Application of Imaging and Artificial Intelligence for Quality Monitoring of Stored Black Currant (Ribes nigrum L.)

Abstract

:1. Introduction

2. Materials and Methods

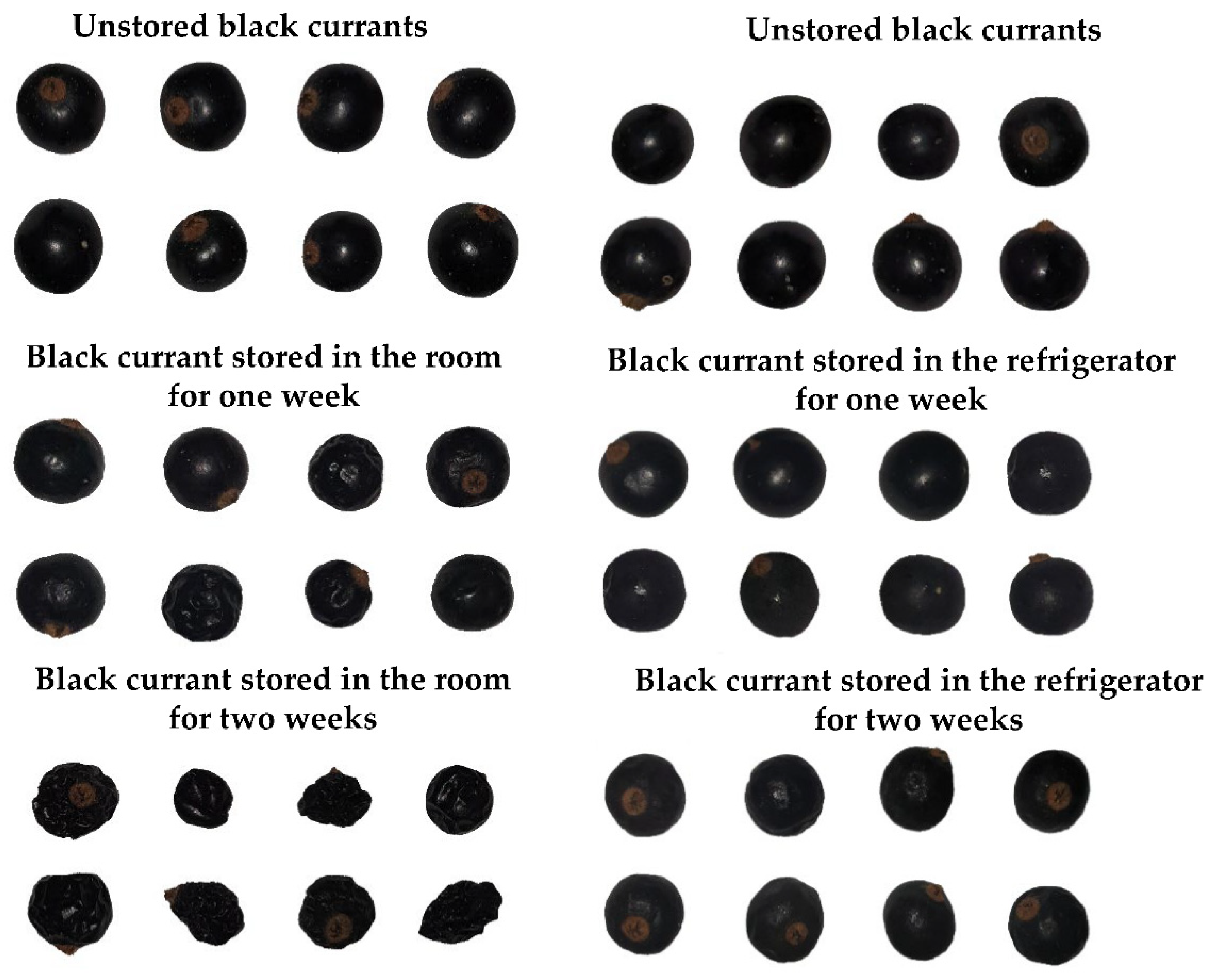

2.1. Materials

2.2. Image Processing

2.3. Classification of Black Currant Stored under Different Conditions

3. Results and Discussion

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| a | Color component—green for negative and red for positive values |

