Future of Structured Lipids: Enzymatic Synthesis and Their New Applications in Food Systems

Abstract

1. Introduction

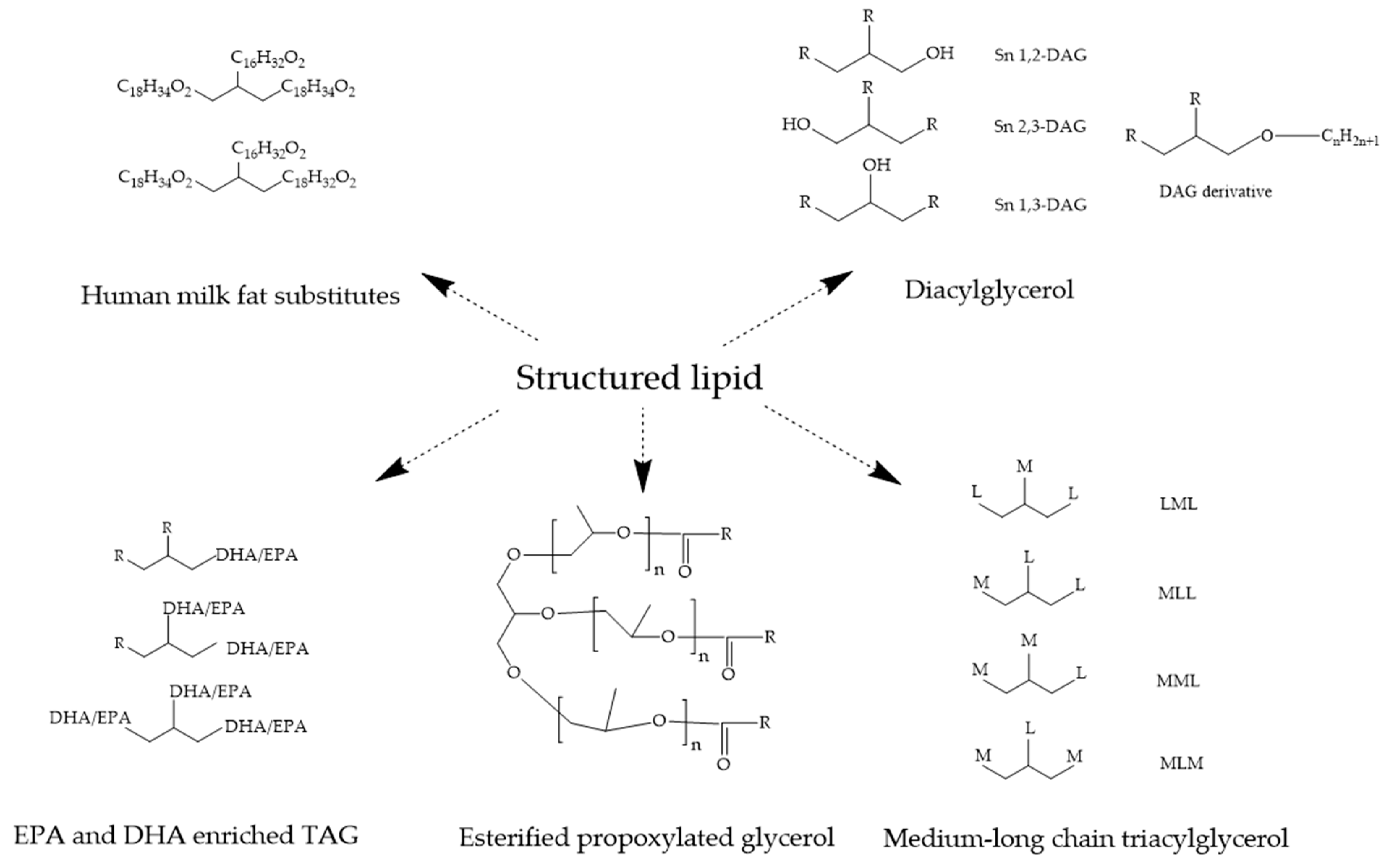

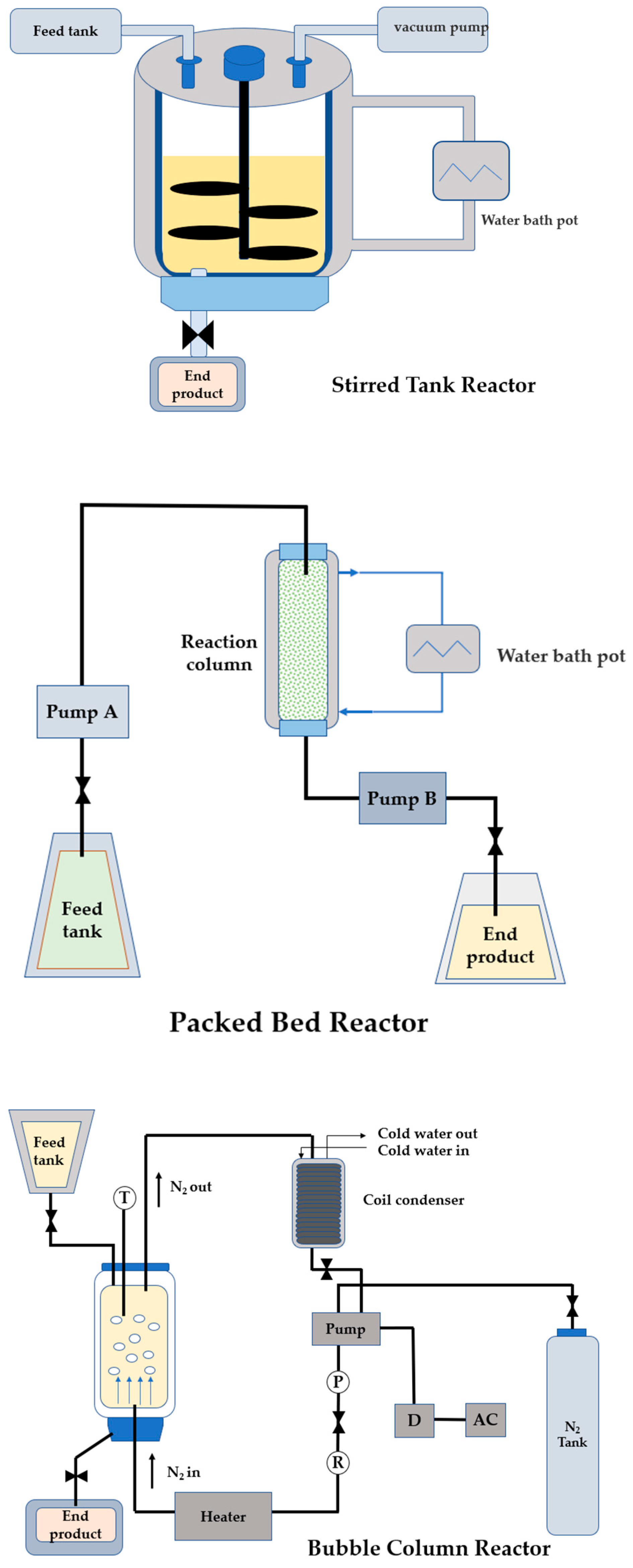

2. Reaction System for SL Production

3. Enzymatic Preparation and Application of SLs

3.1. Medium—To Long-Chain Triacylglycerol (MLCT)

3.2. Diacylglycerol (DAG)

3.3. EPA and DHA-Enriched TAG

3.4. Human Milk Fat Substitutes

3.5. Esterified Propoxylated Glycerol (EPG)

4. Future Applications of SLs in Food Systems

4.1. Powdered Oil

4.2. DAG-Based Plastic Fat

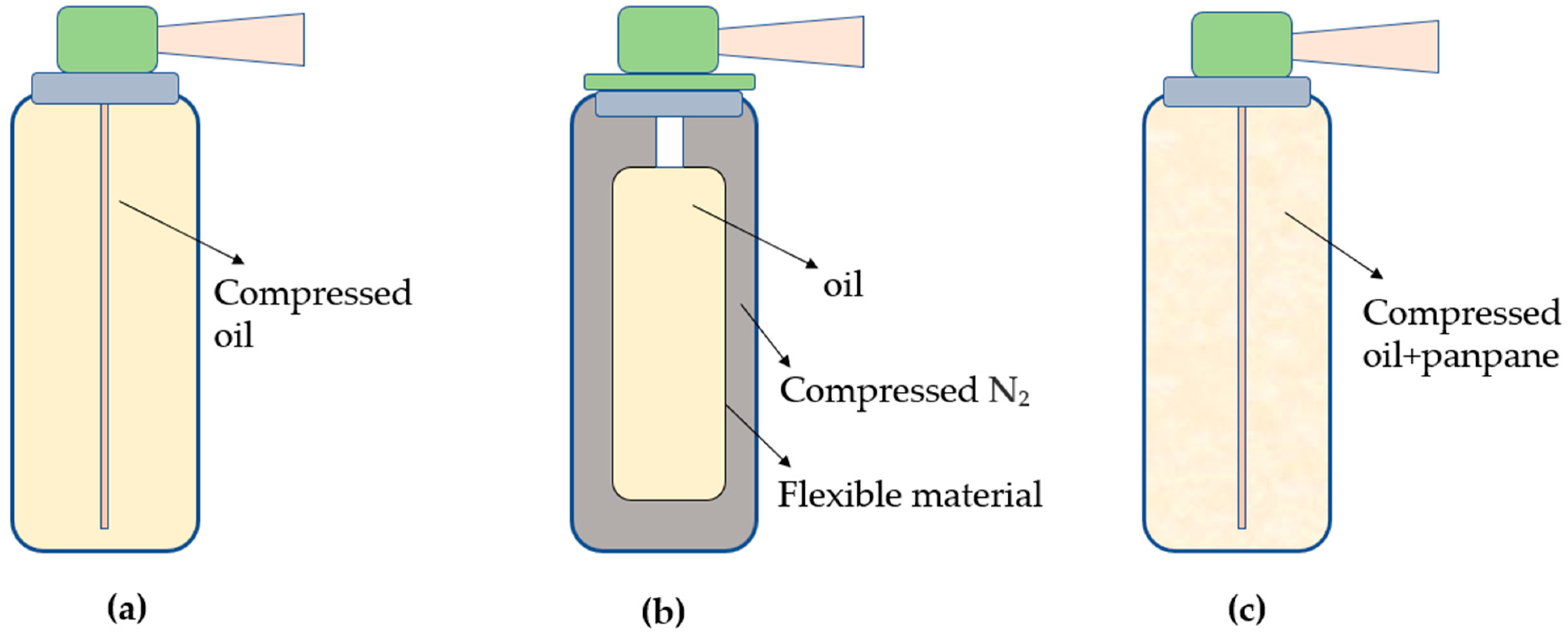

4.3. Inert Gas Spray Oil

4.4. Emulsion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wylie-Rosett, J. Fat substitutes and health: An advisory from the Nutrition Committee of the American Heart Association. Circulation. 2002, 105, 2800–2804. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Heshka, S.; Anderson, J.W.; Atkinson, R.L.; Greenway, F.L.; Hill, J.O.; Phinney, S.D.; Pi-Sunyer, F.X. Weight loss with self-help compared with a structured commercial program: A randomized trial. JAMA. 2003, 289, 1792–1798. [Google Scholar] [CrossRef] [PubMed]

- Takase, H. Metabolism of diacylglycerol in humans. Asia Pac. J. Clin. Nutr. 2007, 16 (Suppl. S1), 398–403. [Google Scholar] [PubMed]

- Guo, Y.; Cai, Z.; Xie, Y.; Ma, A.; Zhang, H.; Rao, P.; Wang, Q. Synthesis, physicochemical properties, and health aspects of structured lipids: A review. Compr. Rev. Food Sci. Food Saf. 2020, 19, 759–800. [Google Scholar] [CrossRef] [PubMed]

- Mu, H.; Porsgaard, T. The metabolism of structured triacylglycerols. Prog. Lipid Res. 2005, 44, 430–448. [Google Scholar] [CrossRef]

- Yang, K.; Bi, Y.; Sun, S.; Yang, G.; Ma, S.; Liu, W. Optimisation of N ovozym-435-catalysed esterification of fatty acid mixture for the preparation of medium-and long-chain triacylglycerols (MLCT) in solvent-free medium. Int. J. Food Sci. Technol. 2014, 49, 1001–1011. [Google Scholar] [CrossRef]

- Abd Razak, N.N.; Pérès, Y.; Gew, L.T.; Cognet, P.; Aroua, M.K. Effect of reaction medium mixture on the lipase catalyzed synthesis of diacylglycerol. Ind. Eng. Chem. Res. 2020, 59, 9869–9881. [Google Scholar] [CrossRef]

- Sitompul, J.P.; Gusdinar, T.; Anggadiredja, K.; Rahman, H. Synthesis of Structured Triacylglycerols Based on Canarium Oil for Food Application. J. Eng. Technol. Sci. 2018, 50, 87–98. [Google Scholar] [CrossRef]

