Sustainable Design of Innovative Kiwi Byproducts-Based Ingredients Containing Probiotics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Fruit Processing

2.3. Extraction of Phytochemicals from Fresh Kiwi Samples

2.4. Customized Design to Develop Kiwi-Based Ingredients Enriched with Probiotics

2.5. Total Polyphenol (TPC) and Total Flavonoid (TFC) Analysis

2.6. Total Monomeric Anthocyanin Content

2.7. Carotenoid Content Evaluation

2.8. Radical Scavenging Activity

2.9. Viable Counts of L. casei 431®

2.10. In Vitro Digestion

2.11. CIEL*a*b* Analysis of Freeze-Dried Powders

2.12. Powder Structure and Morphology

2.13. Food Formulation

2.14. Statistical Analyses

3. Results and Discussion

3.1. The Phytochemical Profiles of the Kiwi Extracts

3.2. The Phytochemical Profiles and Cell Viability of Inoculated Freeze-Dried Kiwi Powders

3.3. Color Parameters

3.4. Survival of L. Casei 431® during Exposure to Simulated Gastrointestinal Conditions

3.5. In Vitro Bioaccessibility of Flavonoids

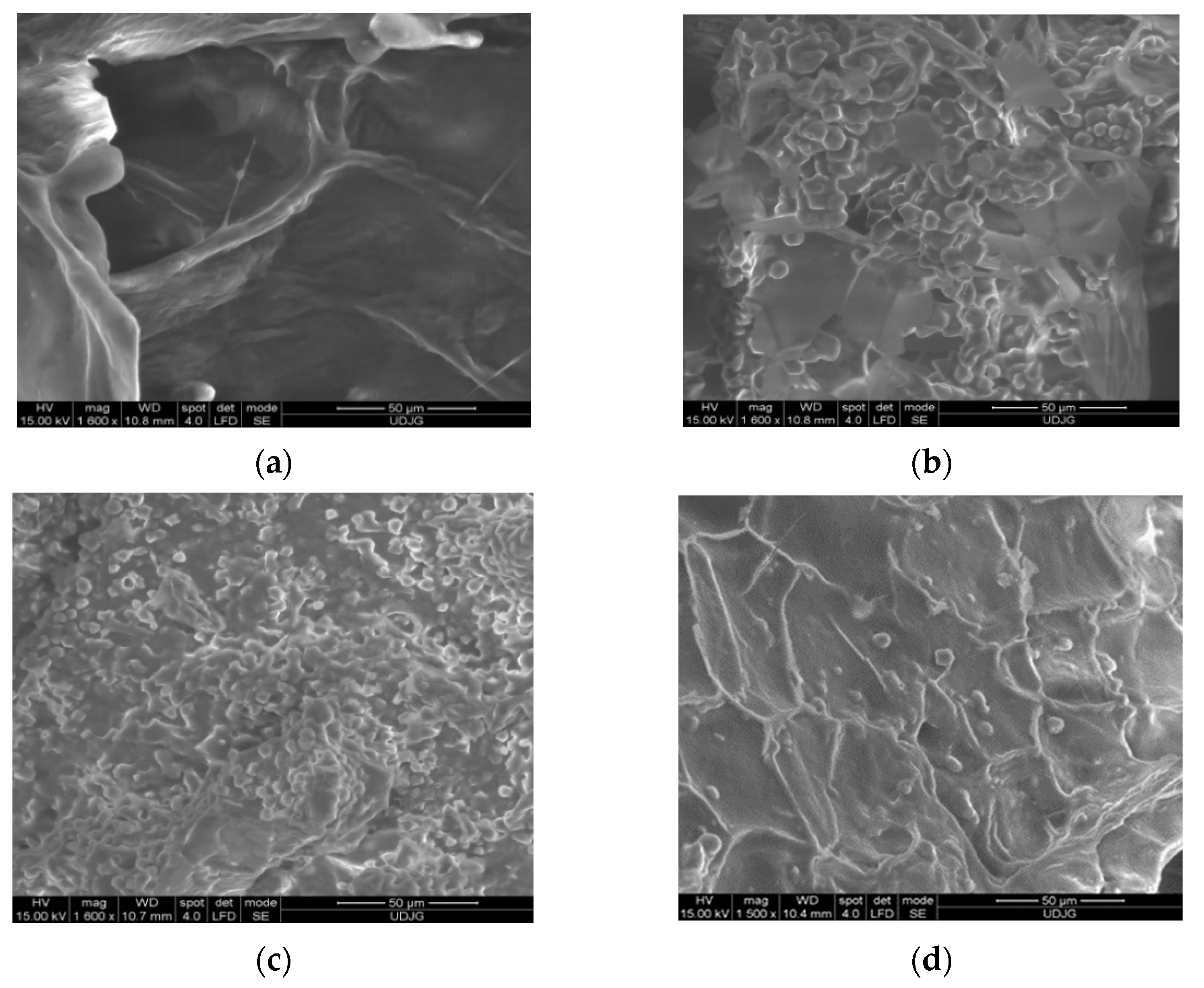

3.6. Microscopic Structure of the Powders

3.7. Food Formulations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Santana-Méridas, O.; González-Coloma, A.; Sánchez-Vioque, R. Agricultural residues as a source of bioactive natural products. Phytochem. Rev. 2012, 11, 447–466. [Google Scholar] [CrossRef]

- Talukder, P.; Talapatra, S.; Ghoshal, N.; Sen Raychaudhuri, S. Antioxidant activity and high-performance liquid chromatographic analysis of phenolic compounds during in vitro callus culture of Plantago ovata Forsk. and effect of exogenous additives on accumulation of phenolic compounds. J. Sci. Food Agric. 2016, 96, 232–244. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Sun, Y.N.; Yan, X.T.; Yang, S.Y.; Kim, S.; Chae, D.; Hyun, J.W.; Kang, H.K.; Koh, Y.-S.; Kim, Y.H. Anti-inflammatory and antioxidant activities of phenolic compounds from Desmodium caudatum leaves and stems. Arch. Pharm. Res. 2014, 37, 721–727. [Google Scholar] [CrossRef] [PubMed]

