Effect of the Addition of Hulless Barley Flour on the Quality of Short-Dough Cookies

Abstract

:1. Introduction

2. Results and Discussion

2.1. Pasting Properties

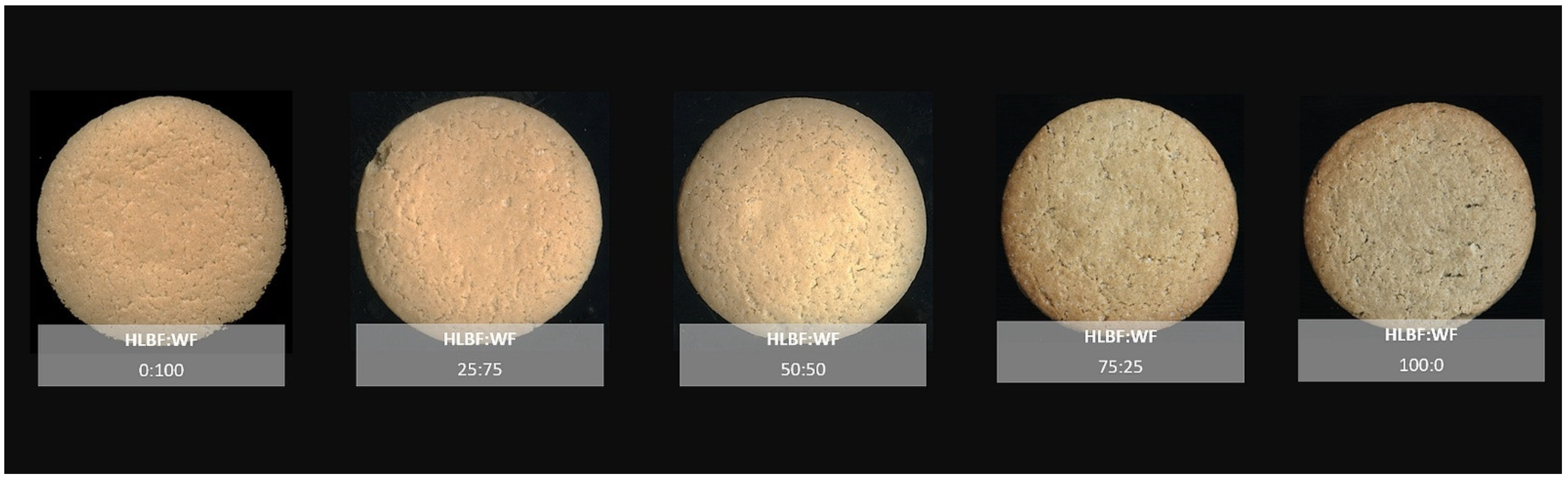

2.2. Physical Characteristics of HLBF:WF Cookies

2.3. Color of HLBF:WF Cookies

2.4. Proximate Composition, Water Activity (aw), and Energy Value of HLBF:WF Cookies

2.5. Total Phenolic Content (TPC) and Antioxidant Capacity (AOC) of HLBF:WF Cookies

2.6. Sensory Evaluation

3. Materials and Methods

3.1. Materials

3.2. Methods

3.2.1. Pasting Properties of HLBF:WF Composite Flours

3.2.2. Production of HLBF:WF Composite Cookies

3.2.3. Physical Characteristics of HLBF:WF Cookies

3.2.4. Chemical Properties of HLBF:WF Cookies

3.2.5. Sensory Evaluation

3.2.6. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nakov, G.; Stamatovska, V.; Jukić, M.; Necinova, L.; Ivanova, N.; Šušak, A.; Komlenić, D.K. Beta Glucans in Biscuits Enriched with Barley Flour Made with Different Sweeteners. J. Hyg. Eng. Des. 2019, 26, 88–92. [Google Scholar]

- Sheikholeslami, Z.; Karimi, M.; Komeili, H.R.; Mahfouzi, M. A New Mixed Bread Formula with Improved Physicochemical Properties by Using Hull-Less Barley Flour at the Presence of Guar Gum and Ascorbic Acid. LWT 2018, 93, 628–633. [Google Scholar] [CrossRef]

