Three-Dimensional Printing Properties of Polysaccharide Hydrocolloids–Unrinsed Sturgeon Surimi Complex Hydrogels

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Surimi

2.3. Preparation of Surimi Gels

2.4. Rheological Properties

2.5. Three-Dimensional Printing Process

2.6. Scanning Electron Microscopy (SEM)

2.7. Gel Properties of 3D-Printed Surimi

2.7.1. Texture Analysis

2.7.2. Water-Holding Capacity (WHC)

2.8. Statistical Analysis

3. Results and Discussion

3.1. Effect of Polysaccharides on the Rheological Properties of Unrinsed Surimi Gel

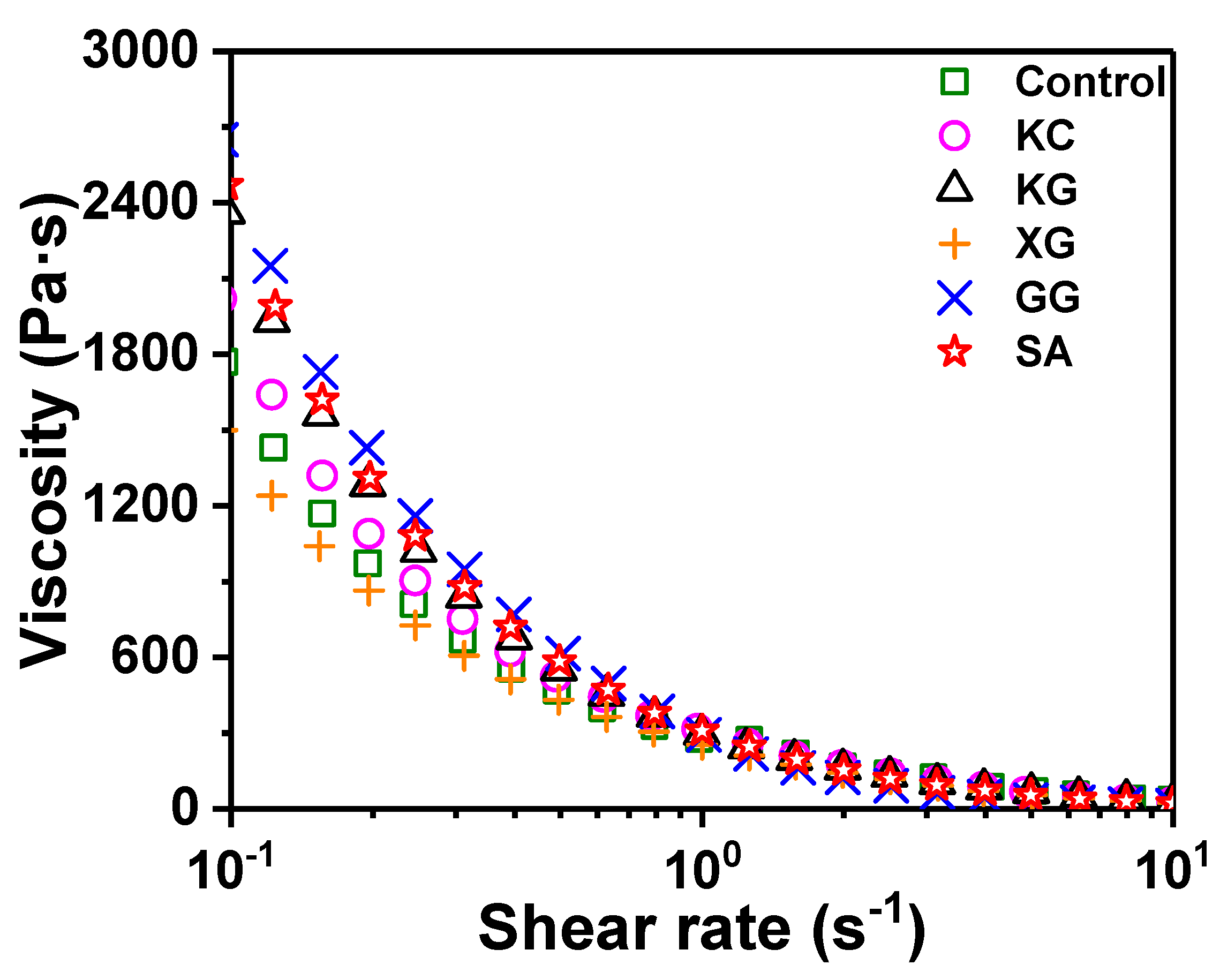

3.1.1. Apparent Viscosity

3.1.2. Viscoelastic Properties

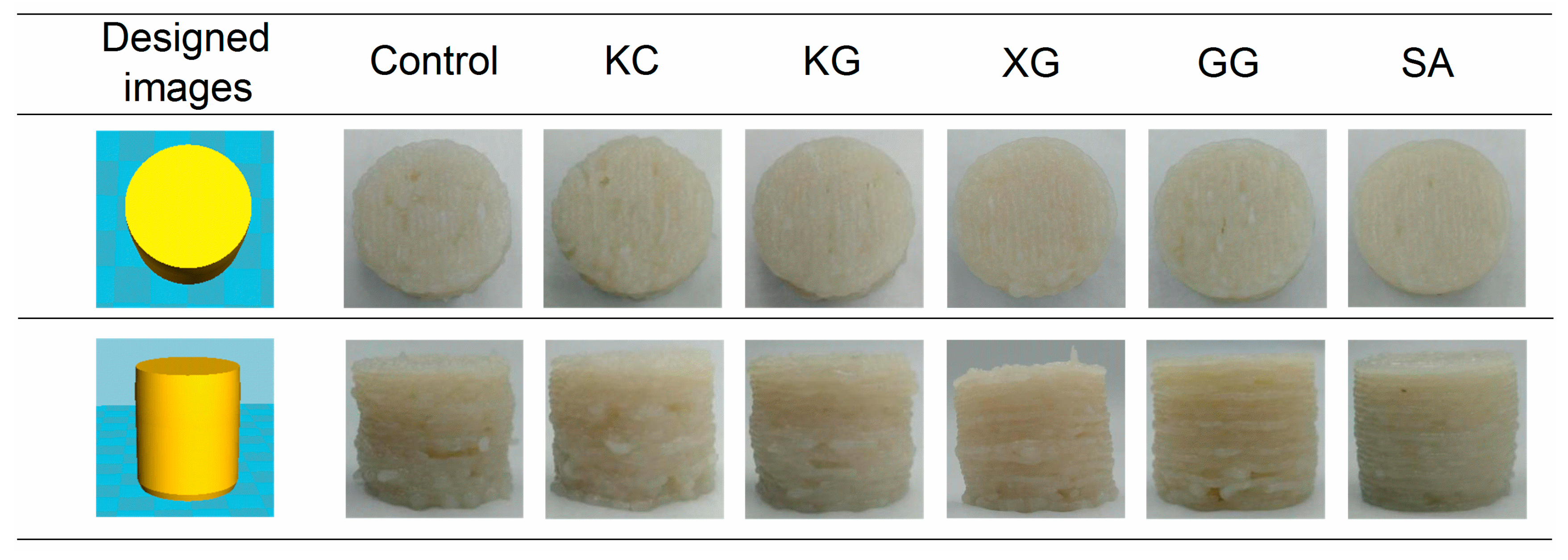

3.2. Evaluation of Printing Effect and Size Deviation

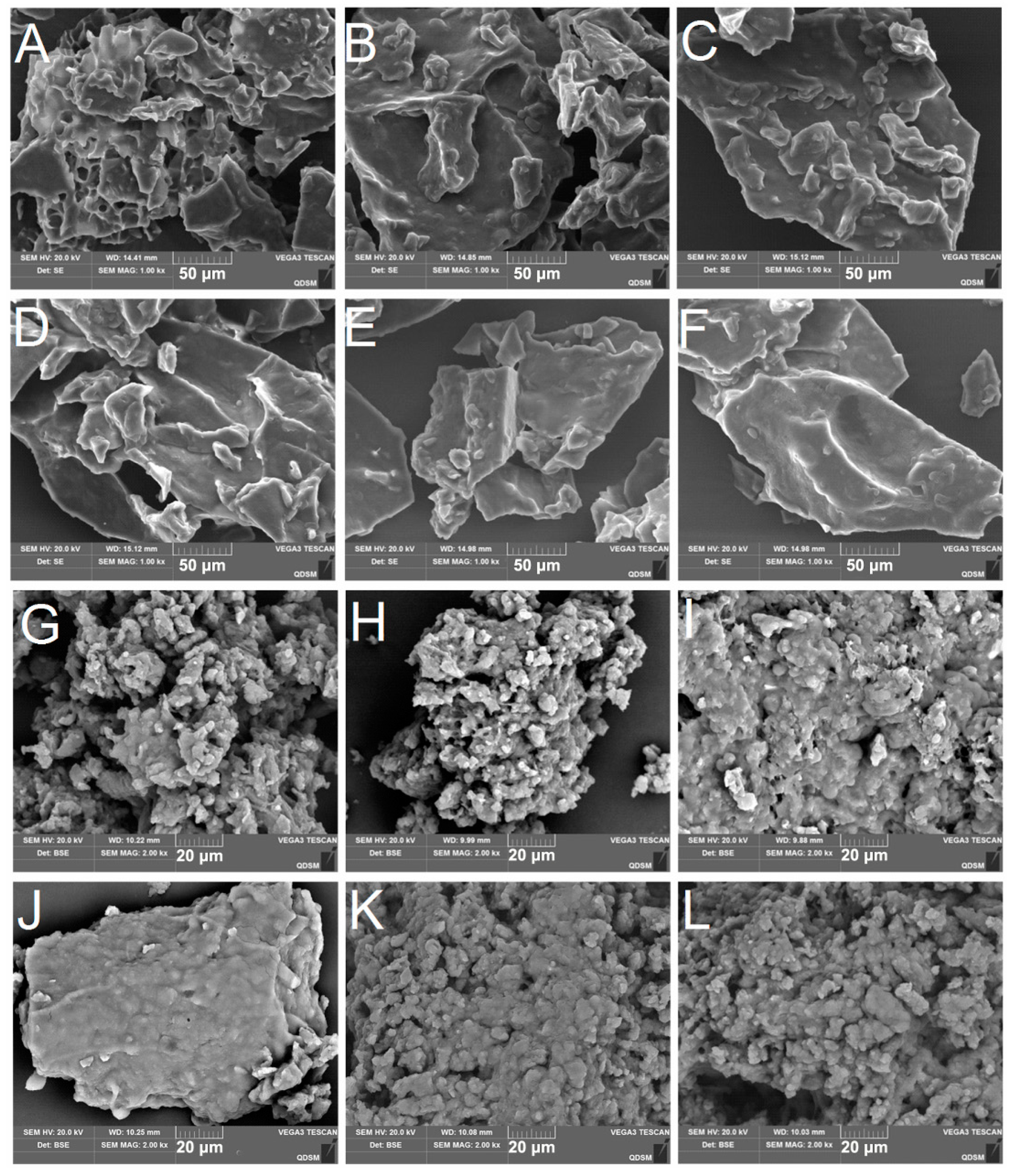

