Relationship between Inherent Cooking Rate and Warner-Bratzler Shear Force of Pork Chops Cooked to Two Degrees of Doneness

Abstract

:1. Introduction

2. Materials and Methods

2.1. Federally Inspected Abattoir Slaughter and Loin Selection

2.2. Aged Postmortem Loin Quality Evaluation

2.3. Cooking Procedures, Temperature, Cooking Loss and Warner-Bratzler Shear Force

2.4. Statistical Analyses

3. Results and Discussion

3.1. Correlations among Cooking Rate, Quality Factors and Chop Characteristics

3.2. Relationships among Cooking Rate, Cooking Loss, and Warner-Bratzler Shear Force

3.3. Prediction of Tenderness Using Quality Traits and Cooking Rate

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statements

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Maltin, C.; Balcerzak, D.; Tilley, R.; Delday, M. Determinants of meat quality: Tenderness. Proc. Nutr. Soc. 2003, 62, 337–347. [Google Scholar] [CrossRef]

- Boler, D.D.; McKeith, F.K.; Puls, C.L.; Ellis, M.; Wood-Follis, S.L.; Miller, R.W.; Vanimisetti, H.B.; Moseley, W.M.; Schroeder, A.L.; Dilger, A.C. Effects of generic ractopamine (Engain) on the growth performance, carcass characteristics, meat quality, and cutablity of finishing barrows and gilts. Prof. Anim. Sci. 2014, 30, 625–636. [Google Scholar] [CrossRef]

- Harsh, B.N.; Arkfeld, E.K.; Mohrhauser, D.A.; King, D.A.; Wheeler, T.L.; Dilger, A.C.; Shackelford, S.D.; Boler, D.D. Effect of hot carcass weight on loin, ham, and belly quality from pigs sourced from a commerical processing facility. J. Anim. Sci. 2017, 95, 4958–4970. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Price, H.E.; Lerner, A.B.; Rice, E.A.; Lowell, J.E.; Harsh, B.N.; Barkley, K.E.; Honegger, L.T.; Richardson, E.; Woodworth, J.C.; Tokach, M.D.; et al. Characterizing ham and loin quality as hot carcass weight increases to an average of 119 kilograms. Meat Musc. Biol. 2019, 3, 330–343. [Google Scholar] [CrossRef] [Green Version]

- Overholt, M.F.; Arkfeld, E.K.; Bryan, E.E.; King, D.A.; Wheeler, T.L.; Dilger, A.C.; Shackelford, S.D.; Boler, D.D. Effect of hot carcass weight on the rate of temperature decline of pork hams and loins in a blast-chilled commercial abattoir. J. Anim. Sci. 2019, 97, 2441–2449. [Google Scholar] [CrossRef] [PubMed]

- Redifer, J.D.; Beever, J.E.; Stahl, C.A.; Boler, D.D.; Dilger, A.C. Characterizing the amount and variability of intramuscular fat deposition throughout pork loins using barrows and gilts from two sire lines. J. Anim. Sci. 2020, 98, skaa275. [Google Scholar] [CrossRef]

- Yancey, J.W.S.; Wharton, M.D.; Apple, J.K. Cookery method and end-point temperature can affect the Warner-Bratzler shear force, cooking loss, and internal cooked color of beef longissimus steaks. Meat Sci. 2011, 88, 1–7. [Google Scholar] [CrossRef]

- Vittadini, E.; Rinaldi, M.; Chiavaro, E.; Barbanti, D.; Massini, R. The effect of different convection cooking methods on the instrumental quality and yield of pork Longissimus dorsi. Meat Sci. 2005, 69, 749–756. [Google Scholar] [CrossRef]

- Ángel-Rendón, S.V.; Filomena-Ambrosio, A.; Hernández-Carrión, M.; Llorca, E.; Hernando, I.; Quiles, A.; Sotelo-Díaz, I. Pork meat prepared by different cooking methods. A microstructural, sensorial and physicochemical approach. Meat Sci. 2020, 163, 108089. [Google Scholar] [CrossRef]

