Effect of Tremella fuciformis and Different Hydrocolloids on the Quality Characteristics of Wheat Noodles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

2.2. Dough and Noodles Preparation

2.3. Texture Profile Analysis (TPA)

2.4. Cooking Properties

2.5. Dynamic Rheological Measurements of Dough

2.6. Protein Secondary Structure

2.7. Thermogravimetric Analysis

2.8. Water Distribution

2.9. In Vitro Digestion Properties of Cooked Noodles

2.10. Microstructure

2.11. Statistics Analysis

3. Results and Analysis

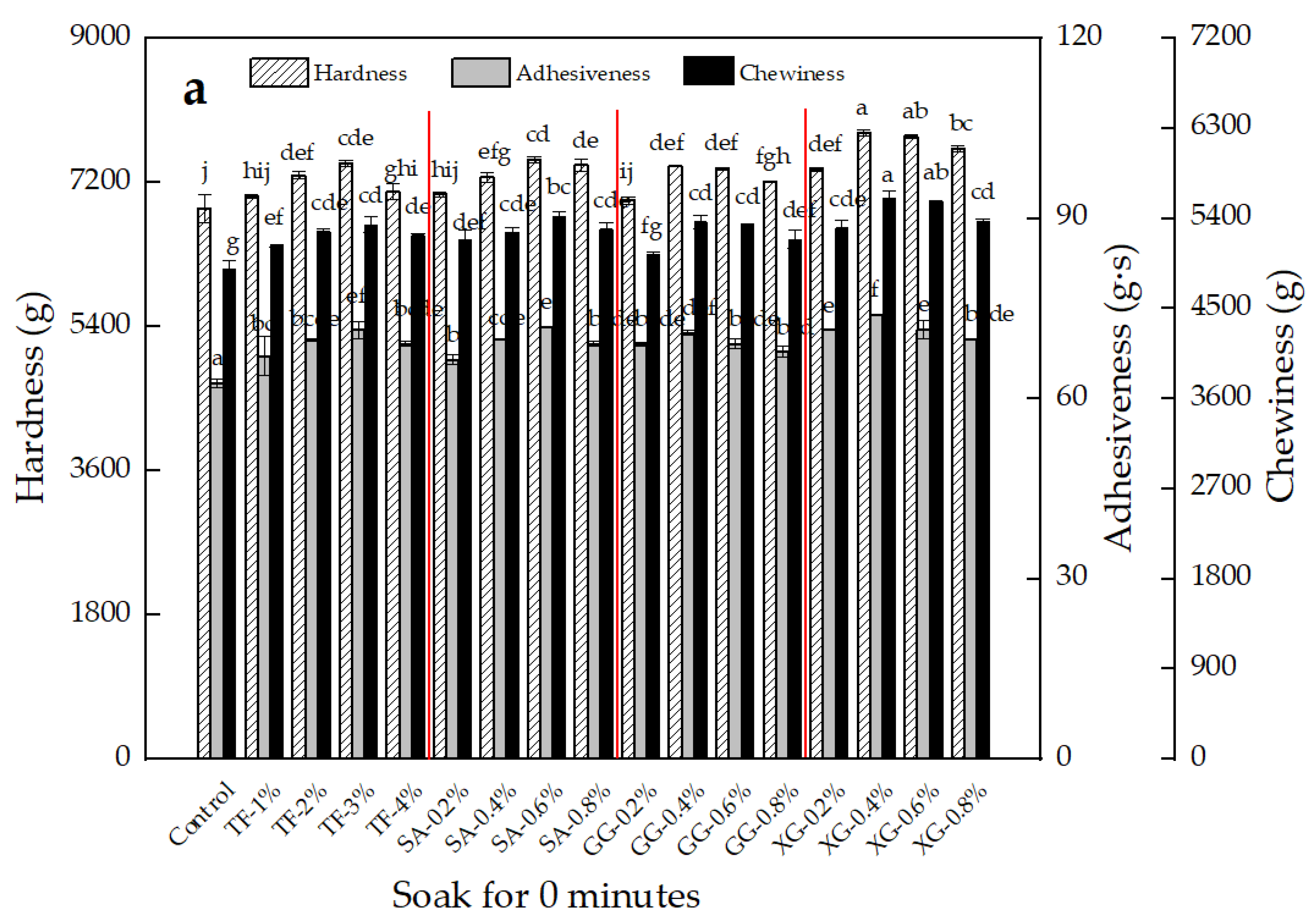

3.1. Texture Properties

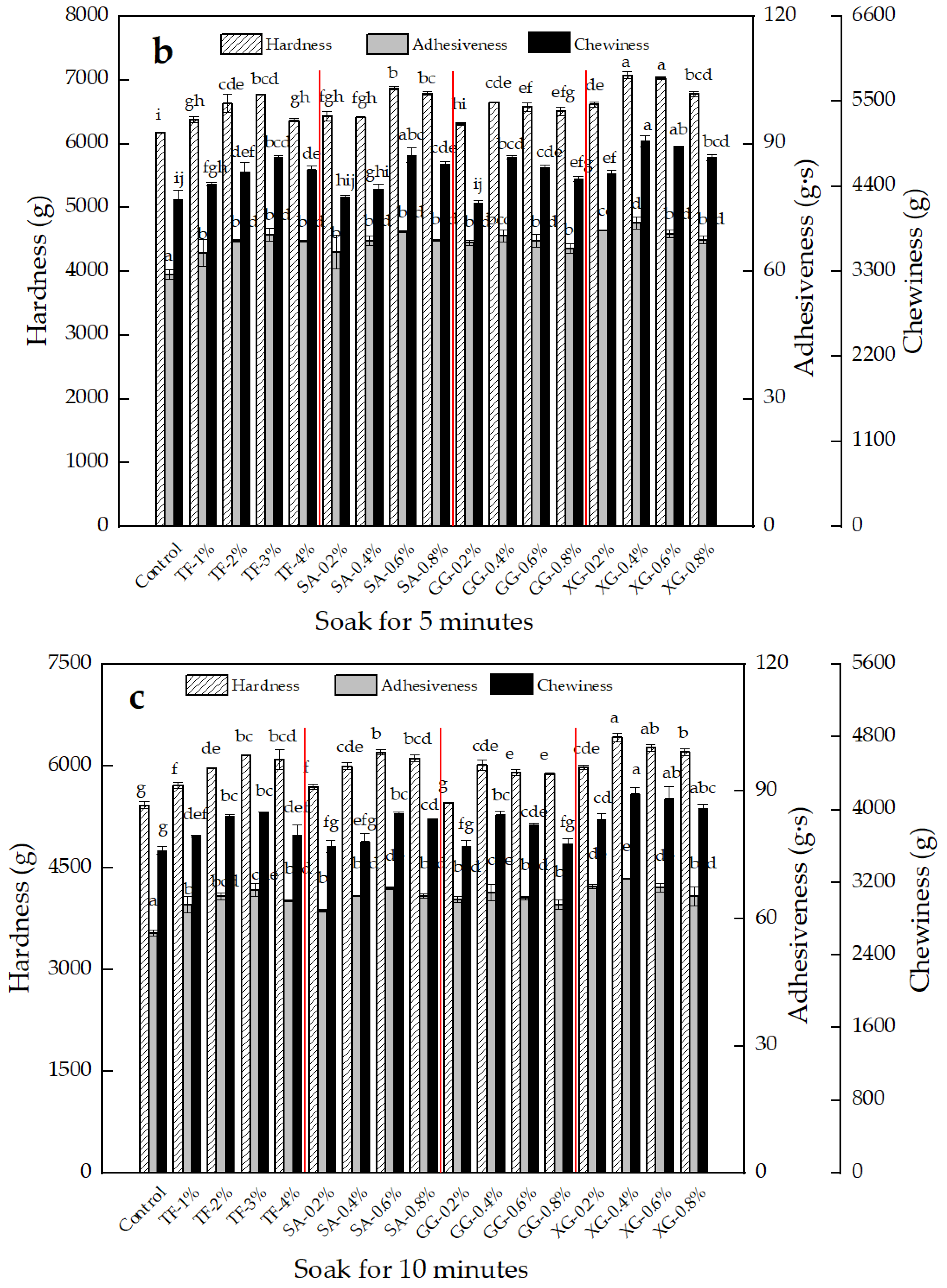

3.2. Cooking Properties

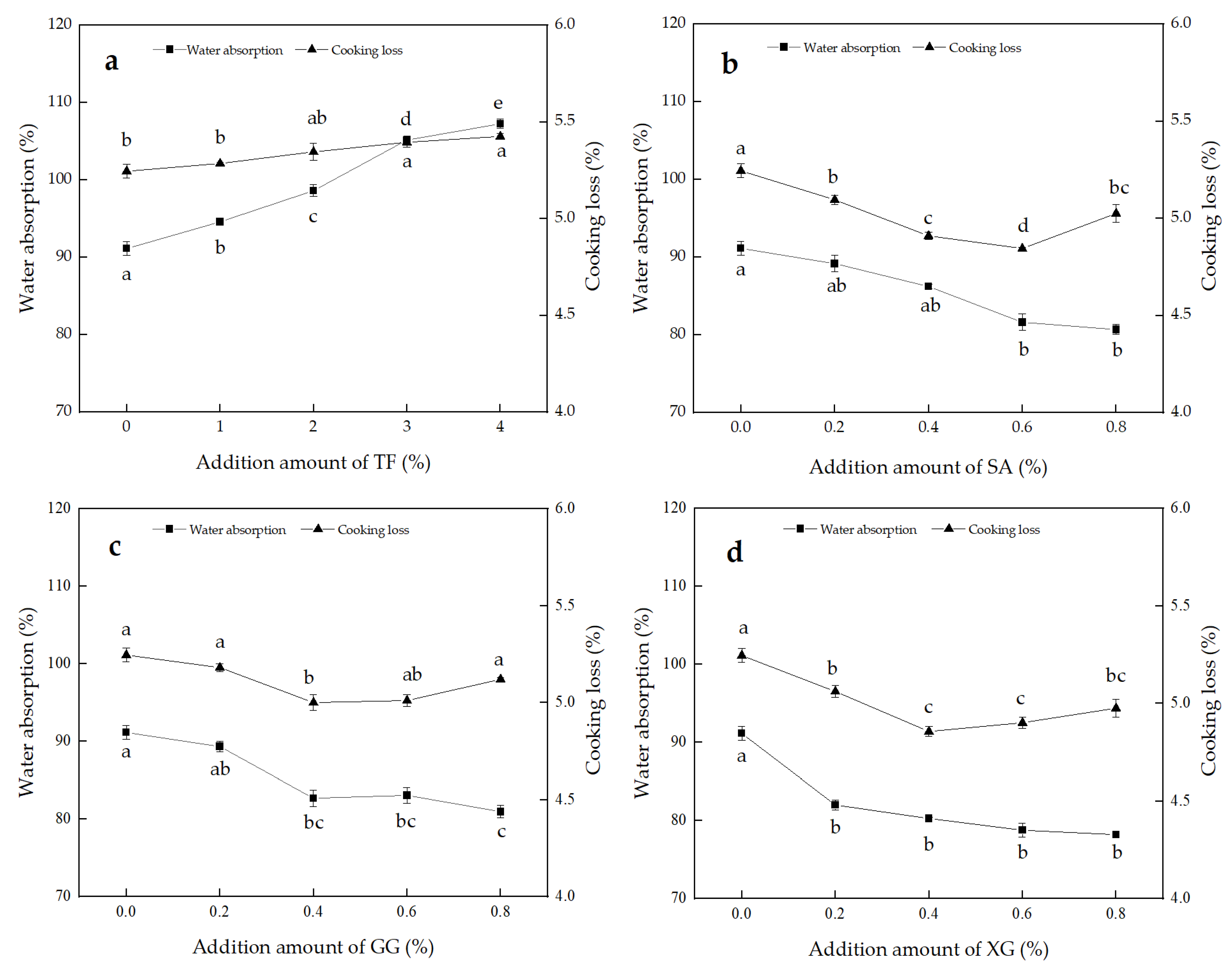

3.3. Dynamic Rheological Measurements of Dough

3.4. Protein Secondary Structure

3.5. Thermogravimetric analysis

3.6. Water Distribution and Migration

3.7. In Vitro Digestion Properties

3.8. Microstructure

3.9. Pearson’s Correlation Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wen, L.; Gao, Q.; Ma, C.W.; Ge, Y.; You, L.; Liu, R. Effect of polysaccharides from Tremella fuciformis on UV-induced photoaging. J. Funct. Foods 2016, 20, 400–410. [Google Scholar] [CrossRef]