- Huang, J.; Lu, Y.; Jin, J.; Song, Z.; Tang, J. Chemical transesterification of flaxseed oil and medium-chain triacylglycerols: MLCT yield, DAG content, physicochemical properties, minor compounds and oxidation stability. Int. J. Food Sci. Technol. 2021, 56, 5160–5167. [Google Scholar] [CrossRef]

- Guebara, S.A.B.; Ract, J.N.R.; Vitolo, M. Conversion of caprylic acid into mono-, di-and triacylglycerols using immobilized lipase. Arab. J. Sci. Eng. 2018, 43, 3631–3637. [Google Scholar] [CrossRef]

- Bornscheuer, U.T. Enzymes in lipid modification. Annu. Rev. Food Sci. Technol. 2018, 9, 85–103. [Google Scholar] [CrossRef] [PubMed]

- Utama, Q.D.; Sitanggang, A.B.; Adawiyah, D.R.; Hariyadi, P. Lipase-catalyzed interesterification for the synthesis of medium-long-medium (MLM) structured lipids–A review. Food Technol. Biotechnol. 2019, 57, 305. [Google Scholar] [CrossRef]

- Phuah, E.T.; Tang, T.K.; Lee, Y.Y.; Choong, T.S.Y.; Tan, C.P.; Lai, O.M. Review on the current state of diacylglycerol production using enzymatic approach. Food Bioprocess Technol. 2015, 8, 1169–1186. [Google Scholar] [CrossRef]

- Feltes, M.M.C.; de Oliveira, D.; Block, J.M.; Ninow, J.L. The production, benefits, and applications of monoacylglycerols and diacylglycerols of nutritional interest. Food Bioprocess Technol. 2013, 6, 17–35. [Google Scholar] [CrossRef]

- van Erp, H.; Bryant, F.M.; Martin-Moreno, J.; Michaelson, L.V.; Bhutada, G.; Eastmond, P.J. Engineering the stereoisomeric structure of seed oil to mimic human milk fat. Proc. Natl. Acad. Sci. USA 2019, 116, 20947–20952. [Google Scholar] [CrossRef]

- Zam, W. Structured lipids: Methods of production, commercial products and nutraceutical characteristics. Prog. Nutr. 2015, 17, 198–213. [Google Scholar]

- Wang, X.; Xiao, J.; Zou, W.; Han, Z.; Jin, Q.; Wang, X. Improved enzymatic synthesis route for highly purified diacid 1,3-diacylglycerols. Process Biochem. 2015, 50, 388–394. [Google Scholar] [CrossRef]

- Utama, Q.D.; Sitanggang, A.B.; Adawiyah, D.R.; Hariyadi, P. Lipase-catalyzed synthesis of medium-long-medium-type of structured lipids from refined bleached deodorized olein. Appl. Food Biotechnol. 2020, 7, 85–94. [Google Scholar]

- Tang, W.; Wang, X.; Huang, J.; Jin, Q.; Wang, X. A novel method for the synthesis of symmetrical triacylglycerols by enzymatic transesterification. Bioresour. Technol. 2015, 196, 559–565. [Google Scholar] [CrossRef]