- O’Neill, C.M.; Cruz-Romero, M.C.; Duffy, G.; Kerry, J.P. Comparative effect of different cooking methods on the physicochemical and sensory characteristics of high pressure processed marinated pork chops. Innov. Food Sci. Emerg. 2019, 54, 19–27. [Google Scholar] [CrossRef]

- Tavman, I.H.; Tavman, S. Measurement of thermal conductivty of dairy products. J. Food. Eng. 1999, 41, 109–114. [Google Scholar] [CrossRef]

- Klinkner, B.T. National Retail Benchmarking Study: Characterizizing Pork Quality Attributes of Multiple Cuts in the Self-Serve Meat Case. Master’s Thesis, North Dakota State University, Fargo, ND, USA, 2013. [Google Scholar]

- Gaffield, K.N.; Schunke, E.D.; Lowell, J.E.; Dilger, A.C.; Harsh, B.N. Evaluation of the changes in composition of pork chops during cooking. Transl. Anim. Sci. 2020, 4, 1–6. [Google Scholar] [CrossRef] [PubMed]

- USDA. Cooking Meat? Check New Recommended Temperatures. Available online: https://www.usda.gov/media/blog/2011/05/25/cooking-meat-check-new-recommended-temperatures (accessed on 23 December 2021).

- NAMI. NAMP Meat Buyer’s Guide, 8th ed.; North American Meat Institute: Washington, DC, USA, 2014. [Google Scholar]

- Lowell, J.E.; Overholt, M.F.; Harsh, B.N.; Stahl, C.A.; Dilger, A.C.; Boler, D.D. Relationships among early postmortem loin quality and aged loin and pork chop quality characteristics between barrows and gilts. Transl. Anim. Sci. 2017, 1, 607–619. [Google Scholar] [CrossRef]

- CIE. Official Recommendations on Uniform Colour Space, Colour Difference Equations and Metric Colour Terms; Publication No. 15, E-1.3.1, Suppl. 2.; Commission Internationale de l’Eclairage: Vienna, Austria, 1976. [Google Scholar]

- NPPC. Official Color and Marbling Standards; National Pork Producers Council: Des Moines, IA, USA, 1999. [Google Scholar]

- NPPC. Procedures to Evaluate Market Hogs, 3rd ed.; National Pork Producers Council: Des Moines, IA, USA, 1991. [Google Scholar]

- AOAC International. Official Methods of Analysis, 16th ed.; AOAC. Int.: Arlington, VA, USA, 1995. [Google Scholar]

- Novakofski, J.; Park, S.; Bechtel, P.J.; McKeith, F.K. Composition of cooked pork chops. Effect of removing subcutaneous fat before cooking. J. Food Sci. 1989, 54, 15–17. [Google Scholar] [CrossRef]

- Taylor, R. Interpretation of the Correlation Coefficient: A Basic Review. J. Dian. Med. Sonogr. 1990, 6, 35–39. [Google Scholar] [CrossRef]

- Arkfeld, E.K.; Mohrhauser, D.A.; King, D.A.; Wheeler, T.L.; Dilger, A.C.; Shackelford, S.D.; Boler, D.D. Characterization of variability in pork carcass composition and primal quality. J. Anim. Sci. 2017, 95, 697–708. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Heldman, D.R. Heat transfer in meat. In Proceedings of the 28th Reciprocal Meats Conference, Columbia, MO, USA, 15–18 June 1975. [Google Scholar]

- Goñi, S.M.; Salvadori, V.O. Prediction of cooking times and weight losses during meat roasting. J. Food Eng. 2010, 100, 1–11. [Google Scholar] [CrossRef]

- Hasgall, P.A.; Di Gennaro, F.; Baumgartner, C.; Neufeld, E.; Lloyd, B.; Gosselin, M.C.; Payne, D.; Klingenböck, A.; Kuster, N. IT’IS Database for Thermal and Electromagnetic Parameters of Biological Tissues, Version 4.0; IT’IS Foundation: Zurich, Switzerland, 2018. [Google Scholar] [CrossRef]