3.3. Scanning Electron Microscopy (SEM)

3.4. Effect of Different Polysaccharides on Gel Properties of 3D-Printed Surimi Products

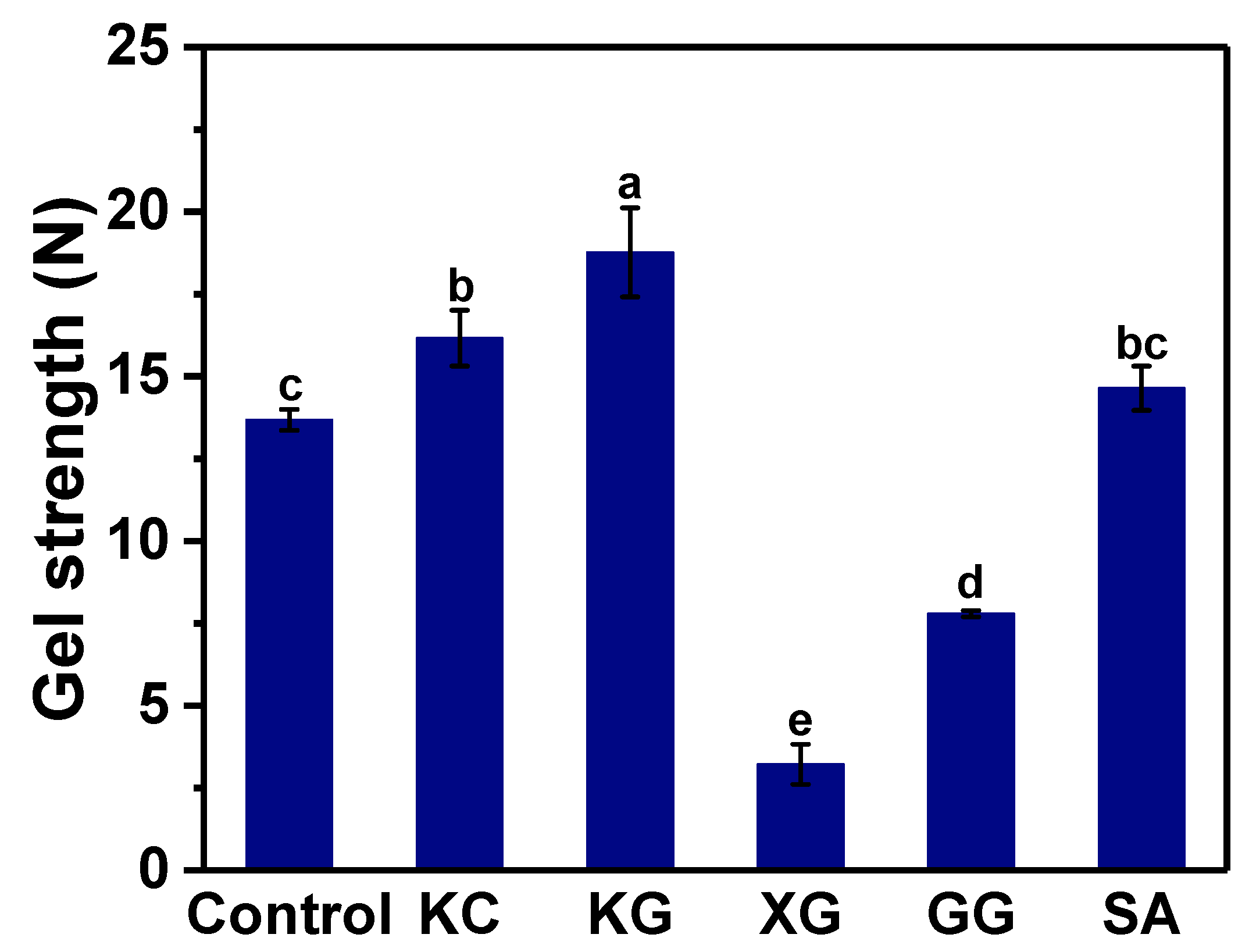

3.4.1. Texture Analysis

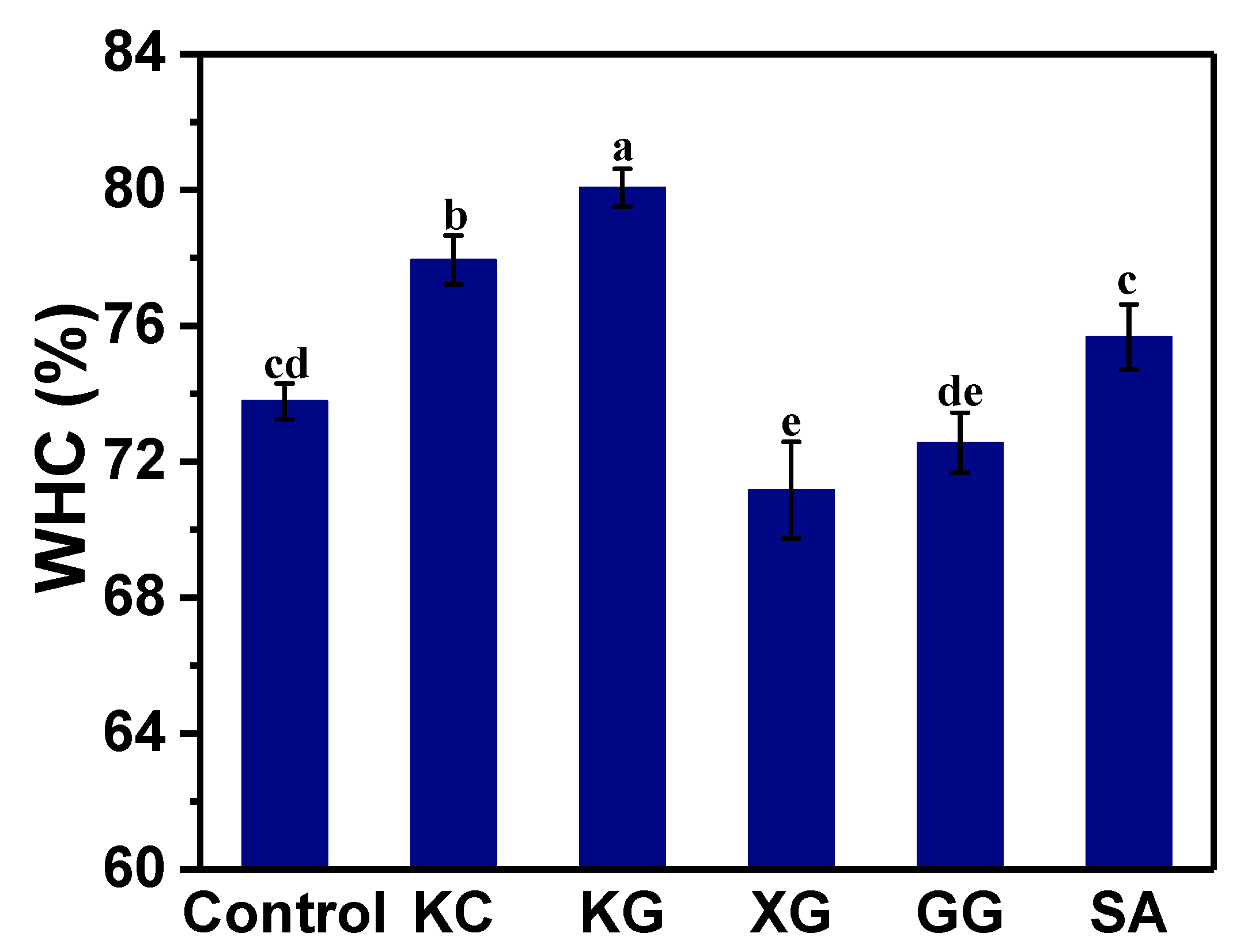

3.4.2. Water-Holding Capacity (WHC)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Azlin, M.N.M.; Ilyas, R.A.; Zuhri, M.Y.M.; Sapuan, S.M.; Harussani, M.M.; Sharma, S.; Nordin, A.H.; Nurazzi, N.M.; Afiqah, A.N. 3D printing and shaping polymers, composites, and nanocomposites: A review. Polymers 2022, 14, 180. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Wu, P.; Chao, Y.; Yu, J.; Zhu, W.; Liu, Z.; Xu, C. Recent advances in 3D printing for catalytic applications. Chem. Eng. J. 2021, 433, 134341. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M.; Bhandari, B. Effect of gums on the rheological, microstructural and extrusion printing characteristics of mashed potatoes. Int. J. Biol. Macromol. 2018, 117, 1179–1187. [Google Scholar] [CrossRef]

- Caporizzi, R.; Derossi, A.; Severini, C. Cereal-based and insect-enriched printable food: From formulation to postprocessing treatments. Status and perspectives. In Fundamentals of 3D Food Printing and Applications; Academic Press: Cambridge, MA, USA, 2019; pp. 93–116. [Google Scholar]

- Liu, Z.; Zhang, M.; Bhandari, B.; Wang, Y. 3D printing: Printing precision and application in food sector. Trends Food Sci. Technol. 2017, 69, 83–94. [Google Scholar] [CrossRef]

- Hao, L.; Mellor, S.; Seaman, O.; Henderson, J.; Sewell, N.; Sloan, M. Material characterisation and process development for chocolate additive layer manufacturing. Virtual Phys. Prototyp. 2010, 5, 57–64. [Google Scholar] [CrossRef]

- Le Tohic, C.; O’Sullivan, J.J.; Drapala, K.P.; Chartrin, V.; Chan, T.; Morrison, A.P.; Kerry, J.P.; Kelly, A.L. Effect of 3D printing on the structure and textural properties of processed cheese. J. Food Eng. 2018, 220, 56–64. [Google Scholar] [CrossRef]

- Liu, Y.; Liang, X.; Saeed, A.; Lan, W.; Qin, W. Properties of 3D printed dough and optimization of printing parameters. Innov. Food Sci. Emerg. Technol. 2019, 54, 9–18. [Google Scholar] [CrossRef]

- Pulatsu, E.; Su, J.W.; Lin, J.; Lin, M. Factors affecting 3D printing and post-processing capacity of cookie dough. Innov. Food Sci. Emerg. Technol. 2020, 61, 102316. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, M.; Bhandari, B.; Liu, Y. Investigation on lemon juice gel as food material for 3D printing and optimization of printing parameters. LWT 2018, 87, 67–76. [Google Scholar] [CrossRef]

- Gani, A.; Benjakul, S.; Nuthong, P. Effect of virgin coconut oil on properties of surimi gel. J. Food Sci. Technol. 2018, 55, 496–505. [Google Scholar] [CrossRef]

- Zhou, X.; Jiang, S.; Zhao, D.; Zhang, J.; Gu, S.; Pan, Z.; Ding, Y. Changes in physicochemical properties and protein structure of surimi enhanced with camellia tea oil. LWT 2017, 84, 562–571. [Google Scholar] [CrossRef]

- Kim, K.Y.; Lee, S.Y.; Song, H.Y.; Park, C.H.; Nam, Y.K. Complete mitogenome of the Russian sturgeon Acipenser gueldenstaedtii (Acipenseriformes; Acipenseridae). Fish. Aquat. Sci. 2009, 12, 35–43. [Google Scholar] [CrossRef]