- Madhujith, T.; Izydorczyk, M.; Shahidi, F. Antioxidant Properties of Pearled Barley Fractions. J. Agric. Food Chem. 2006, 54, 3283–3289. [Google Scholar] [CrossRef] [PubMed]

- Sharma, P.; Gujral, H.S. Cookie Making Behavior of Wheat-Barley Flour Blends and Effects on Antioxidant Properties. LWT-Food Sci. Technol. 2014, 55, 301–307. [Google Scholar] [CrossRef]

- Farag, M.A.; Xiao, J.; Abdallah, H.M. Nutritional Value of Barley Cereal and Better Opportunities for Its Processing as a Value-Added Food: A Comprehensive Review. Crit. Rev. Food Sci. Nutr. 2022, 62, 1092–1104. [Google Scholar] [CrossRef]

- Messia, M.C.; De Arcangelis, E.; Candigliota, T.; Trivisonno, M.C.; Marconi, E. Production of SS-Glucan Enriched Flour from Waxy Barley. J. Cereal Sci. 2020, 93, 102989. [Google Scholar] [CrossRef]

- Messia, M.C.; Oriente, M.; Angelicola, M.; De Arcangelis, E.; Marconi, E. Development of Functional Couscous Enriched in Barley β-Glucans. J. Cereal Sci. 2019, 85, 137–142. [Google Scholar] [CrossRef]

- Zhang, G.; Yang, K.; Xue, W.; Zeng, X.; Xu, Q.; Wang, Y.; Yuan, H.; Zhang, Y.; Nyima, T. Comparative Proteomic Analysis of Hulless Barley Cultivars (Hordeum vulgare L.) Differing Distinctly in β-Glucan Content. LWT 2020, 133, 110085. [Google Scholar] [CrossRef]

- Food and Drug Administration. Food Labeling: Health Claims; Soluble Fiber from Certain Foods and Risk of Coronary Heart Disease. Interim Final Rule; Food and Drug Administration: Silver Spring, MD, USA, 2008; Volume 73, pp. 9938–9947. [Google Scholar]

- European Food Safety Authority. Scientific Opinion on the Substantiation of a Health Claim Related to Barley Beta-Glucans and Lowering of Blood Cholesterol and Reduced Risk of (Coronary) Heart Disease Pursuant to Article 14 of Regulation (EC) No 1924/2006. EFSA J. 2011, 9, 2470. [Google Scholar] [CrossRef]

- Moza, J.; Gujral, H.S. Influence of Barley Non-Starchy Polysaccharides on Selected Quality Attributes of Sponge Cakes. LWT-Food Sci. Technol. 2017, 85, 252–261. [Google Scholar] [CrossRef]

- Meints, B.; Vallejos, C.; Hayes, P. Multi-Use Naked Barley: A New Frontier. J. Cereal Sci. 2021, 102, 103370. [Google Scholar] [CrossRef]

- Narwal, S.; Kumar, D.; Sheoran, S.; Verma, R.P.S.; Gupta, R.K. Hulless Barley as a Promising Source to Improve the Nutritional Quality of Wheat Products. J. Food Sci. Technol. 2017, 54, 2638–2644. [Google Scholar] [CrossRef] [PubMed]

- Elhadidy, G.; Rizk, E.; El-Dreny, E. Improvement of Nutritional Value, Physical and Sensory Properties of Biscuits Using Quinoa, Naked Barley and Carrot. Egypt J. Food Sci. 2020, 48, 147–157. [Google Scholar] [CrossRef]

- Abdelazim, S.A.A.; El-Hadidie, S.T.; Kamel, M.A. Chemical and Technological Evaluation of Some Varieties Naked Barley. Acta Sci. Nutr. Health 2019, 3, 114–123. [Google Scholar] [CrossRef]

- Aly, A.A.; El-Deeb, F.E.; Abdelazeem, A.A.; Hameed, A.M.; Abdulaziz Alfi, A.; Alessa, H.; Alrefaei, A.F. Addition of Whole Barley Flour as a Partial Substitute of Wheat Flour to Enhance the Nutritional Value of Biscuits. Arab. J. Chem. 2021, 14, 103112. [Google Scholar] [CrossRef]