- Lan, X.Y.; Wang, Y.H.; Deng, D.; Zhao, J.Y.; Wang, L.; Yao, K.; Jia, D.Y. Physicochemical and rheological properties of Tremella fuciformis polysaccharide fractions by ethanol precipitation. J. Food 2021, 19, 645–655. [Google Scholar] [CrossRef]

- Wang, L.; Wu, Q.; Zhao, J.Y.; Lan, X.Y.; Yao, K.; Jia, D.Y. Physicochemical and rheological properties of crude polysaccharides extracted from Tremella fuciformis with different methods. J. Food 2021, 19, 247–256. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Y.K.; Liu, Y.; Wang, J.H. Emulsifying Properties of Tremella Fuciformis: A Novel Promising Food Emulsifier. Int. J. Food Eng. 2019, 15. [Google Scholar] [CrossRef]

- Tsai, S.Y.; Tsay, G.J.; Li, C.Y.; Hung, Y.T.; Lin, C.P. Assessment of Melting Kinetics of Sugar-Reduced Silver Ear Mushroom Ice Cream under Various Additive Models. Appl. Sci. 2020, 10, 2664. [Google Scholar] [CrossRef]

- Tu, J.; Brennan, M.A.; Hui, X.D.; Wang, R.B.; Peressini, D.; Bai, W.D.; Cheng, P.; Brennan, C.S. Utilisation of dried shiitake, black ear and silver ear mushrooms into sorghum biscuits manipulates the predictive glycaemic response in relation to variations in biscuit physical characteristics. Int. J. Food Sci. Technol. 2021, 57, 2715–2728. [Google Scholar] [CrossRef]

- Hu, J.; Zhao, T.F.; Li, S.J.; Wang, Z.Y.; Wen, C.R.; Wang, H.T.; Yu, C.X.; Ji, C.F. Stability, microstructure, and digestibility of whey protein isolate—Tremella fuciformis polysaccharide complexes. Food Hydrocoll. 2019, 89, 379–385. [Google Scholar] [CrossRef]

- Tang, R.Y.; Lu, Y.R.; Hou, C.Y.; Peng, J.X.; Wang, W.; Guo, X.L. Co-Supplementation of Flos Sophorae Extract with Tremella fuciformis Polysaccharides Improves Physicochemical, Textural, Rheological, and Antioxidant Properties of Low-Fat Yogurts. J. Food Qual. 2020, 2020, 2048756. [Google Scholar] [CrossRef]

- Hong, T.T.; Zhang, Y.; Xu, D.; Wu, F.F.; Xu, X.M. Effect of sodium alginate on the quality of highland barley fortified wheat noodles. LWT 2021, 140, 110719. [Google Scholar] [CrossRef]

- Tangthanantorn, J.; Wichienchot, S.; Sirivongpaisal, P. Development of fresh and dried noodle products with high resistant starch content from banana flour. Food Sci. Technol. 2022, 42, e68720. [Google Scholar] [CrossRef]

- Gasparre, N.; Rosell, C.M. Role of hydrocolloids in gluten free noodles made with tiger nut flour as non-conventional powder. Food Hydrocoll. 2019, 97, 105194. [Google Scholar] [CrossRef]

- Jang, H.L.; Bae, I.Y.; Lee, H.G. In vitro starch digestibility of noodles with various cereal flours and hydrocolloids. LWT-Food Sci. Technol. 2015, 63, 122–128. [Google Scholar] [CrossRef]

- Wang, L.; Tian, Y.P.; Chen, Z.Q.; Chen, J. Effects of Hericium erinaceus powder on the digestion, gelatinization of starch, and quality characteristics of Chinese noodles. Cereal Chem. 2020, 98, 482–491. [Google Scholar] [CrossRef]

- Ge, H.F.; Zang, Y.Y.; Cao, Z.Y.; Ye, X.J.; Chen, J.C. Rheological properties, textural and compound preservative of kelp recombination noodles. LWT 2019, 118, 108729. [Google Scholar] [CrossRef]