- Álvarez, C.A.; Akoh, C.C. Preparation of infant formula fat analog containing capric acid and enriched with DHA and ARA at the sn-2 position. J. Am. Oil Chem. Soc. 2016, 93, 531–542. [Google Scholar] [CrossRef]

- Lee, Y.Y.; Tang, T.K.; Chan, E.S.; Phuah, E.T.; Lai, O.M.; Tan, C.P.; Tan, J.S. Medium chain triacylglycerol and medium-and long chain triacylglycerol: Metabolism, production, health impacts and its applications–a review. Crit. Rev. Food Sci. Nutr. 2022, 62, 4169–4185. [Google Scholar] [CrossRef] [PubMed]

- Halim, S.F.A.; Hassan, H.; Amri, N.; Bashah, N.A.A. Transesterification catalyzed by Lipozyme TLIM for biodiesel production from low cost feedstock. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2015; Volume 1660, p. 070089. [Google Scholar]

- Zhang, Z.; Zhang, S.; Lee, W.J.; Lai, O.M.; Tan, C.P.; Wang, Y. Production of Structured triacylglycerol via enzymatic interesterification of medium-chain triacylglycerol and soybean oil using a pilot-scale solvent-free packed bed reactor. J. Am. Oil Chem. Soc. 2020, 97, 271–280. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, M.; Ou, S.; Song, K.; Han, X. Preparation of diacylglycerol-enriched palm olein by phospholipase A1-catalyzed partial hydrolysis. Eur. J. Lipid Sci. Technol. 2009, 111, 652–662. [Google Scholar] [CrossRef]

- Baeza-Jiménez, R.; Miranda, K.; García, H.S.; Otero, C. Lipase-catalyzed glycerolysis of fish oil to obtain diacylglycerols. Grasas Y Aceites. 2013, 64, 3. [Google Scholar]

- Hilterhaus, L.; Thum, O.; Liese, A. Reactor concept for lipase-catalyzed solvent-free conversion of highly viscous reactants forming two-phase systems. Org. Process Res. Dev. 2008, 12, 618–625. [Google Scholar] [CrossRef]

- Chen, J.; Lee, W.J.; Qiu, C.; Wang, S.; Li, G.; Wang, Y. Immobilized Lipase in the Synthesis of High Purity Medium Chain Diacylglycerols Using a Bubble Column Reactor: Characterization and Application. Front. Bioeng. Biotechnol. 2020, 8, 466. [Google Scholar] [CrossRef]

- Kavadia, M.R.; Yadav, M.G.; Odaneth, A.A.; Lali, A.M. Synthesis of designer triacylglycerols by enzymatic acidolysis. Biotechnol. Rep. 2018, 18, e00246. [Google Scholar] [CrossRef]

- Diwan, B.; Gupta, P. Synthesis of MCFA and PUFA rich oils by enzymatic structuring of flax oil with single cell oils. LWT 2020, 133, 109928. [Google Scholar] [CrossRef]

- Moreira, D.K.T.; de Pádua Gandra, R.L.; Zuin, J.C.; Ract, J.N.R.; Ribeiro, A.P.B.; Macedo, J.A.; Macedo, G.A. Synthesis and characterization of structured lipid rich in behenic acid by enzymatic interesterification. Food Bioprod. Process. 2020, 122, 303–310. [Google Scholar] [CrossRef]

- Kowalska, M.; Woźniak, M.; Krzton-Maziopa, A.; Tavernier, S.; Pazdur, Ł.; Żbikowska, A. Development of the emulsions containing modified fats formed via enzymatic interesterification catalyzed by specific lipase with various amount of water. J. Dispers. Sci. Technol. 2019, 40, 192–205. [Google Scholar] [CrossRef]

- Bassan, N.; Rodrigues, R.H.; Monti, R.; Tecelão, C.; Ferreira-Dias, S.; Paula, A.V. Enzymatic modification of grapeseed (Vitis vinifera L.) oil aiming to obtain dietary triacylglycerols in a batch reactor. LWT 2019, 99, 600–606. [Google Scholar] [CrossRef]

- Ribeiro, M.D.; Ming, C.C.; Lopes, T.I.; Grimaldi, R.; Marsaioli, A.J.; Gonçalves, L.A. Synthesis of structured lipids containing behenic acid from fully hydrogenated Crambe abyssinica oil by enzymatic interesterification. J. Food Sci. Technol. 2017, 54, 1146–1157. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Fu, J.; Teng, Y.; Zhang, Z.; Zhang, N.; Wang, Y. Fast production of diacylglycerol in a solvent free system via lipase catalyzed esterification using a bubble column reactor. J. Am. Oil Chem. Soc. 2016, 93, 637–648. [Google Scholar] [CrossRef]

- Zhang, Z.; Song, J.; Lee, W.J.; Xie, X.; Wang, Y. Characterization of enzymatically interesterified palm oil-based fats and its potential application as cocoa butter substitute. Food Chem. 2020, 318, 126518. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Chen, J.; Ma, X.; Zhang, Z.; Liu, N.; Wang, Y. Enzymatic preparation and facile purification of medium-chain, and medium-and long-chain fatty acid diacylglycerols. LWT 2018, 92, 227–233. [Google Scholar] [CrossRef]

- Korma, S.A.; Zou, X.; Ali, A.H.; Abed, S.M.; Jin, Q.; Wang, X. Preparation of structured lipids enriched with medium-and long-chain triacylglycerols by enzymatic interesterification for infant formula. Food Bioprod. Process. 2018, 107, 121–130. [Google Scholar] [CrossRef]

- Sousa, V.; Campos, V.; Nunes, P.; Pires-Cabral, P. Incorporation of capric acid in pumpkin seed oil by sn-1,3 regioselective lipase-catalyzed acidolysis. OCL. 2018, 25, A302. [Google Scholar] [CrossRef]

- Lee, Y.Y.; Tang, T.K.; Lai, O.M. Health benefits, enzymatic production, and application of medium-and long-chain triacylglycerol (MLCT) in food industries: A review. J. Food Sci. 2012, 77, R137–R144. [Google Scholar] [CrossRef]

- Koh, S.P.; Tan, C.P.; Lai, O.M.; Arifin, N.; Yusoff, M.S.A.; Long, K. Enzymatic synthesis of medium-and long-chain triacylglycerols (MLCT): Optimization of process parameters using response surface methodology. Food Bioprocess Technol. 2010, 3, 288–299. [Google Scholar] [CrossRef]

- Wang, Y.; Xia, L.; Xu, X.; Xie, L.; Duan, Z. Lipase-catalyzed acidolysis of canola oil with caprylic acid to produce medium-, long-and medium-chain-type structured lipids. Food Bioprod. Process. 2012, 90, 707–712. [Google Scholar] [CrossRef]

- Zhao, M.L.; Hu, J.N.; Zhu, X.M.; Li, H.Y.; Li, J.; Fan, Y.W.; Deng, Z.Y. Enzymatic synthesis of medium-and long-chain triacylglycerols–enriched structured lipid from C innamomum camphora seed oil and camellia oil by L ipozyme RM IM. Int. J. Food Sci. Technol. 2014, 49, 453–459. [Google Scholar] [CrossRef]

- Khodadadi, M.; Kermasha, S. Modeling lipase-catalyzed interesterification of flaxseed oil and tricaprylin for the synthesis of structured lipids. J. Mol. Catal. B Enzym. 2014, 102, 33–40. [Google Scholar] [CrossRef]

- Adhikari, P.; Shin, J.A.; Lee, J.H.; Kim, H.R.; Kim, I.H.; Hong, S.T.; Lee, K.T. Crystallization, physicochemical properties, and oxidative stability of the interesterified hard fat from rice bran oil, fully hydrogenated soybean oil, and coconut oil through lipase-catalyzed reaction. Food Bioprocess Technol. 2012, 5, 2474–2487. [Google Scholar] [CrossRef]

- Yang, H.; Mu, Y.; Chen, H.; Su, C.; Yang, T.; Xiu, Z. Sn-1,3-specific interesterification of soybean oil with medium-chain triacylglycerol catalyzed by Lipozyme TL IM. Chin. J. Chem. Eng. 2014, 22, 1016–1020. [Google Scholar] [CrossRef]

