A Preliminary Study on the Effect of the Instant Controlled Pressure Drop Technology (DIC) on Drying and Rehydration Kinetics of Maize Kernels (Zea mays L.)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Sample Preparation

2.2.2. Drying Methods

Convective Air Drying (CAD)

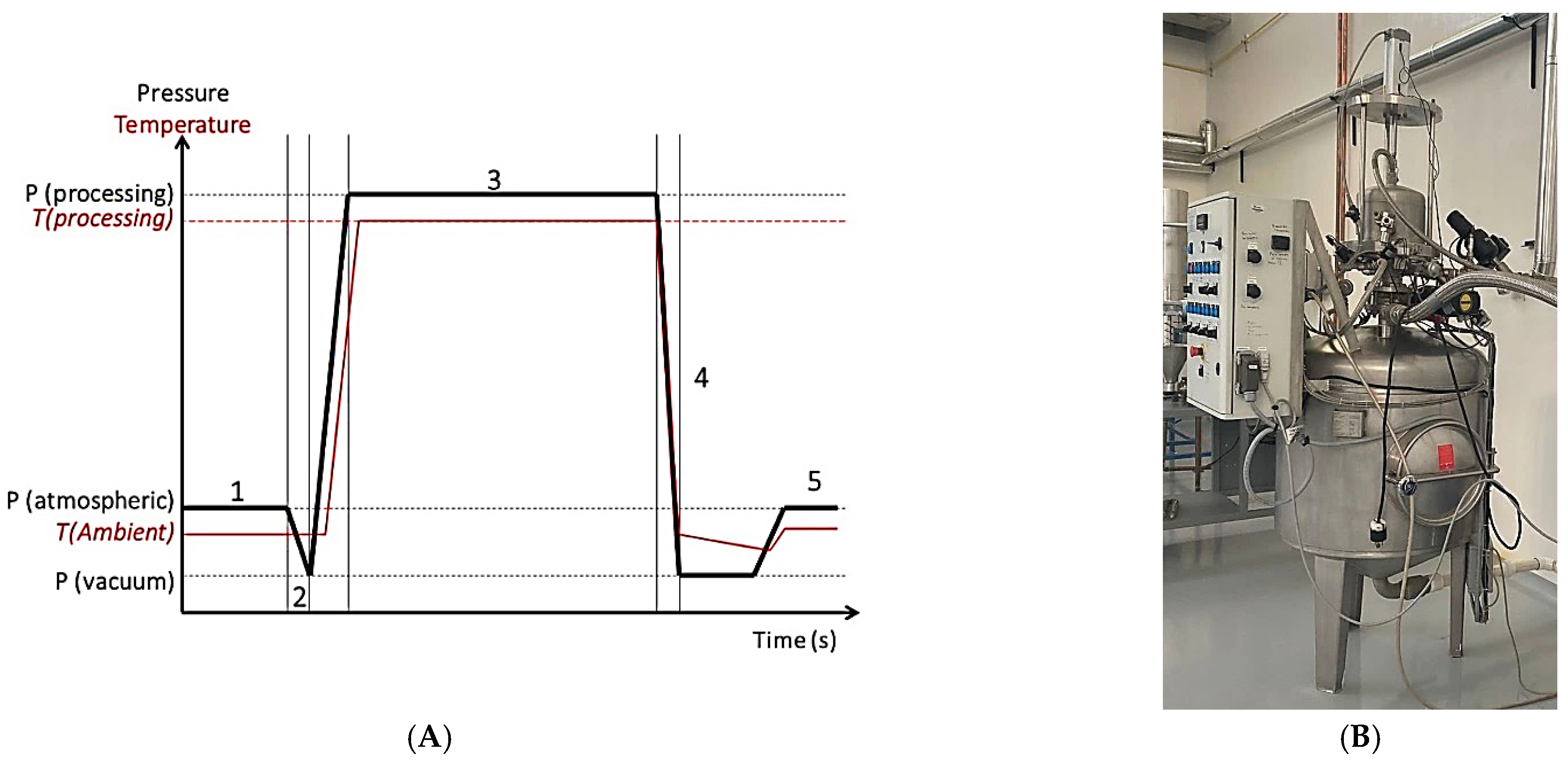

Instant Controlled Pressure Drop (DIC) Coupled with Convective Air Drying (CAD)