- Zheng, M.J.; Lin, Y.; Wu, H.Q.; Zeng, S.X.; Zheng, B.D.; Zhang, Y.; Zeng, H.L. Water migration depicts the effect of hydrocolloids on the structural and textural properties of lotus seed starch. Food Chem. 2020, 315, 126240. [Google Scholar] [CrossRef]

- Sun, L.; Gidley, M.J.; Warren, F.J. Tea polyphenols enhance binding of porcine pancreatic alpha-amylase with starch granules but reduce catalytic activity. Food Chem. 2018, 258, 164–173. [Google Scholar] [CrossRef]

- Li, M.; Sun, Q.J.; Han, C.W.; Chen, H.H.; Tang, W.T. Comparative study of the quality characteristics of fresh noodles with regular salt and alkali and the underlying mechanisms. Food Chem. 2018, 246, 335–342. [Google Scholar] [CrossRef]

- Molina, M.T.; Lamothe, L.; Gunes, D.Z.; Vaz, S.M.; Bouchon, P. The Effect of Arabinoxylan and Wheat Bran Incorporation on Dough Rheology and Thermal Processing of Rotary-Moulded Biscuits. Foods 2021, 10, 2335. [Google Scholar] [CrossRef]

- Hymavathi, T.V.; Thejasri, V.; Roberts, T.P.P. Enhancing cooking, sensory and nutritional quality of finger millet noodles through incorporation of hydrocolloids. Int. J. Chem. Stud. 2019, 7, 877–881. [Google Scholar]

- Xu, X.Q.; Chen, A.J.; Ge, X.Y.; Li, S.; Zhang, T.; Xu, H. Chain conformation and physicochemical properties of polysaccharide (glucuronoxylomannan) from Fruit Bodies of Tremella fuciformis. Carbohydr. Polym. 2020, 245, 116345. [Google Scholar] [CrossRef]

- Tian, L.Y.; Fan, H.X.; Liu, H.C.; Tong, Z.Q.; Liu, T.T.; Zhang, Y.R. Development and properties of zein/Tremella fuciformis polysaccharides blend as a hard capsule material. J. Appl. Polym. Sci. 2021, 138, 51379. [Google Scholar] [CrossRef]

- Jia, F.Y.; Ma, Z.; Hu, X.Z. Controlling dough rheology and structural characteristics of chickpea-wheat composite flour-based noodles with different levels of Artemisia sphaerocephala Krasch. gum addition. Int. J. Biol. Macromol. 2020, 150, 605–616. [Google Scholar] [CrossRef] [PubMed]

- Farbo, M.G.; Fadda, C.; Marceddu, S.; Conte, P.; Del Caro, A.; Piga, A. Improving the quality of dough obtained with old durum wheat using hydrocolloids. Food Hydrocolloids 2019, 101, 105467. [Google Scholar] [CrossRef]

- Gao, J.; Koh, A.H.S.; Tay, S.L.; Zhou, W.B. Dough and bread made from high-and-low-protein flours by vacuum mixing: Part 1: Gluten network formation. J. Cereal. Sci. 2017, 74, 288–295. [Google Scholar] [CrossRef]

- Liu, R.; Zhang, Y.; Wu, L.; Xing, Y.; Kong, Y.; Sun, J.; Wei, Y. Impact of vacuum mixing on protein composition and secondary structure of noodle dough. LWT-Food Sci. Technol. 2017, 85, 197–205. [Google Scholar] [CrossRef]

- Delcour, J.A.; Joye, I.J.; Pareyt, B.; Wilderjans, E.; Brijs, K.; Lagrain, B. Wheat gluten functionlity as a quality determinant in Cereal-Based food products. Annu. Rev. Food Sci. Technol. 2012, 3, 469–492. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Chen, C.; Chen, Y.; Chen, Y. Effect of rice protein on the water mobility, water migration and microstructure of rice starch during retrogradation. Food Hydrocoll. 2019, 91, 136–142. [Google Scholar] [CrossRef]

- Azeem, M.; Mu, T.H.; Zhang, M. Effects of hydrocolloids and proteins on dough rheology and in vitro starch digestibility of sweet potato-wheat bread. LWT 2021, 142, 110970. [Google Scholar] [CrossRef]