- Yuan, T.; Wei, W.; Wang, X.; Jin, Q. Biosynthesis of structured lipids enriched with medium and long-chain triacylglycerols for human milk fat substitute. LWT 2020, 128, 109255. [Google Scholar] [CrossRef]

- Zou, X.; Zhang, S.; Cheng, Y.; Huang, J.; He, X.; Jiang, X.; Zhang, H. Lipase-Catalyzed Interesterification of Schizochytrium sp. Oil and Medium-Chain Triacylglycerols for Preparation of DHA-Rich Medium and Long-Chain Structured Lipids. J. Am. Oil Chem. Soc. 2021, 98, 253–267. [Google Scholar] [CrossRef]

- Jennings, B.H.; Shewfelt, R.L.; Akoh, C.C. Food applications of a rice bran oil structured lipid in fried sweet potato chips and an energy bar. J. Food Qual. 2010, 33, 679–692. [Google Scholar] [CrossRef]

- Lee, W.J.; Zhang, Z.; Lai, O.M.; Tan, C.P.; Wang, Y. Diacylglycerol in food industry: Synthesis methods, functionalities, health benefits, potential risks and drawbacks. Trends Food Sci. Technol. 2020, 97, 114–125. [Google Scholar] [CrossRef]

- Cicero, N.; Albergamo, A.; Salvo, A.; Bua, G.D.; Bartolomeo, G.; Mangano, V.; Dugo, G. Chemical characterization of a variety of cold-pressed gourmet oils available on the Brazilian market. Food Res. Int. 2018, 109, 517–525. [Google Scholar] [CrossRef]

- Salvo, A.; Rotondo, A.; La Torre, G.L.; Cicero, N.; Dugo, G. Determination of 1,2/1,3-diglycerides in Sicilian extra-virgin olive oils by 1H-NMR over a one-year storage period. Nat. Prod. Res. 2017, 31, 822–828. [Google Scholar] [CrossRef]

- Arpi, N.; Lubis, Y.M.; Supardan, M.D.; Mustapha, W.A.W. Diacylglycerol-enriched oil production using chemical glycerolysis. Eur. J. Lipid Sci. Technol. 2016, 118, 1880–1890. [Google Scholar]

- Lo, S.K.; Tan, C.P.; Long, K.; Yusoff, M.; Affandi, S.; Lai, O.M. Diacylglycerol oil—Properties, processes and products: A review. Food Bioprocess Technol. 2008, 1, 223–233. [Google Scholar] [CrossRef]

- Devi, B.P.; Gangadhar, K.N.; Prasad, R.B.N.; Sugasini, D.; Rao, Y.P.C.; Lokesh, B.R. Nutritionally enriched 1,3-diacylglycerol-rich oil: Low calorie fat with hypolipidemic effects in rats. Food Chem. 2018, 248, 210–216. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.Y.; Tang, T.K.; Phuah, E.T.; Tan, C.P.; Wang, Y.; Li, Y.; Lai, O.M. Production, safety, health effects and applications of diacylglycerol functional oil in food systems: A review. Crit. Rev. Food Sci. Nutr. 2020, 60, 2509–2525. [Google Scholar] [CrossRef] [PubMed]

- Feltes, M.M.C.; Villeneuve, P.; Baréa, B.; Barouh, N.; De Oliveira, J.V.; De Oliveira, D.; Ninow, J.L. Enzymatic production of monoacylglycerols (MAG) and diacylglycerols (DAG) from fish oil in a solvent-free system. J. Am. Oil Chem. Soc. 2012, 89, 1057–1065. [Google Scholar] [CrossRef]

- Kristensen, J.B.; Xu, X.; Mu, H. Diacylglycerol synthesis by enzymatic glycerolysis: Screening of commercially available lipases. J. Am. Oil Chem. Soc. 2005, 82, 329–334. [Google Scholar] [CrossRef]

- Zhong, N.; Li, L.; Xu, X.; Cheong, L.Z.; Zhao, X.; Li, B. Production of diacylglycerols through low-temperature chemical glycerolysis. Food Chem. 2010, 122, 228–232. [Google Scholar] [CrossRef]

- Zhao, X.; Sun, Q.; Qin, Z.; Liu, Q.; Kong, B. Ultrasonic pretreatment promotes diacylglycerol production from lard by lipase-catalysed glycerolysis and its physicochemical properties. Ultrason. Sonochemistry. 2018, 48, 11–18. [Google Scholar] [CrossRef]

- Moquin, P.H.; Temelli, F. Production of monoolein from oleic acid and glycerol in supercritical carbon dioxide media: A kinetic approach. J. Supercrit. Fluids. 2008, 44, 40–47. [Google Scholar] [CrossRef]

- Feltes, M.M.C.; Vladimir Oliveira, J.; Treichel, H.; Block, J.M.; de Oliveira, D.; Ninow, J.L. Assessment of process parameters on the production of diglycerides rich in omega-3 fatty acids through the enzymatic glycerolysis of fish oil. Eur. Food Res. Technol. 2010, 231, 701–710. [Google Scholar] [CrossRef]

- Kahveci, D.; Guo, Z.; Özçelik, B.; Xu, X. Optimisation of enzymatic synthesis of diacylglycerols in binary medium systems containing ionic liquids. Food Chem. 2010, 119, 880–885. [Google Scholar] [CrossRef]

- Garba, U.; Singanusong, R.; Jiamyangyuen, S.; Thongsook, T. Preparing spray-dried cholesterol free salad dressing emulsified with enzymatically synthesized mixed mono-and diglycerides from rice bran oil and glycerol. J. Food Sci. Technol. 2021, 58, 968–977. [Google Scholar] [CrossRef]

- Valério, A.; Rovani, S.; Treichel, H.; de Oliveira, D.; Oliveira, J.V. Optimization of mono and diacylglycerols production from enzymatic glycerolysis in solvent-free systems. Bioprocess Biosyst. Eng. 2010, 33, 805–812. [Google Scholar] [CrossRef] [PubMed]

- Liu, N.; Wang, Y.; Zhao, Q.; Zhang, Q.; Zhao, M. Fast synthesis of 1,3-DAG by Lecitase® Ultra-catalyzed esterification in solvent-free system. Eur. J. Lipid Sci. Technol. 2011, 113, 973–979. [Google Scholar] [CrossRef]

- Zhong, N.; Gui, Z.; Xu, L.; Huang, J.; Hu, K.; Gao, Y.; Li, B. Solvent-free enzymatic synthesis of 1,3-Diacylglycerols by direct esterification of glycerol with saturated fatty acids. Lipids Health Dis. 2013, 12, 65. [Google Scholar] [CrossRef]

- von der Haar, D.; Stäbler, A.; Wichmann, R.; Schweiggert-Weisz, U. Enzyme-assisted process for DAG synthesis in edible oils. Food Chem. 2015, 176, 263–270. [Google Scholar] [CrossRef]

- Zhong, N.; Chen, W.; Liu, L.; Chen, H. Immobilization of Rhizomucor miehei lipase onto the organic functionalized SBA-15: Their enzymatic properties and glycerolysis efficiencies for diacylglycerols production. Food Chem. 2019, 271, 739–746. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Zhao, F.; Zhong, N. Production of diacylglycerols through glycerolysis with SBA-15 supported Thermomyces lanuginosus lipase as catalyst. J. Sci. Food Agric. 2020, 100, 1426–1435. [Google Scholar] [CrossRef] [PubMed]

- Liu, N.; Wang, Y.; Zhao, Q.; Cui, C.; Fu, M.; Zhao, M. Immobilisation of lecitase® ultra for production of diacylglycerols by glycerolysis of soybean oil. Food Chem. 2012, 134, 301–307. [Google Scholar] [CrossRef]

- Vázquez, L.; González, N.; Reglero, G.; Torres, C. Solvent-free lipase-catalyzed synthesis of diacylgycerols as low-calorie food ingredients. Front. Bioeng. Biotechnol. 2016, 4, 6. [Google Scholar] [CrossRef]

- Anikisetty, M.; Krishna, A.G.; Panneerselvam, V.; Kamatham, A.N. Diacylglycerol (DAG) rich rice bran and sunflower oils modulate lipid profile and cardiovascular risk factors in Wistar rats. J. Funct. Foods. 2018, 40, 117–127. [Google Scholar] [CrossRef]