- Soquetta, M.B.; Stefanello, F.S.; Huerta, K.M.; Monteiro, S.S.; da Rosa, C.S.; Terra, N.N. Characterization of physiochemical and microbiological properties, and bioactive compounds, of flour made from the skin and bagasse of kiwi fruit (Actinidia deliciosa). Food Chem. 2016, 199, 471–478. [Google Scholar] [CrossRef]

- Asgar, M.A. Anti-diabetic potential of phenolic compounds: A review. Int. J. Food Prop. 2013, 16, 91–103. [Google Scholar] [CrossRef]

- Latocha, P.; Krupa, T.; Wołosiak, R.; Worobiej, E.; Wilczak, J. Antioxidant activity and chemical difference in fruit of different Actinidia sp. Int. J. Food Sci. Nutr. 2010, 61, 381–394. [Google Scholar] [CrossRef]

- Chamorro, F.; Carpena, M.; Fraga-Corral, M.; Echave, J.; Riaz Rajoka, M.M.; Barba, F.J.; Cao, H.; Xiao, J.; Prieto, M.A.; Simal-Gandara, J. Valorization of kiwi agricultural waste and industry by-products by recovering bioactive compounds and applications as food additives: A circular economy model. Food Chem. 2022, 370, 131315. [Google Scholar] [CrossRef]

- Zhu, C.H.; Gong, Q.; Li, J.X.; Zhang, Y.; Yue, J.Q.; Gao, J.Y. Research progresses of the comprehensive processing and utilization of kiwifruit. Storage Proc. 2013, 13, 57–62. [Google Scholar]

- Dias, M.; Caleja, C.; Pereira, C.; Calhelha, R.C.; Kostic, M.; Sokovic, M.; Tavares, D.; Baraldi, I.J.; Barros, L.; Ferreira, I.C.F.R. Chemical composition and bioactive properties of byproducts from two different kiwi varieties. Food Res. Int. 2020, 127, 108753. [Google Scholar] [CrossRef]