- Bello-Pérez, L.A.; Sánchez-Rivera, M.M.; Núñez-Santiago, C.; Rodríguez-Ambriz, S.L.; Román-Gutierrez, A.D. Effect of the Pearled in the Isolation and the Morphological, Physicochemical and Rheological Characteristics of Barley Starch. Carbohydr. Polym. 2010, 81, 63–69. [Google Scholar] [CrossRef]

- Liu, J.; Li, Q.; Zhai, H.; Zhang, Y.; Zeng, X.; Tang, Y.; Tashi, N.; Pan, Z. Effects of the Addition of Waxy and Normal Hull-Less Barley Flours on the Farinograph and Pasting Properties of Composite Flours and on the Nutritional Value, Textural Qualities, and in Vitro Digestibility of Resultant Breads. J. Food Sci. 2020, 85, 3141–3149. [Google Scholar] [CrossRef]

- Sapiga, V.; Polischuk, G.; Buniowska, M.; Shevchenko, I.; Osmak, T. Polyfunctional Properties of Oat β-Glucan in the Composition of Milk-Vegetable Ice Cream. Ukr. Food J. 2021, 10, 691–706. [Google Scholar] [CrossRef]

- Gupta, M.; Bawa, A.S.; Abu-Ghannam, N. Effect of Barley Flour and Freeze-Thaw Cycles on Textural Nutritional and Functional Properties of Cookies. Food Bioprod. Process. 2011, 89, 520–527. [Google Scholar] [CrossRef]

- Frost, D.J.; Adhikari, K.; Lewis, D.S. Effect of Barley Flour on the Physical and Sensory Characteristics of Chocolate Chip Cookies. J. Food Sci. Technol. 2011, 48, 569–576. [Google Scholar] [CrossRef]

- Hamed, A.; Ragaee, S.; Marcone, M.; Abdel-Aal, E.S.M. Quality of Bread and Cookie Baked from Frozen Dough and Batter Containing β-Glucan-Rich Barley Flour Fraction. J. Food Qual. 2015, 38, 316–327. [Google Scholar] [CrossRef]

- Lee, S.; Warner, K.; Inglett, G.E. Rheological Properties and Baking Performance of New Oat β-Glucan-Rich Hydrocolloids. J. Agric. Food Chem. 2005, 53, 9805–9809. [Google Scholar] [CrossRef]

- Mancebo, C.M.; Picón, J.; Gómez, M. Effect of Flour Properties on the Quality Characteristics of Gluten Free Sugar-Snap Cookies. Lwt 2015, 64, 264–269. [Google Scholar] [CrossRef]

- Jukić, M.; Nakov, G.; Komlenić, D.K.; Vasileva, N.; Šumanovac, F.; Lukinac, J. Quality Assessment of Cookies Made from Composite Flours Containing Malted Barley Flour and Wheat Flour. Plants 2022, 11, 761. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Chopra, R. Nutritional, Sensory and Textural Analysis of Biscuits Supplemented with Malted Barley (Hordeum vulgare). Int. J. Food Nutr. Sci. 2015, 4, 97–101. [Google Scholar]

- Žilić, S.; Aktağ, I.G.; Dodig, D.; Gökmen, V. Investigations on the Formation of Maillard Reaction Products in Sweet Cookies Made of Different Cereals. Food Res. Int. 2021, 144, 110352. [Google Scholar] [CrossRef]

- Kaur, H.; Shaveta, S.; Kaur, S.; Sharma, V.; Kaur, K. Hulless Barley: A New Era of Research for Food Purposes. J. Careal Res. 2019, 11, 114–124. [Google Scholar] [CrossRef]

- Mokrzycki, W.S.; Tatol, M. Colour Difference ΔE—A Survey. Mach. Graph. Vis. 2011, 20, 383–411. [Google Scholar]

- Stevenson, A.; Cray, J.A.; Williams, J.P.; Santos, R.; Sahay, R.; Neuenkirchen, N.; McClure, C.D.; Grant, I.R.; Houghton, J.D.; Quinn, J.P.; et al. Is There a Common Water-Activity Limit for the Three Domains of Life. ISME J. 2015, 9, 1333–1351. [Google Scholar] [CrossRef]

