Effect of the Addition of Soybean Residue (Okara) on the Physicochemical, Tribological, Instrumental, and Sensory Texture Properties of Extruded Snacks

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

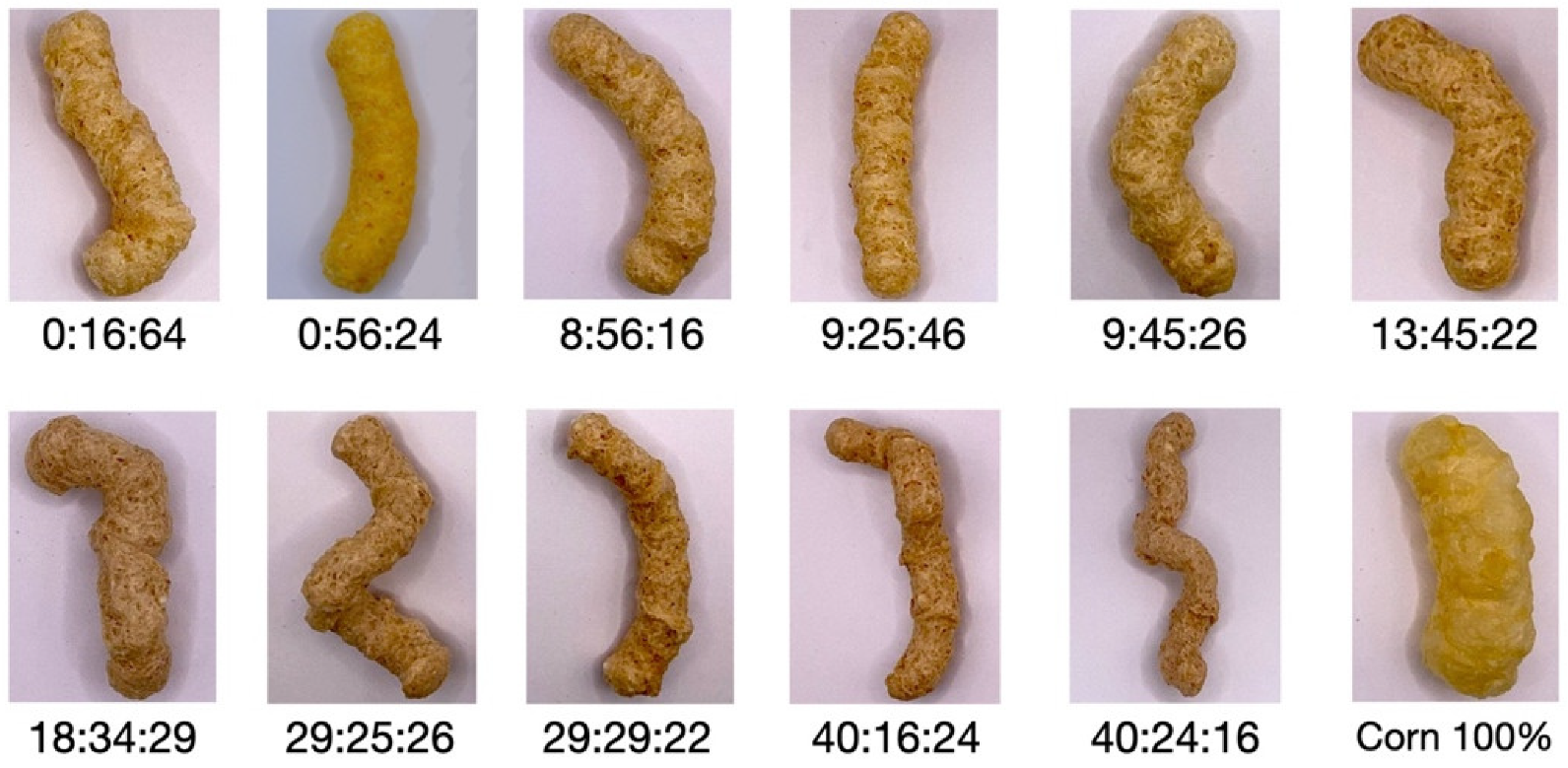

2.2. Formulation of Extruded Snack

2.3. Extrusion Process and Sample Preparation

2.4. Chemical and Physical Properties

2.4.1. Proximate Composition

2.4.2. Color

2.4.3. Radial Expansion Index

2.4.4. Bulk Density

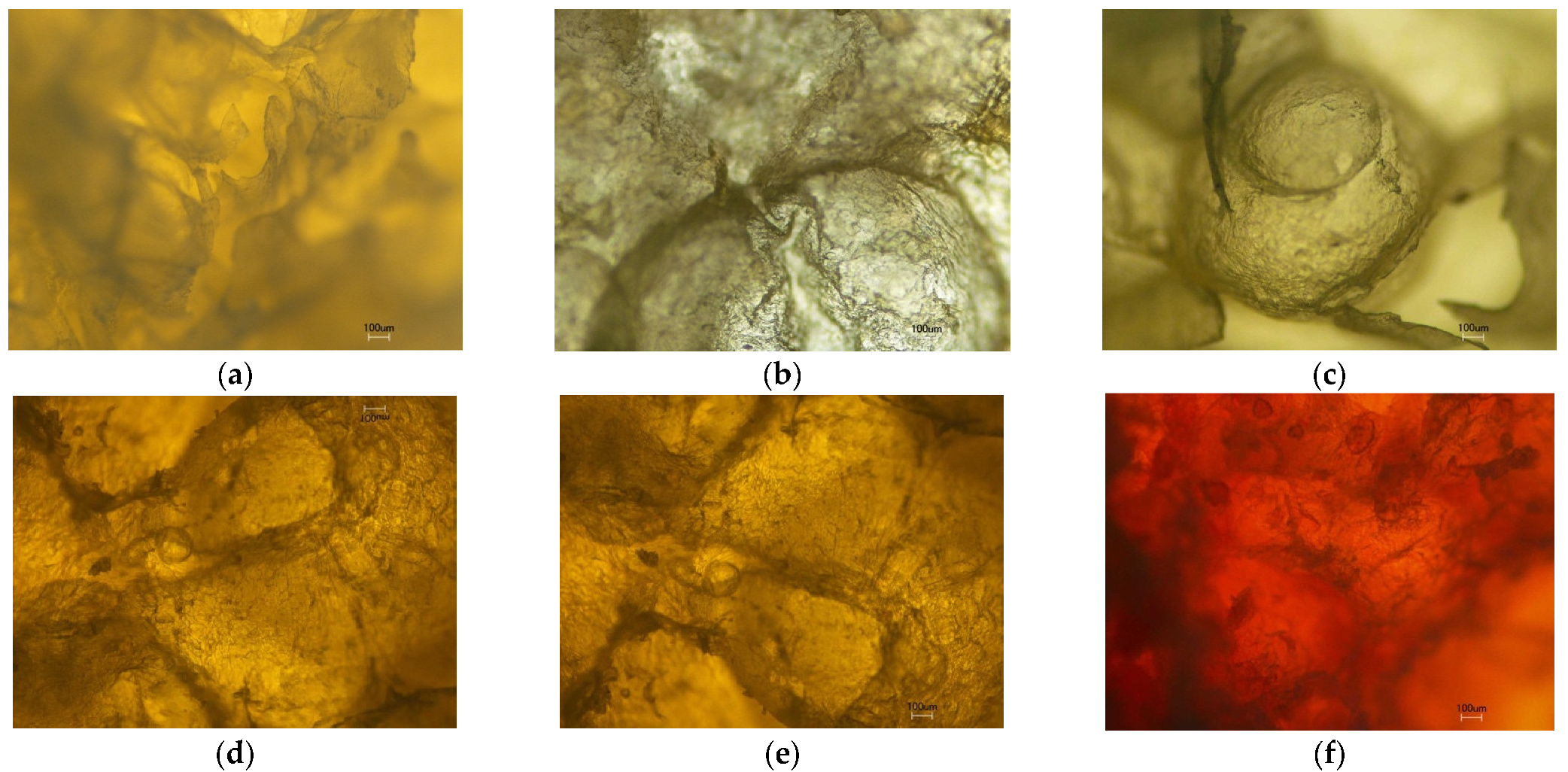

2.4.5. Digital Image and Optical Microscopy