- Kim, S.; Covington, A.; Pamer, E.G. The intestinal microbiota: Antibiotics, colonization resistance, and enteric pathogens. Immunol. Rev. 2017, 279, 90–105. [Google Scholar] [CrossRef]

- Yadav, A.; Chandra, H.; Maurya, V.K. Probiotics: Recent advances and future prospects. J. Plant Dev. Sci. 2017, 9, 967–975. [Google Scholar]

- Song, H.Y.; Zhou, L.; Liu, D.Y.; Yao, X.J.; Li, Y. What roles do probiotics play in the eradication of Helicobacter pylori? Current knowledge and ongoing research. Gastroenterol. Res. Pract. 2018, 2018, 9379480. [Google Scholar] [CrossRef] [Green Version]

- Tegegne, B.A.; Kebede, B. Probiotics, their prophylactic and therapeutic applications in human health development: A review of the literature. Heliyon 2022, 8, e0972. [Google Scholar] [CrossRef] [PubMed]

- Anosike, F.C.; Onyemah, C.O.; Ossai, C.U.; Ofoegbu, J.N.G.; Okpaga, F.O.; Ikpeama, C.C.; Nkwegu, F.M.; Nwankwo, S.C.; Onyeji, G.N.; Inyang, P.; et al. Probiotic potential and viability of bacteria in fermented African oil bean seed (Pentaclethra macropyhlla): A mini review. Appl. Food Res. 2022, 2, 1000082. [Google Scholar] [CrossRef]

- Likotrafiti, E.; Rhoades, J. Probiotics, Prebiotics, Synbiotics, and Foodborne Illness, in Probiotics, Prebiotics, and Synbiotics. Bioactive Foods in Health Promotion; Watson, R.R., Preedy, V.R., Eds.; Academic Press: Cambridge, MA, USA, 2016; pp. 469–476. [Google Scholar]

- Wang, M.; Zhang, Z.; Sun, H.; He, S.; Liu, S.; Zhang, T.; Wang, L.; Ma, G. Research progress of anthocyanin prebiotic activity: A review. Phytomedicine 2022, 102, 154145. [Google Scholar] [CrossRef] [PubMed]

- Gibson, G.R.; Hutkins, R.; Sanders, M.E.; Prescott, S.L.; Reimer, R.A.; Salminen, S.J.; Scott, K.; Stanton, C.; Swanson, K.S.; Cani, P.D.; et al. Expert consensus document: The International Scientific Association for Probiotics and Prebiotics (ISAPP) consensus statement on the definition and scope of prebiotics. Nat. Rev. Gastroenterol. Hepatol. 2017, 14, 491–502. [Google Scholar] [CrossRef] [Green Version]

- Alves-Santos, A.M.; Araújo Sugizaki, C.S.; Lima, G.C.; Veloso Naves, M.M. Prebiotic effect of dietary polyphenols: A systematic review. J. Funct. Foods. 2020, 74, 104169. [Google Scholar] [CrossRef]

- Shen, Y.; Jin, L.; Xiao, P.; Lu, Y.; Bao, J.S. Total phenolics, flavonoids, antioxidant capacity in rice grain and their relations to grain color, size and weight. J. Cereal Sci. 2009, 49, 106–111. [Google Scholar] [CrossRef]

- Zhu, F. Buckwheat proteins and peptides: Biological functions and food applications. Trends Food Sci. Technol. 2021, 110, 155–167. [Google Scholar] [CrossRef]

- FAOSTAT. The Food and Agriculture Organization Corporate Statistical Database. 2020. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 29 July 2022).