- Cheong, L.Z.; Tan, C.P.; Long, K.; Idris, N.A.; Yusoff, M.S.A.; Lai, O.M. Baking performance of palm diacylglycerol bakery fats and sensory evaluation of baked products. Eur. J. Lipid Sci. Technol. 2011, 113, 253–261. [Google Scholar] [CrossRef]

- Doucet, J. Shortening System Products Therewith and Methods for Making the Same. U.S. Patent No. 5,908,655, 1 June 1999. [Google Scholar]

- Obitte, N.C.; Zorn, K.; Oroz-Guinea, I.; Bornscheuer, U.T.; Klein, S. Enzymatically modified Shea butter and Palm Kernel oil as potential lipid drug delivery matrices. Eur. J. Lipid Sci. Technol. 2018, 120, 1700332. [Google Scholar] [CrossRef]

- Macierzanka, A.; Szeląg, H.; Szumała, P.; Pawłowicz, R.; Mackie, A.R.; Ridout, M.J. Effect of crystalline emulsifier composition on structural transformations of water-in-oil emulsions: Emulsification and quiescent conditions. Colloids Surf. A Physicochem. Eng. Asp. 2009, 334, 40–52. [Google Scholar] [CrossRef]

- Yu, H.; Dilbaz, S.; Coßmann, J.; Hoang, A.C.; Diedrich, V.; Herwig, A.; Röszer, T. Breast milk alkylglycerols sustain beige adipocytes through adipose tissue macrophages. J. Clin. Investig. 2019, 129, 2485–2499. [Google Scholar] [CrossRef]

- Zhang, T.T.; Xu, J.; Wang, Y.M.; Xue, C.H. Health benefits of dietary marine DHA/EPA-enriched glycerophospholipids. Prog. Lipid Res. 2019, 75, 100997. [Google Scholar] [CrossRef]

- Fard, S.G.; Loh, S.P.; Turchini, G.M.; Wang, B.; Elliott, G.; Sinclair, A.J. Microencapsulated tuna oil results in higher absorption of DHA in toddlers. Nutrients. 2020, 12, 248. [Google Scholar] [CrossRef]

- Hong, S.I.; Ma, N.; No, D.S.; Choi, N.; Baik, J.Y.; Kim, C.T.; Kim, I.H. Enrichment of DHA from tuna oil in a packed bed reactor via lipase-catalyzed esterification. J. Am. Oil Chem. Soc. 2014, 91, 1877–1884. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Zhang, W.; Barber, A.R.; Su, P.; He, S. Significant enrichment of polyunsaturated fatty acids (PUFAs) in the lipids extracted by supercritical CO2 from the livers of Australian rock lobsters (Jasus edwardsii). J. Agric. Food Chem. 2015, 63, 4621–4628. [Google Scholar] [CrossRef]

- Shanmugam, K.; Donaldson, A.A. Extraction of EPA/DHA from 18/12EE fish oil using AgNO3 (aq): Composition, yield, and effects of solvent addition on interfacial tension and flow pattern in mini-fluidic systems. Ind. Eng. Chem. Res. 2015, 54, 8295–8301. [Google Scholar] [CrossRef]

- Lin, W.; Wu, F.W.; Yue, L.; Du, Q.G.; Tian, L.; Wang, Z.X. Combination of urea complexation and molecular distillation to purify DHA and EPA from sardine oil ethyl esters. J. Am. Oil Chem. Soc. 2014, 91, 687–695. [Google Scholar] [CrossRef]

- Crexi, V.T.; Monte, M.L.; Monte, M.L.; Pinto, L.A. Polyunsaturated fatty acid concentrates of carp oil: Chemical hydrolysis and urea complexation. J. Am. Oil Chem. Soc. 2012, 89, 329–334. [Google Scholar] [CrossRef]

- Wang, W.; Li, T.; Ning, Z.; Wang, Y.; Yang, B.; Ma, Y.; Yang, X. A process for the synthesis of PUFA-enriched triacylglycerols from high-acid crude fish oil. J. Food Eng. 2012, 109, 366–371. [Google Scholar] [CrossRef]

- Akanbi, T.O.; Adcock, J.L.; Barrow, C.J. Selective concentration of EPA and DHA using Thermomyces lanuginosus lipase is due to fatty acid selectivity and not regioselectivity. Food Chem. 2013, 138, 615–620. [Google Scholar] [CrossRef]

- Akanbi, T.O.; Barrow, C.J. Lipase-catalysed incorporation of EPA into emu oil: Formation and characterisation of new structured lipids. J. Funct. Foods. 2015, 19, 801–809. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, F.; Ma, X.; Huang, H.; Wang, Y. Two-stage enzymatic preparation of eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA) enriched fish oil triacylglycerols. J. Agric. Food Chem. 2018, 66, 218–227. [Google Scholar] [CrossRef]

- Gao, K.; Chu, W.; Sun, J.; Mao, X. Identification of an alkaline lipase capable of better enrichment of EPA than DHA due to fatty acids selectivity and regioselectivity. Food Chem. 2020, 330, 127225. [Google Scholar] [CrossRef]

- Castejón, N.; Señoráns, F.J. Strategies for Enzymatic Synthesis of Omega-3 Structured Triacylglycerols from Camelina sativa Oil Enriched in EPA and DHA. Eur. J. Lipid Sci. Technol. 2019, 121, 1800412. [Google Scholar] [CrossRef]

- Li, D.; Wang, W.; Qin, X.; Li, X.; Yang, B.; Wang, Y. A novel process for the synthesis of highly pure n-3 polyunsaturated fatty acid (PUFA)-enriched triacylglycerols by combined transesterification and ethanolysis. J. Agric. Food Chem. 2016, 64, 6533–6538. [Google Scholar] [CrossRef]

- Xu, L.; Zhang, L.; Li, D.; Liu, P.; Tan, C.P.; Wang, W.; Wang, Y. Deep Eutectic Solvents Enable the Enhanced Production of n-3 PUFA-Enriched Triacylglycerols. Eur. J. Lipid Sci. Technol. 2017, 119, 1700300. [Google Scholar] [CrossRef]

- Lei, Q.; Ba, S.; Zhang, H.; Wei, Y.; Lee, J.Y.; Li, T. Enrichment of omega-3 fatty acids in cod liver oil via alternate solvent winterization and enzymatic interesterification. Food Chem. 2016, 199, 364–371. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wang, X.D.; Zhao, X.Y.; Liu, X.; Dong, T.; Wu, F.A. From microalgae oil to produce novel structured triacylglycerols enriched with unsaturated fatty acids. Bioresour. Technol. 2015, 184, 405–414. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Wang, X.; Zhang, Y.; Guo, Z.; Jiang, Y.; Chen, F. Enzymatic ethanolysis subjected to Schizochytrium biomass: Sequential processing for DHA enrichment and biodiesel production. Energy Convers. Manag. 2019, 184, 159–171. [Google Scholar] [CrossRef]

- Solaesa, Á.G.; Sanz, M.T.; Falkeborg, M.; Beltrán, S.; Guo, Z. Production and concentration of monoacylglycerols rich in omega-3 polyunsaturated fatty acids by enzymatic glycerolysis and molecular distillation. Food Chem. 2016, 190, 960–967. [Google Scholar] [CrossRef]

- Haq, M.; Park, S.K.; Kim, M.J.; Cho, Y.J.; Chun, B.S. Modifications of Atlantic salmon by-product oil for obtaining different ω-3 polyunsaturated fatty acids concentrates: An approach to comparative analysis. J. Food Drug Anal. 2018, 26, 545–556. [Google Scholar] [CrossRef]

- Naranjo, J.M.D.; Callejón, M.J.J.; Vásquez, M.P.; Rios, L.A.; Medina, A.R. Optimization of the enzymatic synthesis of structured triacylglycerols rich in docosahexaenoic acid at sn-2 position by acidolysis of Aurantiochytrium limacinum SR21 oil and caprylic acid using response surface methodology. J. Appl. Phycol. 2021, 33, 2031–2045. [Google Scholar] [CrossRef]

