Comparative Flavor Profile of Roasted Germinated Wheat (Triticum aestivum L.) Beverages Served Hot and Cold Using Electronic Sensors Combined with Chemometric Statistical Analysis

Abstract

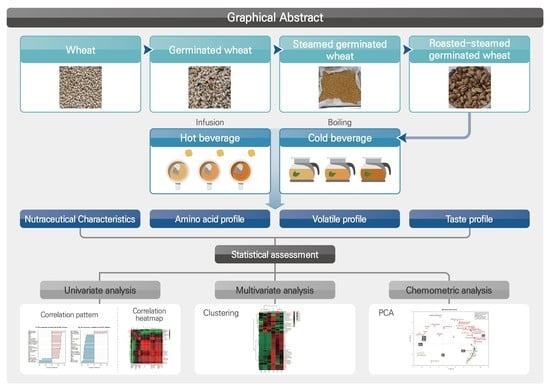

1. Introduction

2. Materials and Methods

2.1. Raw Materials and Chemicals

2.2. Sample Preparation

2.3. Analysis

2.3.1. Nutraceutical Characteristics of Roasted Germinated Wheat Beverages

2.3.2. Amino Acid Profile of Roasted Germinated Wheat Beverages

2.3.3. Volatiles Profile of Roasted Germinated Wheat Beverages

2.3.4. Taste Profile of Roasted Germinated Wheat Beverages

2.4. Statistical Assessment

3. Results and Discussion

3.1. Nutraceutical Characteristics of Roasted Germinated Wheat Beverages

3.2. Amino Acid Profiles of Roasted Germinated Wheat Beverages

3.3. Volatiles Profile of Roasted Germinated Wheat Beverages

3.4. Taste Profile of Roasted Germinated Wheat Beverages

3.5. Correlation Analysis between Aroma Metabolites and Characteristics of Hot and Cold Beverages

3.6. Clustering Analysis and Principal Component Analysis of Metabolites in Hot and Cold Beverages

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kreisz, S.; Arendt, E.; Hübner, F.; Zarnkov, M. Cereal-Based Gluten-Free Functional Drinks. In Gluten-Free Cereal Products and Beverages; Food Science and Technology International Series; Elsevier Academic Press: Amsterdam, The Netherlands, 2008; pp. 373–391. [Google Scholar]

- Kim, M.-J.; Kim, J.-I.; Ryu, C.-H.; Kang, M.-J. Effects of Fermented Beverage in Subjects with Metabolic Syndrome. Prev. Nutr. Food Sci. 2021, 26, 12–20. [Google Scholar] [CrossRef]

- Ghoshal, G.; Kansal, S.K. The emerging trends in functional and medicinal beverage research and its health implication. Funct. Med. Beverages 2019, 11, 41–71. [Google Scholar]

- Feng, J.; Xu, B.; Ma, D.; Hao, Z.; Jia, Y.; Wang, C.; Wang, L. Metabolite identification in fresh wheat grains of different colors and the influence of heat processing on metabolites via targeted and non-targeted metabolomics. Food Res. Int. 2022, 160, 111728. [Google Scholar] [CrossRef] [PubMed]

- Nazari, J.; Yadegari, N.; Khodam, S.; Almasi-Hashian, A.; Amini, S. Effect of consumption of whole-wheat breads on FBS, HbA1c, and blood lipids in patients with type 2 diabetes. Prev. Nutr. Food Sci. 2021, 26, 269–274. [Google Scholar] [CrossRef]

- Aung, T.; Kim, B.R.; Kim, M.J. Optimized Roasting Conditions of Germinated Wheat for a Novel Cereal Beverage and Its Sensory Properties. Foods 2022, 11, 481. [Google Scholar] [CrossRef] [PubMed]

- Tolun, A.; Altintas, Z. Medicinal Properties and Functional Components of Beverages. In Functional and Medicinal Beverages; Elsevier: Amsterdam, The Netherlands, 2019; pp. 235–284. [Google Scholar]

- Kim, S.M.; Aung, T.; Kim, M.J. Optimization of germination conditions to enhance the antioxidant activity in chickpea (Cicer arietimum L.) using response surface methodology. Korean J. Food Preserv. 2022, 29, 632–644. [Google Scholar] [CrossRef]