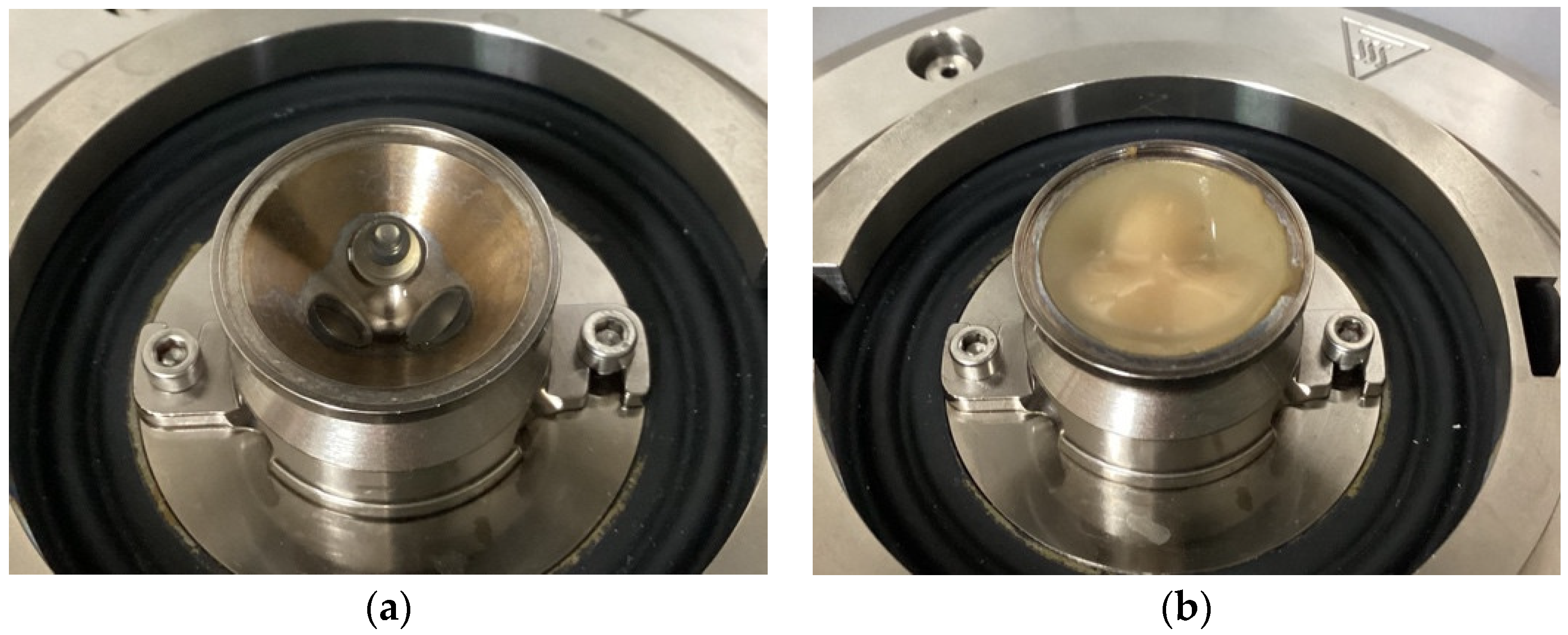

2.5. Tribological Analysis

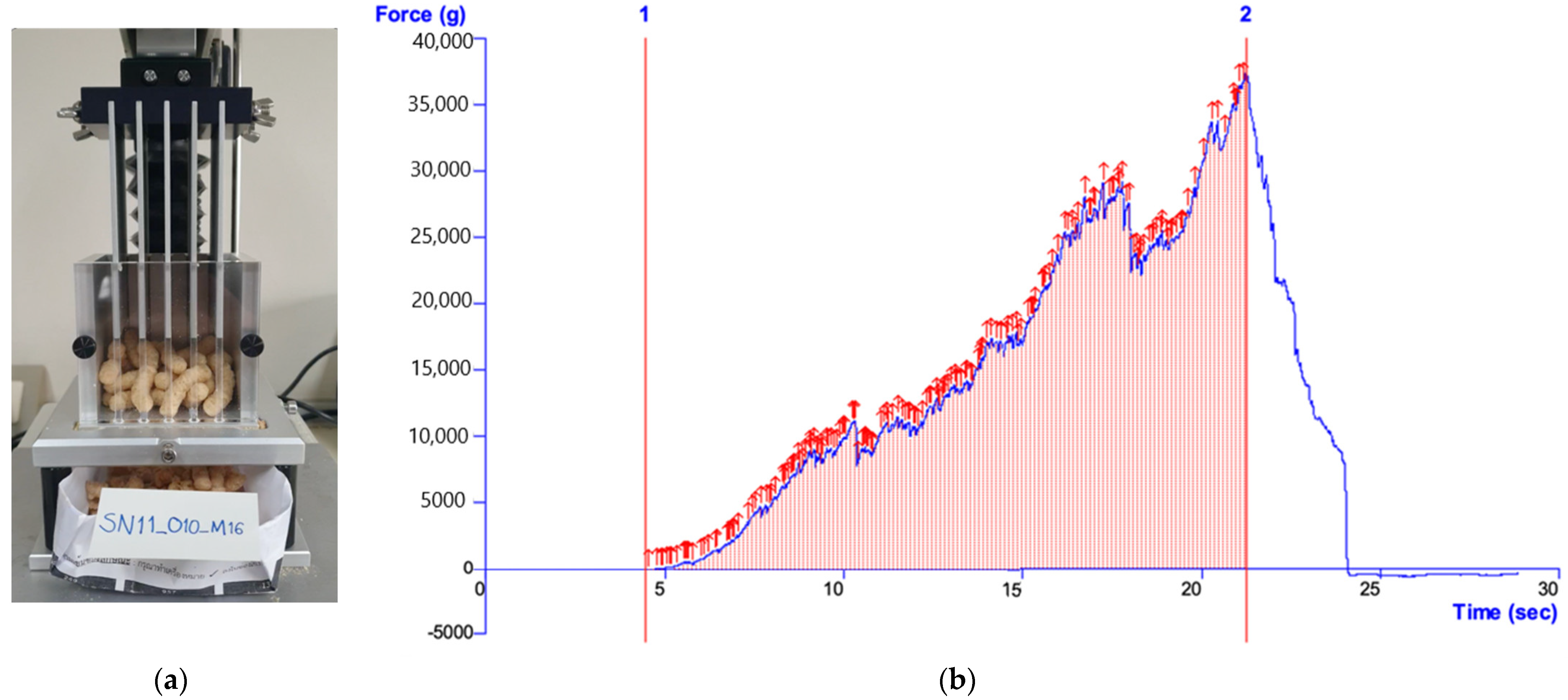

2.6. Instrumental Texture Analysis

2.7. Sensory Analysis

2.8. Statistical Analysis

3. Results and Discussion

3.1. Chemical and Physical Properties

3.1.1. Proximate Composition

3.1.2. Color

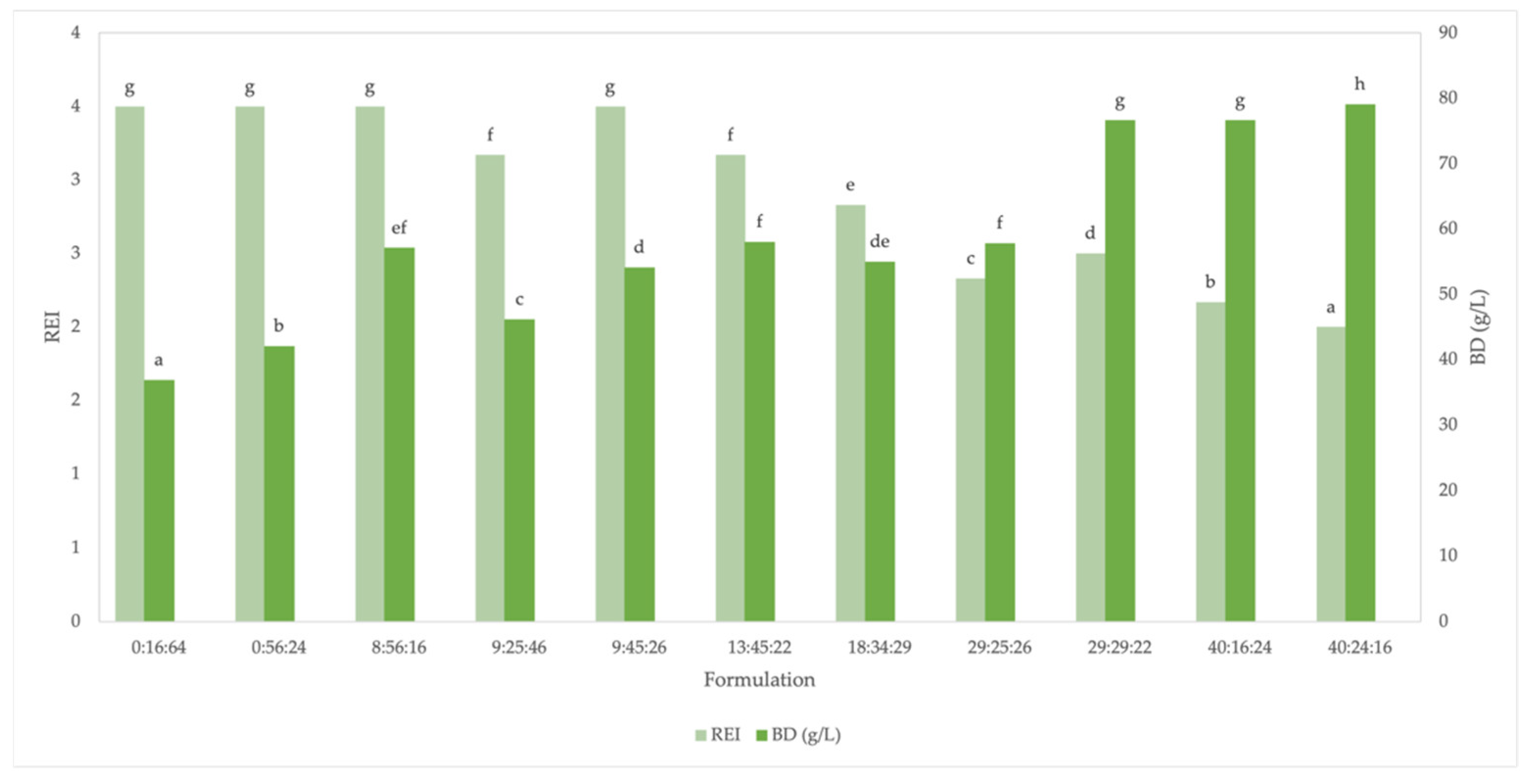

3.1.3. Radial Expansion Index

3.1.4. Bulk Density

3.2. Tribological Properties

3.3. Textural Properties

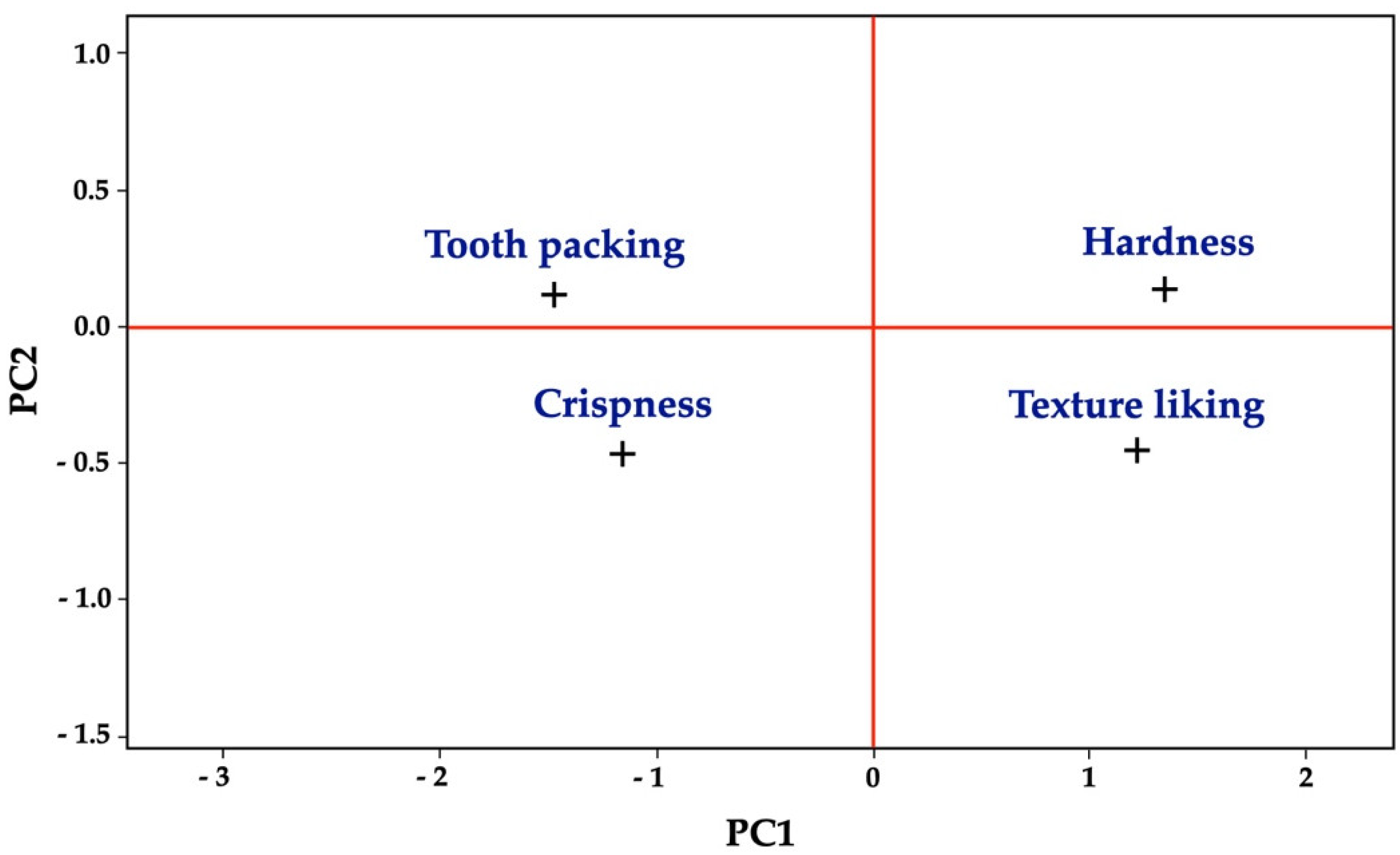

3.4. Sensory Analysis

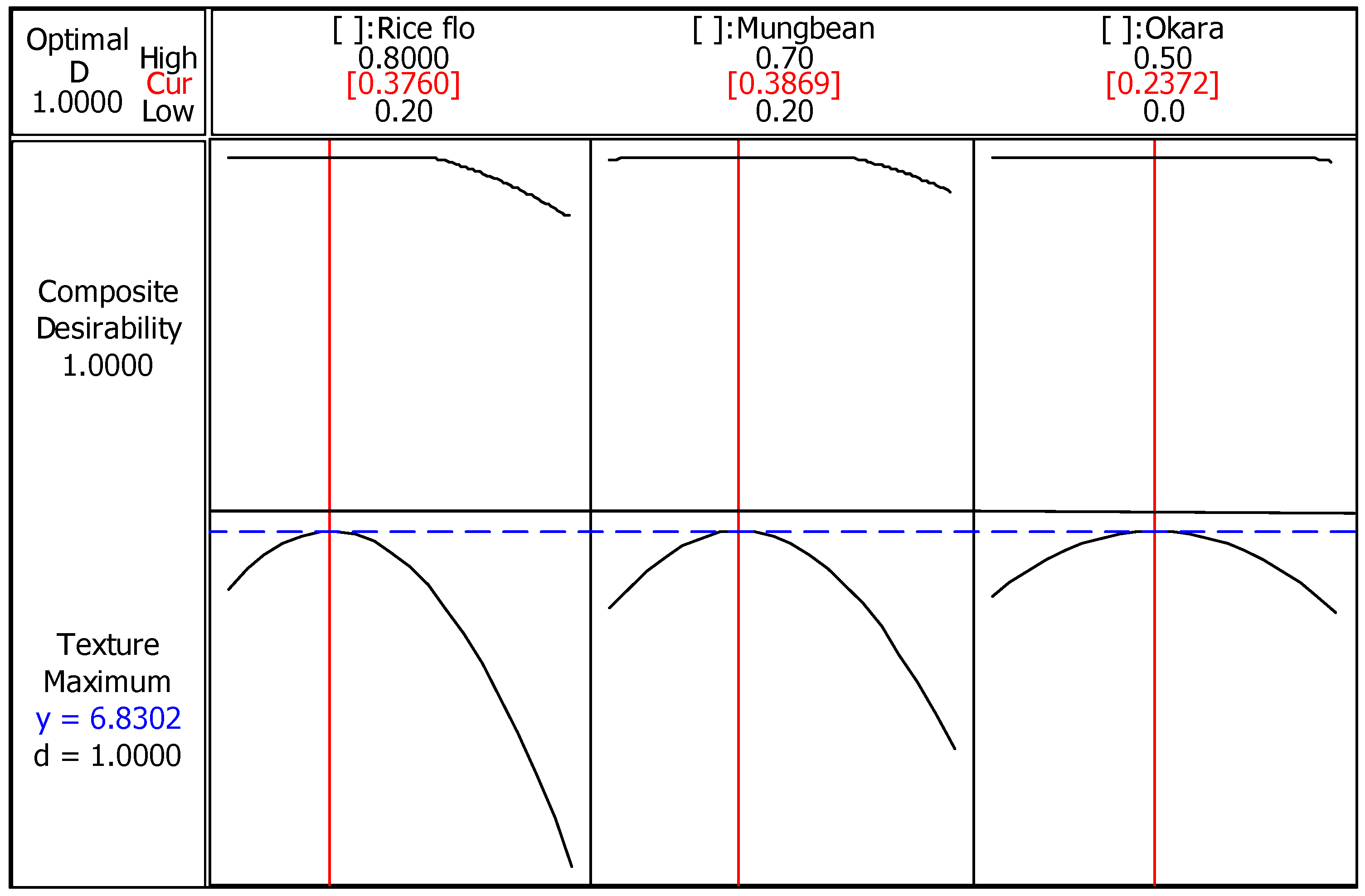