| b | Color component—blue for negative and yellow for positive values |

| B | Blue |

| BMP | Bitmap |

| CA | Controlled atmosphere |

| CFS | Correlation-based feature selection |

| G | Green |

| L | Lightness component from black to white |

| Lab | Color space composed of color channels L, a, and b |

| LED | Light-emitting diode |

| MAP | Modified atmosphere packaging |

| MCC | Matthews correlation coefficient |

| NA | Normal atmosphere |

| O3 | Gaseous ozone |

| PRC Area | Precision–recall area |

| R | Red |

| RGB | Color space composed of color channels R, G, and B |

| ROC Area | Receiver operating characteristic area |

| X | Component with color information |

| XYZ | Color space composed of color channels X, Y, and Z |

| Y | Lightness |

| Z | Component with color information |

References

- Jurčaga, L.; Bobko, M.; Kolesárová, A.; Bobková, A.; Demianová, A.; Haščík, P.; Belej, Ľ.; Mendelová, A.; Bučko, O.; Kročko, M.; et al. Blackcurrant (Ribes nigrum L.) and Kamchatka Honeysuckle (Lonicera caerulea var. Kamtschatica) Extract Effects on Technological Properties, Sensory Quality, and Lipid Oxidation of Raw-Cooked Meat Product (Frankfurters). Foods 2021, 10, 2957. [Google Scholar] [CrossRef]

- Gang, H.; Zhang, D.; Sun, X.; Huo, J.; Qin, D. Influences of Shading on Ascorbic Acid Biosynthesis of Blackcurrant (Ribes nigrum L.). Forests 2022, 13, 1127. [Google Scholar] [CrossRef]

- Djordjević, B.; Djurović, D.; Zec, G.; Dabić Zagorac, D.; Natić, M.; Meland, M.; Fotirić Akšić, M. Does Shoot Age Influence Biological and Chemical Properties in Black Currant (Ribes nigrum L.) Cultivars? Plants 2022, 11, 866. [Google Scholar] [CrossRef]

- Cortez, R.E.; Gonzalez de Mejia, E. Blackcurrants (Ribes nigrum): A Review on Chemistry, Processing, and Health Benefits. J. Food Sci. 2019, 84, 2387–2401. [Google Scholar] [CrossRef] [Green Version]

- Kowalski, R.; Gonzalez de Mejia, E. Phenolic composition, antioxidant capacity and physical characterization of ten blackcurrant (Ribes nigrum) cultivars, their juices, and the inhibition of type 2 diabetes and inflammation biochemical markers. Food Chem. 2021, 359, 129889. [Google Scholar] [CrossRef]

- Georgescu, C.; Frum, A.; Virchea, L.-I.; Sumacheva, A.; Shamtsyan, M.; Gligor, F.-G.; Olah, N.K.; Mathe, E.; Mironescu, M. Geographic Variability of Berry Phytochemicals with Antioxidant and Antimicrobial Properties. Molecules 2022, 27, 4986. [Google Scholar] [CrossRef]

- Marsol-Vall, A.; Laaksonen, O.; Yang, B. Effects of processing and storage conditions on volatile composition and odor characteristics of blackcurrant (Ribes nigrum) juices. Food Chem. 2019, 293, 151–160. [Google Scholar] [CrossRef]

- Rachtan-Janicka, J.; Ponder, A.; Hallmann, E. The Effect of Organic and Conventional Cultivations on Antioxidants Content in Blackcurrant (Ribes nigrum L.) Species. Appl. Sci. 2021, 11, 5113. [Google Scholar] [CrossRef]

- Gopalan, A.; Reuben, S.C.; Ahmed, S.; Darvesh, A.S.; Hohmann, J.; Bishayee, A. The health benefits of blackcurrants. Food Funct. 2012, 3, 795–809. [Google Scholar] [CrossRef]

- Pott, D.M.; Durán-Soria, S.; William Allwood, J.; Pont, S.; Gordon, S.L.; Jennings, N.; Austin, C.; Stewart, D.; Brennan, R.M.; Masny, A.; et al. Dissecting the impact of environment, season and genotype on blackcurrant fruit quality traits. Food Chem. 2023, 402, 134360. [Google Scholar] [CrossRef]