2.2.3. Drying and Rehydration Kinetics

2.2.4. Mathematical Modeling of Drying and Rehydration Kinetics

2.2.5. Experimental Design for DIC Treatment

2.2.6. Assessment Methods

Proximate Analysis of Raw Material

Thousand Kernel Weight

Water Holding Capacity

3. Results

3.1. Proximate Analysis

3.2. Thousand Kernel Weight

3.3. Drying Kinetics

3.4. Rehydration Kinetics

3.5. Water Holding Capacity

4. Discussion

4.1. Proximate Analysis

4.2. Thousand Kernel Weight

4.3. Drying Kinetics

4.4. Rehydration Kinetics

4.5. Water Holding Capacity

4.6. Feasibility of Industrial Applications

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| ρw | apparent density of water in the material (kg m−3) |

| ρm | apparent density of solid material (kg m−3) |

| vw | absolute velocity of water flow within the porous medium (m s−1) |

| vm | absolute velocity of solid medium (m s−1) |

| W | water content (kg water/kg dry matter) in the solid matrix |

| W1 | water content at the starting diffusion time |

| W0 | value of moisture content calculated from diffusion model extrapolated to t = 0 (% db) |

| W∞ | equilibrium water content at a very long time t → ∞ (kg water/kg dry matter) |

| Wi | initial water content (kg water/kg dry matter) |

| Deff | effective diffusivity of water within the solid medium (m2 s−1) for dehydration or rehydration |

| Dapp | apparent drying coefficient (m2 s−1) |

| dp | thickness (m) |

| k | slope of y = Ln (Moisture Ratio) as a function of time (s−1) |

| δWs | starting accessibility of water (kg water/kg dry matter) for dehydration d or rehydration r |

| τ | Fick’s number |

| Ai, qi | Crank’s coefficients according to the geometry of solid matrix |

References

- FAO. Production/Yield Quantities of Maize in World. Available online: http://www.fao.org/faostat/en/#data/QC/visualize/ (accessed on 27 March 2020).

- García-Lara, S.; Chuck-Hernandez, C.; Serna-Saldivar, S.O. Development and Structure of the Corn Kernel. In Corn, 3rd ed.; Serna-Saldivar, S.O., Ed.; AACC International Press: Oxford, UK, 2019; pp. 147–163. [Google Scholar] [CrossRef]

- Erenstein, O.; Jaleta, M.; Sonder, K.; Mottaleb, K.; Prasanna, B.M. Global maize production, consumption and trade: Trends and R&D implications. Food Secur. 2022, 1–25. [Google Scholar] [CrossRef]

- FAO. GIEWS Country Brief: Mexico. Available online: https://www.fao.org/giews/countrybrief/country.jsp?code=MEX&lang=en (accessed on 30 June 2022).

- Palacios-Rojas, N.; McCulley, L.; Kaeppler, M.; Titcomb, T.J.; Gunaratna, N.S.; Lopez-Ridaura, S.; Tanumihardjo, S.A. Mining maize diversity and improving its nutritional aspects within agro-food systems. Compr. Rev. Food Sci. Food Saf. 2020, 19, 1809–1834. [Google Scholar] [CrossRef] [PubMed]

- Janas, S.; Boutry, S.; Malumba, P.; Vander Elst, L.; Béra, F. Modelling dehydration and quality degradation of maize during fluidized-bed drying. J. Food Eng. 2010, 100, 527–534. [Google Scholar] [CrossRef]

- Prachayawarakorn, S.; Soponronnarit, S.; Wetchacama, S.; Chinnabun, K. Methodology for enhancing drying rate and improving maize quality in a fluidised-bed dryer. J. Stored Prod. Res. 2004, 40, 379–393. [Google Scholar] [CrossRef]

- Odjo, S.; Malumba, P.; Dossou, J.; Janas, S.; Béra, F. Influence of drying and hydrothermal treatment of corn on the denaturation of salt-soluble proteins and color parameters. J. Food Eng. 2012, 109, 561–570. [Google Scholar] [CrossRef]

- Malumba, P.; Massaux, C.; Deroanne, C.; Masimango, T.; Béra, F. Influence of drying temperature on functional properties of wet-milled starch granules. Carbohydr. Polym. 2009, 75, 299–306. [Google Scholar] [CrossRef]

- Sun, X.D.; Su, P.; Shan, H. Mycotoxin Contamination of Maize in China. Compr. Rev. Food Sci. Food Saf. 2017, 16, 835–849. [Google Scholar] [CrossRef] [Green Version]

- Hawkins, L.K.; Windham, G.L.; Williams, W.P. Effect of Different Postharvest Drying Temperatures on Aspergillus flavus Survival and Aflatoxin Content in Five Maize Hybrids. J. Food Prot. 2005, 68, 1521–1524. [Google Scholar] [CrossRef]

- Kocsis, L.; Herdovics, M.; Deákvári, J.; Fenyvesi, L. Corn drying experiments by pilot dryer. Agron. Res. 2011, 9, 91–97. [Google Scholar]