- Zou, X.; Ye, L.; He, X.; Wu, S.; Zhang, H.; Jin, Q. Preparation of DHA-rich medium-and long-chain triacylglycerols by lipase-catalyzed acidolysis of microbial oil from Schizochytrium sp. with medium-chain fatty acids. Appl. Biochem. Biotechnol. 2020, 191, 1294–1314. [Google Scholar] [CrossRef]

- Valverde, L.M.; Moreno, P.A.G.; Cerdán, L.E.; López, E.N.; López, B.C.; Medina, A.R. Concentration of docosahexaenoic and eicosapentaenoic acids by enzymatic alcoholysis with different acyl-acceptors. Biochem. Eng. J. 2014, 91, 163–173. [Google Scholar] [CrossRef]

- Hita, E.; Robles, A.; Camacho, B.; Ramírez, A.; Esteban, L.; Jiménez, M.J.; Molina, E. Production of structured triacylglycerols (STAG) rich in docosahexaenoic acid (DHA) in position 2 by acidolysis of tuna oil catalyzed by lipases. Process Biochem. 2007, 42, 415–422. [Google Scholar] [CrossRef]

- Yang, Z.; Jin, W.; Cheng, X.; Dong, Z.; Chang, M.; Wang, X. Enzymatic enrichment of n-3 polyunsaturated fatty acid glycerides by selective hydrolysis. Food Chem. 2021, 346, 128743. [Google Scholar] [CrossRef]

- Qin, X.L.; Wang, Y.M.; Wang, Y.H.; Huang, H.H.; Yang, B. Preparation and characterization of 1,3-dioleoyl-2-palmitoylglycerol. J. Agric. Food Chem. 2021, 59, 5714–5719. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.S.; Chu, M.Y.; Zong, M.H.; Yang, J.G.; Lou, W.Y. Efficient Production of 1, 3-Dioleoyl-2-Palmitoylglycerol through Rhodococcus opacus Fermentation. J. Am. Oil Chem. Soc. 2020, 97, 851–860. [Google Scholar] [CrossRef]

- Gao, L.; Cheng, X.; Yu, X.; Wang, X.; Jin, Q.; Wang, X. Lipase-mediated production of 1-oleoyl-2-palmitoyl-3-linoleoylglycerol by a two-step method. Food Biosci. 2020, 36, 100678. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, C.; Xu, W.; Miu, Z.; Jin, Q.; Wang, X. Enzymatic synthesis of structured triacylglycerols rich in 1,3-dioleoyl-2-palmitoylglycerol and 1-oleoyl-2-palmitoyl-3-linoleoylglycerol in a solvent-free system. LWT 2020, 118, 108798. [Google Scholar] [CrossRef]

- Sun, C.; Wei, W.; Zou, X.; Huang, J.; Jin, Q.; Wang, X. Evaluation of triacylglycerol composition in commercial infant formulas on the Chinese market: A comparative study based on fat source and stage. Food Chem. 2018, 252, 154–162. [Google Scholar] [CrossRef]

- Wei, W.; Jin, Q.; Wang, X. Human milk fat substitutes: Past achievements and current trends. Prog. Lipid Res. 2019, 74, 69–86. [Google Scholar] [CrossRef]

- Hasibuan, H.A.; Sitanggang, A.B.; Andarwulan, N.; Hariyadi, P. Enzymatic Synthesis of Human Milk Fat Substitute-A Review on Technological Approaches. Food Technol. Biotechnol. 2021, 59, 475–495. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, Y.; Zhang, X.; Nie, K.; Deng, L.; Wang, F. The two-step synthesis of 1,3-oleoyl-2-palmitoylglycerol by Candida sp. 99–125 lipase. J. Mol. Catal. B Enzym 2016, 133, S1–S5. [Google Scholar] [CrossRef]

- Cao, X.; Pan, Y.; Qiao, M.; Yuan, Y. Synthesis of human milk fat substitutes based on enzymatic preparation of low erucic acid acyl-donors from rapeseed oil. Food Chem. 2022, 387, 132907. [Google Scholar] [CrossRef]

- Sun, D.; Li, S.; Shang, J.; You, L.; Wang, M.; Sun, C.; Wang, X. Process optimization of simultaneous enzymatic production of 1,3-dioleoyl-2-palmitoylglycerol and 1-oleoyl-2-palmitoyl-3-linoleoylglycerol. J. Am. Oil Chem. Soc. 2021, 98, 1167–1176. [Google Scholar] [CrossRef]

- Gu, S.; Feng, F.; Li, Y.; Wei, W.; Lu, R. Aspergillus oryzae lipase-catalyzed synthesis of dioleoyl; palmitoyl-rich triacylglycerols in two reactors. J. Am. Oil Chem. Soc. 2016, 93, 1347–1354. [Google Scholar] [CrossRef]

- Saini, R.K.; Keum, Y.S. Omega-3 and omega-6 polyunsaturated fatty acids: Dietary sources, metabolism, and significance—A review. Life Sci. 2018, 203, 255–267. [Google Scholar] [CrossRef] [PubMed]

- Bechtel, D.H. Article series: Safety of esterified propoxylated glycerol (EPG), a nonabsorbable fat replacer. Regul. Toxicol. Pharmacol. 2014, 70, S91–S94. [Google Scholar] [CrossRef] [PubMed][Green Version]

- GRAS. Notice for Esterified Propoxylated Glycerol (EPG) for Use in Select Commercial Frying Applications; GRAS: Silver Spring, MD, USA, 2018.

- Yanai, H.; Tomono, Y.; Ito, K.; Furutani, N.; Yoshida, H.; Tada, N. Diacylglycerol oil for the metabolic syndrome. Nutr. J. 2007, 6, 43. [Google Scholar] [CrossRef]

- Busolo, M.A.; Torres-Giner, S.; Prieto, C.; Lagaron, J.M. Electrospraying assisted by pressurized gas as an innovative high-throughput process for the microencapsulation and stabilization of docosahexaenoic acid-enriched fish oil in zein prolamine. Innov. Food Sci. Emerg. Technol. 2019, 51, 12–19. [Google Scholar] [CrossRef]

- Böger, B.R.; Acre, L.B.; Viegas, M.C.; Kurozawa, L.E.; Benassi, M.T. Roasted coffee oil microencapsulation by spray drying and complex coacervation techniques: Characteristics of the particles and sensory effect. Innov. Food Sci. Emerg. Technol. 2021, 72, 102739. [Google Scholar] [CrossRef]

- Bakry, A.M.; Abbas, S.; Ali, B.; Majeed, H.; Abouelwafa, M.Y.; Mousa, A.; Liang, L. Microencapsulation of oils: A comprehensive review of benefits, techniques, and applications. Compr. Rev. Food Sci. Food Saf. 2016, 15, 143–182. [Google Scholar] [CrossRef]

- Avramenko, N.A.; Chang, C.; Low, N.H.; Nickerson, M.T. Encapsulation of flaxseed oil within native and modified lentil protein-based microcapsules. Food Res. Int. 2016, 81, 17–24. [Google Scholar] [CrossRef]

- Hermanto, R.F.; Khasanah, L.U.; Atmaka, W.; Manuhara, G.J.; Utami, R. Physical characteristics of cinnamon oil microcapsule. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Philadelphia, PA, USA, 2016; Volume 107, p. 012064. [Google Scholar]

- Yuan, Y.; Kong, Z.Y.; Sun, Y.E.; Zeng, Q.Z.; Yang, X.Q. Complex coacervation of soy protein with chitosan: Constructing antioxidant microcapsule for algal oil delivery. LWT 2017, 75, 171–179. [Google Scholar] [CrossRef]

- Huang, H.; Hao, S.; Li, L.; Yang, X.; Cen, J.; Lin, W.; Wei, Y. Influence of emulsion composition and spray-drying conditions on microencapsulation of tilapia oil. J. Food Sci. Technol. 2014, 51, 2148–2154. [Google Scholar] [CrossRef]

- Granados-Vallejo, M.; Espinosa-Andrews, H.; Guatemala-Morales, G.M.; Esquivel-Solis, H.; Arriola-Guevara, E. Oxidative stability of green coffee oil (Coffea arabica) microencapsulated by spray drying. Processes 2019, 7, 734. [Google Scholar] [CrossRef]