- Wang, R.; Gao, R.; Xiao, F.; Zhou, X.; Wang, H.; Xu, H.; Gong, C.; Huang, P.; Zhao, Y. Effect of chicken breast on the physicochemical properties of unwashed sturgeon surimi gels. LWT 2019, 113, 108306. [Google Scholar] [CrossRef]

- An, Y.; You, J.; Xiong, S.; Yin, T. Short-term frozen storage enhances cross-linking that was induced by transglutaminase in surimi gels from silver carp (Hypophthalmichthys molitrix). Food Chem. 2018, 257, 216–222. [Google Scholar] [CrossRef] [PubMed]

- Balange, A.; Benjakul, S. Enhancement of gel strength of bigeye snapper (Priacanthus tayenus) surimi using oxidised phenolic compounds. Food Chem. 2009, 113, 61–70. [Google Scholar] [CrossRef]

- Chaijan, M.; Benjakul, S.; Visessanguan, W.; Faustman, C. Characteristics and gel properties of muscles from sardine (Sardinella gibbosa) and mackerel (Rastrelliger kanagurta) caught in Thailand. Food Res. Int. 2004, 37, 1021–1030. [Google Scholar] [CrossRef]

- Zhou, Y.; Yang, H. Effects of calcium ion on gel properties and gelation of tilapia (Oreochromis niloticus) protein isolates processed with pH shift method. Food Chem. 2019, 277, 327–335. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, M.; Bhandari, B.; Yang, C. Investigation on fish surimi gel as promising food material for 3D printing. J. Food Eng. 2018, 220, 101–108. [Google Scholar] [CrossRef]

- Dong, X.; Pan, Y.; Zhao, W.; Huang, Y.; Qu, W.; Pan, J.; Qi, H.; Prakash, S. Impact of microbial transglutaminase on 3D printing quality of Scomberomorus niphonius surimi. LWT 2020, 124, 109123. [Google Scholar] [CrossRef]

- Dick, A.; Bhandari, B.; Dong, X.; Prakash, S. Feasibility study of hydrocolloid incorporated 3D printed pork as dysphagia food. Food Hydrocoll. 2020, 107, 105940. [Google Scholar] [CrossRef]

- Kim, H.W.; Bae, H.; Park, H.J. Classification of the printability of selected food for 3D printing: Development of an assessment method using hydrocolloids as reference material. J. Food Eng. 2017, 215, 23–32. [Google Scholar] [CrossRef]

- Diañez, I.; Gallegos, C.; Brito-de La Fuente, E.; Martínez, I.; Valencia, C.; Sánchez, M.C.; Diaz, M.J.; Franco, J.M. 3D printing in situ gelification of κ-carrageenan solutions: Effect of printing variables on the rheological response. Food Hydrocoll. 2019, 87, 321–330. [Google Scholar] [CrossRef]

- Yang, J.M.; Panda, P.K.; Jie, C.J.; Dash, P.; Chang, Y. Poly (vinyl alcohol)/chitosan/sodium alginate composite blended membrane: Preparation, characterization, and water-induced shape memory phenomenon. Polym. Eng. Sci. 2022, 62, 1526–1537. [Google Scholar] [CrossRef]

- Huang, M.; Zhang, M.; Bhandari, B.; Liu, Y. Improving the three-dimensional printability of taro paste by the addition of additives. J. Food Process Eng. 2020, 43, e13090. [Google Scholar] [CrossRef]

- Pegg, A.M. The application of natural hydrocolloids to foods and beverages. In Natural Food Additives, Ingredients and Flavourings; Woodhead Publishing: Sawston, UK, 2012; pp. 175–196. [Google Scholar]

- Kim, H.W.; Lee, I.J.; Park, S.M.; Lee, J.H.; Nguyen, M.H.; Park, H.J. Effect of hydrocolloid addition on dimensional stability in post-processing of 3D printable cookie dough. LWT 2019, 101, 69–75. [Google Scholar] [CrossRef]

- Balange, A.K.; Benjakul, S. Effect of oxidised tannic acid on the gel properties of mackerel (Rastrelliger kanagurta) mince and surimi prepared by different washing processes. Food Hydrocoll. 2009, 23, 1693–1701. [Google Scholar] [CrossRef]

- Chéret, R.; Chapleau, N.; Delbarre-Ladrat, C.; Verrez-Bagnis, V.; de Lamballerie, M. Effects of high pressure on texture and microstructure of sea bass (Dicentrarchus labrax L.) fillets. J. Food Sci. 2005, 70, e477–e483. [Google Scholar] [CrossRef]

- Vega-Warner, V.; Merkel, R.A.; Smith, D.M. Composition, solubility and gel properties of salt soluble proteins from two bovine muscle types. Meat Sci. 1999, 51, 197–203. [Google Scholar] [CrossRef]