- Navratil, R.J.; Burris, J.S. The effect of drying temperature on corn seed quality. Can. J. Plant Sci. 1984, 64, 487–496. [Google Scholar] [CrossRef] [Green Version]

- Navarro, S.; Noyes, R.T.; Casada, M.; Arthur, F.H. Grain Aeration. Stored Product Protection; Kansas State University: Manhattan, KS, USA, 2012; pp. 121–134. [Google Scholar]

- Mounir, S.; Téllez-Pérez, C.; Alonzo-Macías, M.; Allaf, K. Swell-Drying. In Instant Controlled Pressure Drop (D.I.C.) in Food Processing; Allaf, T., Allaf, K., Eds.; Springer: New York, NY, USA, 2014; pp. 3–43. [Google Scholar] [CrossRef]

- Coradi, P.C.; Maldaner, V.; Lutz, É.; da Silva Daí, P.V.; Teodoro, P.E. Influences of drying temperature and storage conditions for preserving the quality of maize postharvest on laboratory and field scales. Sci. Rep. 2020, 10, 22006. [Google Scholar] [CrossRef] [PubMed]

- Akhtaruzzaman, M.; Mondal, M.H.T.; Biswas, M.; Sheikh, M.A.M.; Khatun, A.A.; Sarker, M.S.H. Evaluation of Drying Performance, Energy Consumption, and Quality of Two-Stage Dried Maize Grain. J. Biosyst. Eng. 2021, 46, 151–162. [Google Scholar] [CrossRef]

- Mondal, M.H.T.; Hossain, M.A.; Sheikh, M.A.M.; Md, A.; Sarker, M.S.H. Energetic and exergetic investigation of a mixed flow dryer: A case study of maize grain drying. Dry. Technol. 2021, 39, 466–480. [Google Scholar] [CrossRef]

- Téllez-Pérez, C.; Sabah, M.M.; Montejano-Gaitán, J.G.; Sobolik, V.; Martínez, C.A.; Allaf, K. Impact of Instant Controlled Pressure Drop Treatment on Dehydration and Rehydration Kinetics of Green Moroccan Pepper (Capsicum annuum). Procedia Eng. 2012, 42, 1077–1101. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, T.H.; Lanoisellé, J.-L.; Allaf, T.; Allaf, K. Experimental and fundamental critical analysis of diffusion model of airflow drying. Dry. Technol. 2016, 34, 1884–1899. [Google Scholar] [CrossRef]

- Berka-Zougali, B.; Ferhat, M.-A.; Hassani, A.; Chemat, F.; Allaf, K.S. Comparative Study of Essential Oils Extracted from Algerian Myrtus communis L. Leaves Using Microwaves and Hydrodistillation. Int. J. Mol. Sci. 2012, 13, 4673. [Google Scholar] [CrossRef] [Green Version]

- Louka, N.; Allaf, K. Expansion ratio and color improvement of dried vegetables texturized by a new process “Controlled Sudden Decompression to the vacuum”: Application to potatoes, carrots and onions. J. Food Eng. 2004, 65, 233–243. [Google Scholar] [CrossRef]

- Asgrow. Hipopótamo Product Detail Template; Asgrow: Kalamazoo, MI, USA, 2015. [Google Scholar]

- Mounir, S.; Allaf, K. Study and Modeling of Dehydration and Rehydration Kinetics within Porous Medium; Association Française de Séchage Pour l’Industrie et l’Agriculture—AFSIA: Lyon, France, 2009. [Google Scholar]

- Al Haddad, M.; Mounir, S.M.; Sobolik, V.; Allaf, K. Fruits and Vegetables Drying Combining Hot Air, DIC Technology and Microwaves. Int. J. Food Eng. 2008, 4, 9. [Google Scholar] [CrossRef]

- Allaf, K. (Ed.) Transfer Phenomena and Industrial Applications; Lebanese University, Faculty of Science: Beirut, Lebanon, 1982; p. 135. [Google Scholar]

- Crank, J. The Mathematics of Diffusion; Oxford University Press: London, UK, 1975. [Google Scholar]

- Muthukumarappan, K.; Gunasekaran, S. Vapor diffusivity and hygroscopic expansion of corn kernels during adsorption. Trans. ASAE 1990, 33, 1637. [Google Scholar] [CrossRef]

- AACC. Approved Methods of the American Association of Cereal Chemists, 10th ed.; American Association of Cereal Chemists: St. Paul, MN, USA, 2000. [Google Scholar]