- Zhu, F. Buckwheat starch: Structures, properties, and applications. Trends Food Sci. Technol. 2016, 49, 121–135. [Google Scholar] [CrossRef]

- Jespersen, L.; Tarnow, I.; Eskesen, D.; Melsaether Morberg, C.; Michelsen, B.; Bügel, S.; Dragsted, L.O.; Rijkers, G.T.; Calder, F.C. Effect of Lactobacillus paracasei subsp. paracasei, L. casei 431 on immune response to influenza vaccination and upper respiratory tract infections in healthy adult volunteers: A randomized, double-blind, placebo-controlled, parallel-group study. Am. J. Clin. Nutr. 2015, 101, 1188–1196. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Trachootham, D.; Chupeerach, C.; Tuntipopipat, S.; Pathomyok, L.; Boonnak, K.; Praengam, K.; Promkam, C.; Santivarangkn, C. Drinking fermented milk containing Lactobacillus paracasei 431 (IMULUS™) improves immune response against H1N1 and cross-reactive H3N2 viruses after influenza vaccination: A pilot randomized triple-blinded placebo controlled trial. J. Funct. Foods 2017, 33, 1–10. [Google Scholar] [CrossRef]

- Milea, Ș.A.; Vasile, M.A.; Crăciunescu, O.; Prelipcean, A.-M.; Bahrim, G.E.; Râpeanu, G.; Stănciuc, N. Co-Microencapsulation of flavonoids from yellow onion skins and lactic acid bacteria lead to multifunctional ingredient for nutraceutical and pharmaceutics applications. Pharmaceutics 2020, 12, 1053. [Google Scholar] [CrossRef]

- AOAC Official Method 2005.02 Total Monomeric Anthocyanin Pigment Content of Fruit Juices, Beverages, Natural Colorants, and Wines. pH Differential Method; AOAC: Gaithersburg, MD, USA, 2005.

- Souza, A.L.R.; Hidalgo-Chávez, D.W.; Pontes, S.M.; Gomes, F.S.; Cabral, L.M.C.; Tonon, R.V. Microencapsulation by spray drying of a lycopene-rich tomato concentrate: Characterization and stability. LWT 2018, 91, 286–292. [Google Scholar] [CrossRef]

- Fathollahi, M.; Aminzare, M.; Mohseni, M.; Hassanzadazar, H. Antioxidant capacity, antimicrobial activities and chemical composition of Pistacia atlantica subsp. kurdica essential oil. Vet. Res. Forum. 2019, 10, 299–305. [Google Scholar] [PubMed]

- Vasile, M.A.; Milea, Ș.A.; Enachi, E.; Barbu, V.; Cîrciumaru, A.; Bahrim, G.E.; Râpeanu, G.; Stănciuc, N. Functional enhancement of bioactives from black beans and lactic acid bacteria into an innovative food ingredient by co-microencapsulation. Food Bioproc. Technol. 2020, 13, 978–987. [Google Scholar] [CrossRef]

- Kim, I.; Moon, J.K.; Hur, S.J.; Lee, J. Structural changes in mulberry (Morus Microphylla. Buckl) and chokeberry (Aronia melanocarpa) anthocyanins during simulated in vitro human digestion. Food Chem. 2020, 318, 126449. [Google Scholar] [CrossRef]

- Paucar-Menacho, M.; Peñas, E.; Hernandez-Ledesma, B.; Frias, J.; Martínez-Villaluenga, C. A comparative study on the phenolic bioaccessibility, antioxidant and inhibitory effects on carbohydrate-digesting enzymes of maca and mashua powders. LWT 2020, 131, 109798. [Google Scholar] [CrossRef]

- Wang, Y.; Li, L.; Liu, H.; Zhao, T.; Meng, C.; Liu, Z.; Liu, X. Bioactive compounds and in vitro antioxidant activities of peel, flesh and seed powder of kiwi fruit. Int. J. Food Sci. Technol. 2018, 53, 2239–2245. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, B.; Qi, Y.; Chen, X.; Liu, C.; Liu, Z.; Ren, X. Expression differences of pigment structural genes and transcription factors explain flesh coloration in three contrasting kiwifruit cultivars. Front. Plant Sci. 2017, 8, 1507. [Google Scholar] [CrossRef]

- Zhang, J.; Gao, N.; Shu, C.; Cheng, S.; Sun, X.; Liu, C.; Xin, G.; Li, B.; Tian, J. Phenolics profile and antioxidant activity analysis of kiwi berry (Actinidia arguta) flesh and peel extracts from four regions in China. Front. Plant Sci. 2021, 12, 689038. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.K.; Low, K.Y.; Siah, K.; Drummond, L.M.; Gwee, K.-A. Kiwifruit (Actinidia deliciosa) changes intestinal microbial profile. Microb. Ecol. Health Dis. 2012, 23, 18572. [Google Scholar] [CrossRef] [PubMed]