- Farghal, H.H.; Mansour, S.T.; Khattab, S.; Zhao, C.; Farag, M.A. A comprehensive insight on modern green analyses for quality control determination and processing monitoring in coffee and cocoa seeds. Food Chem. 2022, 394, 133529. [Google Scholar] [CrossRef] [PubMed]

- Kim, B.R.; Park, S.S.; Youn, G.-J.; Kwak, Y.J.; Kim, M.J. Characteristics of Sunsik, a cereal-based ready-to-drink Korean beverage, with added germinated wheat and herbal plant extract. Foods 2020, 9, 1654. [Google Scholar] [CrossRef]

- Kim, M.J.; Kwak, H.S.; Kim, S.S. Effects of salinity on bacterial communities, Maillard reactions, isoflavone composition, antioxidation and antiproliferation in Korean fermented soybean paste (doenjang). Food Chem. 2018, 245, 402–409. [Google Scholar] [CrossRef]

- Gujral, H.S.; Sharma, P.; Gill, B.S.; Kaur, S. Effect of incorporating hydrothermal, kilned and defatted oats on antioxidant and chapatti making properties of wheat flour. Food Chem. 2013, 138, 1400–1406. [Google Scholar] [CrossRef]

- Wong, S.P.; Leong, L.P.; Koh, J.H.W. Antioxidant activities of aqueous extracts of selected plants. Food Chem. 2006, 99, 775–783. [Google Scholar] [CrossRef]

- Simsek, S.; El, S.N. In Vitro starch digestibility, estimated glycemic index and antioxidant potential of taro (Colocasia esculenta L. Schott) corm. Food Chem. 2015, 168, 257–261. [Google Scholar] [CrossRef]

- Muttucumaru, N.; Halford, N.G.; Elmore, J.S.; Dodson, A.T.; Parry, M.; Shewry, P.R.; Mottram, D.S. Formation of high levels of acrylamide during the processing of flour derived from sulfate-deprived wheat. J. Agric. Food Chem. 2006, 54, 8951–8955. [Google Scholar] [CrossRef] [PubMed]

- Jaganyi, D.; Ndlovu, T. Kinetics of tea infusion. Part 3: The effect of tea bag size and shape on the rate of caffeine extraction from Ceylon orange pekoe tea. Food Chem. 2001, 75, 63–66. [Google Scholar] [CrossRef]

- Kim, H.-J.; Han, J.-A.; Lim, S.-T.; Cho, D.-H. Effects of germination and roasting on physicochemical and sensory characteristics of brown rice for tea infusion. Food Chem. 2021, 350, 129240. [Google Scholar] [CrossRef]

- Dhekne, P.P.; Patwardhan, A.W. Mathematical modeling of tea bag infusion kinetics. J. Food Eng. 2020, 274, 109847. [Google Scholar] [CrossRef]

- Yadav, G.U.; Joshi, B.S.; Patwardhan, A.W.; Singh, G. Swelling and infusion of tea in tea bags. J. Food Sci. Technol. 2017, 54, 2474–2484. [Google Scholar] [CrossRef] [PubMed]

- Kawai, M.; Okiyama, A.; Ueda, Y. Taste enhancements between various amino acids and IMP. Chem. Senses 2002, 27, 739–745. [Google Scholar] [CrossRef]

- Lindqvist, M. Flavour Improvement of Water Solutions Comprising Bitter Amino Acids. Master’s Thesis, Swedish University of Agricultural Sciences, Uppsala, Sweden, 2011. [Google Scholar]

- Torres-Moreno, M.; Tarrega, A.; Blanch, C. Effect of cocoa roasting time on volatile composition of dark chocolates from different origins determined by HS-SPME/GC-MS. CyTA-J. Food 2021, 19, 81–95. [Google Scholar] [CrossRef]

- Chen, J.; Yang, Y.; Deng, Y.; Liu, Z.; Shen, S.; Zhu, J.; Yuan, H.; Jiang, Y. Characterization of the key differential volatile components in different grades of Dianhong Congou tea infusions by the combination of sensory evaluation, comprehensive two-dimensional gas chromatography-time-of-flight mass spectrometry, and odor activity value. LWT 2022, 165, 113755. [Google Scholar]