- Pages-Helary, S.; Dujourdy, L.; Cayot, N. Flavor compounds in blackcurrant berries: Multivariate analysis of datasets obtained with natural variability and various experimental parameters. LWT—Food Sci. Technol. 2022, 153, 112425. [Google Scholar] [CrossRef]

- Xue, B.; Hui, X.; Chen, X.; Luo, S.; Dilrukshi, H.N.N.; Wu, G.; Chen, C. Application, emerging health benefits, and dosage effects of blackcurrant food formats. J. Funct. Foods 2022, 95, 105147. [Google Scholar] [CrossRef]

- Xu, Y.; Niu, X.; Liu, N.; Gao, Y.; Wang, L.; Xu, G.; Li, X.; Yang, Y. Characterization, antioxidant and hypoglycemic activities of degraded polysaccharides from blackcurrant (Ribes nigrum L.) fruits. Food Chem. 2018, 243, 26–35. [Google Scholar] [CrossRef]

- Shin, C.Y.; Lee, M.-H.; Kim, H.-M.; Chung, H.-C.; Kim, D.-U.; Lee, J.-H.; Jeong, K.W. Protective Effect of Ribes nigrum Extract against Blue Light-Induced Retinal Degeneration In Vitro and In Vivo. Antioxidants 2022, 11, 832. [Google Scholar] [CrossRef]

- Bakowska-Barczak, A.M.; Kolodziejczyk, P.P. Black currant polyphenols: Their storage stability and microencapsulation. Ind. Crops Prod. 2011, 34, 1301–1309. [Google Scholar] [CrossRef]

- Djordjevic, B.; Savikin, K.; Zdunic, G.; Jankovic, T.; Vulic, T.; Pljevljakusic, D.; Oparnica, C. Biochemical properties of the fresh and frozen black currants and juices. J. Med. Food. 2013, 16, 73–81. [Google Scholar] [CrossRef]

- Harb, J.; Bisharat, R.; Streif, J. Changes in volatile constituents of blackcurrants (Ribes nigrum L. cv. ‘Titania’) following controlled atmosphere storage. Postharvest Biol. Technol. 2008, 47, 271–279. [Google Scholar] [CrossRef]

- Kampuse, S.; Kampuss, K.; Pizika, L. Stability of anthocyanins and ascorbic acid in raspberry and blackcurrant cultivars during frozen storage. Acta Hortic. ISHS 2002, 585, 507–510. [Google Scholar] [CrossRef]

- King, E.S.; Noll, A.; Glenn, S.; Bolling, B.W. Refrigerated and frozen storage impact aronia berry quality. Food Prod. Process. Nutr. 2022, 4, 3. [Google Scholar] [CrossRef]

- Mikulic-Petkovsek, M.; Koron, D.; Veberic, R. Quality parameters of currant berries from three different cluster positions. Sci. Hortic. 2016, 210, 188–196. [Google Scholar] [CrossRef]

- Segantini, D.M.; Threlfall, R.; Clark, J.R.; Brownmiller, C.R.; Howard, L.R.; Lawless, L.J.R. Changes in fresh-market and sensory attributes of blackberry genotypes after postharvest storage. J. Berry Res. 2017, 7, 129–145. [Google Scholar] [CrossRef]

- Gudkovskii, V.A.; Kozhina, L.V.; Akimov, M.Y.; Zhidekhina, T.V. Innovative storage technology of modern commercial black currant cultivars. Acta Hortic. 2020, 1277, 487–493. [Google Scholar] [CrossRef]

- Nturambirwe, J.F.I.; Opara, U.L. Machine learning applications to non-destructive defect detection in horticultural products. Biosyst. Eng. 2020, 189, 60–83. [Google Scholar] [CrossRef]

- Shaikh, T.A.; Rasool, T.; Lone, F.R. Towards leveraging the role of machine learning and artificial intelligence in precision agriculture and smart farming. Comput. Electron. Agric. 2022, 198, 107119. [Google Scholar] [CrossRef]