3.5. Optimization of Texture Liking

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Colletti, A.; Attrovio, A.; Boffa, L.; Mantegna, S.; Cravotto, G. Valorisation of By-Products from Soybean (Glycine max (L.) Merr.) Processing. Molecules 2020, 25, 2129. [Google Scholar] [CrossRef]

- Feng, J.-Y.; Wang, R.; Thakur, K.; Ni, Z.-J.; Zhu, Y.-Y.; Hu, F.; Zhang, J.-G.; Wei, Z.-J. Evolution of okara from waste to value added food ingredient: An account of its bio-valorization for improved nutritional and functional effects. Trends Food Sci. Technol. 2021, 116, 669–680. [Google Scholar] [CrossRef]

- Dos Santos, D.C.; de Oliveira Filho, J.G.; de Santana, S.J.; Figueiredo, S.M.; da Silva, V.M.; Pereira da Silva, M.A.; Lemes, A.C.; Egea, M.B. Okara flour: Its physicochemical, microscopical and functional properties. Nutr. Food Sci. 2019, 49, 1252–1264. [Google Scholar] [CrossRef]

- Păcularu-Burada, B.; Cantaragiu, A.-M.C.; Vasile, M.A.; Bahrim, G.-E. Novel insights into different kefir grains usefulness as valuable multiple starter cultures to achieve bioactive gluten-free sourdoughs. LWT 2022, 165, 113670. [Google Scholar] [CrossRef]