- Wang, B.; Qu, F.; Wang, P.; Zhao, L.; Wang, Z.; Han, Y.; Zhang, X. Characterization analysis of flavor compounds in green teas at different drying temperature. LWT 2022, 161, 113394. [Google Scholar] [CrossRef]

- Lenahan, F.D.; Piszko, M.; Klein, T.; Fröba, A.P. Diffusivities in Binary Mixtures of n-Decane, n-Hexadecane, n-Octacosane, 2-Methylpentane, 2, 2-Dimethylbutane, Cyclohexane, Benzene, Ethanol, 1-Decanol, Ethyl Butanoate, or n-Hexanoic Acid with Dissolved He or Kr Close to Infinite Dilution. J. Chem. Eng. Data 2022, 67, 622–635. [Google Scholar] [CrossRef]

- Wang, W.; Zhou, X.; Liu, Y. Characterization and evaluation of umami taste: A review. TrAC Trends Anal. Chem. 2020, 127, 115876. [Google Scholar] [CrossRef]

| Amino Acids (mg/100 g) (1) | Hot Beverages | Cold Beverages | ||||

|---|---|---|---|---|---|---|

| HB_1 | HB_2 | HB_3 | CB_1 | CB_2 | CB_3 | |

| Ala | 3.29 ± 0.39 a | 2.75 ± 0.06 ab | 2.61 ± 0.17 c | 10.21 ± 0.95 B | 14.32 ± 0.34 A | 13.50 ± 0.71 A |

| Arg | 2.22 ± 0.46 a | 1.71 ± 0.08 a | 1.62 ± 0.14 a | 6.10 ± 0.96 B | 10.33 ± 1.42 A | 10.53 ± 0.90 A |

| Asp | 2.78 ± 0.42 a | 2.36 ± 0.23 a | 2.18 ± 0.21 a | 8.09 ± 0.29 A | 7.46 ± 0.52 A | 6.42 ± 0.17 B |

| Glu | 1.38 ± 0.28 a | 1.05 ± 0.06 a | 1.00 ± 0.08 a | 4.96 ± 0.30 A | 4.77 ± 0.13 A | 4.21 ± 0.18 B |

| Gly | 1.29 ± 0.25 a | 1.01 ± 0.06 a | 1.02 ± 0.08 a | 3.92 ± 0.67 A | 5.54 ± 0.70 A | 5.98 ± 0.55 A |

| His | 1.02 ± 0.24 a | 0.69 ± 0.03 a | 0.72 ± 0.03 a | 2.96 ± 0.54 A | 3.57 ± 0.84 A | 4.03 ± 0.72 A |

| Ile | 1.90 ± 0.21 a | 1.57 ± 0.21 ab | 0.24 ± 0.02 c | 1.44 ± 0.13 A | 1.66 ± 0.11 A | 1.67 ± 0.07 A |

| Leu | 0.65 ± 0.00 a | 0.45 ± 0.01 a | 0.43 ± 0.01 b | 2.78 ± 0.48 A | 3.25 ± 0.28 A | 3.18 ± 0.34 A |

| Lys | 0.95 ± 0.01 a | 0.61 ± 0.05 a | 0.61 ± 0.05 b | 1.65 ± 0.39 B | 3.36 ± 0.45 A | 3.52 ± 0.29 A |

| Met | ND | ND | ND | ND | 0.37 ± 0.28 A | 0.30 ± 0.07 A |

| Phe | 0.23 ± 0.04 a | 0.15 ± 0.01 a | 0.15 ± 0.01 b | 1.08 ± 0.41 A | 1.55 ± 0.32 A | 1.64 ± 0.25 A |

| Pro | 4.05 ± 0.58 a | 3.26 ± 0.43 a | 2.98 ± 0.54 a | 14.8 ± 1.80 A | 15.59 ± 1.23 A | 14.23 ± 1.47 A |

| Ser | 2.21 ± 0.38 a | 1.77 ± 0.06 a | 1.81 ± 0.11 a | 8.36 ± 1.84 A | 10.54 ± 1.42 A | 11.31 ± 1.00 A |

| Thr | 0.69 ± 0.12 a | 0.54 ± 0.03 ab | 0.50 ± 0.01 b | 2.24 ± 0.31 B | 2.52 ± 0.29 AB | 2.82 ± 0.28 A |