- European Parliament Council. Corrigendum to Regulation (EC) No 1924/2006 of the European Parliament and of the Council of 20 December 2006 on Nutrition and Health Claims Made on Foods. Off. J. Eur. Union 2007, 12, 16. [Google Scholar]

- European Food Safety Authority. Scientific Opinion on Dietary Reference Values for Carbohydrates and Dietary Fibre. EFSA J. 2016, 8, 1462. [Google Scholar] [CrossRef]

- Boros, D.; Rek-Ciepły, B.; Cyran, M. A Note on the Composition and Nutritional Value of Hulless Barley. J. Anim. Feed Sci. 1996, 5, 417–424. [Google Scholar] [CrossRef]

- Borchani, C.; Besbes, S.; Masmoudi, M.; Bouaziz, M.A.; Blecker, C.; Attia, H. Influence of Oven-Drying Temperature on Physicochemical and Functional Properties of Date Fibre Concentrates. Food Bioprocess Technol. 2012, 5, 1541–1551. [Google Scholar] [CrossRef]

- Schneeman, B.O. Soluble vs. Insoluble Fiber: Different Physiological Responses. Food Technol. 1987, 47, 81–82. [Google Scholar]

- Nirmala Prasadi, V.P.; Joye, I.J. Dietary Fibre from Whole Grains and Their Benefits on Metabolic Health. Nutrients 2020, 12, 3045. [Google Scholar] [CrossRef]

- Nakov, G.; Jukić, M.; Vasileva, N.; Stamatovska, V.; Dimov, I.; Komlenić, D.K. The Influence of Different Sweeteners on in Vitro Starch Digestion in Biscuits with Wheat Flour and Whole Barley Flour. Sci. Study Res. Chem. Chem. Eng. Biotechnol. Food Ind. 2019, 20, 53–62. [Google Scholar]

- Official Journal of the European Union. Commission Regulation (EU) No 432/2012 of 16 May 2012 Establishing a List of Permitted Health Claims Made on Foods, Other than Those Referring to the Reduction of Disease Risk and to Children’s Development and Health. Off. J. Eur. Union 2012, 136, 1–40. [Google Scholar]

- Šimić, G.; Horvat, D.; Lalić, A.; Komlenić, D.K.; Abičić, I.; Zdunić, Z. Distribution of β-Glucan, Phenolic Acids, and Proteins as Functional Phytonutrients of Hull-Less Barley Grain. Foods 2019, 8, 680. [Google Scholar] [CrossRef]

- AACC Approved Methods of Analysis, 11th ed.; AACC International: St. Paul, MN, USA, 2010.

- Official Methods of Analysis of the Association of Official Analytical Chemists, 18th ed.; AOAC: Washington, DC, USA, 2005.

- Singleton, V.L.; Rossi, J.A. Colorimetry of Total Phenolics with Phosphomolybdic-Phosphotungstic Acid Reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a Free Radical Method to Evaluate Antioxidant Activity. LWT-Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

| HLBF:WF | Pasting Temperature (°C) | Peak Viscosity (BU) | Peak Temperature (°C) | Breakdown Viscosity (BU) | Setback Viscosity (BU) |

|---|---|---|---|---|---|

| 0:100 | 60.8 a ± 0.2 1 | 897.0 e ± 2.8 | 89.4 a ± 0.2 | 318.7 d ± 1.0 | 437.3 d ± 7.0 |

| 25:75 | 61.0 a ± 0.1 | 1044.3 d ± 7.8 | 89.3 a ± 0.3 | 434.3 c ± 3.7 | 492.0 c ± 8.7 |

| 50:50 | 61.3 a ± 0.4 | 1088.7 c ± 23.3 | 89.3 a ± 0.1 | 440.0 c ± 8.4 | 517.3 bc ± 18.9 |

| 75:25 | 61.5 a ± 0.4 | 1136.0 b ± 14.6 | 89.2 a ± 0.4 | 469.3 b ± 7.9 | 554.3 ab ± 12.7 |

| 100:0 | 61.6 a ± 0.8 | 1254.3 a ± 6.3 | 89.1 a ± 0.1 | 546.7 a ± 4.0 | 582.7 a ± 9.9 |