- Xie, X.; Chen, C.; Huang, Q.; Fu, X. Digestibility, bioactivity and prebiotic potential of phenolics released from whole gold kiwifruit and pomace by in vitro gastrointestinal digestion and colonic fermentation. Food Funct. 2020, 11, 9613–9623. [Google Scholar] [CrossRef] [PubMed]

- Hill, C.; Guarner, F.; Reid, G.; Gibson, G.R.; Merenstein, D.J.; Pot, B.; Morelli, L.; Canani, R.B.; Flint, H.J.; Salminen, S.; et al. Expert consensus document. The International Scientific Association for Probiotics and Prebiotics consensus statement on the scope and appropriate use of the term probiotic: Expert consensus document. Nat. Rev. Gastroenterol. Hepatol. 2014, 11, 506–514. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nakkarach, A.; Withayagiat, U. Comparison of synbiotic beverages produced from riceberry malt extract using selected free and encapsulated probiotic lactic acid bacteria. Agric. Nat. Resour. 2018, 52, 467–476. [Google Scholar] [CrossRef]

- Soccol, C.R.; Vandenberghe, L.P.S.; Spier, M.R.; Medeiros, A.B.P.; Yamaguishi, C.T.; Lindner, J.D.; Pandey, A. The potential of probiotics: A review. Food Technol. Biotechnol. 2010, 48, 413–434. [Google Scholar]

- Tylewicz, U.; Nowacka, M.; Rybak, K.; Drozdzal, K.; Dalla Rosa, M.; Mozzon, M. Design of Healthy Snack Based on Kiwifruit. Molecules 2020, 25, 3309. [Google Scholar] [CrossRef]

- Dietrich, C.G.; Kottmann, T.; Alavi, M. Commercially available probiotic drinks containing Lactobacillus casei Dn-114001 reduce antibiotic-associated diarrhea. World J. Gastroenterol. 2014, 20, 15837–15844. [Google Scholar] [CrossRef]

- Hill, D.; Sugrue, I.; Tobin, C.; Hill, C.; Stanton, C.; Ross, R.P. The Lactobacillus casei Group: History and Health Related Applications. Front Microbiol. 2018, 109, 2107. [Google Scholar] [CrossRef] [Green Version]

- Sanders, M.E.; Shane, A.L.; Merenstein, D.J. Advancing probiotic research in humans in the United States: Challenges and strategies. Gut Microbes 2016, 7, 97–100. [Google Scholar] [CrossRef] [Green Version]

| Phytochemicals | Pomace | Peels |

|---|---|---|

| Hydrophilic profile | ||

| Total flavonoid content, mg CE/g DW | 1.97 ± 0.04 b | 5.34 ± 0.39 a |

| Total polyphenolic content, mg GAE/g DW | 3.79 ± 0.15 b | 9.71 ± 0.28 a |

| Antioxidant activity, µM Trolox/g DW | 9.68 ± 0.43 b | 51.09 ± 2.57 a |

| Hydrophobic profile | ||

| β-Carotene, mg/g DW | 1.19 ± 0.065 b | 4.23 ± 0.027 a |

| Lycopene, mg g DW | 0.55 ± 0.042 b | 1.06 ± 0.027 a |

| Total carotenoids, mg/g DW | 1.55 ± 0.093 b | 5.70 ± 0.033 a |

| Antioxidant activity, µM Trolox/g DW | 5.92 ± 0.13 b | 8.62 ± 0.09 a |

| Variants | KPO | KPB | KBR | KP |

|---|---|---|---|---|

| Hydrophilic profile | ||||

| Total polyphenolic content, mg GAE/g DW | 12.46 ± 0.34 a | 10.56 ± 0.30 c | 11.51 ± 0.16 b | 13.16 ± 0.33 a |