| Tyr | 0.32 ± 0.04 a | 0.24 ± 0.00 b | 0.24 ± 0.02 b | 1.56 ± 0.29 A | 1.97 ± 0.61 A | 1.64 ± 0.26 A |

| Val | 1.01 ± 0.21 b | 0.73 ± 0.05 a | 0.69 ± 0.07 a | 3.67 ± 0.48 A | 4.18 ± 0.12 A | 3.94 ± 0.34 A |

| Compounds | Odor Description | Hot Beverages | Cold Beverages | ||||

|---|---|---|---|---|---|---|---|

| HB_1 | HB_2 | HB_3 | CB_1 | CB_2 | CB_3 | ||

| Acids and esters (5) | |||||||

| Methyl formate | Agreeable, Fruity | 1.32 ± 0.12 c | 2.64 ± 0.45 b | 3.77 ± 0.20 a | 0.17 ± 0.00 A | 0.18 ± 0.02 A | 0.50 ± 0.70 A |

| Propyl propanoate | Sweet, Fruity | 0.22 ± 0.03 a | 0.30 ± 0.11 a | 0.18 ± 0.02 a | 0.18 ± 0.00 B | 0.19 ± 0.02 B | 0.37 ± 0.07 A |

| Methyl pentanoate | Nutty, Sweet | 0.46 ± 0.06 a | 0.71 ± 0.06 a | 0.46 ± 0.01 a | 1.20 ± 0.09 B | 2.35 ± 0.09 B | 4.56 ± 0.95 A |

| Benzyl acetate | Burnt, Sweet | 0.13 ± 0.01 a | 0.13 ± 0.01 a | 0.15 ± 0.02 a | 0.13 ± 0.00 B | 0.22 ± 0.01 A | 0.29 ± 0.05 A |

| Butylate | Aromatic | 1.04 ± 0.12 a | 0.74 ± 0.12 b | 0.65 ± 0.07 b | 0.54 ± 0.06 A | 0.57 ± 0.09 A | 0.64 ± 0.19 A |

| Alcohols (5) | |||||||

| 3-Pentanol | Nutty, Sweet | 0.52 ± 0.06 ab | 0.62 ± 0.23 a | 0.18 ± 0.01 b | 0.25 ± 0.01 B | 0.28 ± 0.02 B | 0.77 ± 0.12 A |

| 3-Methyl-1-butanol | Burnt, Bitter | 0.19 ± 0.04 a | 0.26 ± 0.12 a | 0.12 ± 0.02 a | 0.18 ± 0.01 B | 0.30 ± 0.01 B | 0.73 ± 0.11 A |

| 2-Methyl-1-butanol | Alcoholic, Sweet | 0.55 ± 0.11 a | 0.62 ± 0.11 a | 0.36 ± 0.04 a | 1.47 ± 0.13 B | 2.67 ± 0.02 B | 5.27 ± 0.93 A |

| 1-Hexen-3-ol | Green | 0.32 ± 0.04 a | 0.50 ± 0.04 a | 0.38 ± 0.03 a | 0.22 ± 0.01 B | 0.28 ± 0.01 B | 0.72 ± 0.20 A |

| 2-Octanol | Aromatic, Walnut | 1.39 ± 0.09 a | 1.14 ± 0.09 a | 0.99 ± 0.05 a | 1.47 ± 0.10 B | 1.73 ± 0.20 B | 3.28 ± 0.28 A |

| Aldehydes (2) | |||||||

| 2-Methylbutanal | Almond, Burnt | 0.20 ± 0.03 a | 0.33 ± 0.13 a | 0.21 ± 0.01 a | 0.20 ± 0.01 B | 0.20 ± 0.01 B | 0.43 ± 0.05 A |

| 3-Fenylpropenal | Sweet | 0.77 ± 0.09 a | 0.71 ± 0.03 a | 0.72 ± 0.04 a | 0.73 ± 0.05 A | 0.67 ± 0.02 A | 0.77 ± 0.11 A |

| Heterocyclic compounds (3) | |||||||

| 2,3-Dimethyl-5-ethylpyrazine | Burnt | 0.61 ± 0.19 a | 0.44 ± 0.28 ab | 0.09 ± 0.01 b | 0.34 ± 0.02 B | 0.43 ± 0.03 B | 1.00 ± 0.23 A |