| HLBF:WF | Width (cm) | Thickness (cm) | Spread Factor | Snapping Force (N) | Breaking Distance (mm) | Bending Force Index (N/mm) |

|---|---|---|---|---|---|---|

| 0:100 | 6.76 a ± 0.07 1 | 1.28 a ± 0.07 | 52.80 b ± 0.02 | 106.11 a ± 2.23 | 1.82 b ± 0.33 | 58.30 a ± 2.32 |

| 25:75 | 6.67 ab ± 0.23 | 1.26 a ± 0.07 | 52.98 a ± 0.02 | 106.26 a ± 3.51 | 2.21 ab ± 0.41 | 48.08 b ± 3.49 |

| 50:50 | 6.47 abc ± 0.12 | 1.23 a ± 0.14 | 52.43 c ± 0.07 | 103.53 ab ± 3.27 | 3.44 a ± 0.61 | 30.10 c ± 3.10 |

| 75:25 | 6.19 bc ± 0.16 | 1.23 a ± 0.07 | 50.54 d ± 0.03 | 98.11 ab ± 4.62 | 3.46 a ± 0.48 | 28.36 c ± 2.15 |

| 100:0 | 6.10 c ± 0.17 | 1.22 a ± 0.03 | 50.14 e ± 0.08 | 95.25 b ± 2.16 | 3.61 a ± 0.52 | 26.39 c ± 1.93 |

| HLBF:WF | L* | a* | b* | ΔE |

|---|---|---|---|---|

| 0:100 | 66.18 a ± 0.33 1 | 5.49 d ± 0.32 | 36.51 a ± 0.53 | - |

| 25:75 | 64.99 b ± 0.16 | 6.05 cd ± 0.41 | 35.14 b ± 0.26 | 1.90 |

| 50:50 | 64.07 c ± 0.29 | 6.59 bc ± 0.20 | 33.96 c ± 0.46 | 3.49 |

| 75:25 | 63.43 d ± 0.30 | 7.07 ab ± 0.37 | 32.77 d ± 0.22 | 4.90 |

| 100:0 | 62.90 d ± 0.17 | 7.48 a ± 0.33 | 31.68 e ± 0.37 | 6.16 |

| Parameter | HLBF:WF | ||||

|---|---|---|---|---|---|

| 0:100 | 25:75 | 50:50 | 75:25 | 100:0 | |

| Protein (%. w.b.) | 6.03 d ± 0.12 1 | 6.33 cd ± 0.06 | 6.55 bc ± 0.09 | 6.77 ab ± 0.07 | 7.02 a ± 0.10 |

| Carbohydrates (%. w.b.) | 71.25 a ± 0.05 | 69.92 b ± 0.13 | 68.39 c ± 0.08 | 66.70 d ± 0.04 | 65.03 e ± 0.12 |

| Fat (%. w.b.) | 15.30 bc ± 0.03 | 15.53 a ± 0.06 | 15.58 a ± 0.04 | 15.58 a ± 0.04 | 15.56 a ± 0.09 |

| Ash (%. w.b.) | 0.78 e ± 0.02 | 0.95 d ± 0.01 | 1.12 c ± 0.03 | 1.32 b ± 0.01 | 1.47 a ± 0.03 |

| Moisture (%) | 4.61 d ± 0.07 | 4.63 cd ± 0.07 | 4.89 cd ± 0.06 | 5.35 b ± 0.05 | 5.99 a ± 0.14 |

| Water activity | 0.41 c ± 0.01 | 0.43 bc ± 0.03 | 0.46 abc ± 0.03 | 0.50 ab ± 0.02 | 0.53 a ± 0.02 |

| TDF (%. d.b.) | 3.50 e ± 0.07 | 4.37 d ± 0.04 | 6.25 c ± 0.16 | 8.02 b ± 0.09 | 9.84 a ± 0.19 |

| IDF (%. d.b.) | 2.13 e ± 0.11 | 2.75 d ± 0.11 | 3.63 c ± 0.22 | 4.50 b ± 0.10 | 5.24 a ± 0.16 |