- Chen, H.; Xie, F.; Chen, L.; Zheng, B. Effect of rheological properties of potato, rice and corn starches on their hot-extrusion 3D printing behaviors. J. Food Eng. 2019, 244, 150–158. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M.; Bhandari, B.; Yang, C. Impact of rheological properties of mashed potatoes on 3D printing. J. Food Eng. 2018, 220, 76–82. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Liu, D.; Wei, G.; Ma, Y.; Bhandari, B.; Zhou, P. 3D printed milk protein food simulant: Improving the printing performance of milk protein concentration by incorporating whey protein isolate. Innov. Food Sci. Emerg. Technol. 2018, 49, 116–126. [Google Scholar] [CrossRef]

- Chen, J.; Mu, T.; Goffin, D.; Blecker, C.; Richard, G.; Richel, A.; Haubruge, E. Application of soy protein isolate and hydrocolloids based mixtures as promising food material in 3D food printing. J. Food Eng. 2019, 261, 76–86. [Google Scholar] [CrossRef]

- Godoi, F.C.; Prakash, S.; Bhandari, B.R. 3D printing technologies applied for food design: Status and prospects. J. Food Eng. 2016, 179, 44–54. [Google Scholar] [CrossRef]

- Lille, M.; Nurmela, A.; Nordlund, E.; Metsä-Kortelainen, S.; Sozer, N. Applicability of protein and fiber-rich food materials in extrusion-based 3D printing. J. Food Eng. 2018, 220, 20–27. [Google Scholar] [CrossRef]

- Ramírez, J.A.; Uresti, R.M.; Velazquez, G.; Vázquez, M. Food hydrocolloids as additives to improve the mechanical and functional properties of fish products: A review. Food Hydrocoll. 2011, 25, 1842–1852. [Google Scholar] [CrossRef]

- Eidam, D.; Kulicke, W.M.; Kuhn, K.; Stute, R. Formation of maize starch gels selectively regulated by the addition of hydrocolloids. Starch-Stärke 1995, 47, 378–384. [Google Scholar] [CrossRef]

- Ramırez, J.A.; Barrera, M.; Morales, O.G.; Vázquezc, M. Effect of xanthan and locust bean gums on the gelling properties of myofibrillar protein. Food Hydrocoll. 2002, 16, 11–16. [Google Scholar] [CrossRef]

- Thrimawithana, T.R.; Young, S.; Dunstan, D.E.; Alany, R.G. Texture and rheological characterization of kappa and iota carrageenan in the presence of counter ions. Carbohydr. Polym. 2010, 82, 69–77. [Google Scholar] [CrossRef]

- Huang, Q.; Liu, Z.; Pei, Y.; Li, J.; Li, B. Gelation behaviors of the konjac gum from different origins: A. guripingensis and A. rivirei. Food Hydrocoll. 2021, 111, 106152. [Google Scholar] [CrossRef]

- Park, J.W. Temperature-tolerant fish protein gels using konjac flour. J. Muscle Foods 1996, 7, 165–174. [Google Scholar] [CrossRef]

- Wei, Y.; Wang, Y.L.; He, X.J. Gel properties of k-carrageenan-konjac gum mixed gel and their influence factors. Adv. Mater. Res. 2012, 396, 1389–1393. [Google Scholar] [CrossRef]

- Verbeken, D.; Neirinck, N.; Van Der Meeren, P.; Dewettinck, K. Influence of κ-carrageenan on the thermal gelation of salt-soluble meat proteins. Meat Sci. 2005, 70, 161–166. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Ji, L.; Zhang, T.; Xue, Y.; Xue, C. Effects of pre-emulsification by three food-grade emulsifiers on the properties of emulsified surimi sausage. J. Food Eng. 2019, 247, 30–37. [Google Scholar] [CrossRef]

- Pérez-Mateos, M.; Montero, P. Contribution of hydrocolloids to gelling properties of blue whiting muscle. Eur. Food Res. Technol. 2000, 210, 383–390. [Google Scholar] [CrossRef]

- Rosenvold, K.; Andersen, H.J. Factors of significance for pork quality—A review. Meat Sci. 2003, 64, 219–237. [Google Scholar] [CrossRef]