- Ostermann-Porcel, M.V.; Rinaldoni, A.N.; Rodriguez-Furlán, L.T.; Campderrós, M.E. Quality assessment of dried okara as a source of production of gluten-free flour. J. Sci. Food Agric. 2016, 97, 2934–2941. [Google Scholar] [CrossRef]

- Lian, H.; Luo, K.; Gong, Y.; Zhang, S.; Serventi, L. Okara flours from chickpea and soy are thickeners: Increased dough viscosity and moisture content in gluten-free bread. Int. J. Food Sci. Technol. 2019, 55, 805–812. [Google Scholar] [CrossRef]

- Fei, L. Okara dietary fiber and hypoglycemic effect of okara foods. Bioact. Carbohydr. Diet. Fibre 2013, 2, 126–132. [Google Scholar]

- Qin, P.; Wang, T.; Luo, Y. A review on plant-based proteins from soybean: Health benefits and soy product development. J. Agric. Food Res. 2022, 7, 100265. [Google Scholar] [CrossRef]

- Yang, L.; Zhao, Y.; Huang, J.; Zhang, H.; Lin, Q.; Han, L.; Liu, J.; Wang, J.; Liu, H. Insoluble dietary fiber from soy hulls regulates the gut microbiota in vitro and increases the abundance of bifidobacteriales and lactobacillales. J. Food Sci. Technol. 2019, 57, 152–162. [Google Scholar] [CrossRef]

- Rani, R.; Badwaik, L.S. Functional Properties of Oilseed Cakes and Defatted Meals of Mustard, Soybean and Flaxseed. Waste Biomass-Valorization 2021, 12, 5639–5647. [Google Scholar] [CrossRef]

- Difonzo, G.; de Gennaro, G.; Pasqualone, A.; Caponio, F. Potential use of plant-based by-products and waste to improve the quality of gluten-free foods. J. Sci. Food Agric. 2022, 102, 2199–2211. [Google Scholar] [CrossRef] [PubMed]

- Ostermann-Porcel, M.V.; Quiroga-Panelo, N.; Rinaldoni, A.N.; Campderrós, M.E. Incorporation of Okara into Gluten-Free Cookies with High Quality and Nutritional Value. J. Food Qual. 2017, 2017, 4071585. [Google Scholar] [CrossRef]

- Tobias-Espinoza, J.L.; Amaya-Guerra, C.A.; Quintero-Ramos, A.; Pérez-Carrillo, E.; Núñez-González, M.A.; Martínez-Bustos, F.; Meléndez-Pizarro, C.O.; Báez-González, J.G.; Ortega-Gutiérrez, J.A. Effects of the Addition of Flaxseed and Amaranth on the Physicochemical and Functional Properties of Instant-Extruded Products. Foods 2019, 8, 183. [Google Scholar] [CrossRef]

- Gualberto, D.G.; Bergman, C.J.; Kazemzadeh, M.; Weber, C.W. Effect of extrusion processing on the soluble and insoluble fiber, and phytic acid contents of cereal brans. Mater. Veg. 1997, 51, 187–198. [Google Scholar] [CrossRef]

- Zhang, M.; Bai, X.; Zhang, Z. Extrusion process improves the functionality of soluble dietary fiber in oat bran. J. Cereal Sci. 2011, 54, 98–103. [Google Scholar] [CrossRef]

- Berrios, J.D.J.; Ascheri, J.L.R.; Losso, J.N. Extrusion Processing of Dry Beans and Pulses. In Dry Beans and Pulses Production, Processing and Nutrition; John Wiley & Sons, Inc.: Oxford, UK, 2012; pp. 185–203. [Google Scholar] [CrossRef]

- Wang, L.; Wu, M.; Wang, Y.; Shi, C.; Li, D. Rheological properties of extruded okara-maize blend based on extrusion technology. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2012, 43, 119–125. [Google Scholar]

- Xie, M. Puffing of okara/rice blends using a rice cake machine. J. Food Sci. 2018, 73, E341–E348. [Google Scholar] [CrossRef] [PubMed]

- Rinaldi, V.E.A.; Ng, P.K.W.; Bennink, M.R. Effects of Extrusion on Dietary Fiber and Isoflavone Contents of Wheat Extrudates Enriched with Wet Okara. Cereal Chem. 2000, 77, 237–240. [Google Scholar] [CrossRef]

- Boonyasirikool, P.; Charunuch, C. Development of Corngrit-Broken Rice Based Snack Food by Extrusion Cooking. Kasetsart J. Nat. Sci. 2000, 34, 279–288. [Google Scholar]

- Jozinović, A.; Šubarić, D.; Ačkar, Đ.; Babić, J.; Orkić, V.; Guberac, S.; Miličević, B. Food Industry By-Products as Raw Materials in the Production of Value-Added Corn Snack Products. Foods 2021, 10, 946. [Google Scholar] [CrossRef]

- Karun, G.; Sukumar, A.; Nagamaniammai, G.; Preetha, R. Development of multigrain ready-to-eat extruded snack and process parameter optimization using response surface methodology. J. Food Sci. Technol. 2022, 1–11. [Google Scholar] [CrossRef]

- Curtis, P.C. Untrained sensory panels. In The Science of Meat Quality; John Wiley & Sons, Inc.: Oxford, UK, 2013; pp. 215–231. [Google Scholar]

- Thiex, N.; Novotny, L.; Crawford, A. Determination of Ash in Animal Feed: AOAC Official Method 942.05 Revisited. J. AOAC Int. 2012, 95, 1392–1397. [Google Scholar] [CrossRef] [PubMed]

- Shin, J.-M.; Hwang, Y.-O.; Tu, O.-J.; Jo, H.-B.; Kim, J.-H.; Chae, Y.-Z.; Rhu, K.-H.; Park, S.-K. Comparison of different methods to quantify fat classes in bakery products. Food Chem. 2013, 136, 703–709. [Google Scholar] [CrossRef] [PubMed]

- Ranathunga, S.D.; Kalscheur, K.F.; Anderson, J.L.; Herrick, K.J. Evaluation of a modified method to measure total starch in animal feeds. Anim. Feed Sci. Technol. 2017, 226, 124–132. [Google Scholar] [CrossRef]

- Bhat, N.A.; Wani, I.A.; Hamdani, A.M.; Gani, A. Effect of extrusion on the physicochemical and antioxidant properties of value added snacks from whole wheat (Triticum aestivum L.) flour. Food Chem. 2018, 276, 22–32. [Google Scholar] [CrossRef]

- Fan, J.; Mitchell, J.R.; Blanshard, J.M.V. The effect of sugars on the extrusion of maize grits: I. The role of the glass transition in determining product density and shape. Int. J. Food Sci. Technol. 1996, 31, 55–65. [Google Scholar] [CrossRef]

- HewaNadungodage, N.D.; Torrico, D.D.; Brennan, M.A.; Brennan, C.S. Nutritional, physicochemical, and textural properties of gluten-free extruded snacks containing cowpea and whey protein concentrate. Int. J. Food Sci.Technol. 2022, 57, 3903–3913. [Google Scholar] [CrossRef]