- Carneiro, H.C.; Tonon, R.V.; Grosso, C.R.; Hubinger, M.D. Encapsulation efficiency and oxidative stability of flaxseed oil microencapsulated by spray drying using different combinations of wall materials. J. Food Eng. 2013, 115, 443–451. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Mobli, H.; Madadlou, A.; Rafiee, S. Influence of wall material and inlet drying air temperature on the microencapsulation of fish oil by spray drying. Food Bioprocess Technol. 2013, 6, 1561–1569. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Mobli, H.; Madadlou, A.; Rafiee, S. Fish oil microencapsulation as influenced by spray dryer operational variables. Int. J. Food Sci. Technol. 2013, 48, 1707–1713. [Google Scholar] [CrossRef]

- Li, D.; Zhong, X.; Faiza, M.; Wang, W.; Lian, W.; Liu, N.; Wang, Y. Simultaneous preparation of edible quality medium and high purity diacylglycerol by a novel combined approach. LWT 2021, 150, 111949. [Google Scholar] [CrossRef]

- Diao, X.; Guan, H.; Kong, B.; Zhao, X. Preparation of diacylglycerol from lard by enzymatic glycerolysis and its compositional characteristics. Korean J. Food Sci. Anim. Resour. 2017, 37, 813. [Google Scholar]

- Zhou, Q.; Wei, Z. Food-grade systems for delivery of DHA and EPA: Opportunities, fabrication, characterization and future perspectives. Crit. Rev. Food Sci. Nutr. 2021. [Google Scholar] [CrossRef]

- Li, G.; Lee, W.J.; Tan, C.P.; Lai, O.M.; Wang, Y.; Qiu, C. Tailored rigidity of W/O Pickering emulsions using diacylglycerol-based surface-active solid lipid nanoparticles. Food Funct. 2021, 12, 11732–11746. [Google Scholar] [CrossRef]

- Liu, Y.; Lee, W.J.; Tan, C.P.; Lai, O.M.; Wang, Y.; Qiu, C. W/O high internal phase emulsion featuring by interfacial crystallization of diacylglycerol and different internal compositions. Food Chem. 2022, 372, 131305. [Google Scholar] [CrossRef]

- Guo, Y.; Xu, Y.; Zhang, T.; Wang, Y.; Liu, R.; Chang, M.; Wang, X. Medium and long-chain structured triacylglycerol enhances vitamin D bioavailability in an emulsion-based delivery system: Combination of in vitro and in vivo studies. Food Funct. 2022, 13, 1762–1773. [Google Scholar] [CrossRef]

| Enzymatic Method | Chemical Method | Genetic Method | |

|---|---|---|---|

| Reaction condition | Mild; Efficiency; Green | Strict to catalyst and substrates; Flexible; Stability; Chemicals | Strong pertinence; Complex process; Long cycle |

| Production cost (Energy consumption, catalyst reuse ability) | High lipase cost; Continuous; Low energy consumption | Low catalyst cost; Batch; High energy request | High breeding cost |

| Production efficiency | High yield; Specificity | Easy to degrade; Random | High yield; Specificity |

| Production security | High security in solvent-free system | Chemical and metal issues | Potential gene security issues |

| References | [4,8,9,10,11,12] | [4,13,14] | [4,15,16] |

| Equipment | Substrates | Target Products | Conditions | Advantages | References |

|---|---|---|---|---|---|

| Orbital shaker | Fully hydrogenated soybean oil, caprylic acid | MLCT | PyLip enzyme acidolysis at 60 °C for 1 h, hexane | Substrates mixed evenly; Controllable reaction conditions | [28] |

| Rotary shaker | Flax oil, single cell oils, caprylic acid | MLCT | Immobilized TLL lipase acidolysis at 50 °C for 24 h, solvent-free system | Controllable reaction conditions; Low energy consumption | [29] |

| Stirrer | Extra virgin olive oil, soybean oil, fully hydrogenatedcrambe oil | Behenic acid enriched SL | Lipozyme TL IM interesterification at 60 °C for 4 h, solvent-free system | Controllable reaction conditions; Low energy consumption | [30] |

| Shaker | Mutton tallow, hemp oil | DAG | Immobead 150 lipase interesterification at 60 °C for 6 h | Substrate mixed evenly, Controllable reaction conditions | [31] |

| Batch reactor | Grapeseed oil, capric acid, caprylic acid | MLCT | Lipozyme RM IM® lipase acidolysis at 45 °C for 24 h, solvent-free system | Controllable reaction conditions | [32] |

| Magnetic stirrer | High oleic sun-flower oil, fully hydrogenated Crambe abyssinica oil | Behenic acid enriched SL | Lipozyme TL IM interesterification at 70 °C for 3 h, solvent-free system | Low cost; Controllable reaction conditions | [33] |

| Bubble column reactor | Caprylic acid, capric acid | High Purity Medium Chain DAG | Novozym 435 esterification at 60 °C for 30 min, solvent-free system | Mild; Efficiency; Durable catalyst | [27] |

| Bubble column reactor | Palm oil deodorizer distillate, oleic acid, glycerol | DAG | Lipozyme 435 esterification at 60 °C for 30 min, solvent-free system | Mild; Efficiency; Durable catalyst | [34] |

| Packed bed reactor | Palm olein, fully hydrogenated palm oil, palm kernel oil | Cocoa butter substitutes | Lipozyme TL IM interesterification at 65 °C with feed flow rate of 70 mL/min, solvent-free system | Mild; Efficiency; Durable catalyst | [35] |

| Magnetic stirrer | MAG, caprylic acid | DAG | Novozyme 435 esterification at 65 °C for 30 min, solvent-free system | Low cost; Controllable reaction conditions | [36] |

| Substrates | Type and System of Reaction | Optimal Conditions | Characteristics | References |

|---|---|---|---|---|

| Caprylic acid, capric acid, oleic acid, glycerol | Vacuum and solvent-free system, esterification | Novozym 435 esterification at 90 °C for 12.37 h | MLCT content, Enzyme activity | [6] |

| Arachidonic acid single cell oils, MCTs | Solvent-free system, transesterification | Lipozyme 435 transesterification at 90 °C for 3 h. | Fatty acid and TAG composition, Melting and crystallization behavior | [37] |

| Glycerol, capric acid, oleic acid | Vacuum and solvent-free system, esterification | Lipozyme RM IM esterification at 70 °C for 14 h | MLCT content | [40] |

| Canola oil, caprylic acid | Solvent-free system, acidolysis | Lipozyme RM IM acidolysis at 50–60 °C for 15 h | Fatty acid and TAG composition, Refractive index, Melting profile | [41] |

| Cinnamomum camphora seed oil, camellia oil | Solvent-free system, transesterification | Lipozyme RM IM transesterification at 60 °C for 3 h | Fatty acid and TAG composition, Tocopherol analysis | [42] |

| Flaxseed oil, tricaprylin | Organic solvent system, transesterification | Lipozyme TL IM transesterification at 41.49–50.00 °C for 4.00–4.01 h | Bioconversion yield | [43] |

| Hydrogenated soybean oil, rice bran oil, coconut oil | Solvent-free system, transesterification | Lipozyme TL IM transesterification at 65 °C for 24 h | Fatty acid and TAG composition, Polymorphism, Crystal Morphology, Analysis of Tocopherols and Phytosterols | [44] |

| Soybean oil, MCT | Solvent-free system, transesterification | Lipozyme TL IM transesterification at 55 °C for 30–40 min | Fatty acid and TAG composition, DAG content, Acyl migration | [45] |

| Catfish oil, basa catfish oil | Solvent-free system, transesterification | NS 40086 lipase transesterification at 60 °C for 3 h | Fatty acid and TAG composition, | [46] |

| Microbial oil, MCT containing 99% of caprylic acid | Solvent-free system, transesterification | NS 40086 lipase transesterification at 60 °C for 8 h | Fatty acid and TAG composition | [47] |

| Substrates | Type and System of Reaction | Conditions | Characteristics | References |