- Park, J.W. Surimi and Surimi Seafood; CRC Press: Boca Raton, FL, USA, 2005; p. 636. [Google Scholar]

| Group | Printing Time (min) | Weight (g) | Height (mm) | Height Deviation (%) | Diameter (mm) | Diameter Deviation (%) |

|---|---|---|---|---|---|---|

| Control | 13.63 ± 0.01 a | 10.14 ± 0.02 a | 20.92 ± 0.04 e | 4.60 ± 0.20 e | 24.47 ± 0.01 a | −2.13 ± 0.05 a |

| KC | 13.62 ± 0.01 a | 10.16 ± 0.04 a | 20.75 ± 0.05 c | 3.75 ± 0.25 c | 24.65 ± 0.02 c | −2.17 ± 0.58 a |

| KG | 13.61 ± 0.01 a | 10.19 ± 0.04 a | 20.75 ± 0.03 c | 3.77 ± 0.14 c | 24.55 ± 0.02 b | −1.80 ± 0.09 a |

| XG | 13.61 ± 0.02 a | 10.18 ± 0.03 a | 20.84 ± 0.02 d | 4.20 ± 0.12 d | 24.77 ± 0.02 d | −0.92 ± 0.07 bc |

| GG | 13.60 ± 0.02 a | 10.13 ± 0.04 a | 20.65 ± 0.04 b | 3.25 ± 0.20 b | 24.76 ± 0.02 d | −0.97 ± 0.08 b |

| SA | 13.59 ± 0.03 a | 10.18 ± 0.03 a | 20.56 ± 0.03 a | 2.80 ± 0.14 a | 24.90 ± 0.02 e | −0.40 ± 0.07 c |

| Sample | Hardness (N) | Springiness (mm) | Chewiness (mJ) | Cohesiveness | Adhesiveness (mJ) | Gumminess (N) |

|---|---|---|---|---|---|---|

| Control | 35.48 ± 2.54 b | 6.40 ± 0.13 a | 120.09 ± 6.63 b | 0.50 ± 0.01 b | 0.04 ± 0.01 c | 20.51 ± 2.97 ab |

| KC | 40.21 ± 4.54 ab | 6.33 ± 0.04 a | 135.20 ± 22.25 b | 0.50 ± 0.03 b | 0.05 ± 0.01 c | 21.34 ± 3.43 ab |

| KG | 44.14 ± 1.14 a | 6.47 ± 0.06 a | 160.34 ± 8.33 a | 0.56 ± 0.02 a | 0.04 ± 0.01 c | 24.78 ± 1.06 a |

| XG | 9.17 ± 1.95 d | 4.30 ± 0.10 c | 9.62 ± 0.25 d | 0.24 ± 0.01 d | 0.11 ± 0.01 a | 2.43 ± 0.25 c |

| GG | 21.67 ± 1.14 c | 5.95 ± 0.10 b | 39.27 ± 4.15 c | 0.30 ± 0.02 c | 0.07 ± 0.01 b | 6.59 ± 0.62 c |

| SA | 37.44 ± 2.87 b | 6.44 ± 0.11 a | 128.43 ± 9.04 b | 0.53 ± 0.01 ab | 0.04 ± 0.01 c | 19.89 ± 1.82 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, K.; Zhao, N.; Xiang, C.; Li, Y.; Jiang, X.; Zeng, M.; Xu, H.; Wang, H.; Wu, H.; Yu, X.; et al. Three-Dimensional Printing Properties of Polysaccharide Hydrocolloids–Unrinsed Sturgeon Surimi Complex Hydrogels. Foods 2022, 11, 2947. https://doi.org/10.3390/foods11192947

Liu K, Zhao N, Xiang C, Li Y, Jiang X, Zeng M, Xu H, Wang H, Wu H, Yu X, et al. Three-Dimensional Printing Properties of Polysaccharide Hydrocolloids–Unrinsed Sturgeon Surimi Complex Hydrogels. Foods. 2022; 11(19):2947. https://doi.org/10.3390/foods11192947

Chicago/Turabian StyleLiu, Kang, Nana Zhao, Chenxi Xiang, Yujin Li, Xiaoming Jiang, Mingyong Zeng, He Xu, Haiyan Wang, Haohao Wu, Xiaoqing Yu, and et al. 2022. "Three-Dimensional Printing Properties of Polysaccharide Hydrocolloids–Unrinsed Sturgeon Surimi Complex Hydrogels" Foods 11, no. 19: 2947. https://doi.org/10.3390/foods11192947

APA StyleLiu, K., Zhao, N., Xiang, C., Li, Y., Jiang, X., Zeng, M., Xu, H., Wang, H., Wu, H., Yu, X., & Zhao, Y. (2022). Three-Dimensional Printing Properties of Polysaccharide Hydrocolloids–Unrinsed Sturgeon Surimi Complex Hydrogels. Foods, 11(19), 2947. https://doi.org/10.3390/foods11192947