), 2143. https://doi.org/10.3390/foods10092143