- ASTM F2925–11; Standard Specification for Tenderness Marketing Claims Associated with Meat Cuts Derived from Beef; ASTM International: West Conshohocken, PA, USA, 2018. [CrossRef]

- Aaslyng, M.D.; Bejerholm, C.; Ertbjerg, P.; Bertram, H.C.; Andersen, H.J. Cooking loss and juiciness of pork in relation to raw meat quality and cooking procedure. Food Qual. Prefer. 2003, 14, 277–288. [Google Scholar] [CrossRef]

- Bryan, E.E.; Smith, B.N.; Dilger, R.N.; Dilger, A.C.; Boler, D.D. A method for detection of differences in cook loss and tenderness of aged pork chops cooked to differing degrees of doneness using sous-vide. J. Anim. Sci. 2019, 97, 3348–3353. [Google Scholar] [CrossRef] [PubMed]

- Bouton, P.E.; Ford, A.L.; Harris, P.V.; Ratcliff, D. Objective -subjective assessment of meat tenderness. J. Texture Stud. 1975, 6, 315–328. [Google Scholar] [CrossRef]

- Huff-Lonergan, E.; Baas, T.J.; Malek, M.; Dekkers, J.C.M.; Prusa, K.; Rothschild, M.F. Correlations among selected pork quality traits. J. Anim. Sci. 2002, 80, 617–627. [Google Scholar] [CrossRef] [Green Version]

- Boler, D.D.; Dilger, A.C.; Bidner, B.S.; Carr, S.N.; Eggert, J.M.; Day, J.W.; Ellis, M.; McKeith, F.K.; Killefer, J. Ultimate pH explains variation in pork quality traits. J. Muscle Foods 2010, 21, 119–130. [Google Scholar] [CrossRef]

- Dilger, A.C.; Rincker, P.J.; Eggert, J.M.; McKeith, F.K.; Killefer, J. Pork tenderness and postmortem tenderization: Correlations with meat quality traits and the impact of sire line. J. Muscle Foods 2010, 21, 529–544. [Google Scholar] [CrossRef]

- Richardson, E.L.; Fields, B.; Dilger, A.C.; Boler, D.D. The effects of ultimate pH and color on sensory traits of pork loins cooked to a medium-rare degree of doneness. J. Anim. Sci. 2018, 96, 3768–3776. [Google Scholar] [CrossRef] [PubMed]

- Lonergan, S.M.; Stalder, K.J.; Huff-Lonergan, E.; Knight, T.J.; Goodwin, R.N.; Prusa, K.J.; Beitz, D.C. Influence of lipid content on pork sensory quality within pH classification. J. Anim. Sci. 2007, 85, 1074–1079. [Google Scholar] [CrossRef] [PubMed]

- Norman, J.L.; Berg, E.P.; Heymann, H.; Lorenzen, C.L. Pork loin color relative to sensory and instrumental tenderness and consumer acceptance. Meat Sci. 2003, 65, 927–933. [Google Scholar] [CrossRef]

- Honegger, L.T.; Richardson, E.; Schunke, E.D.; Dilger, A.C.; Boler, D.D. Final internal cooking temperature of pork chops influenced consumer eating experience more than visual color and marbling or ultimate pH. J. Anim. Sci. 2019, 97, 2460–2467. [Google Scholar] [CrossRef] [PubMed]

- Klehm, B.J.; King, D.A.; Dilger, A.C.; Shackelford, S.D.; Boler, D.D. Effect of packaging type during postmortem aging and degree of doneness on pork chop sensory traits of loins selected to vary in color and marbling. J. Anim. Sci. 2018, 96, 1736–1744. [Google Scholar] [CrossRef]

- Overholt, M.F.; Klehm, B.J.; King, D.A.; Dilger, A.C.; Shackelford, S.D.; Boler, D.D. Ability of early postmortem traits to predict sensory quality of pork loin chops may depend on degree-of-doneness. Meat Musc. Biol. 2018, 2, 108. [Google Scholar] [CrossRef]