- Aussanasuwannakul, A.; Pondicherry, K.; Saengprakai, J. Rheological and tribological characterization of herbal sweet sauce with different stabilizing systems. CyTA-J. Food 2022, 20, 158–171. [Google Scholar] [CrossRef]

- Meilgaard, M.; Civille, G.V.; Carr, B.T. Sensory Evaluation Techniques, 4th ed.; CRC Press: Boca Raton, FL, USA; Taylor & Francis: Abingdon, UK, 2007. [Google Scholar]

- Aussanasuwannakul, A.; Puntaburt, K.; Treesuwan, W. Rheological, Tribological, and Sensory Analysis of Coconut-Oil-Modified Coconut Milk Kefir. Curr. Res. Nutr. Food Sci. J. 2020, 8, 496–503. [Google Scholar] [CrossRef]

- Menis, M.E.C.; Milani, T.M.G.; Jordano, A.; Boscolo, M.; Conti-Silva, A.C. Extrusion of flavored corn grits: Structural characteristics, volatile compounds retention and sensory acceptability. LWT 2013, 54, 434–439. [Google Scholar] [CrossRef]

- Dos Santos, D.M.; Ramirez Ascheri, D.P.; de Lacerda Bukzem, A.; Cintra Morais, C.; Piler Carvalho, C.W.; Ramírez Ascheri, j.L. Physicochemical properties of starch from avocado seed (Persea Americana Mill). Bol. Do Cent. De Pesqui. De Processamento De Aliment. 2017, 34, 2. [Google Scholar] [CrossRef]

- Franczak, B.C.; Browne, R.P.; McNicholas, P.D.; Findlay, C.J. Product selection for liking studies: The sensory informed design. Food Qual. Prefer. 2015, 44, 36–43. [Google Scholar] [CrossRef] [Green Version]

- Aussanasuwannakul, A.; Kenney, P.B.; Brannan, R.G.; Slider, S.D.; Salem, M.; Yao, J. Relating Instrumental Texture, Determined by Variable-Blade and Allo-Kramer Shear Attachments, to Sensory Analysis of Rainbow Trout, Oncorhynchus mykiss, Fillets. J. Food Sci. 2010, 75, S365–S374. [Google Scholar] [CrossRef]

- Dey, D.; Richter, J.K.; Ek, P.; Gu, B.-J.; Ganjyal, G.M. Utilization of Food Processing By-products in Extrusion Processing: A Review. Front. Sustain. Food Syst. 2021, 4, 603751. [Google Scholar] [CrossRef]

- Valderrama-Amasifuen, F.; Arteaga, H.; Flores, A.; Obregón, J.; Barraza-Jáuregui, G. Snacks based on purple corn, quinoa and kiwicha. Physical and sensory characteristics. In Proceedings of the LACCEI International Multi-Conference for Engineering, Education and Technology, 2021, Online, 19–23 July 2021. [Google Scholar]

- Katayama, M.; Wilson, L. Utilization of Okara, a Byproduct from Soymilk Production, through the Development of Soy-Based Snack Food. J. Food Sci. 2008, 73, S152–S157. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, M.; Wu, H.; Jing, L.; Gong, B.; Gou, M.; Zhao, K.; Li, W. The compositional, physicochemical and functional properties of germinated mung bean flour and its addition on quality of wheat flour noodle. J. Food Sci. Technol. 2018, 55, 5142–5152. [Google Scholar] [CrossRef]

- Maninder, K.; Sandhu, K.S.; Singh, N. Comparative study of the functional, thermal and pasting properties of flours from different field pea (Pisum sativum L.) and pigeon pea (Cajanus cajan L.) cultivars. Food Chem. 2007, 104, 259–267. [Google Scholar] [CrossRef]

- Wang, S.; Chang, T.; Wang, C.; Shi, L.; Wang, W.; Yang, H.; Cui, M. Effect of Particle Sizes of Soy Okara on Textural, Color, Sensory and Rheological Properties of Pork Meat Gels. J. Food Qual. 2015, 38, 248–255. [Google Scholar] [CrossRef]

- Allen, K.E.; Carpenter, C.E.; Walsh, M.K. Influence of protein level and starch type on an extrusion-expanded whey product. Int. J. Food Sci. Technol. 2007, 42, 953–960. [Google Scholar] [CrossRef]

- Pai, D.A.; Blake, O.A.; Hamaker, B.R.; Campanella, O.H. Importance of extensional rheological properties on fiber-enriched corn extrudates. J. Cereal Sci. 2009, 50, 227–234. [Google Scholar] [CrossRef]

- Seth, D.; Rajamanickam, G. Development of extruded snacks using soy, sorghum, millet and rice blend—A response surface methodology approach. Int. J. Food Sci. Technol. 2012, 47, 1526–1531. [Google Scholar] [CrossRef]

- Kowalski, R.J.; Medina-Meza, I.G.; Thapa, B.B.; Murphy, K.M.; Ganjyal, G.M. Extrusion processing characteristics of quinoa (Chenopodium quinoa Willd.) var. Cherry Vanilla. J. Cereal Sci. 2016, 70, 91–98. [Google Scholar] [CrossRef] [Green Version]

- Aussanasuwannakul, A.; Treesuwan, W.; Butsuwan, P.; Puntaburt, K.; Teangpook, C. Okara Waste Reduction from Community and Industry by Recycling into High-Value Flour Used as Food Ingredient; National Research Council of Thailand: Bangkok, Thaiand, 2022; p. 189. [Google Scholar]

- Martin, A.; Schmidt, V.; Osen, R.; Bez, J.; Ortner, E.; Mittermaier, S. Texture, sensory properties and functionality of extruded snacks from pulses and pseudocereal proteins. J. Sci. Food Agric. 2020, 102, 5011–5021. [Google Scholar] [CrossRef]

- Menis-Henrique, M.E.C.; Scarton, M.; Piran, M.V.F.; Clerici, M.T.P.S. Cereal fiber: Extrusion modifications for food industry. Curr. Opin. Food Sci. 2020, 33, 141–148. [Google Scholar] [CrossRef]

- Saeleaw, M.; Dürrschmid, K.; Schleining, G. The effect of extrusion conditions on mechanical-sound and sensory evaluation of rye expanded snack. J. Food Eng. 2012, 110, 532–540. [Google Scholar] [CrossRef]

- Zambrano, Y.; Contardo, I.; Moreno, M.C.; Bouchon, P. Effect of Extrusion Temperature and Feed Moisture Content on the Microstructural Properties of Rice-Flour Pellets and Their Impact on the Expanded Product. Foods 2022, 11, 198. [Google Scholar] [CrossRef]

- Neder-Suárez, D.; Quintero-Ramos, A.; Meléndez-Pizarro, C.O.; Zazueta-Morales, J.D.J.; Paraguay-Delgado, F.; Ruiz-Gutiérrez, M.G. Evaluation of the physicochemical properties of third-generation snacks made from blue corn, black beans, and sweet chard produced by extrusion. LWT 2021, 146, 111414. [Google Scholar] [CrossRef]

- Nath, A.; Chattopadhyay, P. Effect of process parameters and soy flour concentration on quality attributes and microstructural changes in ready-to-eat potato–soy snack using high-temperature short time air puffing. LWT 2007, 41, 707–715. [Google Scholar] [CrossRef]