- Sharma, A.; Georgi, M.; Tregubenko, M.; Tselykh, A.; Tselykh, A. Enabling smart agriculture by implementing artificial intelligence and embedded sensing. Comput. Ind. Eng. 2022, 165, 107936. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, M.; Xu, B.; Sun, J.; Mujumdar, A.S. Artificial Intelligence Assisted Technologies for Controlling the Drying of Fruits and Vegetables Using Physical Fields: A Review. Trends Food Sci. Technol. 2020, 105, 251–260. [Google Scholar] [CrossRef]

- Addanki, M.; Patra, P.; Kandra, P. Recent advances and applications of artificial intelligence and related technologies in the food industry. Appl. Food Res. 2022, 2, 100126. [Google Scholar] [CrossRef]

- Chen, X.; Zhou, G.; Chen, A.; Pu, L.; Chen, W. The fruit classification algorithm based on the multi-optimization convolutional neural network. Multimed. Tools Appl. 2021, 80, 11313–11330. [Google Scholar] [CrossRef]

- Strzelecki, M.; Szczypiński, P.; Materka, A.; Klepaczko, A. A software tool for automatic classification and segmentation of 2D/3Dmedical images. Nucl. Inst. Methods Phys. Res. A 2013, 702, 137–140. [Google Scholar] [CrossRef]

- Szczypiński, P.M.; Strzelecki, M.; Materka, A.; Klepaczko, A. MaZda—A software package for image texture analysis. Comput. Methods Progr. Biomed. 2009, 94, 66–76. [Google Scholar] [CrossRef]

- Szczypiński, P.M.; Strzelecki, M.; Materka, A. MaZda—A software for texture analysis. In Proceedings of the ISITC, Jeonju, Korea, 23 November 2007; pp. 245–249. [Google Scholar]

- Bouckaert, R.R.; Frank, E.; Hall, M.; Kirkby, R.; Reutemann, P.; Seewald, A.; Scuse, D. WEKA Manual for Version 3-9-1; University of Waikato: Hamilton, New Zealand, 2016. [Google Scholar]

- Frank, E.; Hall, M.A.; Witten, I.H. The WEKA workbench. Online appendix for data mining: Practical machine learning tools and techniques. In Morgan Kaufmann; Morgan Kaufmann Publishers: Burlington, MA, USA, 2016. [Google Scholar]

- Witten, I.H.; Frank, E. Data Mining: Practical Machine Learning Tools and Techniques, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Ropelewska, E.; Szwejda-Grzybowska, J. A comparative analysis of the discrimination of pepper (Capsicum annuum L.) based on the cross-section and seed textures determined using image processing. J. Food Process Eng. 2021, 44, e13694. [Google Scholar] [CrossRef]

- Ropelewska, E. Distinguishing lacto-fermented and fresh carrot slice images using the Multilayer Perceptron neural network and other machine learning algorithms from the groups of Functions, Meta, Trees, Lazy, Bayes and Rules. Eur. Food Res. Technol. 2022, 248, 2421–2429. [Google Scholar] [CrossRef]

- Brondino, L.; Cadario, D.; Giuggioli, N.R. Influence of a Sulphur Dioxide Active Storage System on the Quality of Ribes rubrum L. Berries. Pol. J. Food Nutr. Sci. 2021, 71, 279–288. [Google Scholar] [CrossRef]

- Chen, R.; Wu, P.; Cao, D.; Tian, H.; Chen, C.; Zhu, B. Edible Coatings Inhibit the Postharvest Berry Abscission of Table Grapes Caused by Sulfur Dioxide during Storage. Postharvest Biol. Technol. 2019, 152, 1–8. [Google Scholar] [CrossRef]

- Giuggioli, N.R.; Briano, R.; Girgenti, V.; Peano, C. Quality effect of ozone treatment for the red raspberries storage. Chem. Eng. Trans. 2015, 44, 25–30. [Google Scholar]

- Antos, P.; Kurdziel, A.; Sadło, S.; Balawejder, M. Preliminary study on the use of ozonation for the degradation of dithiocarbamate residues in the fruit drying process, mancozeb residue in blackcurrant is the example used. J. Plant Prot. Res. 2013, 53, 48–52. [Google Scholar] [CrossRef]

- Lone, S.A.; Raghunathan, S.; Davoodbasha, M.A.; Srinivasan, H.; Lee, S.-Y. An investigation on the sterilization of berry fruit using ozone: An option to preservation and long-term storage. Biocatal. Agric. Biotechnol. 2019, 20, 101212. [Google Scholar] [CrossRef]