- Lepetit, J. Collagen contribution to meat toughness. Theoretical aspectis. Meat Sci. 2008, 80, 960–967. [Google Scholar] [CrossRef] [PubMed]

- Berry, B.W.; Smith, G.C.; Carpenter, Z.L. Relationships of certain muscle, cartilage and bone traits to tenderness of the beef longissimus. J. Food Sci. 1974, 39, 819–824. [Google Scholar] [CrossRef]

- Seideman, S.C. Methods of expressing collagen characteristics and their relationship to meat tenderness and muslce fiber types. J. Food Sci. 1986, 51, 273–276. [Google Scholar] [CrossRef]

- Wheeler, T.L.; Shackelford, S.D.; Koohmaraie, M. Variation in proteolysis, sarcomere length, collagen content, and tenderness among major pork muslces. J. Anim. Sci. 2000, 78, 958–965. [Google Scholar] [CrossRef] [PubMed]

- Gondret, F.; Lefaucheur, L.; Juin, H.; Louveau, I.; Lebret, B. Low birth weight is associated with enlarged muscle fiber area and impaired meat tenderness of the longissimus muslce in pigs. J. Anim. Sci. 2006, 84, 93–103. [Google Scholar] [CrossRef] [PubMed]

| Variable | N | Mean | SD | Minimum | Maximum | CV | |

|---|---|---|---|---|---|---|---|

| Loin Quality | |||||||

| pH, 14d | 503 | 5.59 | 0.08 | 5.39 | 6.02 | 1.41 | |

| NPPC subjective quality, 14d | |||||||

| Color | 503 | 3.47 | 0.52 | 2.5 | 5.0 | 14.89 | |

| Marbling | 503 | 2.39 | 0.72 | 1.0 | 5.0 | 30.18 | |

| Firmness | 503 | 2.78 | 0.40 | 1.5 | 3.5 | 14.23 | |

| Moisture, % | 405 | 74.15 | 0.79 | 71.34 | 76.38 | 1.06 | |

| Extractable lipid, % | 405 | 2.37 | 0.77 | 0.61 | 5.44 | 32.32 | |

| Japanese color score | 503 | 2.61 | 0.66 | 1.0 | 5.0 | 25.02 | |