- Tadesse, S.A.; Bultosa, G.; Abera, S. Functional and physical properties of sorghum-based extruded product supplemented with soy meal flour. Cogent Food Agric. 2019, 5, 1. [Google Scholar] [CrossRef]

- Shah, F.-U.; Sharif, M.K.; Butt, M.S.; Shahid, M. Development of protein, dietary fiber, and micronutrient enriched extruded corn snacks. J. Texture Stud. 2016, 48, 221–230. [Google Scholar] [CrossRef]

- Basediya, A.L.; Pandey, S.; Shrivastava, S.P.; Alam Khan, K.; Nema, A. Effect of process and machine parameters on physical properties of extrudate during extrusion cooking of sorghum, horse gram and defatted soy flour blends. J. Food Sci. Technol. 2011, 50, 44–52. [Google Scholar] [CrossRef]

- Shi, C.; Wang, L.-J.; Wu, M.; Adhikari, B.; Li, L.-T. Optimization of Twin-Screw Extrusion Process to Produce Okara-Maize Snack Foods Using Response Surface Methodology. Int. J. Food Eng. 2011, 7, 2. [Google Scholar] [CrossRef]

- Yi, T.; Huang, X.; Pan, S.; Wang, L. Physicochemical and functional properties of micronized jincheng orange by-products (Citrus sinensis Osbeck) dietary fiber and its application as a fat replacer in yogurt. Int. J. Food Sci. Nutr. 2014, 65, 565–572. [Google Scholar] [CrossRef]

- Lii, C.Y.; Chang, Y.H. Study of starch in Taiwan. Food Rev. Int. 1991, 7, 185–203. [Google Scholar] [CrossRef]

- Wu, F.; Meng, Y.; Yang, N.; Tao, H.; Xu, X. Effects of mung bean starch on quality of rice noodles made by direct dry flour extrusion. LWT-Food Sci. Technol. 2015, 63, 1199–1205. [Google Scholar] [CrossRef]

- Steele, C.M.; Van Lieshout, P. Tongue Movements During Water Swallowing in Healthy Young and Older Adults. J. Speech Lang. Hear Res. 2009, 52, 1255–1267. [Google Scholar] [CrossRef]

- Pang, Z.; Cao, J.; Li, H.; Chen, C.; Liu, X. Rheology and tribology properties of cereal and legume flour paste from different botanical origins. J. Food Sci. 2020, 85, 4130–4140. [Google Scholar] [CrossRef]

- Soleimanian, Y.; Sanou, I.; Turgeon, S.L.; Canizares, D.; Khalloufi, S. Natural plant fibers obtained from agricultural residue used as an ingredient in food matrixes or packaging materials: A review. Compr. Rev. Food Sci. Food Saf. 2021, 21, 371–415. [Google Scholar] [CrossRef]

- Kanojia, V.; Singh, M.; Khandelwal, B.M.; Azam, M. Effect of Single Screw Extrusion Parameters on Textural Properties of Rice based Expanded Snacks Enriched with Okara. Indian J. Sci. Technol. 2016, 9, 1–8. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Prakash, M. Extrusion of blends of rice and chick pea flours: A response surface analysis. J. Food Eng. 1994, 21, 315–330. [Google Scholar] [CrossRef]

- Shirani, G.; Ganesharanee, R. Extruded products with Fenugreek (Trigonella foenum-graecium) chickpea and rice: Physical properties, sensory acceptability and glycaemic index. J. Food Eng. 2009, 90, 44–52. [Google Scholar] [CrossRef]

- Jin, Z.; Hsieh, F.; Huff, H. Effects of soy fiber, salt, sugar and screw speed on physical properties and microstructure of corn meal extrudate. J. Cereal Sci. 1995, 22, 185–194. [Google Scholar] [CrossRef]

- de Mesa, N.J.E.; Alavi, S.; Singh, N.; Shi, Y.C.; Dogan, H.; Sang, Y. Soy protein-fortified expanded extrudates: Baseline study using normal corn starch. J. Food Eng. 2009, 90, 262–270. [Google Scholar] [CrossRef]

- Rodríguez-Vidal, A.; Martínez-Flores, H.E.; Jasso, E.G.; De La Cruz, G.V.; Ramírez-Jiménez, A.; Morales-Sánchez, E. Extruded snacks from whole wheat supplemented with textured soy flour: Effect on instrumental and sensory textural characteristics. J. Texture Stud. 2016, 48, 249–257. [Google Scholar] [CrossRef]

- Liu, Y.; Yi, S.; Ye, T.; Leng, Y.; Hossen, A.; Sameen, D.E.; Dai, J.; Li, S.; Qin, W. Effects of ultrasonic treatment and homogenization on physicochemical properties of okara dietary fibers for 3D printing cookies. Ultrason. Sonochem. 2021, 77, 105693. [Google Scholar] [CrossRef] [PubMed]

- Kilcast, D. Sensory Techniques to Study Food Texture, in Food Texture: Measurement and Perception; Rosenthal, A.J., Ed.; Aspen Publishers: Gaithersburg, MD, USA, 1999; pp. 31–64. [Google Scholar]

- Proserpio, C.; Bresciani, A.; Marti, A.; Pagliarini, E. Legume Flour or Bran: Sustainable, Fiber-Rich Ingredients for Extruded Snacks? Foods 2020, 9, 1680. [Google Scholar] [CrossRef] [PubMed]

- Leonard, W.; Zhang, P.; Ying, D.; Fang, Z. Application of extrusion technology in plant food processing byproducts: An overview. Compr. Rev. Food Sci. Food Saf. 2019, 19, 218–246. [Google Scholar] [CrossRef]

- Kreger, J.W.; Lee, S.-Y.; Lee, Y. Perceptual Changes and Drivers of Liking in High Protein Extruded Snacks. J. Food Sci. 2012, 77, S161–S169. [Google Scholar] [CrossRef]

- Saint-Eve, A.; Granda, P.; Legay, G.; Cuvelier, G.; Delarue, J. Consumer acceptance and sensory drivers of liking for high plant protein snacks. J. Sci. Food Agric. 2019, 99, 3983–3991. [Google Scholar] [CrossRef]

| No. | Formulation | Okara (%) | Mung Bean (%) | Rice (%) | Corn Grit (%) |

|---|---|---|---|---|---|

| 1 | 0:16:64 | 0 | 16 | 64 | 20 |

| 2 | 0:56:24 | 0 | 56 | 24 | 20 |

| 3 | 8:56:16 | 8 | 56 | 16 | 20 |

| 4 | 9:25:46 | 9 | 25 | 46 | 20 |

| 5 | 9:45:26 | 9 | 45 | 26 | 20 |

| 6 | 13:45:22 | 13 | 45 | 22 | 20 |

| 7 | 19:31:30 | 19 | 31 | 30 | 20 |

| 8 | 18:34:29 | 18 | 34 | 29 | 20 |

| 9 | 29:25:26 | 29 | 25 | 26 | 20 |

| 10 | 29:29:22 | 29 | 29 | 22 | 20 |

| 11 | 40:16:24 | 40 | 16 | 24 | 20 |

| Attributes | Definitions | Scale |

|---|---|---|

| Crispness | Noise and force with which the sample breaks or fractures | From not crisp/soggy to very crisp |