- Pinto, L.; Palma, A.; Cefola, M.; Pace, B.; D’Aquino, S.; Carboni, C.; Baruzzi, F. Effect of modified atmosphere packaging (MAP) and gaseous ozone pre-packaging treatment on the physico-chemical, microbiological and sensory quality of small berry fruit. Food Packag. Shelf Life 2020, 26, 100573. [Google Scholar] [CrossRef]

- Sachadyn-Król, M.; Agriopoulou, S. Ozonation as a Method of Abiotic Elicitation Improving the Health-Promoting Properties of Plant Products—A Review. Molecules 2020, 25, 2416. [Google Scholar] [CrossRef]

- Nazari, L.; Shaker, M.; Karimi, A.; Ropelewska, E. Correlations between the textural features and chemical properties of sorghum grain using the image processing method. Eur. Food Res. Technol. 2021, 247, 333–342. [Google Scholar] [CrossRef]

- Nazari, L.; Khazaei, A.; Ropelewska, E. Prediction of tannin, protein, and total phenolic content of grain sorghum using image analysis and machine learning. Cereal Chem. 2022, 99, 843–849. [Google Scholar] [CrossRef]

| Algorithm | Average Accuracy (%) | Kappa Statistic | Precision (Weighted Average) | Recall (Weighted Average) | MCC (Weighted Average) | ROC Area (Weighted Average) | PRC Area (Weighted Average) |

|---|---|---|---|---|---|---|---|

| lazy.IBk | 100 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| functions.MultilayerPerceptron | 100 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| meta.MultiClassClassifier | 100 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| rules.JRip | 98.67 | 0.9796 | 0.987 | 0.987 | 0.980 | 0.989 | 0.976 |

| trees.RandomForest | 99.32 | 0.9898 | 0.993 | 0.993 | 0.990 | 1.000 | 1.000 |

| bayes.BayesNet | 99.32 | 0.9898 | 0.993 | 0.993 | 0.990 | 1.000 | 1.000 |

| Algorithm | Average Accuracy (%) | Kappa Statistic | Precision (Weighted Average) | Recall (Weighted Average) | MCC (Weighted Average) | ROC Area (Weighted Average) | PRC Area (Weighted Average) |

|---|---|---|---|---|---|---|---|

| lazy.IBk | 96.67 | 0.950 | 0.968 | 0.967 | 0.951 | 0.975 | 0.947 |

| functions.MultilayerPerceptron | 96.67 | 0.950 | 0.968 | 0.967 | 0.951 | 0.993 | 0.989 |

| meta.MultiClassClassifier | 95.33 | 0.930 | 0.954 | 0.953 | 0.930 | 0.985 | 0.970 |

| rules.JRip | 89.33 | 0.840 | 0.893 | 0.893 | 0.841 | 0.932 | 0.857 |

| trees.RandomForest | 96.00 | 0.940 | 0.960 | 0.960 | 0.940 | 0.997 | 0.993 |

| bayes.BayesNet | 96.67 | 0.950 | 0.967 | 0.967 | 0.950 | 0.998 | 0.996 |

| Algorithm | Average Accuracy (%) | Kappa Statistic | Precision (Weighted Average) | Recall (Weighted Average) | MCC (Weighted Average) | ROC Area (Weighted Average) | PRC Area (Weighted Average) |

|---|---|---|---|---|---|---|---|

| lazy.IBk | 100 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| functions.MultilayerPerceptron | 99.33 | 0.990 | 0.993 | 0.993 | 0.990 | 0.998 | 0.997 |

| meta.MultiClassClassifier | 98.67 | 0.980 | 0.987 | 0.987 | 0.980 | 0.998 | 0.998 |

| rules.JRip | 96.67 | 0.950 | 0.967 | 0.967 | 0.950 | 0.977 | 0.955 |

| trees.RandomForest | 97.33 | 0.960 | 0.973 | 0.973 | 0.960 | 0.999 | 0.998 |

| bayes.BayesNet | 97.33 | 0.960 | 0.974 | 0.973 | 0.960 | 0.998 | 0.997 |

| Algorithm | Average Accuracy (%) | Kappa Statistic | Precision (Weighted Average) | Recall (Weighted Average) | MCC (Weighted Average) | ROC Area (Weighted Average) | PRC Area (Weighted Average) |