- Camelo-Méndez, G.A.; Agama-Acevedo, E.; Tovar, J.; Bello-Pérez, L.A. Functional study of raw and cooked blue maize flour: Starch digestibility, total phenolic content and antioxidant activity. J. Cereal Sci. 2017, 76, 179–185. [Google Scholar] [CrossRef]

- Han, Z.; Zeng, X.-a.; Zhang, B.-s.; Yu, S.-j. Effects of pulsed electric fields (PEF) treatment on the properties of corn starch. J. Food Eng. 2009, 93, 318–323. [Google Scholar] [CrossRef]

- Darrah, L.L.; McMullen, M.D.; Zuber, M.S. Breeding, Genetics and Seed Corn Production. In Corn, 3rd ed.; Serna-Saldivar, S.O., Ed.; AACC International Press: Oxford, UK, 2019; pp. 19–41. [Google Scholar] [CrossRef]

- Győri, Z. Corn: Grain-Quality Characteristics and Management of Quality Requirements. In Cereal Grains, 2nd ed.; Wrigley, C., Batey, I., Miskelly, D., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 257–290. [Google Scholar] [CrossRef]

- Karthik, S.; Mahesh, T.; Sumanth, B.; Tanmay, M. Study of physical and engineering properties of corn (Zea mays). Bull. Environ. Pharmacol. Life Sci. 2017, 6, 404–409. [Google Scholar]

- Rodríguez-Ramírez, J.; Méndez-Lagunas, L.; López-Ortiz, A.; Torres, S.S. True Density and Apparent Density During the Drying Process for Vegetables and Fruits: A Review. J. Food Sci. 2012, 77, R146–R154. [Google Scholar] [CrossRef] [PubMed]

- Hamoud-Agha, M.M.; Allaf, K. Instant controlled pressure drop (DIC) technology in food preservation: Fundamental and industrial applications. Food Preserv. Waste Exploit. 2019, 1, 17. [Google Scholar] [CrossRef] [Green Version]

- Besombes, C.; Berka-Zougali, B.; Allaf, K. Instant controlled pressure drop extraction of lavandin essential oils: Fundamentals and experimental studies. J. Chromatogr. A 2010, 1217, 6807–6815. [Google Scholar] [CrossRef] [Green Version]

- Mounir, S.; Halle, D.; Allaf, K. Characterization of pure cheese snacks and expanded granule powders textured by the instant controlled pressure drop (DIC) process. Dairy Sci. Technol. 2011, 91, 441. [Google Scholar] [CrossRef] [Green Version]

- Akowuah, J.; Maier, D.; Opit, G.; McNeill, S.; Amstrong, P.; Campabadal, C.; Ambrose, K.; Obeng-Akrofi, G. Drying Temperature Effect on Kernel Damage and Viability of Maize Dried in a Solar Biomass Hybrid Dryer. Open J. Appl. Sci. 2018, 8, 506–517. [Google Scholar] [CrossRef] [Green Version]

- Owusu-Sekyere, E.; Obeng-Akrofi, G.; Akowuah, J.; Maier, D. Performance Analysis and Drying Kinetics of Maize in an AflaSTOP Dryer. Open J. Appl. Sci. 2021, 11, 327–342. [Google Scholar] [CrossRef]

- Miano, A.C.; Augusto, P.E.D. The Hydration of Grains: A Critical Review from Description of Phenomena to Process Improvements. Compr. Rev. Food Sci. Food Saf. 2018, 17, 352–370. [Google Scholar] [CrossRef] [Green Version]

- Martínez-Garza, D.R.-T.; García-Lara, S.; Mújica-Paz, H.; Valdez-Fragoso, A. Pressure gradients application for accelerating corn hydration. Rev. Mex. Ing. Química 2018, 17, 669–677. [Google Scholar] [CrossRef]

- Alonzo-Macías, M. Comparative Study of Strawberry Drying Processes: Hot Air Drying, Freeze-Drying and Swell Drying, Application on the Biological Compounds Preservation; University of La Rochelle: La Rochelle, France, 2013. [Google Scholar]

- Mounir, S. Texturing of Chicken Breast Meat as an Innovative Way to Intensify Drying: Use of a Coupled Washing/Diffusion CWD Phenomenological Model to Enhance Kinetics and Functional Properties. Dry. Technol. 2015, 33, 1369–1381. [Google Scholar] [CrossRef]

- Ramos, G.; Pezet-Valdez, M.; O’Connor-Sánchez, A.; Placencia, C.; Pless, R.C. Hydration Rates for Various Types of Mexican Maize Based on Single-Kernel Measurements. Cereal Chem. 2004, 81, 308–313. [Google Scholar] [CrossRef]