| Instrumental loin color, 14d 1 | |||||||

| Lightness (L*) | 503 | 47.02 | 2.92 | 37.05 | 54.65 | 6.20 | |

| Redness (a*) | 503 | 6.91 | 1.12 | 4.17 | 11.69 | 16.20 | |

| Yellowness (b*) | 503 | 5.09 | 1.16 | 1.34 | 8.84 | 22.81 | |

| Purge loss (%), 14 d | 503 | 1.77 | 1.26 | 0.08 | 9.73 | 71.26 | |

| Cooked Traits, 63 °C | |||||||

| Initial temperature, 63 °C | 503 | 4.73 | 1.3 | 0.3 | 11.8 | 27.37 | |

| Off-grill temperature, 63 °C | 503 | 63.08 | 0.27 | 63.0 | 67.2 | 0.43 | |

| Final rest temperature, 63 °C | 503 | 66.09 | 1.08 | 63.0 | 70.0 | 1.63 | |

| Cooking time 2, 63 °C, min | 503 | 19.75 | 2.83 | 13.54 | 30.32 | 14.35 | |

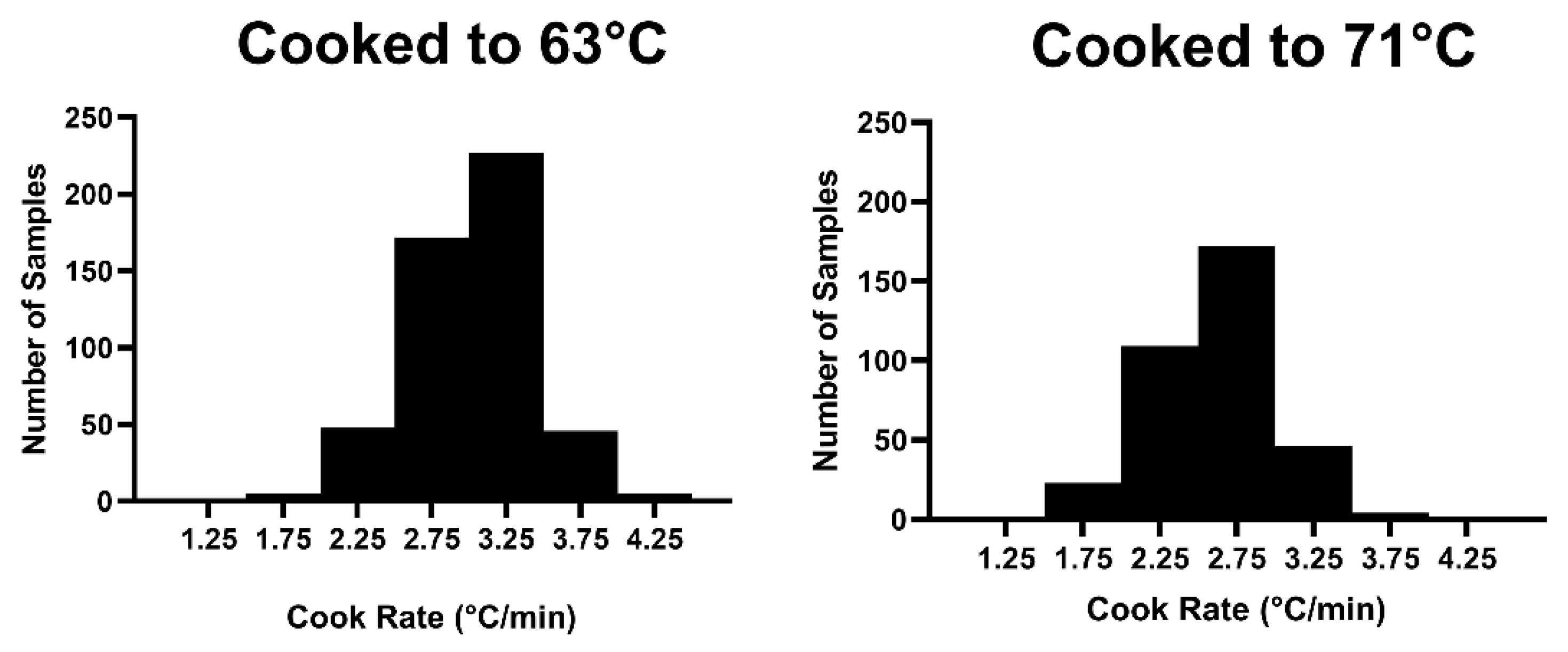

| Cooking rate, °C/min | 503 | 3.01 | 0.40 | 1.86 | 4.21 | 13.26 | |

| Initial chop weight, 63 °C, g | 503 | 228.96 | 22.6 | 168.98 | 300.71 | 9.87 | |

| Cooked chop weight, 63 °C, g | 503 | 177.57 | 18.19 | 129.47 | 243.6 | 10.24 | |

| Cooking loss (%), 63 °C | 503 | 22.42 | 3.08 | 14.58 | 33.78 | 13.74 | |

| WBSF, 63 °C, kg | 503 | 2.98 | 0.68 | 1.66 | 5.49 | 22.75 | |

| Cooked Traits, 71 °C | |||||||

| Initial temperature, 71 °C | 357 | 4.60 | 1.39 | 0.8 | 14.7 | 30.24 | |

| Off-grill temperature, 71 °C | 357 | 71.04 | 0.14 | 71.0 | 72.5 | 0.20 | |

| Final rest temperature, 71 °C | 357 | 72.41 | 0.74 | 67.1 | 74.2 | 1.02 | |

| Cooking time 2, 71 °C, min | 357 | 26.09 | 4.39 | 16.20 | 45.47 | 16.84 | |

| Cooking rate, °C/min | 357 | 2.61 | 0.41 | 1.43 | 4.13 | 15.62 | |

| Initial chop weight, 71 °C, g | 357 | 232.89 | 23.19 | 175.35 | 303.04 | 9.95 | |