| Myristicin | Balsamic, Mild | 0.11 ± 0.10 a | 0.04 ± 0.03 a | 0.04 ± 0.03 a | 0.05 ± 0.03 A | 0.06 ± 0.04 A | 0.06 ± 0.05 A |

| 4-Undecanolide | Fruity | 0.85 ± 0.07 a | 0.88 ± 0.17 a | 0.79 ± 0.13 a | 0.79 ± 0.08 B | 0.91 ± 0.17 AB | 1.27 ± 0.23 A |

| Hydrocarbons (9) | |||||||

| Butane | Pungent, Strong | 16.99 ± 1.97 a | 18.66 ± 12.72 a | 0.77 ± 0.07 a | 3.02 ± 0.39 B | 4.82 ± 0.32 A | 0.16 ± 0.23 C |

| 2-Methylbutane | Pleasant | 2.25 ± 0.11 a | 1.38 ± 0.47 a | 1.12 ± 0.16 a | 0.99 ± 0.06 C | 1.74 ± 0.08 B | 2.43 ± 0.44 A |

| 2-Methylpentane | - | 22.36 ± 2.49 b | 40.38 ± 3.98 a | 0.80 ± 0.05 c | 4.55 ± 0.51 C | 7.59 ± 0.31 B | 14.29 ± 1.10 A |

| Hexane | Alkane, Etheral | 0.31 ± 0.02 a | 0.46 ± 0.25 a | 0.21 ± 0.05 a | 0.22 ± 0.03 B | 0.59 ± 0.05 B | 1.37 ± 0.50 A |

| Cyclohexane | Chloroform | 0.14 ± 0.03 a | 0.52 ± 0.33 a | 0.32 ± 0.01 a | 0.19 ± 0.06 B | 0.43 ± 0.01 B | 0.89 ± 0.20 A |

| 2-Methylheptane | - | 0.05 ± 0.04 a | 0.08 ± 0.03 a | 0.03 ± 0.04 a | 0.17 ± 0.01 C | 0.34 ± 0.01 B | 0.56 ± 0.09 A |

| Vinylbenzene | Roast, Aromatic | 1.62 ± 0.14 a | 2.07 ± 0.59 a | 1.44 ± 0.03 a | 1.77 ± 0.16 B | 2.82 ± 0.13 B | 5.13 ± 0.83 A |

| 1,2,3-Trichlorobenzene | - | 0.39 ± 0.04 a | 0.41 ± 0.07 a | 0.38 ± 0.02 a | 0.36 ± 0.05 B | 0.47 ± 0.03 AB | 0.56 ± 0.12 A |

| 8-Methyl pentadecane | - | 0.35 ± 0.11 a | 0.45 ± 0.19 a | 0.41 ± 0.02 a | 0.10 ± 0.04 A | 0.19 ± 0.11 A | 0.47 ± 0.33 A |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aung, T.; Kim, B.R.; Kim, M.J. Comparative Flavor Profile of Roasted Germinated Wheat (Triticum aestivum L.) Beverages Served Hot and Cold Using Electronic Sensors Combined with Chemometric Statistical Analysis. Foods 2022, 11, 3099. https://doi.org/10.3390/foods11193099

Aung T, Kim BR, Kim MJ. Comparative Flavor Profile of Roasted Germinated Wheat (Triticum aestivum L.) Beverages Served Hot and Cold Using Electronic Sensors Combined with Chemometric Statistical Analysis. Foods. 2022; 11(19):3099. https://doi.org/10.3390/foods11193099

Chicago/Turabian StyleAung, Thinzar, Bo Ram Kim, and Mi Jeong Kim. 2022. "Comparative Flavor Profile of Roasted Germinated Wheat (Triticum aestivum L.) Beverages Served Hot and Cold Using Electronic Sensors Combined with Chemometric Statistical Analysis" Foods 11, no. 19: 3099. https://doi.org/10.3390/foods11193099

APA StyleAung, T., Kim, B. R., & Kim, M. J. (2022). Comparative Flavor Profile of Roasted Germinated Wheat (Triticum aestivum L.) Beverages Served Hot and Cold Using Electronic Sensors Combined with Chemometric Statistical Analysis. Foods, 11(19), 3099. https://doi.org/10.3390/foods11193099