|---|---|---|---|---|

| Menhaden oil | Solvent-free system, glycerolysis | Novozym 435 glycerolysis at 70 °C for 24 h | DAG content, Enzyme activity, Positional Analysis of TAG, Fatty acid composition | [56] |

| Rice bran oil | Solvent-free system, glycerolysis | C.antarctica lipase glycerolysis at 70 °C for 24 h | MAG and DAG content, Particle size | [63] |

| Olive oil | Solvent-free system, glycerolysis | Novozym 435 glycerolysis at 70 °C for 4 h | Fatty acid composition, Enzyme activity | [64] |

| Oleic acid | Solvent-free system, esterification | Lecitase® Ultra esterification at 40 °C for 1.5 h | Acylglycerols compositions, Enzyme activity | [65] |

| Lauric acid | Solvent-free system, esterification | Lipozyme RM IM esterification at 50 °C for 3 h | DAG content, Reusability of lipase | [66] |

| Rapeseed oil, MAG, oleic acid | Solvent-free system, esterification | Immobilized lipase EC3.1.1.3 at 60 °C for 6 h | Acid value, MAG and DAG content | [67] |

| Soybean oil | Solvent-free system, glycerolysis | Immobilized RML glycerolysis at 60 °C for 24 h | DAG content, Enzyme activity, TAG conversion | [68] |

| Soybean oil | Solvent-free system, glycerolysis | Immobilized TLL glycerolysis at 60 °C for 12 h, | MAG, DAG, and TAG content, Enzyme activity | [69] |

| Soybean oil | Solvent-free system, glycerolysis | Immobilisation lecitase® ultra glycerolysis at 45 °C for 12 h | TAG composition, DAG content | [70] |

| Short- and medium-chain fatty acid ethyl esters | Solvent-free system, transesterification | Novozym 435 transesterification at 65 °C for 24 h, Lipozyme RM IM transesterification at 65 °C for 32 h. | MAG, DAG, and TAG content | [71] |

| Substrates | Type of Reaction | Conditions | References |

|---|---|---|---|

| Fish oil | Two-stage enzymatic refining process: hydrolysis, transesterification | 400SD hydrolysis at 35 °C for 10 h, sodium phosphate buffer; Novozym 435 transesterification at 60 °C for 6 h, solvent-free system | [88] |

| Codfish oil | Hydrolysis | OUC-Lipase 6 hydrolysis at 40 °C, for 36 h, Tris-HCl buffer | [89] |

| Camelina sativa oil, omega-3 fatty acid ethyl esters | Two-step reaction: ethanolysis, transesterification | Lipozyme TL IM ethanolysis for 1 h, ethanol; Novozym 435 transesterification at 35 °C for 4 h, solvent-free system | [90] |

| Glycerol, DHA/EPA-rich ethyl esters | Two-step enzymatic reaction: transesterification, ethanolysis | Novozym 435 transesterification at 60 °C for 24 h, solvent-free system; Immobilized SMG1-F278N ethanolysis at 30 °C for 96 h, n-hexane, ethanol | [91] |

| Glycerol, n-3 PUFA | Esterification | Novozym 435 at 50 °C for 50 h, deep eutectic solvents | [92] |

| Arctic cod liver oil | Alternate winterization and enzymatic interesterification | Alternate winterization at −80 °C for 24 h, acetone; Lipozyme TL IM interesterification at 40 °C for 2.5 h, solvent-free system | [93] |

| Microalgae oil and oleic acid | Acidolysis | Lipase RM IM acidolysis at 65 °C for 6 h, solvent-free system | [94] |

| Schizochytrium sp. biomass | Ethanolysis | Four liquid formulated enzymes CALA, PLA, RM and TL ethanolysis at 35 °C for 96 h, ethanol | [95] |

| Refined sardine oil, glycerol and tertpentanol | Glycerolysis | Lipozyme 435 glycerolysis at 50 °C for 2 h, tert-Pentanol | [96] |

| Salmon frame bone oil | Alcoholysis, esterification | Novozym 435 alcoholysis at 37 °C for 3 h, ethanol; Lipozyme RM IM esterification at 55 °C for 48 h, solvent-free system | [97] |

| Caprylic acid, A. limacinum SR21 oil | Acidolysis | Lipozyme TL IM acidolysis at 37 °C for 30.4 h, hexane | [98] |

| Microbial oil, medium-chain fatty acids | Acidolysis | Lipozyme RM IM acidolysis at 55 °C for 6 h, solvent-free system | [99] |

| Equipment | Substrates | Conditions | Type of Reaction | References |

|---|---|---|---|---|

| Stirrer | Leaf lard, camellia oil fatty acids | Fractionation at 60 °C for 20 min followed by 34 °C for 10 h; Lipozyme RM IM acidolysis at 45 °C for 6 h, solvent-free system | Fractionation and acidolysis | [103] |

| Batch reactor | Palm stearin, oleic acid | NS40086 lipase acidolysis at 60 °C for 4 h, hexane, solvent-free system | Acidolysis | [105] |

| Magnetic stirrer | Palm stearin, oleic acid, linoleic acid | NS40086 lipase acidolysis at 60 °C for 4 h, solvent-free system | Acidolysis | [106] |

| Stirrer | Rapeseed oil, tripalmitin | Candida cylindracea lipase hydrolysis at 40 °C for 2 h, Tris-HCl buffer; Novozym 40086 acidolysis at 40 °C for 2 h, n-hexane | Hydrolysis and acidolysis | [111] |

| Magnetic stirrer | Soy oil, palm kernel stearin, palm stearin, oleic acid, linoleic acid | Lipozyme TL IM interesterification at 60 °C for 5 h, solvent free system; Lipozyme RM IM interesterification at 56 °C for 7 h, solvent free system | Interesterification | [112] |

| Stirred tank reactor and continuous PBR | Palm stearin, oleic acid | Stirred tank reactor: Immobilized AOL lipase at 65 °C for 1.5 h, solvent-free system PBR: Immobilized AOL lipase at 62.09 °C for 3 h, solvent-free system | Acidolysis | [113] |

| Core Materials | Wall Materials | Preparation Methods | References |

|---|---|---|---|

| DHA-enriched fish oil | Zein | Electrospraying assisted by pressurized gas | [118] |

| Roasted coffee oil | Starch, gelatin, gum arabic | Spray drying and complex coacervation | [119] |

| Flaxseed oil | Lentil protein, maltodextrin | Freeze-drying | [121] |

| Cinnamon oil | Maltodextrin, gum arabic | Spray drying | [122] |

| Algal oil | Soy protein isolate, chitosan | Complex coacervation | [123] |

| Tilapia oil | Trehalose, gelatin, sucrose, xanthan | Spray drying | [124] |

| Coffee oil | Mesquite gum, octenyl succinic anhydride modified starches | Spray drying | [125] |

| Flaxseed oil | Maltodextrin, gum Arabic, whey protein concentrate, modified starch | Spray drying | [126] |

| Fish oil | Skim milk powder, whey protein concentrate, whey protein isolate, milk protein concentrate, sodium caseinate | Spray drying | [127] |

| Fish oil | Skim milk powder | Spray drying | [128] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, J.; Lee, Y.-Y.; Mao, Y.; Wang, Y.; Zhang, Z. Future of Structured Lipids: Enzymatic Synthesis and Their New Applications in Food Systems. Foods 2022, 11, 2400. https://doi.org/10.3390/foods11162400

Zhou J, Lee Y-Y, Mao Y, Wang Y, Zhang Z. Future of Structured Lipids: Enzymatic Synthesis and Their New Applications in Food Systems. Foods. 2022; 11(16):2400. https://doi.org/10.3390/foods11162400

Chicago/Turabian StyleZhou, Jun, Yee-Ying Lee, Yilin Mao, Yong Wang, and Zhen Zhang. 2022. "Future of Structured Lipids: Enzymatic Synthesis and Their New Applications in Food Systems" Foods 11, no. 16: 2400. https://doi.org/10.3390/foods11162400

APA StyleZhou, J., Lee, Y.-Y., Mao, Y., Wang, Y., & Zhang, Z. (2022). Future of Structured Lipids: Enzymatic Synthesis and Their New Applications in Food Systems. Foods, 11(16), 2400. https://doi.org/10.3390/foods11162400