| Cooked chop weight, 71 °C, g | 357 | 165.43 | 18.3 | 117.08 | 220.78 | 11.06 | |

| Cooking loss (%), 71 °C | 357 | 28.94 | 3.85 | 16.94 | 41.18 | 13.30 | |

| WBSF, 71 °C, kg | 357 | 3.30 | 0.81 | 1.92 | 6.52 | 24.46 | |

| Cooking Rate 5 for Chops Cooked to 63 °C | Cooking Rate 5 for Chops Cooked to 71 °C | |||

|---|---|---|---|---|

| Variable | r | p-Value | r | p-Value |

| pH | 0.01 | 0.91 | 0.09 | 0.09 |

| NPPC color 2 | 0.01 | 0.83 | 0.05 | 0.37 |

| NPPC marbling 2 | 0.09 | 0.04 | 0.12 | 0.02 |

| NPPC firmness 2 | 0.03 | 0.53 | 0.03 | 0.59 |

| Moisture, % | −0.16 | <0.001 | −0.02 | 0.78 |

| Extractable lipid, % | −0.08 | 0.10 | 0.08 | 0.18 |

| Lightness, L* 3 | 0.00 | 0.99 | 0.04 | 0.50 |

| Redness, a* 3 | 0.02 | 0.64 | −0.03 | 0.51 |

| Yellowness, b* 3 | 0.02 | 0.62 | −0.02 | 0.66 |

| Initial chop temp., °C 4 | −0.02 | 0.60 | 0.04 | 0.44 |

| Off-grill temp., °C | 0.17 | <0.01 | 0.21 | <0.0001 |

| Initial chop weight, g 4 | −0.37 | <0.0001 | −0.26 | <0.0001 |

| 63 °C WBSF | Mod. | Cook Loss | Lipid | pH | L* | Sire Line | Firm 1 | Int. | |||

| R2 | 0.209 | 0.102 | 0.034 | 0.19 | 0.037 | 0.011 | 0.006 | -- | |||

| β | -- | 0.056 | −0.141 | −2.106 | −0.05 | −0.077 | 0.138 | 15.975 | |||

| 71 °C WBSF | Mod. | Cook Loss | Marb 1 | L* | pH | Sire Line | b* | Firm 1 | Color 1 | Temp Final 2 | Int. |

| R2 | 0.381 | 0.108 | 0.013 | 0.059 | 0.045 | 0.054 | 0.067 | 0.012 | 0.016 | 0.007 | -- |

| β | -- | 0.06 | −0.154 | −0.068 | −3.999 | −0.226 | −0.139 | 0.269 | 0.249 | 0.087 | 20.77 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nethery, T.N.; Boler, D.D.; Harsh, B.N.; Dilger, A.C. Relationship between Inherent Cooking Rate and Warner-Bratzler Shear Force of Pork Chops Cooked to Two Degrees of Doneness. Foods 2022, 11, 131. https://doi.org/10.3390/foods11010131

Nethery TN, Boler DD, Harsh BN, Dilger AC. Relationship between Inherent Cooking Rate and Warner-Bratzler Shear Force of Pork Chops Cooked to Two Degrees of Doneness. Foods. 2022; 11(1):131. https://doi.org/10.3390/foods11010131

Chicago/Turabian StyleNethery, Taylor N., Dustin D. Boler, Bailey N. Harsh, and Anna C. Dilger. 2022. "Relationship between Inherent Cooking Rate and Warner-Bratzler Shear Force of Pork Chops Cooked to Two Degrees of Doneness" Foods 11, no. 1: 131. https://doi.org/10.3390/foods11010131

APA StyleNethery, T. N., Boler, D. D., Harsh, B. N., & Dilger, A. C. (2022). Relationship between Inherent Cooking Rate and Warner-Bratzler Shear Force of Pork Chops Cooked to Two Degrees of Doneness. Foods, 11(1), 131. https://doi.org/10.3390/foods11010131