|---|---|---|---|---|---|---|---|

| lazy.IBk | 96.69 | 0.9503 | 0.968 | 0.967 | 0.951 | 0.973 | 0.944 |

| functions.MultilayerPerceptron | 98.67 | 0.9801 | 0.987 | 0.987 | 0.980 | 1.000 | 0.999 |

| meta.MultiClassClassifier | 98.01 | 0.9702 | 0.981 | 0.980 | 0.971 | 0.999 | 0.997 |

| rules.JRip | 91.39 | 0.8708 | 0.914 | 0.914 | 0.871 | 0.940 | 0.883 |

| trees.RandomForest | 96.69 | 0.9503 | 0.968 | 0.967 | 0.951 | 0.997 | 0.994 |

| bayes.BayesNet | 95.36 | 0.9305 | 0.954 | 0.954 | 0.933 | 0.996 | 0.993 |

| Algorithm | Average Accuracy (%) | Kappa Statistic | Precision (Weighted Average) | Recall (Weighted Average) | MCC (Weighted Average) | ROC Area (Weighted Average) | PRC Area (Weighted Average) |

|---|---|---|---|---|---|---|---|

| lazy.IBk | 98 | 0.970 | 0.980 | 0.980 | 0.970 | 0.985 | 0.967 |

| functions.MultilayerPerceptron | 98 | 0.970 | 0.980 | 0.980 | 0.970 | 0.995 | 0.995 |

| meta.MultiClassClassifier | 93.33 | 0.900 | 0.933 | 0.933 | 0.900 | 0.969 | 0.954 |

| rules.JRip | 98 | 0.970 | 0.980 | 0.980 | 0.970 | 0.988 | 0.973 |

| trees.RandomForest | 98.67 | 0.980 | 0.987 | 0.987 | 0.980 | 0.997 | 0.996 |

| bayes.BayesNet | 97.33 | 0.960 | 0.973 | 0.973 | 0.960 | 0.999 | 0.998 |

| Algorithm | Average Accuracy (%) | Kappa Statistic | Precision (Weighted Average) | Recall (Weighted Average) | MCC (Weighted Average) | ROC Area (Weighted Average) | PRC Area (Weighted Average) |

|---|---|---|---|---|---|---|---|

| lazy.IBk | 96.03 | 0.9404 | 0.961 | 0.960 | 0.941 | 0.967 | 0.933 |

| functions.MultilayerPerceptron | 94.70 | 0.9205 | 0.947 | 0.947 | 0.921 | 0.996 | 0.993 |

| meta.MultiClassClassifier | 89.33 | 0.841 | 0.893 | 0.893 | 0.841 | 0.983 | 0.964 |

| rules.JRip | 93.38 | 0.9006 | 0.935 | 0.934 | 0.901 | 0.961 | 0.930 |

| trees.RandomForest | 97.33 | 0.9603 | 0.974 | 0.973 | 0.960 | 0.998 | 0.996 |

| bayes.BayesNet | 95.33 | 0.930 | 0.954 | 0.953 | 0.930 | 0.991 | 0.984 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ropelewska, E. Application of Imaging and Artificial Intelligence for Quality Monitoring of Stored Black Currant (Ribes nigrum L.). Foods 2022, 11, 3589. https://doi.org/10.3390/foods11223589

Ropelewska E. Application of Imaging and Artificial Intelligence for Quality Monitoring of Stored Black Currant (Ribes nigrum L.). Foods. 2022; 11(22):3589. https://doi.org/10.3390/foods11223589

Chicago/Turabian StyleRopelewska, Ewa. 2022. "Application of Imaging and Artificial Intelligence for Quality Monitoring of Stored Black Currant (Ribes nigrum L.)" Foods 11, no. 22: 3589. https://doi.org/10.3390/foods11223589

APA StyleRopelewska, E. (2022). Application of Imaging and Artificial Intelligence for Quality Monitoring of Stored Black Currant (Ribes nigrum L.). Foods, 11(22), 3589. https://doi.org/10.3390/foods11223589