- Phiarais, B.P.N.; Arendt, E.K. Malting and Brewing with Gluten-Free Cereals. In Gluten-Free Cereal Products and Beverages; Arendt, E.K., Dal Bello, F., Eds.; Academic Press: San Diego, CA, USA, 2008; pp. 347–372. [Google Scholar] [CrossRef]

- Zondo, S.; Mahlambi, P. Correlation between Chemical Composition, Water Holding Capacity and Flavonoids Content of Maize Verities Harvested at Buxedeni Village of KwaNongoma in KwaZulu Natal, South Africa. J. Food Nutr. Res. 2020, 8, 675–681. [Google Scholar] [CrossRef]

| Assay No. | Run Order | Coded Values | Uncoded Values | ||

|---|---|---|---|---|---|

| Pressure (MPa) | Time (s) | Pressure (MPa) | Time (s) | ||

| 1 | DIC 2 | −1 | −1 | 0.14 | 22 |

| 2 | DIC 11 | 1 | −1 | 0.36 | 22 |

| 3 | DIC 3 | −1 | 1 | 0.14 | 78 |

| 4 | DIC 12 | 1 | 1 | 0.36 | 78 |

| 5 | DIC 1 | –1.414 | 0 | 0.1 | 50 |

| 6 | DIC 13 | 1.414 | 0 | 0.4 | 50 |

| 7 | DIC 4 | 0 | −1.414 | 0.25 | 10 |

| 8 | DIC 10 | 0 | 1.414 | 0.25 | 90 |

| 9 | DIC 9 | 0 | 0 | 0.25 | 50 |

| 10 | DIC 5 | 0 | 0 | 0.25 | 50 |

| 11 | DIC 6 | 0 | 0 | 0.25 | 50 |

| 12 | DIC 8 | 0 | 0 | 0.25 | 50 |

| 13 | DIC 7 | 0 | 0 | 0.25 | 50 |

| 14 | DIC 14 | 1.414 | 1.414 | 0.4 | 90 |

| 15 | DIC 15 | 1.414 | 1.414 | 0.4 | 90 |

| 16 | DIC 16 | 1.414 | 1.414 | 0.4 | 90 |

| 17 | DIC 17 | 1.414 | 1.414 | 0.4 | 10 s × 9 times |

| 18 | DIC 18 | 1.414 | 1.414 | 0.4 | 10 s × 9 times |

| 19 | DIC 19 | 1.414 | 1.414 | 0.4 | 10 s × 9 times |

| Control | NA | NA | NA | 0 | 0 |

| Sample | P (MPa) | t (s) | Thousand Kernel Weight (g) | Dapp (10−10 m²/s) |

|---|---|---|---|---|

| Control | NA | NA | 272.02 | 0.3364 |

| DIC 1 | 0.1 | 50 | 289.48 | 0.2904 |

| DIC 2 | 0.14 | 22 | 311.77 | 0.3563 |

| DIC 3 | 0.14 | 78 | 275.53 | 0.2237 |

| DIC 4 | 0.25 | 10 | 265.67 | 0.2541 |

| DIC 5 | 0.25 | 50 | 248.06 | 0.2041 |

| DIC 6 | 0.25 | 50 | 276.21 | 0.2266 |

| DIC 7 | 0.25 | 50 | 306.35 | 0.3175 |

| DIC 8 | 0.25 | 50 | 277.82 | 0.1873 |

| DIC 9 | 0.25 | 50 | 236.45 | 0.1738 |

| DIC 10 | 0.25 | 90 | 289.67 | 0.2296 |

| DIC 11 | 0.36 | 22 | 275.52 | 0.1928 |

| DIC 12 | 0.36 | 78 | 305.52 | 0.2351 |

| DIC 13 | 0.4 | 50 | 279.19 | 0.2017 |

| DIC 14 | 0.4 | 90 | 287.63 | 0.3741 |

| DIC 15 | 0.4 | 90 | 265.68 | 0.1982 |

| DIC 16 | 0.4 | 90 | 276.83 | 0.2374 |

| DIC 17 | 0.4 | 10 s × 9 | 279.38 | 0.2010 |

| DIC 18 | 0.4 | 10 s × 9 | 241.64 | 0.2251 |

| DIC 19 | 0.4 | 10 s × 9 | 260.05 | 0.3039 |

| Time (min) | Sample | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Control 1 | Control 2 | Control 3 | DIC1 | DIC2 | DIC3 | DIC4 | DIC5 | DIC6 | DIC7 | DIC8 | DIC9 | DIC 10 | DIC 11 | DIC 12 | DIC 13 | DIC 14 | DIC 15 | DIC 16 | DIC 17 | DIC 18 | DIC 19 | |