- Kiyoshi, K.; Keiko, M.; Kana, H.; Yoshio, H. Temperature-dependent quality characteristics of pre-dehydrated cookies: Structure, browning, texture, in vitro starch digestibility, and the effect on blood glucose levels in mice. Food Chem. 2013, 141, 223–228. [Google Scholar]

- Jenkins, D.J.A.; Kendall, C.W.C.; Augustin, L.S.A.; Silvia, F.; Maryam, H.; Augustine, M.; Jenkins, A.L.; Mette, A. Glycemic index: Overview of implications in health and disease. Am. J. Clin. Nutr. 2002, 76, 266S–273S. [Google Scholar] [CrossRef] [Green Version]

| Sample | Secondary Structures | TGA | ||||

|---|---|---|---|---|---|---|

| β-Sheet/% | Random Coil/% | α-Helix/% | β-Turn/% | Degradation Temperature/°C | Weight Loss/% | |

| Control | 33.95 ± 0.99 c | 18.23 ± 0.09 a | 17.16 ± 0.78 b | 30.66 ± 0.30 a | 333.00 ± 0.40 e | 97.47 ± 0.21 a |

| 3% TF | 35.07 ± 0.13 ab | 17.27 ± 0.04 b | 18.55 ± 0.03 a | 29.12 ± 0.07 b | 341.00 ± 0.10 c | 93.85 ± 0.17 c |

| 0.6% SA | 34.68 ± 0.20 bc | 16.67 ± 0.10 c | 18.50 ± 0.61 a | 30.15 ± 0.71 ab | 343.40 ± 0.30 b | 90.56 ± 0.20 d |

| 0.4% GG | 35.41 ± 0.06 a | 16.66 ± 0.01 c | 17.78 ± 0.25 ab | 30.15 ± 0.21 ab | 335.40 ± 0.30 d | 95.56 ± 0.14 b |

| 0.4% XG | 35.60 ± 0.26 a | 16.50 ± 0.34 c | 18.53 ± 0.29 a | 29.38 ± 0.21 ab | 348.70 ± 0.20 a | 85.04 ± 0.19 e |

| Treatment | Sample | Relaxation Time (T2) | Proportion of Peak Area | ∣Δ∣ = A4 h/A8 h − A0 h | |||||

|---|---|---|---|---|---|---|---|---|---|

| T21/ms | T22/ms | T23/ms | A21/% | A22/% | A23/% | ΔA21/% | ΔA23/% | ||

| 0 h | Control | 0.12 ± 0.01 a | 7.84 ± 0.00 a | 117.59 ± 0.00 a | 16.54 ± 0.15 c | 82.70 ± 0.15 a | 0.77 ± 0.00 c | / | / |

| 3% TF | 0.12 ± 0.01 a | 6.37 ± 0.00 c | 77.72 ± 5.39 d | 17.34 ± 0.03 a | 81.69 ± 0.13 c | 0.85 ± 0.01 b | / | / | |

| 0.6% SA | 0.13 ± 0.00 a | 7.32 ± 0.00 b | 113.64 ± 3.94 b | 17.43 ± 0.08 a | 81.43 ± 0.40 c | 0.82 ± 0.01 c | / | / | |

| 0.4% GG | 0.12 ± 0.01 a | 7.84 ± 0.00 a | 102.34 ± 0.00 c | 16.88 ± 0.10 b | 82.18 ± 0.07 ab | 0.95 ± 0.04 a | / | / | |

| 0.4% XG | 0.11 ± 0.00 a | 7.58 ± 0.26 ab | 113.64 ± 3.94 b | 17.14 ± 0.05 a | 82.05 ± 0.04 ab | 0.81 ± 0.01 bc | / | / | |

| 4 h | Control | 0.11 ± 0.00 a | 6.83 ± 0.00 a | 98.91 ± 3.43 b | 16.18 ± 0.13 c | 82.61 ± 0.11 a | 0.98 ± 0.01 ab | 0.36 | 0.21 |

| 3% TF | 0.11 ± 0.00 a | 5.54 ± 0.00 c | 69.91 ± 2.43 d | 17.24 ± 0.04 a | 81.70 ± 0.06 c | 0.99 ± 0.02 ab | 0.11 | 0.15 | |