| Hardness | Force required to bite through | From very soft to very hard |

| Tooth packing | Degree to which the sample sticks on the surface of teeth | From not sticky to very sticky |

| Flour | Protein (%) | Fat (%) | Starch (%) | Fiber (%) | Others (%) |

|---|---|---|---|---|---|

| Okara | 26.52 ± 0.11 c | 3.32 ± 0.02 d | 1.12 ± 0.01 a | 60.75 ± 0.36 d | 3.18 ± 0.02 b |

| Mung bean | 20.19 ± 0.08 b | 1.64 ± 0.01 c | 52.8 ± 0.11 b | 15.2 ± 0.06 c | 3.07 ± 0.01 b |

| Rice | 6.37 ± 0.04 a | 0.07 ± 0.00 a | 86.34 ± 0.26 d | 0.58 ± 0.01 a | 0.29 ± 0.01 a |

| Corn grit | 6.52 ± 0.30 a | 1.2 ± 0.01 b | 77.37 ± 0.12 c | 3.28 ± 0.02 b | 0.3 ± 0.01 a |

| Formulation | Ratio of Flour (%) | Key Composition * (%) | Crispness (Peak) | Toughness (g.sec) | Friction Factor ** | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Okara | Mung Bean | Rice | Protein | Fat | Starch | Fiber | ||||

| 0:16:64 | 0 | 16 | 64 | 8.61 | 0.55 | 79.18 | 3.46 | 296.25 d | 3.27 × 105 b | 4.6 × 10−2 a |

| 0:56:24 | 0 | 56 | 24 | 14.14 | 1.18 | 65.76 | 9.31 | 340.4 e | 2.31 × 105 a | 9.1 × 10−2 c |

| 29:25:26 | 19 | 25 | 26 | 15.70 | 1.63 | 51.45 | 22.22 | 100.25 a | 3.05 × 105 b | 1.0 × 10−1 d |

| 40:24:16 | 40 | 24 | 16 | 17.78 | 1.97 | 42.41 | 28.70 | 125.5 a | 2.65 × 105 a | 7.9 × 10−2 b |

| Sample * | Friction Factor at Specific Sliding Speed (mm/s) | ||||||

|---|---|---|---|---|---|---|---|

| 0.01 | 1 | 5 | 10 | 20 | 50 | 100 | |

| 0:16:64 | 2.7 × 10−2 c | 1.9 × 10−1 b | 9.5 × 10−2 | 4.9 × 10−2 a | 4.8 × 10−2 a | 6.4 × 10−2 | 8.3 × 10−2 |

| 0:56:24 | 1.1 × 10−2 ab | 1.3 × 10−1 a | 1.6 × 10−1 | 8.5 × 10−2 ab | 5.4 × 10−2 a | 6.6 × 10−2 | 1.3 × 10−1 |

| 29:25:26 | 2.7 × 10−2 c | 1.5 × 10−1 ab | 1.7 × 10−1 | 1.5 × 10−1 b | 1.0 × 10−1 b | 5.2 × 10−2 | 5.3 × 10−2 |

| 40:24:16 | 7.8 × 10−3 a | 1.1 × 10−1 a | 1.5 × 10−1 | 1.3 × 10−1 b | 8.6 × 10−2 b | 6.0 × 10−2 | 7.2 × 10−2 |

| Corn 100% | 2.3 × 10−2 bc | 1.5 × 10−1 ab | 1.4 × 10−1 | 1.0 × 10−1 ab | 5.9 × 10−2 a | 6.4 × 10−2 | 8.2 × 10−2 |

| Texture Liking | Crispness | Hardness | Tooth Packing | |

|---|---|---|---|---|

| Texture liking | 1.000 | |||

| Crispness | −0.372 | 1.000 | ||

| Hardness | 0.409 | −0.501 | 1.000 | |

| Tooth packing | −0.646 * | 0.476 | −0.772 * | 1.000 |

| Response | Regression Equation | R2 |

|---|---|---|

| Texture liking | y = 3.8x1 + 3.53x2 + 4.36x3 + 11.72x1x2 + 6.32x1x3 + 7.99x2x3 | 0.9165 |

| Crispness | y = 5.52x1 + 5.406x2 + 4.83x3 + 5.25x1x2 − 4.2x1x3 − 2.2x2x3 | 0.7183 |

| Hardness | y = 3.09x1 + 3.35x2 + 6.3x3 + 1.894x1x2 − 4.72x1 x3 − 1.04x2x3 | 0.7405 |

| Tooth packing | y = 4.79x1 + 3.55x2 + 4.73x3 − 0.01 x1x2 −4.82x1x3 −2.58x2x3 | 0.7168 |

| Bulk density | y = 34.39x1 + 56.4x2 + 131.15x3 − 10.11x1x2 − 92.83x1x3 + 13.94x2x3 | 0.9212 |

| Radial expansion index | y = 6.50x1 + 8.48x2 + 0.56x3 − 21.08x1x2 + 14.20x1x3 − 14.93x2x3 | 0.7392 |

| Crispness | y = 4.73 × 105x1 + 3.61 × 105x2 – 182 × 105x3 – 8.86 × 105x1x2 +10.78 × 105x1x3 + 3.27 × 105 | 0.6132 |

| L* value | y = 88.16x1 + 90.25x2 + 59.90x3 − 45.26x1x2 + 46.78x1x3 − 27.83x2x3 | 0.9312 |

| a* value | y = 0.98x1 + 0.35x2 + 13.64x3 + 16.21x1x2 − 14.56 x1x3 + 11.23x2x3 | 0.9602 |

| b* value | y = 18.54x1 + 24.06x2 + 15.02x3 − 0.40x1x2 + 21.35x1x3 + 19.52x2x3 | 0.8236 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aussanasuwannakul, A.; Teangpook, C.; Treesuwan, W.; Puntaburt, K.; Butsuwan, P. Effect of the Addition of Soybean Residue (Okara) on the Physicochemical, Tribological, Instrumental, and Sensory Texture Properties of Extruded Snacks. Foods 2022, 11, 2967. https://doi.org/10.3390/foods11192967

Aussanasuwannakul A, Teangpook C, Treesuwan W, Puntaburt K, Butsuwan P. Effect of the Addition of Soybean Residue (Okara) on the Physicochemical, Tribological, Instrumental, and Sensory Texture Properties of Extruded Snacks. Foods. 2022; 11(19):2967. https://doi.org/10.3390/foods11192967

Chicago/Turabian StyleAussanasuwannakul, Aunchalee, Chowladda Teangpook, Witcha Treesuwan, Kassamaporn Puntaburt, and Pisut Butsuwan. 2022. "Effect of the Addition of Soybean Residue (Okara) on the Physicochemical, Tribological, Instrumental, and Sensory Texture Properties of Extruded Snacks" Foods 11, no. 19: 2967. https://doi.org/10.3390/foods11192967