| 0 | 0.2553 | 0.2760 | 0.2506 | 0.2812 | 0.2559 | 0.2365 | 0.2483 | 0.2506 | 0.2425 | 0.2600 | 0.2692 | 0.2551 | 0.2624 | 0.2362 | 0.2312 | 0.2271 | 0.2406 | 0.2354 | 0.2517 | 0.2465 | 0.2523 | 0.2628 |

| 5 | 0.2383 | 0.2629 | 0.2379 | 0.2468 | 0.2261 | 0.2078 | 0.2197 | 0.2259 | 0.2217 | 0.2259 | 0.2397 | 0.2301 | 0.2330 | 0.2157 | 0.2067 | 0.2065 | 0.2199 | 0.2148 | 0.2435 | 0.2299 | 0.2357 | 0.2460 |

| 10 | 0.2256 | 0.2498 | 0.2295 | 0.2296 | 0.2090 | 0.1955 | 0.2074 | 0.2135 | 0.2093 | 0.2132 | 0.2271 | 0.2176 | 0.2246 | 0.2034 | 0.1944 | 0.1942 | 0.2035 | 0.2025 | 0.2229 | 0.2132 | 0.2191 | 0.2209 |

| 15 | 0.2128 | 0.2411 | 0.2169 | 0.2167 | 0.1963 | 0.1873 | 0.1951 | 0.1970 | 0.2010 | 0.2046 | 0.2187 | 0.2092 | 0.2120 | 0.1911 | 0.1903 | 0.1900 | 0.1952 | 0.1943 | 0.2105 | 0.2048 | 0.2067 | 0.1999 |

| 20 | 0.2085 | 0.2148 | 0.2127 | 0.2081 | 0.1877 | 0.1833 | 0.1910 | 0.1928 | 0.1927 | 0.1961 | 0.2103 | 0.2051 | 0.2037 | 0.1869 | 0.1821 | 0.1818 | 0.1870 | 0.1861 | 0.1982 | 0.1965 | 0.1984 | 0.1999 |

| 30 | 0.1915 | 0.2017 | 0.2000 | 0.1952 | 0.1792 | 0.1710 | 0.1787 | 0.1804 | 0.1802 | 0.1834 | 0.1935 | 0.1884 | 0.1911 | 0.1746 | 0.1699 | 0.1694 | 0.1746 | 0.1697 | 0.1858 | 0.1840 | 0.1860 | 0.1831 |

| 45 | 0.1745 | 0.1799 | 0.1790 | 0.1780 | 0.1622 | 0.1587 | 0.1624 | 0.1639 | 0.1677 | 0.1706 | 0.1767 | 0.1759 | 0.1743 | 0.1582 | 0.1576 | 0.1530 | 0.1622 | 0.1574 | 0.1693 | 0.1632 | 0.1694 | 0.1663 |

| 60 | 0.1660 | 0.1668 | 0.1664 | 0.1651 | 0.1537 | 0.1464 | 0.1501 | 0.1516 | 0.1594 | 0.1578 | 0.1641 | 0.1592 | 0.1617 | 0.1500 | 0.1453 | 0.1489 | 0.1540 | 0.1492 | 0.1570 | 0.1548 | 0.1569 | 0.1537 |

| 90 | 0.1490 | 0.1537 | 0.1537 | 0.1436 | 0.1367 | 0.1300 | 0.1337 | 0.1309 | 0.1386 | 0.1408 | 0.1431 | 0.1425 | 0.1408 | 0.1336 | 0.1289 | 0.1241 | 0.1334 | 0.1328 | 0.1405 | 0.1381 | 0.1445 | 0.1411 |

| 120 | 0.1362 | 0.1406 | 0.1411 | 0.1307 | 0.1196 | 0.1177 | 0.1214 | 0.1185 | 0.1262 | 0.1280 | 0.1263 | 0.1258 | 0.1282 | 0.1212 | 0.1167 | 0.1077 | 0.1128 | 0.1163 | 0.1199 | 0.1215 | 0.1320 | 0.1244 |

| 150 | 0.1277 | 0.1318 | 0.1285 | 0.1135 | 0.1111 | 0.1055 | 0.1092 | 0.1062 | 0.1095 | 0.1110 | 0.1137 | 0.1133 | 0.1114 | 0.1089 | 0.1085 | 0.1036 | 0.1087 | 0.1081 | 0.1158 | 0.1131 | 0.1196 | 0.1160 |

| 180 | 0.1192 | 0.1231 | 0.1200 | 0.1006 | 0.0983 | 0.0973 | 0.0969 | 0.0938 | 0.1012 | 0.0982 | 0.1011 | 0.1008 | 0.1030 | 0.1007 | 0.1003 | 0.0953 | 0.1004 | 0.0958 | 0.1035 | 0.1048 | 0.1113 | 0.1076 |