| 0.6% SA | 0.10 ± 0.00 a | 6.83 ± 0.00 a | 102.34 ± 0.00 a | 17.25 ± 0.02 a | 81.38 ± 0.03 d | 0.96 ± 0.06 b | 0.18 | 0.14 | |

| 0.4% GG | 0.12 ± 0.01 a | 6.37 ± 0.00 ab | 89.07 ± 0.00 c | 16.66 ± 0.01 b | 82.11 ± 0.10 b | 1.09 ± 0.03 a | 0.23 | 0.14 | |

| 0.4% XG | 0.10 ± 0.00 a | 6.83 ± 0.00 a | 98.91 ± 4.43 b | 16.91 ± 0.10 b | 82.00 ± 0.12 b | 0.93 ± 0.03 b | 0.23 | 0.12 | |

| 8 h | Control | 0.11 ± 0.00 a | 6.83 ± 0.00 a | 95.48 ± 0.00 a | 15.83 ± 0.02 e | 82.95 ± 0.04 a | 1.18 ± 0.02 a | 0.71 | 0.41 |

| 3% TF | 0.11 ± 0.00 a | 5.54 ± 0.00 c | 65.21 ± 2.26 d | 17.12 ± 0.03 a | 82.03 ± 0.26 b | 1.11 ± 0.01 a | 0.23 | 026 | |

| 0.6% SA | 0.10 ± 0.00 a | 6.37 ± 0.00 ab | 95.48 ± 0.00 a | 17.14 ± 0.02 a | 81.84 ± 0.11 b | 1.00 ± 0.04 b | 0.29 | 0.18 | |

| 0.4% GG | 0.12 ± 0.00 a | 6.37 ± 0.00 ab | 89.07 ± 0.00 c | 16.49 ± 0.02 c | 82.32 ± 0.01 b | 1.19 ± 0.01 a | 0.39 | 0.24 | |

| 0.4% XG | 0.10 ± 0.00 a | 6.83 ± 0.00 a | 92.28 ± 3.20 b | 16.81 ± 0.01 b | 82.18 ± 0.01 b | 1.02 ± 0.01 b | 0.33 | 0.21 | |

| Sample | RDS/% | SDS/% | RS/% |

|---|---|---|---|

| Control | 56.87 ± 0.13 a | 27.13 ± 0.12 c | 16.01 ± 0.01 e |

| 3% TF | 52.74 ± 0.12 bc | 29.57 ± 0.13 ab | 17.69 ± 0.01 d |

| 0.6% SA | 52.47 ± 0.12 c | 29.37 ± 0.13 ab | 18.17 ± 0.01 a |

| 0.4% GG | 53.02 ± 0.12 b | 29.16 ± 0.13 b | 17.83 ± 0.02 c |

| 0.4% XG | 52.33 ± 0.12 c | 29.77 ± 0.13 a | 17.91 ± 0.02 b |

| Hardness | Adhesiveness | Chewiness | |

|---|---|---|---|

| α-helix | 0.887 * | 0.875 | 0.881 * |

| β-sheet | 0.866 | 0.899 * | 0.886 * |

| β-turn | −0.888 * | −0.831 | −0.769 |

| Random coil | −0.901 * | −0.836 | −0.950 * |

| Weight loss | −0.881 * | −0.761 | −0.887 * |

| Degradation temperature | 0.896 * | 0.812 | 0.892 * |

| A21 | 0.912 * | 0.803 | 0.881 * |

| A22 | −0.899 * | −0.856 | −0.863 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Chen, J.; Xu, F.; Han, R.; Quan, M. Effect of Tremella fuciformis and Different Hydrocolloids on the Quality Characteristics of Wheat Noodles. Foods 2022, 11, 2617. https://doi.org/10.3390/foods11172617

Zhang L, Chen J, Xu F, Han R, Quan M. Effect of Tremella fuciformis and Different Hydrocolloids on the Quality Characteristics of Wheat Noodles. Foods. 2022; 11(17):2617. https://doi.org/10.3390/foods11172617

Chicago/Turabian StyleZhang, Lifan, Jie Chen, Fei Xu, Rui Han, and Miaomiao Quan. 2022. "Effect of Tremella fuciformis and Different Hydrocolloids on the Quality Characteristics of Wheat Noodles" Foods 11, no. 17: 2617. https://doi.org/10.3390/foods11172617