| Total flavonoid content, mg CE/g DW | 1.49 ± 0.10 b | 2.03 ± 0.29 a | 2.17 ± 0.07 a | 1.89 ± 0.03 a,b |

| Antioxidant activity, µM Trolox/g DW | 57.67 ± 0.14 a | 56.32 ± 1.04 a | 56.93 ± 0.22 a | 56.91 ± 0.29 a |

| Hydrophobic profile | ||||

| β-Carotene, mg/g DW | 0.90 ± 0.07 b | 0.84 ± 0.05 b | 0.81 ± 0.03 b | 1.47 ± 0.05 a |

| Lycopene, mg/g DW | 0.57 ± 0.05 a | 0.55 ± 0.01 a | 0.56 ± 0.07 a | 0.57 ± 0.04 a |

| Total carotenoids, mg/g DW | 1.04 ± 0.02 b | 1.04 ± 0.06 b | 1.04 ± 0.03 b | 1.89 ± 0.05 a |

| AA, µM Trolox/g DW | 3.90 ± 0.08 a | 3.99 ± 0.08 a | 4.07 ± 0.04 a | 4.06 ± 0.11 a |

| L. casei 431®, log CFU/g DW | 7.89 d | 9.27 b | 8.86 c | 9.46 a |

| Parameter | KPO | KPB | KBR | KP |

|---|---|---|---|---|

| L* | 39.48 ± 0.30 a | 37.76 ± 0.30 b | 13.63 ± 0.01 d | 33.78 ± 0.31 c |

| a* | 7.22 ± 0.10 b | 6.055 ± 0.40 c | 13.67 ± 0.09 a | 0.605 ± 0.04 d |

| b* | 22.32 ± 0.20 b | 13.67 ± 0.09 c | 0.91 ± 0.01 d | 25.43 ± 0.21 a |

| Variants | C | V1 | V2 |

|---|---|---|---|

| Total polyphenolic content, mg GAE/g DW | 3.95 ± 0.12 b | 4.18 ± 0.17 b | 4.76 ± 0.07 a |

| Total flavonoid content, mg CE/g DW | 1.36 ± 0.01 b | 1.37 ± 0.03 b | 1.48 ± 0.01 a |

| Antioxidant activity, µM Trolox/g DW | 22.51 ± 0.18 b | 22.67 ± 0.25 b | 23.75 ± 0.16 a |

| β-caroten, mg/g DW | 0.37 ± 0.02 b | 0.43 ± 0.02 b | 0.72 ± 0.06 a |

| Lycopen, mg/g DW | 0.17 ± 0.01 b | 0.19 ± 0.01 b | 0.37 ± 0.03 a |

| Total carotenoids, mg/g DW | 0.37 ± 0.02 c | 0.52 ± 0.02 b | 0.84± 0.06 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ilie, G.-I.; Milea, Ș.-A.; Râpeanu, G.; Cîrciumaru, A.; Stănciuc, N. Sustainable Design of Innovative Kiwi Byproducts-Based Ingredients Containing Probiotics. Foods 2022, 11, 2334. https://doi.org/10.3390/foods11152334

Ilie G-I, Milea Ș-A, Râpeanu G, Cîrciumaru A, Stănciuc N. Sustainable Design of Innovative Kiwi Byproducts-Based Ingredients Containing Probiotics. Foods. 2022; 11(15):2334. https://doi.org/10.3390/foods11152334

Chicago/Turabian StyleIlie, Gheorghe-Ionuț, Ștefania-Adelina Milea, Gabriela Râpeanu, Adrian Cîrciumaru, and Nicoleta Stănciuc. 2022. "Sustainable Design of Innovative Kiwi Byproducts-Based Ingredients Containing Probiotics" Foods 11, no. 15: 2334. https://doi.org/10.3390/foods11152334

APA StyleIlie, G. -I., Milea, Ș. -A., Râpeanu, G., Cîrciumaru, A., & Stănciuc, N. (2022). Sustainable Design of Innovative Kiwi Byproducts-Based Ingredients Containing Probiotics. Foods, 11(15), 2334. https://doi.org/10.3390/foods11152334