| Time (min) | Sample | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Control 1 | Control 2 | Control 3 | DIC 1 | DIC 2 | DIC 3 | DIC 4 | DIC 5 | DIC 6 | DIC 7 | DIC 8 | DIC 9 | DIC 10 | DIC 11 | DIC 12 | DIC 13 | DIC 14 | DIC 15 | DIC 16 | DIC 17 | DIC 18 | DIC 19 | |

| 0 | 0.1192 | 0.1231 | 0.1200 | 0.1006 | 0.0983 | 0.0973 | 0.0969 | 0.0938 | 0.1012 | 0.0982 | 0.1011 | 0.1008 | 0.1030 | 0.1007 | 0.1003 | 0.0953 | 0.1004 | 0.0958 | 0.1035 | 0.1048 | 0.1113 | 0.1076 |

| 5 | 0.3078 | 0.3748 | 0.3113 | 0.3174 | 0.3128 | 0.2834 | 0.3108 | 0.2890 | 0.3452 | 0.3346 | 0.3455 | 0.3173 | 0.3337 | 0.3452 | 0.3183 | 0.3268 | 0.3794 | 0.3328 | 0.3397 | 0.4905 | 0.5150 | 0.3843 |

| 10 | 0.3106 | 0.3761 | 0.3200 | 0.3320 | 0.3436 | 0.3177 | 0.3374 | 0.3285 | 0.3606 | 0.3507 | 0.3505 | 0.3332 | 0.3576 | 0.3474 | 0.3329 | 0.3309 | 0.4176 | 0.3381 | 0.3547 | 0.5137 | 0.5794 | 0.4295 |

| 15 | 0.3286 | 0.3768 | 0.3550 | 0.3457 | 0.3514 | 0.3227 | 0.3528 | 0.3447 | 0.3716 | 0.3634 | 0.3744 | 0.3571 | 0.3578 | 0.3476 | 0.3463 | 0.3426 | 0.4210 | 0.3839 | 0.3559 | 0.5309 | 0.5917 | 0.4648 |

| 30 | 0.3441 | 0.3858 | 0.3606 | 0.3601 | 0.3589 | 0.3435 | 0.3716 | 0.3580 | 0.3722 | 0.3637 | 0.3880 | 0.3779 | 0.3795 | 0.3507 | 0.3590 | 0.4048 | 0.4551 | 0.3896 | 0.3911 | 0.5702 | 0.6006 | 0.5076 |

| 45 | 0.3607 | 0.4077 | 0.3643 | 0.3977 | 0.3656 | 0.3466 | 0.3818 | 0.3700 | 0.3945 | 0.3672 | 0.4194 | 0.3810 | 0.3881 | 0.4086 | 0.3707 | 0.4315 | 0.5205 | 0.4117 | 0.4077 | 0.6423 | 0.6425 | 0.5550 |

| 60 | 0.3971 | 0.4412 | 0.3666 | 0.3982 | 0.3855 | 0.3790 | 0.3885 | 0.3717 | 0.4130 | 0.3712 | 0.4323 | 0.3918 | 0.4119 | 0.4104 | 0.3848 | 0.4459 | 0.5448 | 0.4275 | 0.4684 | 0.6538 | 0.6866 | 0.5569 |

| 90 | 0.3974 | 0.4721 | 0.3995 | 0.4071 | 0.3973 | 0.3798 | 0.3985 | 0.3966 | 0.4467 | 0.3801 | 0.4428 | 0.4226 | 0.4300 | 0.4131 | 0.4173 | 0.4987 | 0.5592 | 0.4293 | 0.4847 | 0.6819 | 0.7050 | 0.6096 |

| 120 | 0.4279 | 0.4802 | 0.4181 | 0.4253 | 0.4344 | 0.3917 | 0.4158 | 0.4059 | 0.4532 | 0.4354 | 0.4681 | 0.4377 | 0.4379 | 0.4137 | 0.4239 | 0.5067 | 0.5632 | 0.4396 | 0.4860 | 0.7530 | 0.7434 | 0.6400 |

| 150 | 0.4504 | 0.4890 | 0.4742 | 0.4409 | 0.4443 | 0.4202 | 0.4257 | 0.4403 | 0.4825 | 0.4519 | 0.4814 | 0.4785 | 0.4542 | 0.4427 | 0.4755 | 0.5165 | 0.6083 | 0.4774 | 0.5320 | 0.7694 | 0.7509 | 0.6404 |