| SDF (%. d.b.) | 1.37 d ± 0.09 | 1.63 d ± 0.14 | 2.62 c ± 0.16 | 3.52 b ± 0.07 | 4.60 a ± 0.25 |

| β-glucan (%. d.b.) | 0.12 e ± 0.03 | 0.77 d ± 0.05 | 1.42 c ± 0.08 | 2.14 b ± 0.12 | 2.80 a ± 0.10 |

| Energy value (kJ/100 g) (kcal/100 g) | 1869.33 (446.78) | 1860.97 (444.78) | 1840.75 (439.95) | 1816.55 (434.17) | 1791.49 (428.18) |

| HLBF:WF | Total Polyphenols (µg GAE/g DW) | DPPH Scavenging Activity (mmol TE/100 g) |

|---|---|---|

| 0:100 | 160.53 e ± 2.71 1 | 2.09 b ± 0.12 |

| 25:75 | 270.51 d ± 1.71 | 2.15 ab ± 0.02 |

| 50:50 | 401.07 c ± 3.41 | 2.23 ab ± 0.04 |

| 75:25 | 521.54 b ± 2.12 | 2.29 ab ± 0.05 |

| 100:0 | 621.42 a ± 4.12 | 2.34 a ± 0.06 |

| HLBF:WF | Color | Shape | Texture | Odor | Taste | Overall |

|---|---|---|---|---|---|---|

| 0:100 | 7.9 a ± 1.0 1 | 7.7 a ± 0.6 | 8.0 a ± 1.1 | 7.6 a ± 1.4 | 7.6 a ± 0.5 | 7.8 a ± 0.4 |

| 25:75 | 7.9 a ± 1.5 | 7.7 a ± 0.9 | 7.8 a ± 1.2 | 7.6 a ± 0.9 | 7.7 a ± 1.1 | 7.7 a ± 0.4 |

| 50:50 | 7.4 a ± 1.2 | 7.4 a ± 1.1 | 7.1 ab ± 1.0 | 7.3 a ± 1.2 | 7.5 a ± 1.2 | 7.3 a ± 0.4 |

| 75:25 | 7.2 a ± 1.6 | 6.8 ab ± 1.2 | 5.6 bc ± 1.1 | 7.1 a ± 1.8 | 7.0 ab ± 1.5 | 6.7 ab ± 0.6 |

| 100:0 | 6.9 a ± 1.3 | 5.9 b ± 0.7 | 5.1 c ± 1.1 | 7.0 a ± 1.1 | 6.2 b ± 1.3 | 6.2 b ± 0.5 |

| HLBF | WF | Shortening | Sucrose | NaCl | NaHCO3 | 6% Dextrose Solution | Water |

|---|---|---|---|---|---|---|---|

| - | 100 | 28.4 | 57.8 | 0.9 | 1.1 | 14.7 | 7.1 |

| 25 | 75 | 28.4 | 57.8 | 0.9 | 1.1 | 14.7 | 7.1 |

| 50 | 50 | 28.4 | 57.8 | 0.9 | 1.1 | 14.7 | 7.1 |

| 75 | 25 | 28.4 | 57.8 | 0.9 | 1.1 | 14.7 | 7.1 |

| 100 | - | 28.4 | 57.8 | 0.9 | 1.1 | 14.7 | 7.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nakov, G.; Jukić, M.; Šimić, G.; Šumanovac, F.; Komlenić, D.K.; Lukinac, J. Effect of the Addition of Hulless Barley Flour on the Quality of Short-Dough Cookies. Foods 2022, 11, 2428. https://doi.org/10.3390/foods11162428

Nakov G, Jukić M, Šimić G, Šumanovac F, Komlenić DK, Lukinac J. Effect of the Addition of Hulless Barley Flour on the Quality of Short-Dough Cookies. Foods. 2022; 11(16):2428. https://doi.org/10.3390/foods11162428

Chicago/Turabian StyleNakov, Gjore, Marko Jukić, Gordana Šimić, Franjo Šumanovac, Daliborka Koceva Komlenić, and Jasmina Lukinac. 2022. "Effect of the Addition of Hulless Barley Flour on the Quality of Short-Dough Cookies" Foods 11, no. 16: 2428. https://doi.org/10.3390/foods11162428