| 180 | 0.4784 | 0.5401 | 0.4868 | 0.4564 | 0.5147 | 0.4392 | 0.4795 | 0.4501 | 0.4917 | 0.4656 | 0.4988 | 0.4876 | 0.4649 | 0.4463 | 0.5075 | 0.5457 | 0.6305 | 0.5031 | 0.5519 | 0.8083 | 0.8406 | 0.6780 |

| Sample | P | t | Deff-rehy (10−10 m²/s) | δWs | Wt = 120 min | WHC |

|---|---|---|---|---|---|---|

| Control | NA | NA | 0.0146 | 0.1975 | 0.4420 | 1.4304 |

| DIC 1 | 0.1 | 50 | 0.0243 | 0.2146 | 0.4253 | 1.3531 |

| DIC 2 | 0.14 | 22 | 0.0082 | 0.1961 | 0.4344 | 1.2859 |

| DIC 3 | 0.14 | 78 | 0.0147 | 0.1737 | 0.3917 | 1.4913 |

| DIC 4 | 0.25 | 10 | 0.0113 | 0.2001 | 0.4158 | 1.4822 |

| DIC 5 | 0.25 | 50 | 0.0138 | 0.1695 | 0.4059 | 1.6066 |

| DIC 6 | 0.25 | 50 | 0.0138 | 0.2406 | 0.4532 | 1.4571 |

| DIC 7 | 0.25 | 50 | 0.0030 | 0.2235 | 0.4354 | 1.4515 |

| DIC 8 | 0.25 | 50 | 0.0169 | 0.2475 | 0.4681 | 1.4524 |

| DIC 9 | 0.25 | 50 | 0.0105 | 0.2036 | 0.4377 | 1.3685 |

| DIC 10 | 0.25 | 90 | 0.0086 | 0.2257 | 0.4379 | 1.4828 |

| DIC 11 | 0.36 | 22 | 0.0193 | 0.2589 | 0.4137 | 1.5135 |

| DIC 12 | 0.36 | 78 | 0.0072 | 0.2123 | 0.4239 | 1.9006 |

| DIC 13 | 0.4 | 50 | 0.0385 | 0.2436 | 0.5067 | 1.6806 |

| DIC 14 | 0.4 | 90 | 0.0237 | 0.2809 | 0.5632 | 2.3838 |

| DIC 15 | 0.4 | 90 | 0.0144 | 0.2309 | 0.4396 | 2.3359 |

| DIC 16 | 0.4 | 90 | 0.0151 | 0.2486 | 0.4860 | 2.3620 |

| DIC 17 | 0.4 | 10 s × 9 | 0.0250 | 0.3941 | 0.7530 | 3.2004 |

| DIC 18 | 0.4 | 10 s × 9 | 0.0237 | 0.3756 | 0.7434 | 3.1834 |

| DIC 19 | 0.4 | 10 s × 9 | 0.0315 | 0.2480 | 0.6400 | 3.5073 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cardador-Martínez, A.; Pech-Almeida, J.L.; Allaf, K.; Palacios-Rojas, N.; Alonzo-Macías, M.; Téllez-Pérez, C. A Preliminary Study on the Effect of the Instant Controlled Pressure Drop Technology (DIC) on Drying and Rehydration Kinetics of Maize Kernels (Zea mays L.). Foods 2022, 11, 2151. https://doi.org/10.3390/foods11142151

Cardador-Martínez A, Pech-Almeida JL, Allaf K, Palacios-Rojas N, Alonzo-Macías M, Téllez-Pérez C. A Preliminary Study on the Effect of the Instant Controlled Pressure Drop Technology (DIC) on Drying and Rehydration Kinetics of Maize Kernels (Zea mays L.). Foods. 2022; 11(14):2151. https://doi.org/10.3390/foods11142151

Chicago/Turabian StyleCardador-Martínez, Anaberta, Juan Leopoldo Pech-Almeida, Karim Allaf, Natalia Palacios-Rojas, Maritza Alonzo-Macías, and Carmen Téllez-Pérez. 2022. "A Preliminary Study on the Effect of the Instant Controlled Pressure Drop Technology (DIC) on Drying and Rehydration Kinetics of Maize Kernels (Zea mays L.)" Foods 11, no. 14: 2151. https://doi.org/10.3390/foods11142151

APA StyleCardador-Martínez, A., Pech-Almeida, J. L., Allaf, K., Palacios-Rojas, N., Alonzo-Macías, M., & Téllez-Pérez, C. (2022). A Preliminary Study on the Effect of the Instant Controlled Pressure Drop Technology (DIC) on Drying and Rehydration Kinetics of Maize Kernels (Zea mays L.). Foods, 11(14), 2151. https://doi.org/10.3390/foods11142151